Selective Laser Sintering of PA 2200 for Hip Implant Applications: Finite Element Analysis, Process Optimization, Morphological and Mechanical Characterization

Abstract

:1. Introduction

2. Materials and Methods

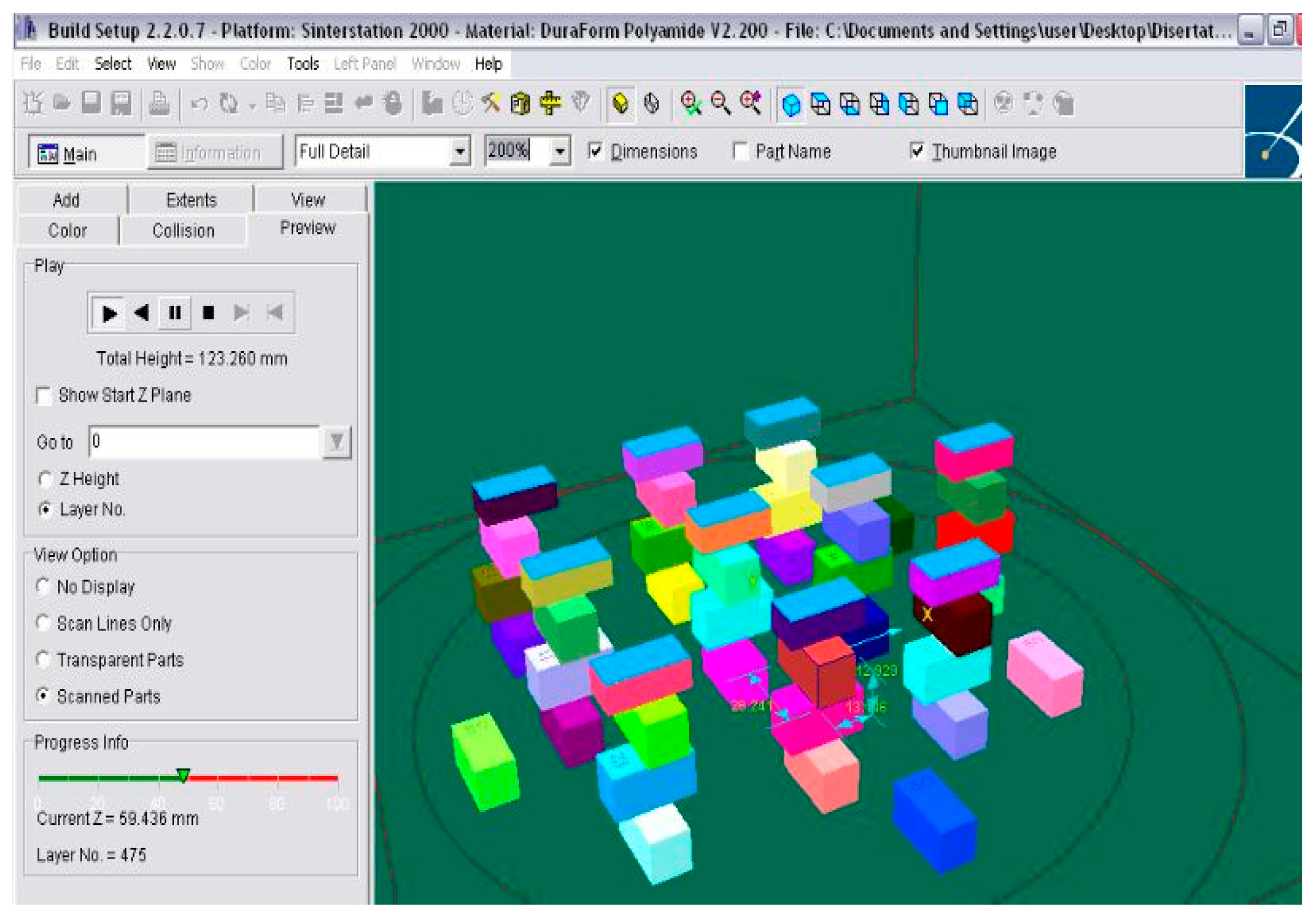

2.1. Manufacturing of Samples Made of PA 2200 by SLS and Compression Test Experiments

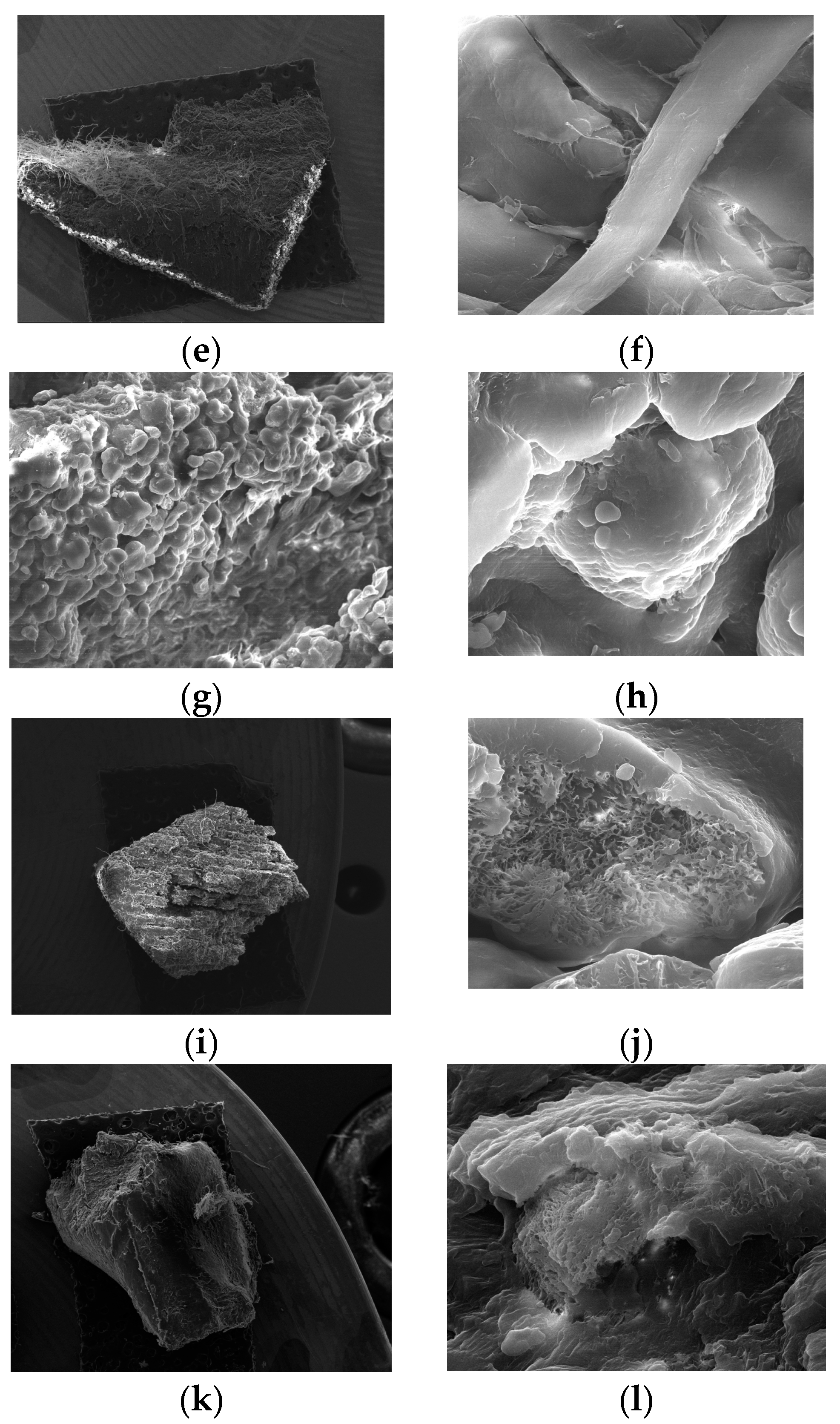

2.2. Microstructural Analyses

2.3. Surface Roughness Evaluation

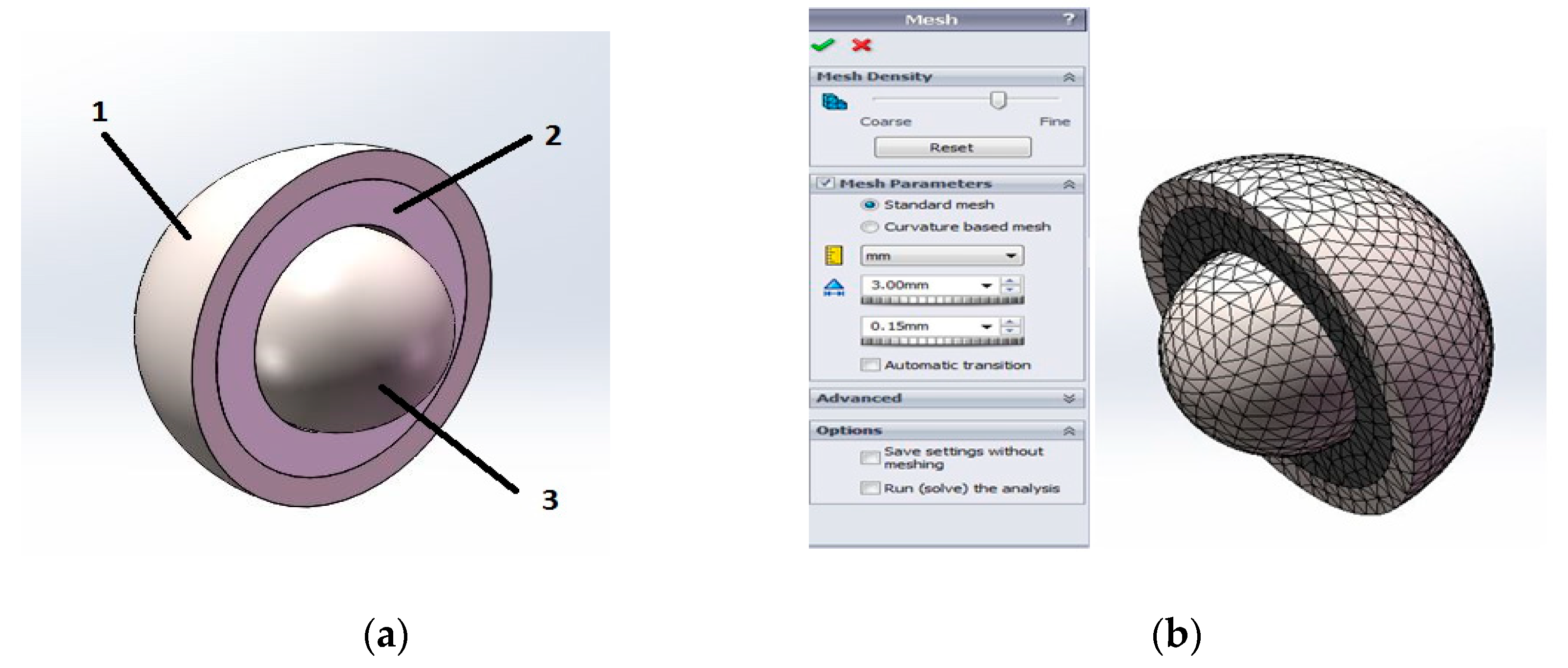

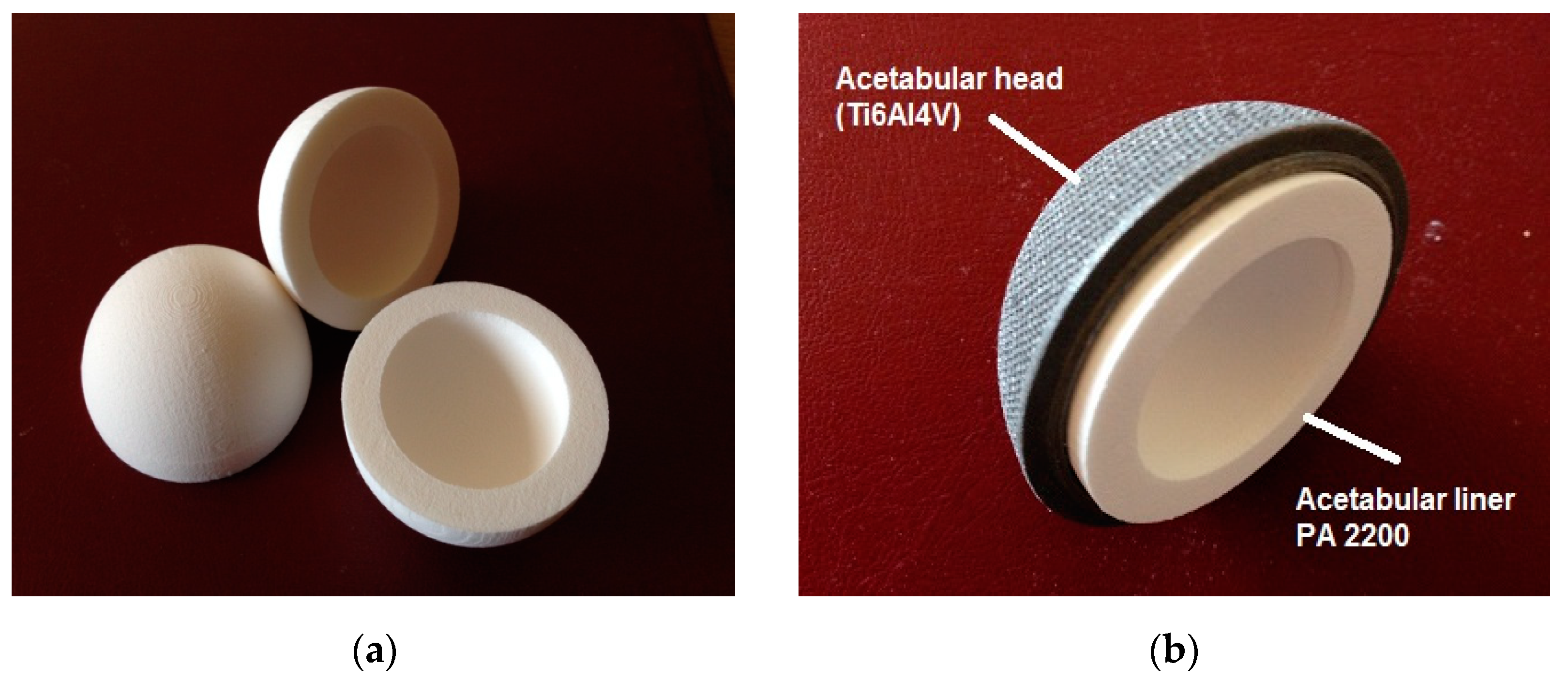

2.4. Finite Element Method for Optimizing the Contact Pressure between the Acetabular Cup and the Acetabular Liner

3. Results and Discussions

3.1. Compression Test Experiments

3.2. Microstructural Analysis

3.3. Surface Roughness of PA 2200 by SLS

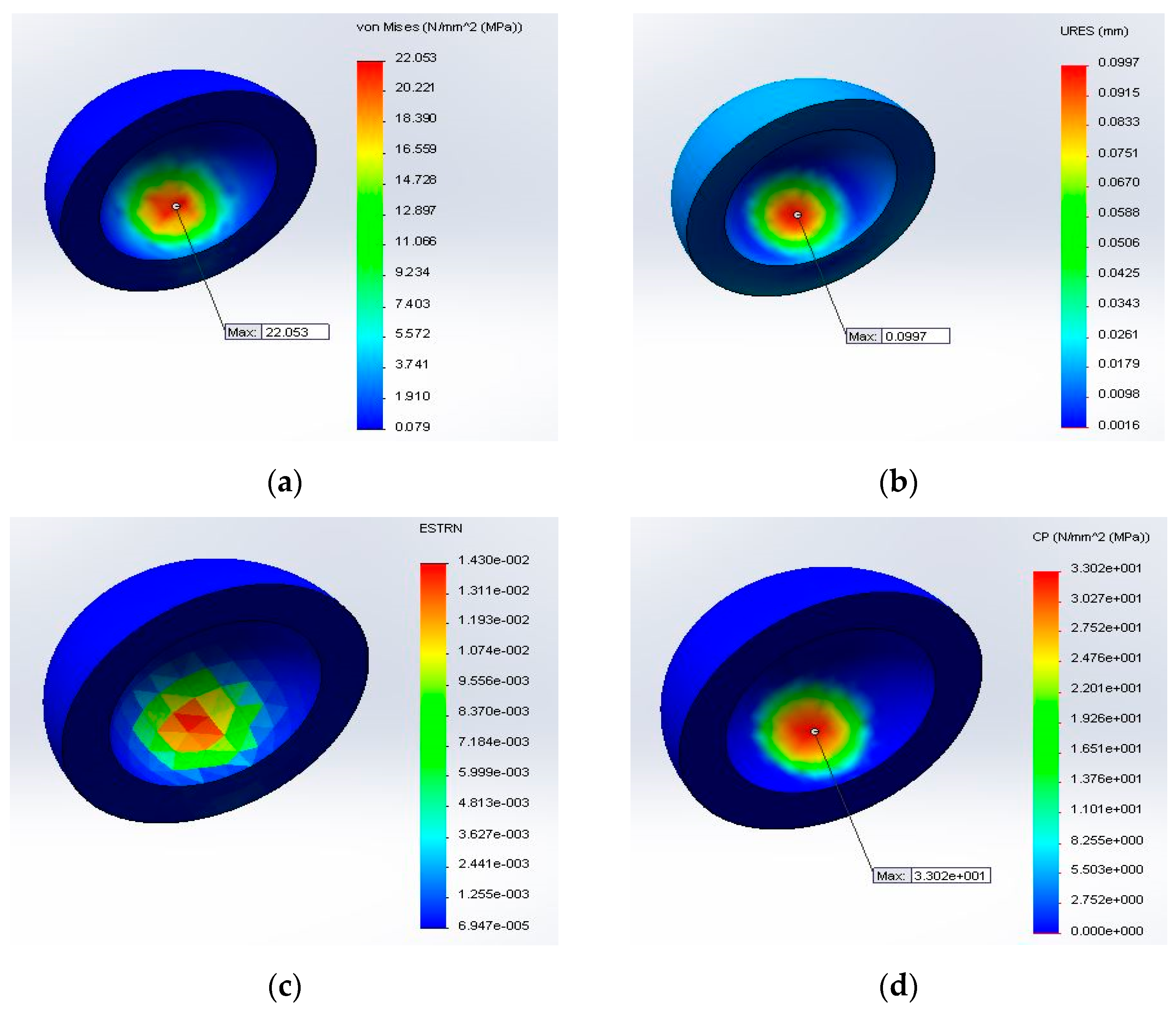

3.4. Finite Element Analysis of the Orthopedic Implant Made from PA 2200 by SLS

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, R.; Kumar, M.; Chohan, J.S. The role of additive manufacturing for biomedical applications: A critical review. J. Manuf. Process. 2021, 64, 828–850. [Google Scholar] [CrossRef]

- Syed, H.R.; Syed, H.M.; Rizwan, A.R.R.; Sanjeet, C. Selective Laser Sintering in Biomedical Manufacturing, Metallic Biomaterials Processing and Medical Device Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Berretta, S.; Ghita, O.; Evans, K. Morphology of polymeric powders in Laser Sintering (LS): From Polyamide to new PEEK powders. Eur. Polym. J. 2014, 59, 218–229. [Google Scholar] [CrossRef]

- Jatender, P.S.; Pulak, M.H. Fitment study of porous polyamide scaffolds fabricated from selective laser sintering. Proceedia Eng. 2013, 59, 59–71. [Google Scholar]

- Rahim, T.N.A.T.; Abdullah, A.M.; Akil, H.M.; Mohamad, D.; Rajion, Z.A. The improvement of mechanical and thermal properties of polyamide 12 3D printed parts by fused deposition modelling. Express Polym. Lett. 2017, 11, 963–982. [Google Scholar] [CrossRef]

- Stoia, D.I.; Linul, E.; Marsavina, L. Influence of Manufacturing Parameters on Mechanical Properties of Porous Materials by Selective Laser Sintering. Materials 2019, 12, 871. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xijin, H.; Junyan, L.; Ling, W.; Zhongmin, J.; Ruth, W.; Fisher, J. Contact mechanics of modular metal-on-polyethylene total hip replacement under adverse edge loading conditions. J. Biomech. 2014, 47, 3303–3309. [Google Scholar]

- Cahill, S.; Lohfeld, S.; McHugh, P.E. Finite element predictions compared to experimental results for the effective modulus of bone tissue engineering scaffolds fabricated by selective laser sintering. J. Mater. Sci. Mater. Med. 2009, 20, 1255–1262. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Liu, H.; Shuang, J.; Wang, J.; Ma, J.; Zhang, S. Microsphere-based selective laser sintering for building macroporous bone scaffolds with controlled microstructure and excellent biocompatibility. Colloids Surf. B Biointerfaces 2015, 135, 81–89. [Google Scholar] [CrossRef]

- Nikhil, K.; Jekaterina, K.; Ramin, R.; Miguel, A.R.; Irina, H. Selective laser sintered bio-inspired silicon-wollastonite scaffolds for bone tissue engineering. Mater. Sci. Eng. C 2020, 116, 111223. [Google Scholar]

- Latifa, A.; Kamel, C.; Skander, B.; Nacira, S.; Hassani, M.; Taher, G.T. Structure and mechanical properties of PMMA/GF/Perlon composite for orthopedic prostheses. Mater. Today 2020, 31, S162–S167. [Google Scholar]

- Stieghorst, J.; Doll, T. Rheological behavior of PDMS silicone rubber for 3D printing of medical implants. Addit. Manuf. 2018, 24, 217–223. [Google Scholar] [CrossRef]

- Wegner, N.; Scholz, R.; Knyazeva, M.; Walther, F. Service life characterization of orthopedic implant material made of ultra-high molecular weight polyethylene under physiological conditions. J. Mech. Behav. Biomed. Mater. 2020, 104, 103617. [Google Scholar] [CrossRef]

- Krishnakumar, S.; Senthilvelan, T. Polymer composites in dentistry and orthopedic applications—A review. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Moussa, A.; Rahman, S.; Xu, M.; Tanzer, M.; Pasini, D. Topology optimization of 3D-printed structurally porous cage for acetabular reinforcement in total hip arthroplasty. J. Mech. Behav. Biomed. Mater. 2020, 105, 103705. [Google Scholar] [CrossRef]

- Hariharan, K.; Arumaikkannu, G. Structural, mechanical and in vitro studies on pulsed laser deposition of hydroxyapatite on additive manufactured polyamide substrate. Int. J. Bioprint. 2016, 2, 85–94. [Google Scholar]

- Lee, D.S.H.; Pai, Y.; Chang, S. Effect of Thermal Treatment of the Hydroxyapatite Powders on the Micropore and Microstructure of Porous Biphasic Calcium Phosphate Composite Granules. J. Biomater. Nanobiotechnol. 2013, 4, 114–118. [Google Scholar] [CrossRef] [Green Version]

- Hui, D.; Goodridge, R.; Scotchford, C.; Grant, D. Laser sintering of nano-hydroxyapatite coated polyamide 12 powders. Addit. Manuf. 2018, 22, 560–570. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Morozov, Y.; Smurov, I. Nanostructural self-organization under selective laser sintering of exothermic powder mixtures. Appl. Surf. Sci. 2009, 255, 5565–5568. [Google Scholar] [CrossRef]

- Rotella, G.; Del Prete, A.; Muzzupappa, M.; Umbrello, D. Innovative Manufacturing Process of Functionalized PA2200 for Reduced Adhesion Properties. J. Manuf. Mater. Process. 2020, 4, 36. [Google Scholar] [CrossRef]

- Dabbas, F.; Stares, S.L.; Schappo, H.; Hotza, D.; Salmoria, G.V. Viscoelastic Properties and Creep-Fatigue Behavior of PA2200/HA Composites Manufactured by Selective Laser Sintering. J. Mater. Sci. Eng. B 2019, 9, 25–31. [Google Scholar] [CrossRef]

- Stichel, T.; Frick, T.; Laumer, T.; Tenner, F.; Hausotte, T.; Merklein, M.; Schmidt, M. A Round Robin study for selective laser sintering of polymers: Back tracing of the pore morphology to the process parameters. J. Mater. Process. Technol. 2018, 252, 537–545. [Google Scholar] [CrossRef]

- Caulfield, B.; McHugh, P.; Lohfeld, S. Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- Hamaid, M.K.; Tolga, B.S.; Gurkan, T.; Mustafa, E.B.; Mert, C.; Ebubekir, K.; Yusuf, K. Improving the surface quality and mechanical properties of selective laser sintered PA2200 components by the vibratory surface finishing process. Appl. Sci. 2021, 3, 364. [Google Scholar]

- Narayana, B.; Venkatesh, S. Parametric Optimization for A Quality Prototype From Selective Laser Sintering: Grey Taguchi Method. Mater. Today Proc. 2019, 18, 4271–4280. [Google Scholar] [CrossRef]

- Beal, V.; Paggi, R.A.; Salmoria, G.V.; Lago, A. Statistical evaluation of laser energy density effect on mechanical properties of polyamide parts manufactured by selective laser sintering. J. Appl. Polym. Sci. 2009, 113, 2910–2919. [Google Scholar] [CrossRef]

- Leirmo, T.; Semeniuta, O. Investigating the Dimensional and Geometric Accuracy of Laser-Based Powder Bed Fusion of PA2200 (PA12): Experiment Design and Execution. Appl. Sci. 2021, 11, 2031. [Google Scholar] [CrossRef]

- Baligidad, S.M.; Chandrasekhar, U.; Elangovan, K.; Shankar, S. Taguchi’s Approach: Design optimization of process parameters in selective inhibition sintering. Mater. Today Proc. 2018, 5, 4778–4786. [Google Scholar] [CrossRef]

- Ali, T.K.; Esakki, B. Study on compressive strength characteristics of selective inhibition sintered UHMWPE specimens based on ANN and RSM approach. CIRP J. Manuf. Sci. Technol. 2020, 31, 281–293. [Google Scholar] [CrossRef]

- Li, M.; Yuchen, H.; Mengyuan, Z.; Peng, C.; Huang, G.; Yun, Z.; Huamin, Z. Experimental investigating and numerical simulations of the thermal behavior and process optimization for selective laser sintering of PA6. J. Manuf. Process. 2020, 56, 271–279. [Google Scholar] [CrossRef]

- Prithvirajan, R.; Balakumar, C.; Arumaikkannu, G. Effect of strut diameter on compressive behaviour of selective laser sintered polyamide rhombic dodecahedron lattice. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Bibo, Y.; Zhenhua, L.; Fei, Z. Effect of powder recycling on anisotropic tensile properties of selective laser sintered PA2200 polyamide. Eur. Polym. J. 2020, 141, 110093. [Google Scholar]

- Phillips, T.; Fish, S.; Beaman, J. Development of an automated laser control system for improving temperature uniformity and controlling component strength in selective laser sintering. Addit. Manuf. 2018, 24, 316–322. [Google Scholar] [CrossRef]

- Dechet, M.A.; Baumeister, I.; Schmidt, J. Development of Polyoxymethylene Particles via the Solution-Dissolution Process and Application to the Powder Bed Fusion of Polymers. Materials 2020, 13, 1535. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stoia, D.I.; Marsavina, L.; Linul, E. Mode I Fracture Toughness of Polyamide and Alumide Samples obtained by Selective Laser Sintering Additive Process. Polymers 2020, 12, 640. [Google Scholar] [CrossRef] [Green Version]

- Lindberg, A.; Alfthan, J.; Pettersson, H.; Flodberg, G.; Yang, L. Mechanical performance of polymer powder bed fused objects—FEM simulation and verification. Addit. Manuf. 2018, 24, 577–586. [Google Scholar] [CrossRef]

- Monzón, M.; Hernández, P.M.; Benftez, A.N.; Marrero, M.D.; Fernández, Á. Predictability of Plastic Parts Behaviour Made from Rapid Manufacturing. Tsinghua Sci. Technol. 2009, 14, 100–107. [Google Scholar] [CrossRef]

- Martynková, G.M.; Slíva, A.; Kratošová, G.; Barabaszov, K.C.; Študentová, S.; Klusák, J.; Brožová, S.; Dokoupil, T.; Holešová, S. Polyamide 12 Materials Study of Morpho-Structural Changes during Laser Sintering of 3D Printing. Polymers 2021, 13, 810. [Google Scholar] [CrossRef]

- Taylor, M.; Tanner, K.; Freeman, M.; Yettram, A. Cancellous bone stresses surrounding the femoral component of a hip prosthesis: An elastic-plastic finite element analysis. Med Eng. Phys. 1995, 17, 544–550. [Google Scholar] [CrossRef]

- Lanzl, L.; Wudy, K.; Drummer, D. The effect of short glass fibers on the process behavior of polyamide 12 during selective laser beam melting. Polym. Test. 2020, 83, 106313. [Google Scholar] [CrossRef]

- Amirouche, F.; Romero, F.; Gonzalez, M.; Aram, L. Study of Micromotion in Modular Acetabular Components During Gait and Subluxation: A Finite Element Investigation. J. Biomech. Eng. 2008, 130, 021002. [Google Scholar] [CrossRef]

- Ajoku, U.; Hopkinson, N.; Caine, M. Experimental measurement and finite element modelling of the compressive properties of laser sintered Nylon-12. Mater. Sci. Eng. A 2006, 428, 211–216. [Google Scholar] [CrossRef]

- Wudy, K.; Drummer, D. Aging effects of polyamide 12 in selective laser sintering: Molecular weight distribution and thermal properties. Addit. Manuf. 2019, 25, 1–9. [Google Scholar] [CrossRef]

- Patel, R.; Monticone, D.; Lua, M.; Grøndahl, L.; Huang, H. Hydrolytic degradation of porous poly(hydroxybutyrate-co-hydroxyvalerate) scaffolds manufactured using selective laser sintering. Polym. Degrad. Stab. 2021, 187, 109545. [Google Scholar] [CrossRef]

- Fernandes, M.G.; Alves, F.J.L.; Fonseca, E.M.M. Diaphyseal femoral fracture: 3D biomodel and intramedullary nail created by additive manufacturing. Int. J. Mater. Eng. Innov. 2016, 7, 130. [Google Scholar] [CrossRef]

- Hughes, A.; O’Donnchadha, B.; Tansey, A.; McMahon, C.; Hurson, C. Acetabular reconstruction using 3D printing in revision hip arthroplasty. Int. J. Surg. 2015, 23, S82. [Google Scholar] [CrossRef] [Green Version]

- Okolie, O.; Stachurek, I.; Kandasubramanian, B.; Njuguna, J. 3D Printing for Hip Implant Applications: A Review. Polymers 2020, 12, 2682. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.; Xue, F.; Zhang, S. The application of 3D printing patient specific instrumentation model in total knee arthroplasty. Saudi J. Biol. Sci. 2020, 27, 1217–1221. [Google Scholar] [CrossRef]

- Mechanical Properties of PA2200 Powder Given by EOS GmbH. Available online: http://www.3dworknet.com/fileupload/Datasheets/Datasheet_PA2200.pdf (accessed on 9 May 2021).

- Calibration Procedure for Compressive Equipment. Available online: https://www.controls-group.com/usa/upgrades-for-compression-testers/special-calibration-procedures.php (accessed on 4 June 2021).

- Passuti, N.; Philippeau, J.M.; Gouin, F. Friction couples in total hip replacement. Orthop. Traumatol. Surg. Res. 2009, 95, 27–34. [Google Scholar] [CrossRef] [Green Version]

- Zienkiewicz, O.C.; Taylor, R.L. Appendix A—Isoparametric Finite Element Approximations. In The Finite Element Method, The Basis, 7th ed.; Wiley: New York, NY, USA, 2014; pp. 597–603. [Google Scholar]

- Hao, Y.; Wang, L.; Jiang, W.; Wu, W.; Ai, S.; Shen, L.; Zhao, S.; Dai, K. 3D Printing Hip Prostheses Offer Accurate Reconstruction, Stable Fixation, and Functional Recovery for Revision Total Hip Arthroplasty with Complex Acetabular Bone Defect. Engineering 2020, 6, 1285–1290. [Google Scholar] [CrossRef]

- Goldsmith, A.; Dowson, D.; Isaac, G.H.; Lancaster, J.G. A comparative joint simulator study of the wear of metal-on-metal and alternative material combinations in hip replacements. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2000, 214, 39–47. [Google Scholar] [CrossRef]

- Chou, C.-M.; Shiao, C.-J.; Chung, C.-J.; He, J.-L. Deposition, characterization, and in vivo performance of parylene coating on general-purpose silicone for examining potential biocompatible surface modifications. Thin Solid Film. 2013, 549, 103–107. [Google Scholar] [CrossRef]

- Bourlidi, S.; Qureshi, J.; Soo, S.; Petridis, H. Effect of different initial finishes and Parylene coating thickness on the surface properties of coated PMMA. J. Prosthet. Dent. 2016, 115, 363–370. [Google Scholar] [CrossRef] [Green Version]

- Borzan, C.Ş.; Berce, P.; Chezan, H.; Sabău, E.; Radu, S.A.; Ridzon, M. Physico-mechanical properties characterization of the parts from pa 2200 manufactured by selective laser sintering technology. Acad. J. Manuf. Eng. 2013, 11, 108–113. [Google Scholar]

- Borzan, C.Ş.; Berce, P.; Leordean, V.D.; Luca, A.; Miron, A.V.; Morovic, L. Study of a tridimensional model of a custom implant in cranio-maxillofacial surgery. Acad. J. Manuf. Eng. 2013, 11, 38–43. [Google Scholar]

- Olejarczyk, M.; Gruber, P.; Ziółkowski, G. Capabilities and Limitations of Using Desktop 3-D Printers in the Laser Sintering Process. Appl. Sci. 2020, 10, 6184. [Google Scholar] [CrossRef]

- Hua, X.; Li, J.; Jin, Z.; Fisher, J. The contact mechanics and occurrence of edge loading in modular metal-on-polyethylene total hip replacement during daily activities. Med. Eng. Phys. 2016, 38, 518–525. [Google Scholar] [CrossRef]

- Hua, X.; Wang, L.; Al-Hajjar, M.; Jin, Z.; Wilcox, R.K.; Fisher, J. Experimental validation of finite element modelling of a modular metal-on-polyethylene total hip replacement. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2014, 228, 682–692. [Google Scholar] [CrossRef] [PubMed]

- Harris, W.H. Edge loading has a paradoxical effect on wear in metal-on-polyethylene total hip arthroplasties. Clin. Orthop. Relat. Res. 2012, 470, 3077–3082. [Google Scholar] [CrossRef] [Green Version]

| Mechanical Properties | Value | Unit | Test Standard | |

|---|---|---|---|---|

| Flexural modulus, 23 °C | 1500 | MPa | ISO 178 | |

| Flexural strength | 58 | MPa | ISO 178 | |

| Izod impact notched, 23 °C | 4.4 | kJ/m2 | ISO 180/1A | |

| Izod impact unnotched, 23 °C | 32.8 | kJ/m2 | ISO 180/1U | |

| Shore D hardness (15 s) | 75 | - | ISO 868 | |

| Ball indentation hardness | 78 | MPa | ISO 2039-1 | |

| 3D Data | Value | Unit | Test Standard | |

| Tensile modulus | X-direction | 1700 | MPa | ISO 527-1/-2 |

| Y-direction | 1700 | MPa | ISO 527-1/-2 | |

| Z-direction | 1650 | MPa | ISO 527-1/-2 | |

| Tensile strength | X-direction | 48 | MPa | ISO 527-1/-2 |

| Y-direction | 48 | MPa | ISO 527-1/-2 | |

| Z-direction | 47 | MPa | ISO 527-1/-2 | |

| Strain at break (X-direction) | 24 | % | ISO 527-1/-2 | |

| Charpy impact strength (+23 °C, X-direction) | 53 | kJ/m2 | ISO 179/1eU | |

| Charpy notched impact strength (+23 °C, X-direction) | 4.8 | kJ/m2 | ISO 179/1eA | |

| Thermal conductivity | X-direction | 0.144 | W/(mK) | DIN 52616 |

| Y-direction | 0.144 | W/(mK) | DIN 52616 | |

| Z-direction | 0.127 | W/(mK) | DIN 52616 | |

| Thermal Properties | Value | Unit | Test Standard | |

| Melting temperature (10 °C/min) | 176 | °C | ISO 11357-1/-3 | |

| Vicat softening temperature A | 181 | °C | ISO 306 | |

| Vicat softening temperature (50 °C/h 50 N) | 163 | °C | ISO 306 | |

| Sample No. | Laser Power (W) | Scan Speed (mm/s) | Layer Thickness (mm) | Orientation |

|---|---|---|---|---|

| Samples 1 to 10 | 4.5 | 1257.3 | 0.1 | y = 0° |

| Samples 11 to 20 | 4.5 | 1257.3 | 0.1 | y = 90° |

| Samples 21 to 30 | 4 | 1257.3 | 0.1 | y = 0° |

| Samples 31 to 40 | 4 | 1257.3 | 0.1 | y = 90° |

| Samples 41 to 45 | 4.5 | 1257.3 | 0.1 | z = −45° |

| Samples 46 to 50 | 4.5 | 1257.3 | 0.1 | z = +45° |

| Side 1 | Side 2 | |||

|---|---|---|---|---|

| Control Group | Paraxylene | Control Group | Paraxylene | |

| Sample No. | Average Value | Average Value | Average Value | Average Value |

| 1 | 13.756 | 12.456 | 11.510 | 10.789 |

| 2 | 13.473 | 11.897 | 11.921 | 11.135 |

| 3 | 13.210 | 11.958 | 10.961 | 10.546 |

| 4 | 13.960 | 12.650 | 11.478 | 10.748 |

| 5 | 14.100 | 12.976 | 11.652 | 10.936 |

| Mean | 13.700 | 12.387 | 11.504 | 10.831 |

| Standard deviation | 0.361 | 0.460 | 0.350 | 0.22 |

| p-value (<0.05) | 0.001209295 | 2.22946 × 10−6 | ||

| t-value | 8.192505921 | 40.46192006 | ||

| PA 2200 Samples | Rdx (MPa) | σa (MPa) | σmax (MPa) | Cp (MPa) |

|---|---|---|---|---|

| I (1–5) | 36.3 | 24.22 | 22.053 | 33.02 |

| II (11–15) | 32.95 | 21.97 | 18.33 | 27.45 |

| III (21–25) | 15.23 | 10.15 | 10.60 | 15.88 |

| IV (31–35) | 12.08 | 8.05 | 9.24 | 13.84 |

| V (41–45) | 10.63 | 7.08 | 6.57 | 9.83 |

| VI (46–50) | 10.81 | 7.20 | 7.08 | 10.59 |

| Laser Power (W) | Scanning Speed (mm/s) | Scanning Distance (mm) | Layer Thickness (mm) | Temperature (°C) | Orientation (°) |

|---|---|---|---|---|---|

| 4.5 | 1257.3 | 0.15 | 0.1 | 170 | y = 90° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Păcurar, R.; Berce, P.; Petrilak, A.; Nemeş, O.; Borzan, C.Ş.M.; Harničárová, M.; Păcurar, A. Selective Laser Sintering of PA 2200 for Hip Implant Applications: Finite Element Analysis, Process Optimization, Morphological and Mechanical Characterization. Materials 2021, 14, 4240. https://doi.org/10.3390/ma14154240

Păcurar R, Berce P, Petrilak A, Nemeş O, Borzan CŞM, Harničárová M, Păcurar A. Selective Laser Sintering of PA 2200 for Hip Implant Applications: Finite Element Analysis, Process Optimization, Morphological and Mechanical Characterization. Materials. 2021; 14(15):4240. https://doi.org/10.3390/ma14154240

Chicago/Turabian StylePăcurar, Răzvan, Petru Berce, Anna Petrilak, Ovidiu Nemeş, Cristina Ştefana Miron Borzan, Marta Harničárová, and Ancuţa Păcurar. 2021. "Selective Laser Sintering of PA 2200 for Hip Implant Applications: Finite Element Analysis, Process Optimization, Morphological and Mechanical Characterization" Materials 14, no. 15: 4240. https://doi.org/10.3390/ma14154240

APA StylePăcurar, R., Berce, P., Petrilak, A., Nemeş, O., Borzan, C. Ş. M., Harničárová, M., & Păcurar, A. (2021). Selective Laser Sintering of PA 2200 for Hip Implant Applications: Finite Element Analysis, Process Optimization, Morphological and Mechanical Characterization. Materials, 14(15), 4240. https://doi.org/10.3390/ma14154240