Hybrid Polymer Composites Used in the Arms Industry: A Review

Abstract

1. Introduction

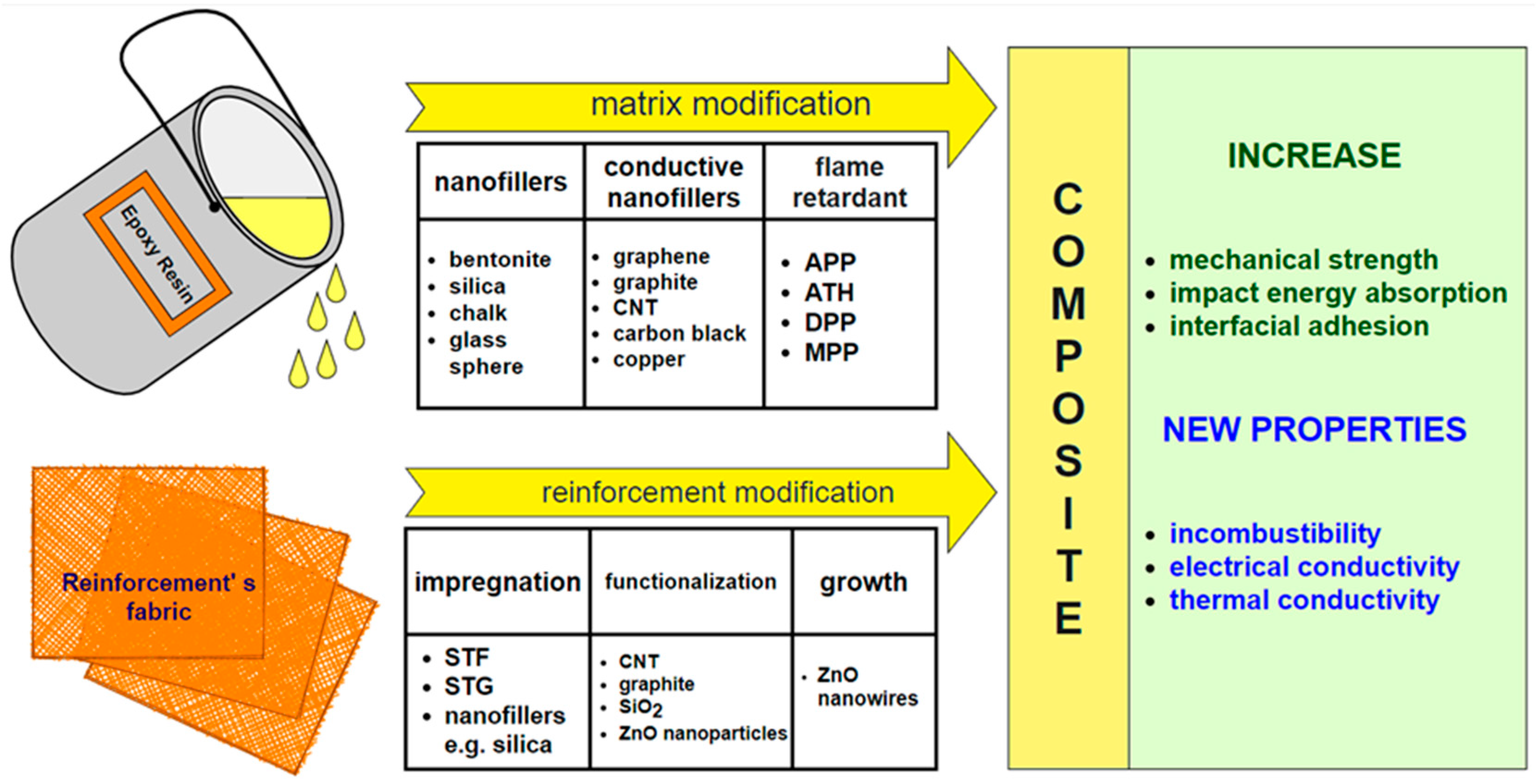

2. Hybrid Composites

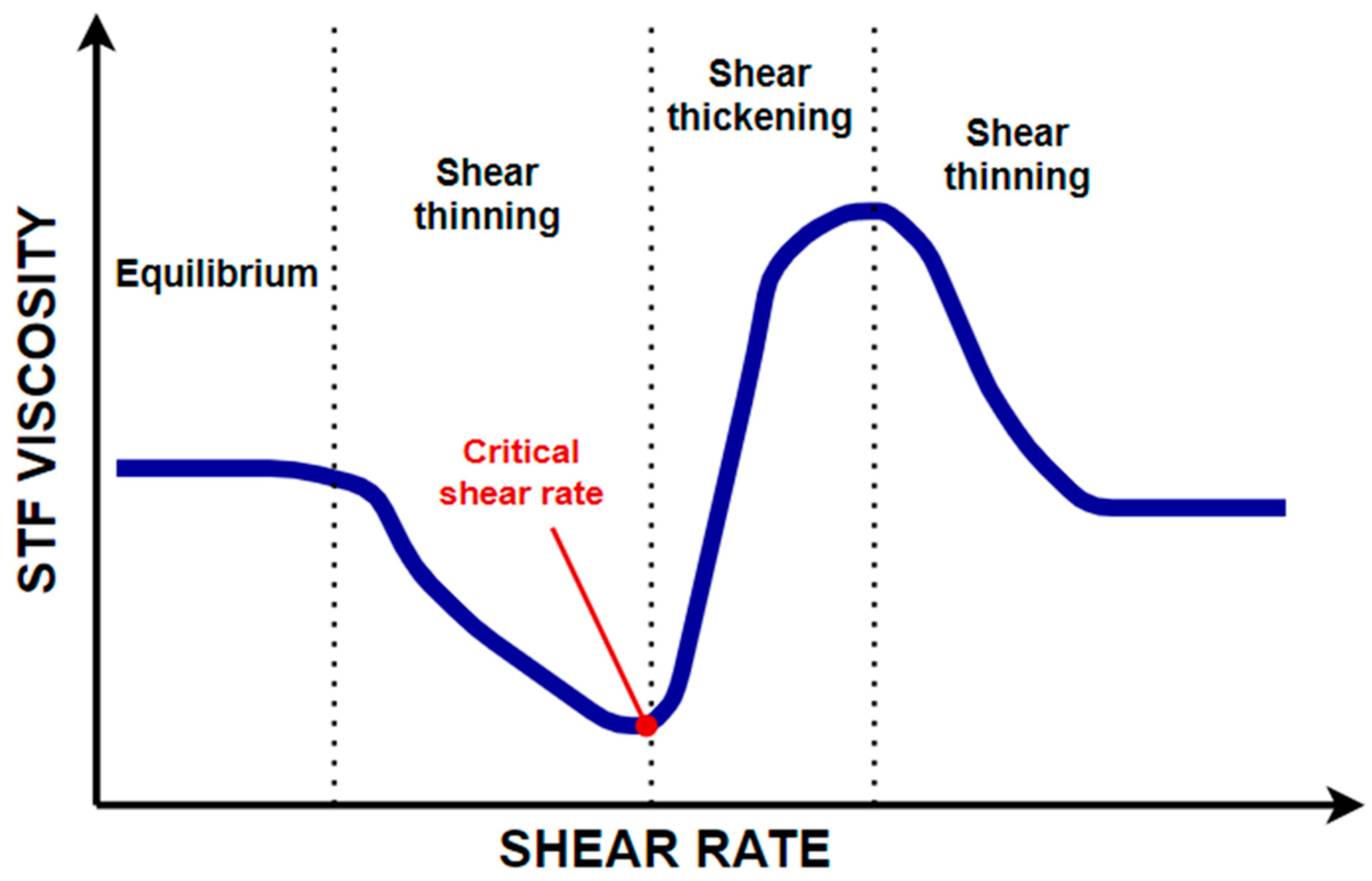

2.1. Composites with the Addition of Nanofillers

2.1.1. Glass-Fiber-Reinforced Polymer Composites

2.1.2. Carbon-Fiber-Reinforced Polymer Composites

2.1.3. p-Aramid-Fiber-Reinforced Composites

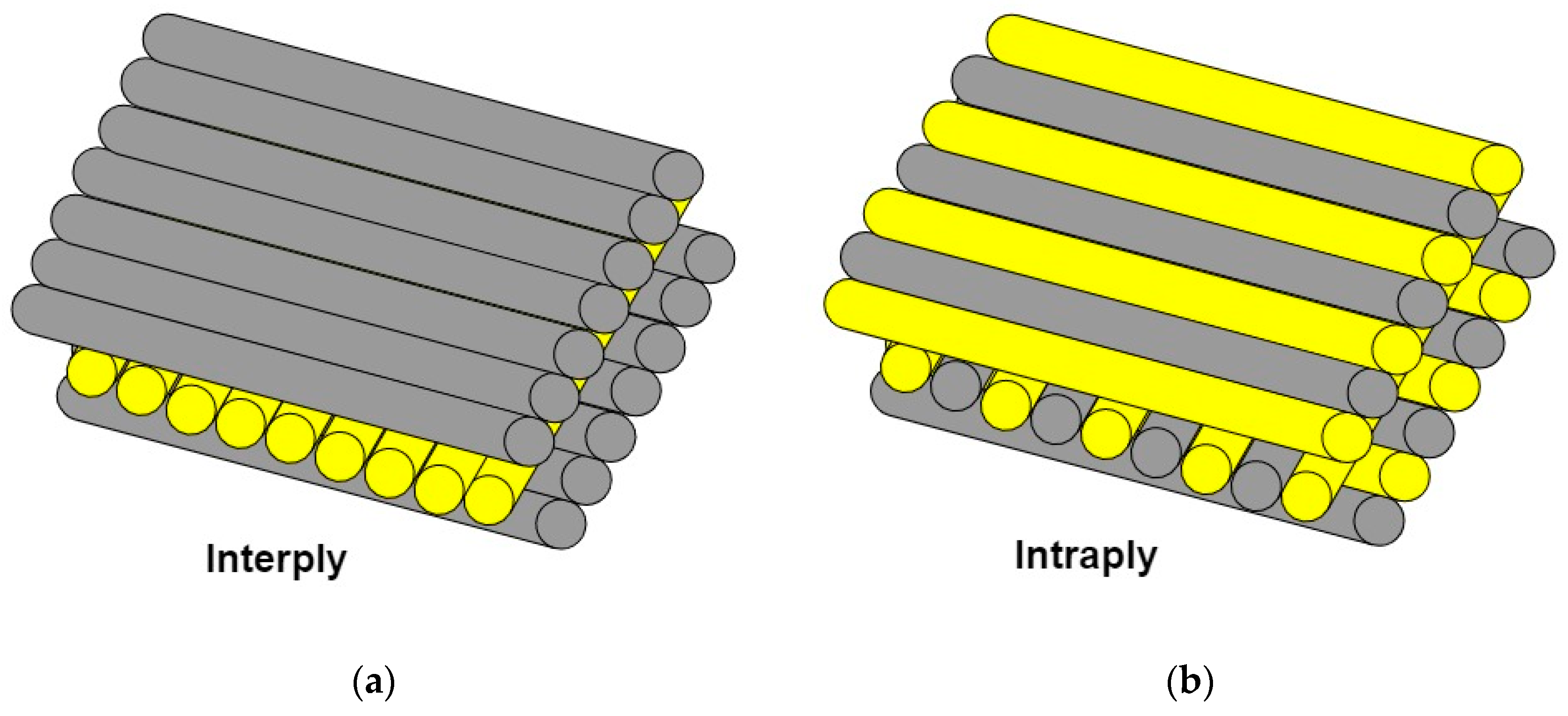

2.2. Hybridization of Fiber Reinforcement of Polymer Composites

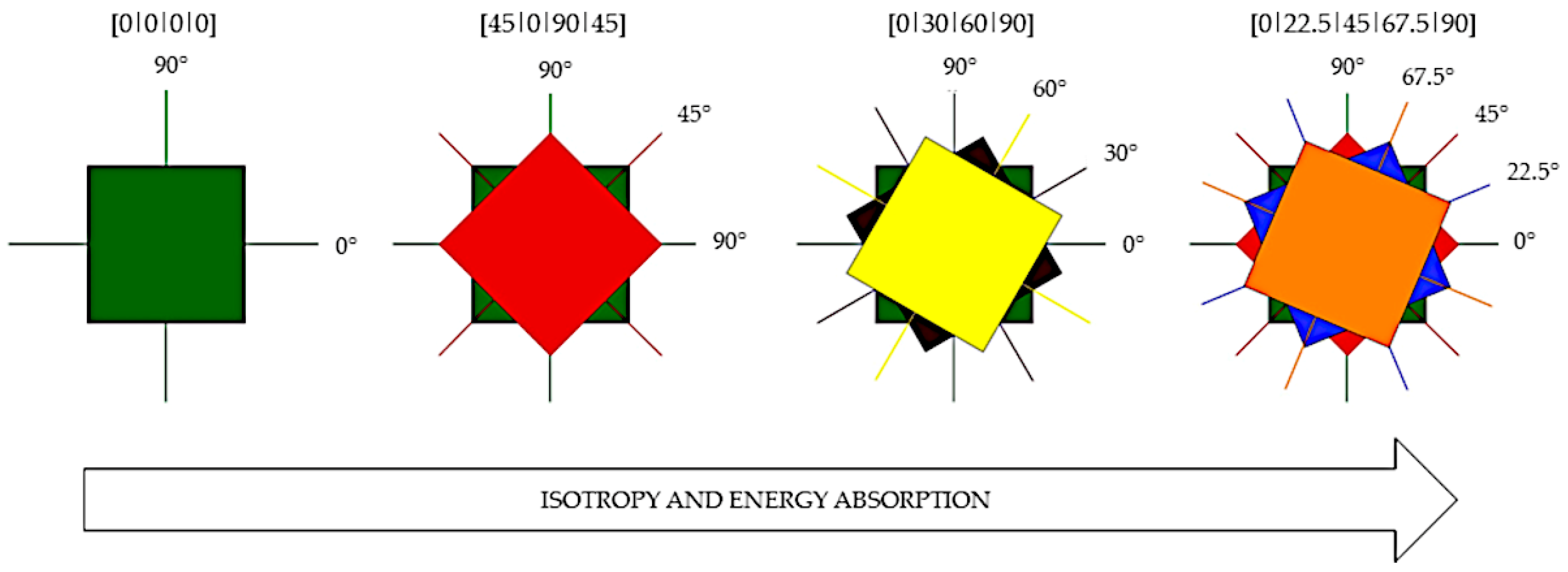

2.2.1. Influence of Ply Orientation on the Performance Properties of Hybrid Polymer Composites

2.2.2. Effect of 2D and 3D Structure on Mechanical Properties of Hybrid Polymer Composites

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barbero, E.J. Introduction to Composite Materials Design; CRC Press: Boca Raton, FL, USA, 2017; ISBN 1-315-29648-9. [Google Scholar]

- Borchert, M.; Bruns, T.; Hohendahl, S. Carbon Fiber Reinforced Polymer—The Fabric of the Future? In Proceedings of the Students International Scientific and Practical Conference. Human. Environment. Technol. 2017, 54–61. [Google Scholar] [CrossRef]

- Mawkhlieng, U.; Majumdar, A.; Laha, A. A Review of Fibrous Materials for Soft Body Armour Applications. RSC Adv. 2020, 10, 1066–1086. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Ballistic Impact Mechanisms—A Review on Textiles and Fibre-Reinforced Composites Impact Responses. Compos. Struct. 2019, 223, 110966. [Google Scholar] [CrossRef]

- Avci, H.; Hassanïn, A.; Hamouda, T.; Kiliç, A. High Performance Fibers: A Review on Current State of Art and Future Challenges. Eskişehir Osman. Üniversitesi Mühendislik Mimar. Fakültesi Derg. 2019, 27, 130–155. [Google Scholar] [CrossRef]

- Wesołowska, M.; Delczyk-Olejniczak, B. Włókna w balistyce-dziś i jutro. Tech. Wyr. Włókiennicze 2011, 11, 41–50. [Google Scholar]

- Boczkowska, A.; Kapuściński, J.; Lindemann, Z.; Witemberg-Perzyk, D.; Wojciechowski, S. Kompozyty, 2nd ed.; Oficyna Wydawnicza Politechniki Warszawskiej: Warszawa, Poland, 2003; pp. 23–30. [Google Scholar]

- Benzait, Z.; Trabzon, L. A Review of Recent Research on Materials Used in Polymer–Matrix Composites for Body Armor Application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Ash, R.A. Vehicle armor. In Lightweight Ballistic Composites; Elsevier: Amsterdam, The Netherlands, 2016; pp. 285–309. ISBN 978-0-08-100406-7. [Google Scholar]

- Kciuk, S.; Mężyk, A.; Świtoński, E. Najnowsze Tendencje w Projektowaniu Pojazdów Specjalnych. Szybkobieżne Pojazdy Gąsienicowe 2018, 48–49, 34–48. (In Polish) [Google Scholar]

- Płonka, B.; Remsak, K.; Rajda, M.; Wilczewski, J. Stopy Metali Lekkich w Wielowarstwowych Pancerzach Pasywnych Dla Pojazdów Wojskowych. Szybkobieżne Pojazdy Gąsienicowe 2015, 38, 123–140. (In Polish) [Google Scholar]

- Xu, J.L.; Chen, Y.W.; Wang, R.H.; Li, F.Q.; Liu, A.Y.; Wei, H.Z.; Wang, D.Y.; Li, S.H. Research Progress in Advanced Polymer Matrix Composites for Armor Protection Systems. J. Phys. Conf. Ser. 2020, 1507, 062011. [Google Scholar] [CrossRef]

- Szymiczek, M. Dobór Materiałów Inżynierskich na lekkie osłony energochłonne. In Przetwórstwo Tworzyw; Instytut Mechaniki Teoretycznej i Stosowanej, Politechnika Śląska: Gliwice, Poland, 2016. [Google Scholar]

- Kowacki, M. Materiały Kompozytowe–Wynalazek Na Miarę XXI w.; Nowoczesne Budownictwo Inżynieryjne: Kraków, Poland, 2019. [Google Scholar]

- Fang, H.; Bai, Y.; Liu, W.; Qi, Y.; Wang, J. Connections and Structural Applications of Fibre Reinforced Polymer Composites for Civil Infrastructure in Aggressive Environments. Compos. Part. B Eng. 2019, 164, 129–143. [Google Scholar] [CrossRef]

- Volpe, V.; Lanzillo, S.; Affinita, G.; Villacci, B.; Macchiarolo, I.; Pantani, R. Lightweight High-Performance Polymer Composite for Automotive Applications. Polymers 2019, 11, 326. [Google Scholar] [CrossRef]

- Zimmermann, N.; Wang, P.H. A Review of Failure Modes and Fracture Analysis of Aircraft Composite Materials. Eng. Fail. Anal. 2020, 115, 104692. [Google Scholar] [CrossRef]

- Woźniak, D.; Kukiełka, L. Kompozyty w Technice w Aspektach Materiałów Nowej Generacji. Autobusy Tech. Eksploat. Syst. Transp. 2014, 15, 292–296. [Google Scholar]

- Konieczny, J. Materiały polimerowe stosowane w przemyśle zbrojeniowym. Przetwórstwo Tworzyw 2011, 17, 29–37. [Google Scholar]

- Tong, Y. Application of New Materials in Sports Equipment. IOP Conf. Ser. Mater. Sci. Eng. 2019, 493, 012112. [Google Scholar] [CrossRef]

- Morka, A.; Niezgoda, T.; Nowak, J. Sprzężona eksperymentalno-numeryczna analiza przebicia konstrukcji wielowarstwowej przez pocisk 7, 62× 54R typu B32. Biul. Wojsk. Akad. Tech. 2012, 14, 84–96. [Google Scholar]

- Oleksy, M.; Budzik, G.; Kozik, B.; Gardzinska, A. Polymer hybrid nanocomposites used in Rapid Prototyping technology. Polimery 2017, 62, 3–10. [Google Scholar] [CrossRef]

- Chavhan, G.R.; Wankhade, L.N. Improvement of the Mechanical Properties of Hybrid Composites Prepared by Fibers, Fiber-Metals, and Nano-Filler Particles–A Review. Mater. Today Proc. 2020, 27, 72–82. [Google Scholar] [CrossRef]

- Haro, E.E. Enhancing Ballistic Impact Resistance of Polymer Matrix Composite Armors by Addition of Micro and Nano-Fillers. PhD Thesis, University of Saskatchewan, Saskatoon, SK, Canada, July 2018. [Google Scholar]

- Clifton, S.; Thimmappa, B.H.S.; Selvam, R.; Shivamurthy, B. Polymer Nanocomposites for High-Velocity Impact Applications-A Review. Compos. Commun. 2020, 17, 72–86. [Google Scholar] [CrossRef]

- Haro, E.E.; Odeshi, A.G.; Szpunar, J.A. The Energy Absorption Behavior of Hybrid Composite Laminates Containing Nano-Fillers under Ballistic Impact. Int. J. Impact Eng. 2016, 96, 11–22. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, S.; Wang, Y.; Fan, X.; Ding, L.; Xuan, S.; Gong, X. Conductive Shear Thickening Gel/Polyurethane Sponge: A Flexible Human Motion Detection Sensor with Excellent Safeguarding Performance. Compos. Part. A Appl. Sci. Manuf. 2018, 112, 197–206. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Y.; Cao, S.; Xuan, S.; Jiang, W.; Gong, X. Conductive Shear Thickening Gel/Kevlar Wearable Fabrics: A Flexible Body Armor with Mechano-Electric Coupling Ballistic Performance. Compos. Sci. Technol. 2019, 182, 107782. [Google Scholar] [CrossRef]

- Nasser, J.; Steinke, K.; Sodano, H. ZnO Nanostructured Interphase for Multifunctional and Lightweight Glass Fiber Reinforced Composite Materials under Various Loading Conditions. ACS Appl. Nano Mater. 2020, 3, 1363–1372. [Google Scholar] [CrossRef]

- Malakooti, M.H.; Hwang, H.-S.; Goulbourne, N.C.; Sodano, H.A. Role of ZnO Nanowire Arrays on the Impact Response of Aramid Fabrics. Compos. Part. B Eng. 2017, 127, 222–231. [Google Scholar] [CrossRef]

- Asija, N.; Chouhan, H.; Gebremeskel, S.A.; Bhatnagar, N. Impact Response of Shear Thickening Fluid (STF) Treated High Strength Polymer Composites–Effect of STF Intercalation Method. Procedia Eng. 2017, 173, 655–662. [Google Scholar] [CrossRef]

- Huo, J.-L.; Sun, F.; Li, T.-T.; Shiu, B.-C.; Lou, C.-W.; Lin, J.-H. Preparation and Properties of Shear Thickening Fluid (STF) Capsule Filled Graded Buffer Composites. J. Mater. Res. Technol. 2020, 9, 10982–10990. [Google Scholar] [CrossRef]

- Grover, G.; Verma, S.K.; Thakur, A.; Biswas, I.; Bhatacharjee, D. The Effect of Particle Size and Concentration on the Ballistic Resistance of Different Shear Thickening Fluids. Mater. Today Proc. 2020, 28, 1472–1476. [Google Scholar] [CrossRef]

- Chatterjee, V.A.; Dey, P.; Verma, S.K.; Bhattacharjee, D.; Biswas, I.; Neogi, S. Probing the Intensity of Dilatancy of High Performance Shear-Thickening Fluids Comprising Silica in Polyethylene Glycol. Mater. Res. Express 2019, 6, 075702. [Google Scholar] [CrossRef]

- Bajya, M.; Majumdar, A.; Butola, B.S.; Verma, S.K.; Bhattacharjee, D. Design Strategy for Optimising Weight and Ballistic Performance of Soft Body Armour Reinforced with Shear Thickening Fluid. Compos. Part. B Eng. 2020, 183, 107721. [Google Scholar] [CrossRef]

- He, Q.; Cao, S.; Wang, Y.; Xuan, S.; Wang, P.; Gong, X. Impact Resistance of Shear Thickening Fluid/Kevlar Composite Treated with Shear-Stiffening Gel. Compos. Part. A Appl. Sci. Manuf. 2018, 106, 82–90. [Google Scholar] [CrossRef]

- Wei, M.; Lin, K.; Liu, H. Experimental Investigation on Hysteretic Behavior of a Shear Thickening Fluid Damper. Struct. Control. Health Monit. 2019, 26. [Google Scholar] [CrossRef]

- Zhao, C.; Xu, C.; Cao, S.; Xuan, S.; Jiang, W.; Gong, X. Anti-Impact Behavior of a Novel Soft Body Armor Based on Shear Thickening Gel (STG) Impregnated Kevlar Fabrics. Smart Mater. Struct. 2019, 28, 075036. [Google Scholar] [CrossRef]

- Prashanth, S.; Km, S.; K, N.; S, S. Fiber Reinforced Composites—A Review. J. Mater. Sci. Eng. 2017, 6. [Google Scholar] [CrossRef]

- Tate, J.S.; Akinola, A.T.; Espinoza, S.; Gaikwad, S.; Kannabiran Vasudevan, D.K.; Sprenger, S.; Kumar, K. Tension–Tension Fatigue Performance and Stiffness Degradation of Nanosilica-Modified Glass Fiber-Reinforced Composites. J. Compos. Mater. 2018, 52, 823–834. [Google Scholar] [CrossRef]

- Ravi Raj, V.; Vijaya Ramnath, B. Mechanical, Thermal and Wear Behavior of SiC Particle Strengthening of PMMA-Toughened Glass-Epoxy Hybrid Composite. Silicon 2020. [Google Scholar] [CrossRef]

- Rahmat, M.; Ashrafi, B.; Naftel, A.; Djokic, D.; Martinez-Rubi, Y.; Jakubinek, M.B.; Simard, B. Enhanced Shear Performance of Hybrid Glass Fiber–Epoxy Laminates Modified with Boron Nitride Nanotubes. ACS Appl. Nano Mater. 2018, 1, 2709–2717. [Google Scholar] [CrossRef]

- Zeng, S.; Shen, M.; Duan, P.; Lu, F.; Cheng, S.; Li, Z. Properties of MWCNT–Glass Fiber Fabric Multiscale Composites: Mechanical Properties, Interlaminar Adhesion, and Thermal Conductivity. Text. Res. J. 2018, 88, 2712–2726. [Google Scholar] [CrossRef]

- Vigneshwaran, G.V.; Shanmugavel, B.P.; Paskaramoorthy, R.; Harish, S. Tensile, Impact, and Mode-I Behaviour of Glass Fiber-Reinforced Polymer Composite Modified by Graphene Nanoplatelets. Archiv. Civ. Mech. Eng. 2020, 20, 94. [Google Scholar] [CrossRef]

- Tareq, M.S.; Zainuddin, S.; Woodside, E.; Syed, F. Investigation of the Flexural and Thermomechanical Properties of Nanoclay/Graphene Reinforced Carbon Fiber Epoxy Composites. J. Mater. Res. 2019, 34, 3678–3687. [Google Scholar] [CrossRef]

- Moghimi Monfared, R.; Ayatollahi, M.R.; Barbaz Isfahani, R. Synergistic Effects of Hybrid MWCNT/Nanosilica on the Tensile and Tribological Properties of Woven Carbon Fabric Epoxy Composites. Theor. Appl. Fract. Mech. 2018, 96, 272–284. [Google Scholar] [CrossRef]

- Khan, N.I.; Halder, S.; Das, S.; Goyat, M.S. Graphitic Nanoparticles Functionalized with Epoxy Moiety for Enhancing the Mechanical Performance of Hybrid Carbon Fiber Reinforced Polymer Laminated Composites. Polym. Compos. 2020, 42, 678–692. [Google Scholar] [CrossRef]

- Suresha, B.; Indushekhara, N.M.; Varun, C.A.; Sachin, D.; Pranao, K. Effect of Carbon Nanotubes Reinforcement on Mechanical Properties of Aramid/Epoxy Hybrid Composites. Mater. Today Proc. 2021, 43, 1478–1484. [Google Scholar] [CrossRef]

- Dharmavarapu, P.; Reddy, M.B.S.S. Mechanical, Low Velocity Impact, Fatigue and Tribology Behaviour of Silane Grafted Aramid Fibre and Nano-Silica Toughened Epoxy Composite. Silicon 2020. [Google Scholar] [CrossRef]

- Yang, G.; Park, M.; Park, S.-J. Recent Progresses of Fabrication and Characterization of Fibers-Reinforced Composites: A Review. Compos. Commun. 2019, 14, 34–42. [Google Scholar] [CrossRef]

- Balaji, K.V.; Shirvanimoghaddam, K.; Rajan, G.S.; Ellis, A.V.; Naebe, M. Surface Treatment of Basalt Fiber for Use in Automotive Composites. Mater. Today Chem. 2020, 17, 100334. [Google Scholar] [CrossRef]

- Carolin, A. Carbon Fibre Reinforced Polymers for Strengthening of Structural Elements. PhD Thesis, Luleå Tekniska Universitet, Luleå, Sweden, 2003. [Google Scholar]

- Carlson, T.; Ordéus, D.; Wysocki, M.; Asp, L.E. Structural Capacitor Materials Made from Carbon Fibre Epoxy Composites. Compos. Sci. Technol. 2010, 70, 1135–1140. [Google Scholar] [CrossRef]

- Yin, J.J.; Li, S.L.; Yao, X.L.; Chang, F.; Li, L.K.; Zhang, X.H. Lightning Strike Ablation Damage Characteristic Analysis for Carbon Fiber/Epoxy Composite Laminate with Fastener. Appl. Compos. Mater. 2016, 23, 821–837. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Hamim, S.U.; Akbari, M.K.; Fakhrhoseini, S.M.; Khayyam, H.; Pakseresht, A.H.; Ghasali, E.; Zabet, M.; Munir, K.S.; Jia, S.; et al. Carbon Fiber Reinforced Metal Matrix Composites: Fabrication Processes and Properties. Compos. Part. A Appl. Sci. Manuf. 2017, 92, 70–96. [Google Scholar] [CrossRef]

- Wang, F.; Cai, X. Improvement of Mechanical Properties and Thermal Conductivity of Carbon Fiber Laminated Composites through Depositing Graphene Nanoplatelets on Fibers. J. Mater. Sci. 2019, 54, 3847–3862. [Google Scholar] [CrossRef]

- Badakhsh, A.; An, K.-H.; Kim, B.-J. Enhanced Surface Energetics of CNT-Grafted Carbon Fibers for Superior Electrical and Mechanical Properties in CFRPs. Polymers 2020, 12, 1432. [Google Scholar] [CrossRef] [PubMed]

- Nasser, J.; Steinke, K.; Hwang, H.; Sodano, H. Nanostructured ZnO Interphase for Carbon Fiber Reinforced Composites with Strain Rate Tailored Interfacial Strength. Adv. Mater. Interfaces 2020, 7, 1901544. [Google Scholar] [CrossRef]

- Selver, E. Tensile and Flexural Properties of Glass and Carbon Fibre Composites Reinforced with Silica Nanoparticles and Polyethylene Glycol. J. Ind. Text. 2020, 49, 809–832. [Google Scholar] [CrossRef]

- Jia, C.; Zhang, R.; Yuan, C.; Ma, Z.; Du, Y.; Liu, L.; Huang, Y. Surface Modification of Aramid Fibers by Amino Functionalized Silane Grafting to Improve Interfacial Property of Aramid Fibers Reinforced Composite. Polym. Compos. 2020, 41, 2046–2053. [Google Scholar] [CrossRef]

- Zhang, J.; Teng, C. Nondestructive Growing Nano-ZnO on Aramid Fibers to Improve UV Resistance and Enhance Interfacial Strength in Composites. Mater. Des. 2020, 192, 108774. [Google Scholar] [CrossRef]

- Bilisik, K. Two-Dimensional (2D) Fabrics and Three-Dimensional (3D) Preforms for Ballistic and Stabbing Protection: A Review. Text. Res. J. 2017, 87, 2275–2304. [Google Scholar] [CrossRef]

- Finckenor, M.M. Comparison of High-Performance Fiber Materials Properties in Simulated and Actual Space Environments; NASA Langley Research Center: Hampton, VA, USA, 2017.

- Ávila, A.F.; de Oliveira, A.M.; Leão, S.G.; Martins, M.G. Aramid Fabric/Nano-Size Dual Phase Shear Thickening Fluid Composites Response to Ballistic Impact. Compos. Part. A Appl. Sci. Manuf. 2018, 112, 468–474. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, S.; Liu, S.; Cao, S.; Wang, S.; Bai, L.; Sang, M.; Xuan, S.; Jiang, W.; Gong, X. CNT/STF/Kevlar-Based Wearable Electronic Textile with Excellent Anti-Impact and Sensing Performance. Compos. Part. A Appl. Sci. Manuf. 2019, 126, 105612. [Google Scholar] [CrossRef]

- Dixit, P.; Ghosh, A.; Majumdar, A. Hybrid Approach for Augmenting the Impact Resistance of P-Aramid Fabrics: Grafting of ZnO Nanorods and Impregnation of Shear Thickening Fluid. J. Mater. Sci. 2019, 54, 13106–13117. [Google Scholar] [CrossRef]

- Priyanka, P.; Dixit, A.; Mali, H.S. High-Strength Hybrid Textile Composites with Carbon, Kevlar, and E-Glass Fibers for Impact-Resistant Structures. A Review. Mech. Compos. Mater. 2017, 53, 685–704. [Google Scholar] [CrossRef]

- Begum, S.; Fawzia, S.; Hashmi, M.S.J. Polymer Matrix Composite with Natural and Synthetic Fibres. Adv. Mater. Process. Technol. 2020, 1–18. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre Hybridisation in Polymer Composites: A Review. Compos. Part. A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Vasudevan, A.; Senthil Kumaran, S.; Naresh, K.; Velmurugan, R. Layer-Wise Damage Prediction in Carbon/Kevlar/S-Glass/E-Glass Fibre Reinforced Epoxy Hybrid Composites under Low-Velocity Impact Loading Using Advanced 3D Computed Tomography. Int. J. Crashworthiness 2020, 25, 9–23. [Google Scholar] [CrossRef]

- Randjbaran, E.; Zahari, R.; Abdul Jalil, N.A.; Abang Abdul Majid, D.L. Hybrid Composite Laminates Reinforced with Kevlar/Carbon/Glass Woven Fabrics for Ballistic Impact Testing. Sci. World J. 2014, 2014, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Yilmazcoban, I.K.; Doner, S. Ballistic Protection Evaluation of Sequencing the Composite Material Sandwich Panels for the Reliable Combination of Armor Layers. Acta Phys. Pol. A 2016, 130, 342–346. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, Y. Technical textiles for ballistic protection. In Handbook of Technical Textiles; Elsevier: Amsterdam, The Netherlands, 2016; pp. 169–192. ISBN 978-1-78242-465-9. [Google Scholar]

- Pandya, K.S.; Veerraju, C.; Naik, N.K. Hybrid Composites Made of Carbon and Glass Woven Fabrics under Quasi-Static Loading. Mater. Des. 2011, 32, 4094–4099. [Google Scholar] [CrossRef]

- Batra, N.K.; Dikshit, I. Evaluation of Mechanical Properties of Polytherimide Reinforced Carbon/Glass/Aramid Hybrid Composites. Mater. Today Proc. 2020, 33, 1472–1476. [Google Scholar] [CrossRef]

- Pandya, K.S.; Pothnis, J.R.; Ravikumar, G.; Naik, N.K. Ballistic Impact Behavior of Hybrid Composites. Mater. Des. 2013, 44, 128–135. [Google Scholar] [CrossRef]

- Hazzard, M.K.; Hallett, S.; Curtis, P.T.; Iannucci, L.; Trask, R.S. Effect of Fibre Orientation on the Low Velocity Impact Response of Thin Dyneema® Composite Laminates. Int. J. Impact Eng. 2017, 100, 35–45. [Google Scholar] [CrossRef]

- Arora, S.; Majumdar, A.; Butola, B.S. Soft Armour Design by Angular Stacking of Shear Thickening Fluid Impregnated High-Performance Fabrics for Quasi-Isotropic Ballistic Response. Compos. Struct. 2020, 233, 111720. [Google Scholar] [CrossRef]

- Hung, P.; Lau, K.; Cheng, L.; Leng, J.; Hui, D. Impact Response of Hybrid Carbon/Glass Fibre Reinforced Polymer Composites Designed for Engineering Applications. Compos. Part. B Eng. 2018, 133, 86–90. [Google Scholar] [CrossRef]

- Yanen, C.; Solmaz, M. Ballistic Performance of 21 Layered Hybrid Composites. In Proceedings of the 23rd International Conference on Latest Trends in Engineering and Technology (ICLTET-2017), Kuala Lumpur, Malaysia, 22–24 May 2017; pp. 15–19. [Google Scholar]

- Wang, Y.; Chen, X.; Young, R.; Kinloch, I.; Wells, G. A Numerical Study of Ply Orientation on Ballistic Impact Resistance of Multi-Ply Fabric Panels. Compos. Part. B Eng. 2015, 68, 259–265. [Google Scholar] [CrossRef]

- Bilisik, K.; Karaduman, N.S.; Bilisik, N.E. Fiber Architectures for Composite Applications. In Fibrous and Textile Materials for Composite Applications; Rana, S., Fangueiro, R., Eds.; Textile Science and Clothing Technology; Springer: Singapore, 2016; pp. 75–134. ISBN 978-981-10-0232-8. [Google Scholar]

- Ahmad, F.; Yuvaraj, N.; Bajpai, P.K. Effect of Reinforcement Architecture on the Macroscopic Mechanical Properties of Fiberous Polymer Composites: A Review. Polym. Compos. 2020, 41, 2518–2534. [Google Scholar] [CrossRef]

- Bijwe, J.; Rattan, R. Influence of Weave of Carbon Fabric in Polyetherimide Composites in Various Wear Situations. Wear 2007, 263, 984–991. [Google Scholar] [CrossRef]

- Cavallaro, P.V. Effects of Weave Styles and Crimp Gradients in Woven Kevlar/Epoxy Composites. Exp. Mech. 2016, 56, 617–635. [Google Scholar] [CrossRef]

- Luo, Y.; Lv, L.; Sun, B.; Qiu, Y.; Gu, B. Transverse Impact Behavior and Energy Absorption of Three-Dimensional Orthogonal Hybrid Woven Composites. Compos. Struct. 2007, 81, 202–209. [Google Scholar] [CrossRef]

- Seltzer, R.; González, C.; Muñoz, R.; LLorca, J.; Blanco-Varela, T. X-Ray Microtomography Analysis of the Damage Micromechanisms in 3D Woven Composites under Low-Velocity Impact. Compos. Part. A Appl. Sci. Manuf. 2013, 45, 49–60. [Google Scholar] [CrossRef]

- Lv, L. Bohong Gu Transverse Impact Damage and Energy Absorption of Three-Dimensional Orthogonal Hybrid Woven Composite: Experimental and FEM Simulation. J. Compos. Mater. 2008, 42, 1763–1786. [Google Scholar] [CrossRef]

| Fiber | Density (g/cm3) | Tensile Strength (GPa) | Young’s Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|---|

| E glass fiber | 2.63 | 3.5 | 68.5 | 4.0 |

| S glass fiber | 2.48 | 4.4 | 90.0 | 5.7 |

| Carbon fiber(Celton) | 1.80 | 4.0 | 230.0 | 1.8 |

| p-Aramid (Kevlar 149) | 1.47 | 3.5 | 179.0 | 1.6 |

| m-Aramid (Nomex) | 1.40 | 0.7 | 17.0 | 22.0 |

| UHMWPE (Dyneema SK76) | 0.97 | 3.6 | 116.0 | 3.8 |

| Zylon AS | 1.54 | 5.8 | 180.0 | 3.5 |

| Zylon HM | 1.56 | 5.8 | 270.0 | 2.5 |

| Vectran | 1.47 | 3.2 | 91.0 | 3.0 |

| M5 | 1.70 | 5.8 | 310.0 | 1.4 |

| Boron fiber | 2.64 | 3.5–4.2 | 420.0–450.0 | 3.7 |

| Silicon carbide | 2.80 | 4.0 | 420.0 | 0.6 |

| Alumina III (Nextel) | 2.50 | 1.7 | 152.0 | 2.0 |

| Ref. | Reinforcement Fiber Type | Filler | Content | Effect |

|---|---|---|---|---|

| [40] Tate et al. | Glass fiber | SiO2 | 6, 7, and 8 wt% | Increase in tensile, flexural, and interlaminar shear strengths Increase in modulus and elongation |

| [41] Ravi et al. | PMMA | 10 vol% | Increase in tensile strength, flexural strength, and modulus Improved thermal stability and abrasion resistance | |

| SiC | 1 vol% | |||

| [42] Rahmat et al. | BNNT | 1 wt% | Increase in flexural, shear, and impact strengths | |

| [44] Vigneshwaran et al. | GnP | 0.2, 0.6, and 1 wt% (of which 50% was used to impregnate the fiber) | Increase in impact energy absorption, tensile strength, and modulus Reduction in surface damage area Improved adhesion between components | |

| [45] Tareq et al. | Carbon fiber | Nanoclay | 2 wt% | Increase in flexural strength and modulus when added separately Higher stiffness and GnP with the best thermomechanical stability in samples with nanoclay |

| GnP | 0.1 wt% | |||

| [46] Moghimi et al. | MWCNTSiO2 | 0.2 and.7 wt% | Increase in tensile strength and Young’s modulus Reduction in the abrasion coefficient Improved interfacial adhesion | |

| 0.7 and 0.2 wt% | ||||

| 0.45 and 0.45 wt% | ||||

| [47] Khan et al. | N-CFRP | Improvement of tensile and flexural strength and modulus by modified graphite | ||

| G-CFRP | ||||

| E-CFRP | ||||

| [48] Suresha et al. | Aramid fiber | MWCNT | 0.15, 0.3, and 0.5 wt% | Increase in tensile strength, flexural strength, modulus, hardness, and impact strength |

| [49] Dharmavarapu and Reddy | SiO2 modified with APTMS | 0.5, 1, and 2 vol% | Improved tensile strength, flexural strength, impact strength, and hardness Increase in impact energy absorption |

| Ref. | Reinforcement Fiber Type | Filler/Impregnator | Effect |

|---|---|---|---|

| [43] Zeng et al. | Glass fiber | MWCNTs modified with APS | Increase in tensile strength, flexural strength, and modulus Improved ILSS and interfacial adhesion |

| [29] Nasser et al. | ZnO nanoparticles functionalized by piranha solution | Decrease in IFSS at medium and high and increase at low strain rates Improved interfacial adhesion | |

| ZnO nanowires functionalized by piranha solution | |||

| [56] Wang and Cai | Carbon fiber | GnP | Increase in flexural strength, interlaminar shear, flexural modulus, and thermal conductivity |

| [57] Badakhsh et al. | Nickel (galvanization): phase I CNT (gas-phase deposition): phase II | Improved flexural strength Decrease in electrical resistance and ductility index | |

| [58] Nasser et al. | ZnO nanoparticles functionalized by 70% nitric acid | Decrease in IFSS at medium and high strain rates | |

| ZnO nanowires functionalized by 70% nitric acid | |||

| [60] Jia et al. | Aramid fiber | Grafting of APS by γ-ray and chemical treatment | Increase in fiber surface roughness and IFSS |

| [30] Malakooti et al. | ZnO nanowires | Increase in Young’s modulus, tensile strength, and impact strength | |

| [61] Zhang and Teng | PDOPA functionalization and ZnO nanowire coating | Increase in UV resistance fiber surface roughness Improved IFSS and interfacial adhesion |

| Ref. | Reinforcement Fiber Type | Impregnation Type | Filler in STF/STG | Filler Content | Effect |

|---|---|---|---|---|---|

| [59] Selver | Glass fiber | STF | SiO2 | 10, 15, and 20 wt% | Improvement in tensile strength, Young’s modulus, and energy absorption for 10 and 15 wt% Decrease in flexural strength and modulus for all samples |

| Carbon fiber | |||||

| [64] Ávila et al. | Aramid fiber | SiO2 | 0, 25, 50, 75, and 100 wt% of the filler mixture | Increase in the impact energy absorption and friction between fibers | |

| CaCO3 | 0, 25, 50, 75, and 100 wt% of the filler mixture | ||||

| [65] Liu et al. | CNT | Increase in resistance to fiber pull-out strength and puncture Increase in energy absorption | |||

| SiO2 | 71 wt% | ||||

| [66] Dixit et al. | SiO2 | 65 wt% | Increase in fiber pull-out strength and impact energy absorption | ||

| Impregnation of ZnO nanowires | |||||

| [38] Zhao et al. | STG | Increase in impact energy absorption and friction between fibers | |||

| [28] Zhao et al. | Carbon black | Increase in impact energy absorption Mechanical–electrical coupling in the form of a change in resistivity as a function of impact energy, due to addition of carbon black | |||

| [36] He et al. | STF + STG | SiO2 (STF) | Increase in impact strength and modulus Improved energy dissipation mechanism Reduction in composite weight and thickness STF stabilization and increase in traction between fibers, due to addition of STG |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czech, K.; Oliwa, R.; Krajewski, D.; Bulanda, K.; Oleksy, M.; Budzik, G.; Mazurkow, A. Hybrid Polymer Composites Used in the Arms Industry: A Review. Materials 2021, 14, 3047. https://doi.org/10.3390/ma14113047

Czech K, Oliwa R, Krajewski D, Bulanda K, Oleksy M, Budzik G, Mazurkow A. Hybrid Polymer Composites Used in the Arms Industry: A Review. Materials. 2021; 14(11):3047. https://doi.org/10.3390/ma14113047

Chicago/Turabian StyleCzech, Kamil, Rafał Oliwa, Dariusz Krajewski, Katarzyna Bulanda, Mariusz Oleksy, Grzegorz Budzik, and Aleksander Mazurkow. 2021. "Hybrid Polymer Composites Used in the Arms Industry: A Review" Materials 14, no. 11: 3047. https://doi.org/10.3390/ma14113047

APA StyleCzech, K., Oliwa, R., Krajewski, D., Bulanda, K., Oleksy, M., Budzik, G., & Mazurkow, A. (2021). Hybrid Polymer Composites Used in the Arms Industry: A Review. Materials, 14(11), 3047. https://doi.org/10.3390/ma14113047