Image Processing of Mg-Al-Sn Alloy Microstructures for Determining Phase Ratios and Grain Size and Correction with Manual Measurement

Abstract

:1. Introduction

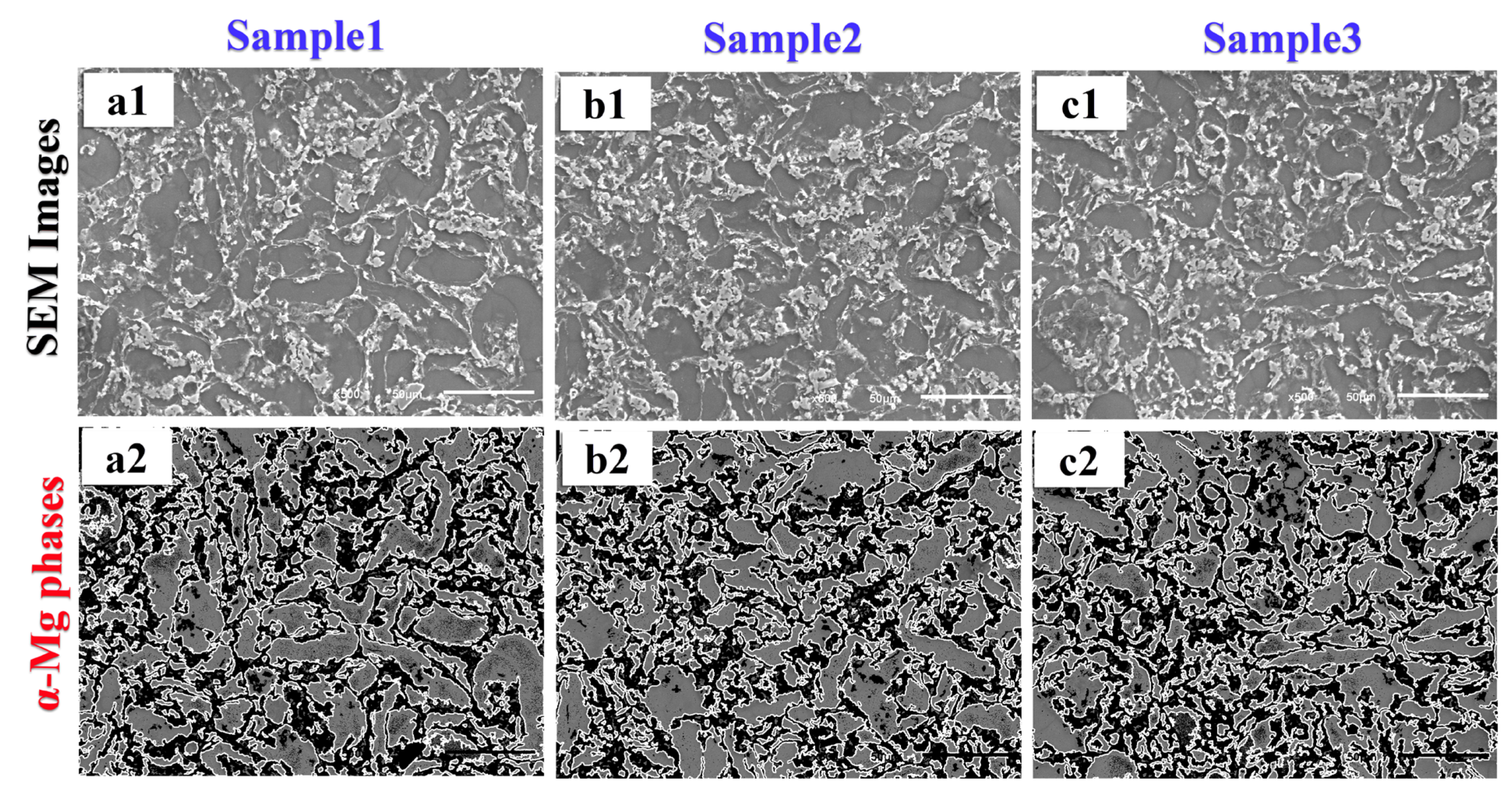

2. Materials and Methods

2.1. Material Production

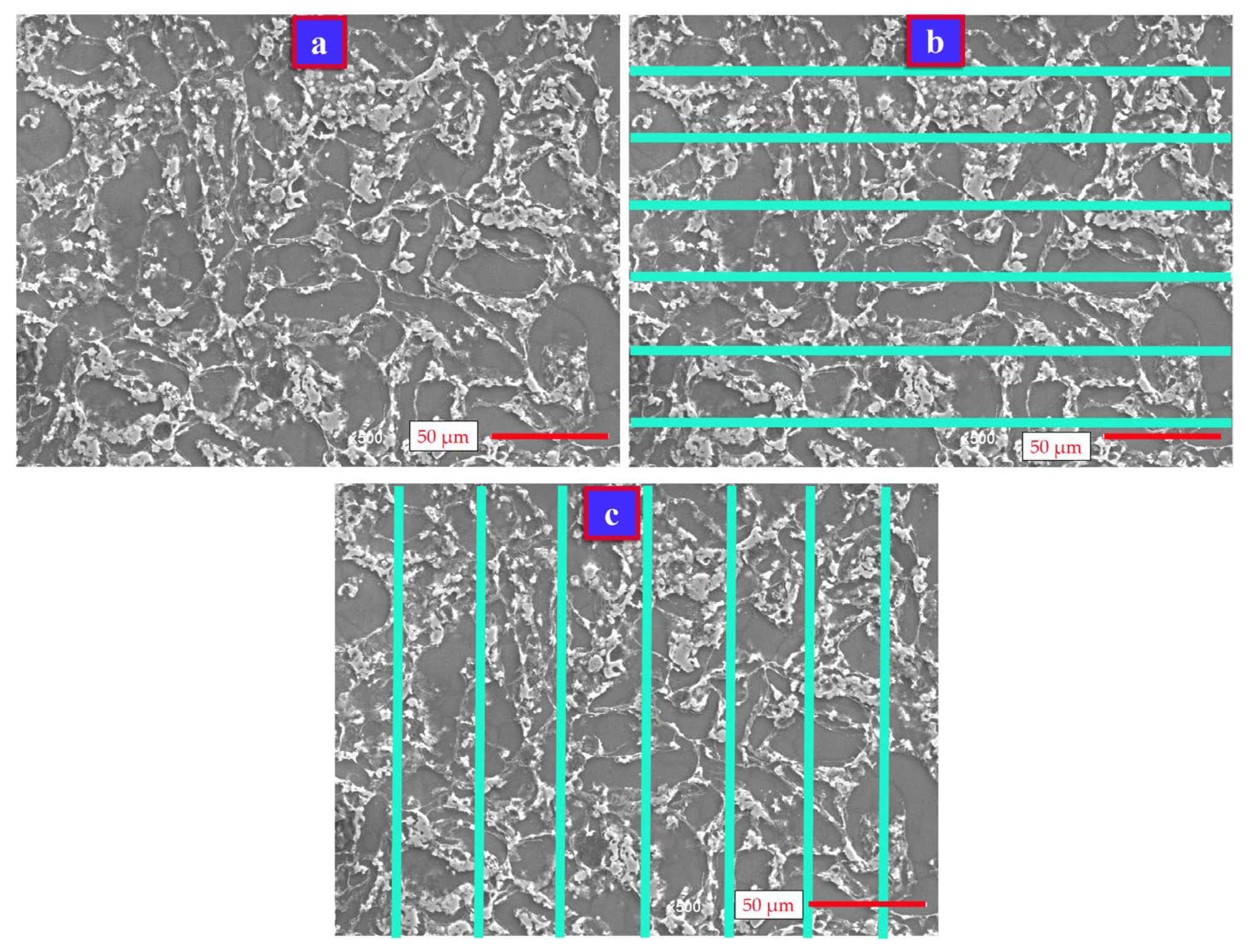

2.2. Manual Measurements and Theoretical Calculations

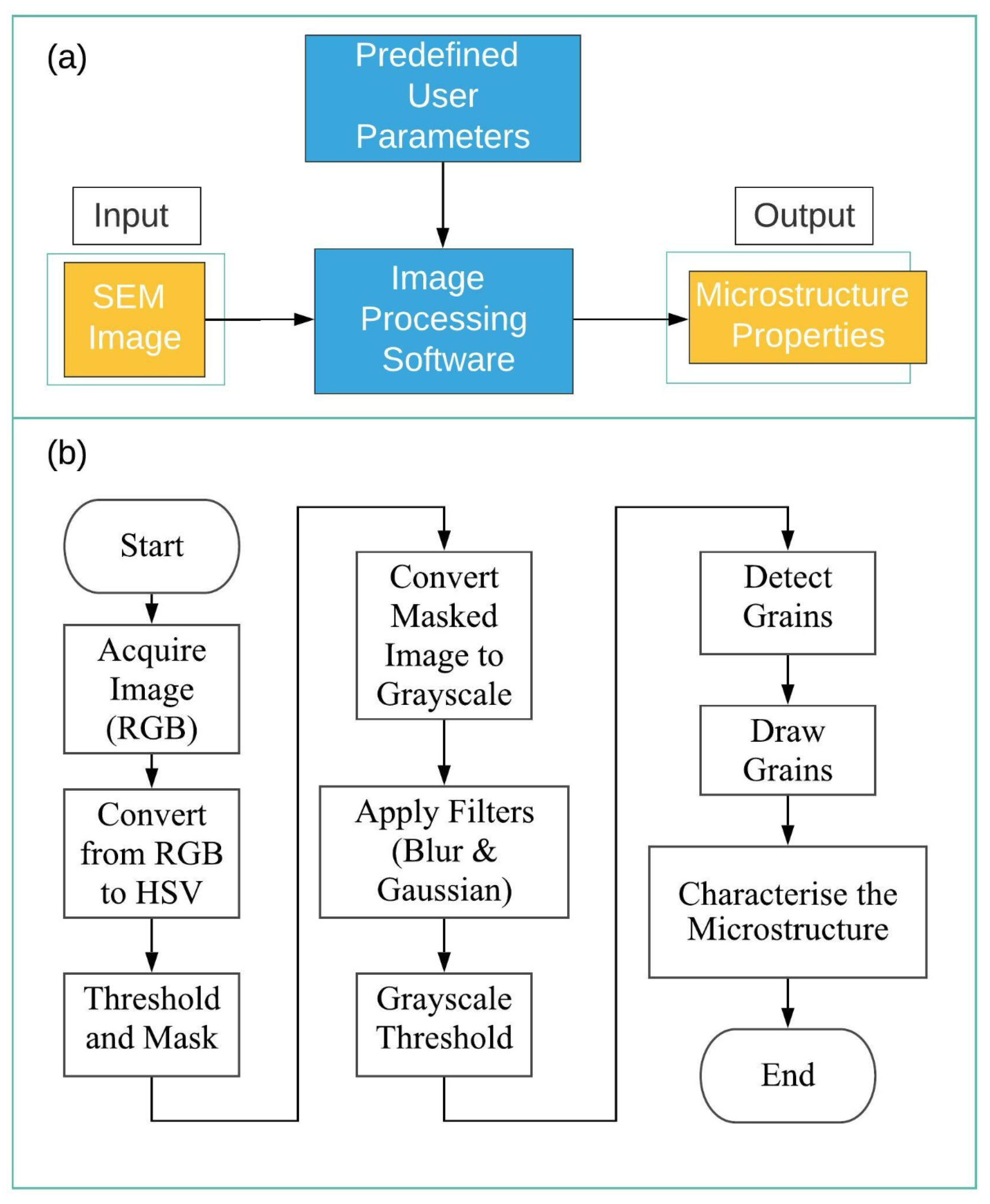

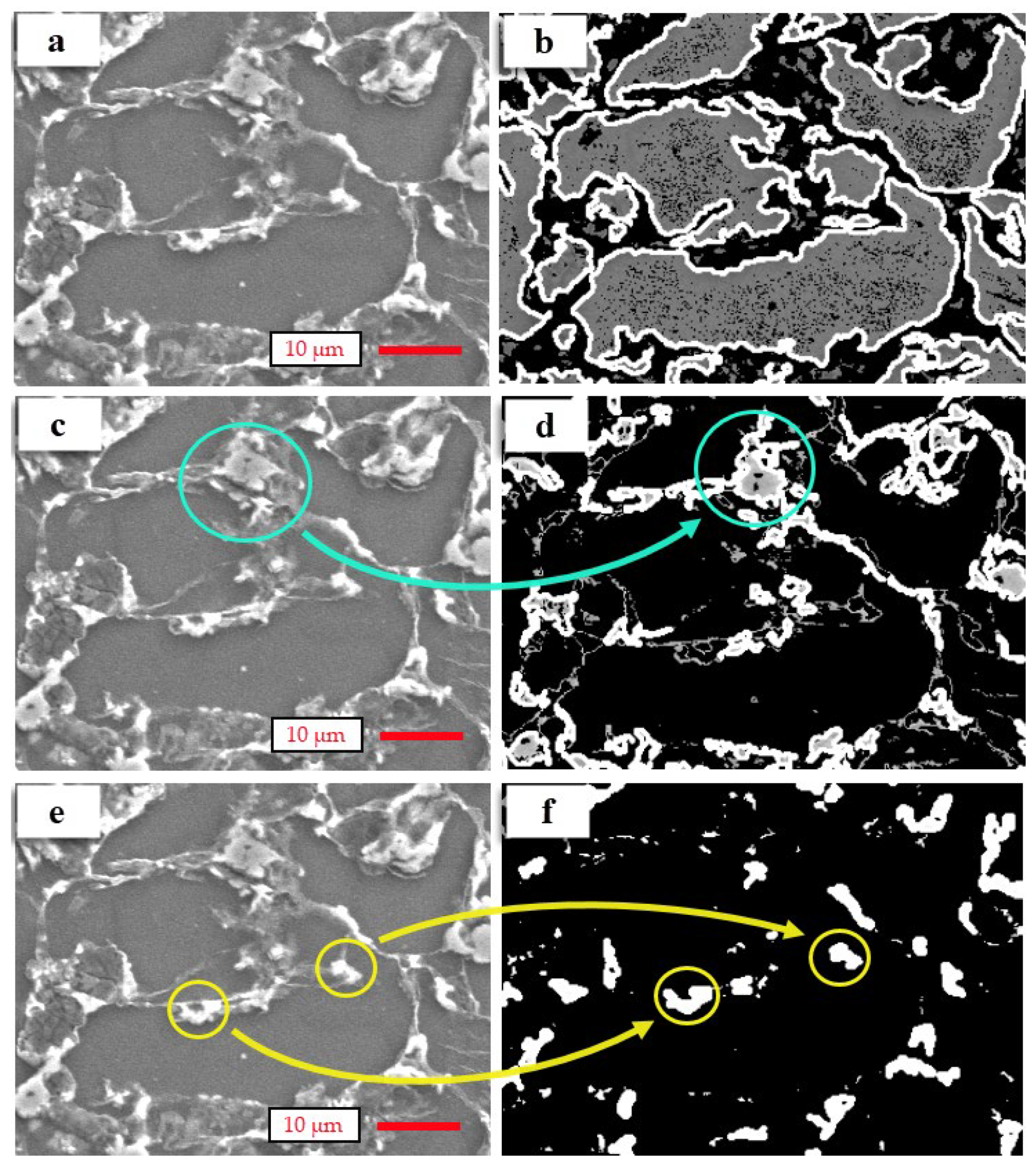

2.3. Parameters and Block Diagram for the Computer Vision Method

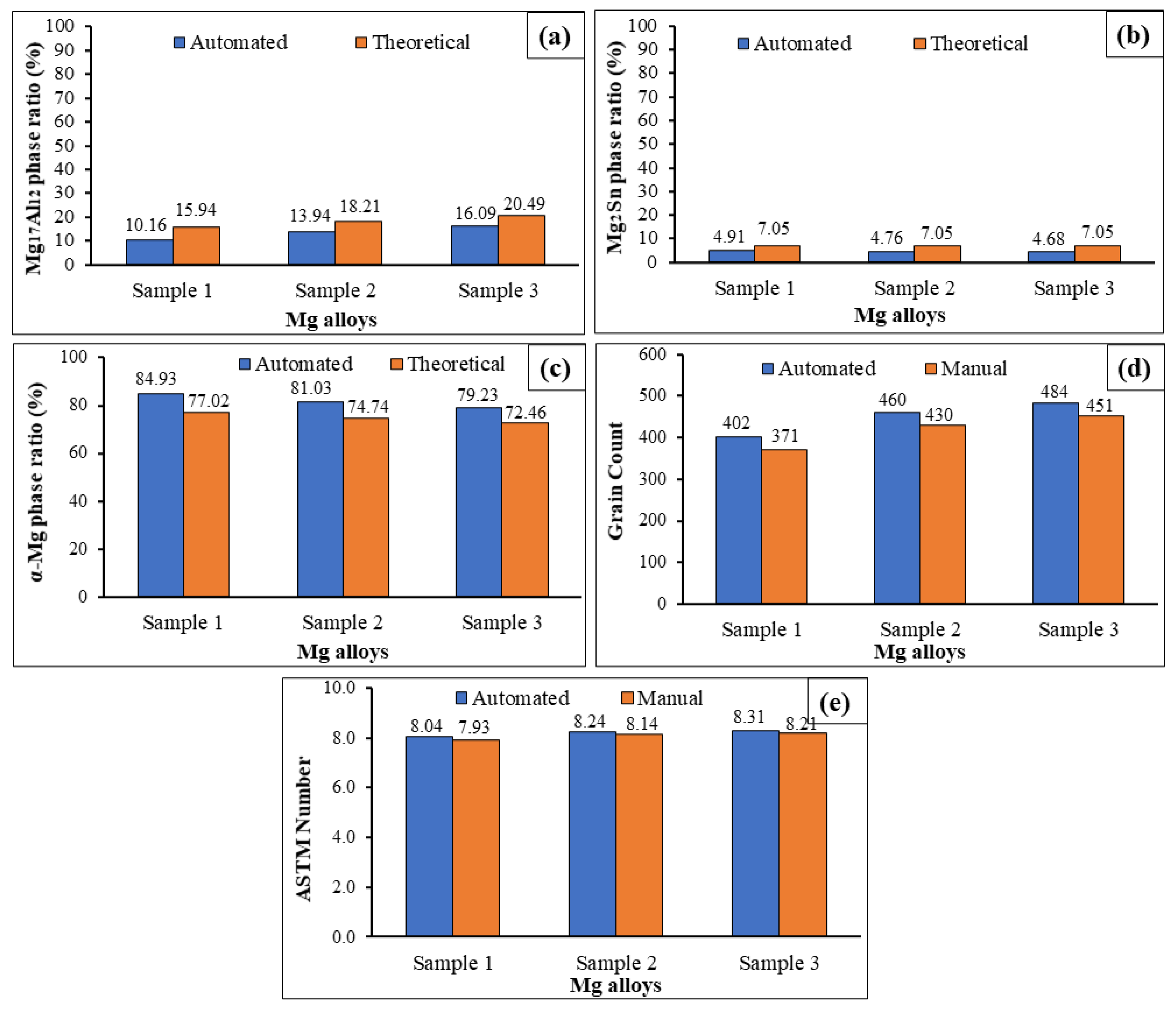

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gray, J.E.; Luan, B. Protective coatings on magnesium and its alloys—A critical review. J. Alloy. Compd. 2002, 336, 88–113. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Gupta, M. Emerging environment friendly, magnesium-based composite technology for present and future generations. JOM 2016, 68, 1890–1901. [Google Scholar] [CrossRef]

- Cherubini, F.; Raugei, M.; Ulgiati, S. LCA of magnesium production: Technological overview and worldwide estimation of environmental burdens. Resour. Conserv. Recycl. 2008, 52, 1093–1100. [Google Scholar] [CrossRef]

- Sathish, T.; Mohanavel, V.; Ansari, K.; Saravanan, R.; Karthick, A.; Afzal, A.; Alamri, S.; Saleel, C.A. Synthesis and characterization of mechanical properties and wire cut EDM process parameters analysis in AZ61 magnesium alloy + B4C + SiC. Materials 2021, 14, 3689. [Google Scholar] [CrossRef]

- Kujur, M.S.; Manakari, V.; Parande, G.; Tun, K.S.; Mallick, A.; Gupta, M. Enhancement of thermal, mechanical, ignition and damping response of magnesium using nano-ceria particles. Ceram. Int. 2018, 44, 15035–15043. [Google Scholar] [CrossRef]

- Karakulak, E. A review: Past, present and future of grain refining of magnesium castings. J. Magnes. Alloy. 2019, 7, 355–369. [Google Scholar] [CrossRef]

- Manakari, V.; Parande, G.; Gupta, M. Selective laser melting of magnesium and magnesium alloy powders: A review. Materials 2017, 7, 2. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.; Li, Y.; Zhang, K.; Li, X.; Ma, M.; Shi, G.; Yuan, J.; Zhang, H. Microstructure and hot deformation behavior of the Mg–8 wt.% Sn–1.5 wt.% Al alloy. Materials 2021, 14, 2050. [Google Scholar] [CrossRef]

- Özgün, Ö.; Aslantaş, K.; Erçetin, A. Powder metallurgy Mg-Sn alloys: Production and characterization. Sci. Iran. 2020, 27, 1255–1265. [Google Scholar] [CrossRef] [Green Version]

- Hertwich, E.G.; Ali, S.; Ciacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Asghari, F.N.; Olivetti, E.; Pauliuk, S.; Tu, Q.; et al. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics—A review. Environ. Res. Lett. 2019, 14, 043004. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, V.; Merchán, M.; Egizabal, P.; García De Cortázar, M.; Irazustabarrena, A.; López-Sabirón, A.M.; Ferreira, G. Technical and environmental evaluation of a new high performance material based on magnesium alloy reinforced with submicrometre-sized TiC particles to develop automotive lightweight components and make transport sector more sustainable. J. Mater. Res. Technol. 2019, 8, 2549–2564. [Google Scholar] [CrossRef]

- Suneesh, E.; Sivapragash, M. Comprehensive studies on processing and characterization of hybrid magnesium composites. Mater. Manuf. Process. 2018, 33, 1324–1345. [Google Scholar] [CrossRef]

- Tekumalla, S.; Gupta, M. Processing, properties and potential applications of magnesium alloy-based nanocomposites: A review. In Minerals, Metals and Materials Series; Springer: Berlin/Heidelberg, Germany, 2019; pp. 3–18. ISBN 9783030357894. [Google Scholar]

- Wang, X.; Chen, C.; Zhang, M. Effect of heat treatment on microstructure and micro-wear resistance of selective laser melted Mg-Al-Zn alloy with La2O3 addition. J. Mater. Eng. Perform. 2021, 30, 2316–2328. [Google Scholar] [CrossRef]

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloy. 2013, 1, 2–22. [Google Scholar] [CrossRef] [Green Version]

- Kittner, K.; Ullmann, M.; Prahl, U. A Comparative study on the hot deformation behavior of as-cast and twin-roll cast Mg-6.8Y-2.5Zn-0.4Zr alloy. Materials 2021, 14, 3628. [Google Scholar] [CrossRef]

- Pan, H.; Yang, C.; Yang, Y.; Dai, Y.; Zhou, D.; Chai, L.; Huang, Q.; Yang, Q.; Liu, S.; Ren, Y.; et al. Ultra-fine grain size and exceptionally high strength in dilute Mg–Ca alloys achieved by conventional one-step extrusion. Mater. Lett. 2019, 237, 65–68. [Google Scholar] [CrossRef]

- Johanes, M.; Tekumalla, S.; Gupta, M. Fe3O4 nanoparticle-reinforced magnesium nanocomposites processed via disintegrated melt deposition and turning-induced deformation techniques. Metals 2019, 9, 1225. [Google Scholar] [CrossRef] [Green Version]

- Towarek, A.; Jurczak, W.; Zdunek, J.; Kulczyk, M.; Mizera, J. Influence of hydrostatic extrusion on the mechanical properties of the model Al-Mg alloys. J. Mater. Eng. Perform. 2021, 30, 3502–3509. [Google Scholar] [CrossRef]

- Wang, X.; Wu, M.; Ma, W.; Lu, Y.; Yuan, S. Achieving superplasticity in AZ31 magnesium alloy processed by hot extrusion and rolling. J. Mater. Eng. Perform. 2016, 25, 64–67. [Google Scholar] [CrossRef]

- Watari, H.; Davey, K.; Rasgado, M.T.; Haga, T.; Izawa, S. Semi-solid manufacturing process of magnesium alloys by twin-roll casting. J. Mater. Process. Technol. 2004, 155–156, 1662–1667. [Google Scholar] [CrossRef]

- Yang, L.; He, J.; Ma, Y.; Zhang, L.; Ma, S.; Gai, X.; Zhang, X. Preparation and characterization of Mg–Al–B alloy (Mg0.5Al0.5B2) via high-temperature sintering. Materials 2021, 14, 3608. [Google Scholar] [CrossRef]

- Eacherath, S.; Murugesan, S. Synthesis and characterization of magnesium-based hybrid composites—A review. Int. J. Mater. Res. 2018, 109, 661–672. [Google Scholar] [CrossRef]

- Turen, Y.U.; Zengin, H.; Sun, Y.; Ahlatci, H.; Unal, M. Effects of 1wt.% Ti, In, and Sn additions on the microstructure, mechanical and corrosion properties of the as-cast and hot-rolled AM60 magnesium alloys. Met. Sci. Heat Treat. 2019, 61, 318–324. [Google Scholar] [CrossRef]

- Erçetin, A. Production of TZ72-xMn magnesium alloys through hot pressing method: Characterization and mechanical properties. Turk. J. Nat. Sci. 2021, 10, 96–102. [Google Scholar]

- Erçetin, A. Production of Mg-Sn-Zr magnesium alloys through hot press method. Eur. J. Sci. Technol. 2021, 23, 649–655. [Google Scholar]

- Jin, S.-C.; Lee, J.U.; Go, J.; Yu, H.; Park, S.H. Effects of Sn addition on the microstructure and mechanical properties of extruded Mg–Bi binary alloy. J. Magnes. Alloy. 2021. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, H.Y.; Wang, J.G.; Rong, J.; Zha, M.; Wang, C.; Ma, P.K.; Jiang, Q.C. The synergy effect of fine and coarse grains on enhanced ductility of bimodal-structured Mg alloys. J. Alloy. Compd. 2019, 780, 312–317. [Google Scholar] [CrossRef]

- Trang, T.T.T.; Zhang, J.H.; Kim, J.H.; Zargaran, A.; Hwang, J.H.; Suh, B.C.; Kim, N.J. Designing a magnesium alloy with high strength and high formability. Nat. Commun. 2018, 9, 1–6. [Google Scholar] [CrossRef]

- Mingo, B.; Arrabal, R.; Mohedano, M.; Mendis, C.L.; del Olmo, R.; Matykina, E.; Hort, N.; Merino, M.C.; Pardo, A. Corrosion of Mg-9Al alloy with minor alloying elements (Mn, Nd, Ca, Y and Sn). Mater. Des. 2017, 130, 48–58. [Google Scholar] [CrossRef] [Green Version]

- Pourbahari, B.; Emamy, M.; Mirzadeh, H. Synergistic effect of Al and Gd on enhancement of mechanical properties of magnesium alloys. Prog. Nat. Sci. Mater. Int. 2017, 27, 228–235. [Google Scholar] [CrossRef]

- Parande, G.; Manakari, V.; Wakeel, S.; Kujur, M.S.; Gupta, M. Enhancing mechanical response of monolithic magnesium using nano-NiTi (Nitinol) particles. Metals 2018, 8, 1014. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Gensch, F.; Ren, Z.; Kainer, K.U.; Hort, N. Effects of Gd solutes on hardness and yield strength of Mg alloys. Prog. Nat. Sci. Mater. Int. 2018, 28, 724–730. [Google Scholar] [CrossRef]

- Gao, C.; Li, S.; Liu, L.; Bin, S.; Yang, Y.; Peng, S.; Shuai, C. Dual alloying improves the corrosion resistance of biodegradable Mg alloys prepared by selective laser melting. J. Magnes. Alloy. 2021, 9, 305–316. [Google Scholar] [CrossRef]

- Ercetin, A.; Özgün, Ö.; Aslantas, K. Investigation of mechanical properties of Mg5Sn-xZn alloys produced through new method in powder metallurgy. J. Test. Eval. 2021, 49, 3506–3518. [Google Scholar] [CrossRef]

- Ercetin, A. Application of the hot press method to produce new Mg alloys: Characterization, mechanical properties, and effect of Al addition. J. Mater. Eng. Perform. 2021, 30, 4254–4262. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y.; Ahlatci, H.; Sun, Y. Microstructure, mechanical properties and corrosion resistance of as-cast and as-extruded Mg–4Zn–1La magnesium alloy. Rare Met. 2020, 39, 909–917. [Google Scholar] [CrossRef]

- Akyüz, B. Wear and machinability of AM series magnesium alloys. Mater. Test. 2019, 61, 49–55. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y.; Elen, L. A comparative study on microstructure, mechanical and tribological properties of A4, AE41, AS41 and AJ41 magnesium alloys. J. Mater. Eng. Perform. 2019, 28, 4647–4657. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, J.; Gupta, M.K.; Mia, M.; Dwivedi, S.P.; Saxena, A.; Chattopadhyaya, S.; Singh, R.; Pimenov, D.Y.; Korkmaz, M.E. Investigation on mechanical, tribological and microstructural properties of Al-Mg-Si-T6/SiC/muscovite-hybrid metal-matrix composites for high strength applications. J. Mater. Res. Technol. 2021, 12, 1564–1581. [Google Scholar] [CrossRef]

- Gorsse, S.; Miracle, D.B.; Senkov, O.N. Mapping the world of complex concentrated alloys. Acta Mater. 2017, 135, 177–187. [Google Scholar] [CrossRef] [Green Version]

- Xu, H.; Zou, Y.-J.; Huang, Y.; Ma, P.-K.; Guo, Z.-P.; Zhou, Y.; Wang, Y.-P. Enhanced electroplasticity through room-temperature dynamic recrystallization in a Mg-3Al-1Sn-1Zn alloy. Materials 2021, 14, 3739. [Google Scholar] [CrossRef]

- Kumar, J.; Singh, D.; Kalsi, N.S.; Sharma, S.; Pruncu, C.I.; Pimenov, D.Y.; Rao, K.V.; Kaplonek, W. Comparative study on the mechanical, tribological, morphological and structural properties of vortex casting processed, Al-SiC-Cr hybrid metal matrix composites for high strength wear-resistant applications: Fabrication and characterizations. J. Mater. Res. Technol. 2020, 9, 13607–13615. [Google Scholar] [CrossRef]

- Erçetin, A.; Aslantas, K.; Özgün, Ö. Micro-end milling of biomedical TZ54 magnesium alloy produced through powder metallurgy. Mach. Sci. Technol. 2020, 24, 924–947. [Google Scholar] [CrossRef]

- Sunil, B.R.; Ganesh, K.V.; Pavan, P.; Vadapalli, G.; Swarnalatha, C.; Swapna, P.; Bindukumar, P.; Pradeep Kumar Reddy, G. Effect of aluminum content on machining characteristics of AZ31 and AZ91 magnesium alloys during drilling. J. Magnes. Alloy. 2016, 4, 15–21. [Google Scholar] [CrossRef] [Green Version]

- Nakai, H.; Inokoshi, M.; Nozaki, K.; Komatsu, K.; Kamijo, S.; Liu, H.; Shimizubata, M.; Minakuchi, S.; Van Meerbeek, B.; Van Vleugels, J.; et al. Additively manufactured zirconia for dental applications. Materials 2021, 14, 3694. [Google Scholar] [CrossRef]

- Aversa, A.; Saboori, A.; Librera, E.; de Chirico, M.; Biamino, S.; Lombardi, M.; Fino, P. The role of directed energy deposition atmosphere mode on the microstructure and mechanical properties of 316L samples. Addit. Manuf. 2020, 34, 101274. [Google Scholar] [CrossRef]

- Yousefi Oderji, S.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Fresh and hardened properties of one-part fly ash-based geopolymer binders cured at room temperature: Effect of slag and alkali activators. J. Clean. Prod. 2019, 225, 1–10. [Google Scholar] [CrossRef]

- Lee, H.T.; Hou, W.H. Fine grains forming process, mechanism of fine grain formation and properties of superalloy 718. Mater. Trans. 2012, 53, 716–723. [Google Scholar] [CrossRef] [Green Version]

- Emadi, P.; Ravindran, C. The influence of high temperature ultrasonic processing time on the microstructure and mechanical properties AZ91E magnesium alloy. J. Mater. Eng. Perform. 2021, 30, 1188–1199. [Google Scholar] [CrossRef]

- Khisamov, R.K.; Safarov, I.M.; Mulyukov, R.R.; Yumaguzin, Y.M. Effect of grain boundaries on the electron work function of nanocrystalline nickel. Phys. Solid State 2013, 55, 1–4. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Guo, E.; Chen, Z.; Kang, H.; Liu, X.; Han, P.; Wang, T. In vitro investigation on microstructure, bio-corrosion properties and cytotoxicity of as-extruded Mg–5Sn–xIn alloys. J. Alloy. Compd. 2021, 877, 160294. [Google Scholar] [CrossRef]

- Erçetin, A.; Aslantaş, K.; Perçin, M. Micro milling of tungsten-copper composite materials produced through powder metallurgy method: Effect of composition and sintering temperature. J. Fac. Eng. Archit. Gazi Univ. 2018, 33, 1369–1381. [Google Scholar] [CrossRef]

- Campbell, A.; Murray, P.; Yakushina, E.; Marshall, S.; Ion, W. New methods for automatic quantification of microstructural features using digital image processing. Mater. Des. 2018, 141, 395–406. [Google Scholar] [CrossRef] [Green Version]

- Mikołajczyk, T.; Nowicki, K.; Bustillo, A.; Pimenov, D.Y. Predicting tool life in turning operations using neural networks and image processing. Mech. Syst. Signal Process. 2018, 104, 503–513. [Google Scholar] [CrossRef]

- Mikołajczyk, T.; Nowicki, K.; Kłodowski, A.; Pimenov, D.Y. Neural network approach for automatic image analysis of cutting edge wear. Mech. Syst. Signal Process. 2017, 88, 100–110. [Google Scholar] [CrossRef]

- Bustillo, A.; Pimenov, D.Y.; Matuszewski, M.; Mikolajczyk, T. Using artificial intelligence models for the prediction of surface wear based on surface isotropy levels. Robot. Comput. Integr. Manuf. 2018, 53, 215–227. [Google Scholar] [CrossRef]

- Tang, Y.; Li, L.; Wang, C.; Chen, M.; Feng, W.; Zou, X.; Huang, K. Real-time detection of surface deformation and strain in recycled aggregate concrete-filled steel tubular columns via four-ocular vision. Robot. Comput. Integr. Manuf. 2019, 59, 36–46. [Google Scholar] [CrossRef]

- Xu, L.; Zhao, J.; Yao, Z.; Shi, A.; Chen, Z. Density peak clustering based on cumulative nearest neighbors degree and micro cluster merging. J. Signal Process. Syst. 2019, 91, 1219–1236. [Google Scholar] [CrossRef]

- Tang, Y.-C.; Li, L.-J.; Feng, W.-X.; Liu, F.; Zou, X.-J.; Chen, M.-Y. Binocular vision measurement and its application in full-field convex deformation of concrete-filled steel tubular columns. Measurement 2018, 130, 372–383. [Google Scholar] [CrossRef]

- Chen, M.; Tang, Y.; Zou, X.; Huang, K.; Li, L.; He, Y. High-accuracy multi-camera reconstruction enhanced by adaptive point cloud correction algorithm. Opt. Lasers Eng. 2019, 122, 170–183. [Google Scholar] [CrossRef]

- Przybył, K.; Gawałek, J.; Koszela, K.; Wawrzyniak, J.; Gierz, L. Artificial neural networks and electron microscopy to evaluate the quality of fruit and vegetable spray-dried powders. Case study: Strawberry powder. Comput. Electron. Agric. 2018, 155, 314–323. [Google Scholar] [CrossRef]

- Lin, C.S.; Yeh, P.T.; Chen, D.C.; Chiou, Y.C.; Lee, C.H. The identification and filtering of fertilized eggs with a thermal imaging system. Comput. Electron. Agric. 2013, 91, 94–105. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Ji, G.; Phillips, P. Fruit classification using computer vision and feedforward neural network. J. Food Eng. 2014, 143, 167–177. [Google Scholar] [CrossRef]

- Golnabi, H.; Asadpour, A. Design and application of industrial machine vision systems. Robot. Comput. Integr. Manuf. 2007, 23, 630–637. [Google Scholar] [CrossRef]

- Hecht, M.D.; Webler, B.A.; Picard, Y.N. Digital image analysis to quantify carbide networks in ultrahigh carbon steels. Mater. Charact. 2016, 117, 134–143. [Google Scholar] [CrossRef] [Green Version]

- Abdelrahman, M.; Reutzel, E.W.; Nassar, A.R.; Starr, T.L. Flaw detection in powder bed fusion using optical imaging. Addit. Manuf. 2017, 15, 1–11. [Google Scholar] [CrossRef]

- Cohn, R.; Holm, E. Unsupervised machine learning via transfer learning and k-means clustering to classify materials image data. Integr. Mater. Manuf. Innov. 2021, 10, 231–244. [Google Scholar] [CrossRef]

- Akkoyun, F.; Ercetin, A.; Aslantas, K.; Pimenov, D.Y.; Giasin, K.; Lakshmikanthan, A.; Aamir, M. Measurement of micro burr and slot widths through image processing: Comparison of manual and automated measurements in micro-milling. Sensors 2021, 21, 4432. [Google Scholar] [CrossRef]

- Decost, B.L.; Holm, E.A. A computer vision approach for automated analysis and classification of microstructural image data. Comput. Mater. Sci. 2015, 110, 126–133. [Google Scholar] [CrossRef] [Green Version]

- Akkoyun, F.; Özçelik, A. Rapid characterization of cell and bacteria counts using computer vision. Turk. J. Nat. Sci. 2021, 10, 269–274. [Google Scholar] [CrossRef]

- DeCost, B.L.; Francis, T.; Holm, E.A. Exploring the microstructure manifold: Image texture representations applied to ultrahigh carbon steel microstructures. Acta Mater. 2017, 133, 30–40. [Google Scholar] [CrossRef] [Green Version]

- DeCost, B.L.; Jain, H.; Rollett, A.D.; Holm, E.A. Computer vision and machine learning for autonomous characterization of AM powder feedstocks. JOM 2017, 69, 456–465. [Google Scholar] [CrossRef] [Green Version]

- Scime, L.; Beuth, J. Anomaly detection and classification in a laser powder bed additive manufacturing process using a trained computer vision algorithm. Addit. Manuf. 2018, 19, 114–126. [Google Scholar] [CrossRef]

- Li, W.; Field, K.G.; Morgan, D. Automated defect analysis in electron microscopic images. Npj Comput. Mater. 2018, 4, 36. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Wu, Z.; Hartley, W.D.; Sietins, J.M.; Williams, C.B.; Yu, H.Z. Unraveling pore evolution in post-processing of binder jetting materials: X-ray computed tomography, computer vision, and machine learning. Addit. Manuf. 2020, 34, 101183. [Google Scholar] [CrossRef]

- Dos Reis, G.; Stroustrup, B. A principled, complete, and efficient representation of C++. Math. Comput. Sci. 2011, 5, 335–356. [Google Scholar] [CrossRef] [Green Version]

| Material | Alloying Elements | Synthesizing Process | Analysed Parameters | Ref |

|---|---|---|---|---|

| Pure Mg | Ca: 0.1–1 wt.% | Casting + Extrusion | ↑ YS, ↑ UTS, ↓ GS | [17] |

| Mg-5Bi | Sn: 4 wt.% | Casting + Extrusion | ↓ GS from 123.9 to 75.2 µm, ↑ YS by 6.63% & ↑ UTS by 8.67% | [27] |

| Pure Mg | Al: 8 wt.%, Sn: 2 wt.%, Zn: 1 wt.% | Casting + HPR | ↓ GS, ↑ ductility | [28] |

| Pure Mg | Al: 3 wt.%, Zn, Mn: 1 wt.%, Ca: 0.5 wt. % | Casting | ↑ S, ↑ F, ↓ GS | [29] |

| Mg-9Al | Mn, Ca, Sn, Y: 0.5 wt.%, Nd: 0.25 wt. % | Casting | ↑ GS with Mn, Nd, Y, ↓ GS with Ca, Sn, ↓ CR with Mn, Y, Ca | [30] |

| Mg-Zn | Gd, Al | Casting | ↓ GS, ↑ YS, ↑ UTS ↑ ductility | [31] |

| Pure Mg | NiTi: 0.5–3 wt.% | DMD + Extrusion | ↑ D, ↓ P, ↓ GS by 76%, ↓ CTE by 10%, ↑ H by 31%, ↑ YS by 129%, ↑ UTS by 46%, ↑ EA by 35%, ↑ CYS by 104%, ↑ UCS by 26% | [32] |

| Pure Mg | Gd: 2–15 wt.%; Zr: 1 wt.% | Casting + Extrusion | ↑ YS by 122.2%, ↓ GS from 650 to 55 µm, ↑ H, ↓CYS by 248.5% | [33] |

| AZ61 | Mn: 0.4 wt.%; Sn: 0.8 wt.% | SLM | ↓ CR, ↑ H, ↑ CS | [34] |

| Pure Mg | Sn: 5–13 wt.% | Hot Pressing | ↑ YS, ↑ UTS | [9] |

| Mg-5Sn | Zn: 1–5 wt.% | Hot Pressing | ↑ YS, ↑ UTS | [35] |

| Mg5Sn4Zn | Al: 1–4 wt.%, Mn: 0.2 wt.% | Hot Pressing | ↑ YS, ↑ UTS | [36] |

| Mg6Sn | Zr: 0.5–2 wt.%, Mn: 0.1 wt.% | Hot Pressing | ↑ YS, ↑ UTS | [26] |

| Mg7Sn2Zn | Mn: 0.15–0.30 wt.% | Hot Pressing | ↑ YS, ↑ UTS | [25] |

| AM60 | Ti: 1 wt.%, In: 1 wt.%, Sn: 1 wt.% | Casting + Hot rolling | ↑ YS, ↑ UTS | [24] |

| Pure Mg | Zn: 4 wt.%, La: 1 wt.% | As-cast and As-extruded | ↑ YS, ↑ UTS | [37] |

| Sample No. | wt.% Al, Purity: 99.9% Size: 8 µm | wt.% Sn, Purity: 99.9% Size: 10 µm | wt.% Mg, Purity: 99.8% Size: 45 µm | Sintering Temperature (°C) | Pressure (MPa) |

|---|---|---|---|---|---|

| Sample 1 | 7 | 5 | Bal. | 620 | 50 |

| Sample 2 | 8 | 5 | Bal. | 620 | 50 |

| Sample 3 | 9 | 5 | Bal. | 620 | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ercetin, A.; Akkoyun, F.; Şimşir, E.; Pimenov, D.Y.; Giasin, K.; Gowdru Chandrashekarappa, M.P.; Lakshmikanthan, A.; Wojciechowski, S. Image Processing of Mg-Al-Sn Alloy Microstructures for Determining Phase Ratios and Grain Size and Correction with Manual Measurement. Materials 2021, 14, 5095. https://doi.org/10.3390/ma14175095

Ercetin A, Akkoyun F, Şimşir E, Pimenov DY, Giasin K, Gowdru Chandrashekarappa MP, Lakshmikanthan A, Wojciechowski S. Image Processing of Mg-Al-Sn Alloy Microstructures for Determining Phase Ratios and Grain Size and Correction with Manual Measurement. Materials. 2021; 14(17):5095. https://doi.org/10.3390/ma14175095

Chicago/Turabian StyleErcetin, Ali, Fatih Akkoyun, Ercan Şimşir, Danil Yurievich Pimenov, Khaled Giasin, Manjunath Patel Gowdru Chandrashekarappa, Avinash Lakshmikanthan, and Szymon Wojciechowski. 2021. "Image Processing of Mg-Al-Sn Alloy Microstructures for Determining Phase Ratios and Grain Size and Correction with Manual Measurement" Materials 14, no. 17: 5095. https://doi.org/10.3390/ma14175095

APA StyleErcetin, A., Akkoyun, F., Şimşir, E., Pimenov, D. Y., Giasin, K., Gowdru Chandrashekarappa, M. P., Lakshmikanthan, A., & Wojciechowski, S. (2021). Image Processing of Mg-Al-Sn Alloy Microstructures for Determining Phase Ratios and Grain Size and Correction with Manual Measurement. Materials, 14(17), 5095. https://doi.org/10.3390/ma14175095