Study on X-ray Induced Two-Dimensional Thermal Shock Waves in Carbon/Phenolic

Abstract

:1. Introduction

2. Theoretical Basis and Modelling Derivation

2.1. Introduction of Numerical Calculation Programme

2.2. Two-Dimensional Orthotropic Elastoplastic Constitutive Model

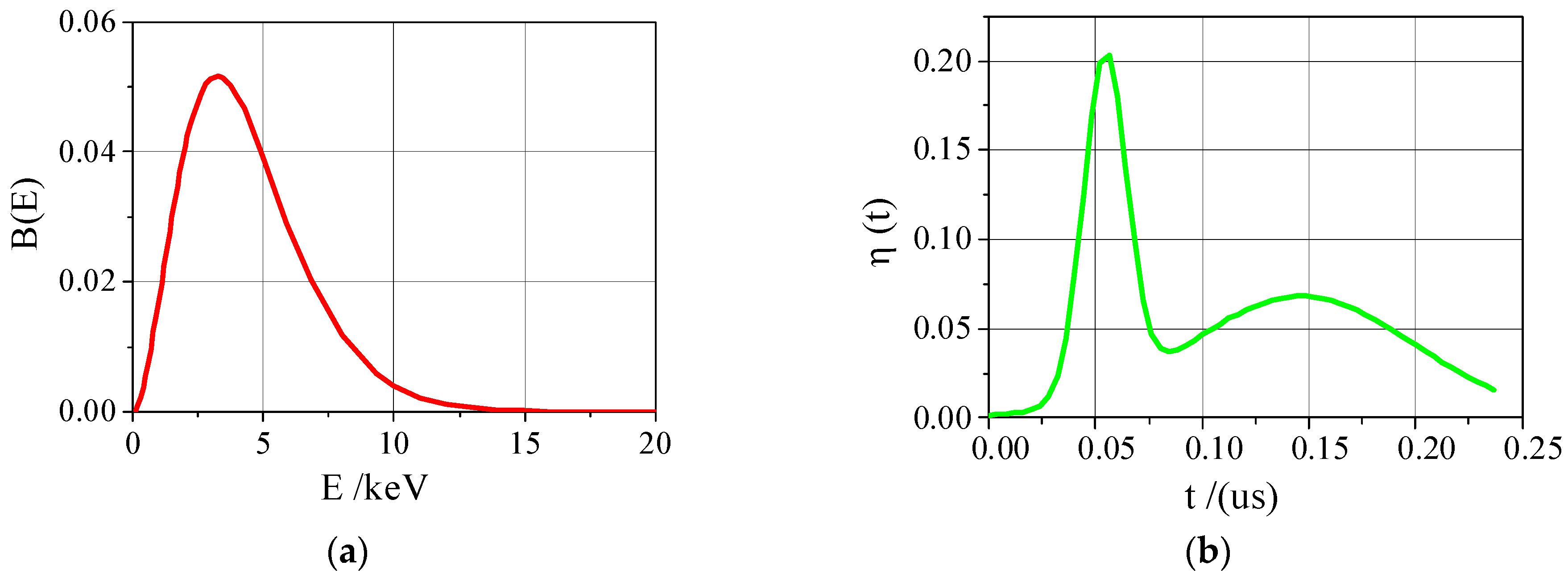

2.3. Energy Deposition of Unit Mass

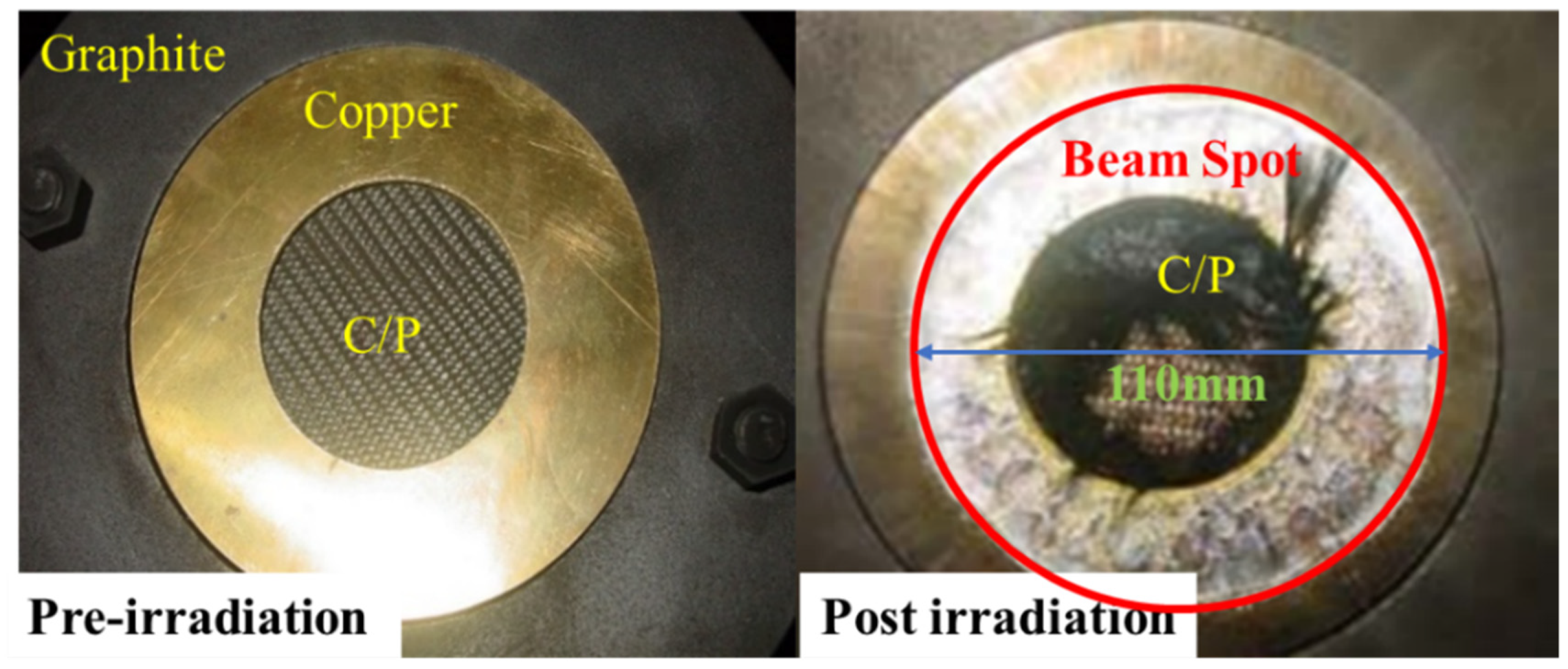

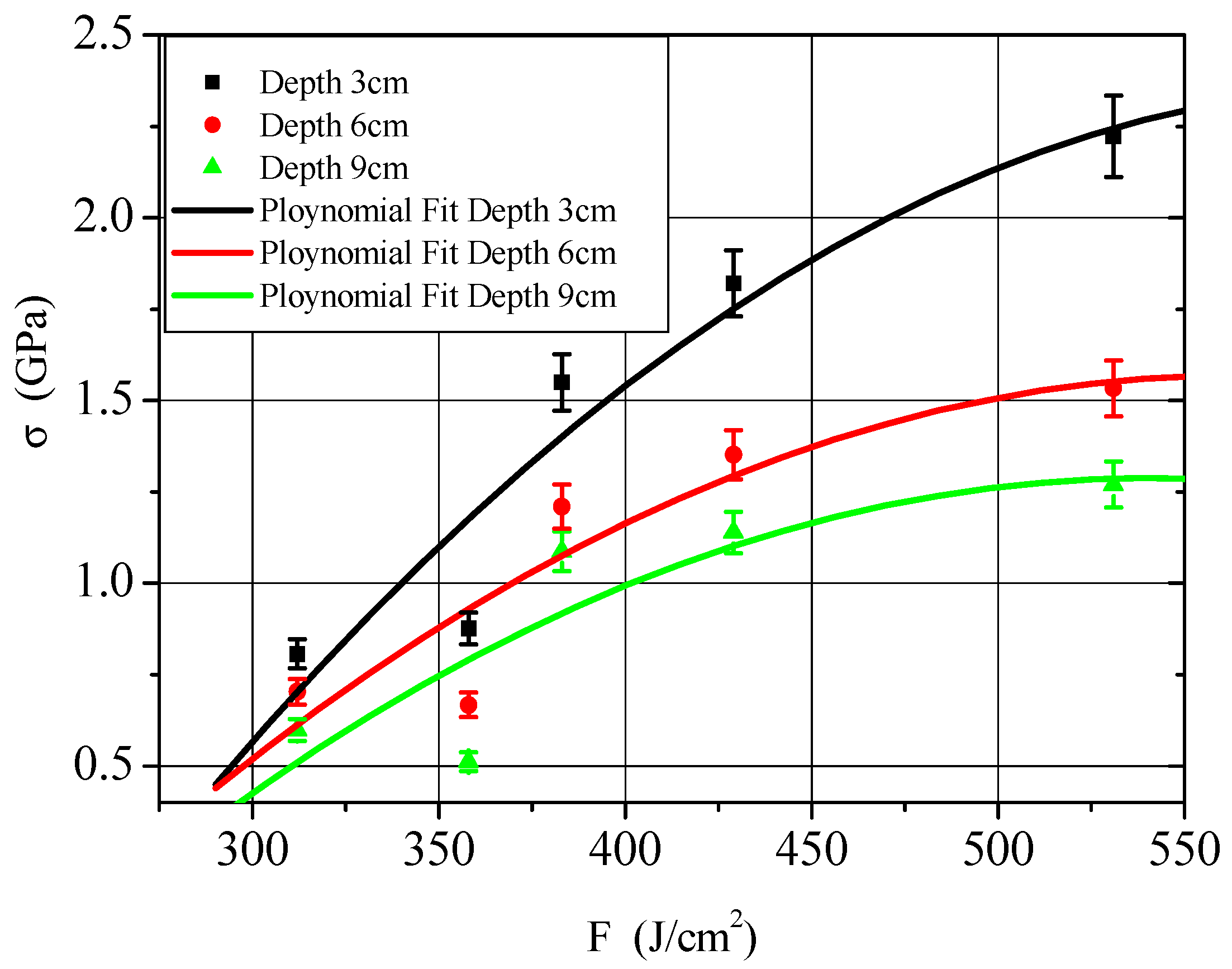

3. Experimental Comparison of C/P Materials Irradiated by Low Energy X-rays

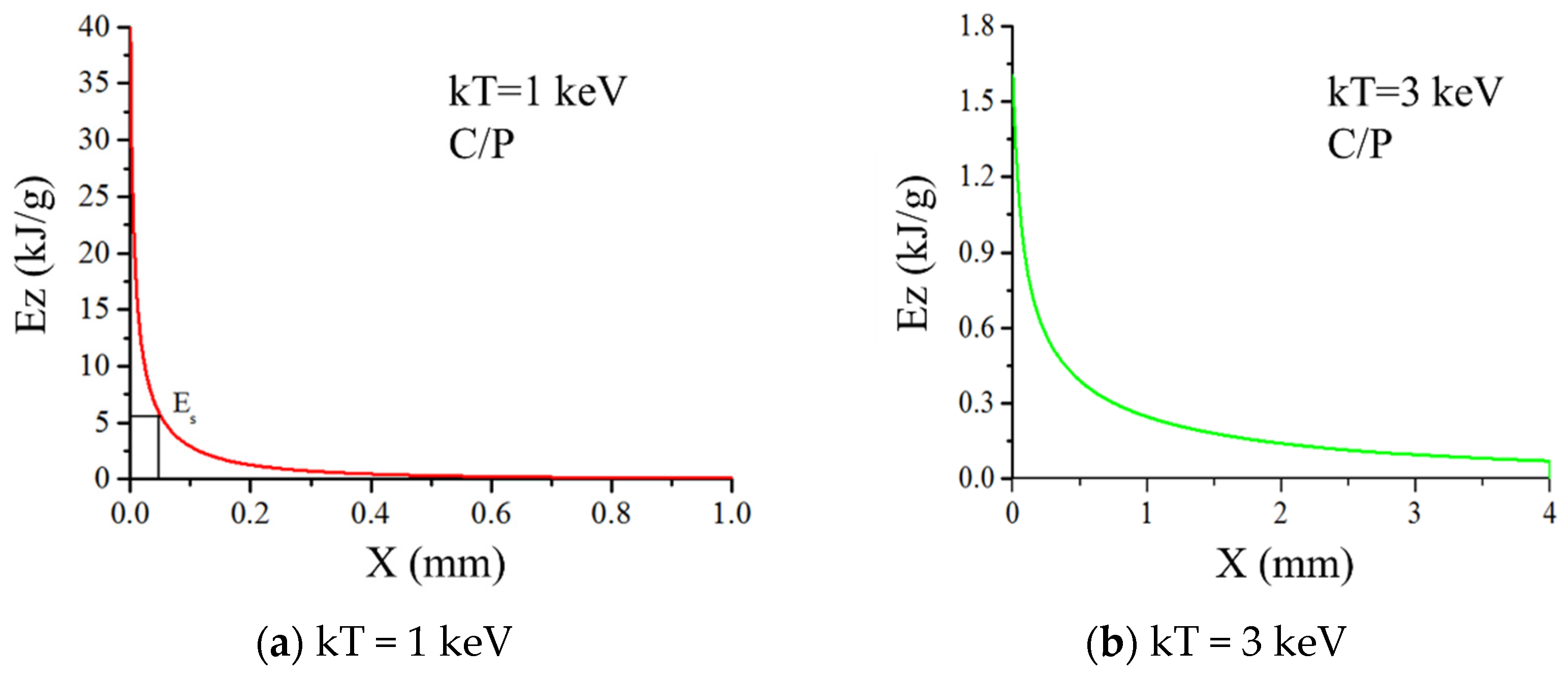

4. Calculation and Analysis of Thermal Shock Wave for Carbon Phenolic (C/P) Materials

5. Conclusions

- (1)

- The adopted elastoplastic constitutive model not only considers rate-dependent effects but also considers the nonlinear characteristics of volume changes during compression, expansion, and the anisotropic strength effects of materials, which can objectively reflect the true changes of materials. The theoretical predictions are in good agreement with the experimental results.

- (2)

- Using the X-rays generated by the high current electron accelerator to irradiate the surface of the C/P material, the stress peaks at the thermal shock wave measurement points are larger than the numerical simulation results, which are related to the X-ray energy deposition and stress attenuation rate.

- (3)

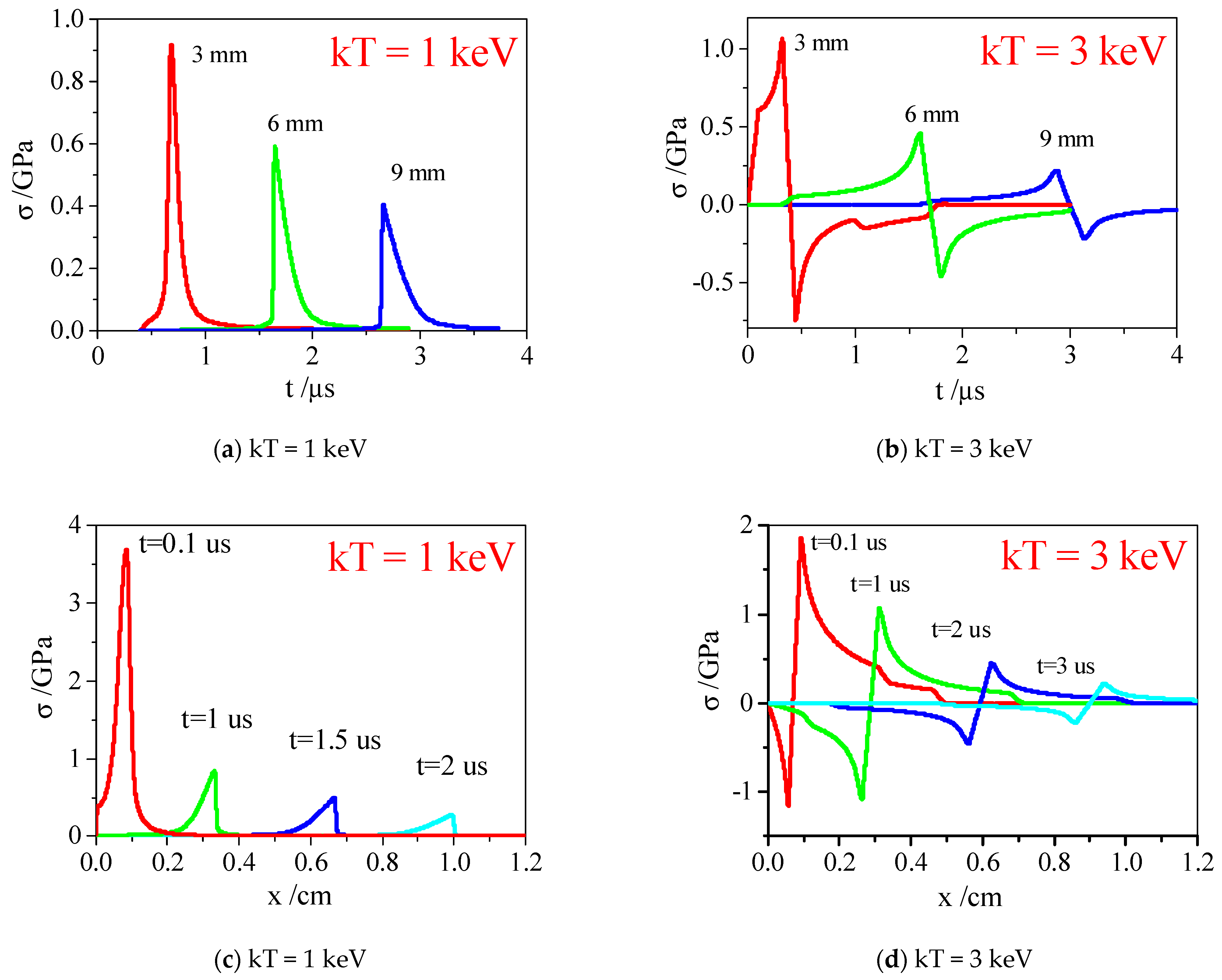

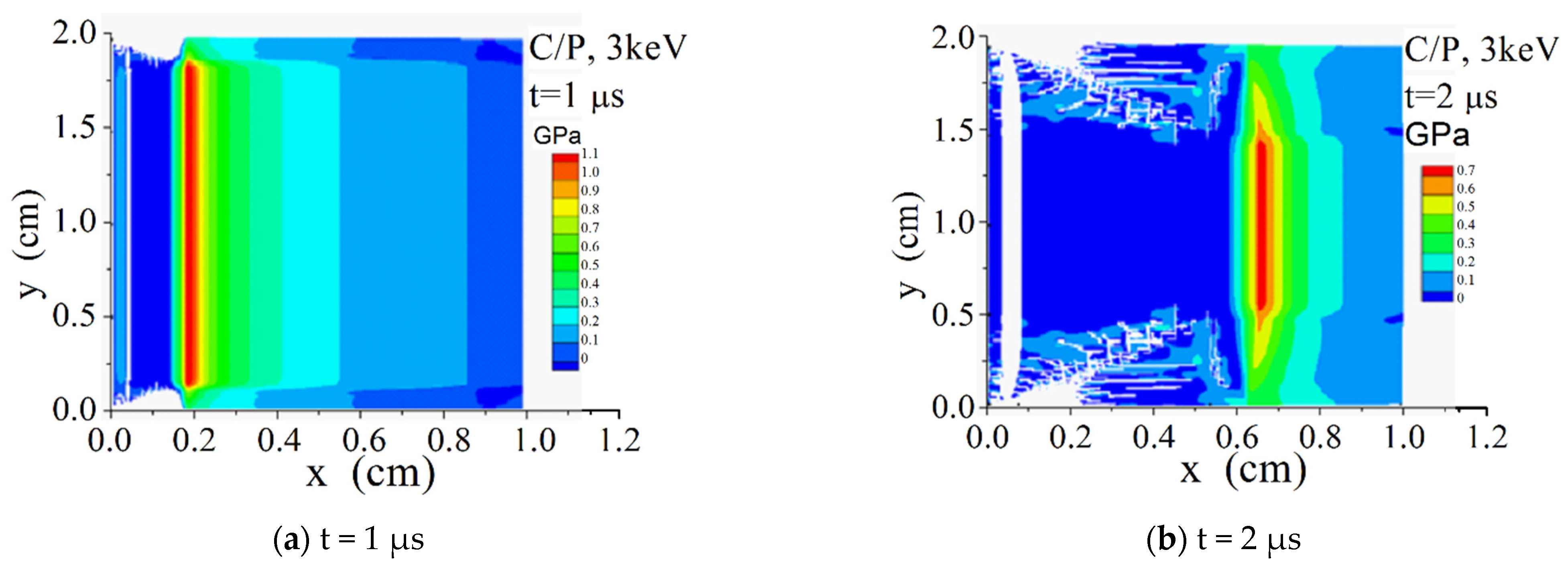

- X-ray-induced thermal shock waves in C/P materials have two mechanisms, namely thermal deformation and vaporization recoil. The vaporization recoil phenomenon appears under 1 keV X-ray irradiation, which is mainly manifested as a compression wave. Under 3 keV X-ray irradiation, X-ray penetration is deeper, and the induced thermal shock wave is caused by thermal deformation, resulting in a strong stretching phenomenon, which becomes the main cause of damage to the material.

- (4)

- The thermal shock waveforms in C/P under 1 keV and 3 keV X-ray irradiation, such as the peak value of thermal shock wave, X-ray penetration depth, vaporization phenomenon, tensile strength, etc., are very different. Thermal shock wave propagation exhibits two-dimensional characteristics. The energy deposition of 1 keV and 3 keV both decays exponentially. The energy deposition peak of 1 keV soft X-ray is high, and the deposition depth is shallow; the hard X-ray energy deposition peak of 3 keV is low, and the deposition depth is large.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- White, S. Radiation Testing of PICA at the Solar Power Tower. In Proceedings of the 10th AIAA/ASME Joint Thermophysics and Heat Transfer Conference, Chicago, IL, USA, 28 June–1 July 2010; p. 28. [Google Scholar]

- Du, Z.; Zhu, M.; Wang, Z.; Yang, J. Design and application of composite platform with extreme low thermal deformation for satellite. Compos. Struct. 2016, 152, 693–703. [Google Scholar]

- Xu, Y.Y. Thermal-Chemical Coupling Analysis of Low-Density Carbon/Phenolic Composites under Ablation Condition. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2016. [Google Scholar]

- Ryan, S.; Schaefer, F.; Riedel, W. Numerical simulation of hypervelocity impact on CFRP/Al HC SP spacecraft structures causing penetration and fragment ejection. Int. J. Impact Eng. 2006, 33, 703–712. [Google Scholar] [CrossRef]

- Min, S.; Chen, X.; Chai, Y.; Lowe, T. Effect of reinforcement continuity on the ballistic performance of composites reinforced with multiply plain weave fabric. Compos. Part B Eng. 2016, 90, 30–36. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, K.; Tang, W. Numerical Simulation of Thermal Shock Waves Induced by Pulsed X-ray in C/PF Materials. J. Phys. Conf. Ser. 2021, 1865, 022066. [Google Scholar] [CrossRef]

- Tang, W.H.; Zhang, R.Q.; Zhao, G.M. Thermal shock wave induced by impulsive X-ray. Chin. J. High Press. Phys. 1995, 9, 107–110. [Google Scholar]

- Zhou, N.; Qiao, D. Materials Dynamics under Pulse Beam Radiation; National Defence Industry Press: Beijing, China, 2002; pp. 401–404. [Google Scholar]

- Huang, X.; Tang, W.H.; Jiang, B.H. Influences of constitutive models on numerically simulated results of X-ray thermal shock waves in composite materials. Explos. Shock Waves 2011, 31, 600–605. [Google Scholar]

- Zhang, R.Q.; Tang, W.H.; Zhao, G.M. Several influential factors ON numerical simulated results for the X-ray thermal shock wave. Chin. J. High Press. Phys. 1998, 12, 161–167. [Google Scholar]

- Hertel, E.S.; Bell, R.L.; Elrick, M.G.; Farnsworth, A.V.; Kerley, G.I.; McGlaun, J.M.; Petney, S.V.; Silling, S.A.; Taylor, P.A.; Yarrington, L. CTH: A Software Family for Multi-Dimensional Shock Physics Analysis; Springer: Berlin/Heidelberg, Germany, 1995; pp. 377–382. [Google Scholar]

- Flock, R.A.; Liu, D.T. Numerical analysis of “thin film” Gruneisen test measurements. In Proceedings of the American Physical Society Topical Conference, Williamsburg, VA, USA, 17–20 June 1991; pp. 403–406. [Google Scholar]

- Grujicic, M.; Pandurangan, B.; Koudela, K.; Cheeseman, B. A computational analysis of the ballistic performance of light-weight hybrid composite armors. Appl. Surf. Sci. 2006, 253, 730–745. [Google Scholar] [CrossRef]

- Clegg, R.; White, D.; Riedel, W.; Harwick, W. Hypervelocity impact damage prediction in composites: Part I—Material model and characterisation. Int. J. Impact Eng. 2006, 33, 190–200. [Google Scholar] [CrossRef]

- Riedel, W.; Nahme, H.; White, D.; Clegg, R. Hypervelocity impact damage prediction in composites: Part II—Experimental investigations and simulations. Int. J. Impact Eng. 2006, 33, 670–680. [Google Scholar] [CrossRef]

- Lukyanov, A.A. Constitutive behaviour of anisotropic material under shock loading. Int. J. Plast. 2008, 24, 140–167. [Google Scholar] [CrossRef]

- Lukyanov, A.A. An equation of state for anisotropic solids under shock loading. Eur. Phys. J. B 2008, 64, 159–164. [Google Scholar] [CrossRef]

- Qiao, D. Thermodynamic Effect and Reinforcing Technology under Pulse X-ray Radiation; National Defense Industry Press: Beijing, China, 2012; pp. 118–196. [Google Scholar]

- Nagai, M.; Ikeda, T.; Miyazaki, N. Stress intensity factor analysis of an interface crack between dissimilar anisotropic materials under thermal stress using the finite element analysis. Int. J. Fract. 2007, 146, 233–248. [Google Scholar] [CrossRef]

- Khan, A.S.; Liu, H. Strain rate and temperature dependent fracture criteria for isotropic and anisotropic metals. Int. J. Plast. 2012, 37, 1–15. [Google Scholar] [CrossRef]

- Castres, M.; Berthe, J.; Brieu, M.; Deletombe, E. A strain rate and temperature dependent criterion to describe the linear nonlinear-behaviour’s transition of organic matrix composite materials in shear: Application to T700GC/M21. Mech. Mater. 2018, 124, 100–105. [Google Scholar] [CrossRef] [Green Version]

| NO. | E /keV | F /(J/cm2) | σ/GPa | ||

|---|---|---|---|---|---|

| 3 mm | 6 mm | 9 mm | |||

| 1 | 0.497 | 383 | 1.549 | 1.209 | 1.087 |

| 2 | 0.422 | 312 | 0.807 | 0.703 | 0.598 |

| 3 | 0.461 | 358 | 0.876 | 0.667 | 0.512 |

| 4 | 0.697 | 531 | 2.223 | 1.533 | 1.270 |

| 5 | 0.587 | 429 | 1.821 | 1.352 | 1.139 |

| 1.38 | 2.35 | 1.66 | 2.32 | 1.4 | 5.15 |

| Elastic Module (GPa) | Shear Module (GPa) | Poisson Ratio | Yield Strength (GPa) | Rate Parameter | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6.96 | 5.45 | 4.87 | 3.5 | 0.30 | 0.40 | 0.313 | 0.12 | 0.063 | 0.17 | 0.07 | 0.0218 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Gao, Y.; Wang, S.; Wang, J.; Li, H. Study on X-ray Induced Two-Dimensional Thermal Shock Waves in Carbon/Phenolic. Materials 2021, 14, 3553. https://doi.org/10.3390/ma14133553

Wang D, Gao Y, Wang S, Wang J, Li H. Study on X-ray Induced Two-Dimensional Thermal Shock Waves in Carbon/Phenolic. Materials. 2021; 14(13):3553. https://doi.org/10.3390/ma14133553

Chicago/Turabian StyleWang, Dengwang, Yong Gao, Sheng Wang, Jie Wang, and Haipeng Li. 2021. "Study on X-ray Induced Two-Dimensional Thermal Shock Waves in Carbon/Phenolic" Materials 14, no. 13: 3553. https://doi.org/10.3390/ma14133553

APA StyleWang, D., Gao, Y., Wang, S., Wang, J., & Li, H. (2021). Study on X-ray Induced Two-Dimensional Thermal Shock Waves in Carbon/Phenolic. Materials, 14(13), 3553. https://doi.org/10.3390/ma14133553