Optimized Zirconia 3D Printing Using Digital Light Processing with Continuous Film Supply and Recyclable Slurry System

Abstract

:1. Introduction

2. Materials and Methods

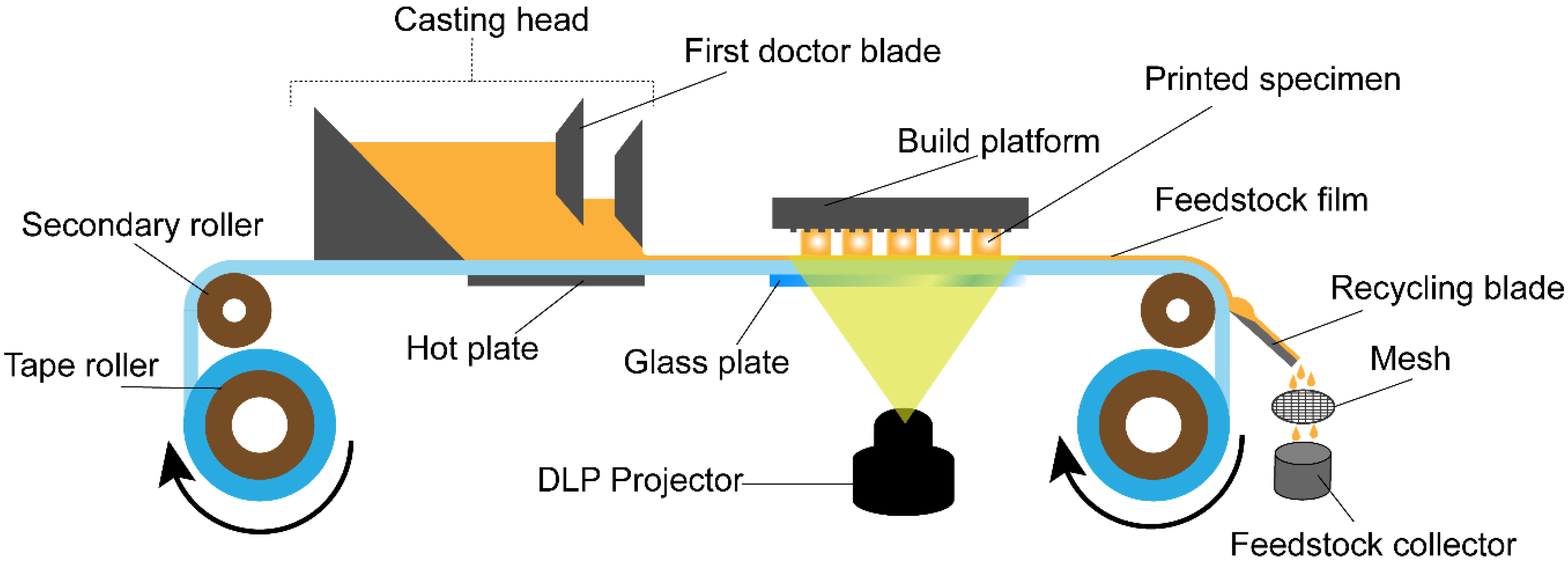

2.1. Printer Design and Processing

2.2. Slurry Preparation

2.3. Specimen 3D Printing

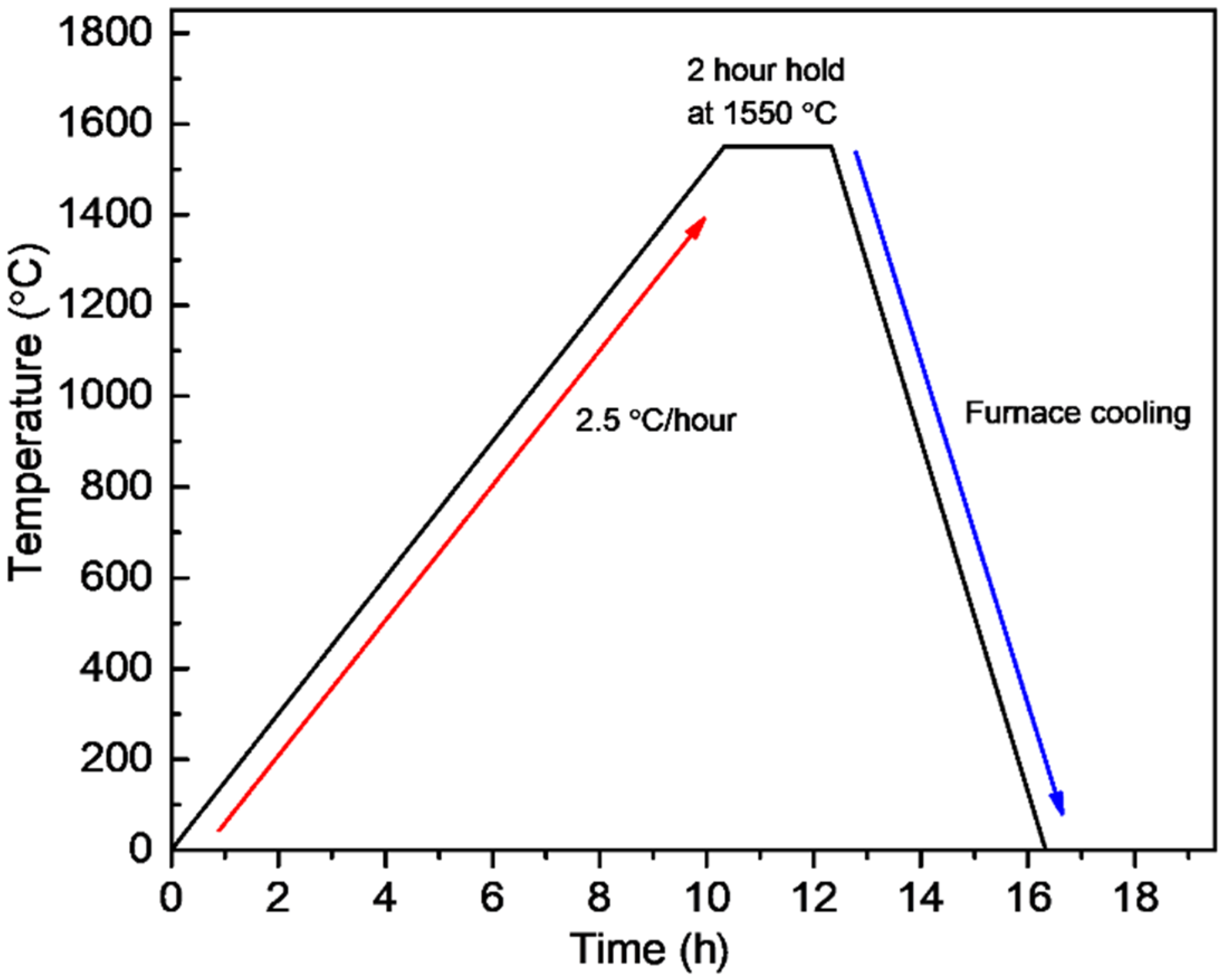

2.4. Postprocessing

2.5. Viscosity Analysis

2.6. Film Thickness Analysis of Slurry

2.7. Thermogravimetric Analysis

2.8. Density Analysis

2.9. Microhardness Testing

2.10. Microstructure Analysis

3. Results and Discussion

3.1. Viscosity Analysis

3.2. Film Thickness of Slurry

3.3. Thermogravimetric Analysis

3.4. Densification

3.5. Slurry Recycling Efficiency

3.6. Microhardness Test

3.7. Microstructure Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jang, K.J.; Kang, J.H.; Fisher, J.G.; Park, S.W. Effect of the volume fraction of zirconia suspensions on the microstructure and physical properties of products produced by additive manufacturing. Dent. Mater. 2019, 35, e97–e106. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.H.; Kaneda, J.; Jang, J.G.; Sakthiabirami, K.; Lui, E.; Kim, C.; Wang, A.; Park, S.W.; Yang, Y.P. The Influence of Electron Beam Sterilization on In Vivo Degradation of beta-TCP/PCL of Different Composite Ratios for Bone Tissue Engineering. Micromachines 2020, 11, 273. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kang, J.-H.; Jang, K.-J.; Sakthiabirami, K.; Oh, G.-J.; Jang, J.-G.; Park, C.; Lim, H.-P.; Yun, K.-D.; Park, S.-W. Mechanical properties and optical evaluation of scaffolds produced from 45S5 bioactive glass suspensions via stereolithography. Ceram. Int. 2020, 46, 2481–2488. [Google Scholar] [CrossRef]

- Ruiz-Morales, J.C.; Tarancón, A.; Canales-Vázquez, J.; Méndez-Ramos, J.; Hernández-Afonso, L.; Acosta-Mora, P.; Marín Rueda, J.R.; Fernández-González, R. Three dimensional printing of components and functional devices for energy and environmental applications. Energy Environ. Sci. 2017, 10, 846–859. [Google Scholar] [CrossRef] [Green Version]

- Hernández, E.; Acosta-Mora, P.; Méndez-Ramos, J.; Borges, M.; Esparza, P.; Canales-Vázquez, J.; Núñez, P.; Ruiz-Morales, J.C. Prospective use of the 3D printing technology for the microstructural engineering of Solid Oxide Fuel Cell components. Comput. Aided Des. 2014, 53, 213–216. [Google Scholar] [CrossRef]

- Tamayo-Domínguez, A.; González, J.M.F.; Sierra-Castañer, M. Stereolithography and Direct Metal Laser Sintering Applied to mm-Wave Antennas. In Proceedings of the 2020 International Symposium on Antennas and Propagation (ISAP), Virtual Conference, 25–28 January 2021; pp. 273–274. [Google Scholar]

- Wang, W.; Sun, J. Dimensional accuracy and clinical adaptation of ceramic crowns fabricated with the stereolithography technique. J. Prosthet. Dent. 2021, 125, 657–663. [Google Scholar] [CrossRef] [PubMed]

- Xing, H.; Zou, B.; Liu, X.; Wang, X.; Huang, C.; Hu, Y. Fabrication strategy of complicated Al2O3-Si3N4 functionally graded materials by stereolithography 3D printing. J. Eur. Ceram. Soc. 2020, 40, 5797–5809. [Google Scholar] [CrossRef]

- Zhang, K.; Meng, Q.; Cai, N.; Qu, Z.; He, R. Effects of solid loading on stereolithographic additive manufactured ZrO2 ceramic: A quantitative defect study by X-ray computed tomography. Ceram. Int. 2021. [Google Scholar] [CrossRef]

- Hu, K.; Wei, Y.; Lu, Z.; Wan, L.; Li, P. Design of a Shaping System for Stereolithography with High Solid Loading Ceramic Suspensions. 3D Print. Addit. Manuf. 2018, 5, 311–318. [Google Scholar] [CrossRef]

- Zhang, K.; Xie, C.; Wang, G.; He, R.; Ding, G.; Wang, M.; Dai, D.; Fang, D. High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceram. Int. 2019, 45, 203–208. [Google Scholar] [CrossRef]

- Li, K.; Zhao, Z. The effect of the surfactants on the formulation of UV-curable SLA alumina suspension. Ceram. Int. 2017, 43, 4761–4767. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, C.; Wang, J.; Zou, B. Development of a novel aqueous hydroxyapatite suspension for stereolithography applied to bone tissue engineering. Ceram. Int. 2019, 45, 3902–3909. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Lee, J.-B.; Maeng, W.-Y.; Koh, Y.-H.; Kim, H.-E. Photocurable ceramic slurry using solid camphor as novel diluent for conventional digital light processing (DLP) process. J. Eur. Ceram. Soc. 2019, 39, 4358–4365. [Google Scholar] [CrossRef]

- Johansson, E.; Lidström, O.; Johansson, J.; Lyckfeldt, O.; Adolfsson, E. Influence of Resin Composition on the Defect Formation in Alumina Manufactured by Stereolithography. Materials 2017, 10, 138. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A poly(d,l-lactide) resin for the preparation of tissue engineering scaffolds by stereolithography. Biomaterials 2009, 30, 3801–3809. [Google Scholar] [CrossRef] [Green Version]

- Jang, J.H.; Wang, S.; Pilgrim, S.M.; Schulze, W.A. Preparation and characterization of barium titanate suspensions for stereolithography. J. Am. Ceram. Soc. 2000, 83, 1804–1806. [Google Scholar] [CrossRef]

- Goswami, A.; Ankit, K.; Balashanmugam, N.; Umarji, A.M.; Madras, G. Optimization of rheological properties of photopolymerizable alumina suspensions for ceramic microstereolithography. Ceram. Int. 2014, 40, 3655–3665. [Google Scholar] [CrossRef]

- Janusziewicz, R.; Tumbleston, J.R.; Quintanilla, A.L.; Mecham, S.J.; DeSimone, J.M. Layerless fabrication with continuous liquid interface production. Proc. Natl. Acad. Sci. USA 2016, 113, 11703–11708. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Wang, M.; Xing, L.; Chu, J.; Bao, Y. Experimental and Numerical Investigation on Surface Damage of Cold Rolled Sheet Caused by Inclusion Movement; Springer International Publishing: Cham, Switzerland, 2020; pp. 239–247. [Google Scholar]

- Wu, Z.; Liu, W.; Wu, H.; Huang, R.; He, R.; Jiang, Q.; Chen, Y.; Ji, X.; Tian, Z.; Wu, S. Research into the mechanical properties, sintering mechanism and microstructure evolution of Al2O3-ZrO2 composites fabricated by a stereolithography-based 3D printing method. Mater. Chem. Phys. 2018, 207, 1–10. [Google Scholar] [CrossRef]

- Hinczewski, C.; Corbel, S.; Chartier, T. Ceramic suspensions suitable for stereolithography. J. Eur. Ceram. Soc. 1998, 18, 583–590. [Google Scholar] [CrossRef]

- O'Masta, M.R.; Stonkevitch, E.; Porter, K.A.; Bui, P.P.; Eckel, Z.C.; Schaedler, T.A. Additive manufacturing of polymer-derived ceramic matrix composites. J. Am. Ceram. Soc. 2020, 103, 6712–6723. [Google Scholar] [CrossRef]

- Alazzawi, M.K.; Beyoglu, B.; Haber, R.A. A study in a tape casting based stereolithography apparatus: Role of layer thickness and casting shear rate. J. Manuf. Process. 2021, 64, 1196–1203. [Google Scholar] [CrossRef]

- Halloran, J.W. Ceramic Stereolithography: Additive Manufacturing for Ceramics by Photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- Gentry, S.P.; Halloran, J.W. Depth and width of cured lines in photopolymerizable ceramic suspensions. J. Eur. Ceram. Soc. 2013, 33, 1981–1988. [Google Scholar] [CrossRef]

- Gentry, S.P.; Halloran, J.W. Light scattering in absorbing ceramic suspensions: Effect on the width and depth of photopolymerized features. J. Eur. Ceram. Soc. 2015, 35, 1895–1904. [Google Scholar] [CrossRef]

- Song, X.; Chen, Y.; Lee, T.W.; Wu, S.; Cheng, L. Ceramic fabrication using Mask-Image-Projection-based Stereolithography integrated with tape-casting. J. Manuf. Process. 2015, 20, 456–464. [Google Scholar] [CrossRef] [Green Version]

- Song, X. Slurry Based Stereolithography: A Solid Freeform Fabrication Method of Ceramics and Composites; University of Southern California: Los Angeles, CA, USA, 2016. [Google Scholar]

- Mills, P.; Raymont, J. Ultraviolet (UV) measurement for formulators: Park I. RadTech Rep. 2009, 23, 34. [Google Scholar]

- Conti, L.; Bienenstein, D.; Borlaf, M.; Graule, T. Effects of the Layer Height and Exposure Energy on the Lateral Resolution of Zirconia Parts Printed by Lithography-Based Additive Manufacturing. Materials 2020, 13, 1317. [Google Scholar] [CrossRef] [Green Version]

- ASTM C1327-15(2019). Standard Test Method for Vickers Indentation Hardness of Advanced Ceramics; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar] [CrossRef]

- Mendelson, M.I. Average Grain Size in Polycrystalline Ceramics. J. Am. Ceram. Soc. 1969, 52, 443–446. [Google Scholar] [CrossRef]

- Robert, G.O.; Timothy, N.P. Computational Rheology; Imperial College Press: London, UK, 2002. [Google Scholar]

- Chou, Y.T.; Ko, Y.T.; Yan, M.F. Fluid flow model for ceramic tape casting. J. Am. Ceram. Soc. 1987, 70, C-280–C-282. [Google Scholar] [CrossRef]

- Huang, X.; Liu, C.; Gong, H. A viscoplastic flow modeling of ceramic tape casting. Mater. Manuf. Process. 1997, 12, 935–943. [Google Scholar] [CrossRef]

- Wonisch, A.; Polfer, P.; Kraft, T.; Dellert, A.; Heunisch, A.; Roosen, A. A Comprehensive Simulation Scheme for Tape Casting: From Flow Behavior to Anisotropy Development. J. Am. Ceram. Soc. 2011, 94, 2053–2060. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Y.; Ma, J. Bingham plastic fluid flow model for ceramic tape casting. Mater. Sci. Eng. A 2002, 337, 274–280. [Google Scholar] [CrossRef]

- Jabbari, M.; Hattel, J. Bingham plastic fluid flow model in tape casting of ceramics using two doctor blades—Analytical approach. Mater. Sci. Technol. 2014, 30, 283–288. [Google Scholar] [CrossRef]

- Trunec, M.; Cihlar, J. Removal of thermoplastic binders from ceramic green bodies. Ceramics 1997, 41, 67–80. [Google Scholar]

- Raigrodski, A.J. Contemporary all-ceramic fixed partial dentures: A review. Dent. Clin. N. Am. 2004, 48, 531–544. [Google Scholar] [CrossRef]

- Besimo, C.E.; Spielmann, H.P.; Rohner, H.P. Computer-assisted generation of all-ceramic crowns and fixed partial dentures. Int. J. Comput. Dent. 2001, 4, 243–262. [Google Scholar]

- Sun, C.; Zhang, X. The influences of the material properties on ceramic micro-stereolithography. Sens. Actuators A Phys. 2002, 101, 364–370. [Google Scholar] [CrossRef]

- Mitteramskogler, G.; Gmeiner, R.; Felzmann, R.; Gruber, S.; Hofstetter, C.; Stampfl, J.; Ebert, J.; Wachter, W.; Laubersheimer, J. Light curing strategies for lithography-based additive manufacturing of customized ceramics. Addit. Manuf. 2014, 1, 110–118. [Google Scholar] [CrossRef]

- Cottom, B.A.; Mayo, M.J. Fracture toughness of nanocrystalline ZrO2-3 mol% Y2O3 determined by Vickers indentation. Scr. Mater. 1996, 34, 809–814. [Google Scholar] [CrossRef]

- Ruiz, L.; Readey, M.J. Effect of Heat Treatment on Grain Size, Phase Assemblage, and Mechanical Properties of 3 mol% Y-TZP. J. Am. Ceram. Soc. 1996, 79, 2331–2340. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Wait time before curing | 12 s |

| Wait time after curing | 5 s |

| Tape speed | 8 mm/s |

| Build platform speed (z-direction) | 1 mm/s |

| Height of first blade | 1 mm |

| Height of second blade | 0.2 mm |

| X-Direction (%) | Y-Direction (%) | Z-Direction (%) |

|---|---|---|

| 22.59 ± 0.19 | 22.48 ± 0.15 | 22.56 ± 0.11 |

| Properties | First Use | Recycled Once | Recycled Twice | Recycled Thrice |

|---|---|---|---|---|

| Weight percent (%) | 81.32 ± 0.03 | 81.44 ± 0.04 | 81.58 ± 0.06 | 81.61 ± 0.02 |

| Relative Density (%) | 98.89 ± 0.03 | 98.86 ± 0.02 | 98.94 ± 0.03 | 98.91 ± 0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarwar, W.A.; Kang, J.-H.; Yoon, H.-I. Optimized Zirconia 3D Printing Using Digital Light Processing with Continuous Film Supply and Recyclable Slurry System. Materials 2021, 14, 3446. https://doi.org/10.3390/ma14133446

Sarwar WA, Kang J-H, Yoon H-I. Optimized Zirconia 3D Printing Using Digital Light Processing with Continuous Film Supply and Recyclable Slurry System. Materials. 2021; 14(13):3446. https://doi.org/10.3390/ma14133446

Chicago/Turabian StyleSarwar, Waqas Ahmed, Jin-Ho Kang, and Hyung-In Yoon. 2021. "Optimized Zirconia 3D Printing Using Digital Light Processing with Continuous Film Supply and Recyclable Slurry System" Materials 14, no. 13: 3446. https://doi.org/10.3390/ma14133446

APA StyleSarwar, W. A., Kang, J.-H., & Yoon, H.-I. (2021). Optimized Zirconia 3D Printing Using Digital Light Processing with Continuous Film Supply and Recyclable Slurry System. Materials, 14(13), 3446. https://doi.org/10.3390/ma14133446