A Literature Review of Concrete Ability to Sustain Strength after Fire Exposure Based on the Heat Accumulation Factor

Abstract

1. Introduction

- -

- At 100 °C, bound water is being evaporated;

- -

- At 180 °C, hydrate calcium silicate is beginning to dehydrate;

- -

- At 500 °C, the decomposition of calcium hydroxide is observed;

- -

- At 700 °C, the decomposition of calcium silicate hydrate occurs.

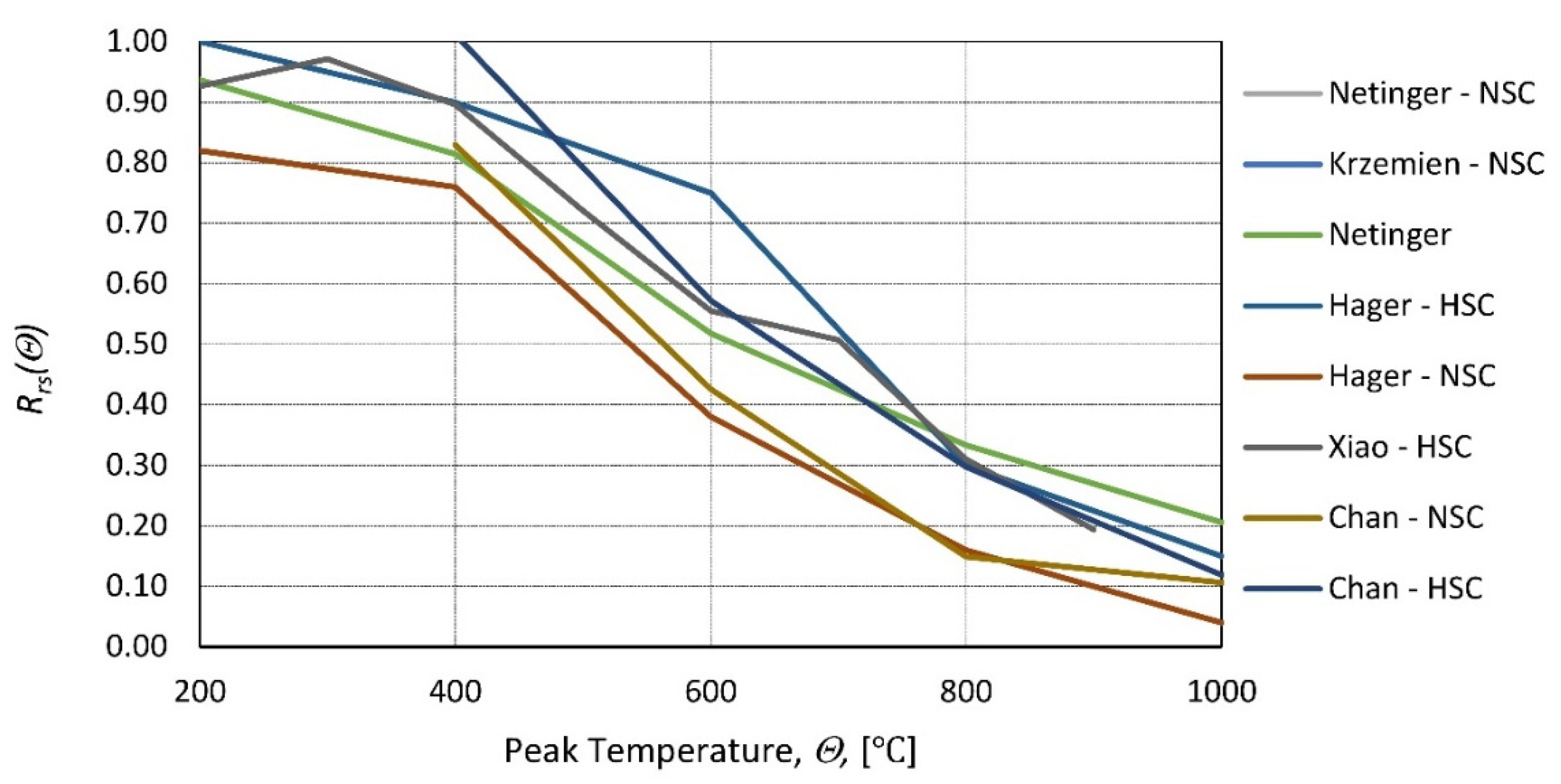

2. Peak Temperature

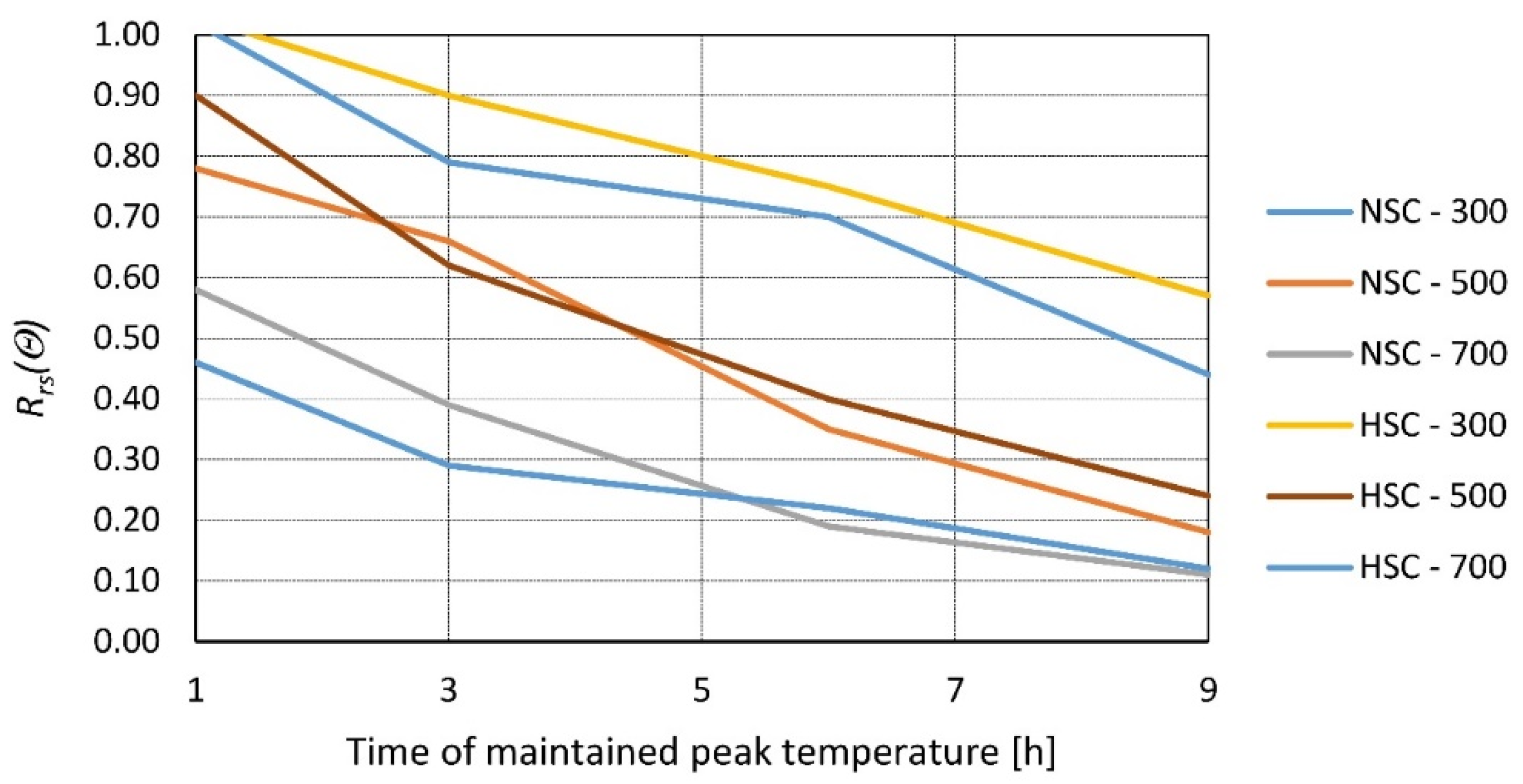

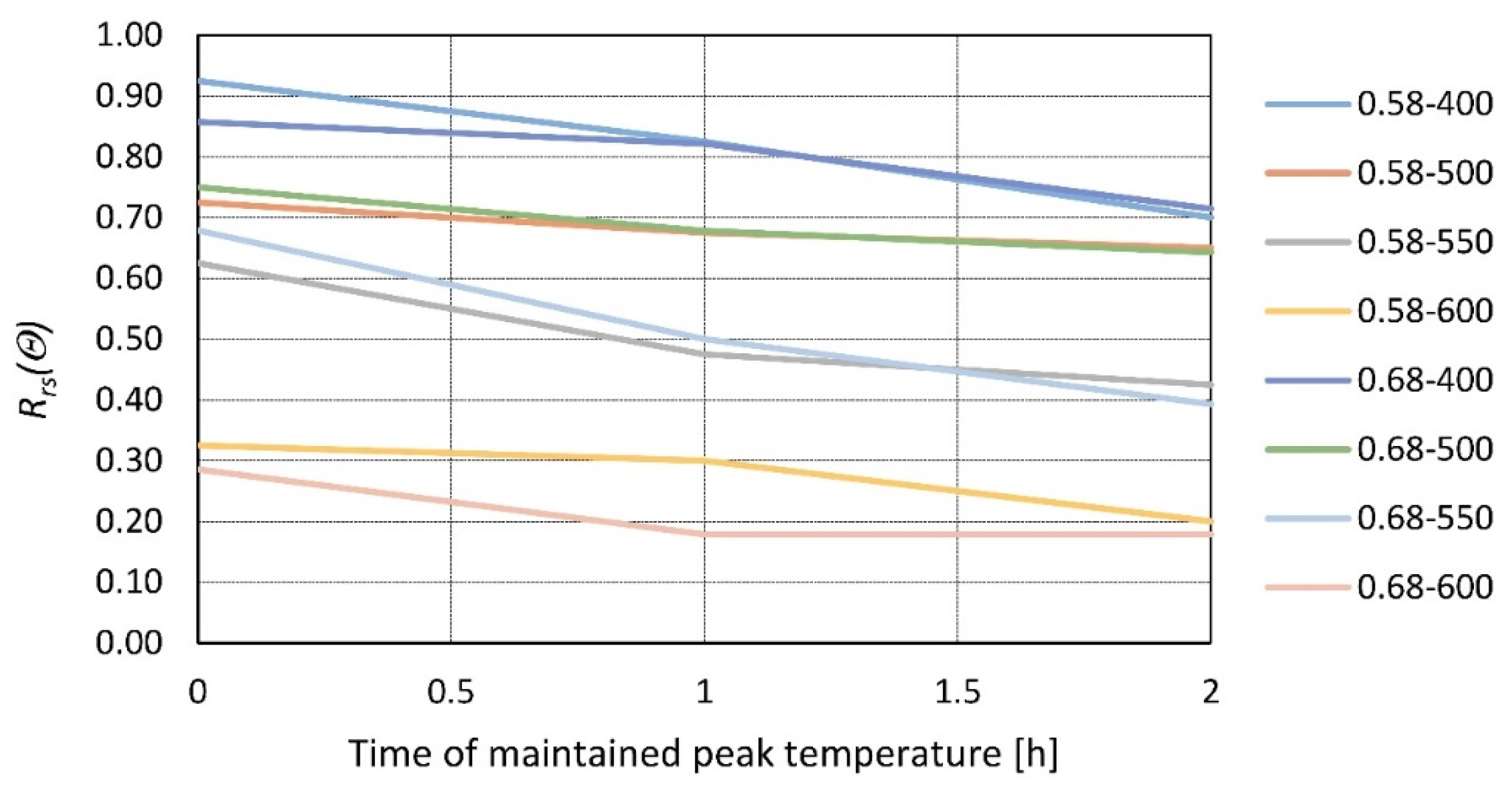

3. Heating Time

- -

- Normal-strength concrete (NSC) with a w/c ratio of 0.5;

- -

- High-strength concrete (HSC) with a w/c ratio of 0.37.

4. Heating Rate

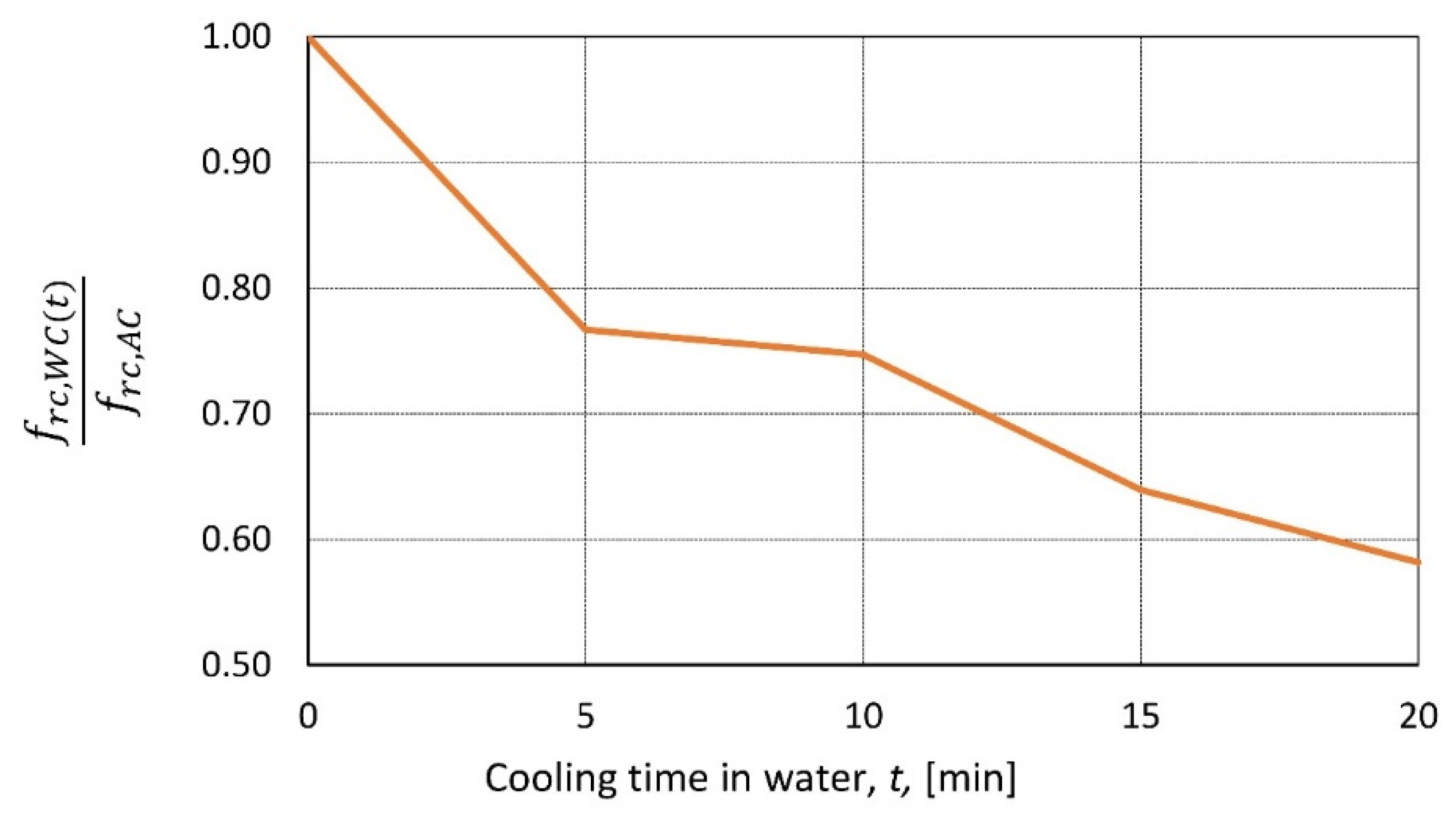

5. Cooling Regime

- -

- High-temperature environment cooling—concrete and environment maintain a high temperature for a long time, and slow temperature lowering from peak value to ambient is performed. This type of cooling corresponds to what happens in the inner parts of the fire-affected elements. The relatively high thermal capacity of concrete and low thermal conductivity cause temperature changes inside elements to be slow, both during heating up and cooling down.

- -

- Cooling at the ambient temperature environment—hot concrete is kept at room temperature for cooling. This can be equated to the occurrence in the outer parts of fire-affected elements.

- -

- Water cooling—hot concrete is treated with cold water and cooled down. This type can be compared with the outer parts of fire-affected elements covered by water used to extinguish the fire.

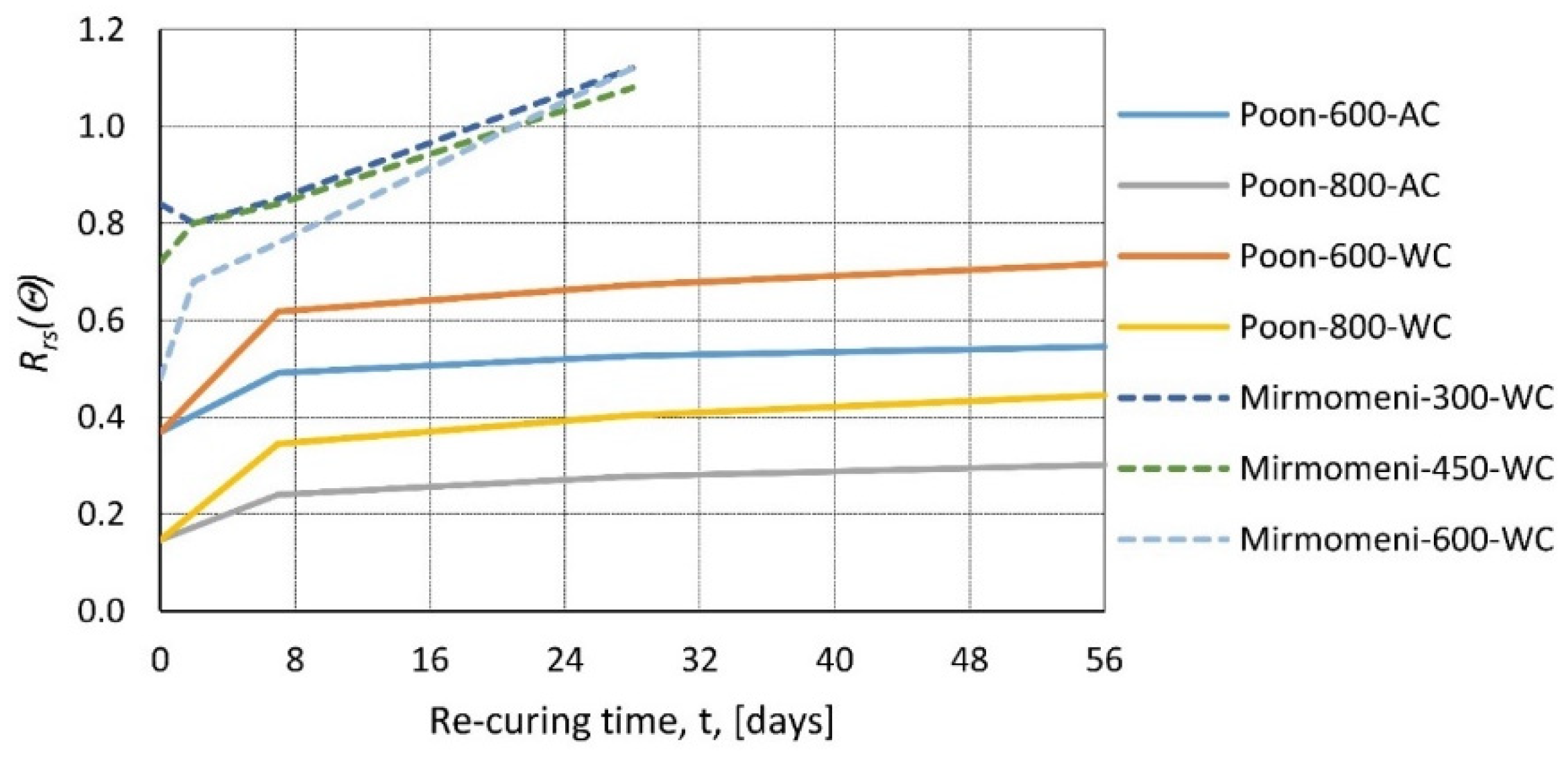

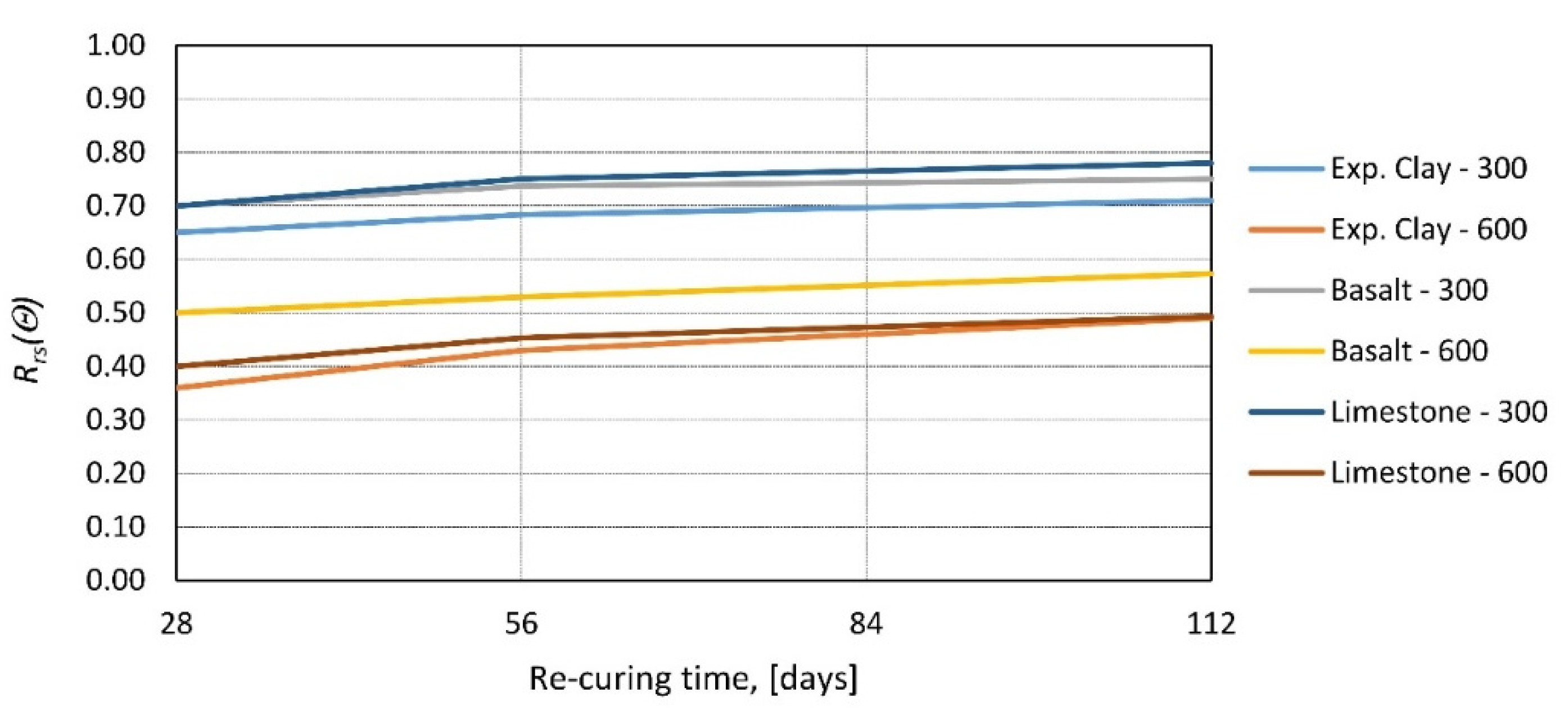

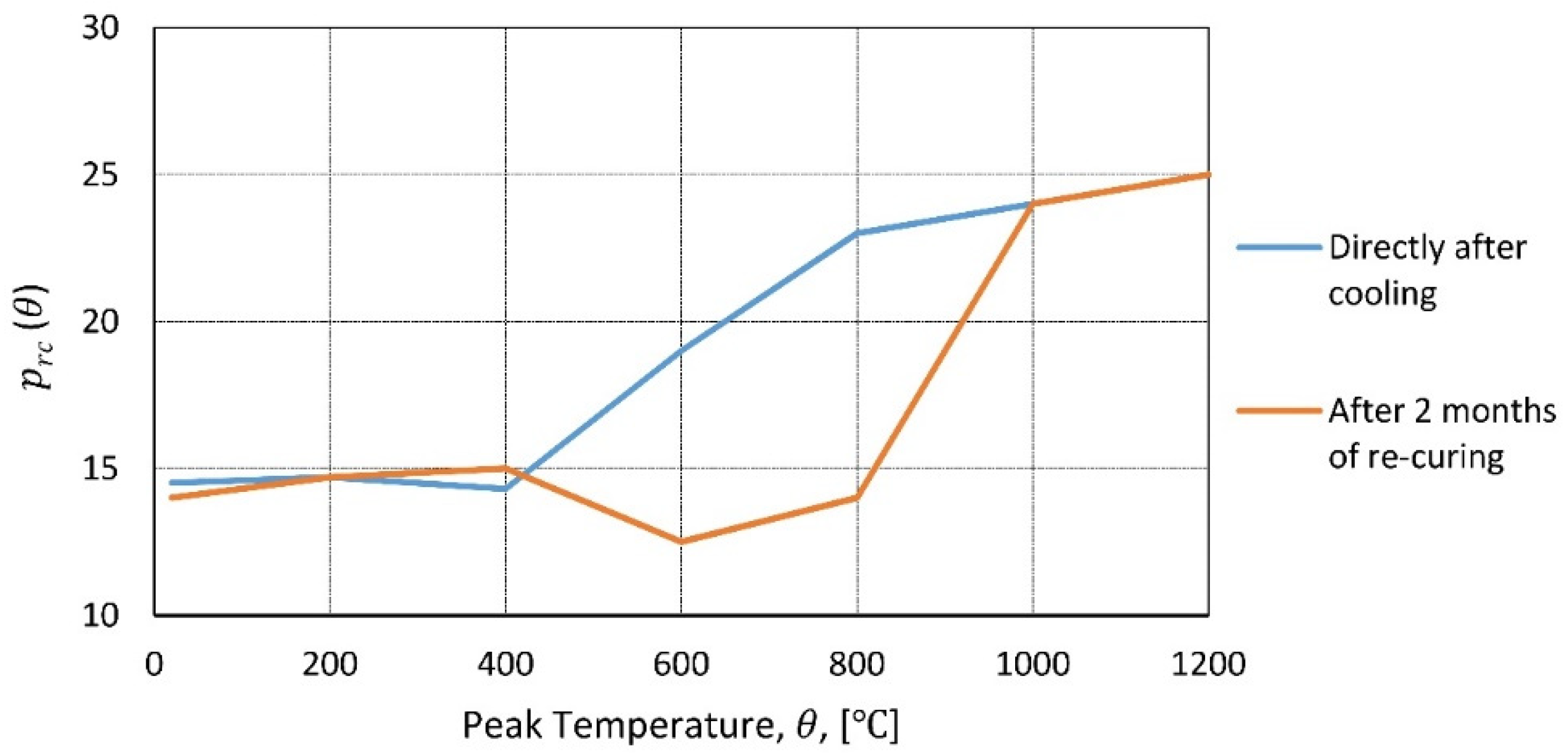

6. Post-Fire Re-Curing Effect on Residual Strength

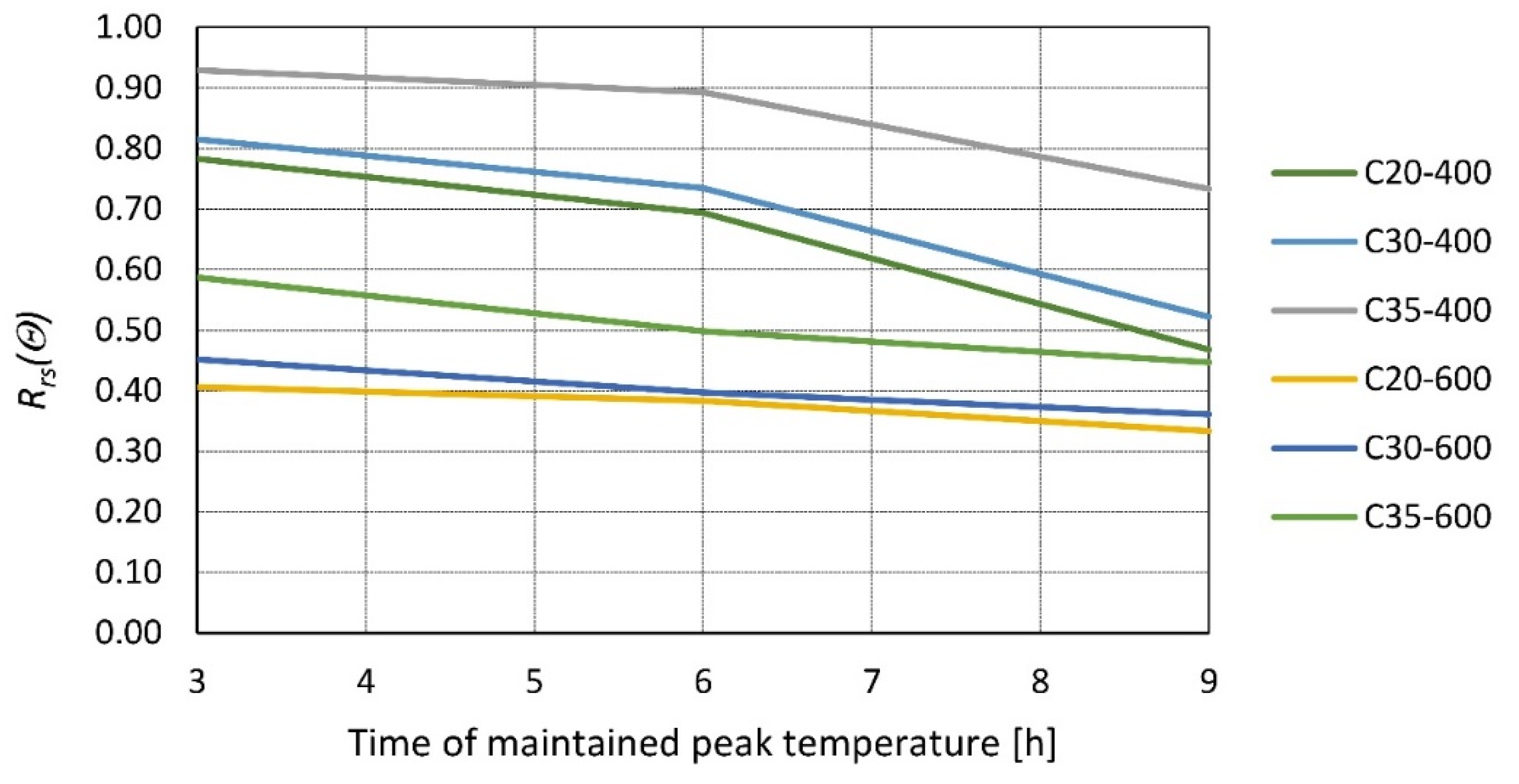

7. Concrete Composition

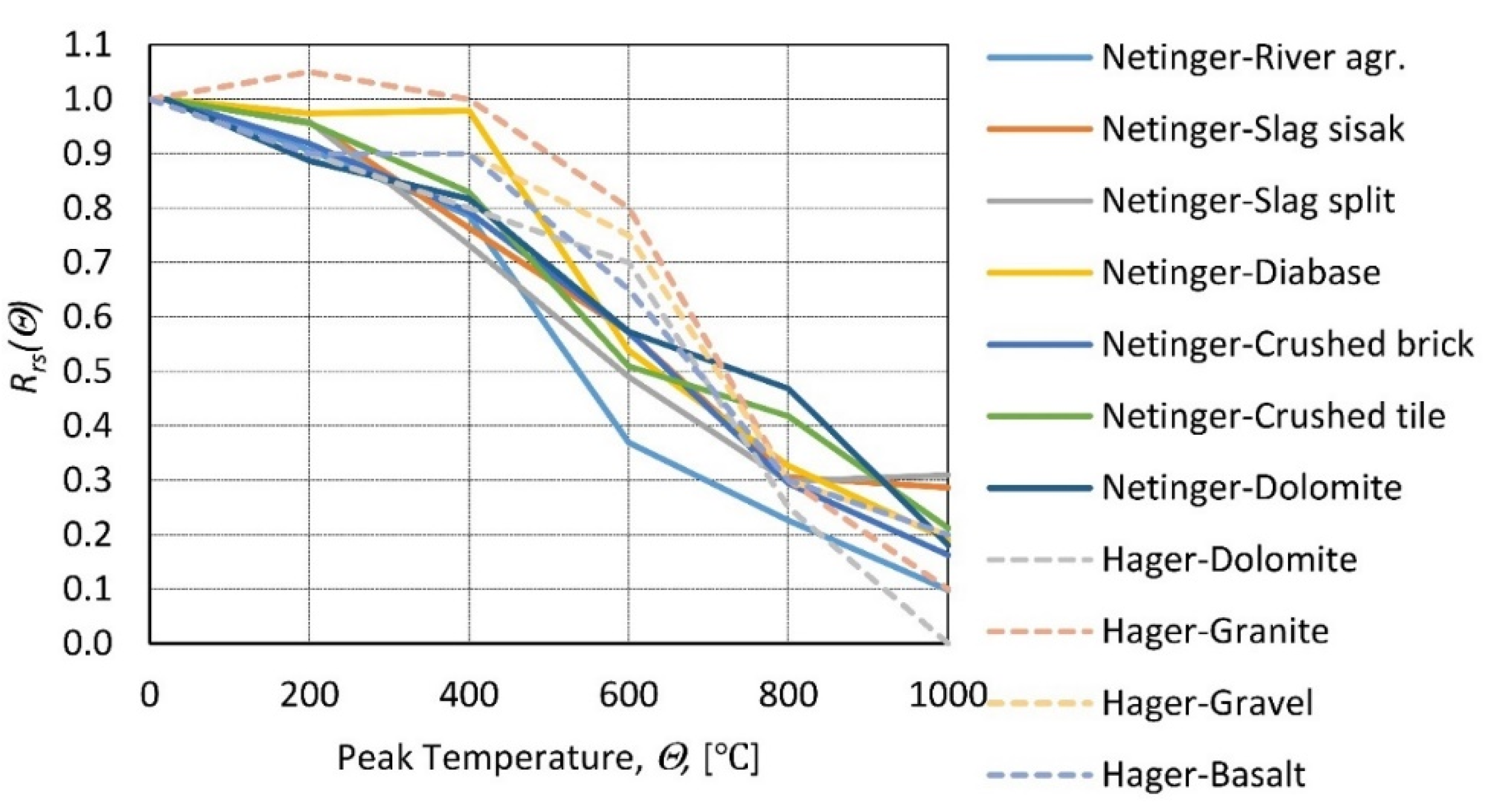

7.1. Type of Aggregate

7.2. Cement Dosage and Type

7.3. Additives and Fibers

8. Porosity

9. Age of Concrete at Exposure

10. Load Level at Exposure

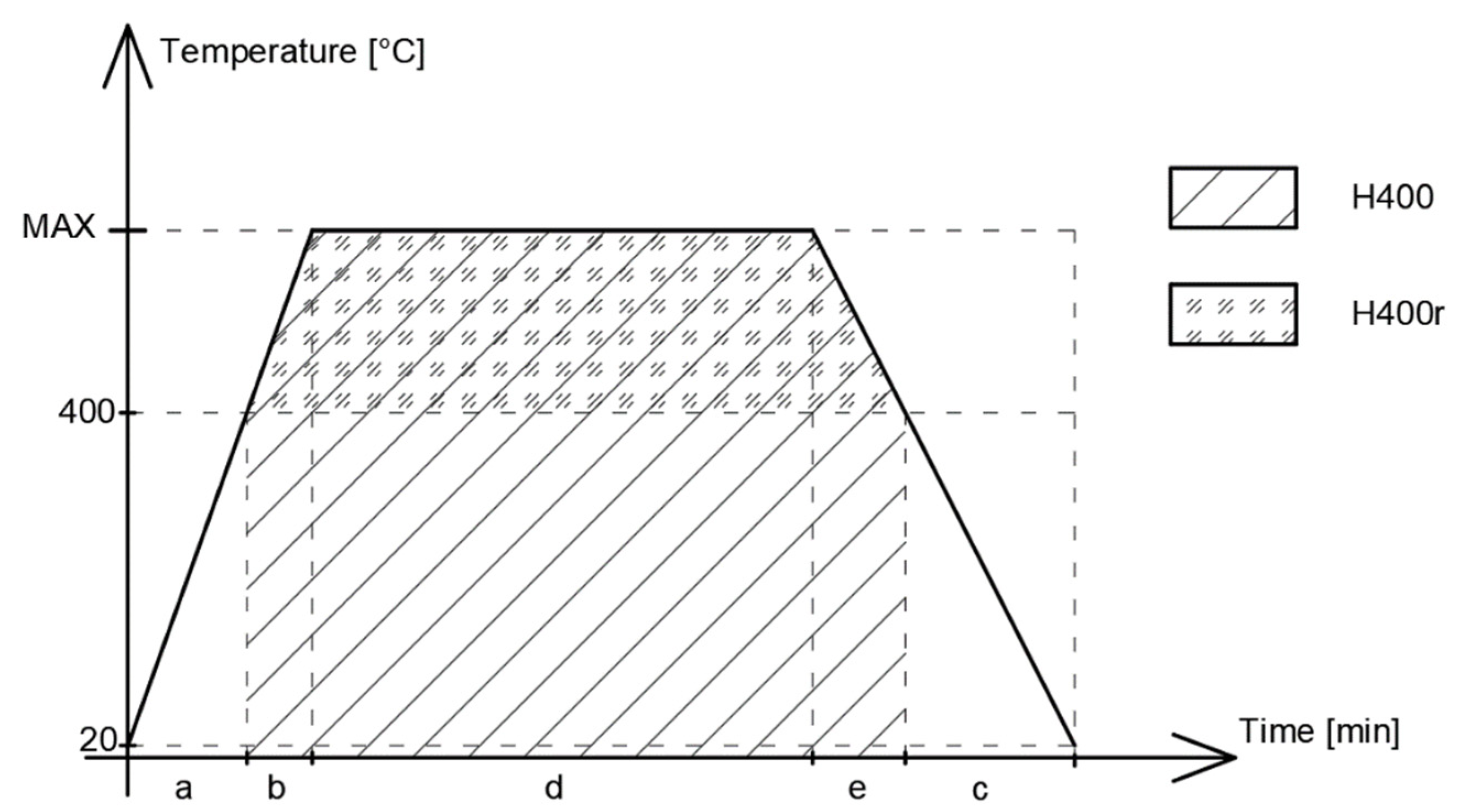

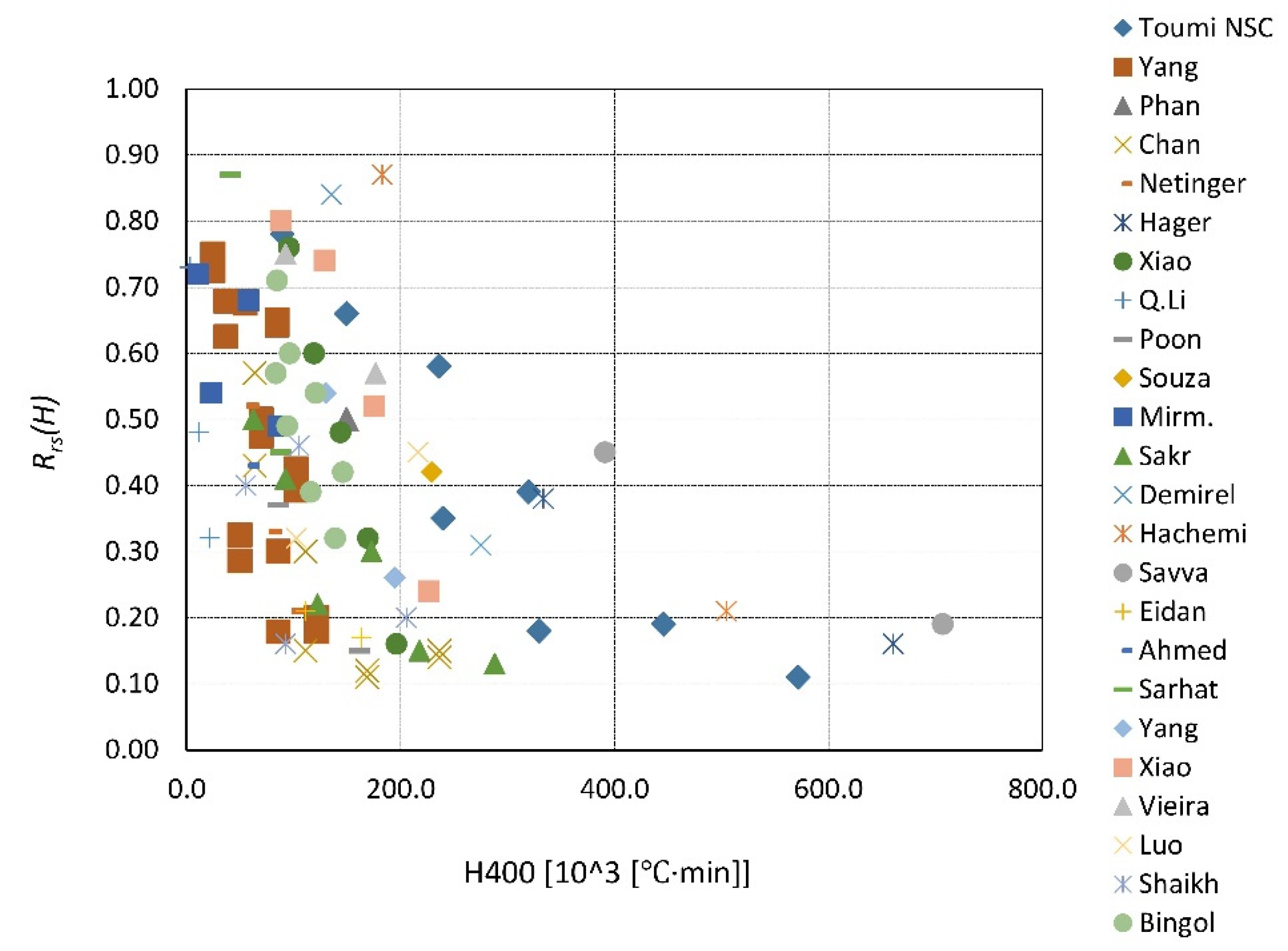

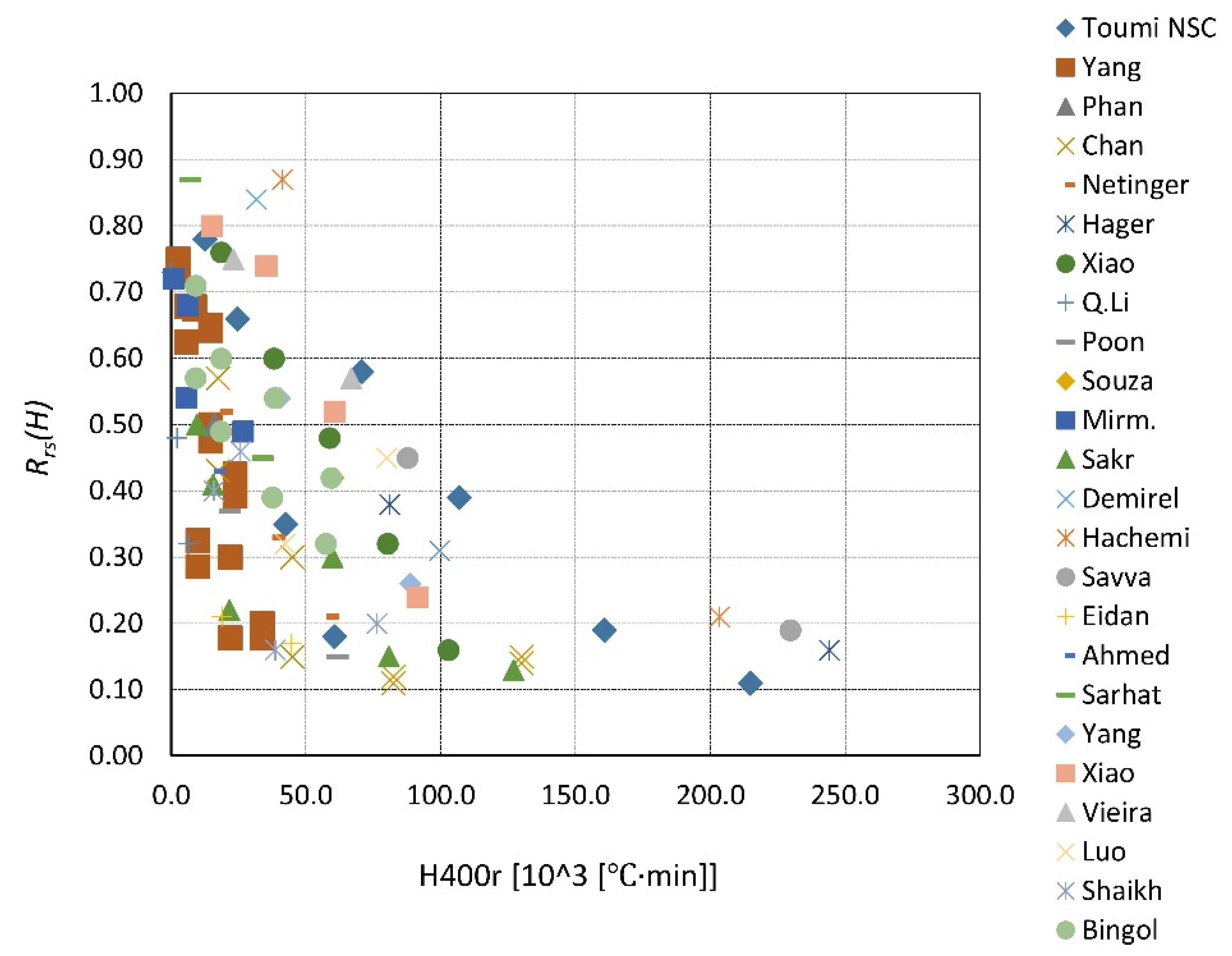

11. Heat Accumulation Factor

12. Discussion

13. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviation

| Upper case letters | |

| C-S-H gel | calcium-silicate-hydrate gel |

| FGP | finely ground pumice |

| GGBFS | ground granulated blast furnace slag |

| HSC | high strength concrete |

| ME | natural pozzolana of volcanic origin, Milos Earth |

| MFA | Megalopolis fly ash |

| MIT | mercury intrusion porosimetry test |

| NSC | normal strength concrete |

| OPC | ordinary Portland cement |

| PFA | Ptolemaida fly ash |

| PP fibers | polypropylene fibers |

| RCA | recycled concrete aggregate |

| RCCA | recycled ceramic coarse aggregate |

| SF | silica fume |

| Lower case letters | |

| residual strength of concrete after exposure to elevated temperature () then cooled down and tested in temperature () | |

| strength of unexposed concrete tested in temperature () | |

| residual strength of concrete after exposure to elevated temperature then cooled down to ambient temperature in air and tested | |

| residual strength of concrete after exposure to elevated temperature then cooled down in the water to ambient temperature and tested | |

| residual strength of concrete after exposure to elevated temperature then cooled down in the water for time (t), then cooled down to ambient temperature in air and tested | |

| residual strength of concrete after exposure to elevated temperature then cooled down in closed furnace to ambient temperature and tested | |

| porosity of unexposed concrete | |

| porosity of concrete after exposure to elevated temperature () then cooled down and tested at a temperature of 20 °C after (t) days of re-curing | |

| relative porosity of concrete tested in 20 °C | |

| w/c | water to cement ratio |

| Subscripts | |

| AC | value pertaining to air re-curing |

| c | value pertaining to unexposed concrete |

| FC | value pertaining to cooling in closed furnance |

| rc | residual value |

| Tt | temperature of sample in test |

| WC | value pertaining to water re-curing |

References

- Kim, G.Y.; Kim, Y.S.; Lee, T.G. Mechanical properties of high-strength concrete subjected to high temperature by stressed test. Trans. Nonferrous Met. Soc. China 2009, 19, s128–s133. [Google Scholar] [CrossRef]

- EN 1992-1-2 Eurocode 2: Design of Concrete Structures–Part. 1–2: General Rules–Structural Fire Design; Comité Européen de Normalisation. Rules-Structural Fire Design de Normalisation: Brussels, Belgium, 2004.

- RILEM Technical Committee 200-HTC. Recommendation of RILEM TC 200-HTC: Mechanical concrete properties at high temperatures—modelling and applications. Mater. Struct. 2007, 40, 855–864. [Google Scholar] [CrossRef]

- ASTM Standard E119-20 Standard Test. Methods for Fire Tests of Building Construction and Materials; ASTM International: West Conshohocken, PA, USA, 2020.

- Chang, Y.F.; Chen, Y.H.; Sheu, M.S.; Yao, G.C. Residual stress-strain relationship for concrete after exposure to high temperatures. Cem. Concr. Res. 2006, 36, 1999–2005. [Google Scholar] [CrossRef]

- Nassif, A. Postfire Full Stress–Strain Response of Fire-Damaged Concrete. Fire Mater. 2006, 30, 323–332. [Google Scholar] [CrossRef]

- Hager, I.; Krzemień, K. An Overview of Concrete Modulus of Elasticity Evolution with Temperature and Comments to European Code Provisions. In Proceedings of the IFireSS—International Fire Safety Symposium, Coimbra, Portugal, 20–23 April 2015. [Google Scholar]

- Felicetti, R.; Gambarova, P.G.; Meda, A. Residual behavior of steel rebars and R/C sections after a fire. Constr. Build. Mater. 2009, 23, 3546–3555. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Raut, N.K.; Mao, X.Y.; Khaliq, W. Simplified approach for evaluating residual strength of fire-exposed reinforced concrete columns. Mater. Struct. Constr. 2013, 46, 2059–2075. [Google Scholar] [CrossRef]

- Wróblewski, R.; Gierczak, J.; Smardz, P.; Kmita, A. Fire and collapse modelling of a precast concrete hall. Struct. Infrastruct. Eng. 2016, 12, 714–729. [Google Scholar] [CrossRef]

- Mróz, K.; Hager, I. Non-Destructive Assessment of Residual Strength of Thermally Damaged Concrete Made with Different Aggregate Types. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 32034. [Google Scholar] [CrossRef]

- Hager, I.; Carré, H.; Krzemie, K. Damage Assessment of Concrete Subjected To High Temperature By Means of the Ultrasonic Pulse Velocity–Upv Method. Stud. Res. 2013, 32, 197–211. [Google Scholar]

- Hager, I. Methods for assessing the state of concrete in fire damaged structures | Metody oceny stanu betonu w konstrukcji po pożarze. Cem. Wapno Bet. 2009, 29, 167–178. [Google Scholar]

- Wróblewski, R.; Stawiski, B. Ultrasonic Assessment of the Concrete Residual Strength after a Real Fire Exposure. Buildings 2020, 10, 154. [Google Scholar] [CrossRef]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Luccioni, B.M.; Figueroa, M.I.; Danesi, R.F. Thermo-mechanic model for concrete exposed to elevated temperatures. Eng. Struct. 2003, 25, 729–742. [Google Scholar] [CrossRef]

- Türkmen, İ.; Fındık, S.B. Several properties of mineral admixtured lightweight mortars at elevated temperatures. Fire Mater. 2013, 37, 337–349. [Google Scholar] [CrossRef]

- Kodur, V. Properties of concrete at elevated temperatures. ISRN Civ. Eng. 2014, 2014, 468510. [Google Scholar] [CrossRef]

- Sarshar, R. Effect of Elevated Temperatures on the Strength of Different Cement Pastes and Concretes. Ph.D. Thesis, University of London, London, UK, 1989. [Google Scholar]

- Biolzi, L.; Cattaneo, S.; Rosati, G. Evaluating residual properties of thermally damaged concrete. Cem. Concr. Compos. 2008, 30, 907–916. [Google Scholar] [CrossRef]

- Arioz, O. Retained properties of concrete exposed to high temperatures: Size effect. Fire Mater. 2009, 33, 211–222. [Google Scholar] [CrossRef]

- Xiao, J.; Li, Z.; Xie, Q.; Shen, L. Effect of strain rate on compressive behaviour of high-strength concrete after exposure to elevated temperatures. Fire Saf. J. 2016, 83, 25–37. [Google Scholar] [CrossRef]

- Toumi, B.; Resheidat, M.; Guemmadi, Z.; Chabil, H. Coupled effect of high temperature and heating time on the residual strength of normal and high-strength concretes. Jordan J. Civ. Eng. 2009, 3, 322–330. [Google Scholar]

- Yang, H.; Lin, Y.; Hsiao, C.; Liu, J.Y. Evaluating residual compressive strength of concrete at elevated temperatures using ultrasonic pulse velocity. Fire Saf. J. 2009, 44, 121–130. [Google Scholar] [CrossRef]

- Phan, L.T.; Lawson, J.R.; Davis, F.L. Effects of elevated temperature exposure on heating characteristics, spalling, and residual properties of high performance concrete. Mater. Struct. Constr. 2001, 34, 83–91. [Google Scholar] [CrossRef]

- Netinger, I.; Kesegic, I.; Guljas, I. The effect of high temperatures on the mechanical properties of concrete made with different types of aggregates. Fire Saf. J. 2011, 46, 425–430. [Google Scholar] [CrossRef]

- Hager, I.; Tracz, T.; Śliwiński, J.; Krzemień, K. The influence of aggregate type on the physical and mechanical properties of high-performance concrete subjected to high temperature. Fire Mater. 2016, 40, 668–682. [Google Scholar] [CrossRef]

- Krzemień, K.; Hager, I. Post-fire assessment of mechanical properties of concrete with the use of the impact-echo method. Constr. Build. Mater. 2015, 96, 155–163. [Google Scholar] [CrossRef]

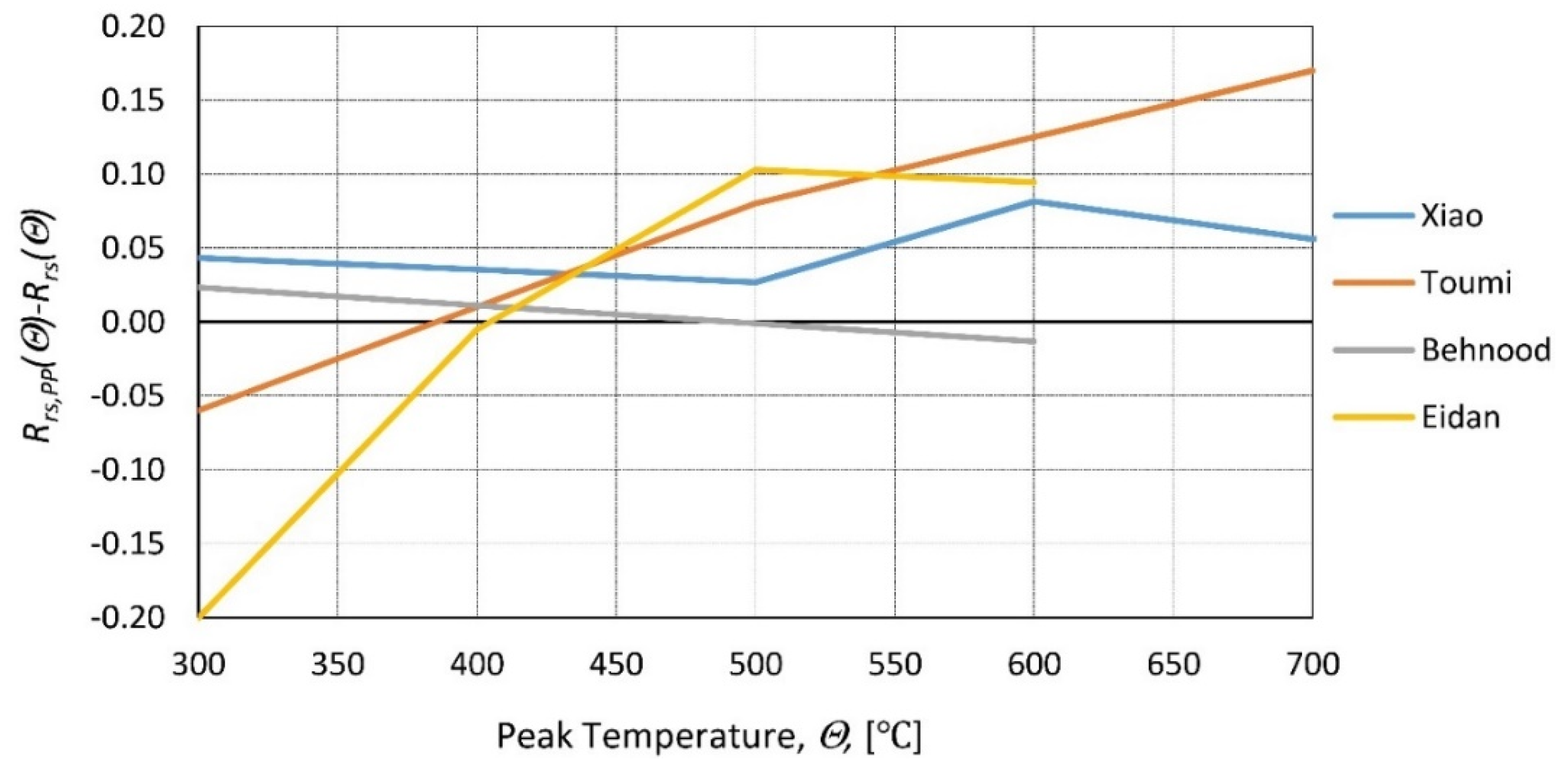

- Xiao, J.; Falkner, H. On residual strength of high-performance concrete with and without polypropylene fibres at elevated temperatures. Fire Saf. J. 2006, 41, 115–121. [Google Scholar] [CrossRef]

- Chan, Y.N.; Peng, G.F.; Anson, M. Residual strength and pore structure of high-strength concrete and normal strength concrete after exposure to high temperatures. Cem. Concr. Compos. 1999, 21, 23–27. [Google Scholar] [CrossRef]

- Tolentino, E.; Lameiras, F.S.; Gomes, A.M.; da Silva, C.A.R.; Vasconcelos, W.L. Effects of High Temperature on the Residual Performance of Portland Cement Concretes. Mater. Res. 2002, 5, 301–307. [Google Scholar] [CrossRef]

- Ashkezari, G.D.; Razmara, M. Thermal and mechanical evaluation of ultra-high performance fiber-reinforced concrete and conventional concrete subjected to high temperatures. J. Build. Eng. 2020, 32, 101621. [Google Scholar] [CrossRef]

- Xiao, J.; Xie, M.; Zhang, C. Residual compressive behaviour of pre-heated high-performance concrete with blast-furnace-slag. Fire Saf. J. 2006, 41, 91–98. [Google Scholar] [CrossRef]

- Zhai, Y.; Deng, Z.; Li, N.; Xu, R. Study on compressive mechanical capabilities of concrete after high temperature exposure and thermo-damage constitutive model. Constr. Build. Mater. 2014, 68, 777–782. [Google Scholar] [CrossRef]

- Comité Européen de Normalisation. EN 1991-1-2 Eurocode 1. Actions on Structures. General Actions. Actions on Structures Exposed to Fire; Comité Européen de Normalisation: Brussels, Belgium, 2002. [Google Scholar]

- Pertiwi, N.; Ahmad, I.A.; Taufieq, N.A.S. Analysis-Residual Strength of Post Fire Concrete. Asian J. Appl. Sci. 2017, 5, 602–607. [Google Scholar]

- Wu, Y.; Wu, B. Residual compressive strength and freeze-thaw resistance of ordinary concrete after high temperature. Constr. Build. Mater. 2014, 54, 596–604. [Google Scholar] [CrossRef]

- Mohamedbhai, G.T.G. Effect of exposure time and rates of heating and cooling on residual strength of heated concrete. Mag. Concr. Res. 1986, 38, 151–158. [Google Scholar] [CrossRef]

- Annerel, E.; Taerwe, L.R. Approaches for the assessment of the residual strength of concrete exposed to fire. In Concrete Repair, Rehabilitation and Retrofitting II; CRC Press: Boca Raton, FL, USA, 2007; p. 12. [Google Scholar]

- Kowalski, R. The effects of the cooling rate on the residual properties of heated-up concrete. Struct. Concr. 2007, 8, 11–15. [Google Scholar] [CrossRef]

- Peng, G.F.; Bian, S.H.; Guo, Z.Q.; Zhao, J.; Peng, X.L.; Jiang, Y.C. Effect of thermal shock due to rapid cooling on residual mechanical properties of fiber concrete exposed to high temperatures. Constr. Build. Mater. 2008, 22, 948–955. [Google Scholar] [CrossRef]

- Yang, H.; Zhao, H.; Liu, F. Residual cube strength of coarse RCA concrete after exposure to elevated temperatures. Fire Mater. 2018, 42, 424–435. [Google Scholar] [CrossRef]

- Husem, M. The effects of high temperature on compressive and flexural strengths of ordinary and high-performance concrete. Fire Saf. J. 2006, 41, 155–163. [Google Scholar] [CrossRef]

- Mendes, A.; Sanjayan, J.G.; Collins, F. Effects of slag and cooling method on the progressive deterioration of concrete after exposure to elevated temperatures as in a fire event. Mater. Struct. Constr. 2011, 44, 709–718. [Google Scholar] [CrossRef]

- Bingöl, A.F.; Gül, R. Effect of elevated temperatures and cooling regimes on normal strength concrete. Fire Mater. 2009, 33, 79–88. [Google Scholar] [CrossRef]

- Li, L.; Jia, P.; Dong, J.; Shi, L.; Zhang, G.; Wang, Q. Effects of cement dosage and cooling regimes on the compressive strength of concrete after post-fire-curing from 800 °C. Constr. Build. Mater. 2017, 142, 208–220. [Google Scholar] [CrossRef]

- Luo, X.; Sun, W.; Chan, S.Y.N. Effect of heating and cooling regimes on residual strength and microstructure of normal strength and high-performance concrete. Cem. Concr. Res. 2000, 30, 379–383. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Vimonsatit, V. Effect of cooling methods on residual compressive strength and cracking behavior of fly ash concretes exposed at elevated temperatures. Fire Mater. 2016, 40, 335–350. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Xu, L.; Zhao, H. Effect of elevated temperatures and cooling methods on strength of concrete made with coarse and fine recycled concrete aggregates. Constr. Build. Mater. 2019, 210, 540–547. [Google Scholar] [CrossRef]

- Li, Q.; Yuan, G.; Shu, Q. Effects of heating/cooling on recovery of strength and carbonation resistance of fire-damaged concrete. Mag. Concr. Res. 2014, 66, 925–936. [Google Scholar] [CrossRef]

- Karakoç, M.B. Effect of cooling regimes on compressive strength of concrete with lightweight aggregate exposed to high temperature. Constr. Build. Mater. 2013, 41, 21–25. [Google Scholar] [CrossRef]

- Yu, J.; Weng, W.; Yu, K. Effect of different cooling regimes on the mechanical properties of cementitious composites subjected to high temperatures. Sci. World J. 2014, 2014, 1–7. [Google Scholar] [CrossRef]

- Tanaçan, L.; Ersoy, H.Y.; Arpacioǧlu, Ü. Effect of high temperature and cooling conditions on aerated concrete properties. Constr. Build. Mater. 2009, 23, 1240–1248. [Google Scholar] [CrossRef]

- Zhai, Y.; Li, Y.; Li, Y.; Wang, S.; Liu, Y.; Song, K.I. Impact of high-temperature-water cooling damage on the mechanical properties of concrete. Constr. Build. Mater. 2019, 215, 233–243. [Google Scholar] [CrossRef]

- Awal, A.S.M.A.; Shehu, I.A.; Ismail, M. Effect of cooling regime on the residual performance of high-volume palm oil fuel ash concrete exposed to high temperatures. Constr. Build. Mater. 2015, 98, 875–883. [Google Scholar] [CrossRef]

- Xuan, D.X.; Shui, Z.H. Rehydration activity of hydrated cement paste exposed to high temperature. Fire Mater. 2011, 35, 481–490. [Google Scholar] [CrossRef]

- Akca, A.H.; Özyurt, N. Effects of re-curing on microstructure of concrete after high temperature exposure. Constr. Build. Mater. 2018, 168, 431–441. [Google Scholar] [CrossRef]

- Li, L.; Shi, L.; Wang, Q.; Liu, Y.; Dong, J.; Zhang, H.; Zhang, G. A review on the recovery of fire-damaged concrete with post-fire-curing. Constr. Build. Mater. 2020, 237, 117564. [Google Scholar] [CrossRef]

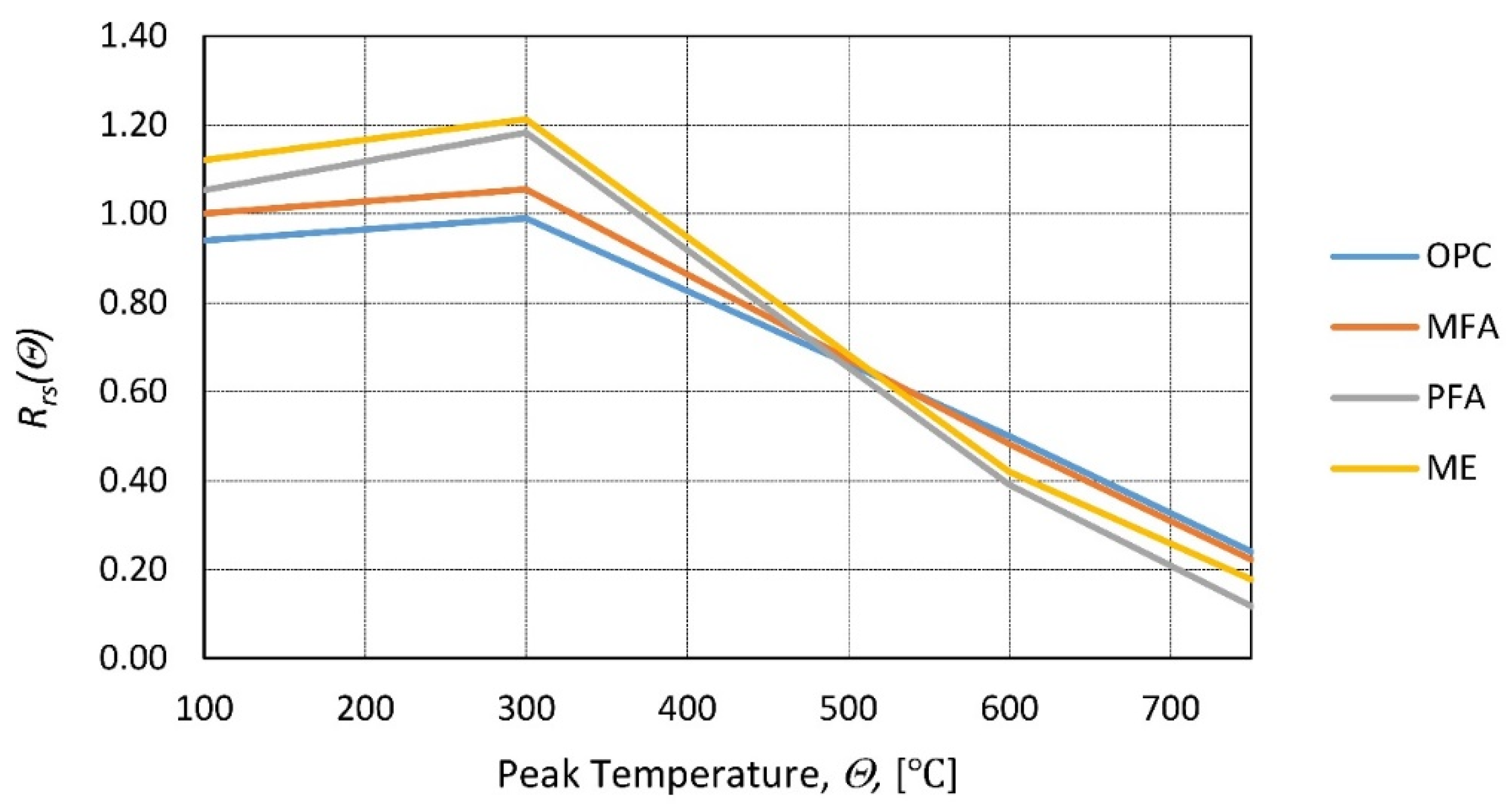

- Papayianni, J.; Valiasis, T. Residual mechanical properties of heated concrete incorporating different pozzolanic materials. Mater. Struct. 1991, 24, 115–121. [Google Scholar] [CrossRef]

- Poon, C.S.; Azhar, S.; Anson, M.; Wong, Y.L. Strength and durability recovery of fire-damaged concrete after post-fire-curing. Cem. Concr. Res. 2001, 31, 1307–1318. [Google Scholar] [CrossRef]

- de Souza, A.A.A.; Moreno, A.L., Jr. Assessment of the influence of the type of aggregates and rehydration on concrete submitted to high temperatures. Rev. IBRACON Estrut. Mater. 2010, 3, 477–493. [Google Scholar] [CrossRef]

- Lin, Y.; Hsiao, C.; Yang, H.; Lin, Y.F. The effect of post-fire-curing on strengthvelocity relationship for nondestructive assessment of fire-damaged concrete strength. Fire Saf. J. 2011, 46, 178–185. [Google Scholar] [CrossRef]

- Mirmomeni, M.; Heidarpour, A.; Schlangen, E.; Smith, S. Effect of Post-Fire Curing on the Residual Mechanical Properties of Fire-Damaged Self-Compacting Concrete. In Proceedings of the 9th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Berkeley, CA, USA, 29 May–1 June 2016. [Google Scholar] [CrossRef]

- Horiguchi, T.; Suhaendi, S.L. Recovery behavior of hybrid fiber reinforced high strength concrete after fire exposure. J. Struct. Fire Eng. 2010, 1, 219–229. [Google Scholar] [CrossRef]

- Park, S.J.; Yim, H.J.; Kwak, H.G. Effects of post-fire curing conditions on the restoration of material properties of fire-damaged concrete. Constr. Build. Mater. 2015, 99, 90–98. [Google Scholar] [CrossRef]

- Eden, M.A. Fire damaged concrete—The potential for on-going deterioration post-fire in concrete heated to temperatures of less than 300 °C. In Concrete Solutions 2011, 1st ed.; Grantham, M., Mechtcherine, V., Schneck, U., Eds.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar] [CrossRef]

- Cree, D.; Green, M.; Noumowé, A. Residual strength of concrete containing recycled materials after exposure to fire: A review. Constr. Build. Mater. 2013, 45, 208–223. [Google Scholar] [CrossRef]

- Razafinjato, R.N.; Beaucour, A.L.; Hebert, R.L.; Ledesert, B.; Bodet, R.; Noumowe, A. High temperature behaviour of a wide petrographic range of siliceous and calcareous aggregates for concretes. Constr. Build. Mater. 2016, 123, 261–273. [Google Scholar] [CrossRef]

- Savva, A.; Manita, P.; Sideris, K.K. Influence of elevated temperatures on the mechanical properties of blended cement concretes prepared with limestone and siliceous aggregates. Cem. Concr. Compos. 2005, 27, 239–248. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Waris, M.B.; Al-Saidy, A.H. Effect of aggregate and water to cement ratio on concrete properties at elevated temperature. Fire Mater. 2016, 40, 913–925. [Google Scholar] [CrossRef]

- Monte, F.L.; Gambarova, P.G. Thermo-mechanical behavior of baritic concrete exposed to high temperature. Cem. Concr. Compos. 2014, 53, 305–315. [Google Scholar] [CrossRef]

- Sakr, K.; El-Hakim, E. Effect of high temperature or fire on heavy weight concrete properties. Cem. Concr. Res. 2005, 35, 590–596. [Google Scholar] [CrossRef]

- Sarhat, S.R.; Sherwood, E.G. Residual mechanical response of recycled aggregate concrete after exposure to elevated temperatures. J. Mater. Civ. Eng. 2013, 25, 1721–1730. [Google Scholar] [CrossRef]

- Vieira, J.P.B.; Correia, J.R.; De Brito, J. Post-fire residual mechanical properties of concrete made with recycled concrete coarse aggregates. Cem. Concr. Res. 2011, 41, 533–541. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, F.; Yang, H. Residual compressive response of concrete produced with both coarse and fine recycled concrete aggregates after thermal exposure. Constr. Build. Mater. 2020, 244, 118397. [Google Scholar] [CrossRef]

- Laneyrie, C.; Beaucour, A.L.; Green, M.F.; Hebert, R.L.; Ledesert, B.; Noumowe, A. Influence of recycled coarse aggregates on normal and high performance concrete subjected to elevated temperatures. Constr. Build. Mater. 2016, 111, 368–378. [Google Scholar] [CrossRef]

- Khan, A.U.R.; Aziz, T.; Fareed, S.; Xiao, J. Behaviour and Residual Strength Prediction of Recycled Aggregates Concrete Exposed to Elevated Temperatures. Arab. J. Sci. Eng. 2020, 45, 8241–8253. [Google Scholar] [CrossRef]

- Xiao, J.; Fan, Y.; Tawana, M.M. Residual compressive and flexural strength of a recycled aggregate concrete following elevated temperatures. Struct. Concr. 2013, 14, 168–175. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Etxeberria, M. Residue strength, water absorption and pore size distributions of recycled aggregate concrete after exposure to elevated temperatures. Cem. Concr. Compos. 2014, 53, 73–82. [Google Scholar] [CrossRef]

- Gales, J.; Parker, T.; Cree, D.; Green, M. Fire Performance of Sustainable Recycled Concrete Aggregates: Mechanical Properties at Elevated Temperatures and Current Research Needs. Fire Technol. 2016, 52, 817–845. [Google Scholar] [CrossRef]

- Martins, D.J.; Correia, J.R.; de Brito, J. The effect of high temperature on the residual mechanical performance of concrete made with recycled ceramic coarse aggregates. Fire Mater. 2016, 40, 289–304. [Google Scholar] [CrossRef]

- Hachemi, S.; Ounis, A. Performance of concrete containing crushed brick aggregate exposed to different fire temperatures. Eur. J. Environ. Civ. Eng. 2015, 19, 805–824. [Google Scholar] [CrossRef]

- Yüksel, S.; Siddique, R.; Özkan, Ö. Influence of high temperature on the properties of concretes made with industrial by-products as fine aggregate replacement. Constr. Build. Mater. 2011, 25, 967–972. [Google Scholar] [CrossRef]

- Xing, Z.; Hébert, R.; Beaucour, A.L.; Ledésert, B.; Noumowé, A. Influence of chemical and mineralogical composition of concrete aggregates on their behaviour at elevated temperature. Mater. Struct. Constr. 2014, 47, 1921–1940. [Google Scholar] [CrossRef]

- Biró, A.; Lublóy, É. Classification of aggregates for fire. Constr. Build. Mater. 2020, 266, 121024. [Google Scholar] [CrossRef]

- Mindeguia, J.C.; Pimienta, P.; Carré, H.; La Borderie, C. On the influence of aggregate nature on concrete behaviour at high temperature. Eur. J. Environ. Civ. Eng. 2012, 16, 236–253. [Google Scholar] [CrossRef]

- Xing, Z.; Beaucour, A.L.; Hebert, R.; Noumowe, A.; Ledesert, B. Influence of the nature of aggregates on the behaviour of concrete subjected to elevated temperature. Cem. Concr. Res. 2011, 41, 392–402. [Google Scholar] [CrossRef]

- Phan, L.T.; Carino, N.J. Effects of test conditions and mixture proportions on behavior of high-strength concrete exposed to high temperatures. ACI Mater. J. 2002, 99, 54–66. [Google Scholar] [CrossRef]

- Zega, C.J.; Di Maio, A.A. Recycled concrete made with different natural coarse aggregates exposed to high temperature. Constr. Build. Mater. 2009, 23, 2047–2052. [Google Scholar] [CrossRef]

- Zega, C.J.; Di Maio, A.A. Recycled concrete exposed to high temperatures. Mag. Concr. Res. 2006, 58, 675–682. [Google Scholar] [CrossRef]

- Nadeem, A.; Memon, S.A.; Lo, T.Y. The performance of Fly ash and Metakaolin concrete at elevated temperatures. Constr. Build. Mater. 2014, 62, 67–76. [Google Scholar] [CrossRef]

- Tanyildizi, H.; Coskun, A. The effect of high temperature on compressive strength and splitting tensile strength of structural lightweight concrete containing fly ash. Constr. Build. Mater. 2008, 22, 2269–2275. [Google Scholar] [CrossRef]

- Pathak, N.; Siddique, R. Properties of self-compacting-concrete containing fly ash subjected to elevated temperatures. Constr. Build. Mater. 2012, 30, 274–280. [Google Scholar] [CrossRef]

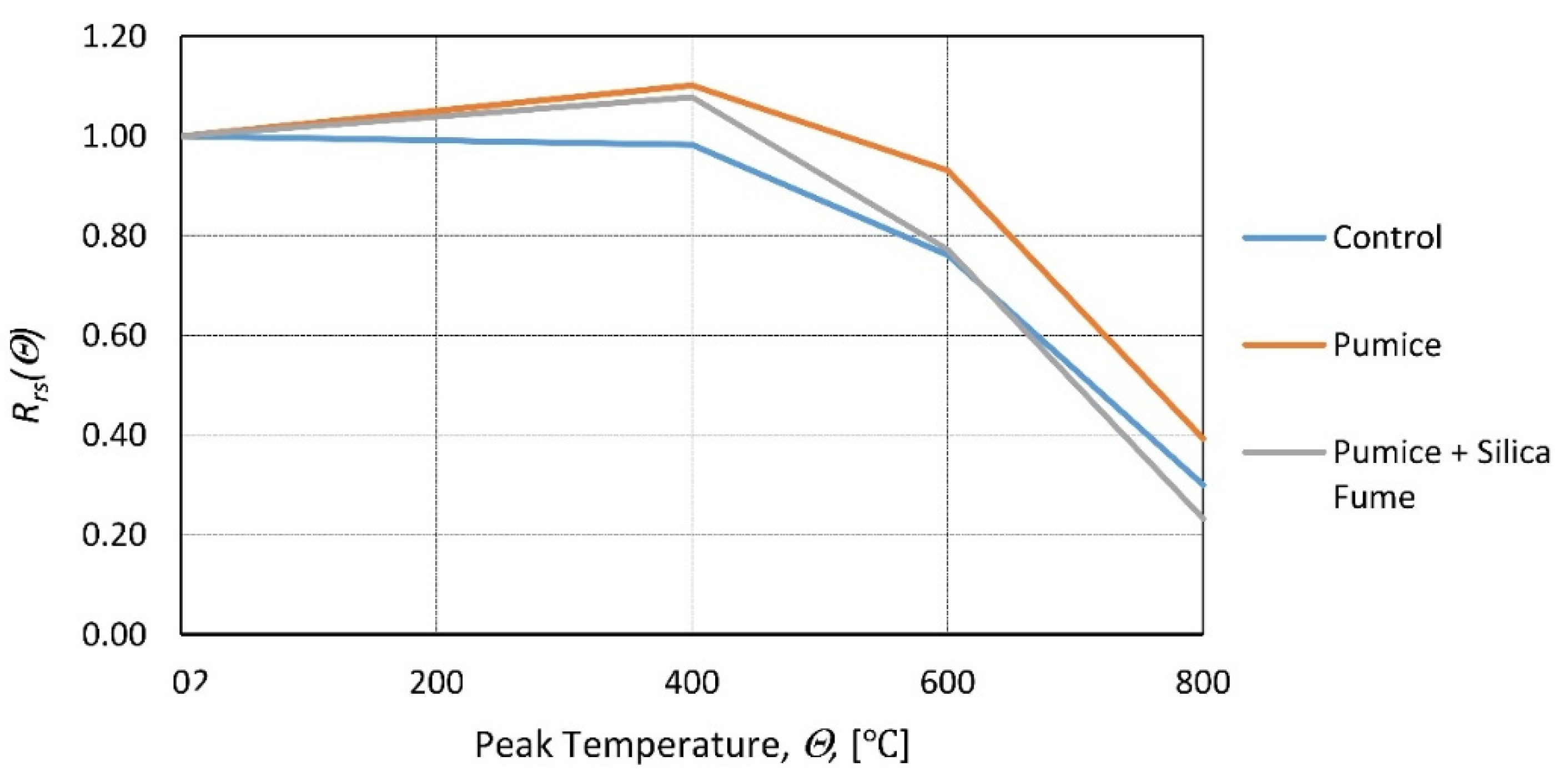

- Demirel, B.; Keleştemur, O. Effect of elevated temperature on the mechanical properties of concrete produced with finely ground pumice and silica fume. Fire Saf. J. 2010, 45, 385–391. [Google Scholar] [CrossRef]

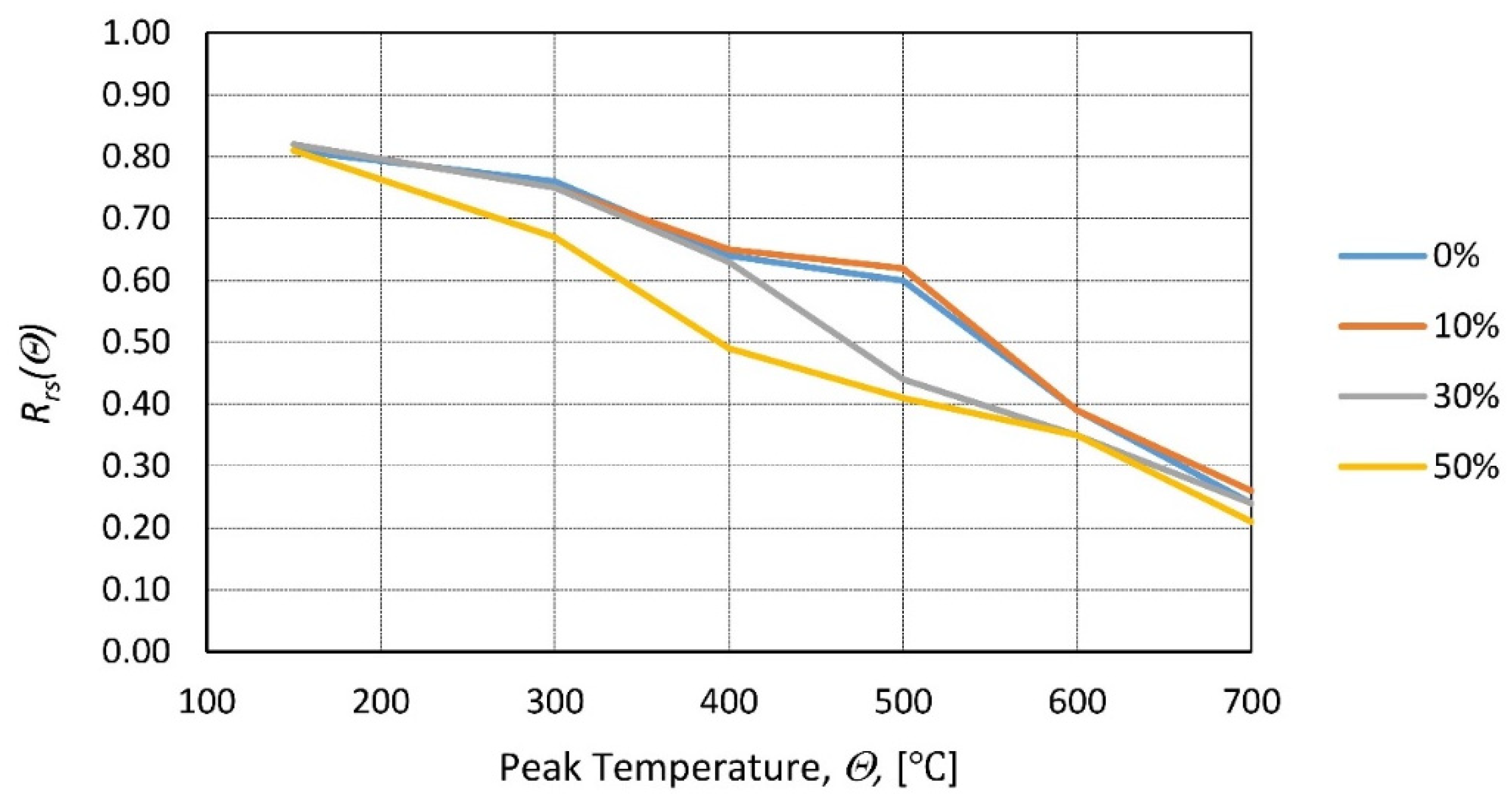

- Behnood, A.; Ziari, H. Effects of silica fume addition and water to cement ratio on the properties of high-strength concrete after exposure to high temperatures. Cem. Concr. Compos. 2008, 30, 106–112. [Google Scholar] [CrossRef]

- Li, Q.; Li, Z.; Yuan, G. Effects of elevated temperatures on properties of concrete containing ground granulated blast furnace slag as cementitious material. Constr. Build. Mater. 2012, 35, 687–692. [Google Scholar] [CrossRef]

- Mendes, A.; Sanjayan, J.G.; Collins, F. Long-term progressive deterioration following fire exposure of OPC versus slag blended cement pastes. Mater. Struct. Constr. 2009, 42, 95–101. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Gashti, S.H.; Tahmouresi, B. Residual strength and microstructure of fiber reinforced self-compacting concrete exposed to high temperatures. Constr. Build. Mater. 2020, 230, 116969. [Google Scholar] [CrossRef]

- Abid, M.; Hou, X.; Zheng, W.; Hussain, R.R. High temperature and residual properties of reactive powder concrete—A review. Constr. Build. Mater. 2017, 147, 339–351. [Google Scholar] [CrossRef]

- Maanser, A.; Benouis, A.; Ferhoune, N. Effect of high temperature on strength and mass loss of admixtured concretes. Constr. Build. Mater. 2018, 166, 916–921. [Google Scholar] [CrossRef]

- Ahmad, A.H.; Abdulkareem, O.M. Effect of High Temperature on Mechanical Properties of Concrete Containing Admixtures. AL-Rafdain Eng. J. 2010, 18, 43–54. [Google Scholar] [CrossRef]

- Zeiml, M.; Leithner, D.; Lackner, R.; Mang, H.A. How do polypropylene fibers improve the spalling behavior of in-situ concrete? Cem. Concr. Res. 2006, 36, 929–942. [Google Scholar] [CrossRef]

- Yermak, N.; Pliya, P.; Beaucour, A.L.; Simon, A.; Noumowé, A. Influence of steel and/or polypropylene fibres on the behaviour of concrete at high temperature: Spalling, transfer and mechanical properties. Constr. Build. Mater. 2017, 132, 240–250. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures. Cem. Concr. Res. 2004, 34, 2215–2222. [Google Scholar] [CrossRef]

- Behnood, A.; Ghandehari, M. Comparison of compressive and splitting tensile strength of high-strength concrete with and without polypropylene fibers heated to high temperatures. Fire Saf. J. 2009, 44, 1015–1022. [Google Scholar] [CrossRef]

- Eidan, J.; Rasoolan, I.; Rezaeian, A.; Poorveis, D. Residual mechanical properties of polypropylene fiber-reinforced concrete after heating. Constr. Build. Mater. 2019, 198, 195–206. [Google Scholar] [CrossRef]

- Serrano, R.; Cobo, A.; Prieto, M.I.; de las Nieves González, M. Analysis of fire resistance of concrete with polypropylene or steel fibers. Constr. Build. Mater. 2016, 122, 302–309. [Google Scholar] [CrossRef]

- Akca, A.H.; Özyurt, N. Deterioration and recovery of FRC after high temperature exposure. Cem. Concr. Compos. 2018, 93, 260–273. [Google Scholar] [CrossRef]

- Sideris, K.K.; Manita, P.; Chaniotakis, E. Performance of thermally damaged fibre reinforced concretes. Constr. Build. Mater. 2009, 23, 1232–1239. [Google Scholar] [CrossRef]

- Düʇenci, O.; Haktanir, T.; Altun, F. Experimental research for the effect of high temperature on the mechanical properties of steel fiber-reinforced concrete. Constr. Build. Mater. 2015, 75, 82–88. [Google Scholar] [CrossRef]

- Moghadam, M.A.; Izadifard, R.A. Effects of steel and glass fibers on mechanical and durability properties of concrete exposed to high temperatures. Fire Saf. J. 2020, 113, 102978. [Google Scholar] [CrossRef]

- Rudnik, E.; Drzymała, T. Thermal behavior of polypropylene fiber-reinforced concrete at elevated temperatures. J. Therm. Anal. Calorim. 2018, 131, 1005–1015. [Google Scholar] [CrossRef]

- Chromá, M.; Vo, D.; Bayer, P. Concrete Rehydration after Heating to Temperatures of up to 1200 °C. In Proceedings of the International Conference on Durability of Building Materials and Components, Porto, Portugal, 12–15 April 2011. [Google Scholar]

- Chan, S.Y.N.; Luo, X.; Sun, W. Effect of high temperature and cooling regimes on the compressive strength and pore properties of high performance concrete. Constr. Build. Mater. 2000, 14, 261–266. [Google Scholar] [CrossRef]

- Chen, B.; Li, C.; Chen, L. Experimental study of mechanical properties of normal-strength concrete exposed to high temperatures at an early age. Fire Saf. J. 2009, 44, 997–1002. [Google Scholar] [CrossRef]

- Endait, M.; Wagh, S. Effect of elevated temperature on mechanical properties of early-age concrete. Innov. Infrastruct. Solut. 2020, 5, 4. [Google Scholar] [CrossRef]

- Yu, K.Q.; Lu, Z.D.; Yu, J. Residual compressive properties of strain-hardening cementitious composite with different curing ages exposed to high temperature. Constr. Build. Mater. 2015, 98, 146–155. [Google Scholar] [CrossRef]

- Kowalski, R. Mechanical properties of concrete subjected to high temperature. Archit. Civ. Eng. Environ. 2010, 3, 61–70. [Google Scholar]

- Castillo, C. Effect of Transient High Temperature on High Strength Concrete. Master’s Thesis, Rice University, Houston, TX, USA, 1987. [Google Scholar]

- Yoon, M.; Kim, G.; Choe, G.C.; Lee, Y.; Lee, T. Effect of coarse aggregate type and loading level on the high temperature properties of concrete. Constr. Build. Mater. 2015, 78, 26–33. [Google Scholar] [CrossRef]

- Kim, Y.S.; Lee, T.G.; Kim, G.Y. An experimental study on the residual mechanical properties of fiber reinforced concrete with high temperature and load. Mater. Struct. Constr. 2013, 46, 607–620. [Google Scholar] [CrossRef]

- Li, Q.; Wang, M.; Sun, H.; Yu, G. Effect of heating rate on the free expansion deformation of concrete during the heating process. J. Build. Eng. 2020, 34, 101896. [Google Scholar] [CrossRef]

- Shui, Z.; Xuan, D.; Chen, W.; Yu, R.; Zhang, R. Cementitious characteristics of hydrated cement paste subjected to various dehydration temperatures. Constr. Build. Mater. 2009, 23, 531–537. [Google Scholar] [CrossRef]

- Vyšvařil, M.; Bayer, P.; Chromá, M.; Rovnaníková, P. Physico-mechanical and microstructural properties of rehydrated blended cement pastes. Constr. Build. Mater. 2014, 54, 413–420. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, C.; Zhang, B.; Li, Q.; Shui, Z. Study on the high-temperature behavior and rehydration characteristics of hardened cement paste. Fire Mater. 2015, 39, 741–750. [Google Scholar] [CrossRef]

| Author | Citation | Sample Type | Sample Size | Concrete Strength | Temp. Range | Heating Time | Heating Rate | Age of Concrete at Exposure |

|---|---|---|---|---|---|---|---|---|

| Toumi | 24 | Cubic | 100 mm | NSC, HSC | 300–700 °C | 3–9 h | 10 °C/min | 28 days |

| Yang | 25 | Cylindrical | D 100 mm H 200 mm | NSC | 400–600 °C | 0–2 h | 2.5 °C/min | 90 days |

| Phan | 26 | Cylindrical | D 100 mm H 200 mm | NSC, HSC | 100–450 °C | 5 h 30 min | 5 °C/min | 200 + days |

| Netinger | 27 | Beam | 40 mm × 40 mm × 160 mm | NSC | 200–1000 °C | 1 h 30 min | - | 28 days |

| Hager | 28 | Cubic Cylindrical | Cubic: 150 mm Cyl.: D 100 mm H 200 mm | HSC | 200–1000 °C | 3 h | 0.5 °C/min | 90 days |

| Krzemień | 29 | Cubic | 150 mm | NSC | 200–1000 °C | 3 h | 0.5 °C/min | 120 days |

| Xiao | 30 | Cubic | 100 mm | HSC | 100–900 °C | 3 h | ISO-834 | NA |

| Chan | 31 | Cubic | 100 mm | NSC, HSC | 400–1200 °C | 1 h | BS476:Part20:1987 | 90 days |

| Tolentino | 32 | Cylindrical | D 100 mm H 200 mm | NSC, HSC | 600 °C | 2 h | 0.5 °C/min | NA |

| Xiao | 34 | Cubic | 100 mm | HSC | 200–800 °C | 2–3 h | 25 °C/min | 150 days |

| Heating Time | 1 h | 3 h |

|---|---|---|

| Pearson | −0.90 | −0.95 |

| Spearman | −0.94 | −0.96 |

| Kendall | −0.82 | −0.87 |

| Author | Citation | Sample Type | Sample Size | Concrete Strength | Temp. Range | Heating Time | Heating Rate | Age of Concrete at Exposure |

|---|---|---|---|---|---|---|---|---|

| Toumi | 24 | Cubic | 100 mm | NSC, HSC | 300–700 °C | 3–9 h | 10 °C/min | 28 days |

| Yang | 25 | Cylindrical | D 100 mm H 200 mm | NSC | 400–600 °C | 0–2 h | 2.5 °C/min | 90 days |

| Pertiwi | 38 | Cubic | 150 mm | NSC | 400–600 °C | 3–9 h | NA | 28 days |

| Wu | 39 | Cylindrical | D 100 mm H 200 mm | NSC | 100–600 °C | 1–6 h | 5 °C/min | 28 days |

| Mohamedbhai | 40 | Cubic | 100 mm | NSC | 200–800 °C | 1–4 h | - | 84 days |

| Correlation Coefficient | Coefficient Value |

|---|---|

| Pearson | −0.98 |

| Spearman | −0.86 |

| Kendall | −0.75 |

| Correlation Coefficient | Coefficient Value |

|---|---|

| Pearson | 0.21 |

| Spearman | 0.21 |

| Kendall | 0.17 |

| Author | Citation | Sample Type | Sample Size | Concrete Strength | Temp. Range | Heating Time | Cooling Regime | Age of Concrete at Exposure |

|---|---|---|---|---|---|---|---|---|

| Kowalski | 42 | Cylindrical | D 100 mm, H 200 mm | NSC | 330–550 °C | 3–5 h | Air cooling Water cooling | 130 days |

| Peng | 43 | Cubic | 100 mm | HSC | 200–800 °C | 1 h | Air cooling Water cooling | 56 days |

| Yang | 44 | Cubic | 100 mm | NSC | 200–800 °C | 3 h | Air cooling Water cooling | 90 days 120 days |

| Husem | 45 | Beam | 40 mm × 40 mm × 160 mm | NSC, HSC | 200–1000 °C | 1 h | Air cooling Water cooling | 28 days |

| Mendes | 46 | Cylindrical | D 100 mm, H 200 mm | NSC | 400–800 °C | 1 h | Air cooling Water cooling | 90 days |

| Bingol | 47 | Cylindrical | D 100 mm, H 200 mm | NSC | 100–700 °C | 3 h | Air cooling Water cooling | 28 days |

| Li | 48 | Cubic | 100 mm | HSC | 100–800 °C | 0 | Air cooling | 90 days |

| Luo | 49 | Cubic | 100 mm | NSC, HSC | 800–1100 °C | 1 h | Air cooling Water cooling | 90 days |

| Shaikh | 50 | Cylindrical | D 100 mm, H 200 mm | NSC | 200–800 °C | 2 h | Air cooling Water cooling | 56 days |

| Wang | 51 | Cubic | 100 mm | NSC | 200–800 °C | 3 h | Air cooling Water cooling | 130–142 days |

| Li | 52 | Cylindrical | D 100 mm, H 200 mm | NSC | 150–750 °C | 2 h 30 min | Air cooling Water cooling | 90 days |

| Karakoç | 53 | Cylindrical | D 100 mm, H 200 mm | NSC | 700 °C | 1 h | Air cooling Water cooling | 1 year |

| Re-Curing Time | 0 Days | 30 Days | |

|---|---|---|---|

| Cooling Method | |||

| 0.77 | 0.82 | ||

| 0.65 | 0.87 | ||

| Temp. | 150 °C | 200 °C | 300 °C | 400 °C | 450 °C | 600 °C | 750 °C | 800 °C | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Re-Curing | ||||||||||

| [50] | 0 days | 1.5% | - | 2.5% | - | 5.8% | 14.0% | 13.6% | - | |

| 30 days | 0.0% | - | −0.2% | - | 2.9% | 4.5% | 1.5% | - | ||

| 60 days | 0.1% | - | 2.9% | - | 3.7% | −6.3% | −3.0% | - | ||

| 90 days | −1.1% | - | 0.5% | - | 1.7% | −6.5% | −2.5% | - | ||

| [49] | 30 days | - | 5.5% | - | 6.7% | - | - | - | −1.5% | |

| Author | Cit. | Sample Type | Sample Size | Concrete Strength | Temp. Range | Heating Time | Cooling Regime | Re-Curing Regime | Re-Curing Time | Age of Concrete at Exposure |

|---|---|---|---|---|---|---|---|---|---|---|

| Li | 52 | Cylindrical | D 100 mm, H 200 mm | NSC | 150–750 °C | 2 h 30 min | Air cooling Water cooling | Air re-curing | 30–90 days | 90 days |

| Papayianni | 61 | Cylindrical | D 150 mm, H 300 mm | NSC | 200–800 °C | 3 h | Air cooling | NA | 1–90 days | 180 days |

| Poon | 62 | Cubic | 100 mm | NSC, HSC | 600–800 °C | 1 h | Air cooling | Air re-curing Water re-curing | 7–56 days | 60 days |

| Souza | 63 | Cylindrical | D 100 mm, H 200 mm | NSC | 300–600 °C | 2 h 2 h 40 min | Air cooling | Air re-curing Water re-curing | 28–112 days | 100 days |

| Lin | 64 | NA | NA | NSC | 400–1000 °C | 2 h | NA | Air re-curing Water re-curing | 7–180 days | 90 days |

| Mirmomeni | 65 | Cylindrical | D 40 mm, H 40 mm | NSC | 300–600 °C | 15 min 2 h | Air cooling Water cooling | Water re-curing | 2–28 days | 28 days |

| Horiguchi | 66 | NA | NA | HSC | 200–400 °C | 2 h | NA | Air re-curing Water re-curing | 90–180 days | NA |

| Park | 67 | Cylindrical | D 100 mm, H 25 mm | NSC | 300–700 °C | 1 h | Water cooling | Air re-curing Water re-curing | 7–30 days | 28 days |

| Correlation Coefficient | Coefficient Value |

|---|---|

| Pearson | 0.617 |

| Spearman | 0.777 |

| Kendall | 0.661 |

| Rrs (θ) | w/c = 0.58 | Peak temperature | |||

| Time * [h] | 400 °C | 500 °C | 550 °C | 600 °C | |

| 0 | 0.93 | 0.73 | 0.63 | 0.33 | |

| 1 | 0.83 | 0.68 | 0.48 | 0.30 | |

| 2 | 0.70 | 0.65 | 0.43 | 0.20 | |

| w/c = 0.68 | Peak temperature | ||||

| Time * [h] | 400 °C | 500 °C | 550 °C | 600 °C | |

| 0 | 0.86 | 0.75 | 0.68 | 0.29 | |

| 1 | 0.82 | 0.68 | 0.50 | 0.18 | |

| 2 | 0.71 | 0.64 | 0.39 | 0.18 | |

| Difference | Peak temperature | ||||

| Time * [h] | 400 °C | 500 °C | 550 °C | 600 °C | |

| 0 | 6.79% | −2.50% | −5.36% | 3.93% | |

| 1 | 0.36% | −0.36% | −2.50% | 12.14% | |

| 2 | −1.43% | 0.71% | 3.21% | 2.14% | |

| Author | Citation | Sample Type | Sample Size | Concrete Strength | Temp. Range | Heating Time | Porosity | Age of Concrete at Exposure |

|---|---|---|---|---|---|---|---|---|

| Hager | 28 | Cubic Cylindrical | Cubic: 150 mm Cyl.: D 100 mm, H 200 mm | HSC | 200–1000 °C | 3 h | 1.4–2% | 90 days |

| Poon | 62 | Cubic | 100 mm | NSC, HSC | 600–800 °C | 1 h | 6.69–9.52% | 60 days |

| Chromá | 115 | Beam | 40 mm × 40 mm × 160 mm | NSC | 200–1200 °C | 2 h | 15% | 28 days |

| Chan | 116 | Cubic | NA | NSC, HSC | 800–1100 °C | 1 h | NA | 90 days |

| Directly after Cooling—t = 0 Days | Re-Curing—Air—t = 28 Days | Re-Curing—Water—t = 56 Days | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Peak Temp. [°C] | |||||||||||||

| Initial Porosity [%] | Rrs (θ,t) | Rrs (θ,t) | Rrs (θ,t) | Rrs (θ,t) | Rrs (θ,t) | Rrs (θ,t) | |||||||

| HS-CC | 9.52 | 18.3 | 0.58 | 17.71 | 0.24 | 16.56 | 0.67 | 26.66 | 0.37 | 16.96 | 0.69 | 23.04 | 0.52 |

| HS-FA30 | 6.69 | 11.3 | 0.67 | 10.44 | 0.32 | 10.1 | 0.77 | 19.6 | 0.47 | 7.96 | 0.93 | 11.91 | 0.79 |

| HS-CC | 1.00 | 1.00 | 1.00 | 1.00 | 0.90 | 1.16 | 1.51 | 1.54 | 0.93 | 1.19 | 1.30 | 2.17 | |

| HS-FA30 | 1.00 | 1.00 | 1.00 | 1.00 | 0.90 | 1.15 | 1.88 | 1.47 | 0.71 | 1.39 | 1.14 | 2.47 | |

| Temperature [°C] | |||||

|---|---|---|---|---|---|

| 20 | 200 | 400 | 600 | 800 | |

| 1.00 | 1.65 | 1.85 | 2.46 | 2.74 | |

| Rrs (θ) | 1.00 | 1.00 | 0.90 | 0.70 | 0.25 |

| Correlation Coefficient | Coefficient Value |

|---|---|

| Pearson | −0.697 |

| Spearman | −0.755 |

| Kendall | −0.593 |

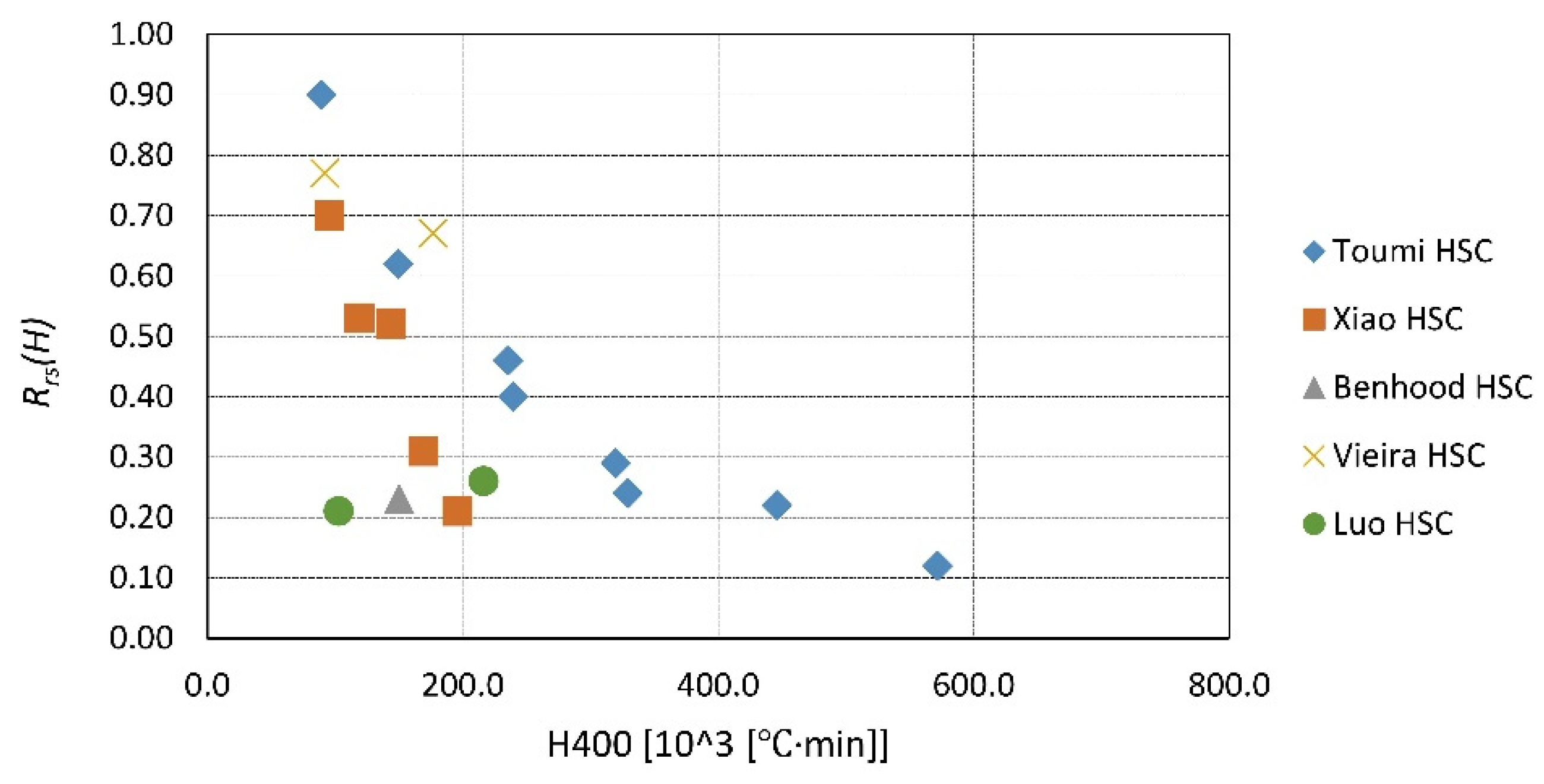

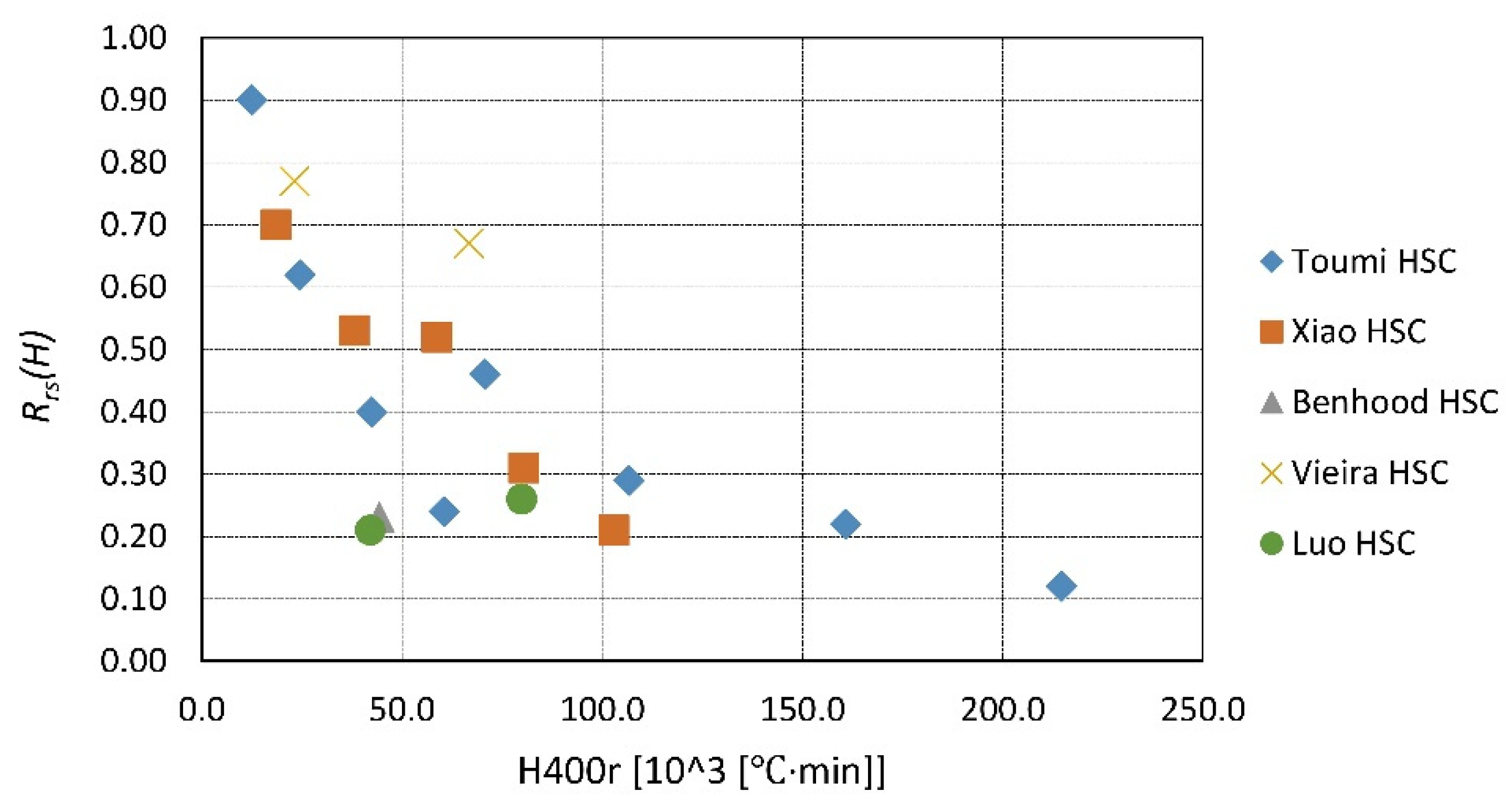

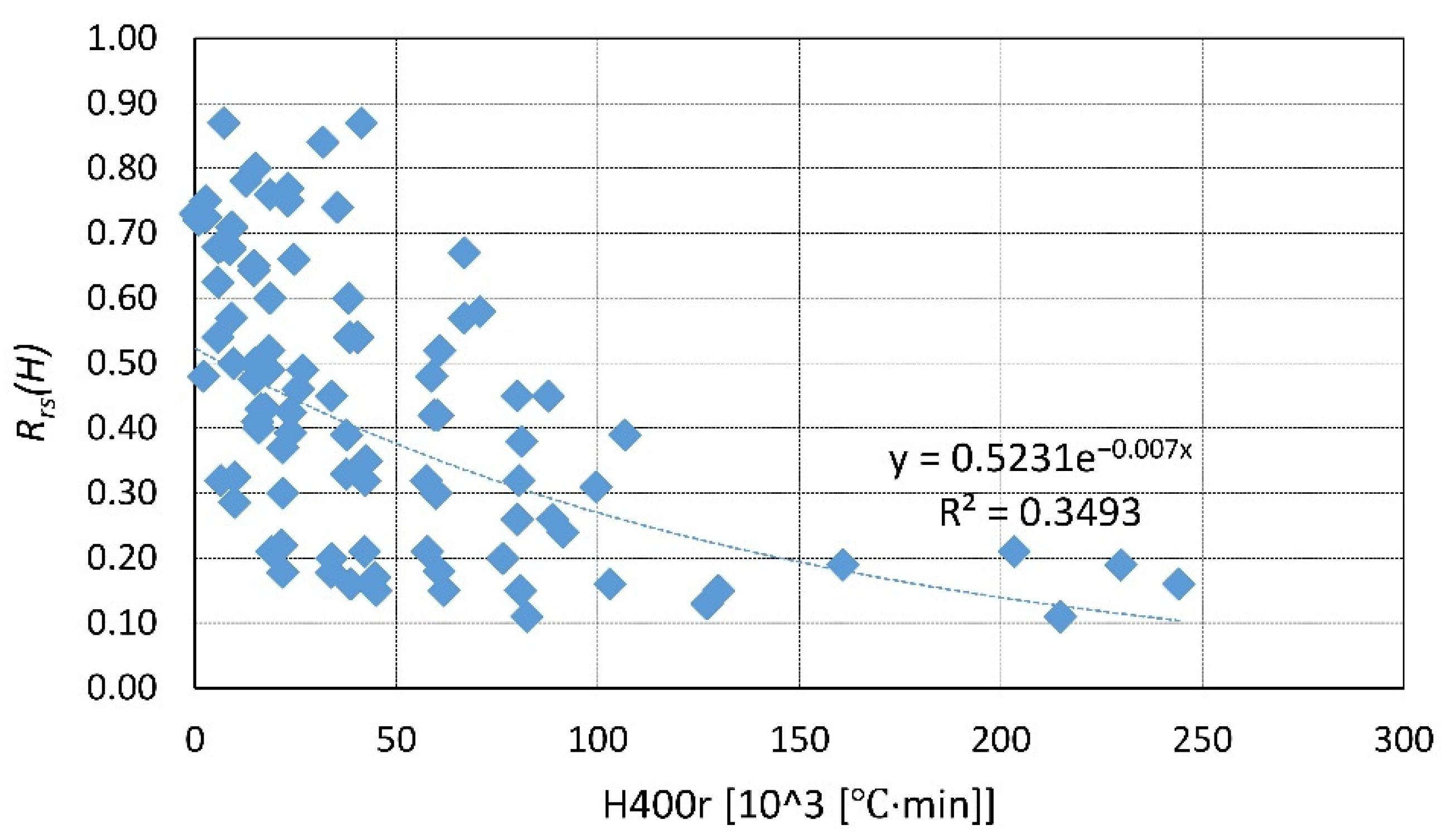

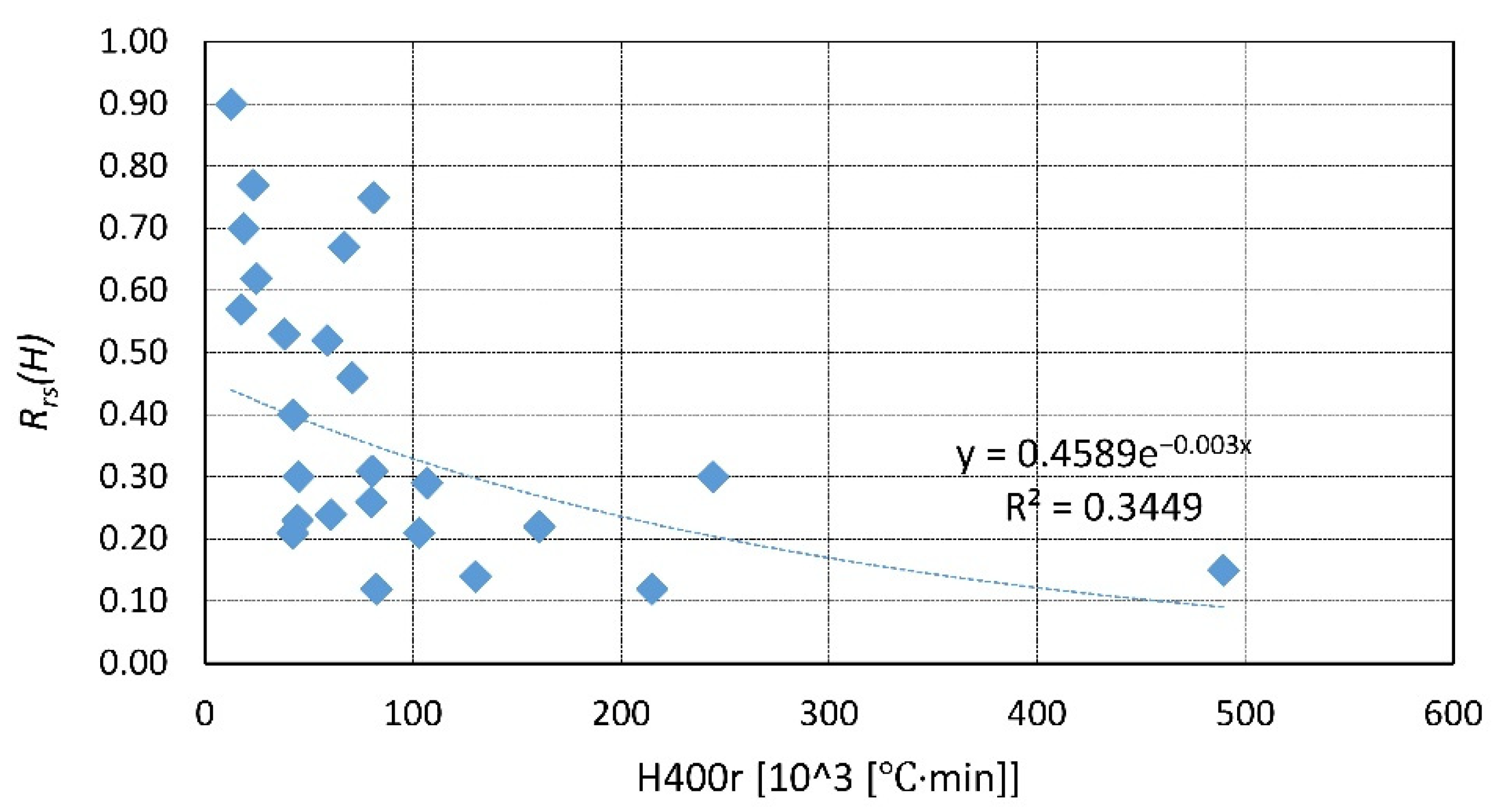

| Coefficient | NSC | HSC | ||

|---|---|---|---|---|

| H400 | H400r | H400 | H400r | |

| Pearson | −0.455 | −0.543 | −0.434 | −0.498 |

| Spearman | −0.494 | −0.615 | −0.500 | −0.675 |

| Kendall | −0.335 | −0.435 | −0.363 | −0.490 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasztetnik, M.; Wróblewski, R. A Literature Review of Concrete Ability to Sustain Strength after Fire Exposure Based on the Heat Accumulation Factor. Materials 2021, 14, 4719. https://doi.org/10.3390/ma14164719

Pasztetnik M, Wróblewski R. A Literature Review of Concrete Ability to Sustain Strength after Fire Exposure Based on the Heat Accumulation Factor. Materials. 2021; 14(16):4719. https://doi.org/10.3390/ma14164719

Chicago/Turabian StylePasztetnik, Michał, and Roman Wróblewski. 2021. "A Literature Review of Concrete Ability to Sustain Strength after Fire Exposure Based on the Heat Accumulation Factor" Materials 14, no. 16: 4719. https://doi.org/10.3390/ma14164719

APA StylePasztetnik, M., & Wróblewski, R. (2021). A Literature Review of Concrete Ability to Sustain Strength after Fire Exposure Based on the Heat Accumulation Factor. Materials, 14(16), 4719. https://doi.org/10.3390/ma14164719