1. Introduction

Fiber-reinforced plastic composites have been extensively used in armor protection due to low density and effective ballistic performance [

1,

2,

3,

4]. For the sake of the armor design, the parameter study of the ballistic impact has attracted intensive attention. These parameters include the mechanical property and structure of the composites [

1,

5], impact velocity, and projectile geometry [

6,

7,

8]. The studies have found that the projectile shape has significant influence on the deformation and failure mechanisms the composites [

9,

10,

11].

Relevant research demonstrates that the projectile shape can invoke different deformation and failure mechanism of the fiber-reinforced plastic composite. The majority of studies focus on the aramid fiber reinforced polymer (AFRP), glass fiber reinforced polymer (GFRP), and carbon fiber reinforced polymer (CFRP) composites [

12,

13]. Ulven [

14] found that the conical shaped projectile resulted in the highest ballistic limit velocity, followed by the flat, hemispherical shaped projectiles. The primary failure modes of composites were a combination of the shear plugging and the separation of fibers. However, Millán [

15] found that the effect of projectile shape on the ballistic limit of AFRP composite depended on the composite thickness. Jordan [

16] revealed that the ballistic limit and energy absorption ability of the GFRP composite were significantly affected by the projectile nose shape. The results showed that the sharper nose shapes were the most efficient penetrators, and the flat nose projectiles exhibited the lowest penetration ability. In addition, the investigation also revealed that penetration of thinner targets was not influenced as much by the projectile nose shape [

15]. Mitrevski [

17] found that the blunter hemispherical impactor produced the largest damage area, while sharper conical impactor could produce a localized damage area.

Wen [

18,

19] proposed an analytical model for predicting the ballistic limit velocity of the composites impacted with various shaped projectiles. Ben-Dor [

20] developed Wen’s model and found that the ballistic responses varied with the properties and thickness of the composites and the projectile nose shape. Tan [

21] and Gibbon [

22] confirmed the conclusions discovered by Ben-Dor [

20] and found that the sharper nose projectile tended to push fibers aside as they penetrated through the composite. For the blunt nose projectile penetration, the primary deformation features consisted of the shear plugging and tensile deformation. Moreover, Ulven [

14], Jordan [

16], and Sasikumar [

23] found that there was a high deviation between the predicted ballistic limit velocity and the experimental values, and they simultaneously pointed out that the accuracy of the analytical model was depended on the failure modes of the composite. The current analytical model was more suitable for the composites with local and shear failure mode damage [

24].

Compared with other composites, the ballistic efficiency of the UHMWPE composite is found to be at least 30% higher than Kevlar

® KM2/polyvinyl butyral, 50% higher than E-glass/polyester composite, and 60% higher than carbon fiber/epoxy [

25]. The unique mechanical property makes the UHMWPE composite exhibit different deformation and failure process [

25,

26,

27]. The high fiber failure strain make the UHMWPE composite absorb the energy though large area tensile deformation [

27,

28]. The current studies reveal that the damage of the UHMWPE composite is a progressive deformation process containing the shear plugging, delamination, and tensile deformation [

29,

30,

31,

32]. However, few studies focus on the effect of projectile nose shape on the deformation features, penetration mechanisms, and energy absorption ability.

The current study mainly investigates the effect of projectile nose shape on the deformation and energy dissipation mechanisms of the UHMWPE composite. Eight projectiles such as conical, flat, hemispherical, and ogival nose projectiles are used in this study. The effect of projectile nose shape on the target responses of the deformation evolution, failure mechanisms, and energy absorption ability of the UHMWPE composite, and the residual velocity of the projectile were analyzed by the experimental and numerical analysis. Furthermore, the ballistic resistance analytical model was built based on the cavity expansion theory to predict the energy absorption ability of the UHMWPE composite. The current work can provide more understanding of the penetration and failure mechanism of the UHMWPE composite, which is meaningful guidance on the use of UHMWPE composite for specific protection needs.

4. Analytical Model

Wen’s model [

18,

19] was widely used in the studies to analyze the effect of projectile nose shape on the ballistic limit of fiber-reinforced plastic (FRP) composites [

14,

16]. However, Wen’s model was more applicable for the FRP composite under the shear failure, rather than the composite under tensile failure [

18,

27]. Based on the cavity expansion theory [

37], the ballistic resistance models with various nose shape projectiles were built in the present study.

Due to the high hardness and strength of the projectile, the mass loss and deformation of the projectile were negligible during the penetration process. The projectile could be regarded as a rigid body. The typically projectile nose shape is shown in

Figure 10; based on the cavity expansion theory, when the rigid projectile penetrated the UHMWPE composite, the ballistic resistance of the projectile was expressed as follows [

37,

38]:

Herein, the was the radius of the projectile, and were the static and dynamic coefficients of frictional resistance, respectively. was the density of the UHMWPE composite, was the initial velocity of the projectile, and and were the coefficients of the projectile nose shape.

Typically, the projectile nose shape could be expressed by a bus function, and the coefficient of the projectile nose shape,

and

, could be simplified to [

39]:

Herein, the non-dimensional parameter

,

was the radius of the projectile nose, as shown in

Figure 11. Therefore, for the conical nose shape projectile, the coefficient of the projectile nose shape,

,

and

could be further simplified as follows [

39]:

For the hemispherical nose shape projectile, the coefficients of the projectile nose shape,

,

, and

could be further simplified as follows [

39]:

For the ogival nose shape projectile, the coefficient of the projectile nose shape,

,

, and

could be further simplified as follows [

39]:

Especially for the flat nose projectile,

, while for the hemispherical nose projectile,

,

,

. In the penetration process, the value of the

was about 0.1 [

39]; therefore,

. The ballistic resistance of the projectile Formula (1) could be simplified and expressed as follows:

For conical nose shape projectile:

For hemispherical nose shape projectile:

For ogival nose shape projectile:

In this study, the parameters,

πr2,

, and

were constant, which were related to the projectile and UHMWPE composite themselves. Therefore, the ballistic resistance was proportionate to the coefficient of the projectile nose shape of

N*. Firstly, the parameter s was measured, and then the parameters φ were calculated according to the formula

. Finally, the parameters of

N* were obtained according to the formulas of (7), (10), and (14), as shown in

Table 7. The SEA ability of the UHMWPE composite directly reflected the ballistic resistance of the projectile.

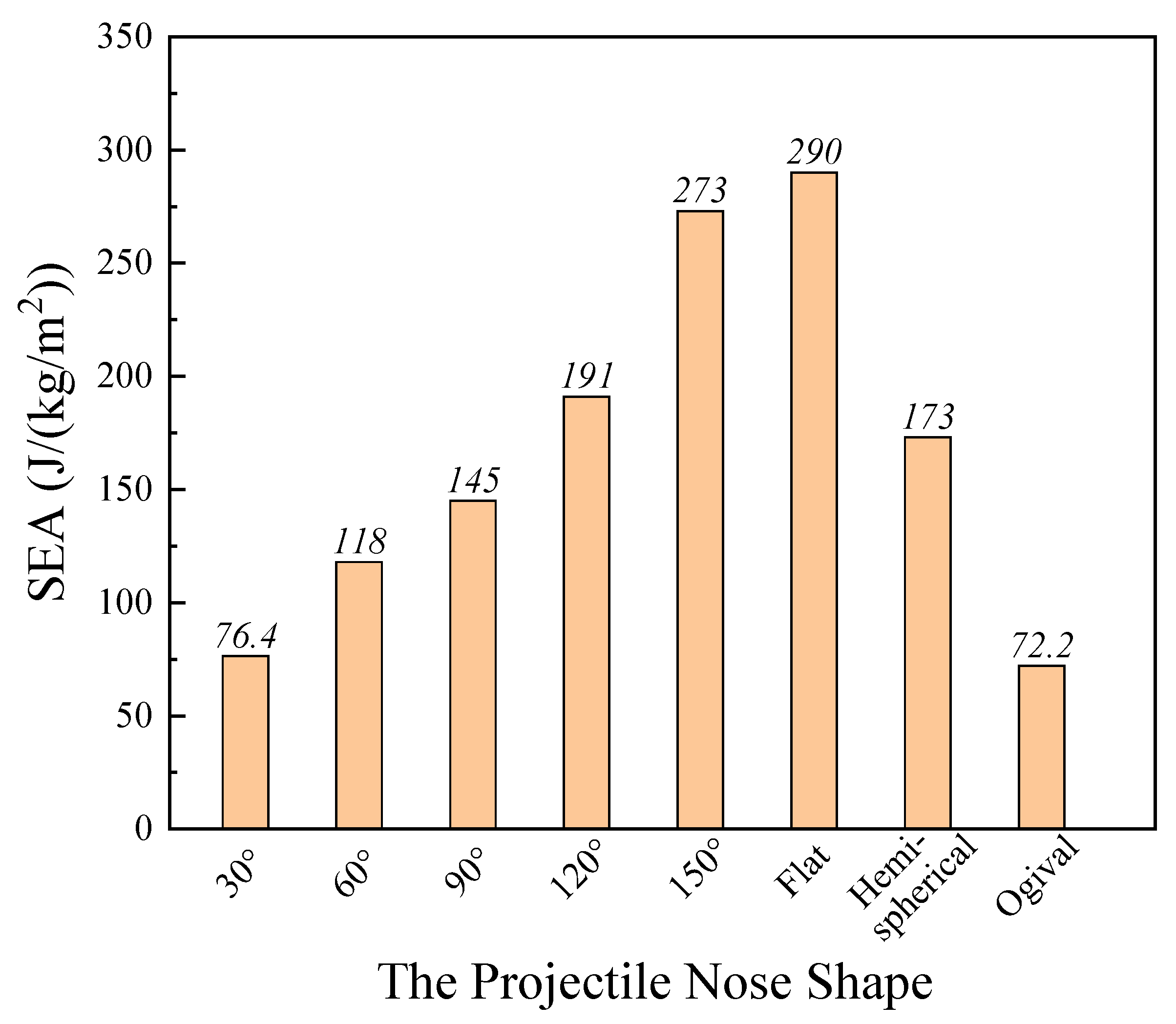

Figure 12a shows the effect of the projectile nose shape on the parameters of SEA and

N*, and these two parameters had a similar changing trend. The parameter of SEA and

N* increased with the increase of the conical nose angle. The maximum value of

N* was 1.0 for the flat nose projectile. The coefficient of the ogival projectile was 0.065, which was approximately equal to that of the 30° conical nose projectile, resulting in the similar SEA ability of the UHMWPE composite.

To further analyze the effect of the projectile nose shape on the response of the projectile, the ballistic resistance curves of various projectiles were shown in

Figure 12b. Obviously, the curves could be divided into three types, namely, the curves of 30°, 60°, and ogival projectiles, the curves of 90°, 120°, and hemispherical projectiles and the curves of 150° and flat. The 30°, 60°, and ogival nosed projectile possessed a high nose length of 28 mm, 13 mm, and 29 mm, respectively, as shown in

Figure 1 and

Table 2. In the first period, the projectile nose was sharp and high enough to penetrate through the UHMWPE composite easily. Due to the increase of contact area between the projectile and the composite, the ballistic resistance curves increased slowly. However, the different parameters

φ made the contact area between the projectile and the composite slight differences, resulting in a difference in the slope and the amplitude value. In the second period, the projectile shoulder began to penetrate the composite, and the fibers were pushed aside and the ballistic resistance decreased.

The nose length of the 90°, 120°, and hemispherical projectiles was 7.5 mm, 4.3 mm, and 7.5 mm, respectively. Due to the lower nose length and parameters

φ, the ballistic resistance increasing rate was larger than those of 30°, 60°, and ogival projectiles. The ballistic resistance remained steady as the projectile shoulder penetrated the composite. Afterwards, the failure mechanisms of the UHMWPE composite transformed from the shear deformation to the tensile deformation, resulting in a small decrease of the ballistic resistance. Finally, the fibers on the back face absorbed the kinetic energy of the projectile through large tensile deformation. Although the ballistic resistance was decreasing, the duration of the tensile deformation stage was the longest. Significantly, the 150° and flat ballistic resistance curves were similar with those of the 90°, 120°, and hemispherical, indicating the similar deformation process. However, the lower nose length and parameters of

φ made a larger contact area than others, causing a higher ballistic resistance amplitude values, as shown in

Figure 12b. In summary, the nose length and the parameters

φ had a significant effect on the deformation mechanism of the composites and the ballistic resistance of the projectiles. Therefore, for the projectiles with different nose angle and shapes, when the length and the parameters of

φ were comparable, the UHMWPE composite would exhibit similar deformation features and energy dissipation ability.

5. Conclusions

The projectile nose shape had a significant effect on the deformation and energy dissipation of the UHMWPE composite. For the sharper 30°, 60°, and ogival nose projectile penetration, the laminate showed a completely shear failure, and the damage was limited to a small zone, while for the 90°, 120°, and hemispherical nose projectile penetration, the pushing effect on the fibers diminished gradually, and the tensile deformation was more and more obvious. For the 150° and flat nose projectile penetration, the tensile deformation was predominant, and the back face deformation and delamination covered the whole plane.

The results showed that the sharper nose projectiles were the most efficient penetrators, and the flat nose projectiles exhibited the lowest penetration ability. The SEA ability of UHMWPE composite increased largely in a certain range; however, the further increase of projectile nose angle had little improvement on the SEA. The maximum SEA value of composite under the flat nose projectile penetration was 290 J/(kg/m2), about 3.8 times higher than that of 30° conical nose projectile penetration.

A ballistic resistance analytical model was built based on the cavity expansion theory to predict the energy absorption ability of the UHMWPE composite. The model exhibited a good match between the ballistic resistance curves in simulations and the specific energy absorption ability of a UHMWPE composite in experiments. Furthermore, when the length and the parameter φ of the projectile nose were comparable, the UHMWPE composite would exhibit similar deformation features and energy dissipation ability.