Structural Analysis of Low Defect Ammonothermally Grown GaN Wafers by Borrmann Effect X-ray Topography

Abstract

:1. Introduction

2. Experimental

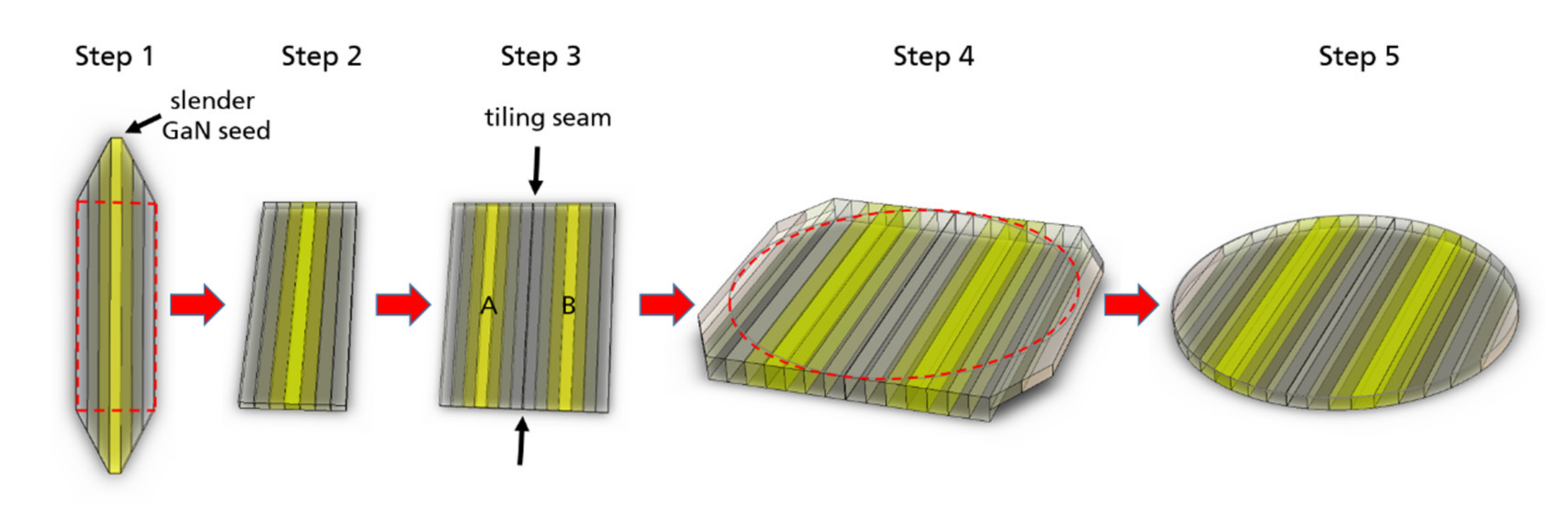

2.1. GaN Crystal Growth and Wafer Preparation

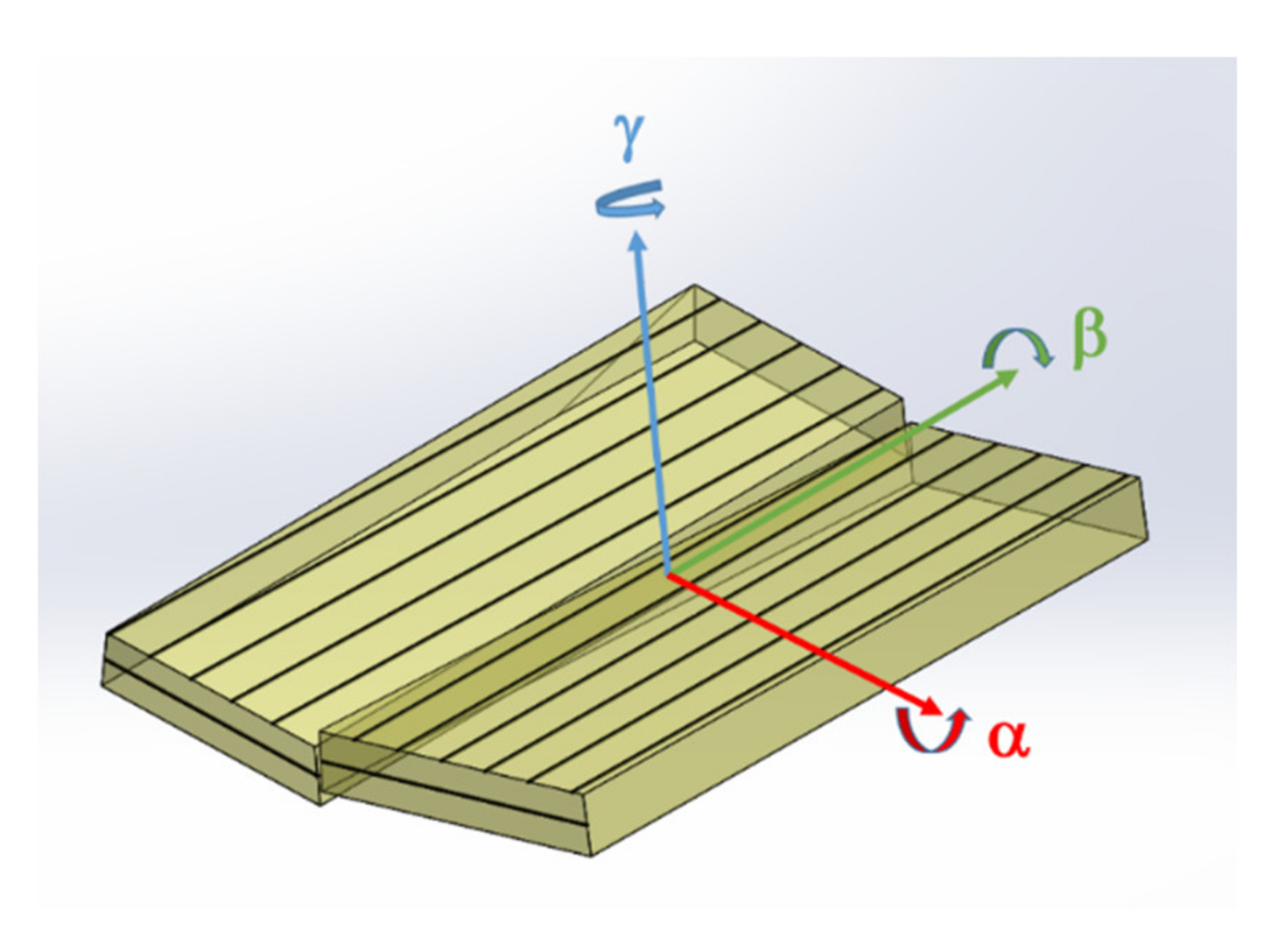

2.2. Structural Analysis of the GaN Wafers

3. Results

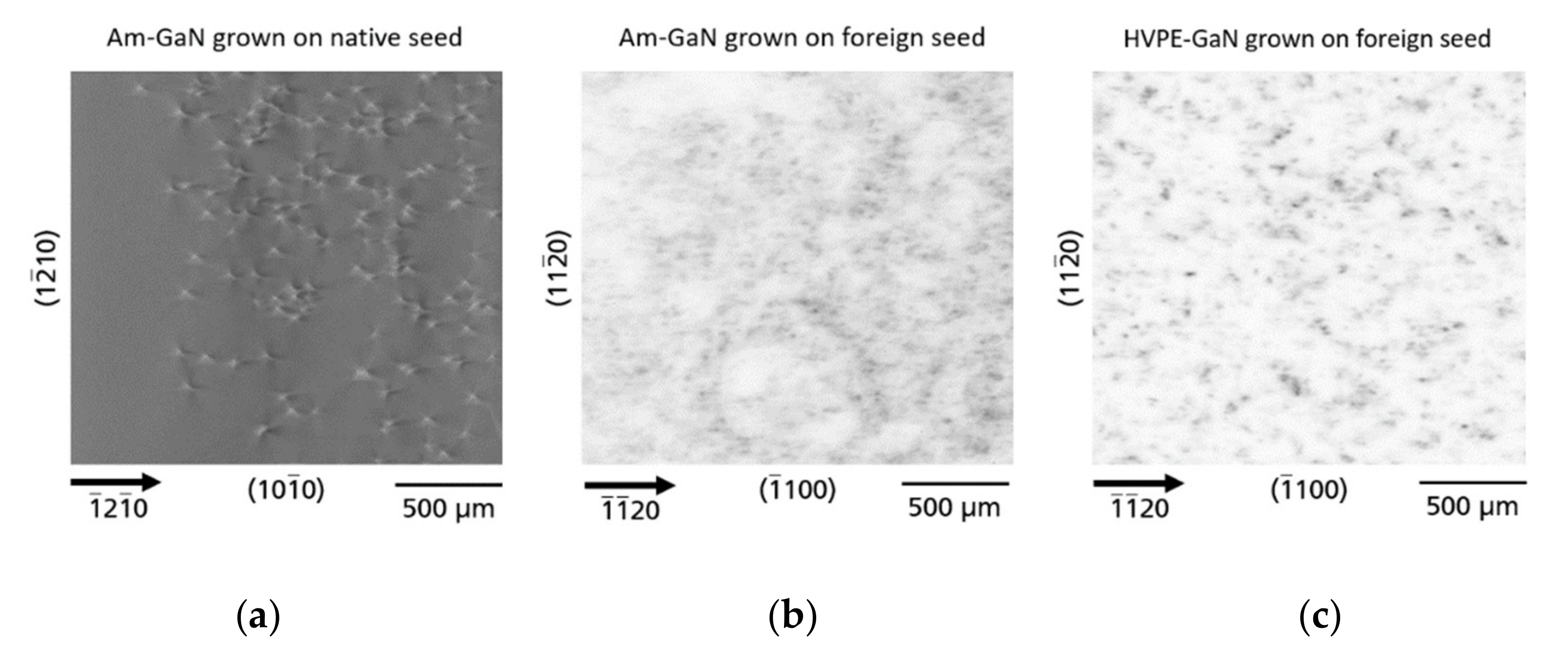

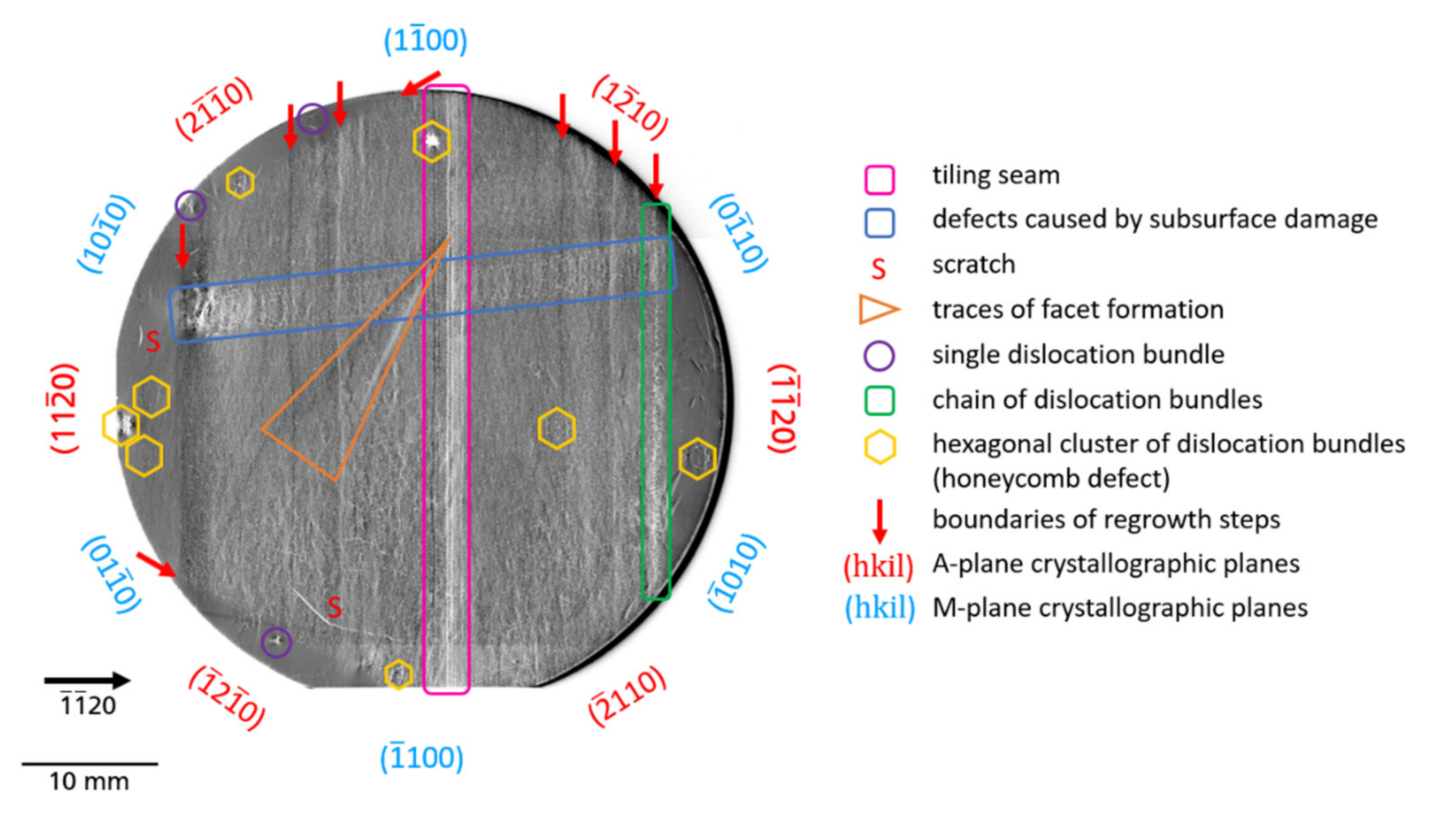

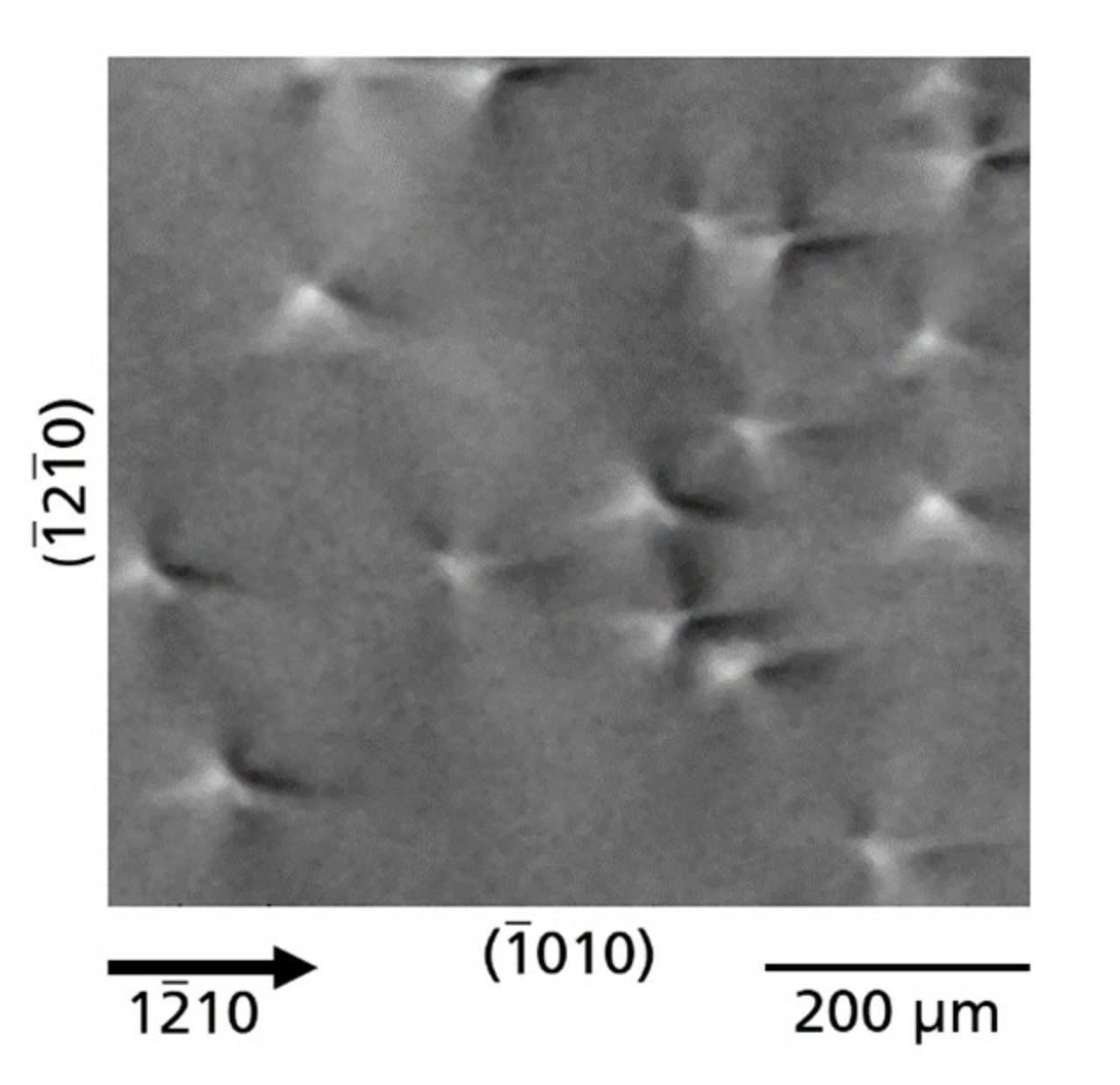

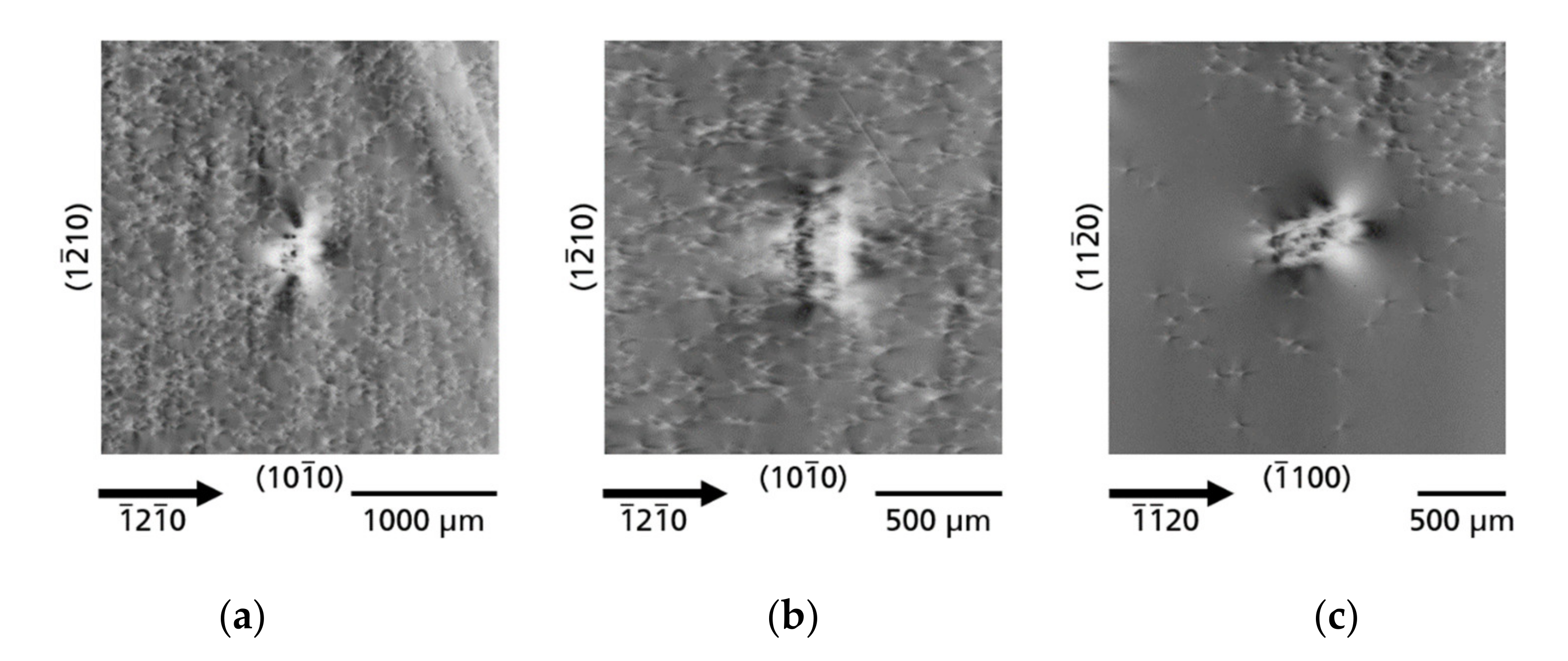

3.1. Microscopic Defects

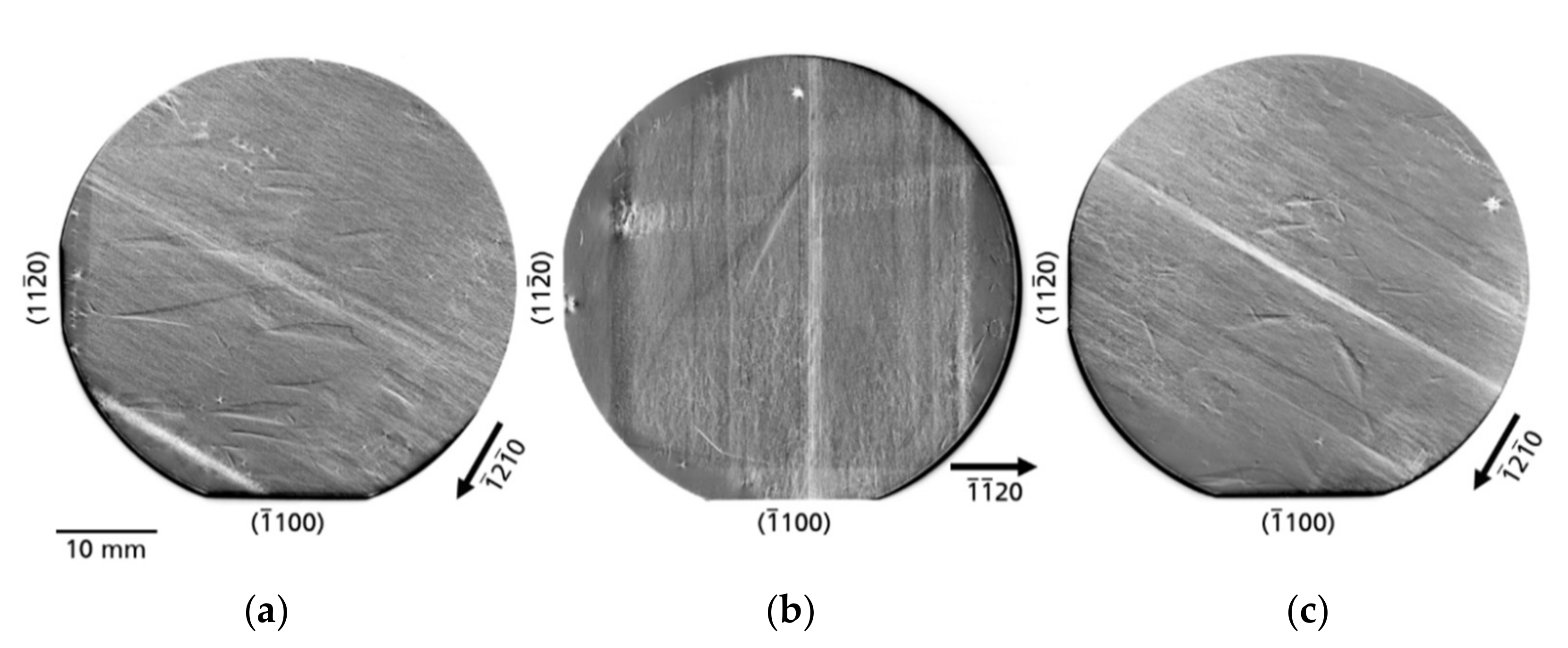

3.2. Macroscopic Defects

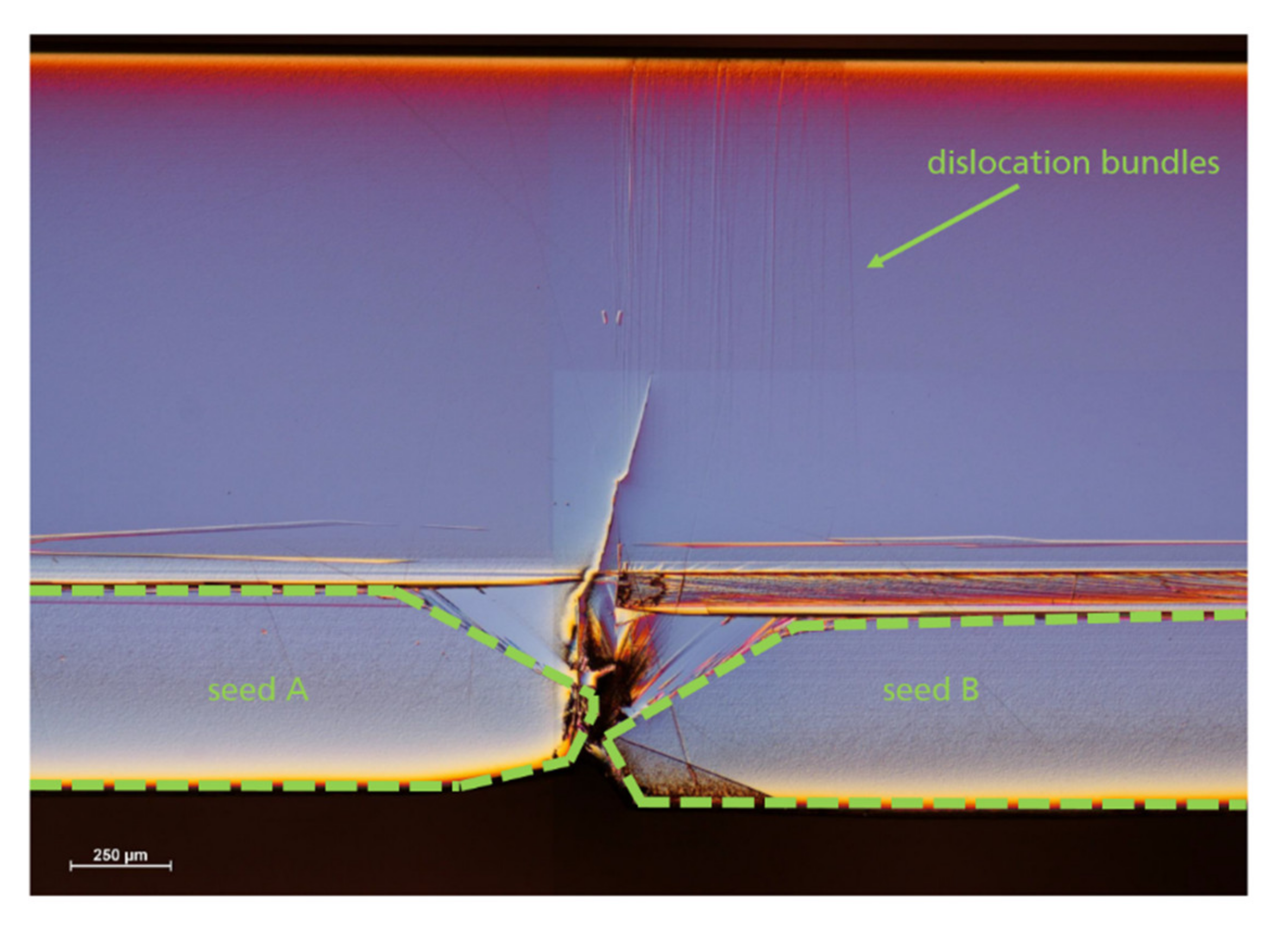

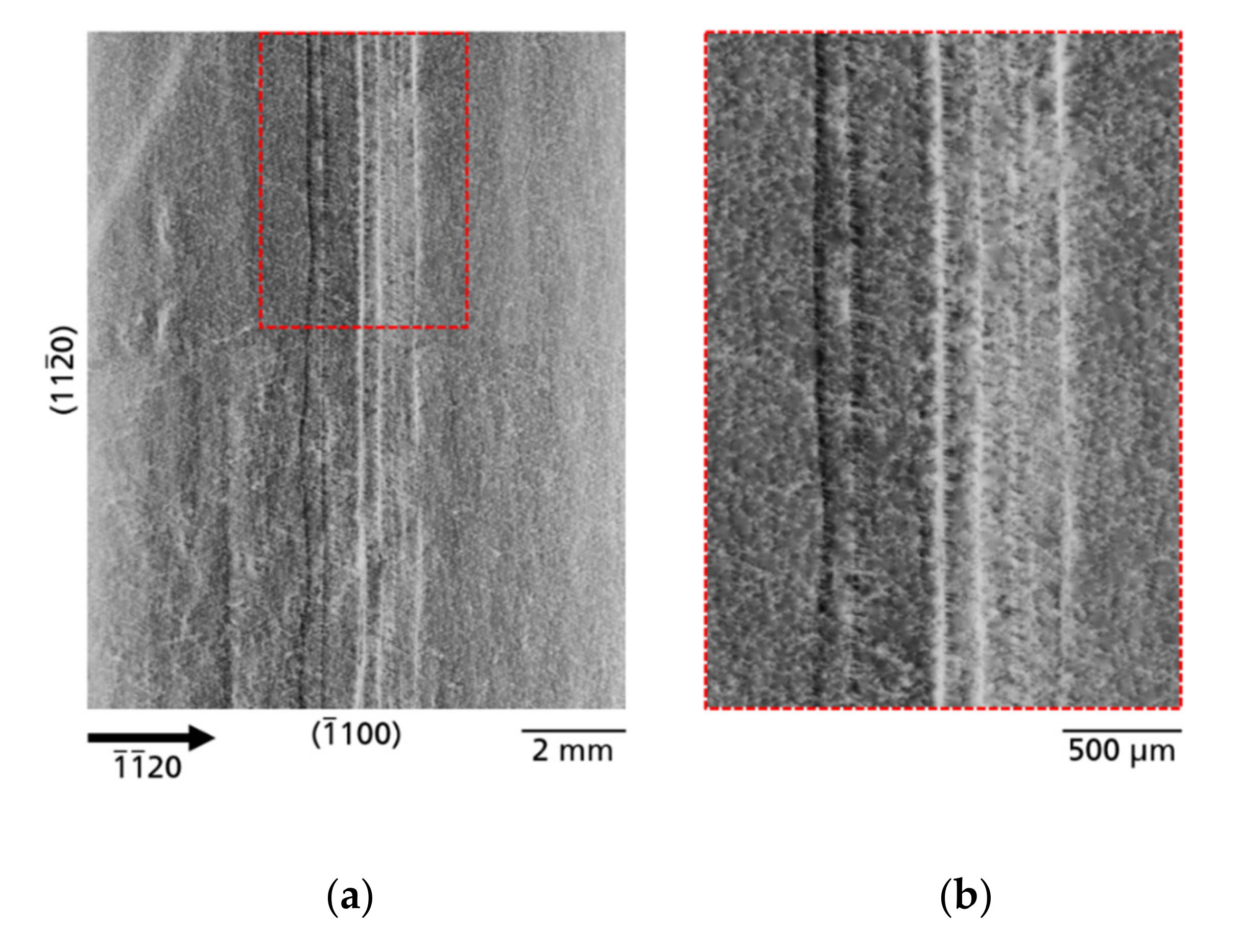

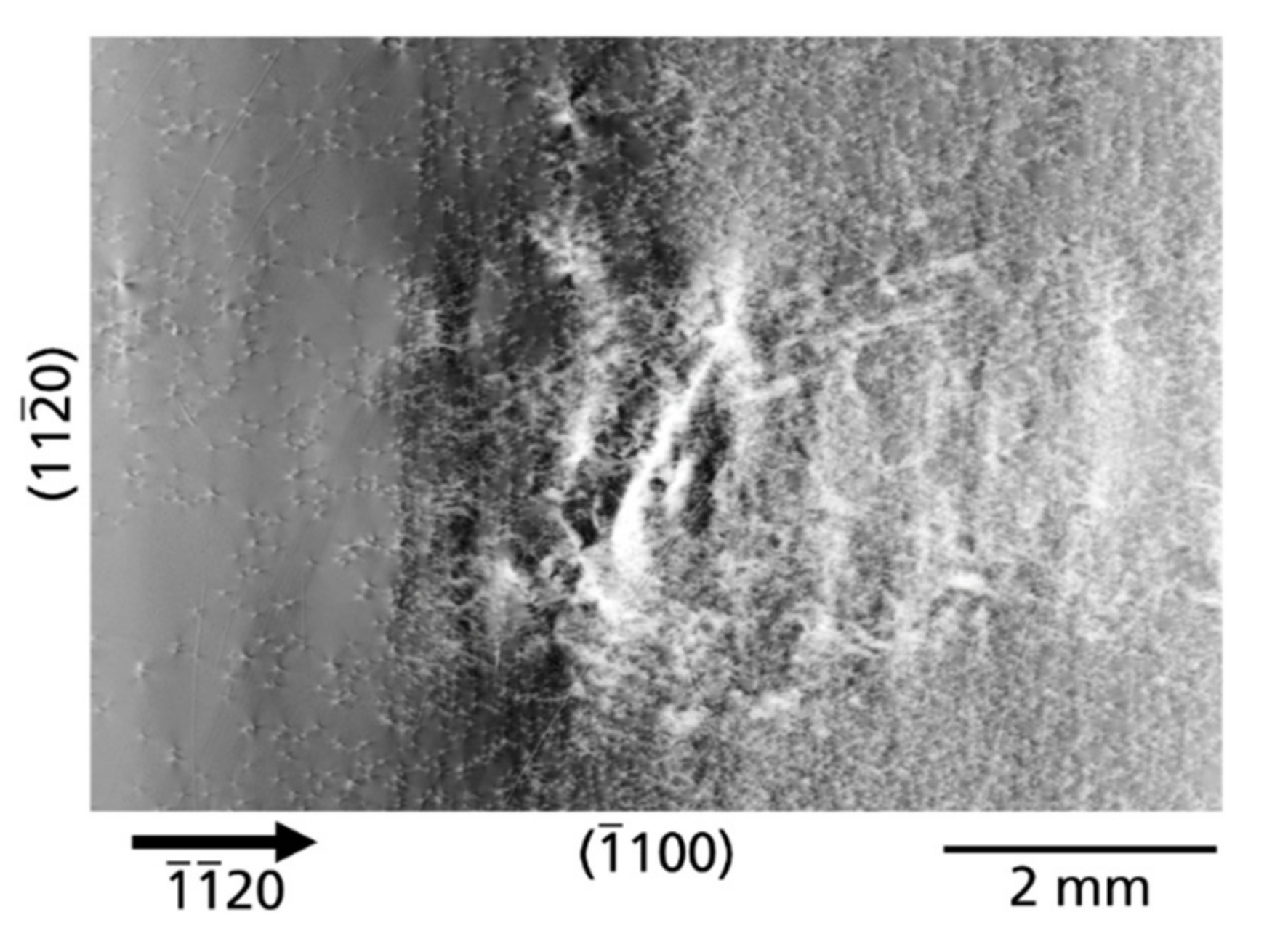

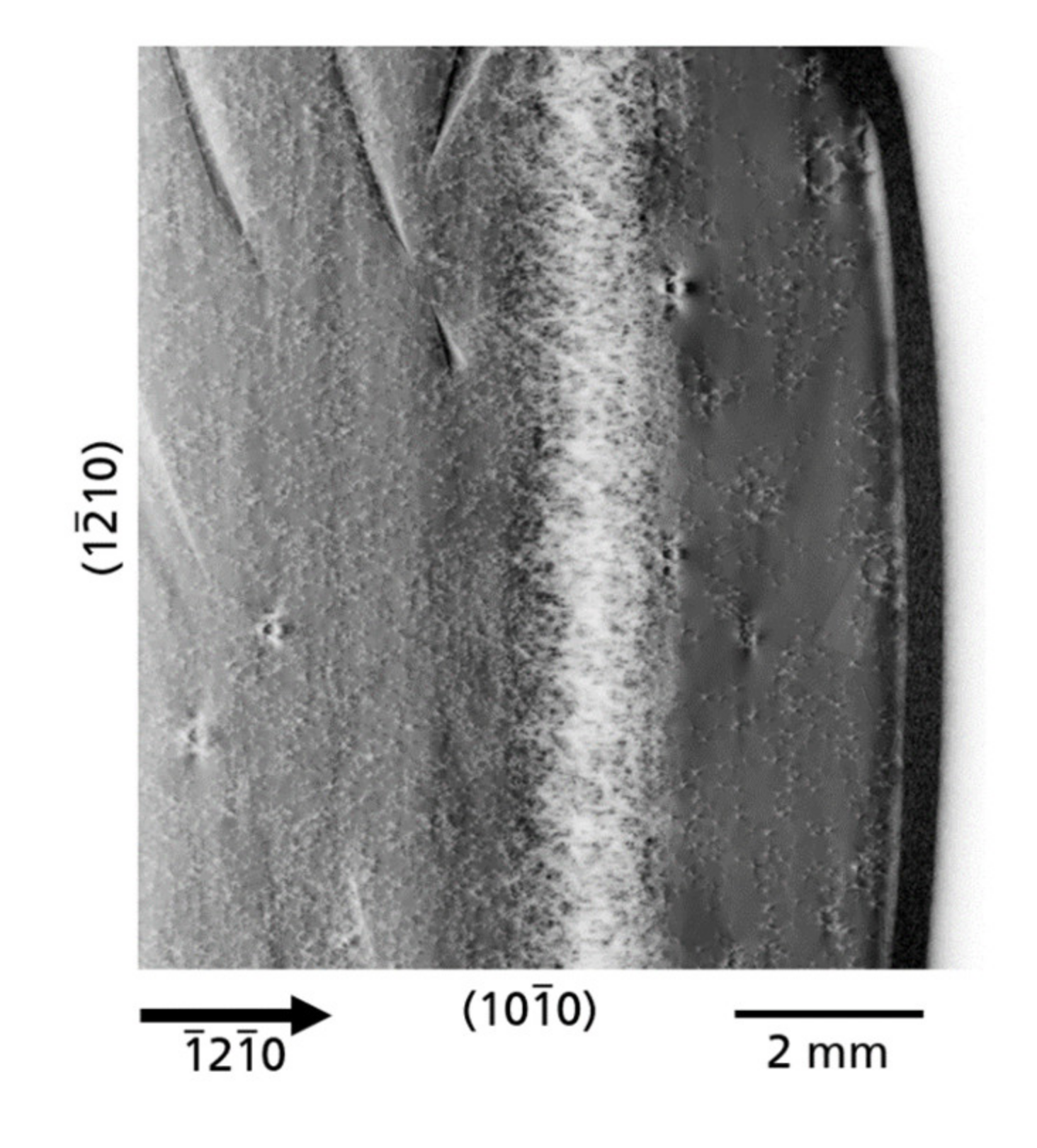

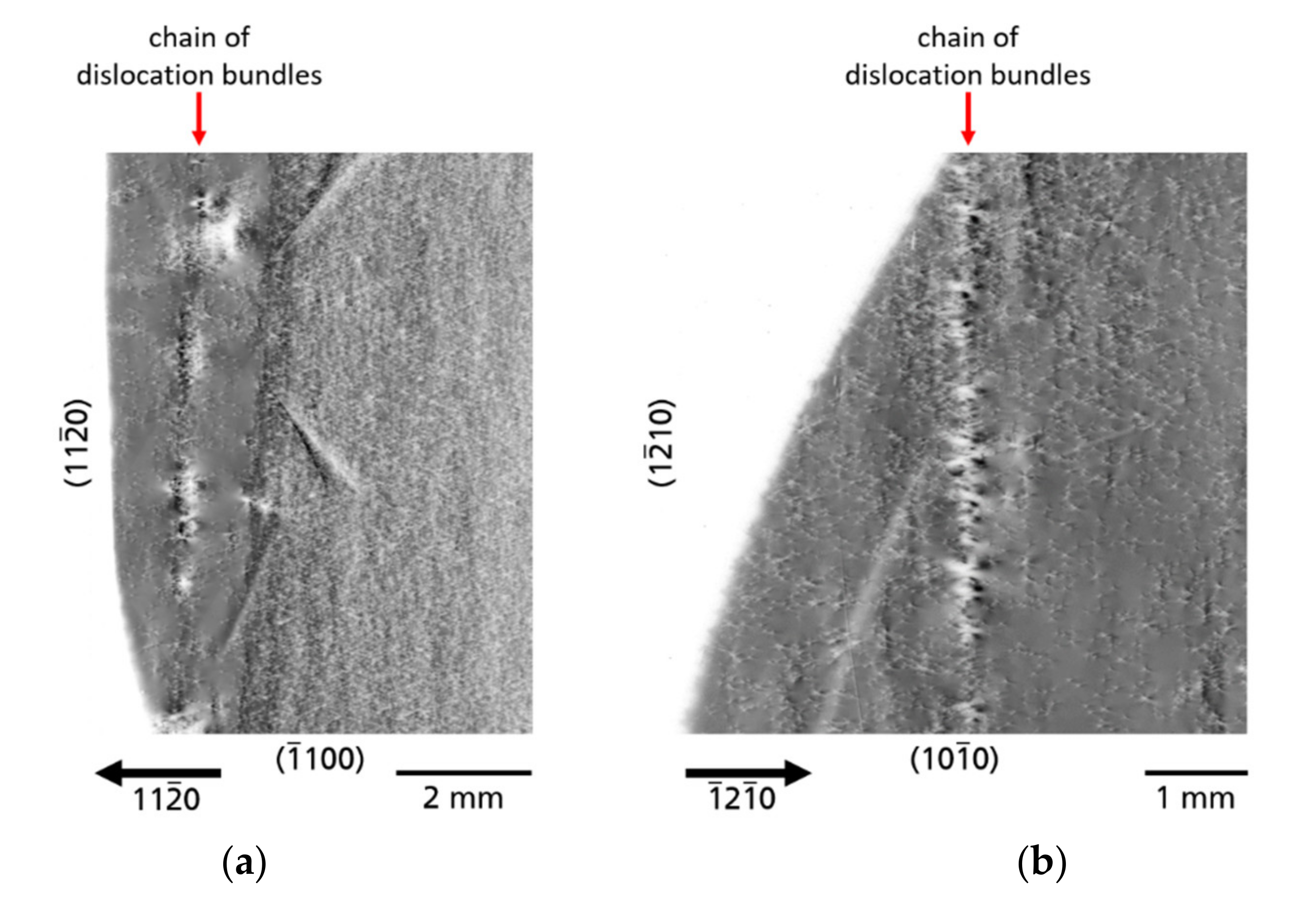

3.2.1. Defects Related to Seed/Crystal Preparation

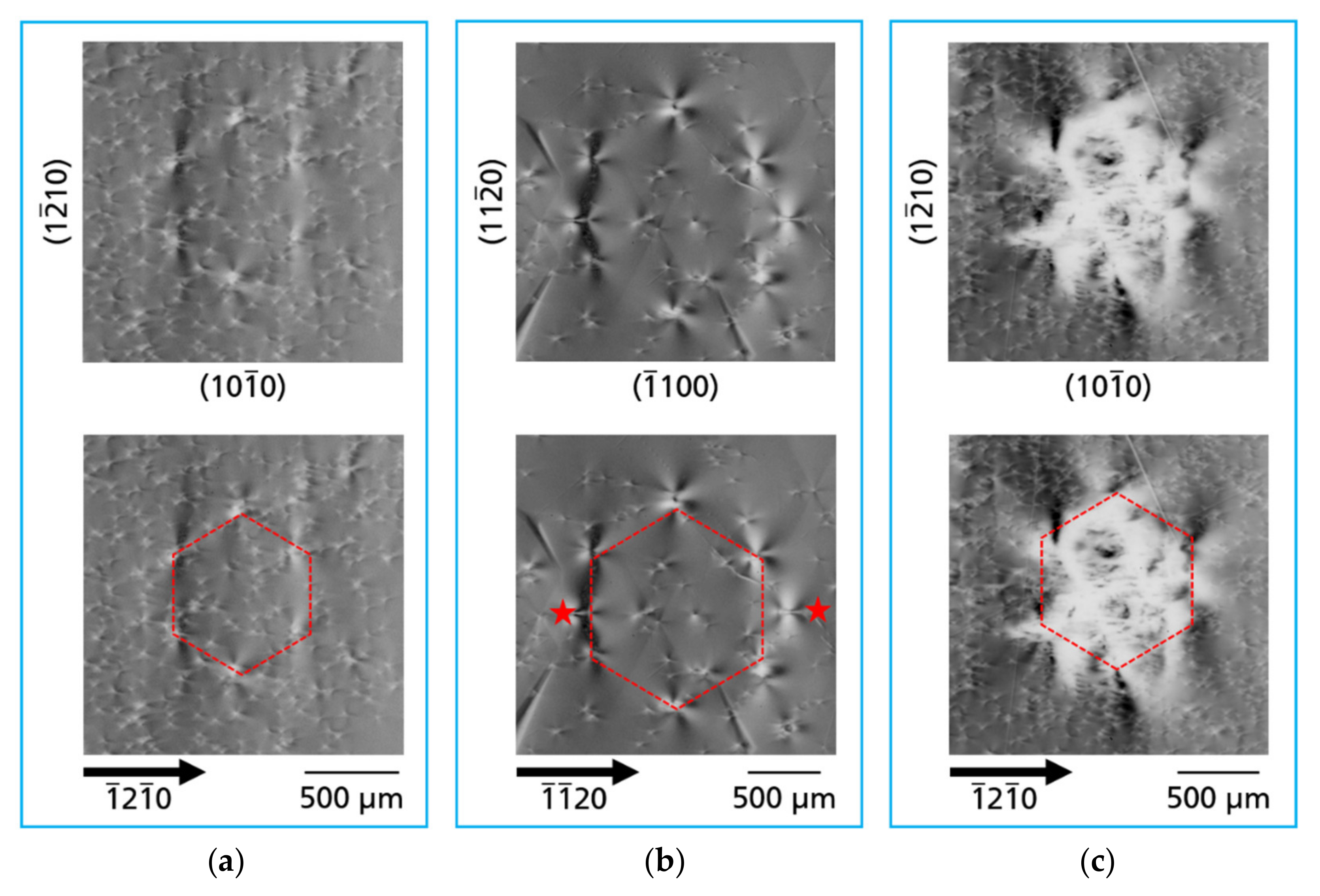

3.2.2. Defects Related to Growth

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Würfl, J. GaN High-Voltage Power Devices. In Gallium Nitride (GaN); Medjdoub, F., Ed.; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2016; pp. 1–44. [Google Scholar]

- Zhang, Y.; Zubair, A.; Liu, Z.; Xiao, M.; Perozek, J.A.; Ma, Y.; Palacios, T. GaN FinFETs and trigate devices for power and RF applications: Review and perspective. Semicond. Sci. Technol. 2021, 36, 054001. [Google Scholar] [CrossRef]

- Bojarska-Cieślińska, A.; Marona, Ł.; Smalc-Koziorowska, J.; Grzanka, S.; Weyher, J.; Schiavon, D.; Perlin, P. Role of dislocations in nitride laser diodes with different indium content. Sci. Rep. 2021, 11, 21. [Google Scholar] [CrossRef] [PubMed]

- Bockowski, M.; Iwinska, M.; Amilusik, M.; Fijalkowski, M.; Lucznik, B.; Sochacki, T. Challenges and future perspectives in HVPE-GaN growth on ammonothermal GaN seeds. Semicond. Sci. Technol. 2016, 31, 093002. [Google Scholar] [CrossRef]

- Takino, J.; Sumi, T.; Okayama, Y.; Nobuoka, M.; Kitamoto, A.; Imanishi, M.; Yoshimura, M.; Mori, Y. Development of a 2-inch GaN wafer by using the oxide vapor phase epitaxy method. Jpn. J. Appl. Phys. 2019, 58, SC1043. [Google Scholar] [CrossRef]

- Nakamura, D.; Kimura, T. Ultrahigh-yield growth of GaN via halogen-free vapor-phase epitaxy. Appl. Phys. Express 2018, 11, 065502. [Google Scholar] [CrossRef]

- Grabianska, K.; Jaroszynski, P.; Sidor, A.; Bockowski, M.; Iwinska, M. GaN Single Crystalline Substrates by Ammonothermal and HVPE Methods for Electronic Devices. Electronics 2020, 9, 1342. [Google Scholar] [CrossRef]

- Mikawa, Y.; Ishinabe, T.; Kagamitani, Y.; Mochizuki, T.; Ikeda, H.; Iso, K.; Takahashi, T.; Kubota, K.; Enatsu, Y.; Tsukada, Y.; et al. Recent progress of large size and low dislocation bulk GaN growth. In Proceedings of the SPIE Photonics West 2020, Proc. SPIE Vol. 11280, Gallium Nitride Materials and Devices XV, San Francisco, CA, USA, 16 February 2020. [Google Scholar] [CrossRef]

- Mori, Y.; Imade, M.; Maruyama, M.; Yoshimura, M.; Yamane, H.; Kawamura, F.; Kawamura, T. Bulk Crystal Growth: Basic Techniques, and Growth Mechanisms and Dynamics. In Handbook of Crystal Growth, 2nd ed.; Rudolph, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 505–533. [Google Scholar]

- Kucharski, R.; Sochacki, T.; Lucznik, B.; Bockowski, M. Growth of bulk GaN crystals. J. Appl. Phys. 2020, 128, 050902. [Google Scholar] [CrossRef]

- Grabianska, K.; Kucharski, R.; Puchalski, A.; Sochacki, T.; Bockowski, M. Recent progress in basic ammonothermal GaN crystal growth. J. Cryst. Growth 2020, 547, 125805. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, H.; Ailihumaer, T.; Raghothamachar, B.; Dudley, M. X-ray Topography Characterization of GaN Substrates Used for Power Electronic Devices. J. Electron. Mater. 2021, 50, 2981–2989. [Google Scholar] [CrossRef]

- UNIPRESS. Available online: http://www.unipress.waw.pl/growth/index.php/ammono-gan-wafers-sales (accessed on 7 July 2021).

- Kaun, S.W.; Burke, P.G.; Wong, M.H.; Kyle, E.C.H.; Mishra, U.K.; Speck, J.S. Effect of dislocations on electron mobility in AlGaN/GaN and AlGaN/AlN/GaN heterostructures. Appl. Phys. Lett. 2012, 101, 262102. [Google Scholar] [CrossRef]

- Zhang, Y.; Wong, H.Y.; Sun, M.; Joglekar, S.; Yu, L.; Braga, N.A.; Mickevicius, R.V.; Palacios, T. Design space and origin of off-state leakage in GaN vertical power diodes. In Proceedings of the 2015 IEEE International Electron Devices Meeting (IEDM), Washington, DC, USA, 7–9 December 2015; pp. 35.1.1–35.1.4. [Google Scholar] [CrossRef]

- Weyher, J.L.; Ashraf, H.; Hageman, P.R. Reduction of dislocation density in epitaxial GaN layers by overgrowth of defect-related etch pits. Appl. Phys. Lett. 2009, 95, 031913. [Google Scholar] [CrossRef]

- Klapper, H.; Smolsky, I.L. Borrmann-Effect Topography of Thick Potassium Dihydrogen Phosphate (KDP) Crystals. Cryst. Res. Technol. 1998, 33, 605–611. [Google Scholar] [CrossRef]

- Authier, A. Dynamical Theory of X-ray Diffraction, 2nd ed.; Oxford University Press: Oxford, UK, 2003. [Google Scholar]

- Borrmann, G. Die Absorption von Röntgenstrahlen im Fall der Interferenz. Z. Physik 1950, 127, 297–323. [Google Scholar] [CrossRef]

- Borrmann, G. Der kleinste Absorptionskoeffizient interferierender Röntgenstrahlung. Z. Krist. 1954, 106, 109–121. [Google Scholar] [CrossRef]

- Borrmann, G.; Hartwig, W.; Irmler, H. Schatten von Versetzungslinien im Röntgen-Diagramm. Z. Naturforschg. A 1958, 13, 423–425. [Google Scholar] [CrossRef]

- James, R.W. The Dynamical Theory of X-ray Diffraction. In Solid State Physics; Seitz, F., Turnbull, D., Eds.; Academic Press: New York, NY, USA, 1963; Volume 15, pp. 53–220. [Google Scholar]

- Pinsker, Z.G. Dynamical Scattering of X-rays in Crystals; Springer Series in Solid State Sciences; Springer: Berlin/Heidelberg, Germany, 1978. [Google Scholar]

- Okkerse, B. Anomalous transmission of X-rays in germanium. Philips Res. Rpts. 1962, 17, 464–478. [Google Scholar]

- Builov, A.N.; Danil’chuk, L.N. Edge dislocations with large burgers vector in sphalerite crystals. Tech. Phys. Lett. 2002, 28, 762–764. [Google Scholar] [CrossRef]

- Möck, P. Analysis of thermal-treatment-induced dislocation bundles in GaAs wafers by means of X-ray transmission topography and complementary methods. J. Appl. Cryst. 2001, 34, 65–75. [Google Scholar] [CrossRef]

- Yildirim, C.; Gout, E.; Pagot, A.; Tran Thi Caliste, T.N.; Baruchel, J.; Brellier, D.; Ballet, P. Bragg Diffraction Imaging of CdZnTe Single Crystals. J. Electron. Mater. 2020, 49, 4550–4556. [Google Scholar] [CrossRef]

- Okunev, A.O.; Verozubova, G.A.; Trukhanov, E.M.; Dzjuba, I.V.; Galtier, P.R.J.; Said Hassani, S.A. Study of structural defects in ZnGeP2 crystals by X-ray topography based on the Borrmann effect. J. Appl. Cryst. 2009, 42, 994–998. [Google Scholar] [CrossRef]

- Okunev, A.O.; Verozubova, G.A. X-ray topography contrast from edge dislocations in ZnGeP2 single crystals. J. Appl. Cryst. 2015, 48, 1228–1233. [Google Scholar] [CrossRef]

- Lei, Z.; Okunev, A.; Zhu, C.; Verozubova, G.; Yang, C. Low-angle boundaries in ZnGeP2 single crystals. J. Appl. Cryst. 2018, 51, 361–367. [Google Scholar] [CrossRef]

- Doradziński, R.; Dwiliński, R.; Garczyński, J.; Sierzputowski, L.P.; Kanbara, Y. Ammonothermal Growth of GaN Under Ammono-Basic Conditions. In Technology of Gallium Nitride Crystal Growth; Ehrentraut, D., Meissner, E., Bockowski, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 137–160. [Google Scholar]

- Hashimoto, T.; Nakamura, S. A Pathway Toward Bulk Growth of GaN by the Ammonothermal Method. In Technology of Gallium Nitride Crystal Growth; Ehrentraut, D., Meissner, E., Bockowski, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 161–182. [Google Scholar]

- Lang, A.R. The projection topograph: A new method in X-ray diffraction microradiography. Acta Cryst. 1959, 12, 249–250. [Google Scholar] [CrossRef]

- Rozgonyi, G.A.; Miller, D.C. X-ray characterization of stresses and defects in thin films and substrates. Thin Solid Films 1976, 31, 185–216. [Google Scholar] [CrossRef]

- Sintonen, S.; Rudziński, M.; Suihkonen, S.; Jussila, H.; Knetzger, M.; Meissner, E.; Danilewsky, A.; Tuomi, T.O.; Lipsanen, H. Synchrotron radiation x-ray topography and defect selective etching analysis of threading dislocations in GaN. J. Appl. Phys. 2014, 116, 083504. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Ishikawa, Y.; Sugawara, Y.; Takahashi, Y.; Hirano, K. Observation of Threading Dislocations in Ammonothermal Gallium Nitride Single Crystal Using Synchrotron X-ray Topography. J. Electron. Mater. 2018, 47, 5007–5012. [Google Scholar] [CrossRef]

- Raghothamachar, B.; Liu, Y.; Peng, H.; Ailihumaer, T.; Dudley, M.; Shahedipour-Sandvik, F.S.; Jones, K.A.; Armstrong, A.; Allerman, A.A.; Han, J.; et al. X-ray topography characterization of gallium nitride substrates for power device development. J. Cryst. Growth 2020, 544, 125709. [Google Scholar] [CrossRef]

- Klapper, H. Defects in Non-metal Crystals. In Characterization of Crystal Growth Defects by X-Ray Methods, Tanner, B.K., Bowen, D.K., Eds.; Plenum Press: New York, NY, USA, 1980; pp. 133–160. [Google Scholar]

- Sintonen, S.; Wahl, S.; Richter, S.; Meyer, S.; Suihkonen, S.; Schulz, T.; Irmscher, K.; Danilewsky, A.; Tuomi, T.; Stankiewicz, R.; et al. Evolution of impurity incorporation during ammonothermal growth of GaN. J. Cryst. Growth 2016, 456, 51–57. [Google Scholar] [CrossRef]

- Prokhorov, I.A.; Serebryakov, Y.A.; Zakharov, B.G.; Bezbakh, I.Z.; Ratnikov, V.V.; Shulpina, I.L. Growth striations and dislocations in highly doped semiconductor single crystals. J. Cryst. Growth 2008, 310, 5477–5482. [Google Scholar] [CrossRef]

- Kirste, L.; Tran Caliste, T.N.; Weyher, J.L.; Bockowski, M.; Baruchel, J. Analysis of defect clusters with honeycomb arrangement in ammonothermal GaN crystals. J. Appl. Crystallogr. (paper in preparation).

- Schimmel, S.; Kobelt, I.; Heinlein, L.; Kimmel, A.-C.L.; Steigerwald, T.G.; Schlücker, E.; Wellmann, P. Flow Stability, Convective Heat Transfer and Chemical Reactions in Ammonothermal Autoclaves—Insights by In Situ Measurements of Fluid Temperatures. Crystals 2020, 10, 723. [Google Scholar] [CrossRef]

- Kirste, L.; Danilewsky, A.N.; Sochacki, T.; Köhler, K.; Zajac, M.; Kucharski, R.; Boćkowski, M.; McNally, P.J. Synchrotron White-Beam X-Ray Topography Analysis of the Defect Structure of HVPE-GaN Substrates. ECS J. Solid State Sci. Technol. 2015, 4, P324–P330. [Google Scholar] [CrossRef] [Green Version]

- Letts, E.; Key, D.; Hashimoto, T. Reduction of crack density in ammonothermal bulk GaN growth. J. Cryst. Growth 2016, 456, 27–32. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirste, L.; Grabianska, K.; Kucharski, R.; Sochacki, T.; Lucznik, B.; Bockowski, M. Structural Analysis of Low Defect Ammonothermally Grown GaN Wafers by Borrmann Effect X-ray Topography. Materials 2021, 14, 5472. https://doi.org/10.3390/ma14195472

Kirste L, Grabianska K, Kucharski R, Sochacki T, Lucznik B, Bockowski M. Structural Analysis of Low Defect Ammonothermally Grown GaN Wafers by Borrmann Effect X-ray Topography. Materials. 2021; 14(19):5472. https://doi.org/10.3390/ma14195472

Chicago/Turabian StyleKirste, Lutz, Karolina Grabianska, Robert Kucharski, Tomasz Sochacki, Boleslaw Lucznik, and Michal Bockowski. 2021. "Structural Analysis of Low Defect Ammonothermally Grown GaN Wafers by Borrmann Effect X-ray Topography" Materials 14, no. 19: 5472. https://doi.org/10.3390/ma14195472

APA StyleKirste, L., Grabianska, K., Kucharski, R., Sochacki, T., Lucznik, B., & Bockowski, M. (2021). Structural Analysis of Low Defect Ammonothermally Grown GaN Wafers by Borrmann Effect X-ray Topography. Materials, 14(19), 5472. https://doi.org/10.3390/ma14195472