Printing of Zirconia Parts via Fused Filament Fabrication

Abstract

:1. Introduction

2. Materials and Methods

- Suitable material (filler, binder, surfactant) selection

- Compounding and flow properties characterization

- Filament extrusion

- Printing via FFF

- Debinding and sintering.

2.1. Material Properties and Feedstock Composition

- Particle size distribution: Laser diffraction (LA-950 Horiba Ltd., Kyoto, Japan)

- Specific surface area: BET method (Gemini VII 2390, Micromeritics Instruments Corp., Norcross, GA, USA)

- Particle density: Helium pycnometry (Pycnomatic ATC, Porotec, Germany)

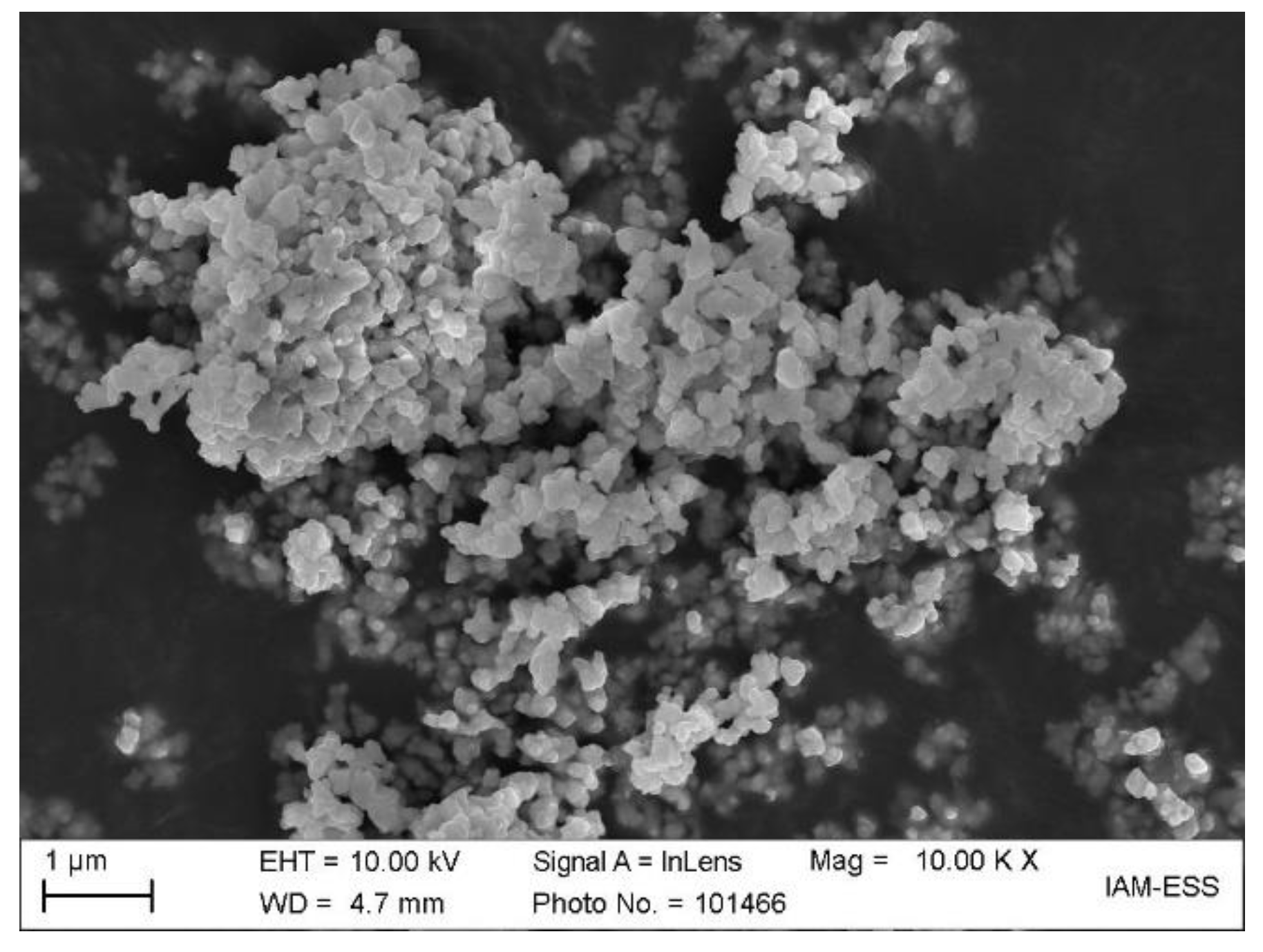

- Particle morphology: SEM (Supra 55, Zeiss).

2.2. Compounding and Feedstock Characterization

2.3. Filament Extrusion and Printing

2.4. Thermal Postprocessing: Debinding and Sintering

- Grinding with different diamond grinding wheels (70 µm until planarity, 40 µm for 30 s, 10 µm for 2 min)

- Polishing with diamond paste (6 µm, 3 µm) and lubricant, each 30 min, surface pressure 25 N, wheel rotation speed 150 rpm.

3. Results and Discussion

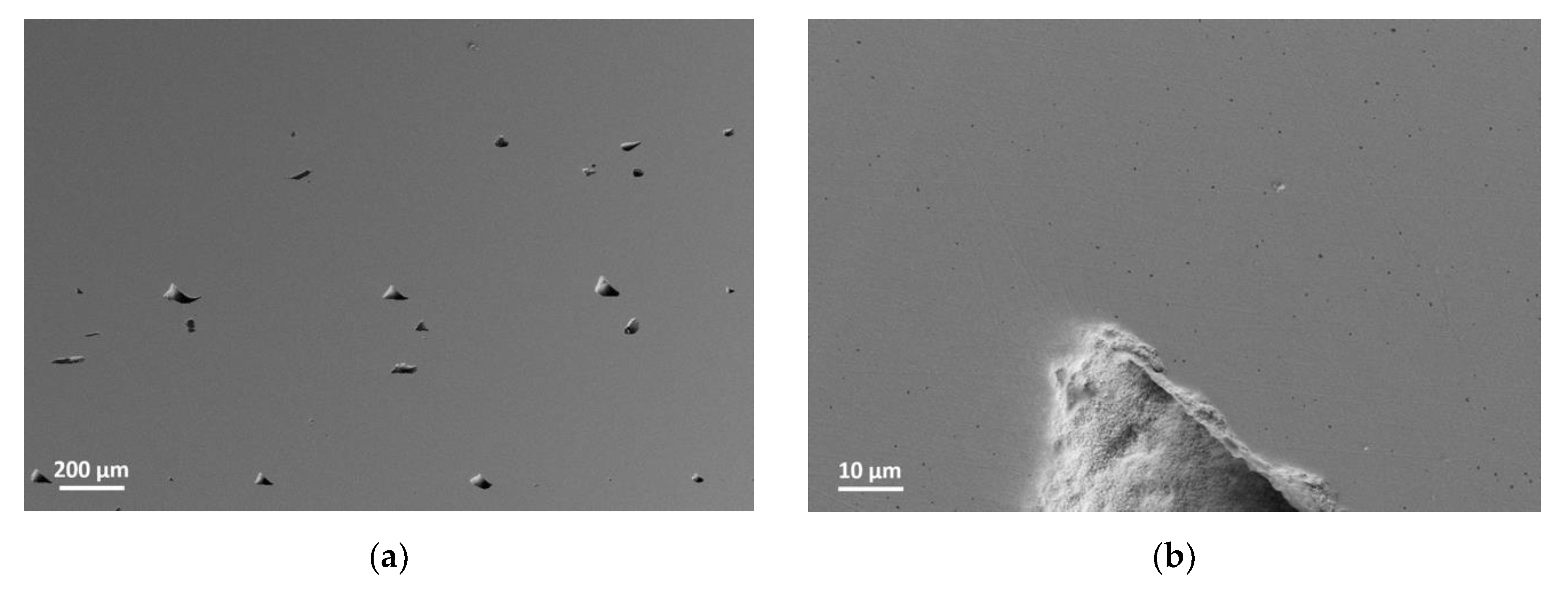

3.1. Material Properties

3.2. Compounding and Feedstock Characterization

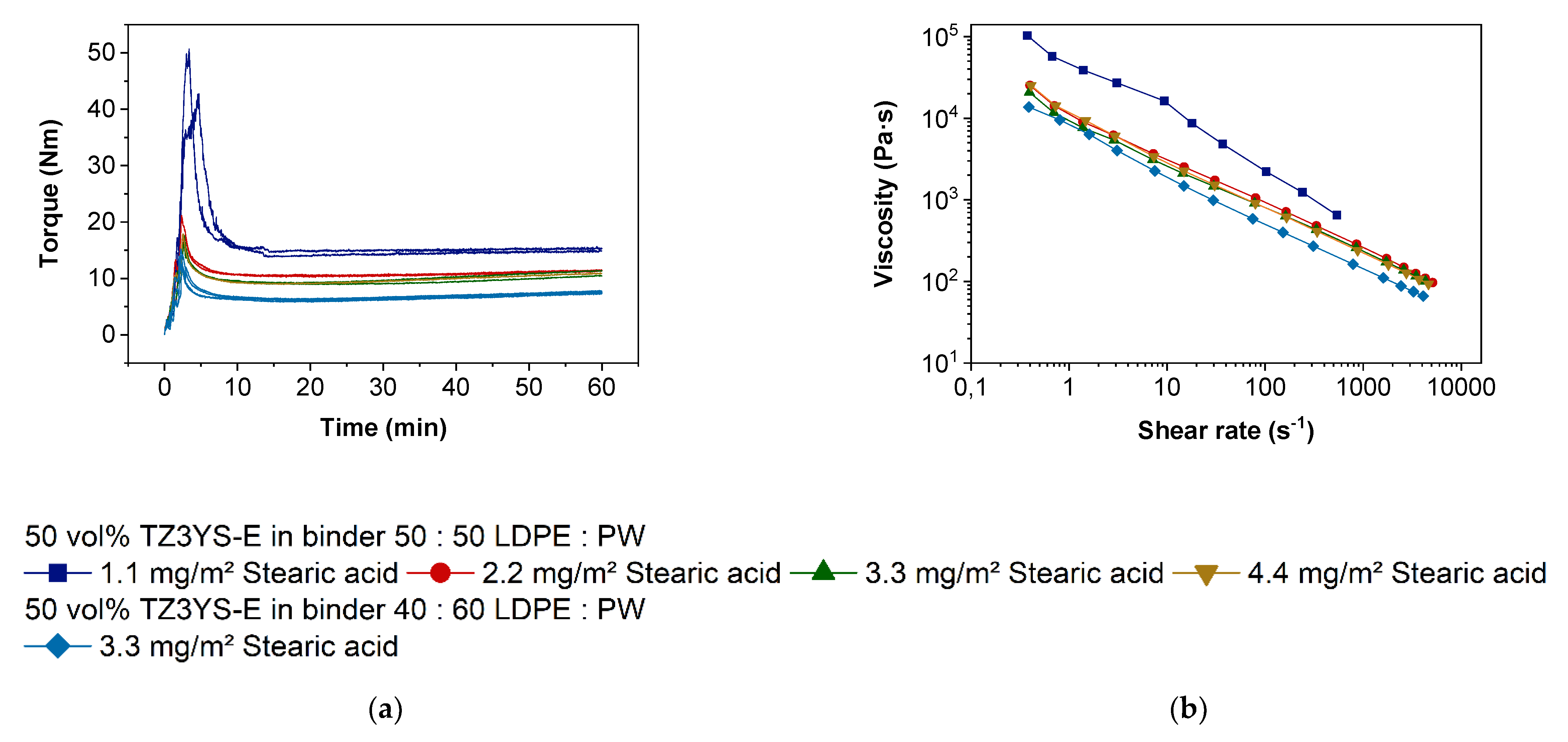

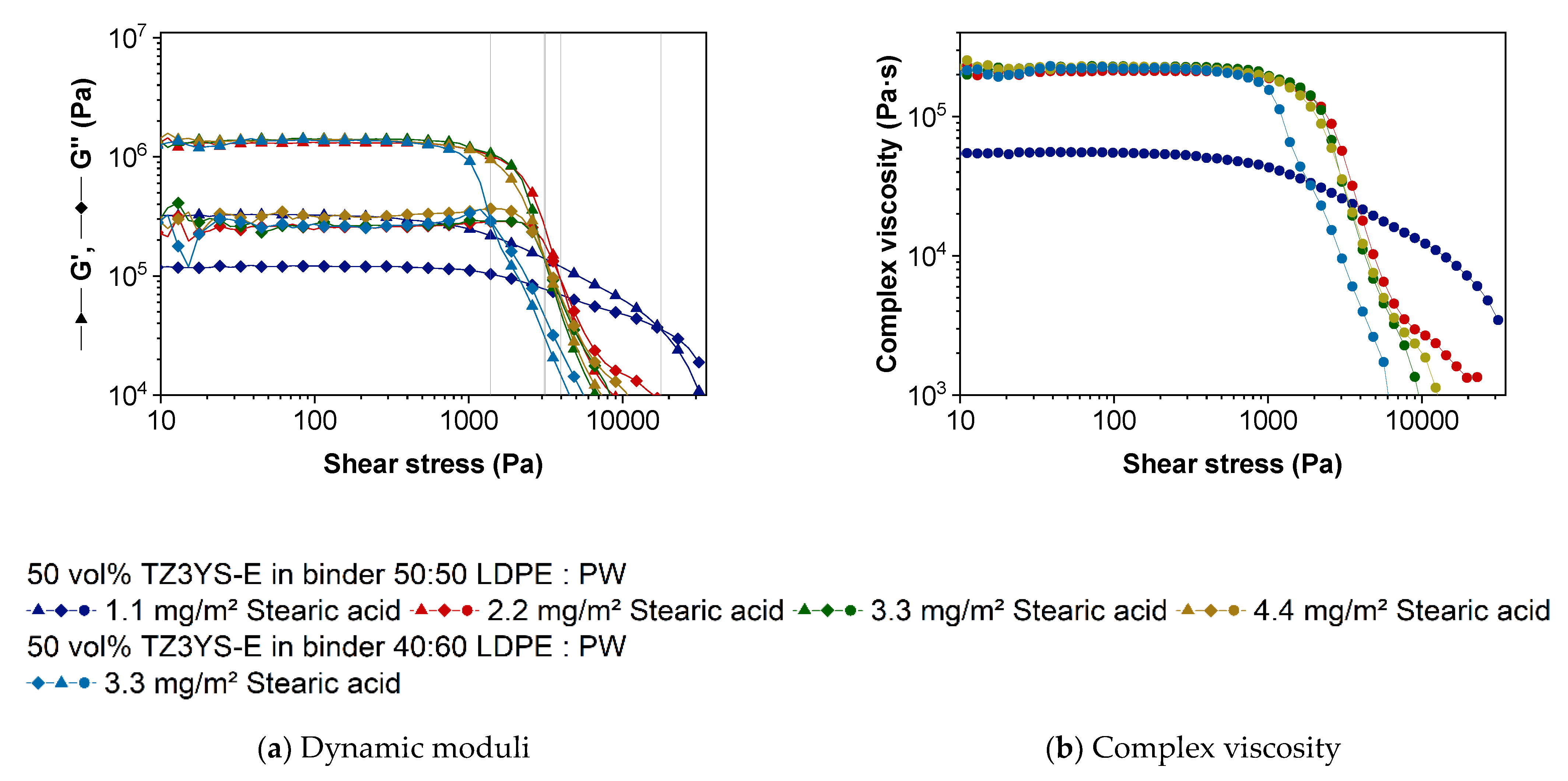

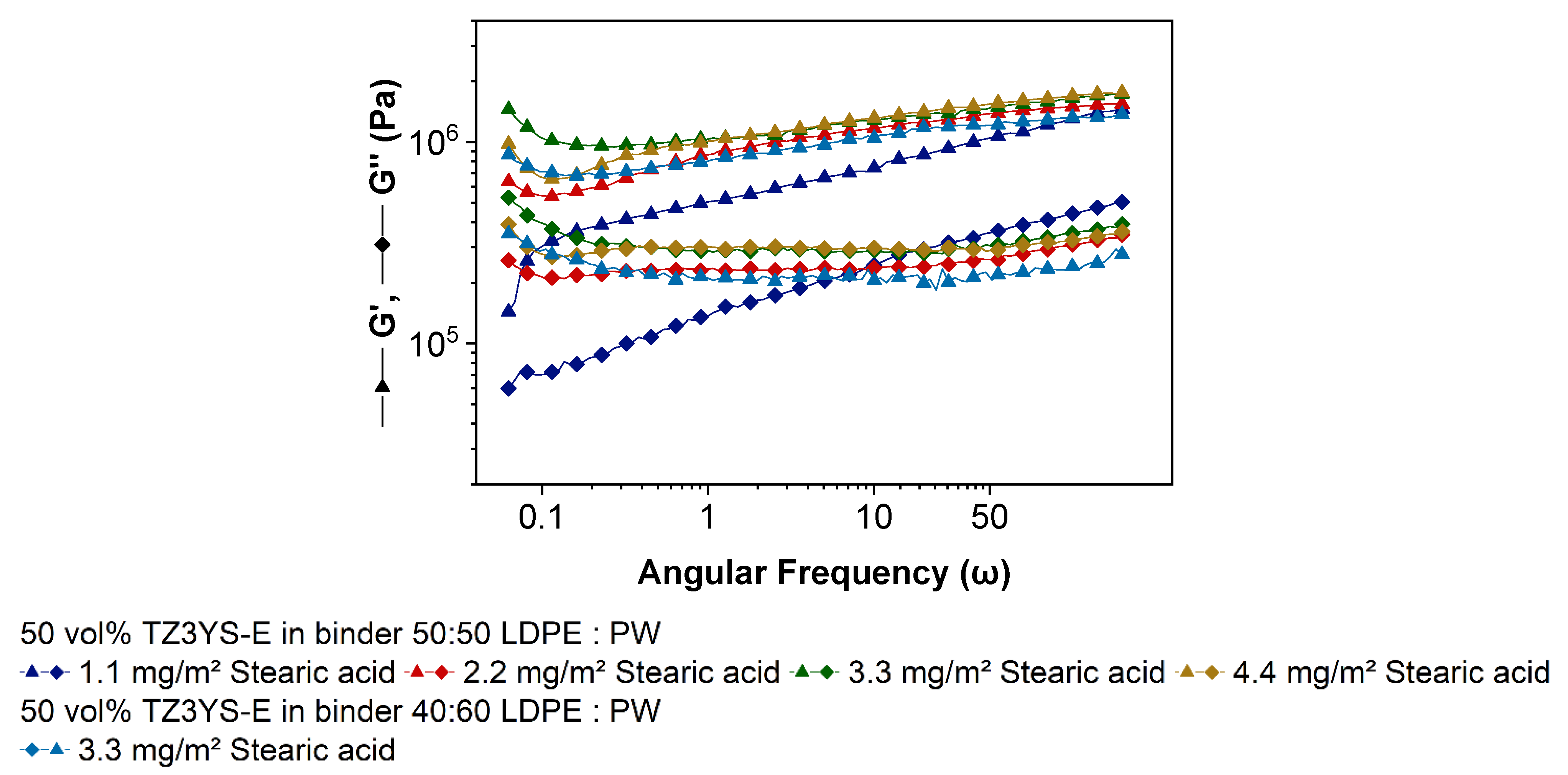

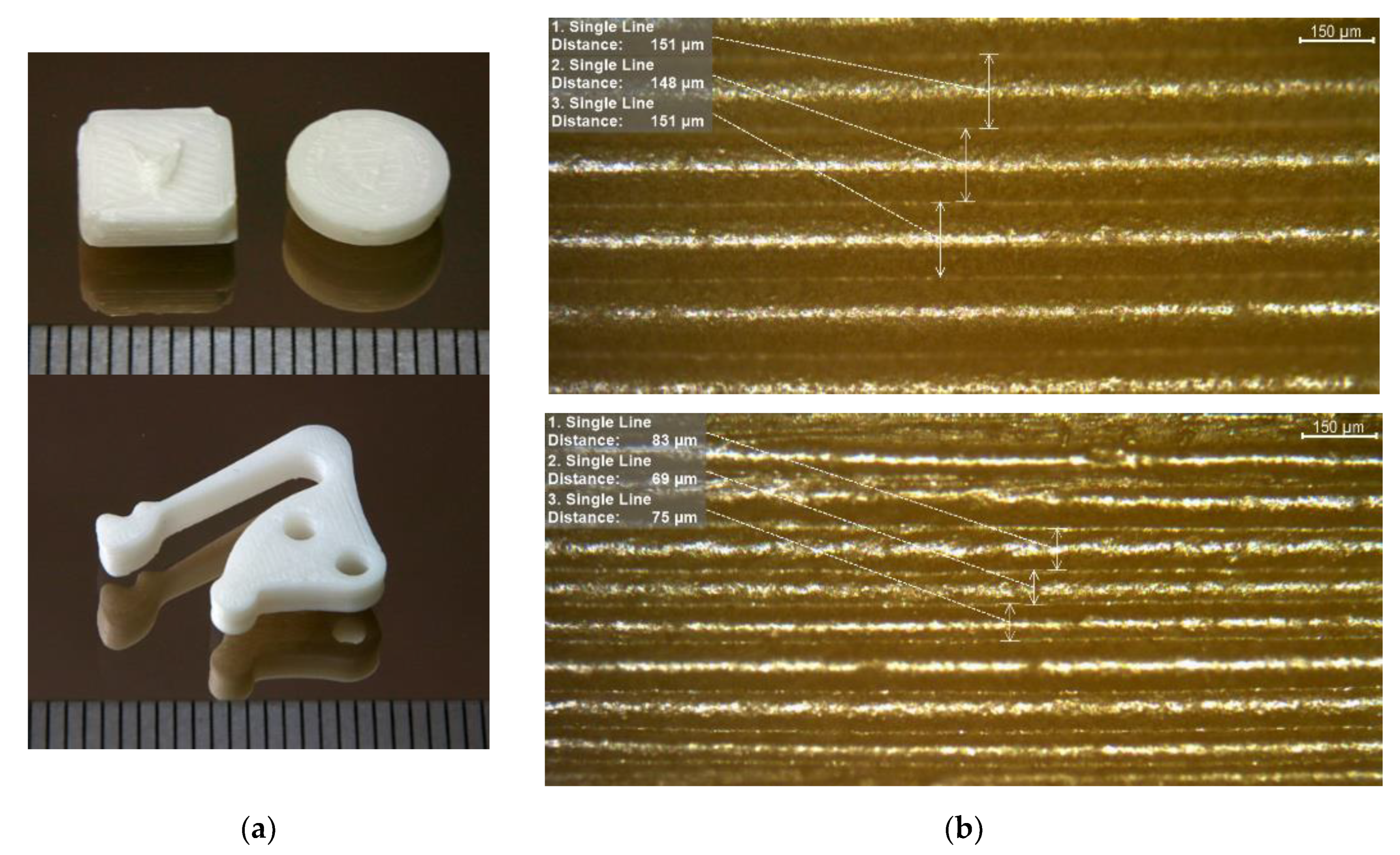

3.3. Filament Extrusion and Printing

- Print head extruder temperature: <170 °C

- Printing speed: 10 mm/s

- Platform temperature: 70 °C

- Smallest nozzle diameter: 0.4 mm

- Layer height: 0.1 mm

3.4. Thermal Postprocessing: Debinding and Sintering

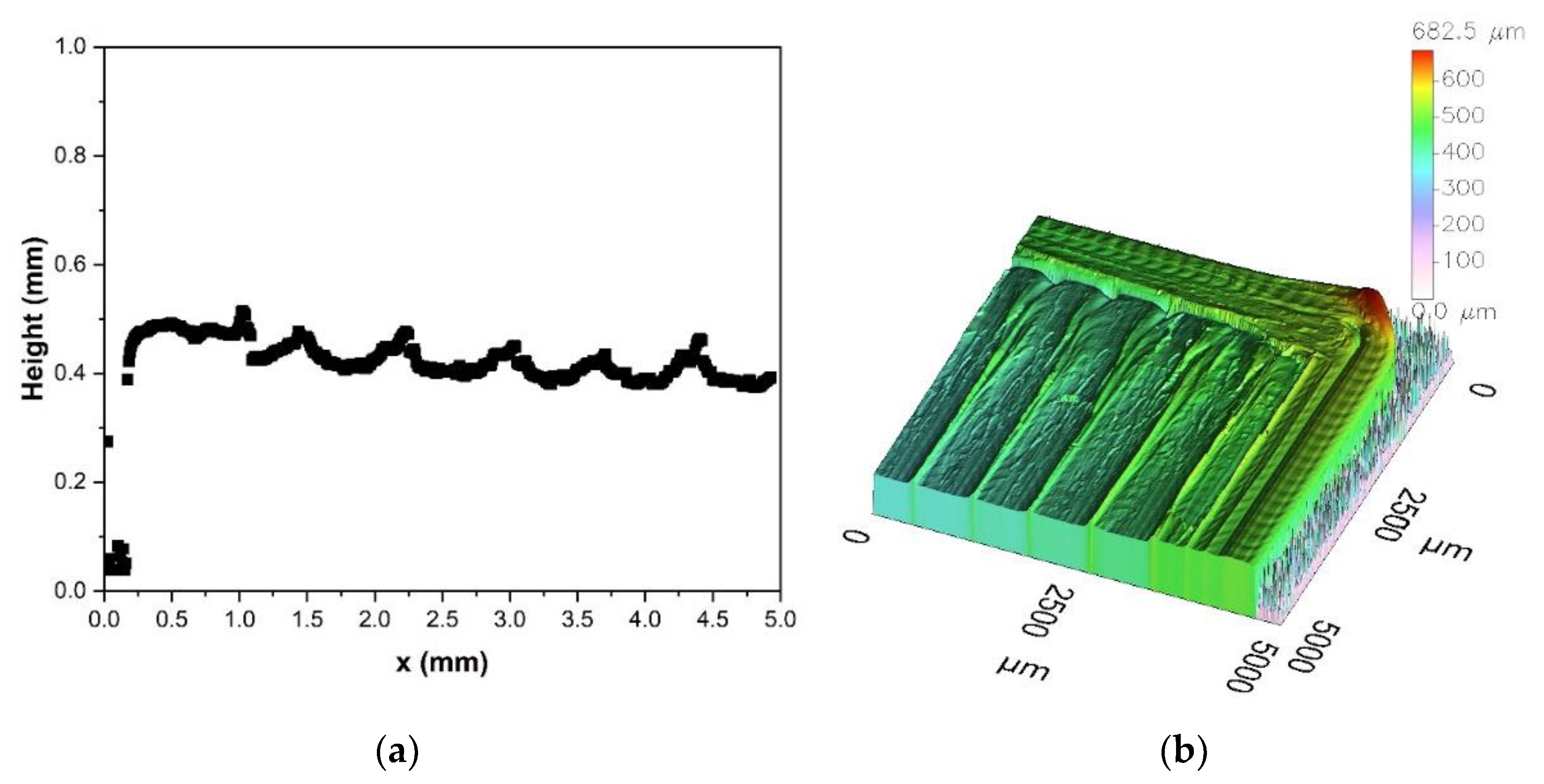

3.5. Process Validation

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yadav, A.; Srivastav, A.; Singh, A.; Mushtaque, M.D.; Khan, S.A.; Kumar, H.; Arora, P.K. Investigation on the materials used in additive manufacturing: A study. Mater. Today Proc. 2021, 43, 154–157. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef] [PubMed]

- Pazhamannil, R.V.; Govindan, P. Current state and future scope of additive manufacturing technologies via vat photopolymerization. Mater. Today Proc. 2021, 43, 130–136. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Lin, L.; Corker, J.; Fan, M. Overview of 3D additive manufacturing (AM) and corresponding AM composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106114. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, R.; Singh Chohan, J. Polymer matrix composites in 3D printing: A state of art review. Mater. Today Proc. 2020, 33, 1562–1567. [Google Scholar] [CrossRef]

- Quanjin, M.; Rejab, M.R.M.; Idris, M.S.; Kumar, N.M.; Abdullah, M.H.; Reddy, G.R. Recent 3D and 4D intelligent printing technologies: A comparative review and future perspective. Procedia Comput. Sci. 2020, 167, 1210–1219. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric composites for powder-based additive manufacturing: Materials and applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A review on the various processing parameters in FDM. Mater. Today Proc. 2021, 37, 509–514. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices. Polymers 2018, 10, 666. [Google Scholar] [CrossRef] [Green Version]

- Piotter, V.; Hanemann, T.; Heldele, R.; Mueller, T.; Plewa, K.; Ruh, A. Metal and Ceramic Parts fabricated by Microminiature powder injection molding. Int. J. Powder Metall. 2010, 46, 21–28. [Google Scholar]

- BASF. Ultrafuse Filament Portfolio. Available online: https://www.ultrafusefff.com (accessed on 8 April 2021).

- Hayek, K. Ceramic Injection Moulding: Binder innovations and Additive Manufacturing open up new opportunities. Powder Inject. Molding Int. 2018, 12, 67–72. [Google Scholar]

- Additive Manufacturing. Available online: https://www.ikts.fraunhofer.de/en/industrial_solutions/additive_manufacturing.html (accessed on 11 August 2021).

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [Green Version]

- Aramian, A.; Razavi, S.M.J.; Sadeghian, Z.; Berto, F. A review of additive manufacturing of cermets. Addit. Manuf. 2020, 33, 101130. [Google Scholar] [CrossRef]

- Li, T.; Gonzalez-Gutierrez, J.; Raguž, I.; Holzer, C.; Li, M.; Cheng, P.; Kitzmantel, M.; Shi, L.; Huang, L. Material extrusion additively manufactured alumina monolithic structures to improve the efficiency of plasma-catalytic oxidation of toluene. Addit. Manuf. 2021, 37, 101700. [Google Scholar] [CrossRef]

- Orlovská, M.; Chlup, Z.; Bača, L.; Janek, M.; Kitzmantel, M. Fracture and mechanical properties of lightweight alumina ceramics prepared by fused filament fabrication. J. Eur. Ceram. Soc. 2020, 40, 4837–4843. [Google Scholar] [CrossRef]

- Clemens, F.J.; Kerber, A. FDM/FFF an Alternative to CIM Manufacturing of Prototype and Small Quantities of Ceramic Part? Ceram Appl. 2020, 8, 27–31. [Google Scholar]

- Carloni, D.; Zhang, G.; Wu, Y. Transparent alumina ceramics fabricated by 3D printing and vacuum sintering. J. Eur. Ceram. Soc. 2021, 41, 781–791. [Google Scholar] [CrossRef]

- Noetzel, D.; Eickhoff, R.; Hanemann, T. Fused Filament Fabrication of Small Ceramic Components. Materials 2018, 11, 1463. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Noetzel, D.; Hanemann, T. New Feedstock System for Fused Filament Fabrication of Sintered Alumina Parts. Materials 2020, 13, 4461. [Google Scholar] [CrossRef]

- Eickenscheidt, M.; Langenmair, M.; Dbouk, A.; Noetzel, D.; Hanemann, T.; Stieglitz, T. 3D-Printed Hermetic Alumina Housings. Materials 2021, 14, 200. [Google Scholar] [CrossRef] [PubMed]

- Cano, S.; Gonzalez-Gutierrez, J.; Sapkota, J.; Spoerk, M.; Arbeiter, F.; Schuschnigg, S.; Holzer, C.; Kukla, C. Additive manufacturing of zirconia parts by fused filament fabrication and solvent debinding: Selection of binder formulation. Addit. Manuf. 2019, 26, 117–128. [Google Scholar] [CrossRef]

- Cano, S.; Lube, T.; Huber, P.; Gallego, A.; Naranjo, J.A.; Berges, C.; Schuschnigg, S.; Herranz, G.; Kukla, C.; Holzer, C.; et al. Influence of the Infill Orientation on the Properties of Zirconia Parts Produced by Fused Filament Fabrication. Materials 2020, 13, 3158. [Google Scholar] [CrossRef] [PubMed]

- Kataoka, Y.; Yokota, K. Fabrication of Three-dimensional Zirconia Ceramics by Material Extrusion. J. Soc. Powder Technol. Jpn. 2020, 57, 520–525. [Google Scholar] [CrossRef]

- Li, W.; Ghazanfari, A.; McMillon, D.; Scherff, A.; Leu, M.C.; Hilmas, G.E. Fabricating Zirconia Parts with Organic Support Material by the Ceramic On-Demand Extrusion Process. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017; pp. 605–615. [Google Scholar]

- He, Q.; Jiang, J.; Yang, X.; Zhang, L.; Zhou, Z.; Zhong, Y.; Shen, Z. Additive manufacturing of dense zirconia ceramics by fused deposition modeling via screw extrusion. J. Eur. Ceram. Soc. 2021, 41, 1033–1040. [Google Scholar] [CrossRef]

- Hadian, A.; Koch, L.; Koberg, P.; Sarraf, F.; Liersch, A.; Sebastian, T.; Clemens, F. Material Extrusion Based Additive Manufacturing of Large Zirconia Structures Using Filaments with Ethylene Vinyl Acetate Based Binder Composition. Addit. Manuf. 2021, 47, 102227. [Google Scholar] [CrossRef]

- Goh, G.D.; Neo, S.J.C.; Dikshit, V.; Yeong, W.Y. Quasi-static indentation and sound-absorbing properties of 3D printed sandwich core panels. J. Sandw. Struct. Mater. 2021. [Google Scholar] [CrossRef]

- Su, R.; Wen, J.; Su, Q.; Wiederoder, M.S.; Koester, S.J.; Uzarski, J.R.; McAlpine, M.C. 3D printed self-supporting elastomeric structures for multifunctional microfluidics. Sci. Adv. 2020, 6, eabc9846. [Google Scholar] [CrossRef]

- Bek, M.; Gonzalez-Gutierrez, J.; Kukla, C.; Pušnik Črešnar, K.; Maroh, B.; Slemenik Perše, L. Rheological Behaviour of Highly Filled Materials for Injection Moulding and Additive Manufacturing: Effect of Particle Material and Loading. Appl. Sci. 2020, 10, 7993. [Google Scholar] [CrossRef]

- Gloeckle, C.; Konkol, T.; Jacobs, O.; Limberg, W.; Ebel, T.; Handge, U.A. Processing of Highly Filled Polymer-Metal Feedstocks for Fused Filament Fabrication and the Production of Metallic Implants. Materials 2020, 13, 4413. [Google Scholar] [CrossRef]

- Mezger, T.G. The Rheology Handbook, 4th ed.; Vincentz Network: Hanover, Germany, 2014; ISBN 3-86630-650-4. [Google Scholar]

- Rueda, M.M.; Auscher, M.-C.; Fulchiron, R.; Périé, T.; Martin, G.; Sonntag, P.; Cassagnau, P. Rheology and applications of highly filled polymers: A review of current understanding. Prog. Polym. Sci. 2017, 66, 22–53. [Google Scholar] [CrossRef]

- Hanemann, T.; Honnef, K. Process chain development for the realization of zirconia microparts using composite reaction molding. Ceram. Int. 2009, 35, 269–275. [Google Scholar] [CrossRef]

- Hanemann, T.; Weber, O. Polymethylmethacrylate/polyethyleneglycol-based partially water soluble binder system for micro ceramic injection moulding. Microsyst. Technol. 2014, 20, 51–58. [Google Scholar] [CrossRef]

- Hanemann, T.; Weber, O. Ceramic injection moulding using a partially water-soluble binder system: Effect of back-bone polymers on the process. In Advanced Processing and Manufacturing Technologies for Structural and Multifunctional Materials VI; Ihji, T., Singh, M., Halbig, M., Mathur, S., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 52–61. [Google Scholar]

- Hanemann, T.; Weber, O. Green-conscious ceramic injection moulding. In Advanced Processing and Manufacturing Technologies for Structural and Multifunctional Materials VI; Ihji, T., Singh, M., Halbig, M., Mathur, S., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 63–71. [Google Scholar]

- Ruh, A.; Piotter, V.; Plewa, K.; Ritzhaupt-Kleissl, H.-J.; Haußelt, J. Studies on size accuracy of microgear wheels produced by powder injection molding of zirconia feedstocks. Int. J. Adv. Manuf. Technol. 2011, 58, 1051–1059. [Google Scholar] [CrossRef]

- Ruh, A.; Hanemann, T.; Heldele, R.; Piotter, V.; Ritzhaupt-Kleissl, H.-J.; Hausselt, J. Development of Two-Component Micropowder Injection Molding (2C MicroPIM): Characteristics of Applicable Materials. Int. J. Appl. Ceram. Technol. 2011, 8, 194–202. [Google Scholar] [CrossRef]

- Mei, X.-Y.; Zhou, Y.-G.; Sun, H.-L.; Dong, B.-B.; Liu, C.-T.; Turng, L.-S. Evaluating the gas-laden ability of polymer melt under atmospheric conditions using a modified torque rheometer. J. Cell. Plast. 2021. [Google Scholar] [CrossRef]

- Hanemann, T.; Heldele, R. Modern Alchemy: Ceramic Feedstock Optimization by Surfactant Screening. CFI Ceram. Forum Int. 2010, 87, E38–E40. [Google Scholar]

- Gorjan, L.; Galusca, C.; Sami, M.; Sebastian, T.; Clemens, F. Effect of stearic acid on rheological properties and printability of ethylene vinyl acetate based feedstocks for fused filament fabrication of alumina. Addit. Manuf. 2020, 36, 101391. [Google Scholar] [CrossRef]

- Tseng, W.J.; Liu, D.-M.; Hsu, C.-K. Influence of stearic acid on suspension structure and green microstructure of injection-molded zirconia ceramics. Ceram. Int. 1999, 25, 191–195. [Google Scholar] [CrossRef]

- Auscher, M.C.; Fulchiron, R.; Fougerouse, N.; Périé, T.; Cassagnau, P. Zirconia based feedstocks: Influence of particle surface modification on the rheological properties. Ceram. Int. 2017, 43, 16950–16956. [Google Scholar] [CrossRef]

- Nötzel, D.; Hanemann, T.; Eickhoff, R. Charakterisierung additiv gefertigter keramischer Bauteile via FFF-Verfahren. Keram. Z. 2019, 6, 56–61. [Google Scholar] [CrossRef]

- Go, J.; Schiffres, S.N.; Stevens, A.G.; Hart, A. Rate limits of additive manufacturing by fused filament fabrication and guidelines for high-throughput system design. Addit. Manuf. 2017, 16, 1–11. [Google Scholar] [CrossRef]

- Barnes, H.A. A Review of The Rheology of Filled Viscoelastic Systems: Rheology Reviews. Br. Soc. Rheol. 2003, 1–36, Edited DM Binding & K Walters. [Google Scholar]

- Venkataraman, N.; Rangarajan, S.; Matthewson, M.J.; Harper, B.; Safari, A.; Danforth, S.C.; Wu, G.; Langrana, N.; Guceri, S.; Yardimci, A. Feedstock material property—Process relationships in fused deposition of ceramics (FDC). Rapid Prototyp. J. 2000, 6, 244–253. [Google Scholar] [CrossRef]

- Greeff, G.P.; Schilling, M. Closed loop control of slippage during filament transport in molten material extrusion. Addit. Manuf. 2017, 14, 31–38. [Google Scholar] [CrossRef]

- Handge, U.A.; Wolff, M.F.H.; Abetz, V.; Heinrich, S. Viscoelastic and dielectric properties of composites of poly(vinyl butyral) and alumina particles with a high filling degree. Polymer 2016, 82, 337–348. [Google Scholar] [CrossRef] [Green Version]

- Rueda, M.M.; Fulchiron, R.; Martin, G.; Cassagnau, P. Rheology of polypropylene filled with short-glass fibers: From low to concentrated filled composites. Eur. Polym. J. 2017, 93, 167–191. [Google Scholar] [CrossRef]

| Vendor | Grade | d10 (µm) | d50 (µm) | d90 (µm) | Specific Surface Area (m²/g) | Density (g/cm³) |

|---|---|---|---|---|---|---|

| Tosoh | TZ-3YS-E | 0.34 | 1.04 | 2.85 | 6.6 | 6.01 |

| Step/Temperature (°C) | Rate (°C/min) | Dwell Time @ Temperature (min) |

|---|---|---|

| RT → 120 | 0.2 | 120 |

| 180 | 0.2 | 120 |

| 250 | 0.2 | 120 |

| 500 | 0.2 | 60 |

| RT | n.a. | n.a. |

| Step/Temperature (°C) | Rate (°C/min) | Dwell Time @ Temperature (min) |

|---|---|---|

| 25–1450 | 5 | 180 |

| 1450–25 | 5 | n.a. |

| Feature | Zirconia |

|---|---|

| Maximum solid load of FFF-printable feedstock | 50 vol% |

| Average density of sintered parts | 5.96 ± 0.11 g/cm3 |

| Average shrinkage in x,y,z directions | x: 20.7%; y: 20.9%; z: 21.3% |

| Max. ceramic part density | 99.2% Th |

| Average smallest structural detail (z-axes) | 78 ± 8 µm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nötzel, D.; Eickhoff, R.; Pfeifer, C.; Hanemann, T. Printing of Zirconia Parts via Fused Filament Fabrication. Materials 2021, 14, 5467. https://doi.org/10.3390/ma14195467

Nötzel D, Eickhoff R, Pfeifer C, Hanemann T. Printing of Zirconia Parts via Fused Filament Fabrication. Materials. 2021; 14(19):5467. https://doi.org/10.3390/ma14195467

Chicago/Turabian StyleNötzel, Dorit, Ralf Eickhoff, Christoph Pfeifer, and Thomas Hanemann. 2021. "Printing of Zirconia Parts via Fused Filament Fabrication" Materials 14, no. 19: 5467. https://doi.org/10.3390/ma14195467

APA StyleNötzel, D., Eickhoff, R., Pfeifer, C., & Hanemann, T. (2021). Printing of Zirconia Parts via Fused Filament Fabrication. Materials, 14(19), 5467. https://doi.org/10.3390/ma14195467