Rubrene Thin Films with Viably Enhanced Charge Transport Fabricated by Cryo-Matrix-Assisted Laser Evaporation

Abstract

1. Introduction

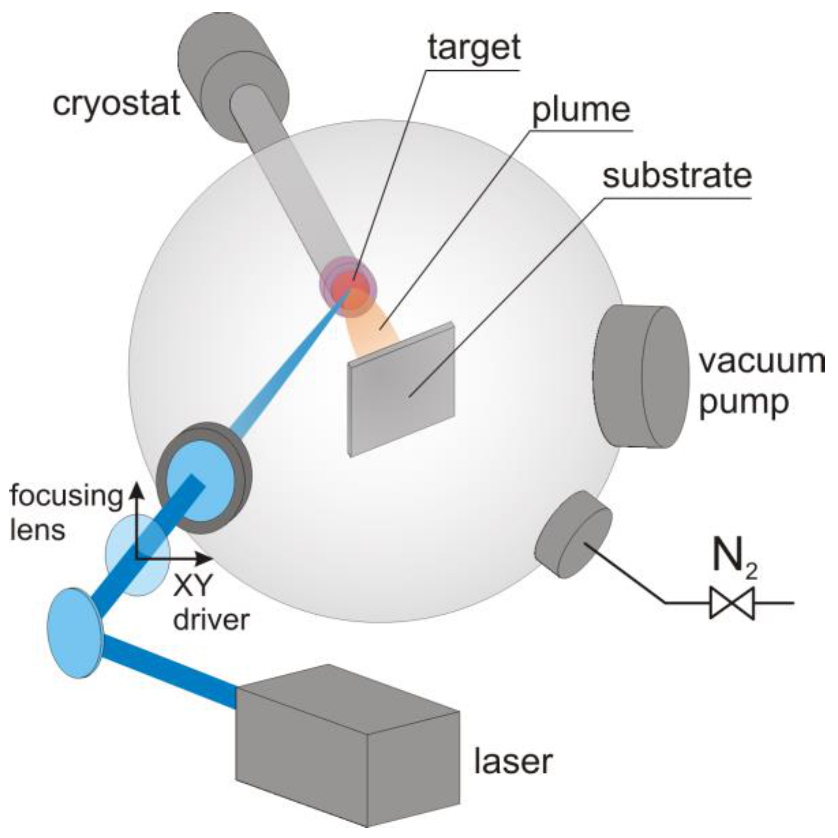

2. Materials and Methods

3. Results and Discussion

3.1. Optical Properties

3.2. Surface Observation

3.3. Structure Analyses

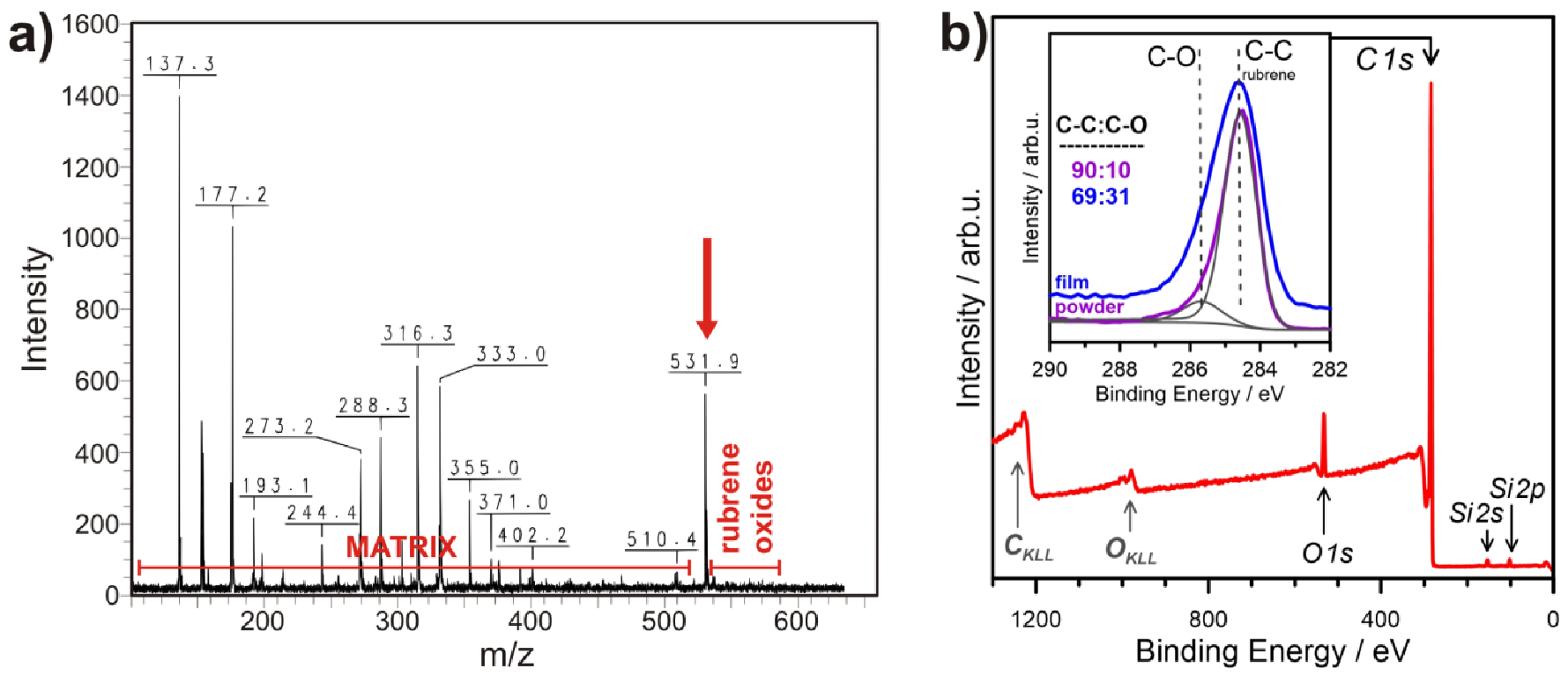

3.4. Chemical Composition

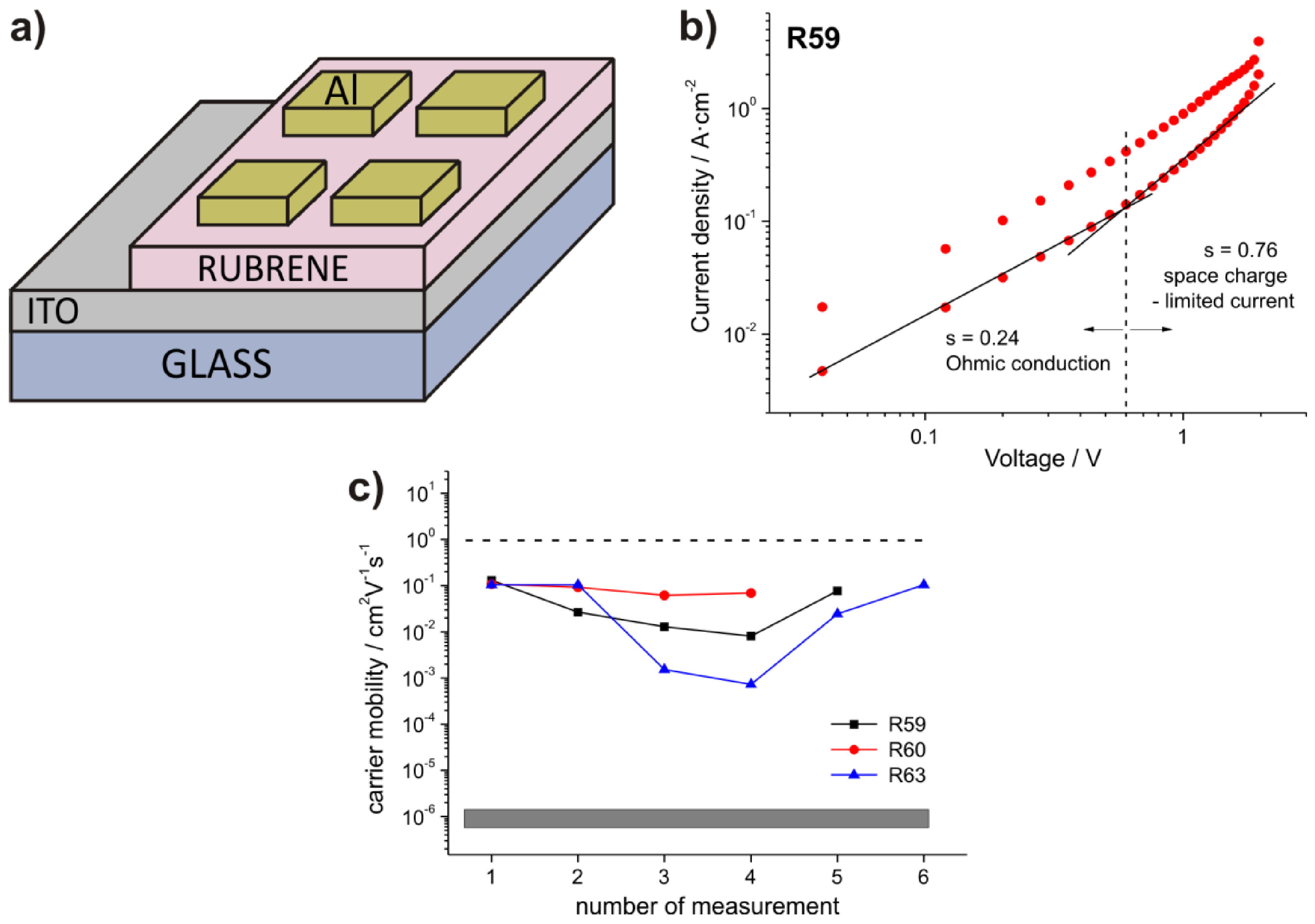

3.5. Carrier Transport Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Löhmannsröben, H.-G. Photophysical properties and laser performance of rubrene. Appl. Phys. B 1988, 47, 195–199. [Google Scholar] [CrossRef]

- Podzorov, V.; Menard, E.; Borissov, A.; Kiryukhin, V.; Rogers, J.A.; Gershenson, M.E. Intrinsic charge transport on the surface of organic semiconductors. Phys. Rev. Lett. 2004, 93, 086602. [Google Scholar] [CrossRef] [PubMed]

- Majumdar, S.; Śliwiński, G.; Garcia, Y. Hybrid organic–inorganic nanostructures for spin switching and spintronic applications. In Hybrid Organic-Inorganic Interfaces: Towards Advanced Functional Materials; Delville, M.H., Taubert, A., Eds.; Viley-VCH Book: Weinheim, Germany, 2018; pp. 301–354. [Google Scholar]

- Majumdar, S.; Grochowska, K.; Sawczak, M.; Śliwiński, G.; Huhtinen, H.; Dahl, J.; Tuominen, M.; Laukkanen, P.; Majumdar, H.S. Interfacial properties of organic semiconductor–inorganic magnetic oxide hybrid spintronic systems fabricated using pulsed laser deposition. ACS Appl. Mater. Interfaces 2015, 7, 22228–22237. [Google Scholar] [CrossRef] [PubMed]

- Jurchescu, O.D.; Meetsma, A.; Palstra, T. Low-temperature structure of rubrene single crystals grown by vapor transport. Acta Cryst. B 2006, 62, 330–334. [Google Scholar] [CrossRef]

- Huang, L.; Liao, Q.; Shi, Q.; Fu, H.; Ma, J.; Yao, J. Rubrene micro-crystals from solution routes: Their crystallography, morphology and optical properties. J. Mater. Chem. 2010, 20, 159–166. [Google Scholar] [CrossRef]

- Reese, C.; Bao, Z. High-resolution measurement of the anisotropy of charge transport in single crystals. Adv. Mater. 2007, 19, 4535–4538. [Google Scholar] [CrossRef]

- da Silva Filho, D.A.; Kim, E.-G.; Brèdas, J.-L. Transport properties in the rubrene crystal: Electronic coupling and vibrational reorganization energy. Adv. Mater. 2005, 17, 1072–1076. [Google Scholar] [CrossRef]

- Podzorov, V. Organic single crystals: Addressing the fundamentals of organic electronics. MRS Bull. 2013, 38, 15–24. [Google Scholar] [CrossRef]

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices, 3rd ed.; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- Matsukawa, T.; Takahashi, Y.; Tokiyama, T.; Sasai, K.; Murai, Y.; Hirota, N.; Tominari, Y.; Mino, N.; Yoshimura, M.; Abe, M.; et al. Solution growth of rubrene single crystals using various organic solvents. Jpn. J. Appl. Phys. 2008, 47, 8950–8954. [Google Scholar] [CrossRef]

- Matsukawa, T.; Yoshimura, M.; Sasai, K.; Uchiyama, M.; Yamagishi, M.; Tominari, Y.; Takahashi, Y.; Takeya, J.; Kitaoka, Y.; Mori, Y.; et al. Growth of thin rubrene single crystals from 1-propanol solvent. J. Cryst. Growth 2010, 312, 310–313. [Google Scholar] [CrossRef]

- Zeng, X.; Zhang, D.; Duan, L.; Wang, L.; Dong, G.; Qiu, Y. Morphology and fluorescence spectra of rubrene single crystals grown by physical vapor transport. Appl. Surf. Sci. 2007, 253, 6047–6051. [Google Scholar] [CrossRef]

- Park, Y.D.; Lim, J.A.; Lee, H.S.; Cho, K. Interface engineering in organic transistors. Mater. Today 2007, 10, 46–54. [Google Scholar] [CrossRef]

- Gogoi, D.; Hussain, A.A.; Biswasi, S.; Pal, A.R. Crystalline rubrene via a novel process and realization of a pyro-phototronic device with a rubrene-based film. J. Mater. Chem. C 2020, 8, 6450–6460. [Google Scholar] [CrossRef]

- Sun, D.; Ehrenfreund, E.; Vardeny, Z.V. The first decade of organic spintronics research. Chem. Commun. 2014, 50, 1781–1793. [Google Scholar] [CrossRef] [PubMed]

- Cavallini, M. Status and perspectives in thin films and patterning of spin crossover compounds. Phys. Chem. Chem. Phys. 2012, 14, 11867–11876. [Google Scholar] [CrossRef] [PubMed]

- Shepherd, H.J.; Molnár, G.; Nicolazzi, W.; Salmon, L.; Bousseksou, A. Spin crossover at the nanometre scale. Eur. J. Inorg. Chem. 2013, 2013, 653–661. [Google Scholar] [CrossRef]

- Kloc, C.; Siegrist, T.; Pflaum, J. Growth of single-crystal organic semiconductors. In Springer Handbook of Crystal Growth; Dhanaraj, G., Byrappa, K., Prasad, V., Dudley, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 845–867. [Google Scholar]

- Park, S.-W.; Choi, J.-M.; Lee, K.H.; Yeom, H.W.; Im, S.; Lee, Y.K. Amorphous-to-Crystalline phase transformation of thin film rubrene. J. Phys. Chem. B 2010, 114, 5661–5665. [Google Scholar] [CrossRef] [PubMed]

- Käfer, D.; Ruppel, L.; Witte, G.; Wöll, C. Role of molecular conformations in rubrene thin film growth. Phys. Rev. Lett. 2005, 95, 166602. [Google Scholar] [CrossRef]

- Shim, J.H.; Raman, K.V.; Park, Y.J.; Santos, T.S.; Miao, G.X.; Satpati, B.; Moodera, J.S. Large spin diffusion length in an amorphous organic semiconductor. Phys. Rev. Lett. 2008, 100, 226603. [Google Scholar] [CrossRef] [PubMed]

- Käfer, D.; Witte, G. Growth of crystalline rubrene films with enhanced stability. Phys. Chem. Chem. Phys. 2005, 7, 2850–2853. [Google Scholar] [CrossRef]

- Lee, H.M.; Moon, H.; Kim, H.-S.; Kim, Y.N.; Choi, S.-M.; Yoo, S.; Cho, S.O. Abrupt heating-induced high-quality crystalline rubrene thin films for organic thin-film transistors. Org. Electron. 2011, 12, 1446–1453. [Google Scholar] [CrossRef]

- Lan, M.; Xiong, Z.-H.; Li, G.-Q.; Shao, T.-N.; Xie, J.-L.; Yang, X.-F.; Wang, J.-Z.; Liu, Y. Strain-driven formation of rubrene crystalline films on Bi(001). Phys. Rev. B 2011, 83, 195322. [Google Scholar] [CrossRef]

- Zaglmayr, H.; Sun, L.D.; Weidlinger, G.; Abd Al-Baqi, S.M.; Sitter, H.; Zeppenfeld, P. Initial stage of crystalline rubrene thin film growth on mica (0 0 1). Synth. Met. 2011, 161, 271–274. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Campione, M. Rubrene heteroepitaxial nanostructures with unique orientation. J. Phys. Chem. C 2008, 112, 16178–16181. [Google Scholar] [CrossRef]

- Campione, M.; Moret, M.; Raimondo, L.; Sassella, A. Kinetic phase selection of rubrene heteroepitaxial domains. J. Phys. Chem. C 2009, 113, 20927–20933. [Google Scholar] [CrossRef]

- Hu, W.S.; Weng, S.Z.; Tao, Y.T.; Liu, H.J.; Lee, H.Y. Oriented growth of rubrene thin films on aligned pentacene buffer layer and its anisotropic thin-film transistor characteristics. Org. Electron. 2008, 9, 385–395. [Google Scholar] [CrossRef]

- Haemori, M.; Yamaguchi, J.; Yaginuma, S.; Itaka, K.; Koinuma, H. Fabrication of highly oriented rubrene thin films by the use of atomically finished substrate and pentacene buffer layer. Jpn. J. Appl. Phys. 2005, 44, 3740–3742. [Google Scholar] [CrossRef]

- Chang, H.; Li, W.; Tian, H.; Geng, Y.; Wang, H.; Yan, D.; Wang, T. High performance of rubrene thin film transistor by weak epitaxy growth method. Org. Electron. 2015, 20, 43–48. [Google Scholar] [CrossRef]

- Hong, C.; Chae, H.B.; Lee, K.H.; Ahn, S.K.; Kim, C.K.; Kim, T.W.; Cho, N.I.; Kim, S.O. The possibility of pulsed laser deposited organic thin films for light-emitting diodes. Thin Solid Films 2002, 409, 37–42. [Google Scholar] [CrossRef]

- Salih, A.J.; Lau, S.P.; Marshall, J.M.; Maud, J.M.; Bowen, W.R.; Hilal, N.; Lovitt, R.W.; Williams, P.M. Improved thin films of pentacene via pulsed laser deposition at elevated substrate temperatures. Appl. Phys. Lett. 1996, 69, 2231–2233. [Google Scholar] [CrossRef]

- Blanchet, G.B.; Fincher, C.R.; Malajovich, I. Laser evaporation and the production of pentacene films. J. Appl. Phys. 2003, 94, 6181–6184. [Google Scholar] [CrossRef]

- Greer, J.A. History and current status of commercial pulsed laser deposition equipment. J. Phys. D: Appl. Phys. 2014, 47, 034005. [Google Scholar] [CrossRef]

- Grochowska, K.; Majumdar, S.; Laukkanen, P.; Majumdar, H.S.; Sawczak, M.; Śliwiński, G. Pulsed laser deposition of organic semiconductor rubrene thin films. Proc. SPIE 2015, 9447, 94470F. [Google Scholar] [CrossRef]

- Seo, S.; Park, B.-N.; Evans, P.G. Ambipolar rubrene thin film transistors. Appl. Phys. Lett. 2006, 88, 232114. [Google Scholar] [CrossRef]

- Piqué, A.; Wu, P.; Ringeisen, B.R.; Bubb, D.M.; Melinger, J.S.; McGill, R.A.; Chrisey, D.B. Processing of functional polymers and organic thin films by the matrix-assisted pulsed laser evaporation (MAPLE) technique. Appl. Surf. Sci. 2002, 186, 408–415. [Google Scholar] [CrossRef]

- Shepard, K.B.; Priestley, R.D. MAPLE deposition of macromolecules. Macromol. Chem. Phys. 2013, 214, 862–872. [Google Scholar] [CrossRef]

- Icriverzi, M.; Rusen, L.; Brajnicov, S.; Bonciu, A.; Dinescu, M.; Cimpean, A.; Evans, R.W.; Dinca, V.; Roseanu, A. Macrophage in vitro Response on Hybrid Coatings Obtained by Matrix Assisted Pulsed Laser Evaporation. Coatings 2019, 9, 236. [Google Scholar] [CrossRef]

- O’Malley, S.M.; Amin, M.; Borchert, J.; Jimenez, R.; Steiner, M.; Fitz-Gerald, J.M.; Bubb, D.M. Formation of rubrene nanocrystals by laser ablation in liquids utilizing MAPLE deposited thin films. Chem. Phys. Lett. 2014, 595–596, 171–174. [Google Scholar] [CrossRef]

- Majewska, N.; Gazda, M.; Jendrzejewski, R.; Majumdar, S.; Sawczak, M.; Śliwiński, G. Organic semiconductor rubrene thin films deposited by pulsed laser evaporation of solidified solutions. Proc. SPIE 2017, 10453, 104532H. [Google Scholar] [CrossRef]

- Park, D.H.; Jo, S.G.; Hong, Y.K.; Cui, C.; Lee, H.; Ahn, D.J.; Kim, J.; Joo, J. Highly bright and sharp light emission of a single nanoparticle of crystalline rubrene. J. Mater. Chem. 2011, 21, 8002–8007. [Google Scholar] [CrossRef]

- Farag, A.A.M.; Yahia, I.S. Structural, absorption and optical dispersion characteristics of rhodamine B thin films prepared by drop casting technique. Opt. Commun. 2010, 283, 4310–4317. [Google Scholar] [CrossRef]

- Chen, L.; Deng, J.-X.; Kong, L.; Cui, M.; Chen, R.-G.; Zhang, Z.-J. Optical properties of rubrene thin film prepared by thermal evaporation. Chin. Phys. B 2015, 24, 047801. [Google Scholar] [CrossRef]

- Petrenko, T.; Krylova, O.; Neese, F.; Sokolowski, M. Optical absorption and emission properties of rubrene: Insight from a combined experimental and theoretical study. New J. Phys. 2009, 11, 015001. [Google Scholar] [CrossRef]

- Mitrofanov, O.; Kloc, C.; Siegrist, T.; Lang, D.V.; So, W.-Y.; Ramirez, A.P. Role of synthesis for oxygen defect incorporation in crystalline rubrene. Appl. Phys. Lett. 2007, 91, 212106. [Google Scholar] [CrossRef]

- Luo, Y.; Brun, M.; Rannou, P.; Grevin, B. Growth of Rubrene thin film, spherulites and nanowires on SiO2. Phys. Status Solidi A 2007, 204, 1851–1855. [Google Scholar] [CrossRef]

- Magill, J.H. Review Spherulites: A personal perspective. J. Mater. Sci. 2001, 36, 3143–3164. [Google Scholar] [CrossRef]

- Ikegami, T.; Ishibashi, S.; Yamagata, Y.; Ebihara, K.; Thareja, R.K.; Narayan, J. Spatial distribution of carbon species in laser ablation of graphite target. J. Vac. Sci. Technol. A 2001, 19, 1304–1307. [Google Scholar] [CrossRef]

- Chung, J.; Hyon, J.; Park, K.-S.; Cho, B.; Baek, J.; Kim, J.; Lee, S.U.; Sung, M.M.; Kang, Y. Controlled growth of rubrene nanowires by eutectic melt crystallization. Sci. Rep. 2016, 6, 23108. [Google Scholar] [CrossRef]

- Fumagalli, E.; Campione, M.; Raimondo, L.; Sassella, A.; Moret, M.; Barba, L.; Arrighetti, G. Grazing-incidence X-ray diffraction study of rubrene epitaxial thin films. J. Synchrotron Radiat. 2012, 19, 682–687. [Google Scholar] [CrossRef] [PubMed]

- Paez, B.A.; Abd-Al-Baqi, S.; Sosa, G.H.; Andreev, A.; Winder, C.; Padinger, F.; Simbrunner, C.; Sitter, H. Crystalline stages of rubrene films probed by raman spectroscopy. In Interface Controlled Organic Thin Films; Rubahn, H.-G., Sitter, H., Horowitz, G., Al-Shamery, K., Eds.; Springer: Berlin/Heidelberg, Germany, 1999; pp. 37–41. [Google Scholar]

- Hochstrasser, R.M.; Ritchie, M. The photoformation and thermal decomposition of rubrene peroxide. Trans. Faraday Soc. 1956, 52, 1363–1373. [Google Scholar] [CrossRef]

- Sinha, S.; Wang, C.-H.; Mukherjee, M.; Mukherjee, T.; Yang, Y.-W. Oxidation of Rubrene Thin Films: An Electronic Structure Study. Langmuir 2014, 30, 15433–15441. [Google Scholar] [CrossRef] [PubMed]

- Mastrogiovanni, D.D.T.; Mayer, J.; Wan, A.S.; Vishnyakov, A.; Neimark, A.V.; Podzorov, V.; Feldman, L.C.; Garfunkel, E. Oxygen incorporation in rubrene single crystals. Sci. Rep. 2014, 4, 4753. [Google Scholar] [CrossRef] [PubMed]

- Mangolini, F.; McClimon, J.B.; Rose, F.; Carpick, R.W. Accounting for Nanometer-Thick Adventitious Carbon Contamination in X-ray Absorption Spectra of Carbon-Based Materials. Anal. Chem. 2014, 86, 12258–12265. [Google Scholar] [CrossRef] [PubMed]

- Saeki, A.; Seki, S.; Takenobu, T.; Iwasa, Y.; Tagawa, S. Mobility and dynamics of charge carriers in rubrene single crystals studied by flash-photolysis microwave conductivity and optical spectroscopy. Adv. Mater. 2008, 20, 920–923. [Google Scholar] [CrossRef]

- Chiu, F.-C. A Review on Conduction Mechanisms in Dielectric Films. Adv. Mater. Sci. Eng. 2014, 2014, 578168. [Google Scholar] [CrossRef]

- Hathwar, V.R.; Sist, M.; Jørgensen, M.R.V.; Mamakhel, A.H.; Wang, X.; Hoffmann, C.M.; Sugimoto, K.; Overgaard, J.; Iversen, B.B. Quantitative analysis of intermolecular interactions in orthorhombic rubrene. IUCrJ 2015, 2, 563–574. [Google Scholar] [CrossRef]

- Sim, K.; Na, H.; Park, J.; Lee, J.; Do, J.; Pyo, S. High-performance organic transistors based on solution-processed rubrene crystals directly grown on a polymeric dielectric. Org. Electron. 2018, 56, 76–81. [Google Scholar] [CrossRef]

- Park, B.; In, I.; Gopalan, P.; Evans, P.G.; King, S.; Lyman, P.F. Enhanced hole mobility in ambipolar rubrene thin film transistors on polystyrene. Appl. Phys. Lett. 2008, 92, 133302. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jendrzejewski, R.; Majewska, N.; Majumdar, S.; Sawczak, M.; Ryl, J.; Śliwiński, G. Rubrene Thin Films with Viably Enhanced Charge Transport Fabricated by Cryo-Matrix-Assisted Laser Evaporation. Materials 2021, 14, 4413. https://doi.org/10.3390/ma14164413

Jendrzejewski R, Majewska N, Majumdar S, Sawczak M, Ryl J, Śliwiński G. Rubrene Thin Films with Viably Enhanced Charge Transport Fabricated by Cryo-Matrix-Assisted Laser Evaporation. Materials. 2021; 14(16):4413. https://doi.org/10.3390/ma14164413

Chicago/Turabian StyleJendrzejewski, Rafał, Natalia Majewska, Sayani Majumdar, Mirosław Sawczak, Jacek Ryl, and Gerard Śliwiński. 2021. "Rubrene Thin Films with Viably Enhanced Charge Transport Fabricated by Cryo-Matrix-Assisted Laser Evaporation" Materials 14, no. 16: 4413. https://doi.org/10.3390/ma14164413

APA StyleJendrzejewski, R., Majewska, N., Majumdar, S., Sawczak, M., Ryl, J., & Śliwiński, G. (2021). Rubrene Thin Films with Viably Enhanced Charge Transport Fabricated by Cryo-Matrix-Assisted Laser Evaporation. Materials, 14(16), 4413. https://doi.org/10.3390/ma14164413