A Comparative Study on the Hot Deformation Behavior of As-Cast and Twin-Roll Cast Mg-6.8Y-2.5Zn-0.4Zr Alloy

Abstract

:1. Introduction

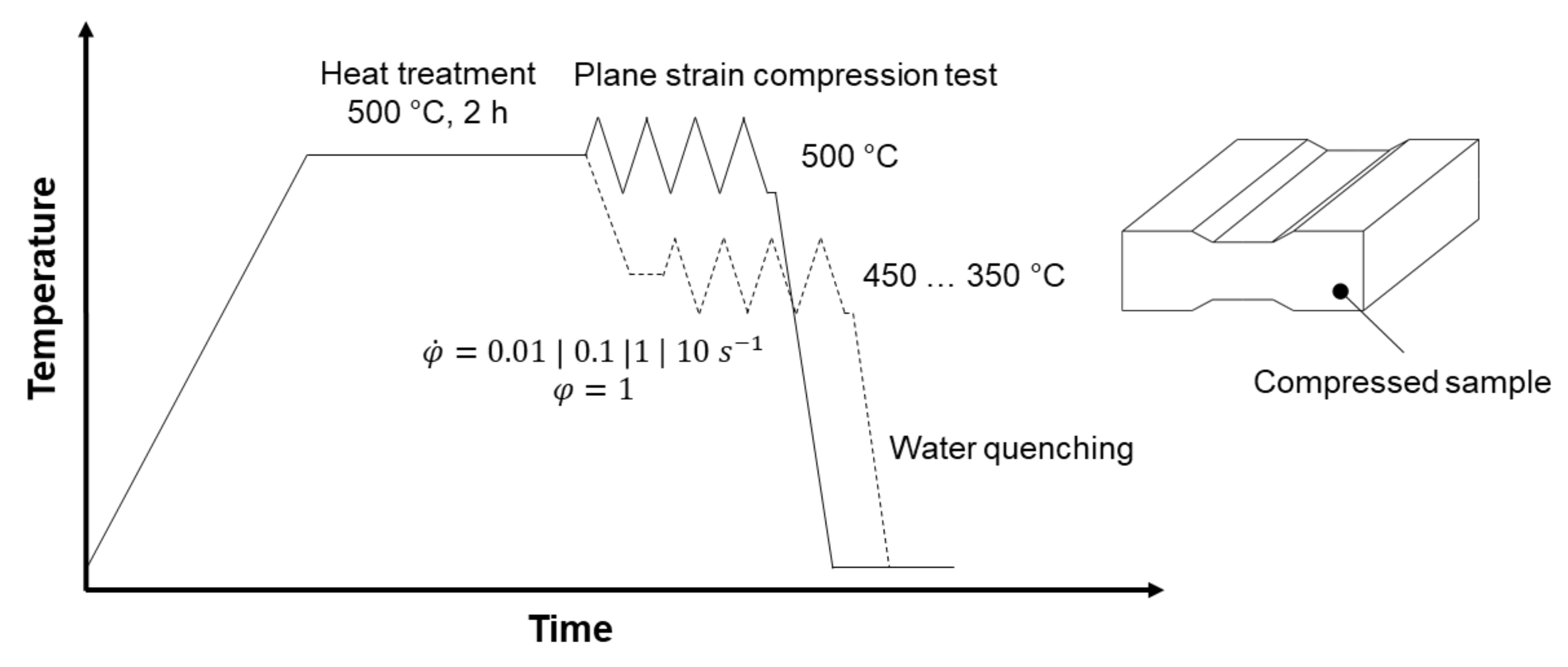

2. Materials and Methods

3. Results

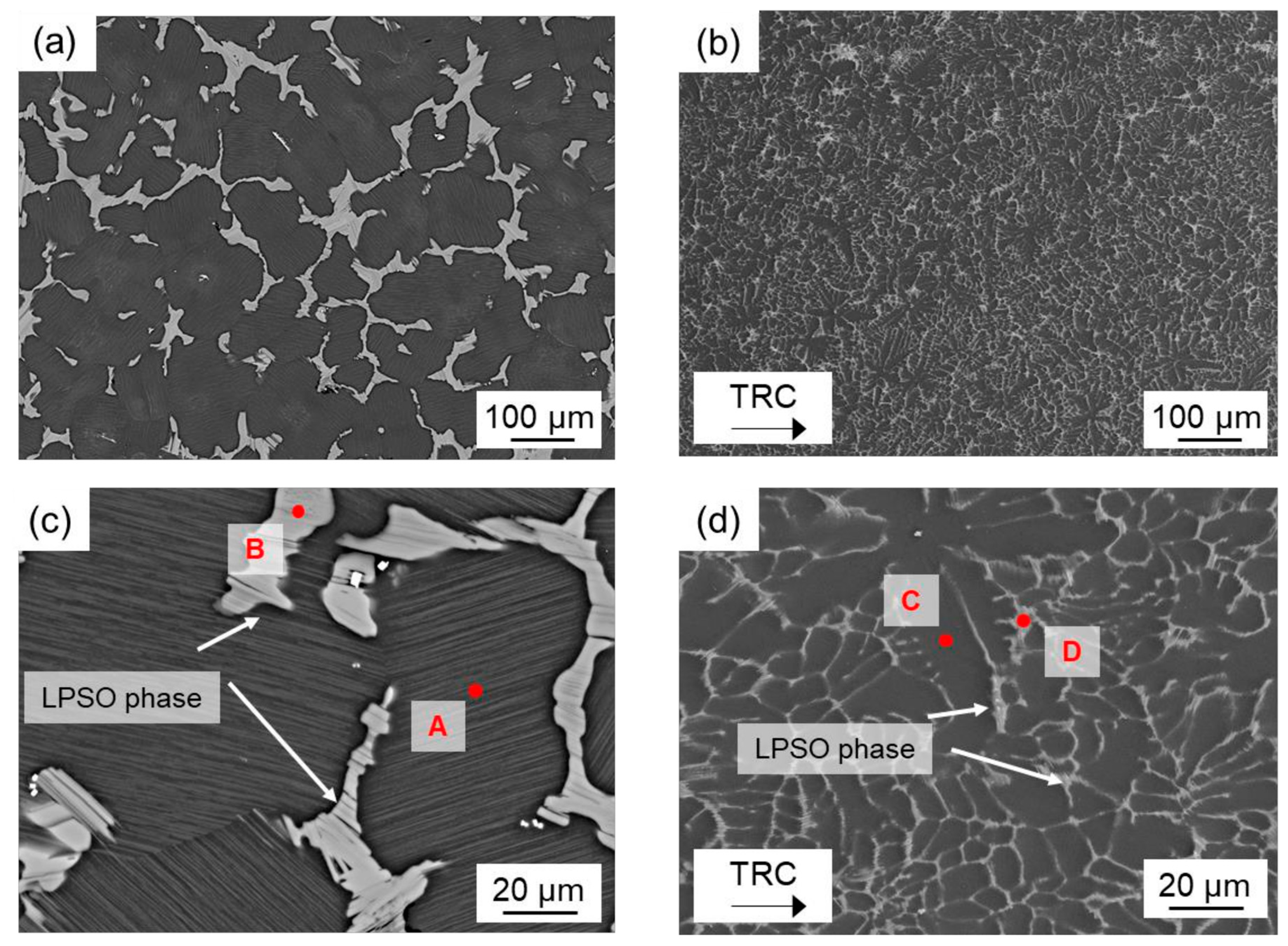

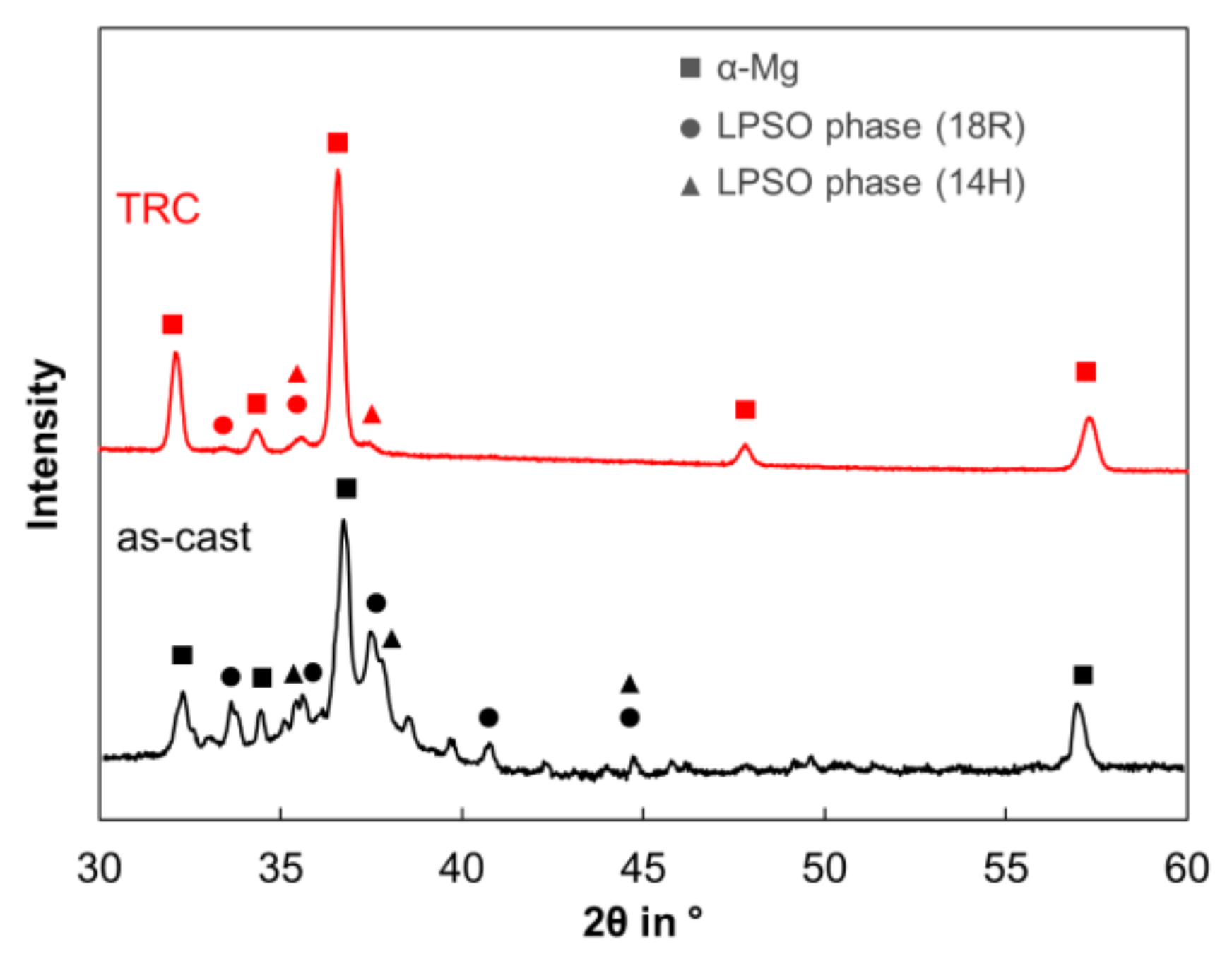

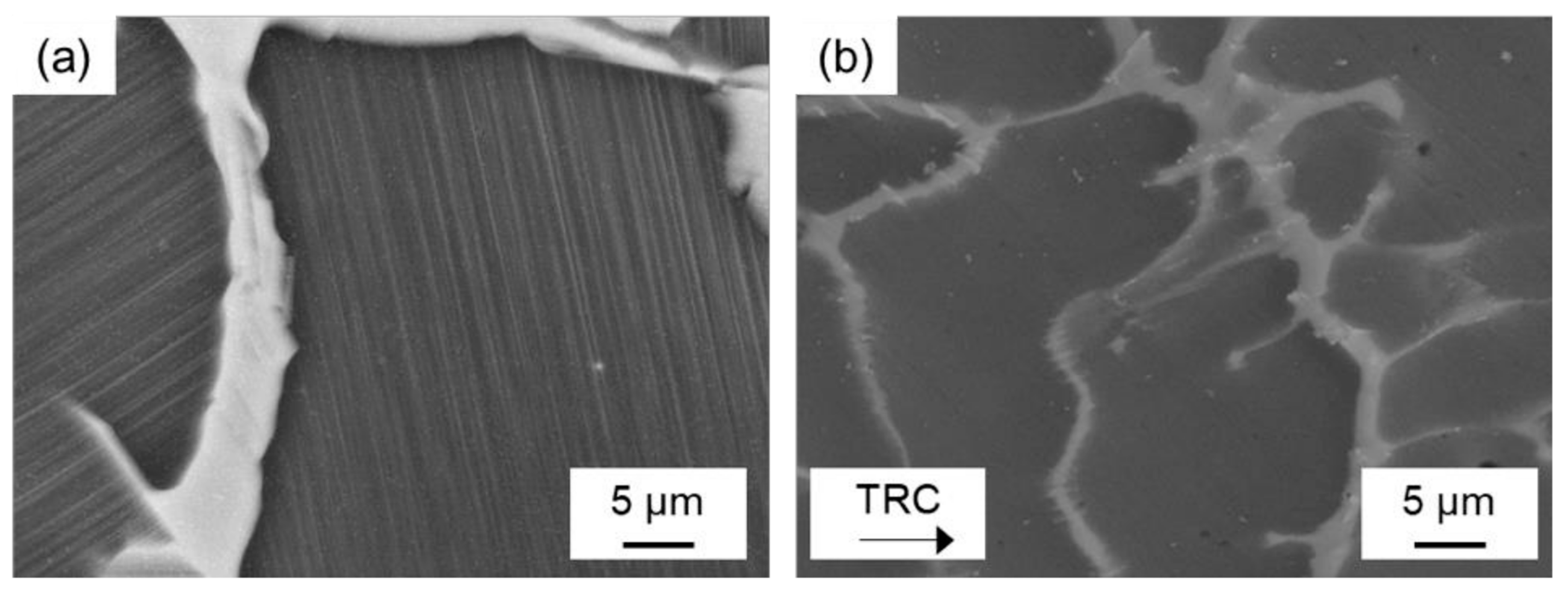

3.1. Characterization of Initial States

3.2. Hot Deformation Behavior

3.2.1. Flow Stress Behavior

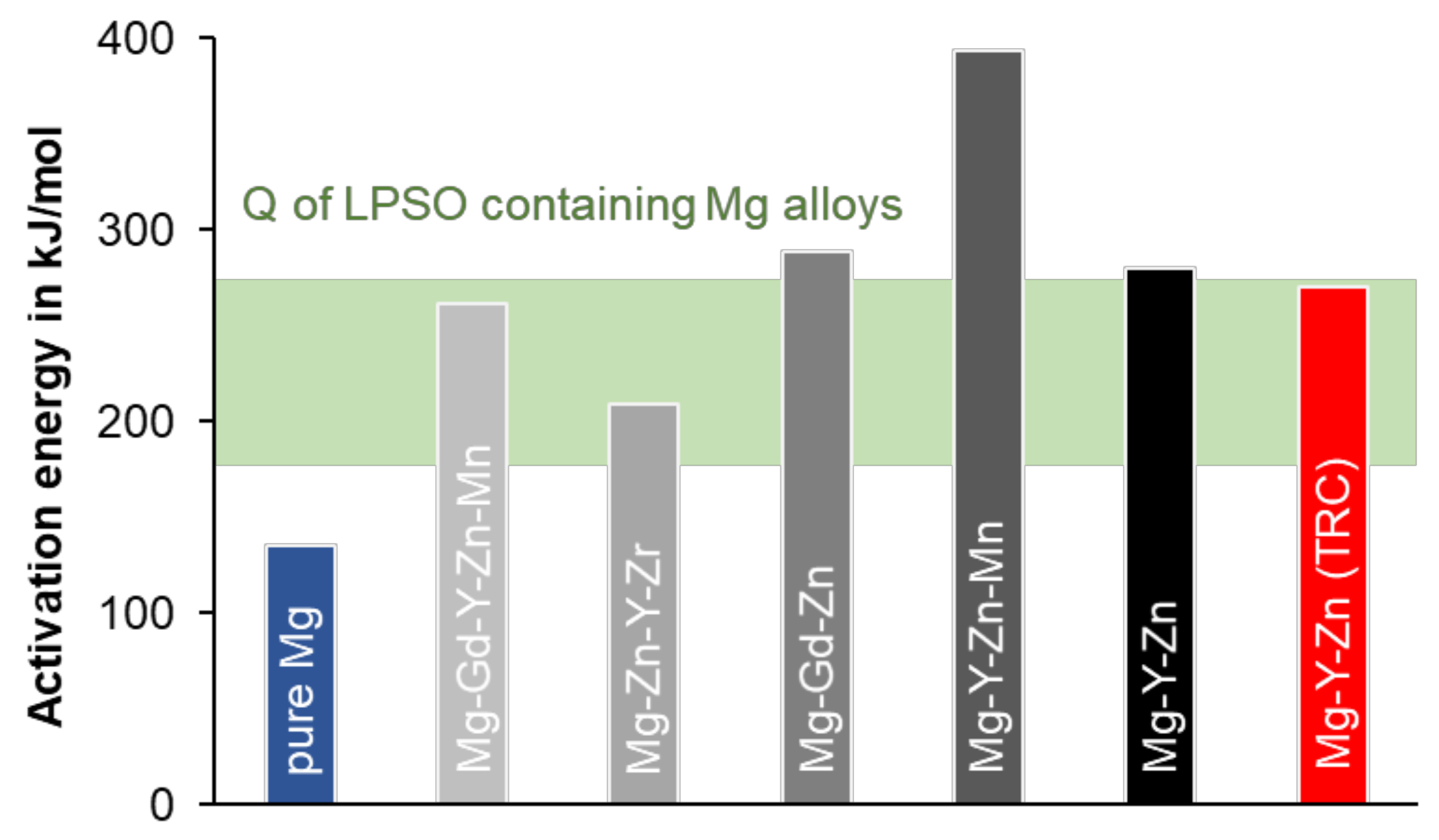

3.2.2. Constitutive Equation

3.2.3. Deformation and Recrystallization Behavior

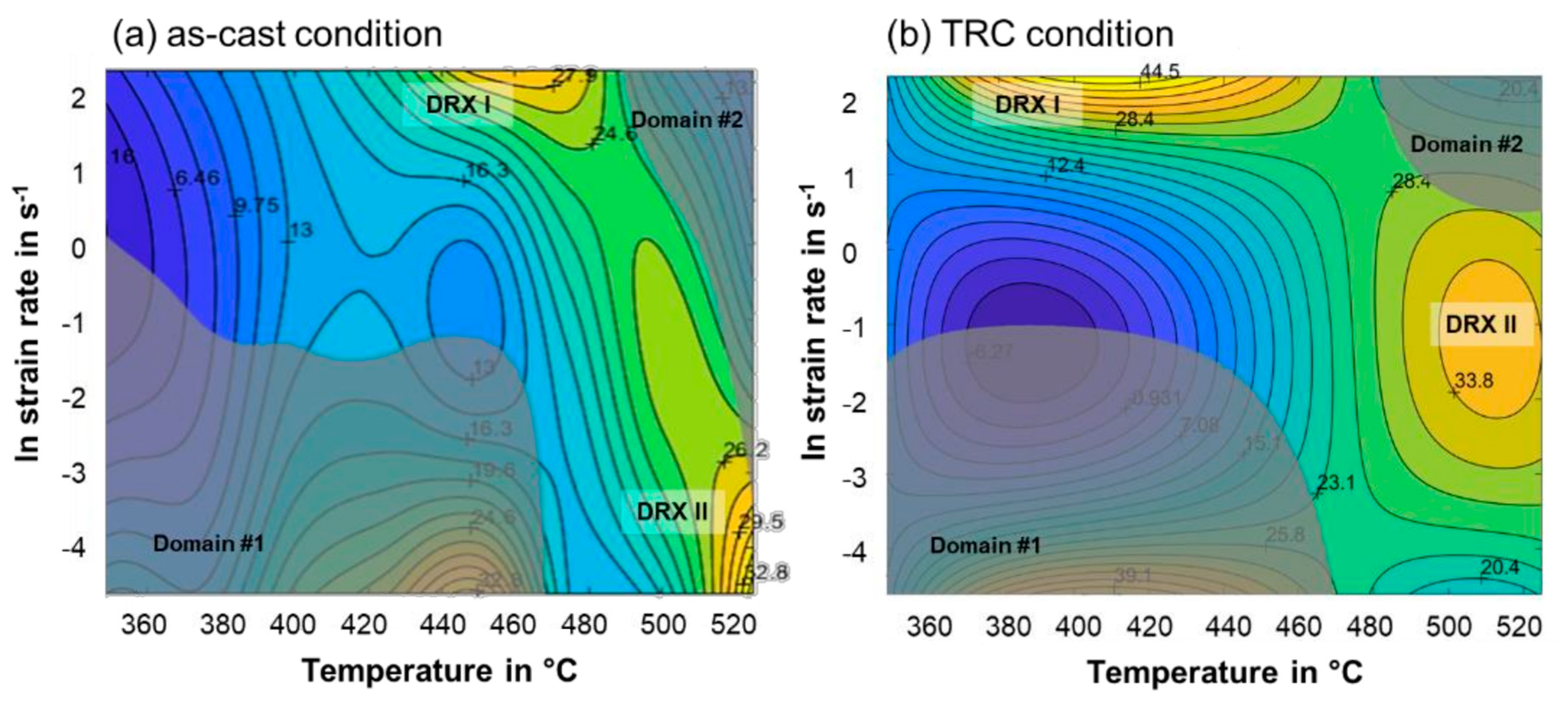

3.2.4. Processing Maps

4. Conclusions

- The microstructure of both conditions mainly consists of the α-magnesium matrix and network-like LPSO phases located along the grain boundaries. LPSO phases could be assigned to 18R or 14H structures. Twin-roll casting leads to a finer microstructure compared to conventional casting. After conventional casting, thin lamellar LPSO phases arise within the α-magnesium grains, which can be assigned to the 14H structure. In the TRC condition, lamellar LPSO phases are not observed.

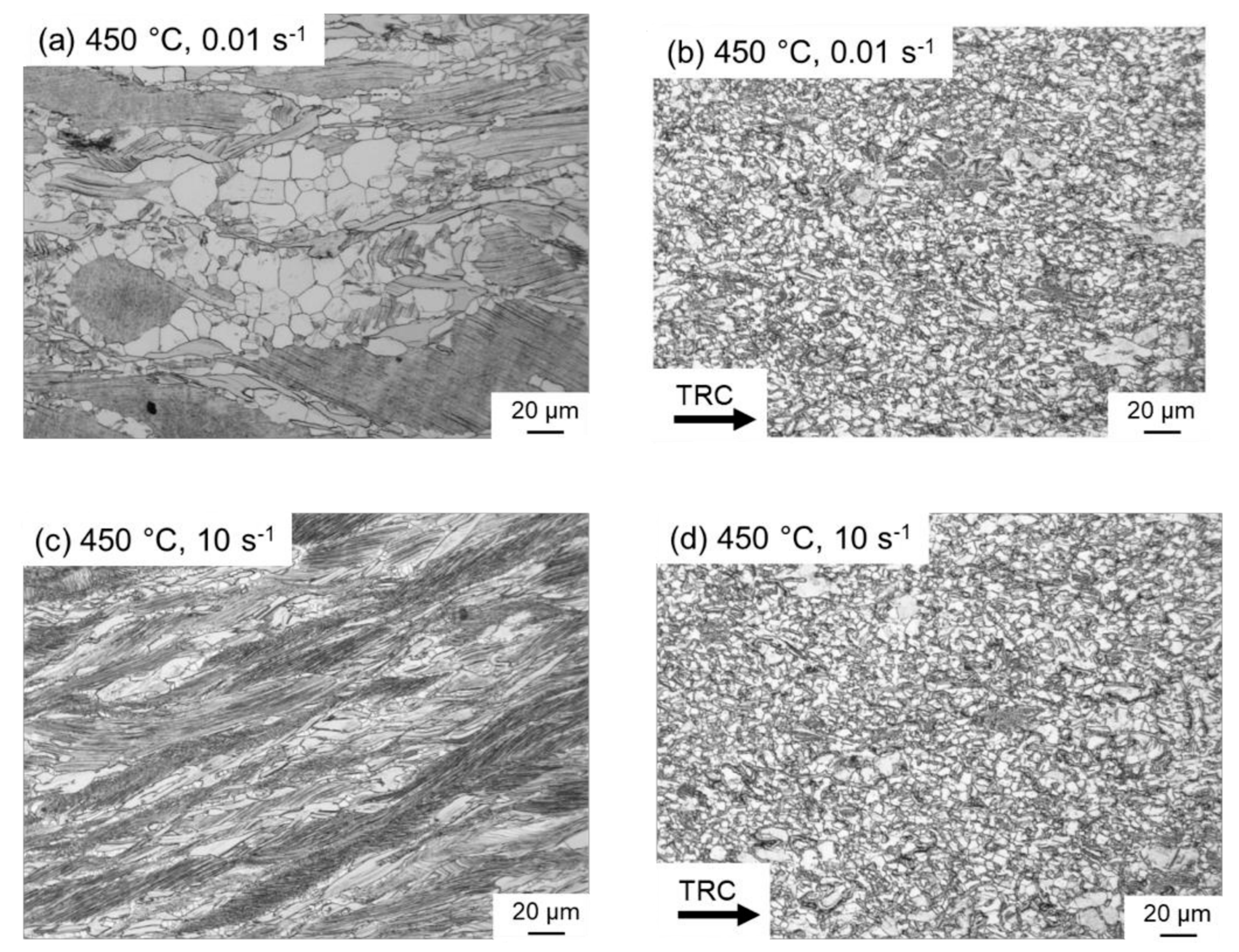

- During hot deformation of the conventionally cast material, it is assumed that at 450 °C dynamic recovery is the dominant softening mechanism. Only a small amount of dynamic recrystallization can be observed, indicating that the DRX remains incomplete even at high strains and low strain rates. The TRC samples showed softening via dynamic recrystallization, where an almost completely recrystallized structure developed at both high (10 s−1) and low (0.01 s−1) strain rates.

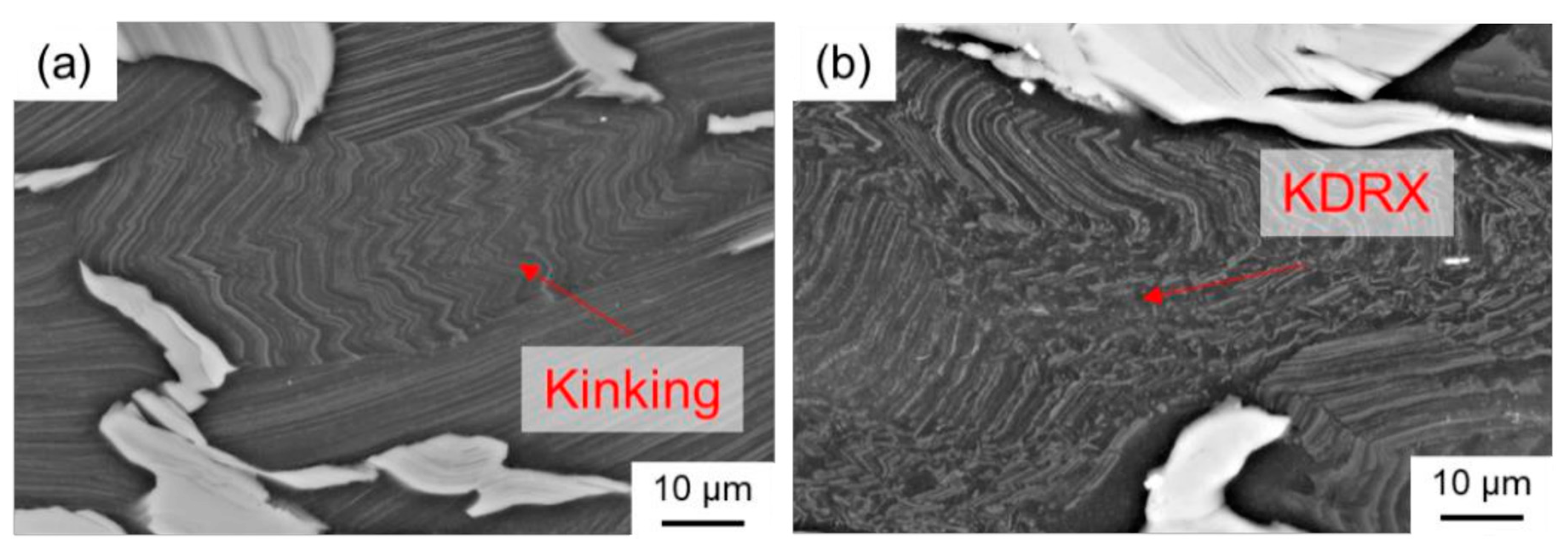

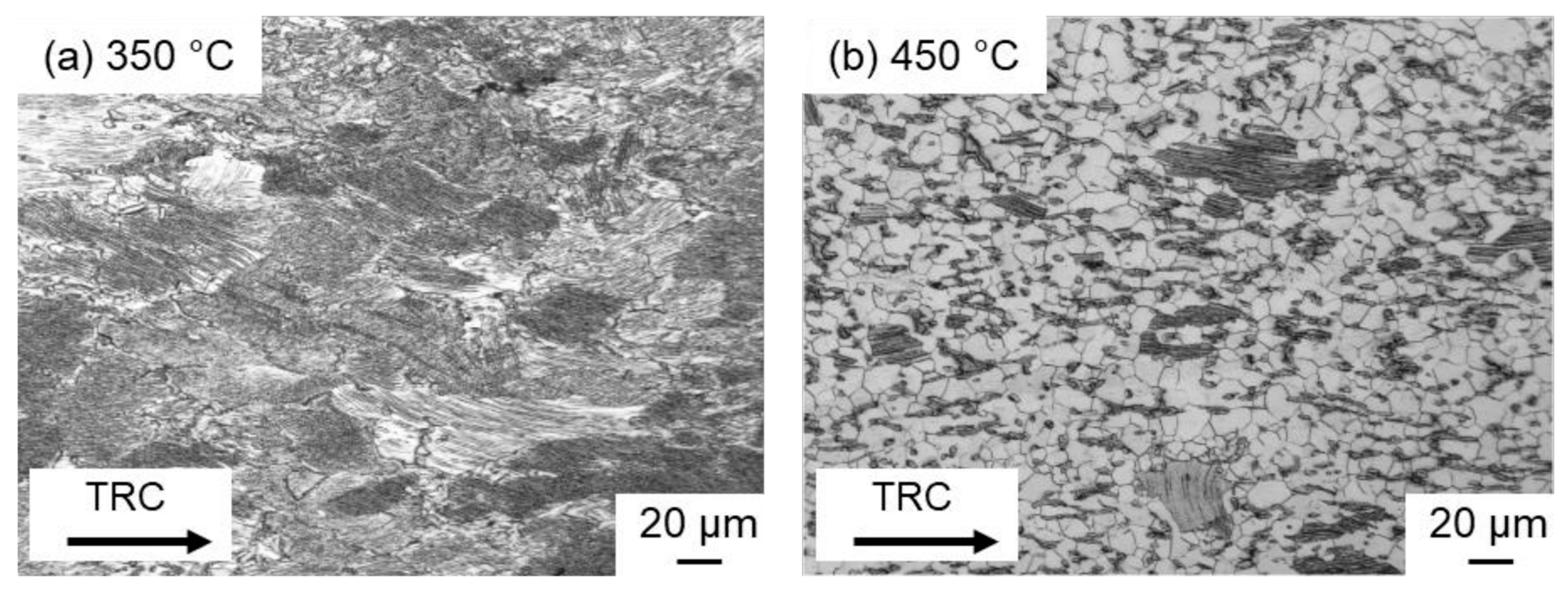

- At higher temperatures (500 °C), DRX occurs in both conditions. The as-cast state exhibits a high amount of network-like and lamellar LPSO phases, which are assumed to be responsible for a delayed DRX. The main recrystallization mechanisms of the as-cast condition are CDRX, PSN and TDRX. Kink-aided dynamic recrystallization can hardly be detected. In the TRC initial state, the block-like LPSO phase is more finely distributed and, above all, less strongly connected. Lamellar LPSO phases are precipitated within the Mg matrix during cooling and different DRX mechanism take place depending on deformation temperature. The fine distribution of the LPSO phase and less network-like nature favor DRX by PSN. Besides this, TDRX and KDRX can be observed.

- Optimum deformation conditions are temperatures from 500 °C to 520 °C and strain rates ranging from 0.01 s−1 to 0.1 s−1 for the as-cast material as well as a strain rate of 1 s−1 for the TRC material.

Author Contributions

Funding

|

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Ullmann, M.; Schmidtchen, M.; Kittner, K.; Henseler, T.; Kawalla, R.; Prahl, U. Hot Deformation Behaviour and Processing Maps of an as-Cast Mg-6.8Y-2.5Zn-0.4Zr Alloy. Mater. Sci. Forum 2019, 949, 57–65. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Morton, A.; Nie, J. The 18R and 14H long-period stacking ordered structures in Mg–Y–Zn alloys. Acta Mater. 2010, 58, 2936–2947. [Google Scholar] [CrossRef]

- Kawamura, Y.; Hayashi, K.; Inoue, A.; Masumoto, T. Rapidly Solidified Powder Metallurgy Mg97Zn1Y2Alloys with Excellent Tensile Yield Strength above 600 MPa. Mater. Trans. 2001, 42, 1172–1176. [Google Scholar] [CrossRef] [Green Version]

- Kittner, K.; Ullmann, M.; Arndt, F.; Kawalla, R.; Prahl, U. Microstructure and Texture Evolution during Twin-Roll Casting and Annealing of a Mg–6.8Y2.5Zn–0.4Zr Alloy (WZ73). Crystals 2020, 10, 513. [Google Scholar] [CrossRef]

- Kittner, K.; Ullmann, M.; Arndt, F.; Berndorf, S.; Henseler, T.; Prahl, U. Analysis of defects in a twin roll cast Mg-Y-Zn magnesium alloy. Eng. Rep. 2021, 17, e12394. [Google Scholar] [CrossRef]

- Liu, H.; Yan, K.; Yan, J.-L.; Xue, F.; Sun, J.-P.; Jiang, J.-H.; Ma, A.-B. Precipitation behavior of 14H LPSO structure in single 18R phase Mg–Y–Zn alloy during annealing at 773 K. Trans. Nonferrous Met. Soc. China 2017, 27, 63–72. [Google Scholar] [CrossRef]

- Zhu, Y.; Morton, A.; Nie, J. Growth and transformation mechanisms of 18R and 14H in Mg–Y–Zn alloys. Acta Mater. 2012, 60, 6562–6572. [Google Scholar] [CrossRef]

- Li, L.; Qi, F.; Wang, Q.; Hou, C.; Zhao, N.; Yang, Y.; Chai, S.; Ouyang, X. Hot deformation behavior of Mg95.21Zn1.44Y2.86Mn0.49 alloy containing LPSO phase. Mater. Charact. 2020, 169, 110649. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, Z.; Du, Y.; Zhang, G.; Zhu, J.; Ren, L.; Wang, Y. Hot Deformation Behavior of Homogenized Mg-13.5Gd-3.2Y-2.3Zn-0.5Zr Alloy via Hot Compression Tests. Materials 2018, 11, 2282. [Google Scholar] [CrossRef] [Green Version]

- Fekete, K.H.; Drozdenko, D.; Čapek, J.; Máthis, K.; Tolnai, D.; Stark, A.; Garcés, G.; Dobron, P. Hot deformation of Mg-Y-Zn alloy with a low content of the LPSO phase studied by in-situ synchrotron radiation diffraction. J. Magnes. Alloy. 2020, 8, 199–209. [Google Scholar] [CrossRef]

- Li, K.; Chen, Z.; Chen, T.; Shao, J.; Wang, R.; Liu, C. Hot deformation and dynamic recrystallization behaviors of Mg-Gd-Zn alloy with LPSO phases. J. Alloy. Compd. 2019, 792, 894–906. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, W.; Wang, F.; Hu, T.; Ma, C. The roles of long period stacking ordered structure and Zn solute in the hot deformation behavior of Mg-Gd-Zn alloys. J. Alloy. Compd. 2018, 745, 33–43. [Google Scholar] [CrossRef]

- Shao, X.; Jin, Q.; Zhou, Y.; Yang, H.; Zheng, S.; Zhang, B.; Chen, Q.; Ma, X. Basal shearing of twinned stacking faults and its effect on mechanical properties in an Mg–Zn–Y alloy with LPSO phase. Mater. Sci. Eng. A 2020, 779, 139109. [Google Scholar] [CrossRef]

- Allen, R.V.; East, D.; Johnson, T.J.; Borbidge, W.E.; Liang, D. Magnesium Alloy Sheet Produced by Twin Roll Casting. Magnes. Technol. 2001, 2013, 74–79. [Google Scholar]

- Kawalla, R.; Ullmann, M.; Schmidt, C.; Dembińska, J.; Vogt, H.P. Properties of Magnesium Strips Produced by Twin-Roll-Casting and Hot Rolling. Mater. Sci. Forum 2011, 690, 21–24. [Google Scholar] [CrossRef]

- Siebel, E. Die Formgebung im Bildsamen Zustande, Theoretische Grundlagen der Technischen Formgebungsverfahren; Verlag Stahleisen: Düsseldorf, Germany, 1932. [Google Scholar]

- Kittner, K.; Ullmann, M.; Henseler, T.; Kawalla, R.; Prahl, U. Microstructure and Hot Deformation Behavior of Twin Roll Cast Mg-2Zn-1Al-0.3Ca Alloy. Materials 2019, 12, 1020. [Google Scholar] [CrossRef] [Green Version]

- Luo, Z.P.; Zhang, S.Q. High-resolution electron microscopy on the X-Mg12ZnY phase in a high strength Mg-Zn-Zr-Y magnesium alloy. J. Mater. Sci. Lett. 2000, 19, 813–815. [Google Scholar] [CrossRef]

- Oñorbe, E.; Garces, G.; Pérez, P.; Adeva, P. Effect of the LPSO volume fraction on the microstructure and mechanical properties of Mg–Y2X –Zn X alloys. J. Mater. Sci. 2012, 47, 1085–1093. [Google Scholar] [CrossRef] [Green Version]

- Wen, K.; Du, W.-B.; Liu, K.; Wang, Z.-H.; Li, S.-B. Precipitation behavior of 14H-LPSO structure in Mg–12Gd–2Er–1Zn–0.6Zr Alloy. Rare Met. 2016, 35, 367–373. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, J.; Liu, H.; Saleh, B.; Ma, A. Microstructure characterization and corrosion behavior of Mg–Y–Zn alloys with different long period stacking ordered structures. J. Magnes. Alloy. 2020, 8, 1208–1220. [Google Scholar] [CrossRef]

- Shi, B.-Q.; Chen, R.-S.; Ke, W. Effects of processing route on texture and mechanical properties of WZ62 alloy. Trans. Nonferr. Met. Soc. China 2011, 21, 830–835. [Google Scholar] [CrossRef]

- Suzawa, K.; Inoue, S.-I.; Nishimoto, S.; Fuchigami, S.; Yamasaki, M.; Kawamura, Y.; Yoshida, K.; Kawabe, N. High-strain-rate superplasticity and tensile behavior of fine-grained Mg97Zn1Y2 alloys fabricated by chip/ribbon-consolidation. Mater. Sci. Eng. A 2019, 764, 138179. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, C.; Que, Z.; Cheng, W.; Xu, J.; Kang, J. 18R and 14H long-period stacking ordered structures in the Mg93.96Zn2Y4Sr0.04 alloy and the modification effect of Sr on X-phase. Mater. Sci. Eng. A 2012, 552, 81–88. [Google Scholar] [CrossRef]

- Wu, Y.; Zeng, X.; Lin, D.; Peng, L.; Ding, W. The microstructure evolution with lamellar 14H-type LPSO structure in an Mg96.5Gd2.5Zn1 alloy during solid solution heat treatment at 773K. J. Alloy. Compd. 2009, 477, 193–197. [Google Scholar] [CrossRef]

- Trojanova, Z.; Lukac, P. Hardening and Softening in Magnesium Alloys. In Magnesium Alloys—Design, Processing and Properties; Czerwinski, F., Ed.; InTech: Rijeka, Croatia, 2011. [Google Scholar]

- Lv, B.-J.; Peng, J.; Zhu, L.-L.; Wang, Y.-J.; Tang, A.-T. The effect of 14H LPSO phase on dynamic recrystallization behavior and hot workability of Mg–2.0Zn–0.3Zr–5.8Y alloy. Mater. Sci. Eng. A 2014, 599, 150–159. [Google Scholar] [CrossRef]

- Garofalo, F. Fundamentals of Creep and Creep-Rupture in Metals; McMillan Series in Materials Science: New York, NY, USA, 1965; p. 258. [Google Scholar]

- Weertman, J. Dislocation climb theory of steady-state creep. ASM Trans. Quart. Metal Sci. 1968, 61, 681–694. [Google Scholar] [CrossRef]

- González, S.; Pérez, P.; Garcés, G.; Adeva, P. Influence of the processing route on the mechanical properties at high temperatures of Mg-Ni-Y-RE alloys containing LPSO-phases. Mater. Sci. Eng. A 2016, 673, 266–279. [Google Scholar] [CrossRef]

- Vagarali, S.S.; Langdon, T.G. Deformation mechanims in H.C.P. metals at eleveted temperatures—II. Creep behavior of a Mg-0.8%Al solid solution alloy. Acta Metall. 1982, 30, 1157–1170. [Google Scholar] [CrossRef]

- Ullmann, M. Rekristallisationsverhalten von Geglühtem AZ31-Gießwalzband Beim Warmwalzen. Ph.D. Thesis, Technische Universität Bergakademie Freiberg, Freiberg, Germany, 2014. [Google Scholar]

- Jingfeng, W.; Feizhou, X.; Shijie, L.; Song, H.; Fusheng, P. Hot Deformation Behavior and Processing Maps of As-Homogenized Mg-Gd-Y-Zn-Mn Alloy. Rare Met. Mater. Eng. 2018, 47, 1700–1707. [Google Scholar] [CrossRef]

- Chen, Q.; Xia, X.; Yuan, B.; Shu, D.; Zhao, Z.; Han, J. Hot workfability behavior of as-cast Mg–Zn–Y–Zr alloy. Mater. Sci. Eng. A 2014, 593, 38–47. [Google Scholar] [CrossRef]

- Hagihara, K.; Okamoto, T.; Izuno, H.; Yamasaki, M.; Matsushita, M.; Nakano, T.; Kawamura, Y. Plastic deformation behavior of 10H-type synchronized LPSO phase in a Mg–Zn–Y system. Acta Mater. 2016, 109, 90–102. [Google Scholar] [CrossRef]

- Hagihara, K.; Yokotani, N.; Umakoshi, Y. Plastic deformation behavior of Mg12YZn with 18R long-period stacking ordered structure. Intermetallics 2010, 18, 267–276. [Google Scholar] [CrossRef]

- Chen, T.; Chen, Z.; Shao, J.; Wang, R.; Mao, L.; Liu, C. The role of long period stacking ordered phase in dynamic recrystallization of a Mg–Zn–Y alloy during hot compression. J. Alloy. Compd. 2020, 818, 152814. [Google Scholar] [CrossRef]

- Ullmann, M.; Kittner, K.; Prahl, U. Hot Deformation and Dynamic Recrystallisation Behaviour of Twin-Roll Cast Mg-6.8Y-2.5Zn-0.4Zr Magnesium Alloy. Materials 2021, 14, 307. [Google Scholar] [CrossRef]

- Prasad, Y.; Rao, K. Processing maps for hot deformation of rolled AZ31 magnesium alloy plate: Anisotropy of hot workability. Mater. Sci. Eng. A 2008, 487, 316–327. [Google Scholar] [CrossRef]

- Zhou, X.; Yao, Y.; Zhang, J.; Lu, X.; Xu, K.; Liu, H.; Wu, Z. Improved workability for Mg-Y-Zn alloys via increased volume fraction of block LPSO phases. Mater. Sci. Eng. A 2020, 794, 139934. [Google Scholar] [CrossRef]

- Tahreen, N.; Zhang, D.; Pan, F.; Jiang, X.; Li, D.; Chen, D. Strengthening mechanisms in magnesium alloys containing ternary I, W and LPSO phases. J. Mater. Sci. Technol. 2018, 34, 1110–1118. [Google Scholar] [CrossRef]

- Xue, Z.; Luo, W.; Zhao, Z.; Ren, Y. Thermal compression, processing maps and microstructural evolution of as-cast Mg-Gd-Y-Zn-Zr alloy with long period stacking ordered phase. Mater. Res. Express 2020, 7, 056512. [Google Scholar] [CrossRef]

| Y | Zn | Zr | Si | Fe | Cu | Ni | Others | Mg |

|---|---|---|---|---|---|---|---|---|

| 6.8 | 2.5 | 0.4 | 0.01 | 0.005 | 0.001 | 0.001 | 0.01 | Balance |

| Name | Mg | Y | Zn | |

|---|---|---|---|---|

| A | matrix as-cast | 95.0 | 3.6 | 1.4 |

| B | LPSO as-cast | 73.2 | 17.2 | 9.6 |

| C | matrix TRC | 97.1 | 2.2 | 0.7 |

| D | LPSO TRC | 74.2 | 15.6 | 10.2 |

| Model Coefficient | As-Cast State | TRC State |

|---|---|---|

| A in s−1 | 5.33817 × 1019 | 2.61662 × 1019 |

| α in MPa−1 | 0.010677 | 0.010849 |

| n | 6.6051 | 7.4871 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kittner, K.; Ullmann, M.; Prahl, U. A Comparative Study on the Hot Deformation Behavior of As-Cast and Twin-Roll Cast Mg-6.8Y-2.5Zn-0.4Zr Alloy. Materials 2021, 14, 3628. https://doi.org/10.3390/ma14133628

Kittner K, Ullmann M, Prahl U. A Comparative Study on the Hot Deformation Behavior of As-Cast and Twin-Roll Cast Mg-6.8Y-2.5Zn-0.4Zr Alloy. Materials. 2021; 14(13):3628. https://doi.org/10.3390/ma14133628

Chicago/Turabian StyleKittner, Kristina, Madlen Ullmann, and Ulrich Prahl. 2021. "A Comparative Study on the Hot Deformation Behavior of As-Cast and Twin-Roll Cast Mg-6.8Y-2.5Zn-0.4Zr Alloy" Materials 14, no. 13: 3628. https://doi.org/10.3390/ma14133628

APA StyleKittner, K., Ullmann, M., & Prahl, U. (2021). A Comparative Study on the Hot Deformation Behavior of As-Cast and Twin-Roll Cast Mg-6.8Y-2.5Zn-0.4Zr Alloy. Materials, 14(13), 3628. https://doi.org/10.3390/ma14133628