Development of Novel Lightweight Al-Rich Quinary Medium-Entropy Alloys with High Strength and Ductility

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microstructure Characterization

2.3. Mechanical Testing

3. Results and Discussion

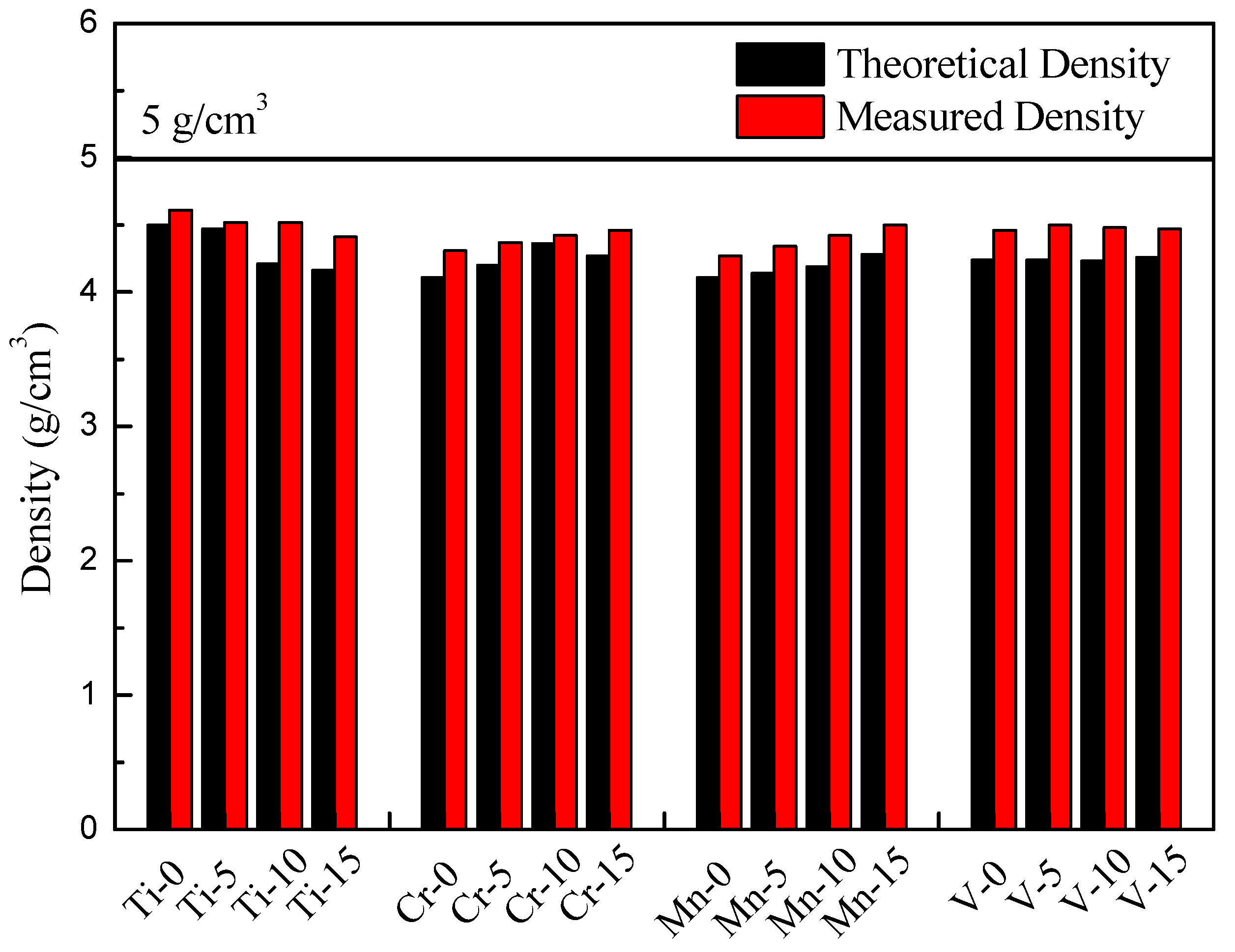

3.1. Density of the Al50–Ti–Cr–Mn–V MEAs

3.2. Optimization of the Mechanical Properties of the Al50–Ti–Cr–Mn–V MEAs

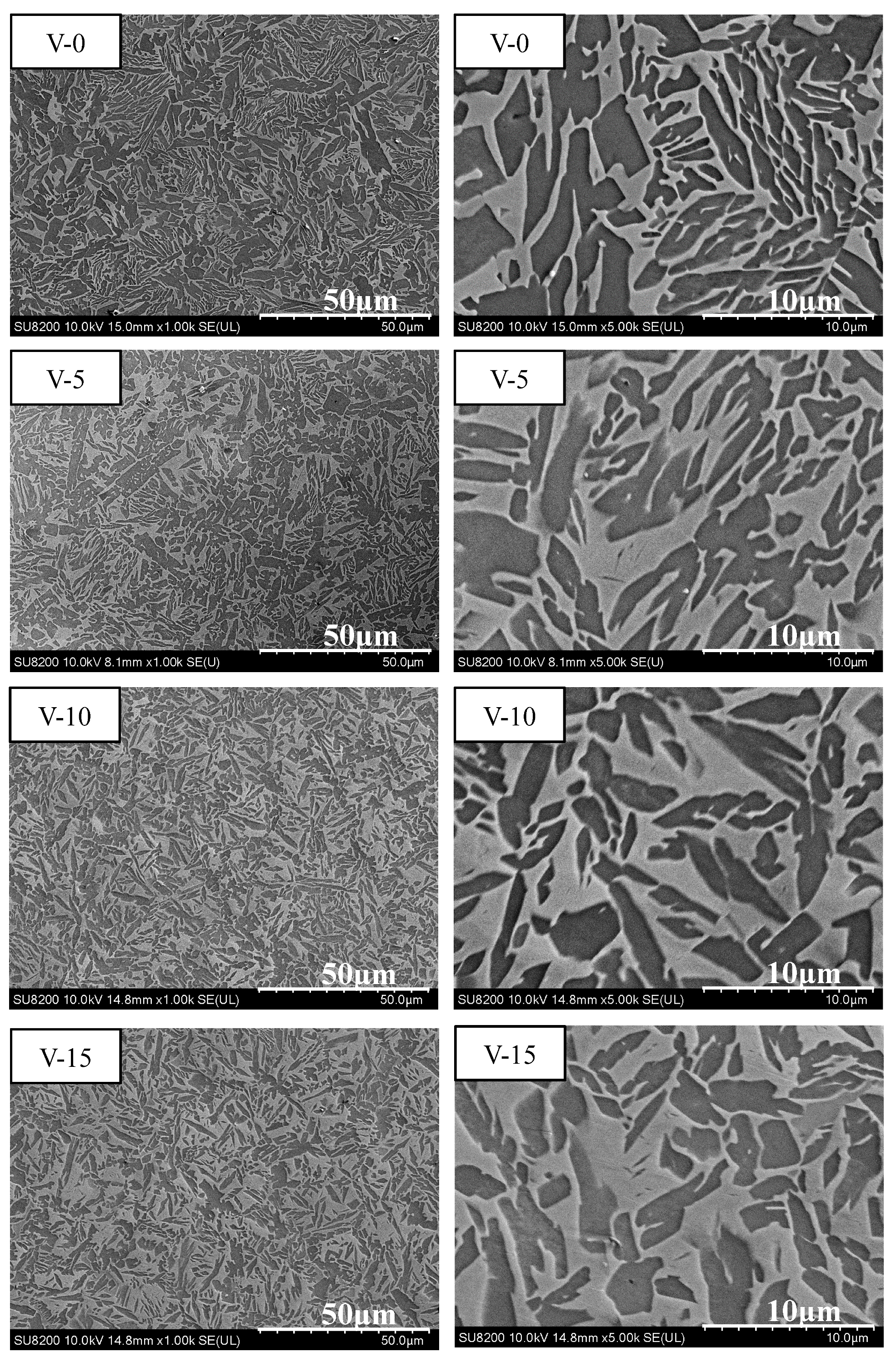

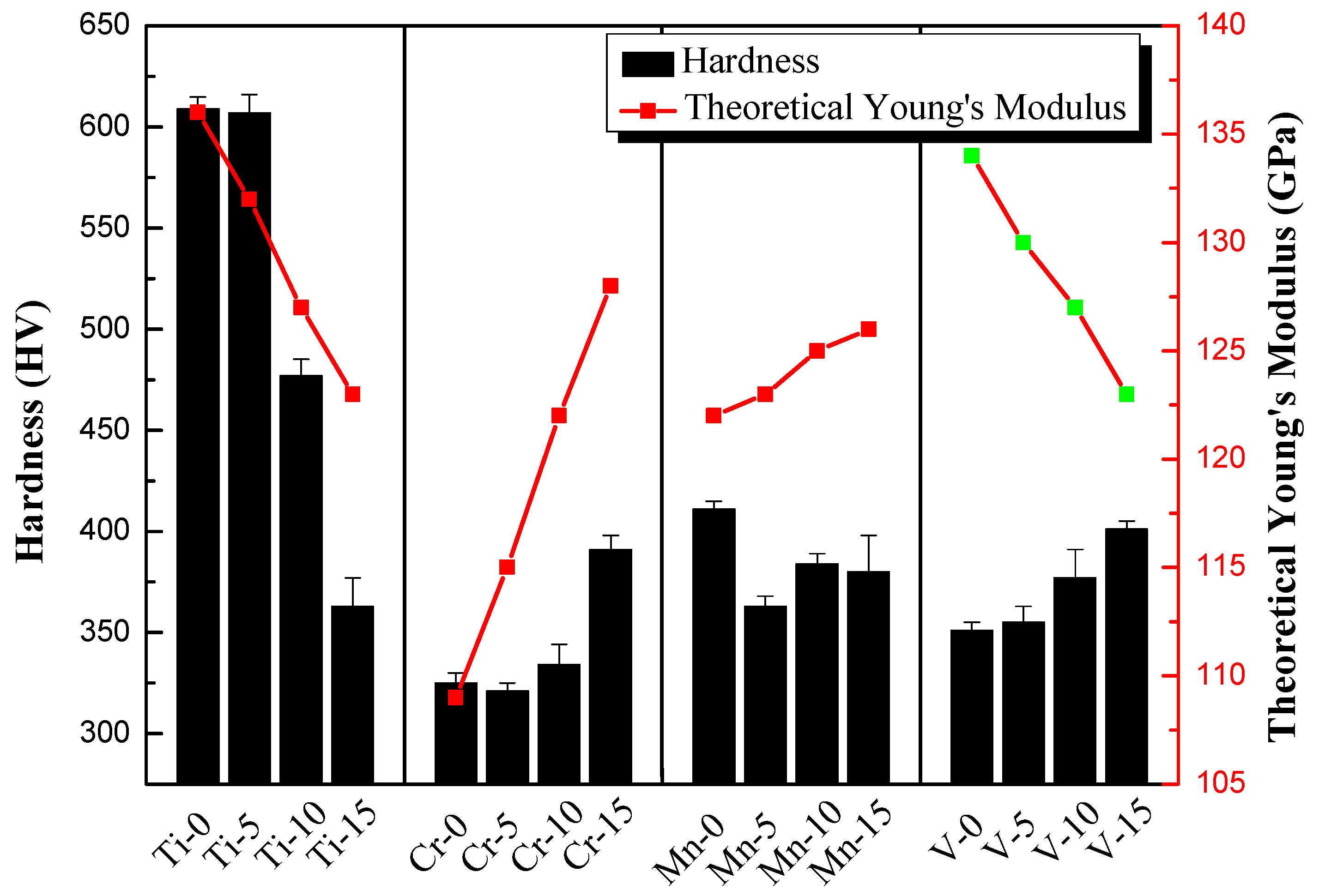

3.3. Al50(Ti2Cr1Mn2)50-xVx Series

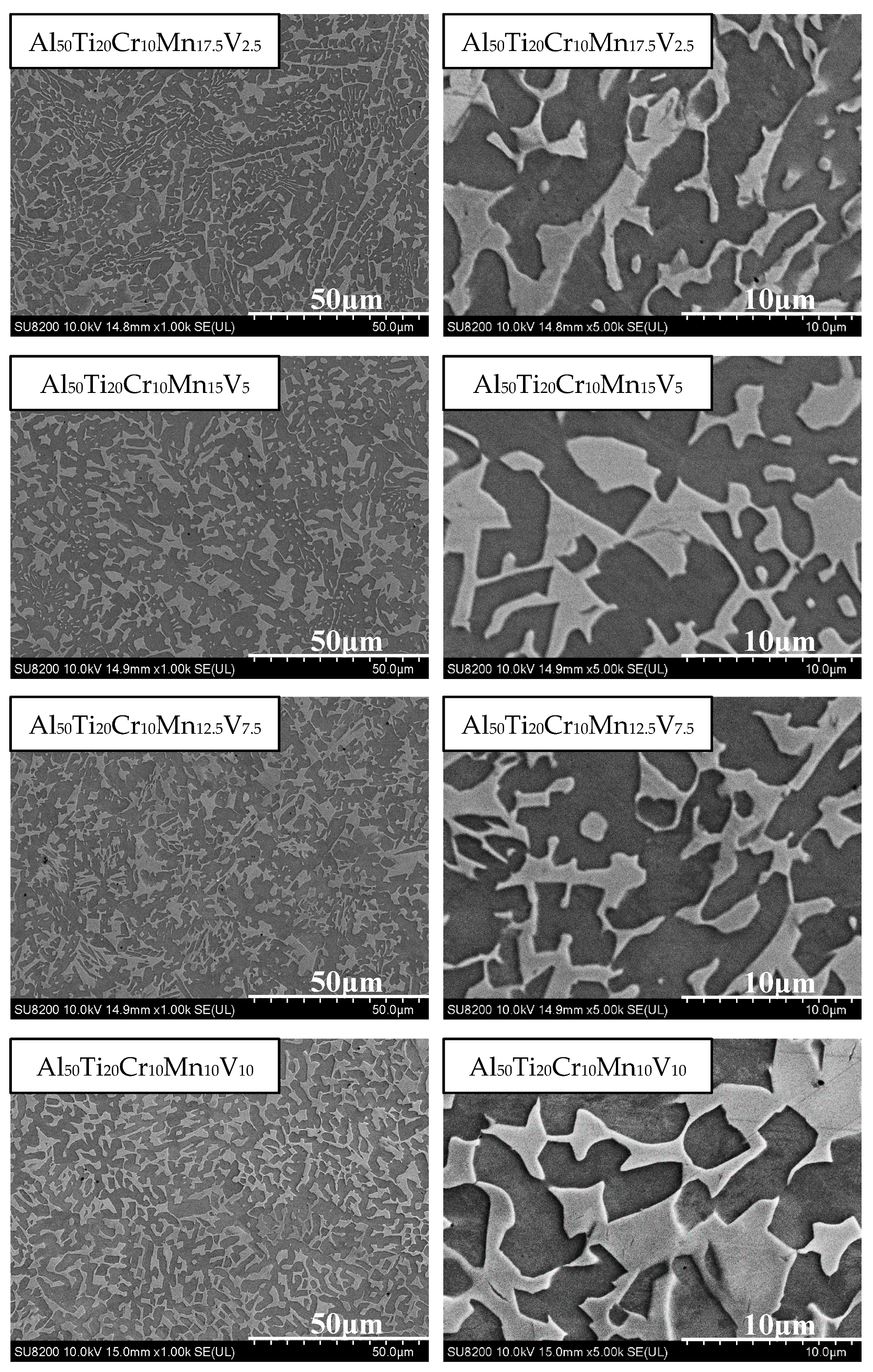

3.4. Al50Ti20Cr10Mn20-xVx Series

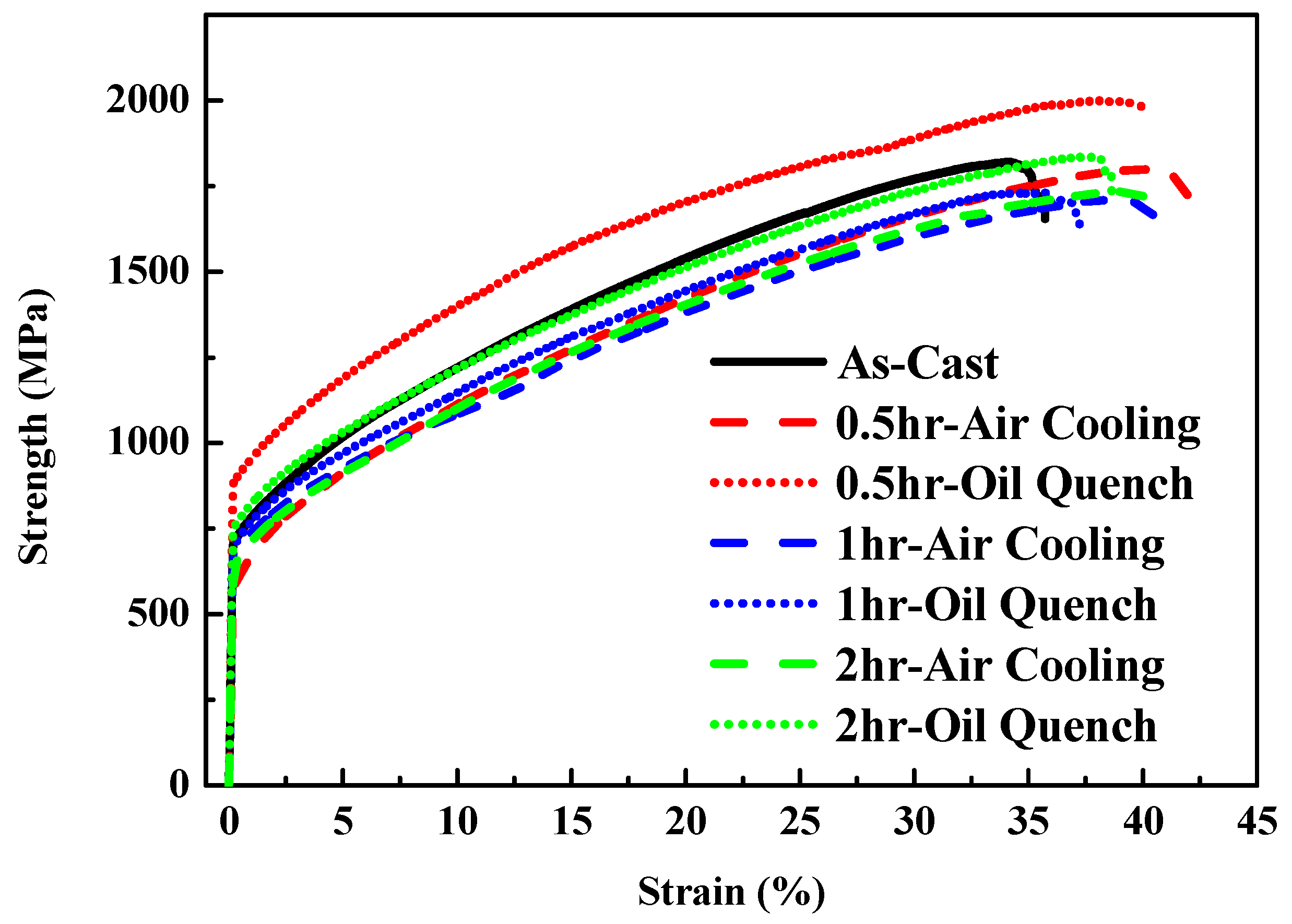

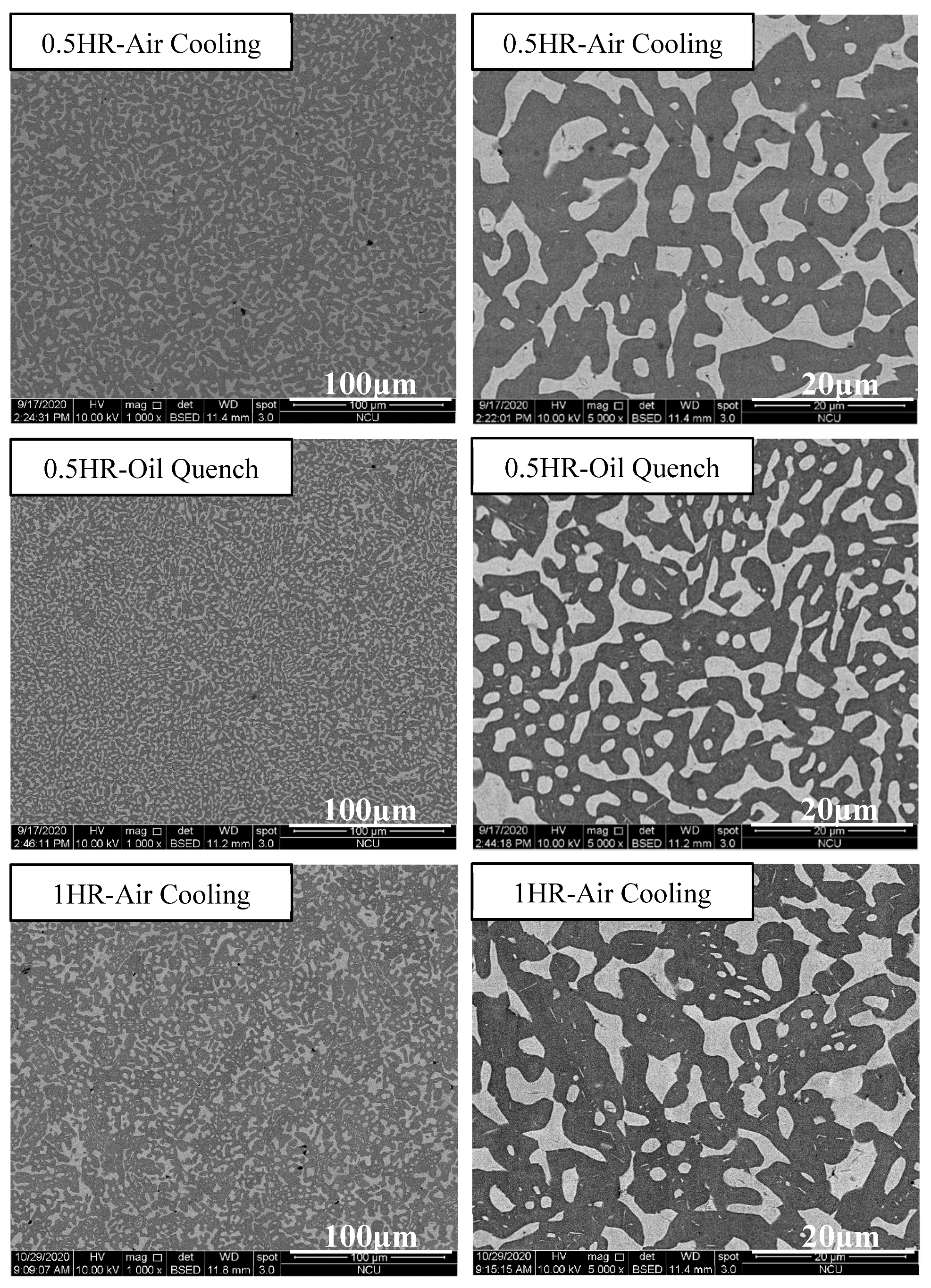

3.5. Annealing Treatment on the Al50Ti20Cr10Mn15V5 Series

4. Conclusions

- By maintaining a 50% Al atomic ratio, all designed alloys could achieve the low density (<5 g/cm3) target.

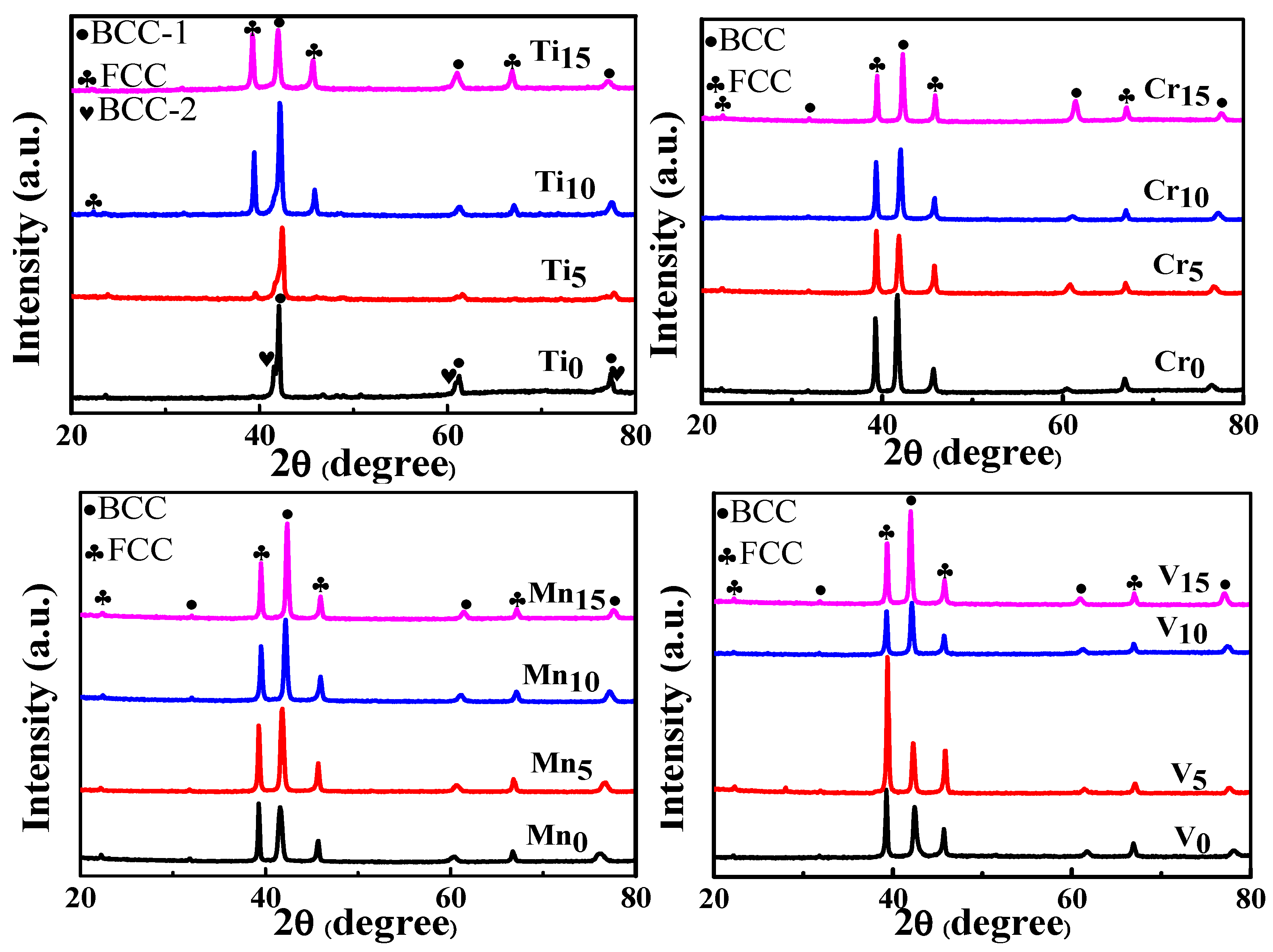

- Most of the MEAs exhibited a dual-phase (FCC + BCC) structure. Cr, Mn, and V with their small atomic radii were mainly distributed in the BCC phase, and Al and Ti with their large atomic radii were mainly distributed in the FCC phase. However, if the Ti element concentration was not sufficient in the alloy, the structure converted to dual BCC phases.

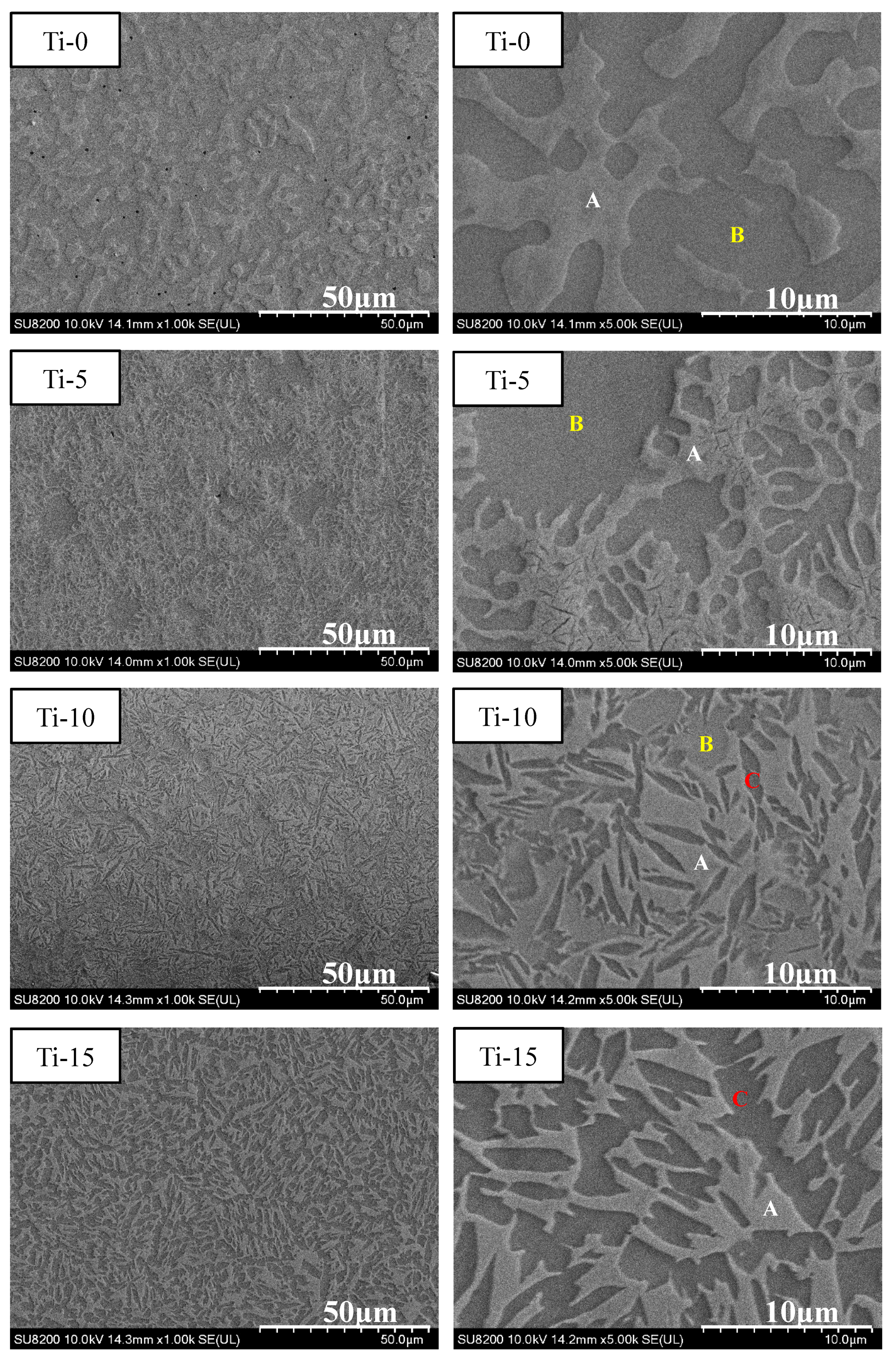

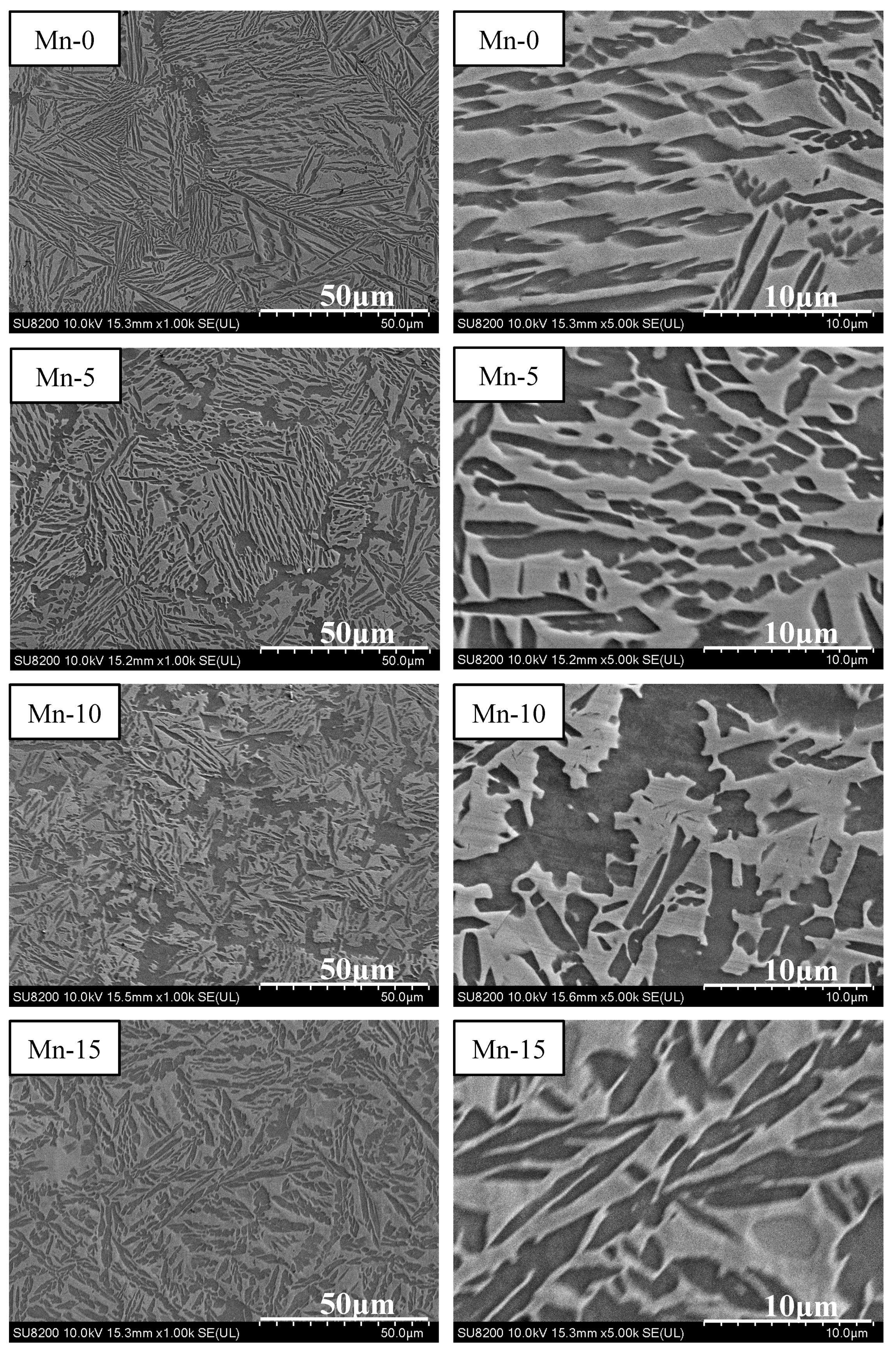

- Increasing the Ti content softened the MEAs. Different Mn concentrations affected the shape of the BCC phase, resulting in changes to the mechanical properties. An increase in Cr and V contents significantly increased the hardness and strength of the alloy.

- The fraction and morphology of the BCC phase played a key role in the resultant mechanical properties. By increasing the fraction of the BCC phase, the strength of the MEAs could be enhanced. In addition, the MEAs with a round-shaped BCC phase possessed higher ductility than those with a sharp-edged phase.

- Concerning the Al50–Ti–Cr–Mn–V MEA systems, the Al50Ti20Cr10Mn15V5 MEA exhibited the best mechanical properties after annealing (at 1000 °C for 0.5 h) and oil-quenching, with an 802 MPa yield strength, 1966 MPa compressive strength, and 40% plastic strain. The specific strength-to-density ratio could reach 452 MPa·g/cm3.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASM International. Handbook Committee, “Properties and Selection: Irons, Steels, and High-Performance Alloys”; ASM International: Materials Park, OH, USA, 1990; Volume 1. [Google Scholar]

- Huang, K.H.; Yeh, J.W. A Study On Multicomponent Alloy Systems Containing Equal-Mole Elements; Department of Materials Science and Engineering, Hsinchu: National Tsing Hua University: Beijing, China, 1996. [Google Scholar]

- Yeh, J.W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mat. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructure High-Entropy Alloys with Multiple Principle Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Lilensten, L.; Couzinie, J.-P.; Perrière, L.; Bourgon, J.; Emery, N.; Guillot, I. New structure in refractory high-entropy alloys. Mater. Lett. 2014, 132, 123–125. [Google Scholar] [CrossRef]

- Ma, D.; Yao, M.; Pradeep, K.; Tasan, C.; Springer, H.; Raabe, D. Phase stability of non-equiatomic CoCrFeMnNi high entropy alloys. Acta Mater. 2015, 98, 288–296. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Z.; Zhang, P.; Zhang, K.; Chena, C.L.; Shen, B.L. Influence of Al content on high temperature oxidation behavior of AlxCoCrFeNiTi0.5 high entropy alloys. Vacuum 2019, 163, 263–268. [Google Scholar] [CrossRef]

- Choi, M.; Ondicho, I.; Park, N.; Tsuji, N. Strength–ductility balance in an ultrafine-grained non-equiatomic Fe50(CoCrMnNi)50 medium-entropy alloy with a fully recrystallized microstructure. J. Alloys Compd. 2019, 780, 959–966. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhou, D.; Jin, X.; Zhang, L.; Du, X.; Li, B. Design of non-equiatomic medium-entropy alloys. Sci. Rep. 2018, 8, 1236. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stepanov, N.; Shaysultanov, D.; Chernichenko, R.; Tikhonovsky, M.; Zherebtsov, S. Effect of Al on structure and mechanical properties of Fe-Mn-Cr-Ni-Al non-equiatomic high entropy alloys with high Fe content. J. Alloys Compd. 2019, 770, 194–203. [Google Scholar] [CrossRef] [Green Version]

- Yao, M.; Pradeep, K.; Tasan, C.; Raabe, D. A novel, single phase, non-equiatomic FeMnNiCoCr highentropy alloy with ex-ceptional phase stability and tensile ductility. Scr. Mater. 2014, 72–73, 5–8. [Google Scholar] [CrossRef]

- Youssef, K.; Zaddach, A.J.; Niu, C.; Irving, D.L.; Koch, C.C. A Novel Low-Density, High-Hardness, High-entropy Alloy with Close-packed Single-phase Nanocrystalline Structures. Mater. Res. Lett. 2014, 3, 95–99. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Gao, J.C.; Fan, K. Study to Microstructure and Mechanical Properties of Mg Containing High Entropy Alloys. Mater. Sci. Forum 2010, 650, 265–271. [Google Scholar] [CrossRef]

- Du, X.H.; Wang, R.; Chen, C.; Wu, B.L.; Huang, J. Preparation of a Light-Weight MgCaAlLiCu High-Entropy Alloy. Key Eng. Mater. 2017, 727, 132–135. [Google Scholar] [CrossRef]

- Stepanov, N.; Yurchenko, N.; Skibin, D.; Tikhonovsky, M.; Salishchev, G. Structure and mechanical properties of the AlCrxNbTiV (x = 0, 0.5, 1, 1.5) high entropy alloys. J. Alloys Compd. 2015, 652, 266–280. [Google Scholar] [CrossRef]

- Liao, Y.C.; Chen, P.S.; Li, C.H.; Tsai, P.H.; Jang, J.S.C. Development of Novel Lightweight Dual-Phase Al-Ti-Cr-Mn-V Medium-Entropy Alloys with High Strength and Ductility. Entropy 2020, 22, 74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sanchez, J.M.; Vicario, I.; Albizuri, J.; Guraya, T.; Acuña, E.M. Design, microstructure and mechanical properties of cast medium entropy aluminium alloys. Sci. Rep. 2019, 9, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.; Park, J.M.; Bae, J.W.; Do, H.S.; Lee, B.J.; Kim, H.S. A new strategy for designing immiscible medium-entropy alloys with excellent tensile properties. Acta Mater. 2020, 193, 71–82. [Google Scholar] [CrossRef]

- Zhang, B.; Liaw, P.K.; Brechtl, J.; Ren, J.; Guo, X.; Zhang, Y. Effects of Cu and Zn on microstructures and mechanical behavior of the medium-entropy aluminum alloy. J. Alloys Compd. 2020, 820, 153092. [Google Scholar] [CrossRef]

| Constituent | Hardness (HV) | Yield Strength (MPa) | Ultimate Strength (MPa) | Ductility (%) |

|---|---|---|---|---|

| Al50(CrMnV)50 | 609 ± 6 | Cannot be produced | ||

| Al50(CrMnV)45Ti5 | 607 ± 9 | |||

| Al50(CrMnV)40Ti10 | 477 ± 8 | 1164 ± 58 | 1182 ± 40 | 1 ± 1 |

| Al50(CrMnV)35Ti15 | 363 ± 14 | 870 ± 95 | 1171 ± 388 | 11 ± 10 |

| Al50(TiMnV)50 | 335 ± 5 | 756 ± 30 | 1349 ± 131 | 18 ± 3 |

| Al50(TiMnV)45Cr5 | 321 ± 4 | 851 ± 18 | 1293 ± 113 | 17 ± 5 |

| Al50(TiMnV)40Cr10 | 334 ± 10 | 977 ± 50 | 1457 ± 110 | 16 ± 3 |

| Al50(TiMnV)35Cr15 | 391 ± 7 | 989 ± 123 | 1042 ± 109 | 1 ± 1 |

| Al50(TiCrV)50 | 411 ± 4 | 1258 ± 148 | 1752 ± 118 | 18 ± 2 |

| Al50(TiCrV)45Mn5 | 363 ± 5 | 1004 ± 15 | 1430 ± 144 | 14 ± 3 |

| Al50(TiCrV)40Mn10 | 384 ± 5 | 861 ± 63 | 958 ± 136 | 5 ± 4 |

| Al50(TiCrV)35Mn15 | 380 ± 18 | 1005 ± 27 | 1294 ± 88 | 9 ± 1 |

| Al50(TiCrMn)50 | 351 ± 4 | 737 ± 45 | 1415 ± 42 | 17 ± 1 |

| Al50(TiCrMn)45V5 | 355 ± 8 | 930 ± 22 | 1833 ± 165 | 26 ± 3 |

| Al50(TiCrMn)40V10 | 377 ± 14 | 948 ± 27 | 1424 ± 198 | 15 ± 8 |

| Al50(TiCrMn)35V15 | 401 ± 4 | 905 ± 33 | 964 ± 26 | 3 ± 1 |

| Constituent | Young’s Modulus (GPa) | Atom Size Difference (pm) | FCC/BCC-1/BCC-2 |

|---|---|---|---|

| Al50(CrMnV)50 | 136 | 5.12 | 0/28/72 |

| Al50(CrMnV)45Ti5 | 132 | 5.14 | 0/49/51 |

| Al50(CrMnV)40Ti10 | 127 | 5.09 | 41/25/34 |

| Al50(CrMnV)35Ti15 | 123 | 4.98 | 66/34/0 |

| Al50(TiMnV)50 | 109 | 3.72 | 61/39/0 |

| Al50(TiMnV)45Cr5 | 115 | 4.33 | 57/43/0 |

| Al50(TiMnV)40Cr10 | 122 | 4.82 | 68/32/0 |

| Al50(TiMnV)35Cr15 | 128 | 5.24 | 68/32/0 |

| Al50(TiCrV)50 | 122 | 5.57 | 57/43/0 |

| Al50(TiCrV)45Mn5 | 123 | 5.36 | 60/40/0 |

| Al50(TiCrV)40Mn10 | 125 | 5.15 | 53/47/0 |

| Al50(TiCrV)35Mn15 | 126 | 4.93 | 59/41/0 |

| Al50(TiCrMn)50 | 134 | 5.24 | 71/29/0 |

| Al50(TiCrMn)45V5 | 130 | 5.16 | 61/39/0 |

| Al50(TiCrMn)40V10 | 127 | 5.08 | 53/47/0 |

| Al50(TiCrMn)35V15 | 123 | 5.00 | 57/43/0 |

| Constituent | FCC/BCC | Yield Strength (MPa) | Ultimate Strength (MPa) | Ductility (%) |

|---|---|---|---|---|

| Al50Ti19Cr9.5Mn19V2.5 | 69/31 | 727 ± 23 | 1484 ± 140 | 25 ± 5 |

| Al50Ti18Cr9Mn18V5 | 68/32 | 773 ± 32 | 1610 ± 45 | 26 ± 1 |

| Al50Ti17Cr8.5Mn17V7.5 | 65/35 | 791 ± 40 | 1291 ± 346 | 20 ± 7 |

| Al50Ti16Cr8Mn16V10 | 62/38 | 865 ± 83 | 1473 ± 59 | 20 ± 1 |

| Al50Ti20Cr10Mn17.5V2.5 | 71/28 | 743 ± 17 | 1576 ± 77 | 27 ± 2 |

| Al50Ti20Cr10Mn15V5 | 69/31 | 713 ± 9 | 1802 ± 22 | 34 ± 1 |

| Al50Ti20Cr10Mn12.5V7.5 | 67/33 | 763 ± 6 | 1882 ± 35 | 33 ± 3 |

| Al50Ti20Cr10Mn10V10 | 66/34 | 876 ± 33 | 1266 ± 6 | 14 ± 4 |

| Constituent | FCC/BCC | Yield Strength (MPa) | Ultimate Strength (MPa) | Ductility (%) |

|---|---|---|---|---|

| 0.5 h-air cooling | 72/28 | 659 ± 83 | 1779 ± 13 | 34 ± 5 |

| 0.5 h-oil quenching | 68/32 | 802 ± 47 | 1966 ± 27 | 40 ± 1 |

| 1 h-air cooling | 71/29 | 659 ± 13 | 1696 ± 17 | 38 ± 2 |

| 1 h-oil quenching | 69/31 | 714 ± 14 | 1720 ± 12 | 36 ± 2 |

| 2 h-air cooling | 71/29 | 671 ± 31 | 1675 ± 57 | 35 ± 5 |

| 2 h-oil quenching | 67/33 | 744 ± 18 | 1724 ± 79 | 33 ± 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.-S.; Liao, Y.-C.; Lin, Y.-T.; Tsai, P.-H.; Jang, J.S.C.; Hsieh, K.-C.; Chen, C.-Y.; Huang, J.C.; Wu, H.-J.; Tsao, I.-Y. Development of Novel Lightweight Al-Rich Quinary Medium-Entropy Alloys with High Strength and Ductility. Materials 2021, 14, 4223. https://doi.org/10.3390/ma14154223

Chen P-S, Liao Y-C, Lin Y-T, Tsai P-H, Jang JSC, Hsieh K-C, Chen C-Y, Huang JC, Wu H-J, Tsao I-Y. Development of Novel Lightweight Al-Rich Quinary Medium-Entropy Alloys with High Strength and Ductility. Materials. 2021; 14(15):4223. https://doi.org/10.3390/ma14154223

Chicago/Turabian StyleChen, Po-Sung, Yu-Chin Liao, Yen-Ting Lin, Pei-Hua Tsai, Jason S. C. Jang, Ker-Chang Hsieh, Chih-Yen Chen, Jacob C. Huang, Hsin-Jay Wu, and I-Yu Tsao. 2021. "Development of Novel Lightweight Al-Rich Quinary Medium-Entropy Alloys with High Strength and Ductility" Materials 14, no. 15: 4223. https://doi.org/10.3390/ma14154223

APA StyleChen, P.-S., Liao, Y.-C., Lin, Y.-T., Tsai, P.-H., Jang, J. S. C., Hsieh, K.-C., Chen, C.-Y., Huang, J. C., Wu, H.-J., & Tsao, I.-Y. (2021). Development of Novel Lightweight Al-Rich Quinary Medium-Entropy Alloys with High Strength and Ductility. Materials, 14(15), 4223. https://doi.org/10.3390/ma14154223