Effects of MOVPE Growth Conditions on GaN Layers Doped with Germanium

Abstract

:1. Introduction

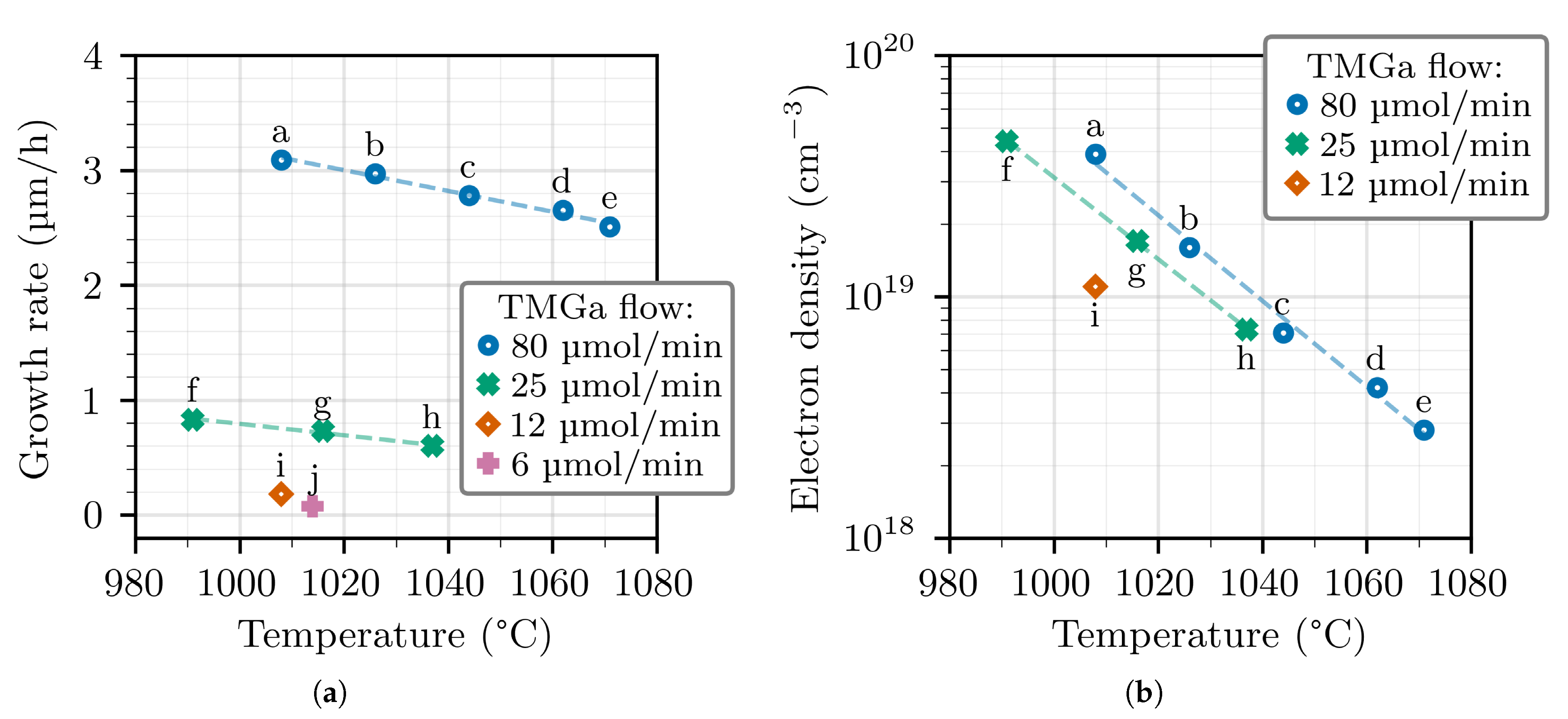

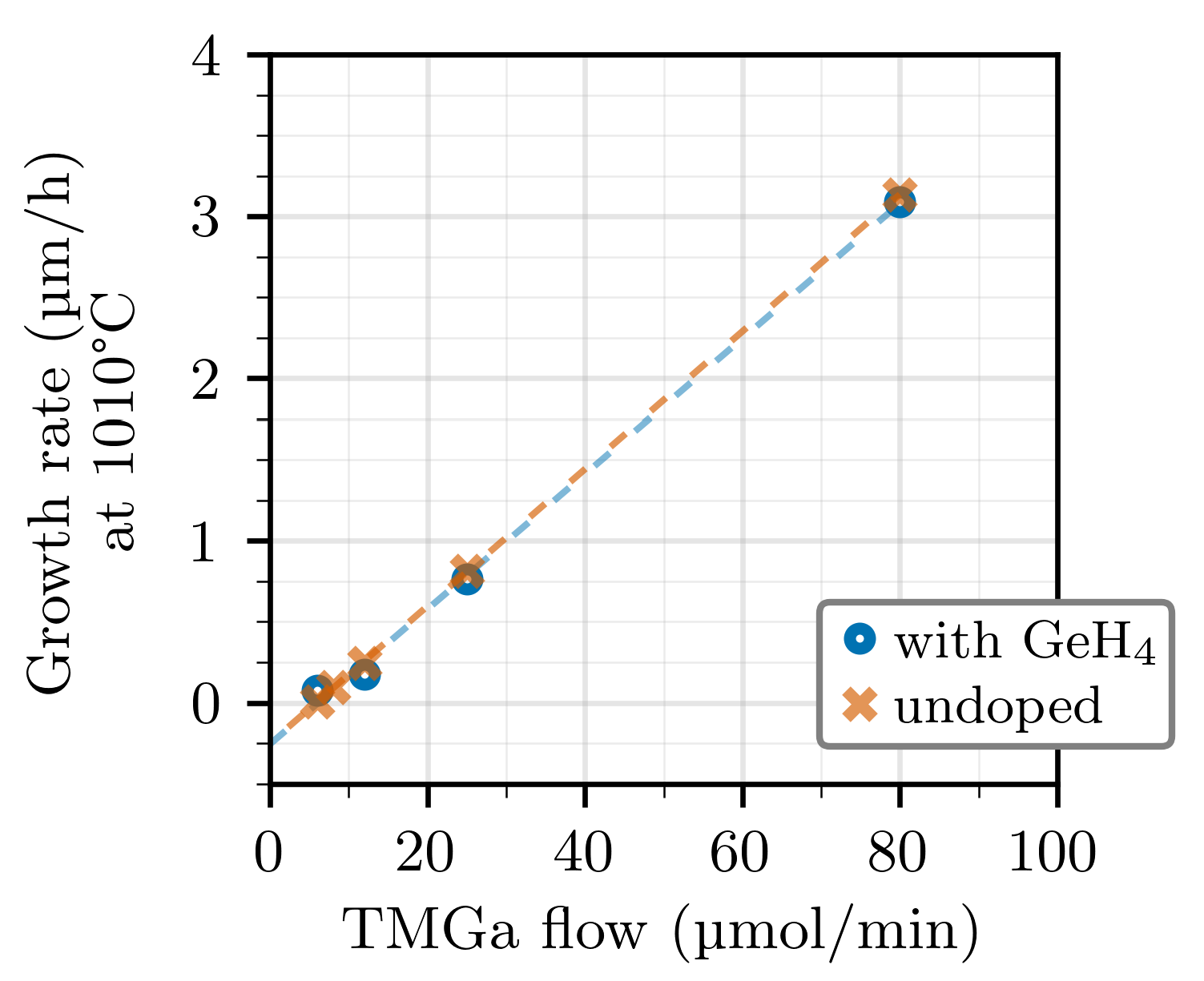

2. Effect of Temperature and TMGa Flow

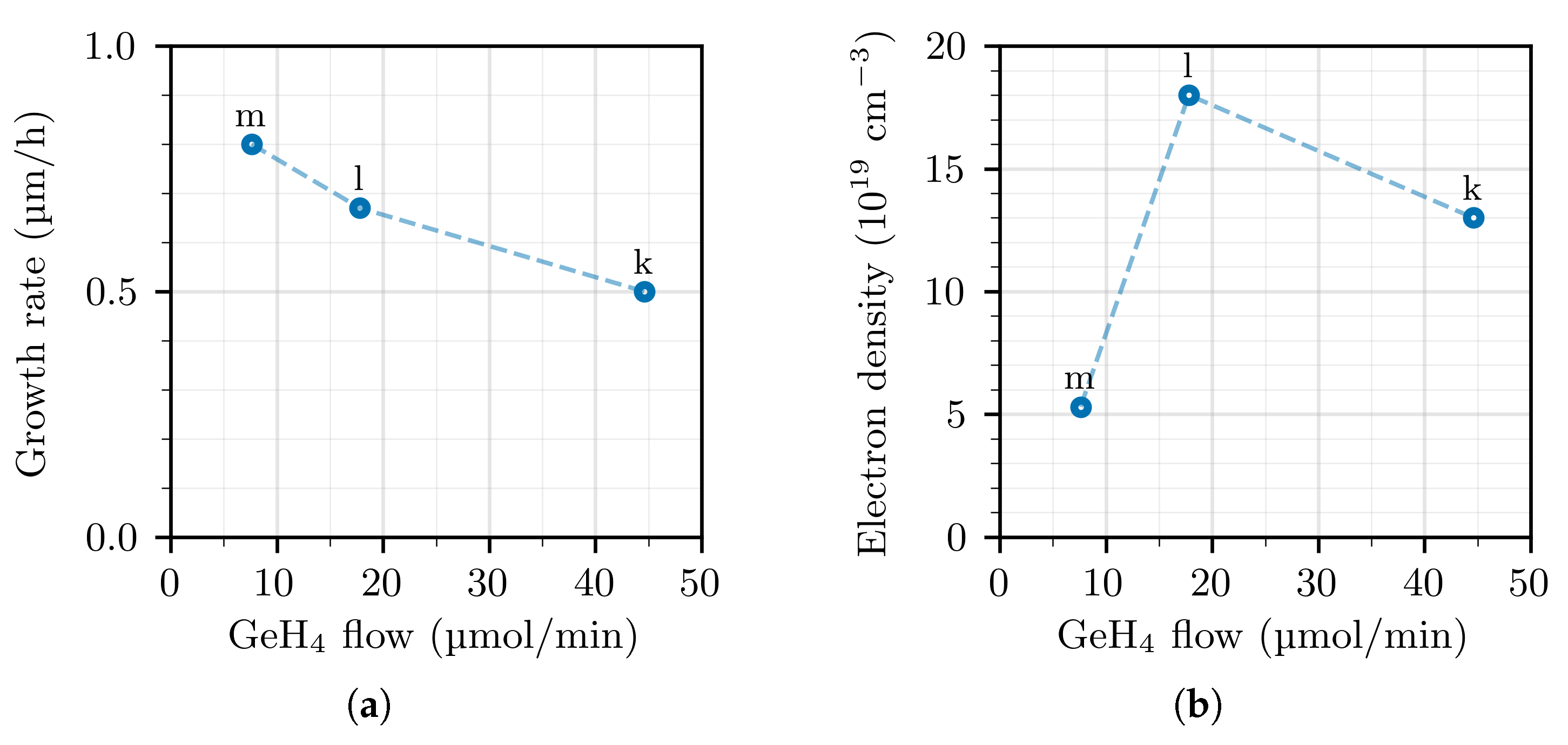

3. Effect of GeH4 and NH3 Flow

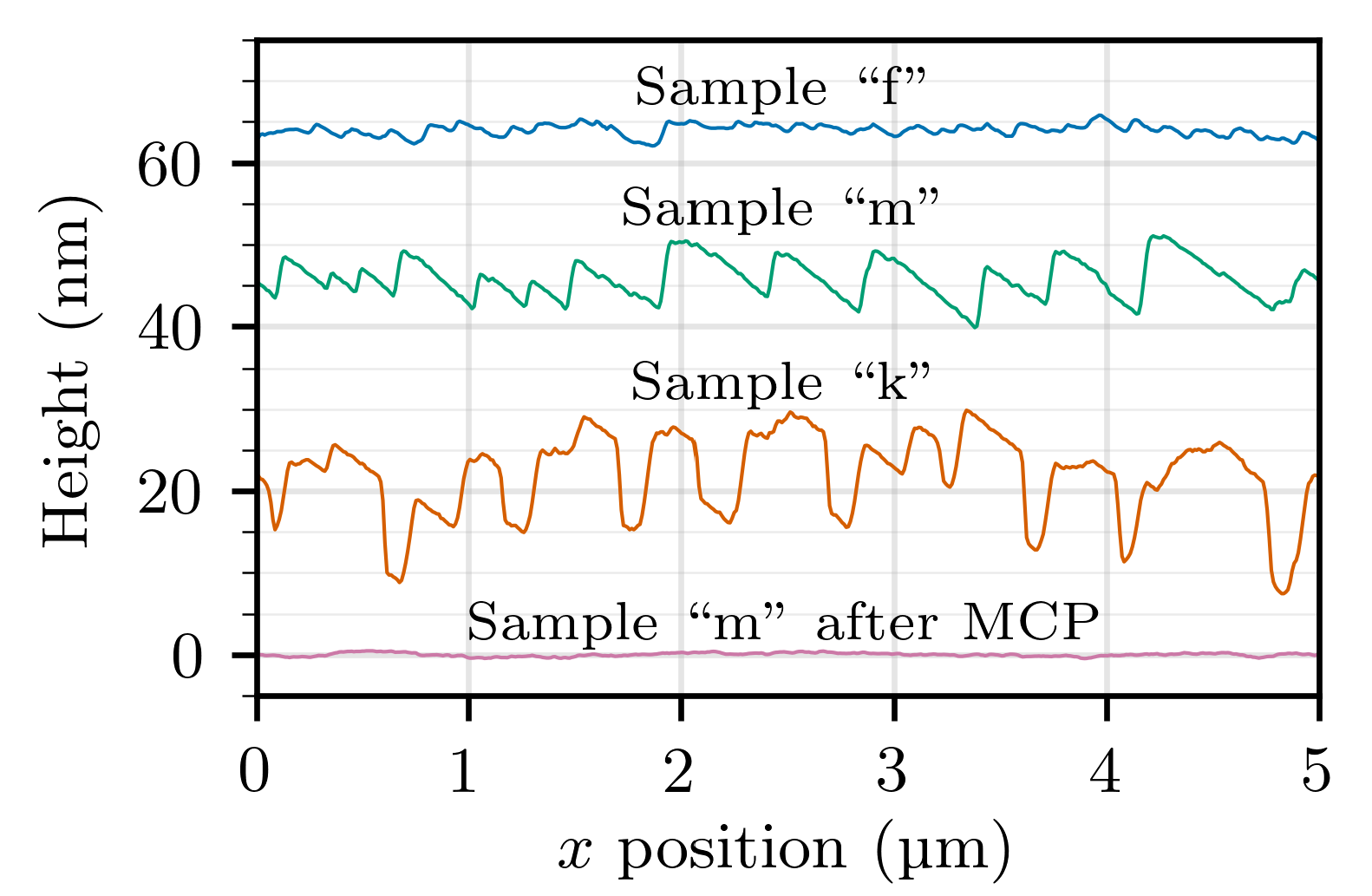

4. Surface Morphology

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arcara, V.F.; Damilano, B.; Feuillet, G.; Vézian, S.; Ayadi, K.; Chenot, S.; Duboz, J.Y. Ge doped GaN and Al0.5Ga0.5N-based tunnel junctions on top of visible and UV light emitting diodes. J. Appl. Phys. 2019, 126, 224503. [Google Scholar] [CrossRef]

- Stanczyk, S.; Czyszanowski, T.; Kafar, A.; Czernecki, R.; Targowski, G.; Leszczynski, M.; Suski, T.; Kucharski, R.; Perlin, P. InGaN laser diodes with reduced AlGaN cladding thickness fabricated on GaN plasmonic substrate. Appl. Phys. Lett. 2013, 102, 151102. [Google Scholar] [CrossRef]

- Fritze, S.; Dadgar, A.; Witte, H.; Bügler, M.; Rohrbeck, A.; Bläsing, J.; Hoffmann, A.; Krost, A. High Si and Ge n-type doping of GaN doping—Limits and impact on stress. Appl. Phys. Lett. 2012, 100, 122104. [Google Scholar] [CrossRef] [Green Version]

- Markurt, T.; Lymperakis, L.; Neugebauer, J.; Drechsel, P.; Stauss, P.; Schulz, T.; Remmele, T.; Grillo, V.; Rotunno, E.; Albrecht, M. Blocking Growth by an Electrically Active Subsurface Layer: The Effect of Si as an Antisurfactant in the Growth of GaN. Phys. Rev. Lett. 2013, 110, 036103. [Google Scholar] [CrossRef] [PubMed]

- Götz, W.; Kern, R.S.; Chen, C.H.; Liu, H.; Steigerwald, D.A.; Fletcher, R.M. Hall-effect characterization of III–V nitride semiconductors for high efficiency light emitting diodes. Mater. Sci. Eng. C 1999, 59, 211–217. [Google Scholar] [CrossRef]

- Wang, H.; Chen, A.B. Calculation of shallow donor levels in GaN. J. Appl. Phys. 2000, 87, 7859. [Google Scholar] [CrossRef]

- Oshima, Y.; Yoshida, T.; Watanabe, K.; Mishima, T. Properties of Ge-doped, high-quality bulk GaN crystals fabricated by hydride vapor phase epitaxy. J. Cryst. Growth 2010, 312, 3569–3573. [Google Scholar] [CrossRef]

- Wieneke, M.; Witte, H.; Lange, K.; Feneberg, M.; Dadgar, A.; Bläsing, J.; Goldhahn, R.; Krost, A. Ge as a surfactant in metal-organic vapor phase epitaxy growth of a-plane GaN exceeding carrier concentrations of 1020 cm-3. Appl. Phys. Lett. 2013, 103, 012103. [Google Scholar] [CrossRef]

- Nenstiel, C.; Bügler, M.; Callsen, G.; Nippert, F.; Kure, T.; Fritze, S.; Dadgar, A.; Witte, H.; Bläsing, J.; Krost, A.; et al. Germanium—The superior dopant in n-type GaN. Phys. Status Solidi RRL 2015, 9, 716–721. [Google Scholar] [CrossRef]

- Perlin, P.; Holc, K.; Sarzyński, M.; Scheibenzuber, W.; Łucja, M.; Czernecki, R.; Leszczyński, M.; Bockowski, M.; Grzegory, I.; Porowski, S.; et al. Application of a composite plasmonic substrate for the suppression of an electromagnetic mode leakage in InGaN laser diodes. Appl. Phys. Lett. 2009, 95, 261108. [Google Scholar] [CrossRef]

- Kirste, R.; Hoffmann, M.P.; Sachet, E.; Bobea, M.; Bryan, Z.; Bryan, I.; Nenstiel, C.; Hoffmann, A.; Maria, J.P.; Collazo, R.; et al. Ge doped GaN with controllable high carrier concentration for plasmonic applications. Appl. Phys. Lett. 2013, 103, 242107. [Google Scholar] [CrossRef]

- Kim, I.H.; Park, H.S.; Park, Y.J.; Kim, T. Formation of V-shaped pits in InGaN/GaN multiquantum wells and bulk InGaN films. Appl. Phys. Lett. 1998, 73, 1634. [Google Scholar] [CrossRef]

- Iwinska, M.; Takekawa, N.; Ivanov, V.Y.; Amilusik, M.; Kruszewski, P.; Piotrzkowski, R.; Litwin-Staszewska, E.; Lucznik, B.; Fijalkowski, M.; Sochacki, T.; et al. Crystal growth of HVPE-GaN doped with germanium. J. Cryst. Growth 2017, 480, 102–107. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Su, X.; Cai, D.; Xu, Y.; Wang, M.; Hu, X.; Zheng, S.; Xu, L.; Xu, K. Investigation of pits in Ge-doped GaN grown by HVPE. Jpn. J. Appl. Phys. 2019, 58, 120910. [Google Scholar] [CrossRef]

- Santos, R.B.D.; Rivelino, R.; de Brito Mota, F.; Gueorguiev, G.K.; Kakanakova-Georgieva, A. Dopant species with Al–Si and N–Si bonding in the MOCVD of AlN implementing trimethylaluminum, ammonia and silane. J. Phys. D Appl. Phys. 2015, 48, 295104. [Google Scholar] [CrossRef]

- Dauelsberg, M.; Talalaev, R. Progress in Modeling of III-Nitride MOVPE. Prog. Cryst. Growth Charact. Mater. 2020, 66, 100486. [Google Scholar] [CrossRef]

- Bogusławski, P.; Bernholc, J. Doping properties of C, Si, and Ge impurities in GaN and AlN. Phys. Rev. B 1997, 56, 9496. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.H.; Liu, H.; Steigerwald, D.; Imler, W.; Kuo, C.P.; Craford, M.G.; Ludowise, M.; Lester, S.; Amano, J. A study of parasitic reactions between NH3 and TMGa or TMAl. J. Electron. Mater. 1996, 25, 1004–1008. [Google Scholar] [CrossRef]

- Ohkawa, K.; Nakamura, K.; Hirako, A.; Iida, D. Influence of polymerization among Al- and Ga-containing molecules on growth rate and Al content in AlGaN. J. Cryst. Growth 2019, 516, 17–20. [Google Scholar] [CrossRef]

- Creighton, J.R.; Wang, G.T. Kinetics of Metal Organic-Ammonia Adduct Decomposition: Implications for Group-III Nitride MOCVD. J. Phys. Chem. A 2005, 109, 10554–10562. [Google Scholar] [CrossRef]

- L’vov, B.V. Kinetics and mechanism of thermal decomposition of GaN. Thermochim. Acta 2000, 360, 85–91. [Google Scholar] [CrossRef]

- Koleske, D.D.; Wickenden, A.E.; Henry, R.L.; Culbertson, J.C.; Twigg, M.E. GaN decomposition in H2 and N2 at MOVPE temperatures and pressures. J. Cryst. Growth 2001, 223, 466–483. [Google Scholar] [CrossRef]

- Koleske, D.D.; Wickenden, A.E.; Henry, R.L.; Twigg, M.E. Influence of MOVPE growth conditions on carbon and silicon concentrations in GaN. J. Cryst. Growth 2002, 242, 55–69. [Google Scholar] [CrossRef]

- Piner, E.L.; McIntosh, F.G.; Roberts, J.C.; Boutros, K.S.; Aumer, M.E.; Joshkin, V.A.; El-Masry, N.A.; Bedair, S.M.; Liu, S.X. A Model for Indium Incorporation in the Growth of InGaN Films. Mater. Res. Soc. Symp. Proc. 1997, 449, 85–88. [Google Scholar] [CrossRef]

- Matsuoka, T.; Yoshimoto, N.; Sasaki, T.; Katsui, A. Wide-gap semiconductor InGaN and InGaAln grown by MOVPE. J. Electron. Mater. 1992, 21, 157–163. [Google Scholar] [CrossRef]

- Ou, J.; Chen, W.K.; Lin, H.C.; Pan, Y.C.; Lee, M.C. An Elucidation of Solid Incorporation of InGaN Grown by Metalorganic Vapor Phase Epitaxy. Jpn. J. Appl. Phys. 1998, 37, L633–L636. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, X.L.; Song, H.P.; Yang, A.L.; Xu, X.Q.; Zheng, G.L.; Wei, H.Y.; Yang, S.Y.; Zhu, Q.S.; Wang, Z.G. A study of indium incorporation in In-rich InGaN grown by MOVPE. Appl. Surf. Sci. 2010, 256, 3352–3356. [Google Scholar] [CrossRef]

- Oliver, R.A.; Kappers, M.J.; Humphreys, C.J.; Briggs, G.A.D. The influence of ammonia on the growth mode in InGaN/GaN heteroepitaxy. J. Cryst. Growth 2004, 272, 393–399. [Google Scholar] [CrossRef]

- Kim, D.J.; Moon, Y.T.; Song, K.M.; Lee, I.H.; Park, S.J. Effect of Growth Pressure on Indium Incorporation During the Growth of InGaN by MOCVD. J. Electron. Mater. 2001, 30, 99–102. [Google Scholar] [CrossRef]

- Fujimoto, N.; Kitano, T.; Narita, G.; Okada, N.; Balakrishnan, K.; Iwaya, M.; Kamiyama, S.; Amano, H.; Akasaki, I.; Shimono, K.; et al. Growth of high-quality AlN at high growth rate by high-temperature MOVPE. Phys. Status Solidi C 2006, 3, 1617–1619. [Google Scholar] [CrossRef]

- Brunner, F.; Protzmann, H.; Heuken, M.; Knauer, A.; Weyers, M.; Kneissl, M. High-temperature growth of AlN in a production scale 11x2” MOVPE reactor. Phys. Status Solidi C 2008, 5, 1799–1801. [Google Scholar] [CrossRef]

- Nakamura, S.; Mukai, T.M.T.; Senoh, M.S.M. Si- and Ge-Doped GaN Films Grown with GaN Buffer Layers. Jpn. J. Appl. Phys. 1992, 31, 2883. [Google Scholar] [CrossRef]

- Young, N.G.; Farrell, R.M.; Iza, M.; Nakamura, S.; DenBaars, S.P.; Weisbuch, C.; Speck, J.S. Germanium doping of GaN by metalorganic chemical vapor deposition for polarization screening applications. J. Cryst. Growth 2016, 455, 105–110. [Google Scholar] [CrossRef]

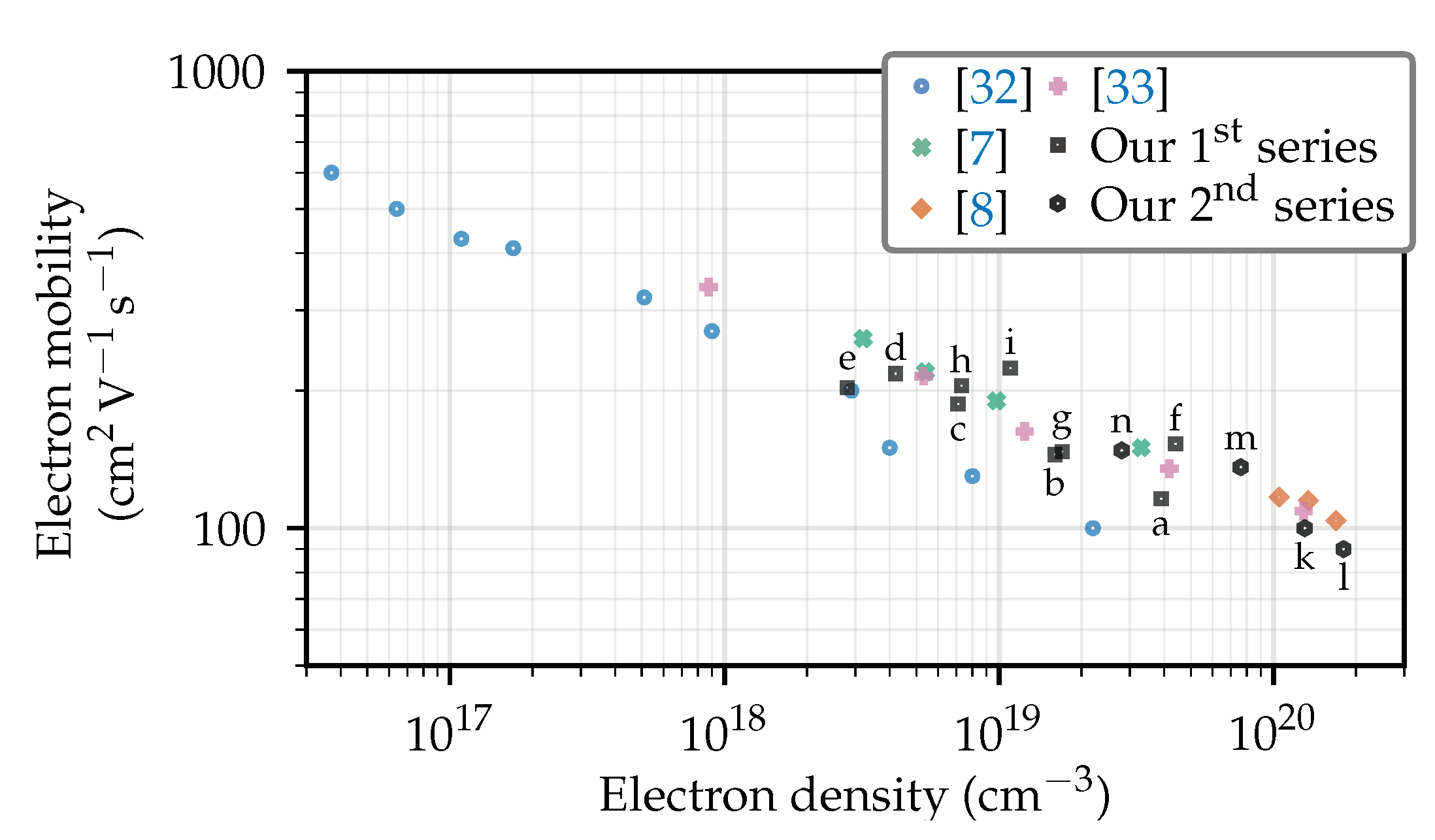

| Id | T | GR | NH | TMGa | GeH | [Ge] | n | |

|---|---|---|---|---|---|---|---|---|

| a | 1008 | 3.09 | 2 | 80 | 07.6 | 3– | 116 | |

| b | 1026 | 2.97 | 2 | 80 | 07.6 | 145 | ||

| c | 1044 | 2.78 | 2 | 80 | 07.6 | 187 | ||

| d | 1062 | 2.65 | 2 | 80 | 07.6 | 218 | ||

| e | 1071 | 2.51 | 2 | 80 | 07.6 | 203 | ||

| f | 0991 | 0.83 | 2 | 25 | 07.6 | 153 | ||

| g | 1016 | 0.73 | 2 | 25 | 07.6 | 1– | 147 | |

| h | 1037 | 0.60 | 2 | 25 | 07.6 | 205 | ||

| i | 1008 | 0.19 | 2 | 12 | 07.6 | 1– | 224 | |

| j | 1014 | 0.05 | 2 | 06 | 07.6 | 3– |

| Id | T | GR | NH | TMGa | GeH | [Ge] | n | |

|---|---|---|---|---|---|---|---|---|

| k | 0970 | 0.50 | 0.5 | 25 | 45.0 | 100 | ||

| l | 0970 | 0.67 | 0.5 | 25 | 18.0 | 090 | ||

| m | 0976 | 0.81 | 0.5 | 25 | 07.6 | 6– | 136 | |

| n | 0999 | 0.73 | 0.5 | 25 | 07.6 | 148 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schiavon, D.; Litwin-Staszewska, E.; Jakieła, R.; Grzanka, S.; Perlin, P. Effects of MOVPE Growth Conditions on GaN Layers Doped with Germanium. Materials 2021, 14, 354. https://doi.org/10.3390/ma14020354

Schiavon D, Litwin-Staszewska E, Jakieła R, Grzanka S, Perlin P. Effects of MOVPE Growth Conditions on GaN Layers Doped with Germanium. Materials. 2021; 14(2):354. https://doi.org/10.3390/ma14020354

Chicago/Turabian StyleSchiavon, Dario, Elżbieta Litwin-Staszewska, Rafał Jakieła, Szymon Grzanka, and Piotr Perlin. 2021. "Effects of MOVPE Growth Conditions on GaN Layers Doped with Germanium" Materials 14, no. 2: 354. https://doi.org/10.3390/ma14020354

APA StyleSchiavon, D., Litwin-Staszewska, E., Jakieła, R., Grzanka, S., & Perlin, P. (2021). Effects of MOVPE Growth Conditions on GaN Layers Doped with Germanium. Materials, 14(2), 354. https://doi.org/10.3390/ma14020354