Temperature Profile in Starch during Irradiation. Indirect Effects in Starch by Radiation-Induced Heating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Electron Beam (E-Beam) Irradiation

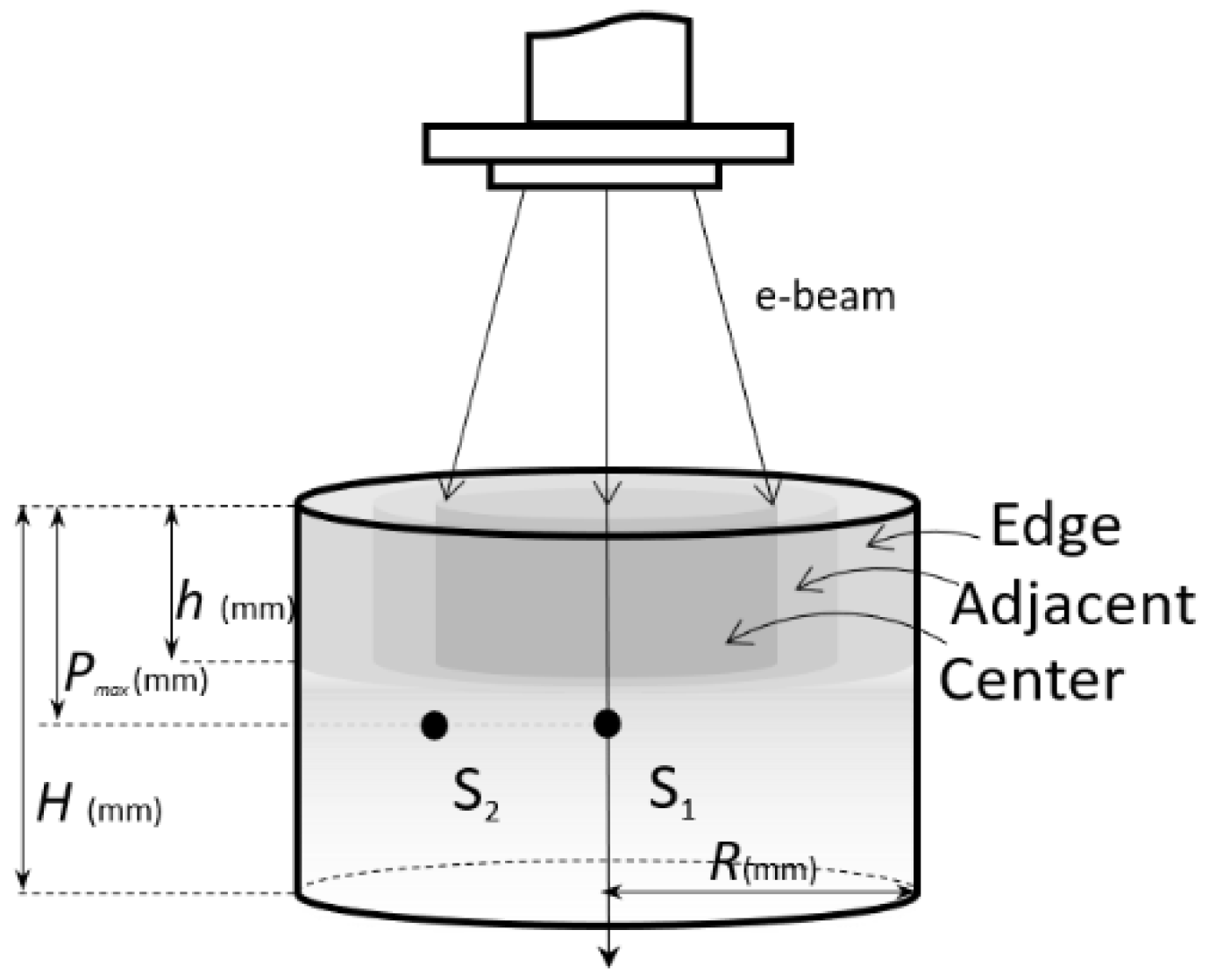

2.3. Irradiation Geometry and Temperature Measurement

2.4. Sampling of Batches

2.5. Moisture Content Determination

2.6. pH Measurement

2.7. Optical Measurements

2.8. Statistical Approach

3. Results and Discussion

3.1. Temperature Profile

3.2. Moisture Content and Specific Heat Capacity

3.3. pH Evaluation

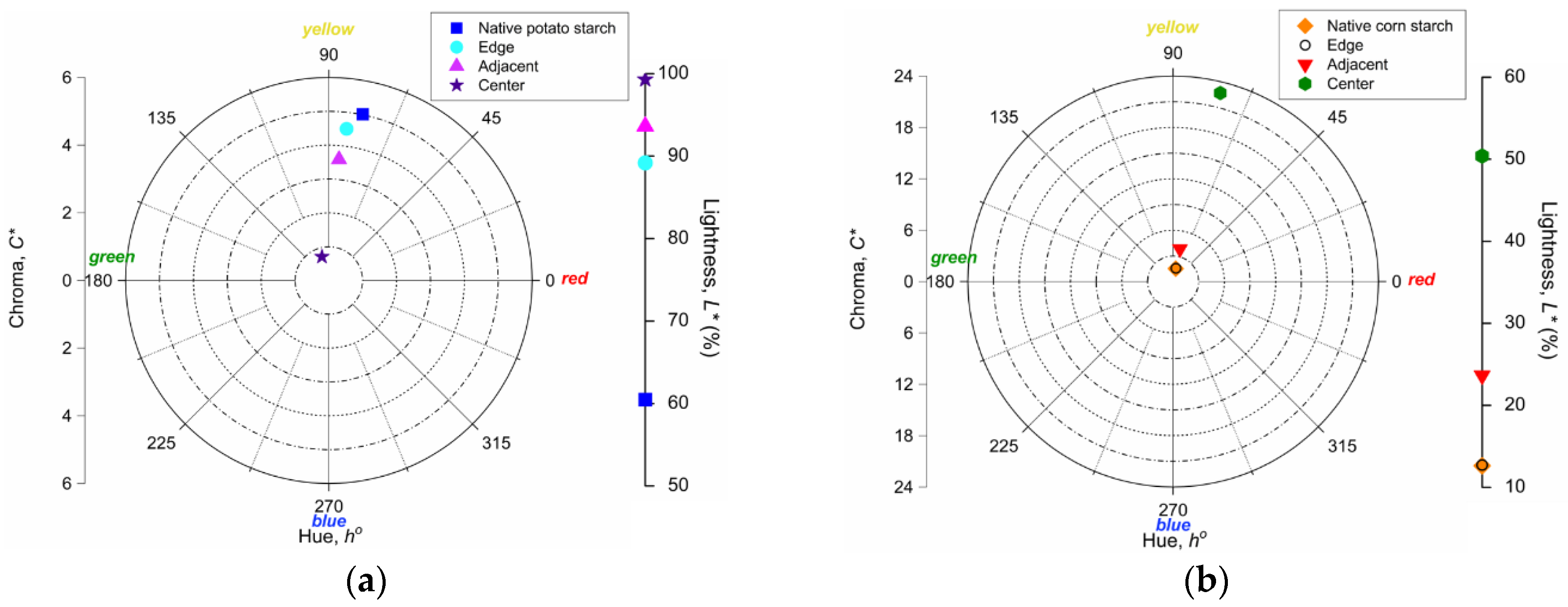

3.4. Color Parameters

4. Conclusions

- The temperature profiles recorded in starch samples showed three major stages: (i) heating during irradiation, (ii) post-irradiation heating, up to the maximum temperature is reached, and (iii) cooling to the room temperature.

- The maximum values of temperatures reached and the heating rates were different for both starches in the studied location sectors. However, the cooling rates were similar for both starches in each location sector thermally studied.

- The evolution of the measured temperatures was modeled as a function of the parameters that depend on the starch type and the location sector considered inside the batch. Based on this modeling, a material constant having the significance of a relaxation time was identified with values around 5800 s.

- Dehydration and changes in the values of the specific heat capacity, pH and color parameters of the starch were noticed due to the irradiation and radiation-induced heating, depending on the starch type and the batch sectors. The changes in the irradiated batch sectors (with maximum or “residual” dose rate) could be explained by irradiation and radiation-induced heating. On the other hand, the changes in the sector where the starch was practically not irradiated could be attributed only to the heating. Although the reached temperatures here were lower than in the other batch sectors, these changes cannot be ignored.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zarski, A.; Bajer, K.; Kapuśniak, J. Review of the most important methods of improving the processing properties of starch toward non-food applications. Polymers 2021, 13, 832. [Google Scholar] [CrossRef]

- Mi, G.; Wang, T.; Li, J.; Li, X.; Xie, J. Phase separation affects the rheological properties of starch dough fortified with fish actomyosin. RSC Adv. 2021, 11, 9303–9314. [Google Scholar] [CrossRef]

- Nemţanu, M.R.; Braşoveanu, M. Degradation of amylose by ionizing radiation processing. Starch-Stärke 2017, 69, 1600027. [Google Scholar] [CrossRef]

- Ghobashy, M.M.; Abd El-Wahab, H.; Ismail, M.A.; Naser, A.M.; Abdelhai, F.; El-Damhougy, B.K.; Nady, N.; Meganid, A.S.; Alkhursani, S.A. Characterization of starch-based three components of gamma-ray cross-linked hydrogels to be used as a soil conditioner. Mater. Sci. Eng. B 2020, 260, 114645. [Google Scholar] [CrossRef]

- López, O.V.; Ninago, M.D.; Lencina, M.M.S.; Ciolino, A.E.; Villar, M.A.; Andreucetti, N.A. Starch/Poly(ε-caprolactone) Graft Copolymers Synthetized by γ-Radiation and Their Application as Compatibilizer in Polymer Blends. J. Polym. Environ. 2019, 27, 2906–2914. [Google Scholar] [CrossRef]

- Nemțanu, M.R.; Brașoveanu, M. Ionizing irradiation grafting of natural polymers having applications in wastewater treatment. In Polymer Science: Research Advances, Practical Applications and Educational Aspects; Méndez-Vilas, A., Solano-Martín, A., Eds.; Formatex Research Center: Badajoz, Spain, 2016; pp. 270–277. [Google Scholar]

- Rummeli, M.H.; Ta, H.Q.; Mendes, R.G.; Gonzalez-Martinez, I.G.; Zhao, L.; Gao, J.; Fu, L.; Gemming, T.; Bachmatiuk, A.; Liu, Z. New frontiers in electron beam-driven chemistry in and around graphene. Adv. Mater. 2019, 31, 1800715. [Google Scholar] [CrossRef]

- Siwek, M.; Edgecock, T. Application of electron beam water radiolysis for sewage sludge treatment—A review. Environ. Sci. Pollut. Res. 2020, 27, 42424–42448. [Google Scholar] [CrossRef]

- Jokisch, T.; Doynov, N.; Ossenbrink, R.; Vesselin, G.M. Heat source model for electron beam welding of nickel-based superalloys. Mater. Test. 2021, 63, 17–28. [Google Scholar] [CrossRef]

- Vutova, K.; Vassileva, V.; Stefanova, V.; Amalnerkar, D.; Tanaka, T. Effect of electron beam method on processing of titanium technogenic material. Metals 2019, 9, 683. [Google Scholar] [CrossRef] [Green Version]

- Vutova, K.; Vassileva, V.; Koleva, E.; Stefanova, V.; Amalnerkar, D.P. Effects of process parameters on electron beam melting technogenic materials for obtaining rare metals. J. Phys. Conf. Ser. 2018, 1089, 012013. [Google Scholar] [CrossRef]

- Copeland, L.; Blazek, J.; Salman, H.; Tang, M.C. Form and functionality of starch. Food Hydrocoll. 2009, 23, 1527–1534. [Google Scholar] [CrossRef]

- Braşoveanu, M.; Oane, M.; Nemţanu, M.R. Heat transport in starch exposed to ionizing radiation: Experiment versus theoretical computer modeling. Starch-Stärke 2019, 71, 1900147. [Google Scholar] [CrossRef]

- Martin, D.; Ighigeanu, D.; Toma, M.; Oproiu, C. Constructive and functional peculiarities of electron linear accelerators used in conjunction with microwave sources. In Practical Aspects and Applications of Electron Beam Irradiation; Nemţanu, M.R., Braşoveanu, M., Eds.; Research Signpost/Transworld Research Network: Trivandrum, India, 2011; pp. 1–16. [Google Scholar]

- Ticoș, D.; Scurtu, A.; Oane, M.; Diplașu, C.; Giubega, G.; Călina, I.; Ticoș, C.M. Complementary dosimetry for a 6MeV electron beam. Results Phys. 2019, 14, 102377. [Google Scholar] [CrossRef]

- Craciun, G.; Manaila, E.; Stelescu, M.D. New elastomeric materials based on natural rubber obtained by electron beam irradiation for food and pharmaceutical use. Materials 2016, 9, 999. [Google Scholar] [CrossRef] [Green Version]

- Călina, I.; Demeter, M.; Scărișoreanu, A.; Sătulu, V.; Mitu, B. One step e-beam radiation cross-linking of quaternary hydrogels dressings based on chitosan-poly(vinyl-pyrrolidone)-poly(ethylene glycol)-poly(acrylic acid). Int. J. Mol. Sci. 2020, 21, 9236. [Google Scholar] [CrossRef] [PubMed]

- Braşoveanu, M.; Nemţanu, M.R. Pasting properties modeling and comparative analysis of starch exposed to ionizing radiation. Radiat. Phys. Chem. 2020, 168, 108492. [Google Scholar] [CrossRef]

- ASTM International. ISO/ASTM 51649:2002(E): Standard practice for dosimetry in an electron beam facility for radiation processing at energies between 300 keV and 25 MeV. In Standards on Dosimetry for Radiation Processing, 2nd ed.; ASTM International: West Conshohocken, PA, USA, 2004; pp. 133–152. [Google Scholar]

- Di Rienzo, J.A.; Casanoves, F.; Balzarini, M.G.; Gonzalez, L.; Tablada, M.; Robledo, C.W. InfoStat Versión 2018; InfoStat Group, Facultad de Ciencias Agropecuarias, Universidad Nacional de Córdoba: Córdoba, Argentina, 2018. [Google Scholar]

- Wilhelm, L.R.; Suter, D.A.; Brusewitz, G.H. Food & Process Engineering Technology; ASAE: St. Joseph, MI, USA, 2004; pp. 23–49. [Google Scholar]

- Ershov, B.G. Radiation-chemical degradation of cellulose and other polysaccharides. Russ. Chem. Rev. 1998, 67, 315–334. [Google Scholar] [CrossRef]

- Nemţanu, M.R.; Braşoveanu, M. Exposure of starch to combined physical treatments based on corona electrical discharges and ionizing radiation. Impact on physicochemical properties. Radiat. Phys. Chem. 2021, 184, 109480. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Yu, L.; Tong, Z.; Chen, L.; Liu, H.; Li, X. Thermal degradation and stability of starch under different processing conditions. Starch-Stärke 2012, 65, 48–60. [Google Scholar] [CrossRef]

- Zhu, X.; He, Q.; Hu, Y.; Huang, R.; Shao, N.; Gao, Y. A comparative study of structure, thermal degradation, and combustion behavior of starch from different plant sources. J. Therm. Anal. Calorim. 2018, 132, 927–935. [Google Scholar] [CrossRef]

- Liu, X.; Yu, L.; Xie, F.; Li, M.; Chen, L.; Li, X. Kinetics and mechanism of thermal decomposition of cornstarches with different amylose/ amylopectin ratios. Starch-Stärke 2010, 62, 139–146. [Google Scholar] [CrossRef]

- Stawski, D. New determination method of amylose content in potato starch. Food Chem. 2008, 110, 777–781. [Google Scholar] [CrossRef]

- Wu, H.; Corke, H. Genetic variation in thermal properties and gel texture of Amaranthus starch. In Cassava, Starch and Starch Derivatives, Proceedings of the International Symposium, Nanning, China, 11–15 November 1996; Howeler, R.H., Oates, C.G., O’Brien, G.M., Eds.; Centro Internacional de Agricultura Tropica (CIAT): Cali-Palmira, Colombia, 1996; pp. 292–301. [Google Scholar]

- Giuberti, G.; Gallo, A.; Moschini, M.; Masoero, F. In vitro production of short-chain fatty acids from resistant starch by pig faecal inoculum. Animal 2013, 7, 1446–1453. [Google Scholar] [CrossRef] [PubMed]

- Nemţanu, M.R.; Braşoveanu, M. Functional properties of some non-conventional treated starches. In Biopolymers; Eknashar, M., Ed.; Scyio: Rijeka, Croatia, 2010; pp. 319–344. [Google Scholar]

| Parameter | Potato Starch | Corn Starch | ||

|---|---|---|---|---|

| S1potato | S2potato | S1corn | S2 corn | |

| τ0 (s) | 6260 ± 108 | 7585 ± 409 | 5981 ± 116 | 6964 ± 248 |

| τi (s) | 381 ± 31 | 1914 ± 448 | 267 ± 22 | 1117 ± 252 |

| τ0 − τi (s) | 5879 ± 139 | 5671 ± 857 | 5714 ± 138 | 5847 ± 500 |

| Δt (s) | 670 ± 19 | 3993 ± 1675 | 627 ± 15 | 3834 ± 2126 |

| T0 (°C) | 23.0 ± 0.3 | 13.1 ± 0.7 | 24.6 ± 0.2 | 14.7 ± 0.3 |

| Ti (°C) | 40.9 ± 3.6 | 6.9 ± 4.0 | 45.5 ± 4.9 | 5.7 ± 4.1 |

| R2 | 0.9944 | 0.9754 | 0.9973 | 0.9866 |

| Location Sector | Potato Starch | Corn Starch | ||

|---|---|---|---|---|

| u (%) | cp (J kg−1 K−1) | u (%) | cp (J g−1 K−1) | |

| Control sample (native) | 17.7 ± 0.5 a | 1434 ±15 a | 11.2 ± 0.3 a | 1215 ± 10 a |

| Edge | 17.5 ± 0.1 ab | 1429 ± 5 ab | 11.2 ± 0.4 a | 1216 ± 12 a |

| Adjacent | 16.5 ± 0.4 b | 1395 ± 14 b | 10.6 ± 0.4 a | 1196 ± 12 a |

| Center | 13.9 ± 0.4 c | 1308 ± 14 c | 9.1 ± 0.5 b | 1147 ± 17 b |

| Location Sector | Potato Starch | Corn Starch |

|---|---|---|

| Control sample (native) | 5.56 ± 0.06 a | 5.43 ± 0.09 a |

| Edge | 5.14 ± 0.18 b | 5.32 ± 0.12 a |

| Adjacent | 4.41 ± 0.19 c | 4.12 ± 0.05 b |

| Center | 3.57 ± 0.04 d | 3.54 ± 0.03 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Braşoveanu, M.; Nemţanu, M.R. Temperature Profile in Starch during Irradiation. Indirect Effects in Starch by Radiation-Induced Heating. Materials 2021, 14, 3061. https://doi.org/10.3390/ma14113061

Braşoveanu M, Nemţanu MR. Temperature Profile in Starch during Irradiation. Indirect Effects in Starch by Radiation-Induced Heating. Materials. 2021; 14(11):3061. https://doi.org/10.3390/ma14113061

Chicago/Turabian StyleBraşoveanu, Mirela, and Monica R. Nemţanu. 2021. "Temperature Profile in Starch during Irradiation. Indirect Effects in Starch by Radiation-Induced Heating" Materials 14, no. 11: 3061. https://doi.org/10.3390/ma14113061