Effect of Different Polymer Modifiers on the Long-Term Rutting and Cracking Resistance of Asphalt Mixtures

Abstract

1. Introduction

2. Test Materials and Mixture Design

2.1. Asphalt Binder

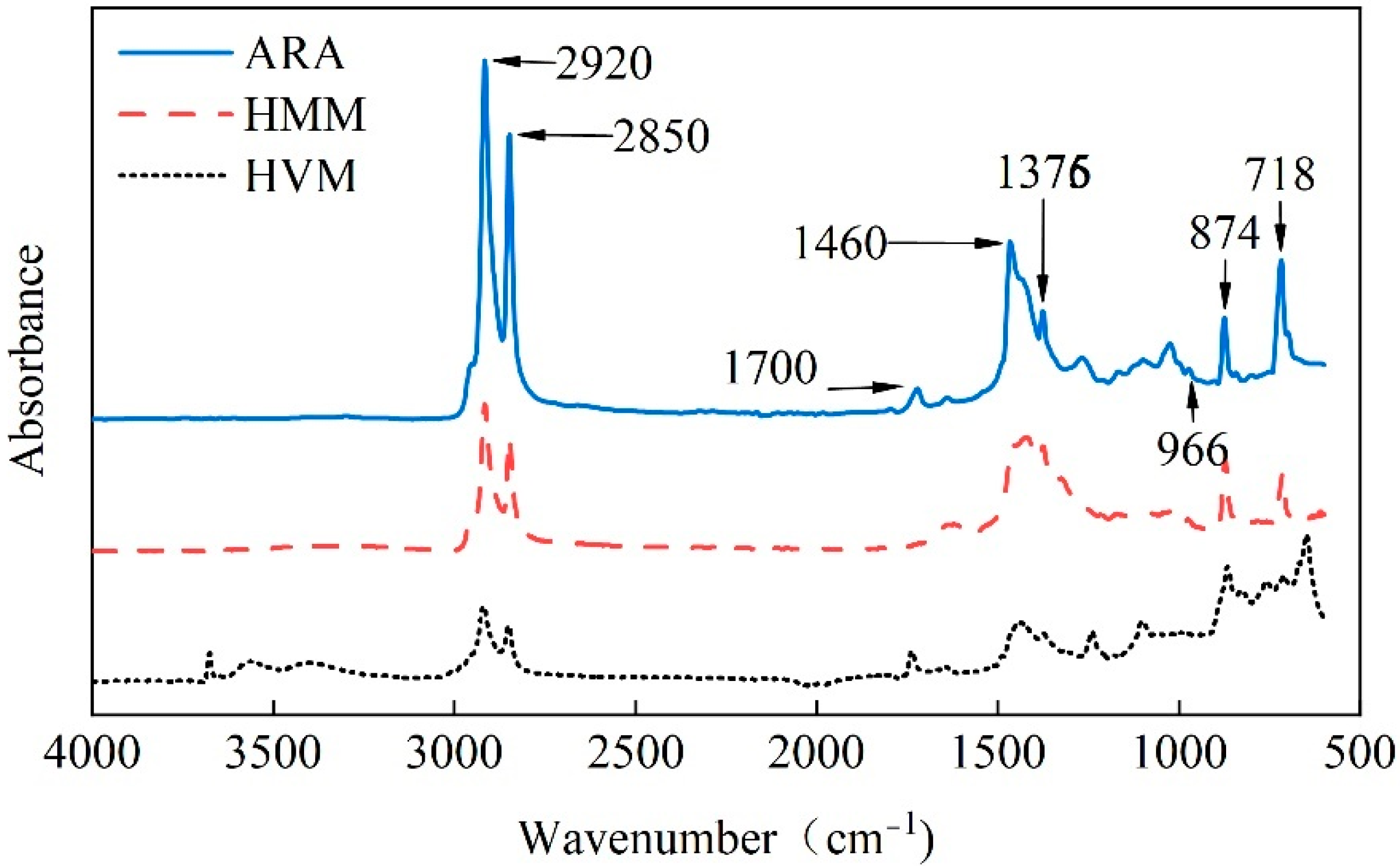

2.2. Polymer Additives

2.3. Aggregates

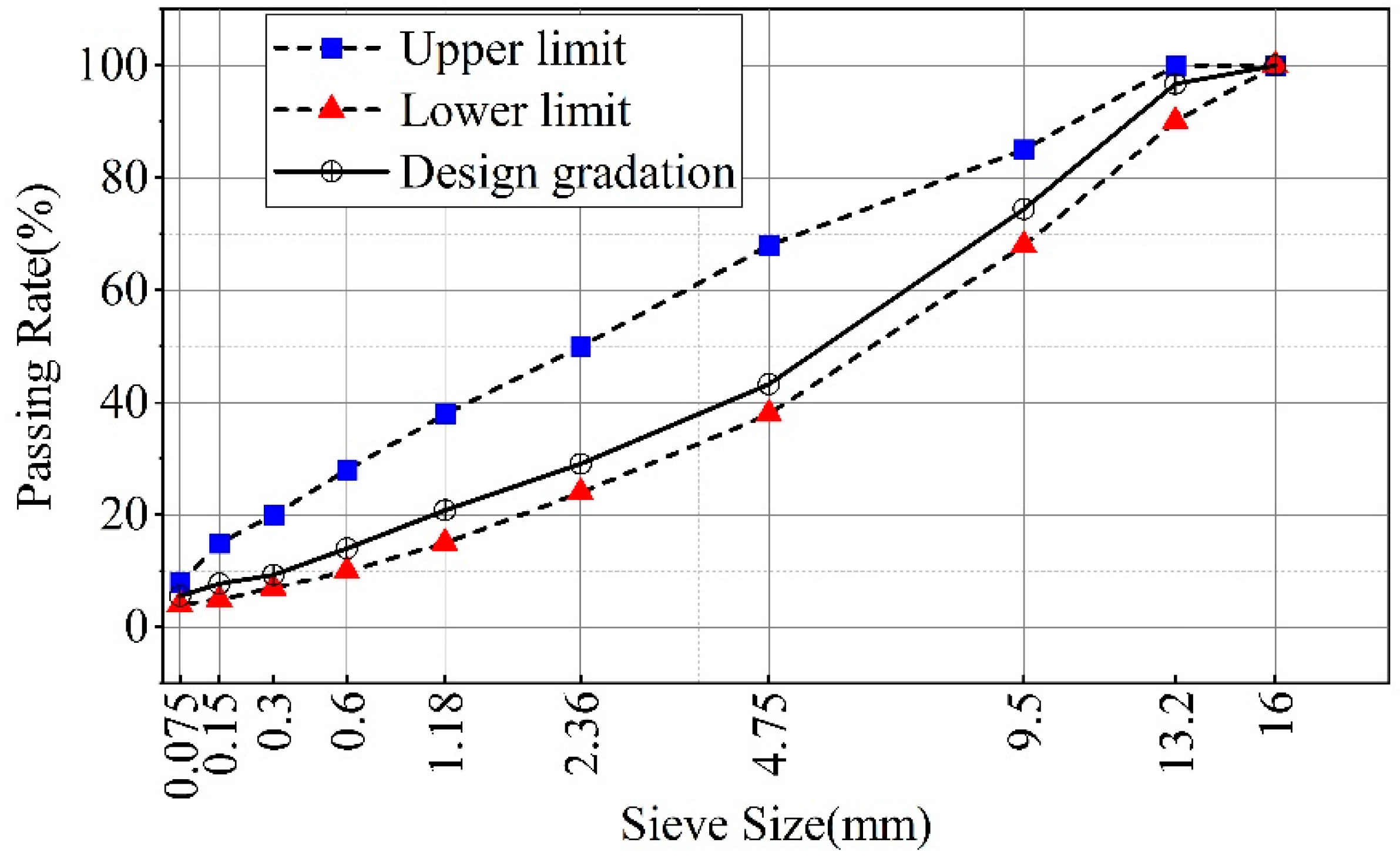

2.4. Asphalt Mixture Design

3. Methods

3.1. Aging Method

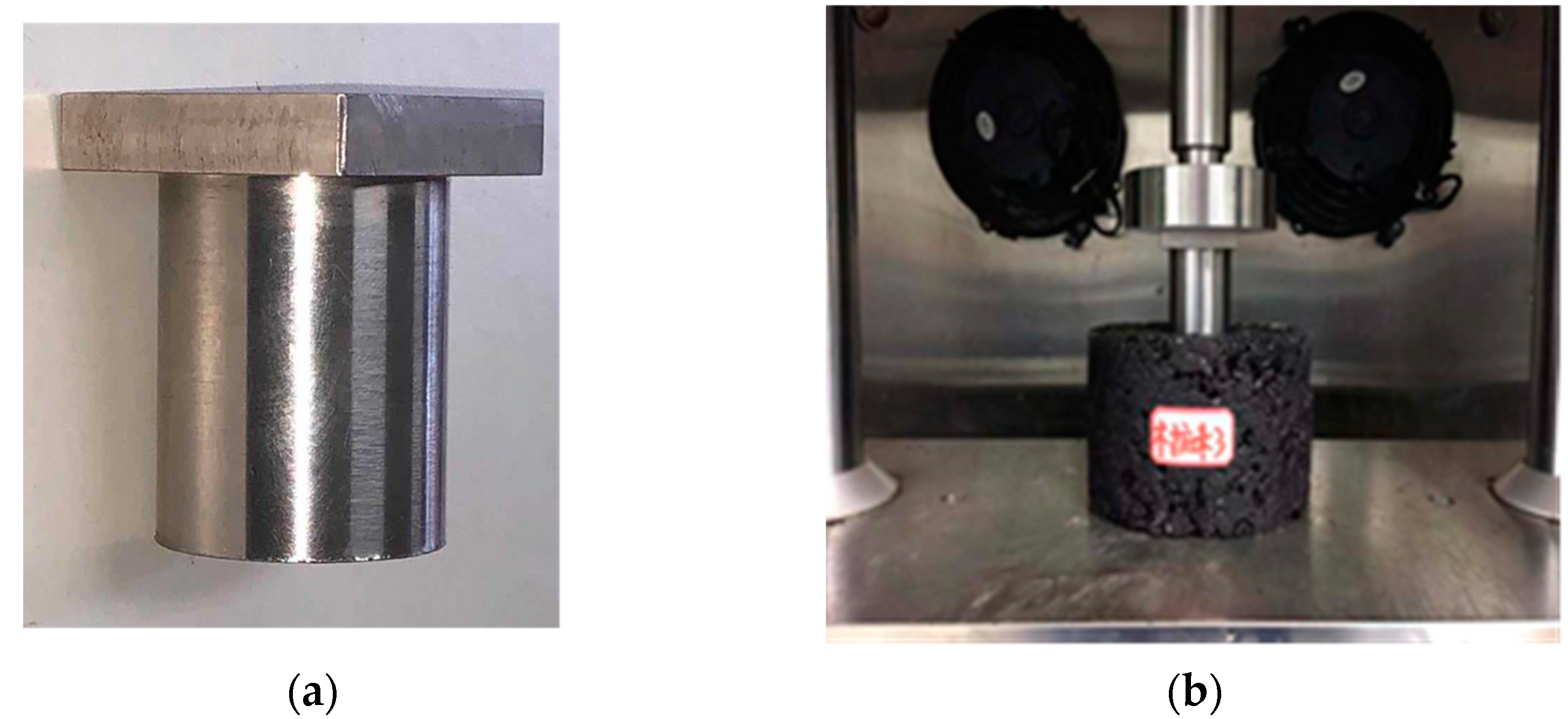

3.2. Test Methods for Deformation Property

3.2.1. Uniaxial Penetration Test

3.2.2. Hamburg Wheel-Tracking Test

3.3. Test Methods for Cracking Property

3.3.1. Semicircular Bending Test

3.3.2. IDEAL-CT

4. Results and Discussion

4.1. Effect of Modifiers on Deformation Performance of Asphalt Mixtures

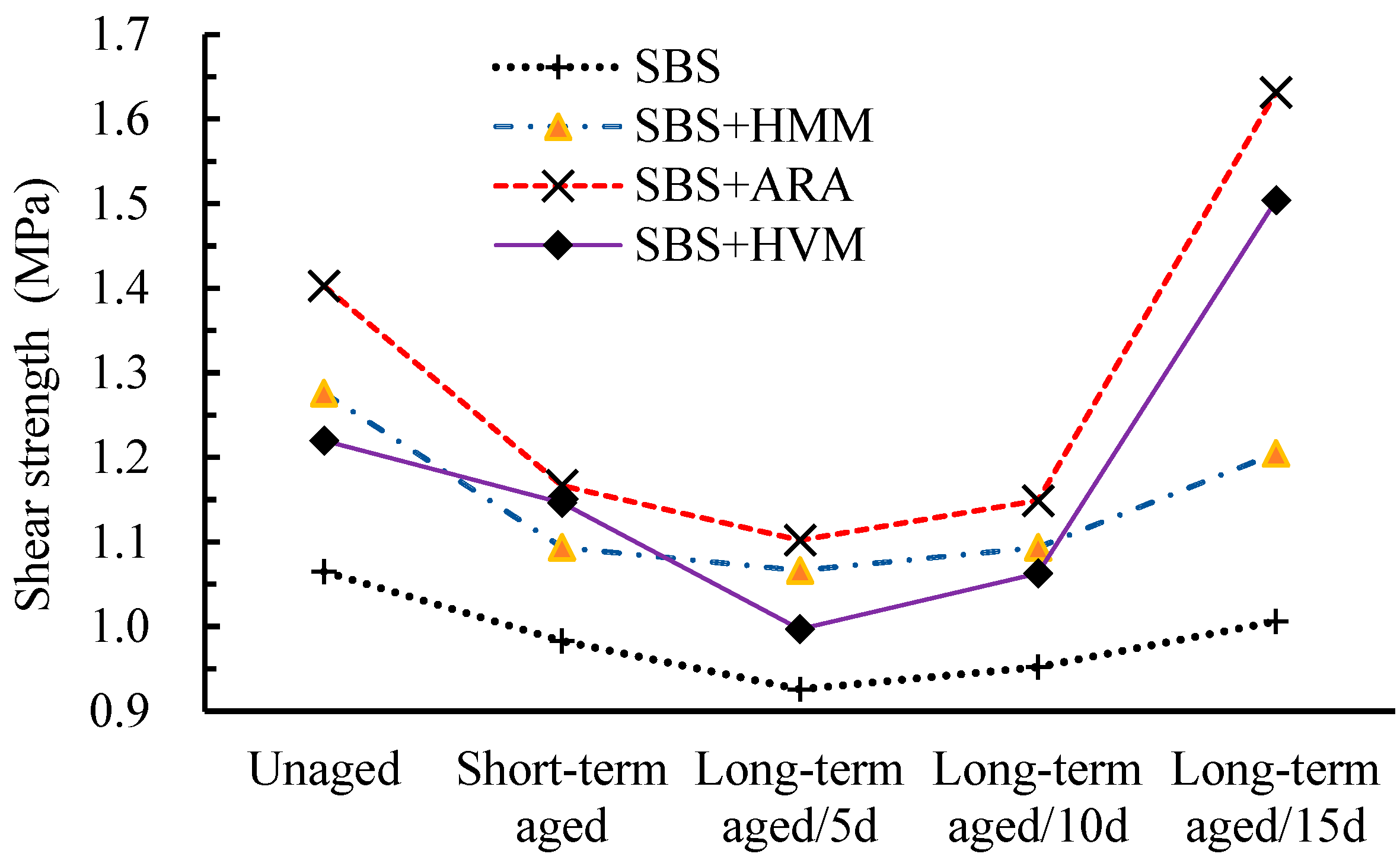

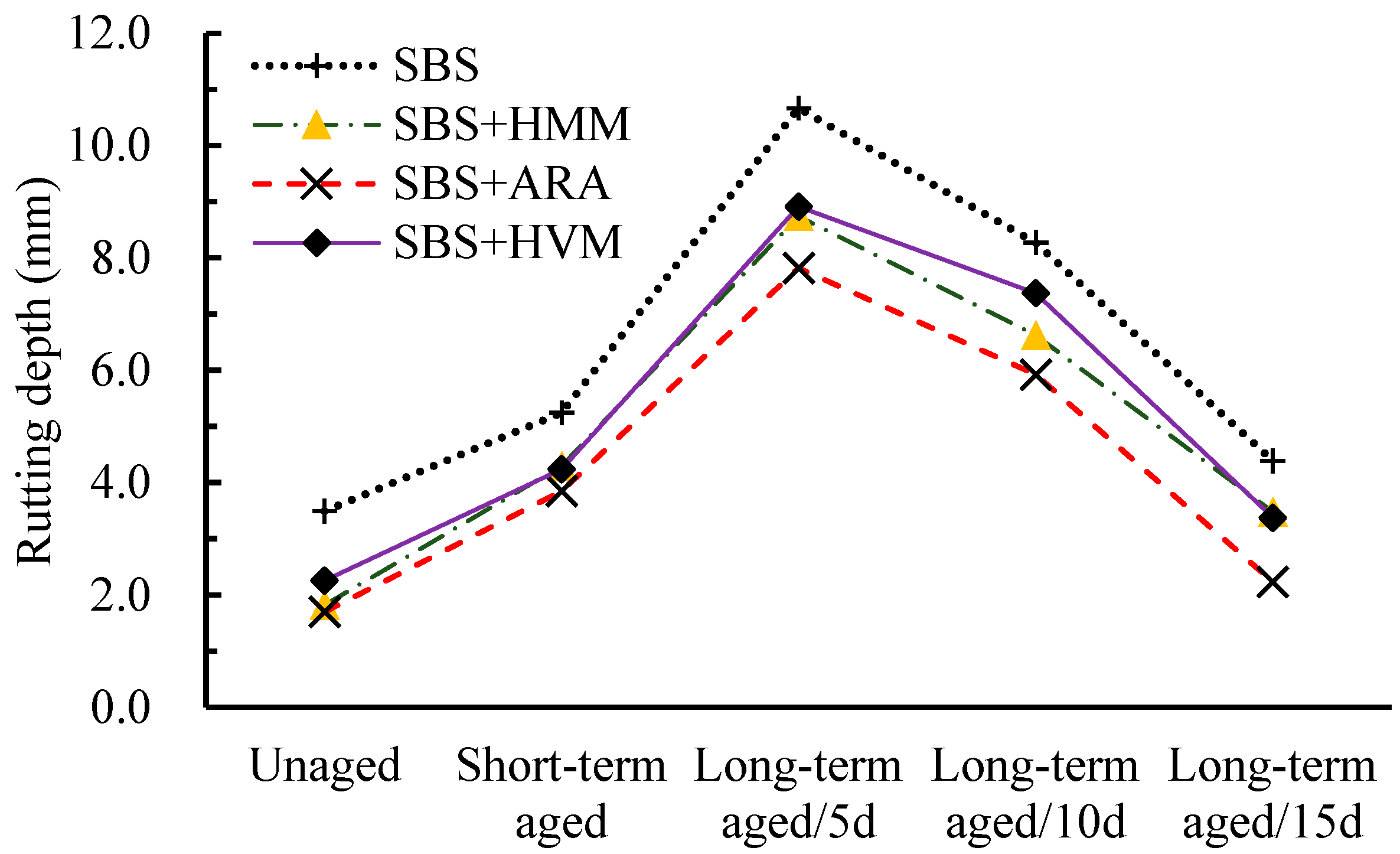

4.1.1. Uniaxial Penetration Test Results

- (1)

- All the three modifier additives improved the shear strength of SBS AC-13, and the improvement varied at different aging stages of the asphalt mixture. For instance, at the unaged stage, HMM, ARA, and HVM improved the shear strength by up to 19.8%, 31.7%, and 14.5%, respectively. At the short-term aging stage, however, the corresponding improvements were 11.3%, 18.7%, and 16.6%, respectively. Additionally, ARA improved the shear strength of AC-13 the most in all the aging stages. At the short-term aging stage and long-term aging (15 days) stage, HMM increased the shear strength more than HVM; in other aging states, however, the situation was reversed. This phenomenon indicated that the sensitivity of different modifiers to the aging process was different.

- (2)

- The shear strength of all asphalt mixtures changed into a V-shape as the aging progressed. From the unaged stage to the long-term aging stage (5 days), the shear strength decreased gradually. After the long-term aging stage (5 days), the shear strength increased gradually. Taking SBS AC13 as an example, its shear strength decreased by 7.7% and 13.1% after short-term aging and long-term aging, respectively, compared to the shear strength in the unaged stage. In contrast, based on the short-term aging shear strength, the 10-day-long-term aging and the 15-day-long-term aging performances increased by 2.8% and 8.6%, respectively. In addition, the shear strength of each asphalt mixture did not decrease or increase to the same extent, which further indicated that different modifiers have different sensitivities to aging, but they all have the lowest shear strength at the 5-day-long-term stage.

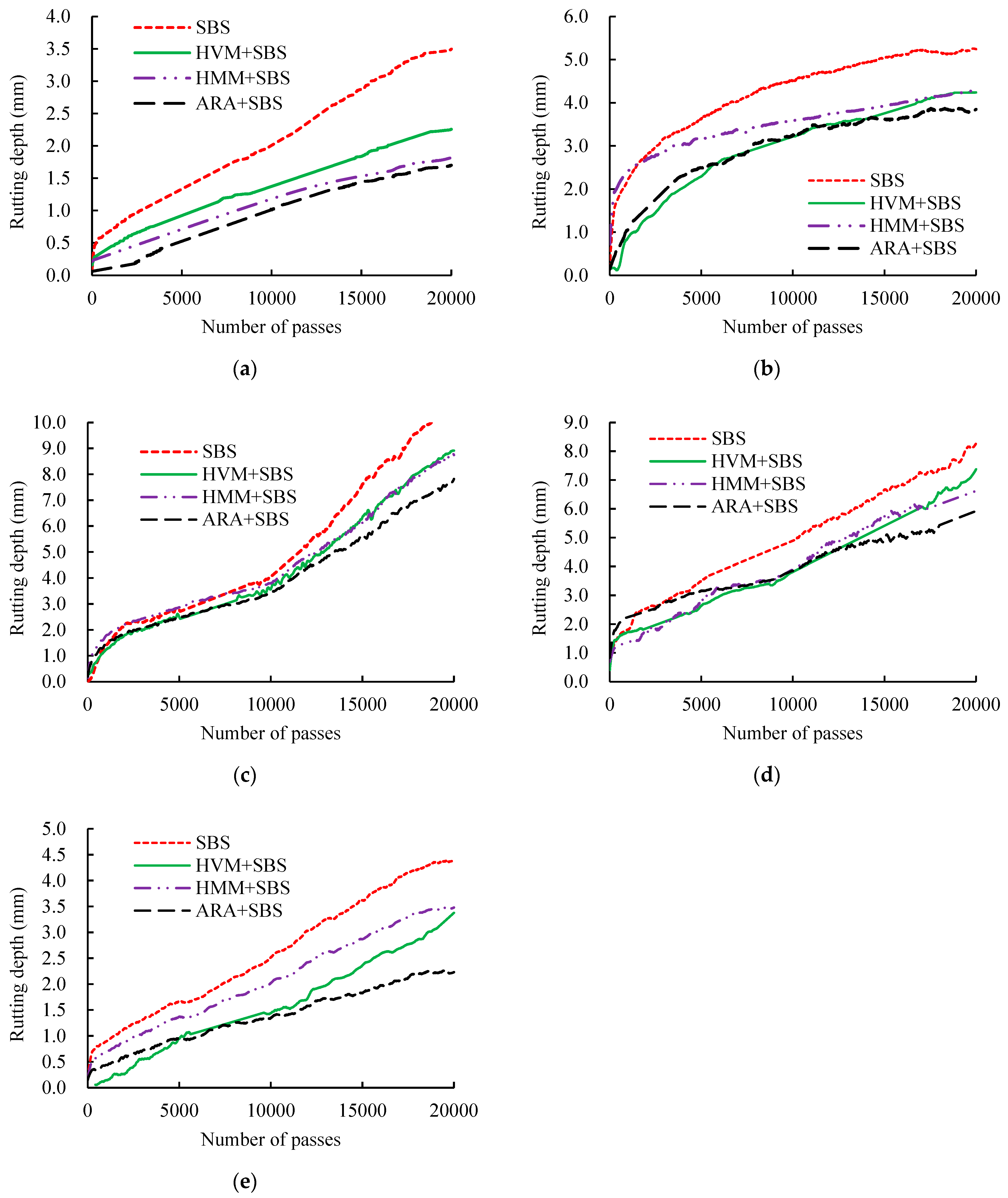

4.1.2. Hamburg Wheel-Tracking Test Results

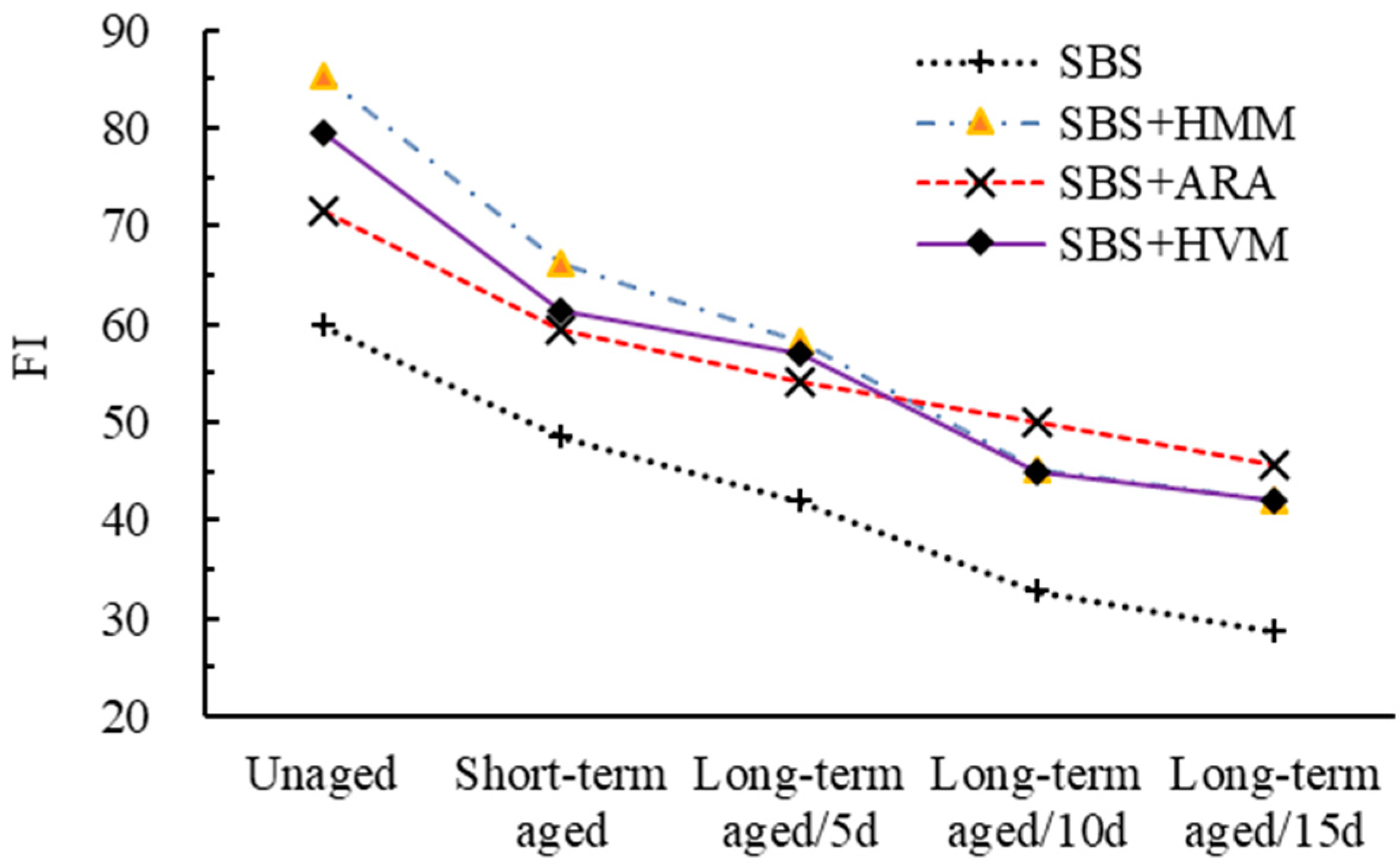

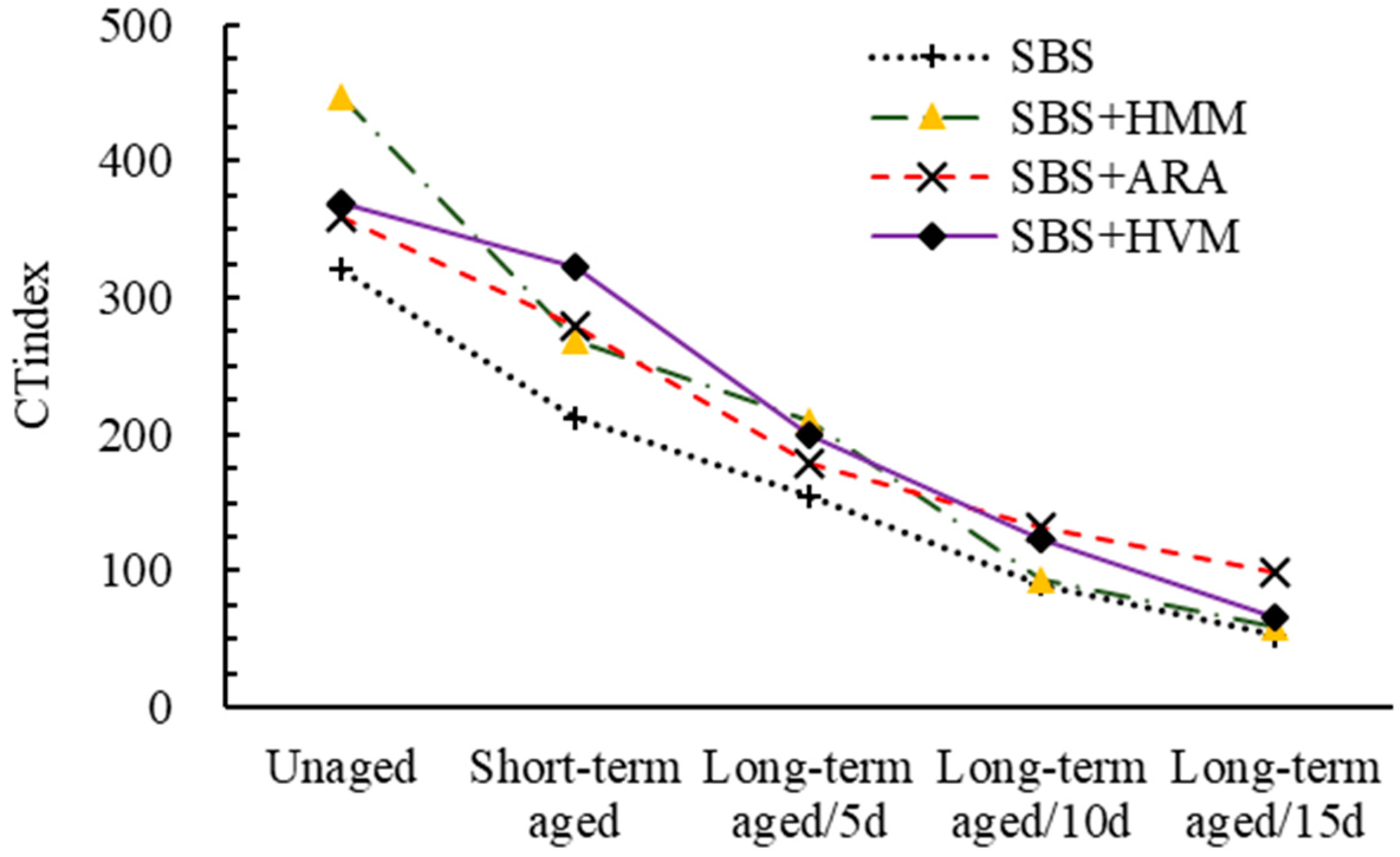

4.2. Effect of Modifiers on Cracking Resistance of Asphalt Mixtures

5. Conclusions and Recommendations

- (1)

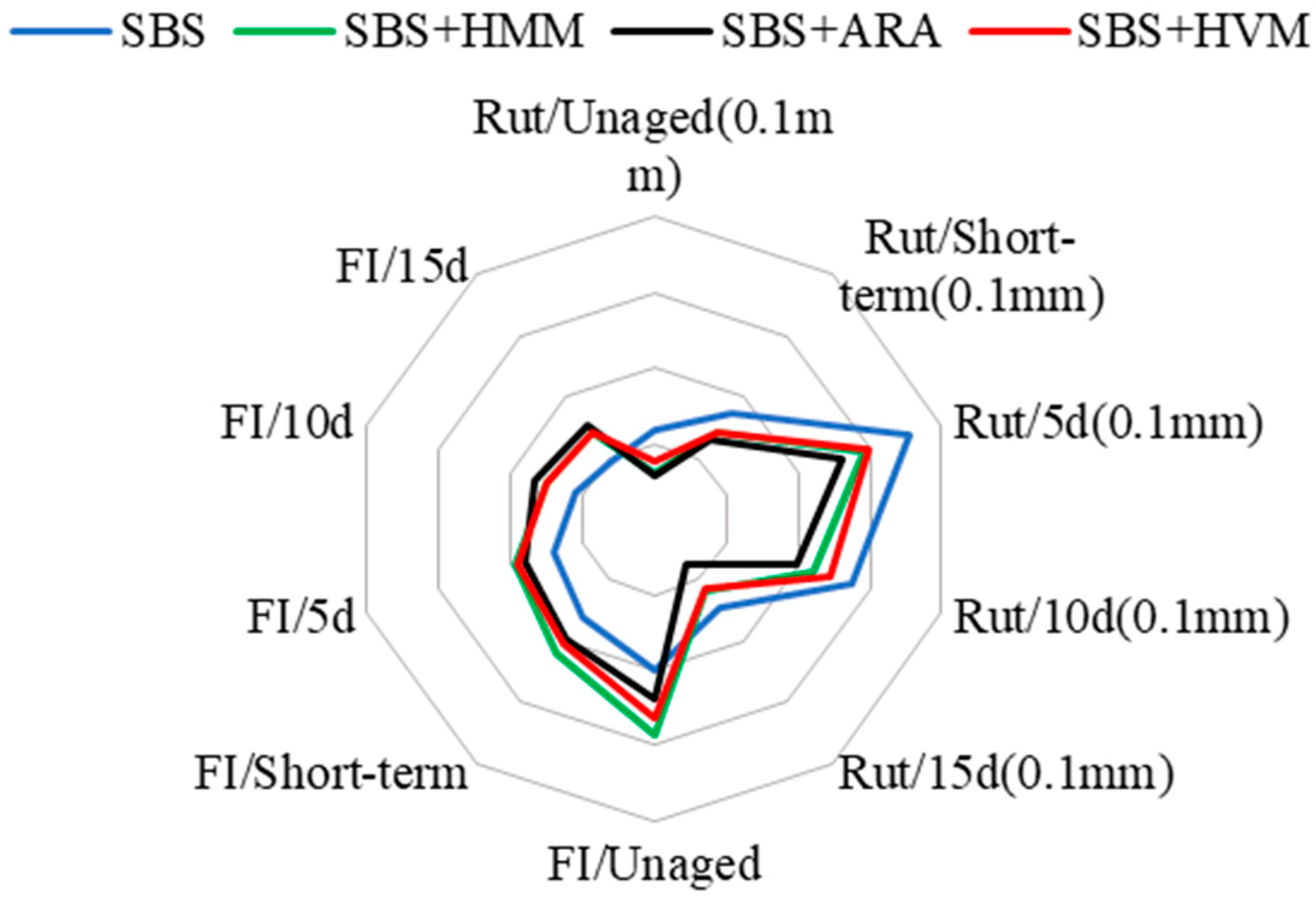

- The rutting resistance of all asphalt mixtures changed into a V-shape as the aging progressed. From the unaged stage to the long-term aging stage (5 days), the shear strength decreased gradually. While after the long-term aging stage (5 days), the shear strength increased gradually.

- (2)

- Both FI and CTindex gradually declined with the increasing of the aging degree, indicating that aging weakened the crack resistance of the asphalt mixtures.

- (3)

- Different polymer modifiers showed different sensitivities to aging. The long-term rutting resistance of ARA AC-13 was the best, and the long-term cracking resistance of ARA AC, HMM AC, and HVM AC showed no significant differences. In this study, the effect of ARA on the long-term performance of asphalt mixtures was more significant.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Huang, W.; Hao, G.; Yan, C.; Lv, Q.; Cai, Q. Evaluation of open-grade friction course (OGFC) mixtures with high content SBS polymer modified asphalt. Constr. Build. Mater. 2020, 270, 121374. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Gao, J.; You, Z.; Yang, X. High temperature performance of SBS modified bio-asphalt. Constr. Build. Mater. 2017, 144, 99–105. [Google Scholar] [CrossRef]

- Li, L.; Chen, Z.; Zhang, H.; Duan, H. Effect of Thermochromic Materials on the Properties of SBS-Modified Asphalt Mixture. J. Mater. Civil Eng. 2020, 32, 04020388. [Google Scholar] [CrossRef]

- Li, L.; Chen, Z.; Zhang, H.; Duan, H. Phase II NCAT Test Track Results; NCAT Report 06-05; National Center for Asphalt Technology: Auburn, AL, USA, 2006. [Google Scholar]

- Padhan, R.K.; Sreeram, A. Enhancement of storage stability and rheological properties of polyethylene (PE) modified asphalt using cross linking and reactive polymer based additives. Constr. Build. Mater. 2018, 188, 772–780. [Google Scholar] [CrossRef]

- Sureshkumar, M.S.; Filippi, S.; Polacco, G.; Kazatchkov, I.; Stastna, J.; Zanzotto, L. Internal structure and linear viscoelastic properties of EVA/asphalt nanocomposites. Eur. Polym. J. 2010, 46, 621–633. [Google Scholar] [CrossRef]

- Liang, P.; Liang, M.; Fan, W.; Zhang, Y.; Qian, C.; Ren, S. Improving thermo-rheological behavior and compatibility of SBR modified asphalt by addition of polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 139, 183–192. [Google Scholar] [CrossRef]

- Wu, C.Y.; Jing, B.; Li, X.Y. Performance Evaluation of High-Modulus Asphalt Mixture. Adv. Mater. Res. 2011, 311–313, 2138–2141. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, J.H.; Park, H.M. Performance evaluation of high modulus asphalt mixtures for long-life asphalt pavements. Constr. Build. Mater. 2007, 21, 1079–1087. [Google Scholar] [CrossRef]

- Ulucayli, M. Utilization of Anti-rutting additives and experience gained in Turkey. In Proceedings of the 3rd International Conference Bituminous Mixtures and Pavements, Thessaloniki, Greece, 5–6 November 2002. [Google Scholar]

- Chen, Z.; Zhang, X.; Cong, L.; Lu, H.; Yang, J. Rutting resistance performance evaluation of superpave mixes with antirutting additives. In Proceedings of the Transportation Research Board 89th Annual Meeting, Washington, DC, USA, 10–14 January 2010. [Google Scholar]

- Sun, J.; Huang, L.; Li, C. Research on the technology applying anti-rutting additive to asphalt mixture. In Proceedings of the International Conference on Mechanical Engineering and Control Systems, Wuhan, China, 26–27 July 2015. [Google Scholar]

- Yang, Y.S.; Dong, Q. Study on durability of granulated crumb rubber asphalt pavement based on TPS high-viscosity asphalt. Appl. Mech. Mater. 2014, 587–589, 985–989. [Google Scholar] [CrossRef]

- Li, M.; Zeng, F.; Xu, R.; Cao, D.; Li, J. Study on compatibility and rheological properties of high-viscosity modified asphalt prepared from low-grade asphalt. Materials 2019, 12, 3776. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, J.; Xiao, F.; Amirkhanian, S.; Wang, J.; Xu, Z. Impacts of multiple-polymer components on high temperature performance characteristics of airfield modified binders. Constr. Build. Mater. 2017, 134, 694–702. [Google Scholar] [CrossRef]

- Herrington, P.R. Diffusion and reaction of oxygen in bitumen films. Fuel 2012, 94, 86–92. [Google Scholar] [CrossRef]

- Pipintakos, G.; Soenen, H.; Ching, H.V.; Velde, C.V.; Van Doorslaer, S.; Lemière, F.; Varveri, A.; Varveri, A. Exploring the oxidative mechanisms of bitumen after laboratory short-and long-term ageing. Constr. Build. Mater. 2021, 289, 123182. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. Influence of aging on thermal behavior and characterization of SBR compound-modified asphalt. J. Therm. Anal. Calorim. 2014, 115, 1211–1218. [Google Scholar] [CrossRef]

- Cortizo, M.S.; Larsen, D.O.; Bianchetto, H.; Alessandrini, J.L. Effect of the thermal degradation of SBS copolymers during the ageing of modified asphalts. Polym. Degrad. Stab. 2004, 86, 275–282. [Google Scholar] [CrossRef]

- Sugano, M.; Iwabuchi, Y.; Watanabe, T.; Kajita, J.; Iwata, K.; Hirano, K. Relations between thermal degradations of SBS copolymer and asphalt substrate in polymer modified asphalt. Clean Technol. Environ. Policy 2010, 12, 653–659. [Google Scholar] [CrossRef]

- Zhao, Y.; Gu, F.; Xu, J.; Jin, J. Analysis of aging mechanism of SBS polymer modified asphalt based on Fourier transform infrared spectrum. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 1047–1052. [Google Scholar] [CrossRef]

- Yan, C.; Huang, W.; Xiao, F.; Wang, L.; Li, Y. Proposing a new infrared index quantifying the aging extent of SBS-modified asphalt. Road Mater. Pavement Des. 2018, 19, 1406–1421. [Google Scholar] [CrossRef]

- Margaritis, A.; Pipintakos, G.; Jacobs, G.; Hernando, D.; Bruynen, M.; Bruurs, J.; Van den Bergh, W. Evaluating the role of recycling rate and rejuvenator on the chemo-rheological properties of reclaimed polymer-modified binders. Road Mater. Pavement Des. 2021, 22, s83–s98. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. (JTG F40-2004). Technical Specification for Construction of Highway Asphalt Pavements; China Communication Press: Beijing, China, 2004. [Google Scholar]

- AASHTO R30-2015. Standard Practice for Mixture Conditioning of Hot Mix Asphalt (HMA); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- Su, K.; Sun, L.J.; Hachiya, Y. A new method for predicting rutting in asphalt pavements employing static uniaxial penetration test. International. J. Pavement Res. Technol. 2008, 1, 24–33. [Google Scholar]

- AASHTO T 324-2014. Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Hot Mix Asphalt (HMA); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- AASHTO TP 124. Standard Method of Test for Determining the Fracture Potential of Asphalt Mixtures Using the Illinois Flexibility Index Test (I-FIT); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- Zhou, F.; Im, S.; Sun, L.; Scullion, T. Development of an IDEAL cracking test for asphalt mix design and QC/QA. Road Mater. Pavement Des. 2017, 18 (Suppl. 4), 405–427. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Fan, W.; Wang, H.; Erkens, S. Rheological properties, compatibility, and storage stability of SBS latex-modified asphalt. Materials 2019, 12, 3683. [Google Scholar] [CrossRef] [PubMed]

- Cavalcante, L.; Aguiar, S.; Barbosa, S.J. Characterization and thermal behavior of polymer-modified asphalt. Mater. Res. 2004, 7, 529–534. [Google Scholar]

- Yut, I.; Zofka, A. Correlation between rheology and chemical composition of aged polymer-modified asphalts. Constr. Build. Mater. 2014, 62, 109–117. [Google Scholar] [CrossRef]

| Index | Unit | Value | Test Method |

|---|---|---|---|

| Penetration at 25 °C | 0.1 mm | 71 | JTG E20 T0604 |

| Penetration Index | - | 0.5 | JTG E20 T0604 |

| Ductility at 5 °C | cm | 48 | JTG E20 T0605 |

| Softening point | °C | 64 | JTG E20 T0606 |

| Viscosity at 135 °C | Pa·s | 1.8 | JTG E20 T0625 |

| Items | Results of Various Mofifiers | ||

|---|---|---|---|

| HVM | HMM | ARA | |

| Exterior | Black granules | Black granules | Black granules |

| Melt index (g/10 min) | 6–12 | 5–11 | 5–11 |

| Softening point (°C) | 160–175 | 120–130 | 120–150 |

| Dry mix dispersibility | No residue | No residue | No residue |

| Modifer content (%) | ≥95 | ≥95 | ≥95 |

| Aggregate Size (mm) | 10–15 | 5–10 | 3–5 | 0–3 |

|---|---|---|---|---|

| Bulk relative density | 2.753 | 2.746 | 2.721 | 2.635 |

| Apparent relative gravity | 2.776 | 2.778 | 2.768 | 2.695 |

| Water absorption (%) | 0.30 | 0.42 | 0.62 | 0.84 |

| Items | Optimal Asphalt Content (OAC) (%) | Voids Volume (VV) (%) | Voids in the Minreal Aggregate (VMA) (%) | Voids Filled with Asphalt (VFA) (%) |

|---|---|---|---|---|

| Values | 4.67 | 4.1 | 14.2 | 71.1 |

| Specification | - | 3~6 | ≮14.0 | 65~75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, B.; Luo, C.; Pei, Z.; Xia, J.; Chen, C.; Kang, A. Effect of Different Polymer Modifiers on the Long-Term Rutting and Cracking Resistance of Asphalt Mixtures. Materials 2021, 14, 3359. https://doi.org/10.3390/ma14123359

Wu B, Luo C, Pei Z, Xia J, Chen C, Kang A. Effect of Different Polymer Modifiers on the Long-Term Rutting and Cracking Resistance of Asphalt Mixtures. Materials. 2021; 14(12):3359. https://doi.org/10.3390/ma14123359

Chicago/Turabian StyleWu, Bangwei, Chufan Luo, Zhaohui Pei, Ji Xia, Chuangchuang Chen, and Aihong Kang. 2021. "Effect of Different Polymer Modifiers on the Long-Term Rutting and Cracking Resistance of Asphalt Mixtures" Materials 14, no. 12: 3359. https://doi.org/10.3390/ma14123359

APA StyleWu, B., Luo, C., Pei, Z., Xia, J., Chen, C., & Kang, A. (2021). Effect of Different Polymer Modifiers on the Long-Term Rutting and Cracking Resistance of Asphalt Mixtures. Materials, 14(12), 3359. https://doi.org/10.3390/ma14123359