Microwave Sintering and Microwave Dielectric Properties of (1–x)Ca0.61La0.26TiO3-xNd(Mg0.5Ti0.5)O3 Ceramics

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

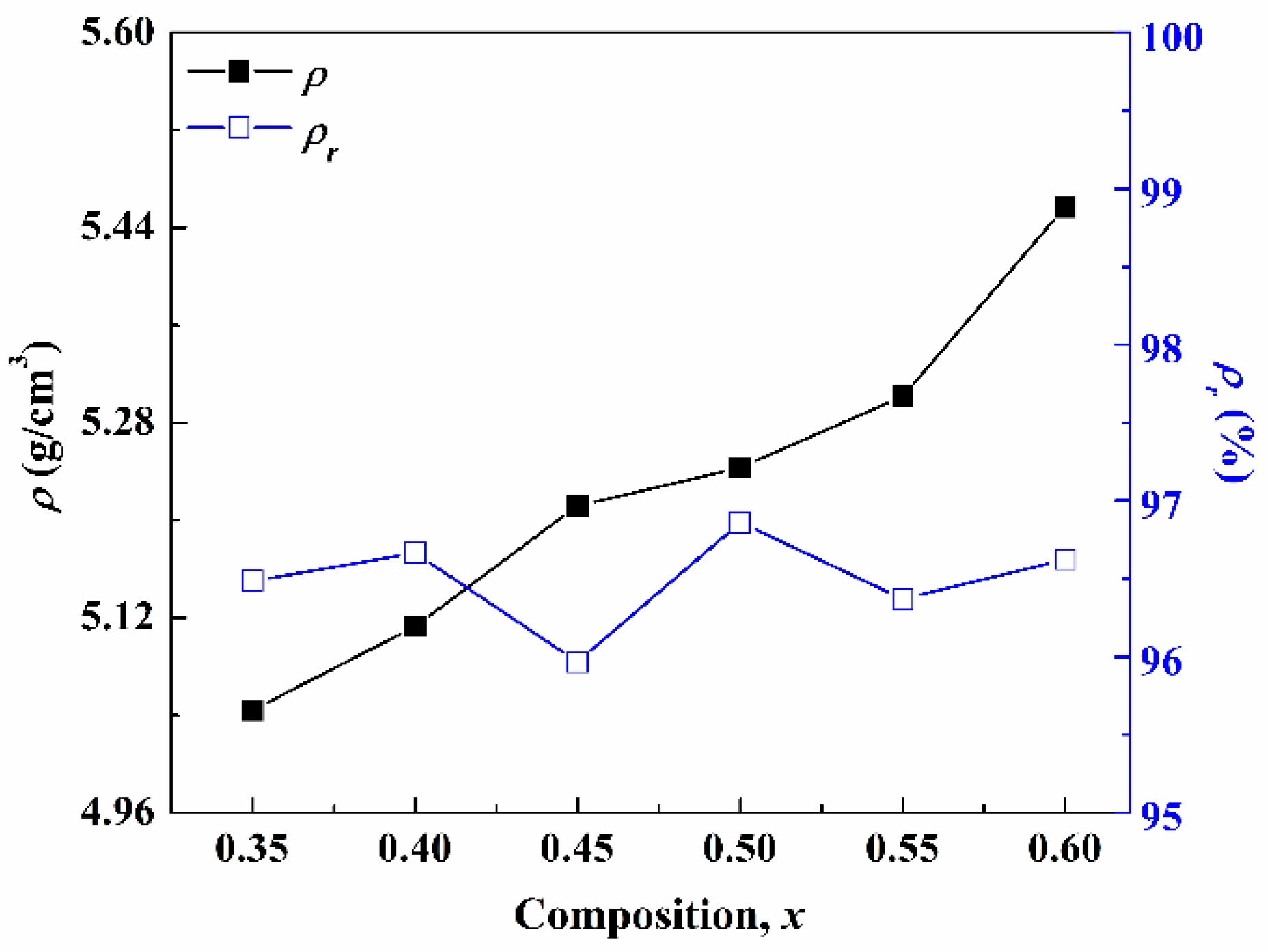

3.1. Sintering Characteristics

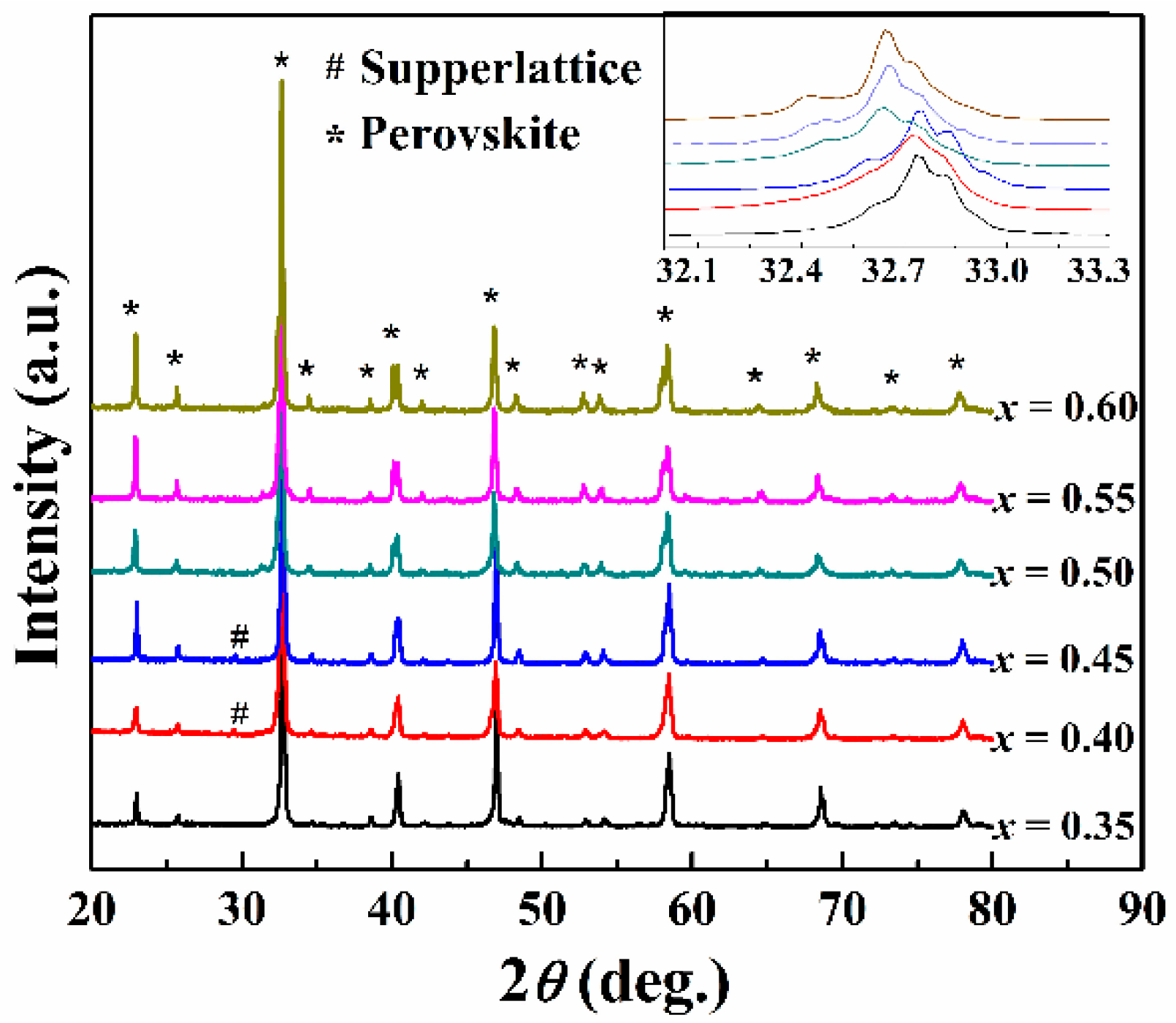

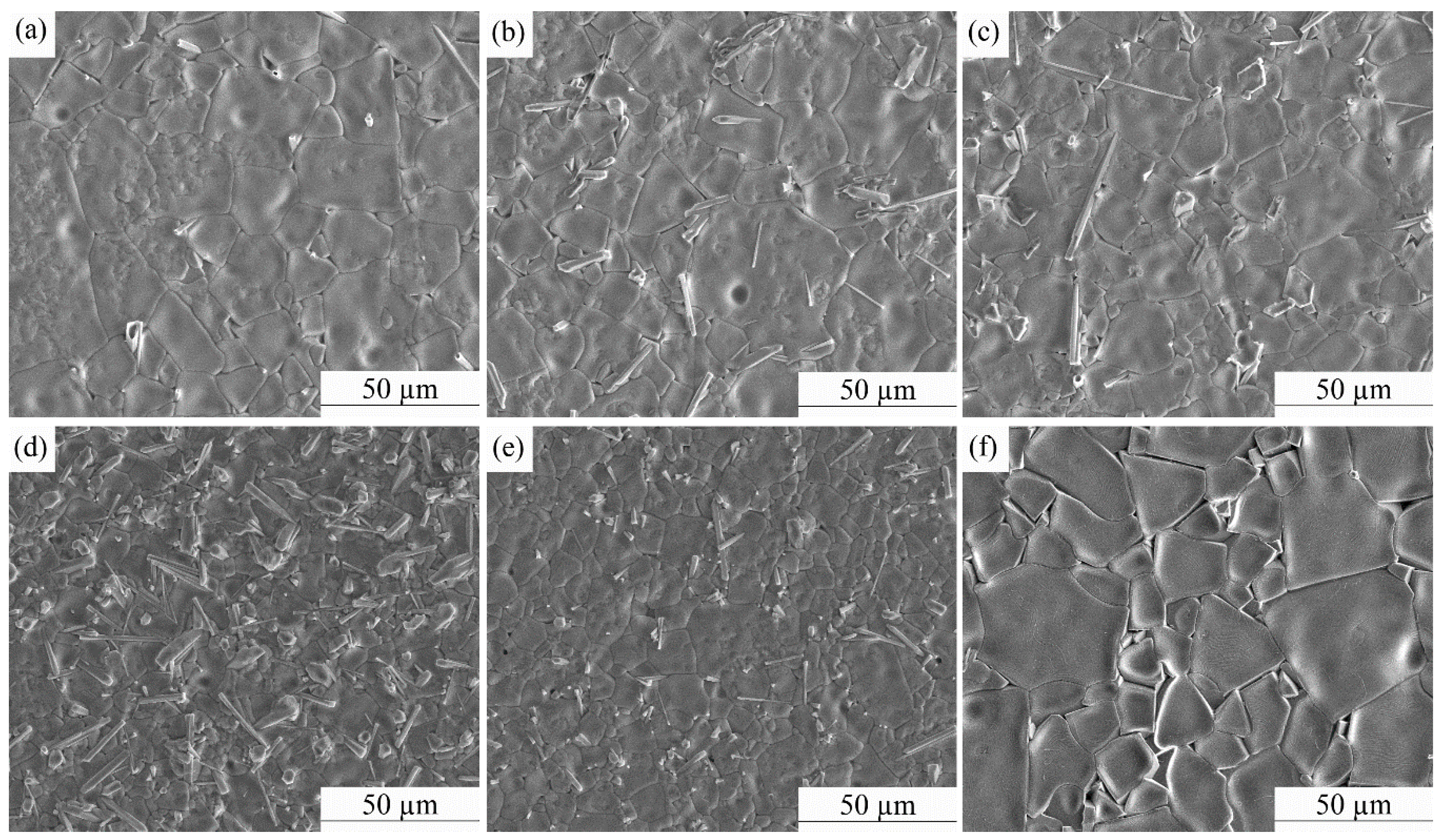

3.2. Phase and Microstructure

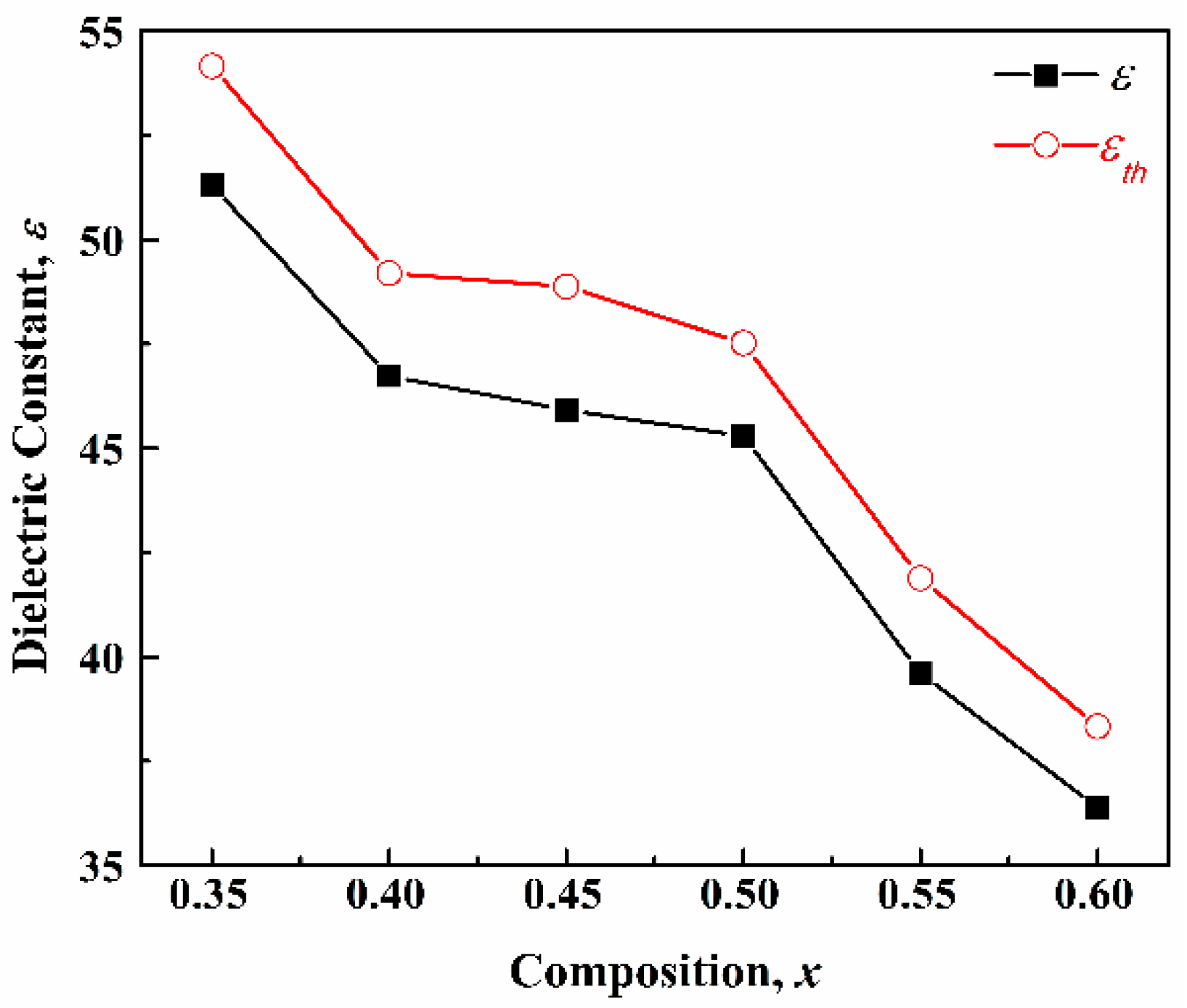

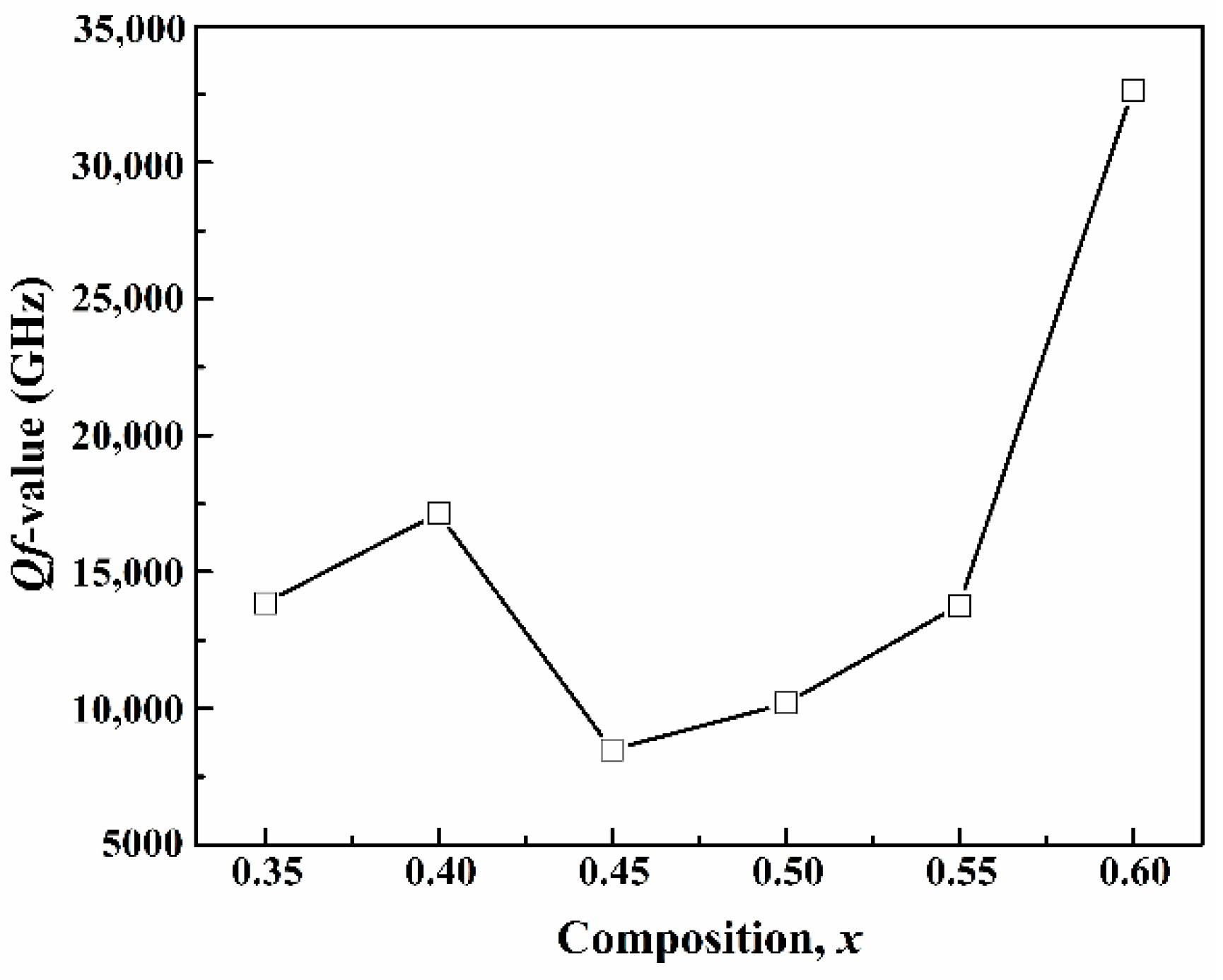

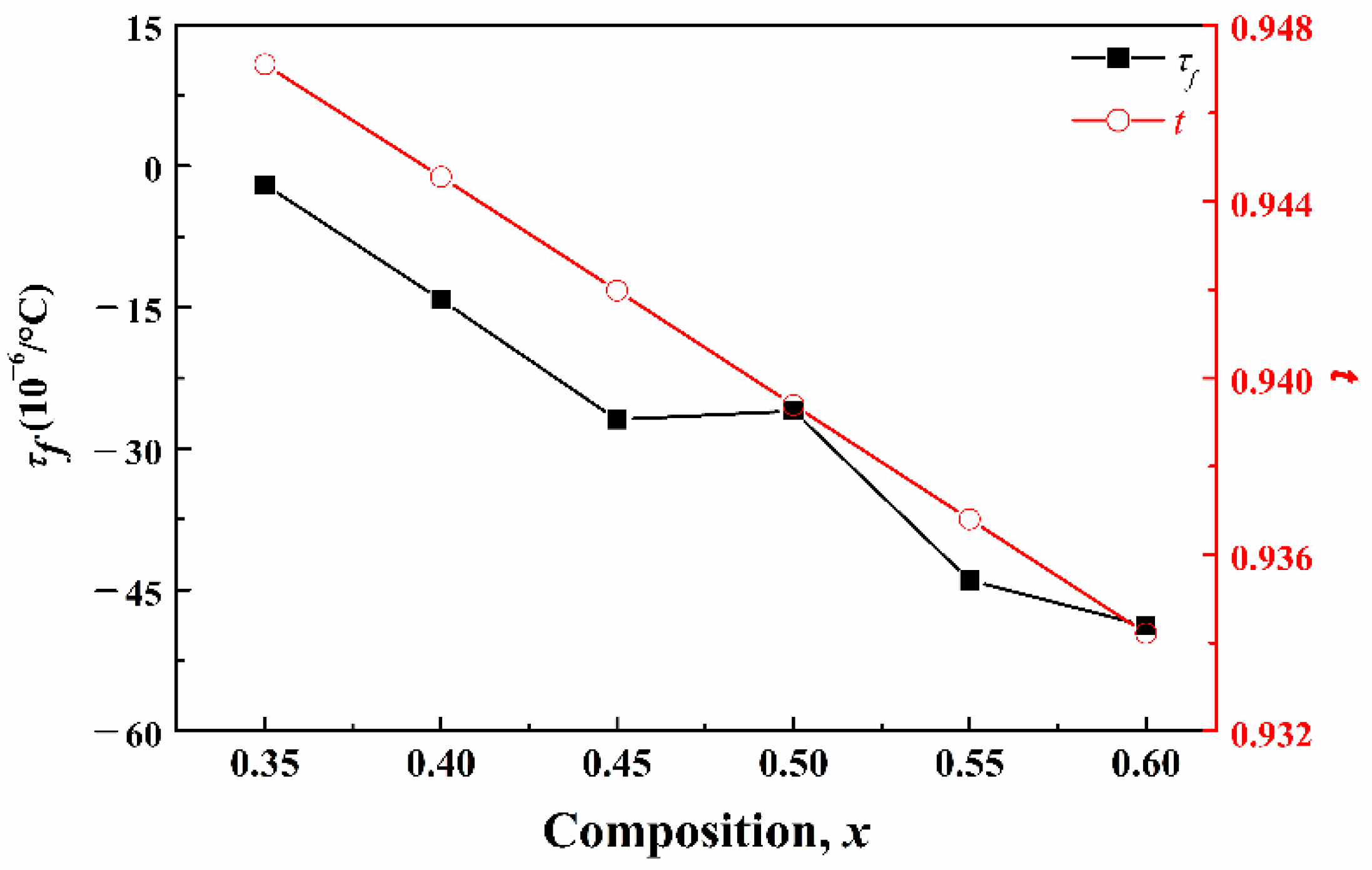

3.3. Microwave Dielectric Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, D.; Pang, L.; Wang, D.; Reaney, I.M. BiVO4 based high k microwave dielectric materials: A review. J. Mater. Chem. C 2018, 6, 9290–9313. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Zhang, S.; Zhou, D.; Song, K.; Feteira, A.; Vardaxoglou, Y.; Whittow, W.; Cadman, D.; Reaney, I.M. Temperature stable cold sintered (Bi0.95Li0.05)(V0.9Mo0.1)O4-Na2Mo2O7 microwave dielectric composites. Materials 2019, 12, 1370. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wersing, W. Microwave ceramics for resonators and filters. Curr. Opin. Solid State Mater. Sci. 1996, 1, 715–731. [Google Scholar] [CrossRef]

- Wang, S.; Luo, W.J.; Li, L.X.; Du, M.K.; Qiao, J.L. Improved tri-layer microwave dielectric ceramic for 5G applications. J. Eur. Ceram. Soc. 2021, 41, 418. [Google Scholar] [CrossRef]

- Liang, B.L.; Zheng, X.H.; Ni, W.Q.; Tang, D.P. Ca1−3xLn2xTiO3(x = 0.13, 0.2; Ln=La, Nd, Sm): High ε microwave dielectric ceramics. Rare Met. Mater. Eng. 2007, 36, 418–421. (In Chinese) [Google Scholar]

- Seabra, M.P.; Salak, A.N.; Avdeev, M.; Ferreira, V.M. Structure and dielectric characterization of the La(Mg1/2Ti1/2)O3-Nd(Mg1/2Ti1/2)O3 system. J. Phys. Condens. Matter 2003, 15, 4229–4238. [Google Scholar] [CrossRef]

- Kim, J.B.; Yoon, K.H.; Cho, Y.S. Compositional dependence of microwave dielectric properties in (1-x)(Na1/2Nd1/2)TiO3-xNd(Mg1/2Ti1/2)O3 ceramics. J. Am. Ceram. Soc. 2003, 86, 1159–1161. [Google Scholar] [CrossRef]

- Lin, S.H.; Chen, Y.B. Structure and characterization of B2O3 modified yNd(Mg1/2Ti1/2)O3-(1-y)Ca0.8Sr0.2TiO3 ceramics with a near-zero temperature coefficient at microwave frequency. Ceram. Int. 2017, 43, 2368–2371. [Google Scholar] [CrossRef]

- Chen, Y.B. Structure and dielectric characterization of xNd(Mg1/2Ti1/2)O3-(1−x)Ca0.6La0.8/3TiO3 in the microwave frequency range. J. Alloys Compd. 2011, 509, 6285–6288. [Google Scholar] [CrossRef]

- Chen, Y.B. Structural and dielectric properties of La(Mg1/2Ti1/2)O3-Ca0.6La0.8/3TiO3-doped CuO. J. Alloys Compd. 2009, 480, 820–823. [Google Scholar] [CrossRef]

- Chen, Y.B. New dielectric material system of La(Mg1/2Ti1/2)O3-Ca0.6La0.8/3TiO3 for microwave applications. J. Alloys Compd. 2009, 480, 265–269. [Google Scholar] [CrossRef]

- Tian, L.; Nan, J.; Wang, H.; Shen, C. Effect of microwave sintering on the properties of 0.95(Ca0.88Sr0.12)TiO3–0.05(Bi0.5Na0.5)TiO3 ceramics. Materials 2019, 12, 803. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Benavente, R.; Salvador, M.D.; Centeno, A.; Alonso, B.; Zurutuza, A.; Borrell, A. study of microwave heating effect in the behaviour of graphene as second phase in ceramic composites. Materials 2020, 13, 1119. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatiomic distances in halides and chalcogenides. Acta Crystallogr. 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Kipkoech, E.R.; Azough, F.; Freer, R. Microstructural control of microwave dielectric properties in CaTiO3-La(Mg1/2Ti1/2)O3 ceramics. J. Appl. Physiol. 2005, 97, 1–11. [Google Scholar] [CrossRef]

- Luo, W.; Guo, J.; Randall, C.; Lanagan, M. Effect of porosity and microstructure on the microwave dielectric properties of rutile. Mater. Lett. 2017, 200, 101–104. [Google Scholar] [CrossRef] [Green Version]

- Penn, S.J.; Alford, N.M.; Templeton, A.; Wang, X.; Xu, M.; Reece, M.; Schrapel, K. Effect of porosity and grain size on the microwave dielectric properties of sintered alumina. J. Am. Ceram. Soc. 1997, 80, 1885–1888. [Google Scholar] [CrossRef]

- Kim, E.S.; Park, H.S.; Yoon, K.H. Porosity dependence of microwave dielectric properties of complex perovskite (Pb0.5Ca0.5)(Fe0.5Ta0.5)O3 ceramics. Mater. Chem. Phys. 2003, 79, 213–217. [Google Scholar] [CrossRef]

- Kajfez, D. Temperature characterization of dielectric−resonator materials. J. Eur. Ceram. Soc. 2001, 21, 2663–2667. [Google Scholar] [CrossRef]

- Xiong, Z.; Tang, B.; Luo, F.C.; Yang, H.Y.; Zhang, X.; Yang, C.T.; Fang, Z.X.; Zhang, S.R. Characterization of structure, chemical bond and microwave dielectric properties in Ca0.61Nd0.26TiO3 ceramic substituted by chromium for titanium. J. Alloys Compd. 2020, 835, 155249. [Google Scholar] [CrossRef]

- Colla, E.L.; Reaney, I.M.; Setter, N. Effect of structural changes in complex perovskites on the temperature coefficient of the relative permittivity. J. Appl. Physiol. 1993, 74, 3414–3425. [Google Scholar] [CrossRef]

- Goldschmidt, V.M. The laws of crystal chemistry. Naturwissenschaften 1926, 14, 477–485. [Google Scholar]

- Reaney, I.M.; Colla, E.L.; Setter, N. Dielectric and structural characteristics of Ba− and Sr−based complex perovskites as a function of tolerance factor. Jpn. J. Appl. Phys. 1994, 33, 3984–3990. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Liang, B.; Liu, C.; Liu, J.; Fang, C.; Ai, Y. Microwave Sintering and Microwave Dielectric Properties of (1–x)Ca0.61La0.26TiO3-xNd(Mg0.5Ti0.5)O3 Ceramics. Materials 2021, 14, 438. https://doi.org/10.3390/ma14020438

Yang S, Liang B, Liu C, Liu J, Fang C, Ai Y. Microwave Sintering and Microwave Dielectric Properties of (1–x)Ca0.61La0.26TiO3-xNd(Mg0.5Ti0.5)O3 Ceramics. Materials. 2021; 14(2):438. https://doi.org/10.3390/ma14020438

Chicago/Turabian StyleYang, Shuwei, Bingliang Liang, Changhong Liu, Jin Liu, Caisheng Fang, and Yunlong Ai. 2021. "Microwave Sintering and Microwave Dielectric Properties of (1–x)Ca0.61La0.26TiO3-xNd(Mg0.5Ti0.5)O3 Ceramics" Materials 14, no. 2: 438. https://doi.org/10.3390/ma14020438