The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

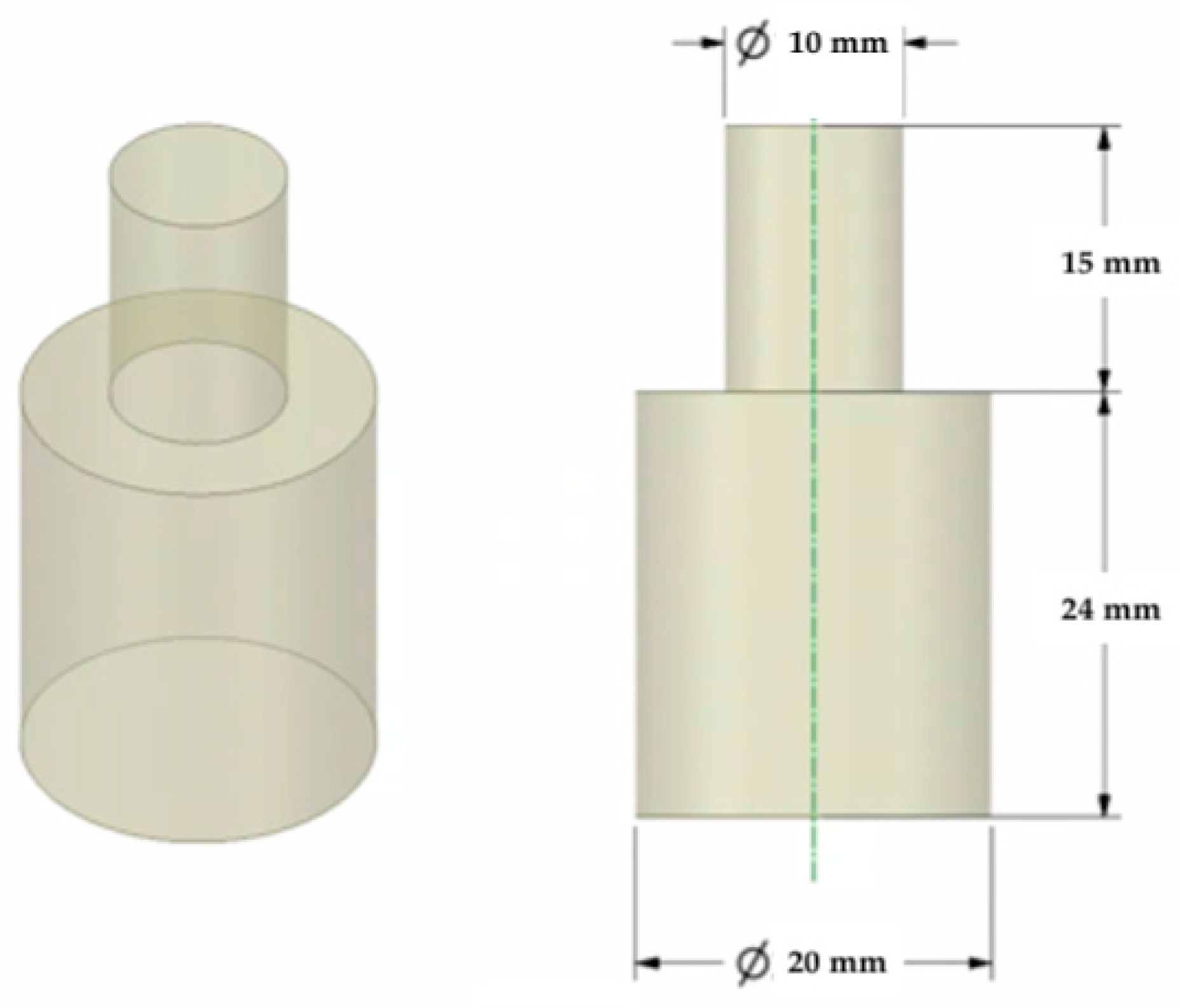

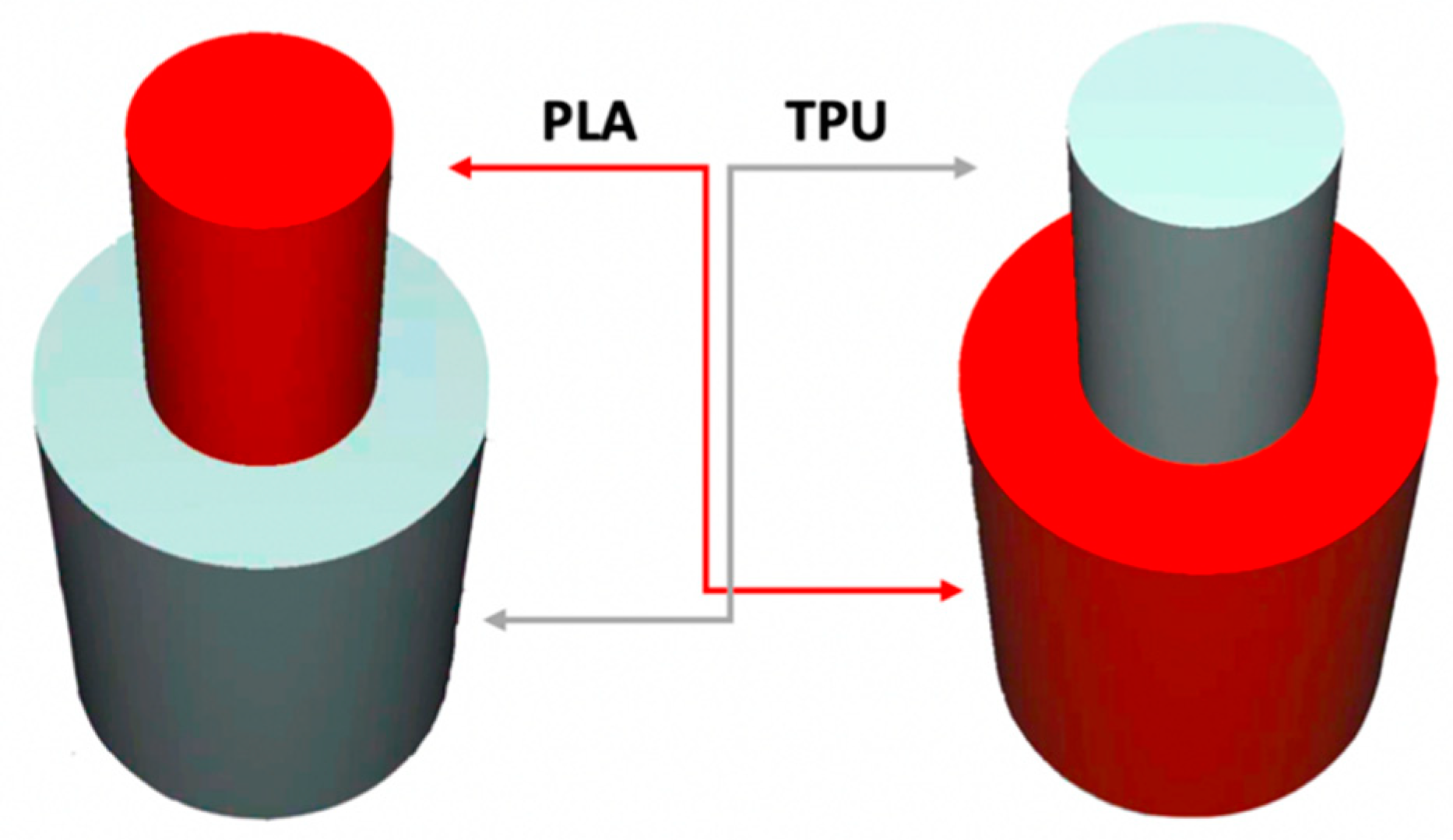

2.2. Samples

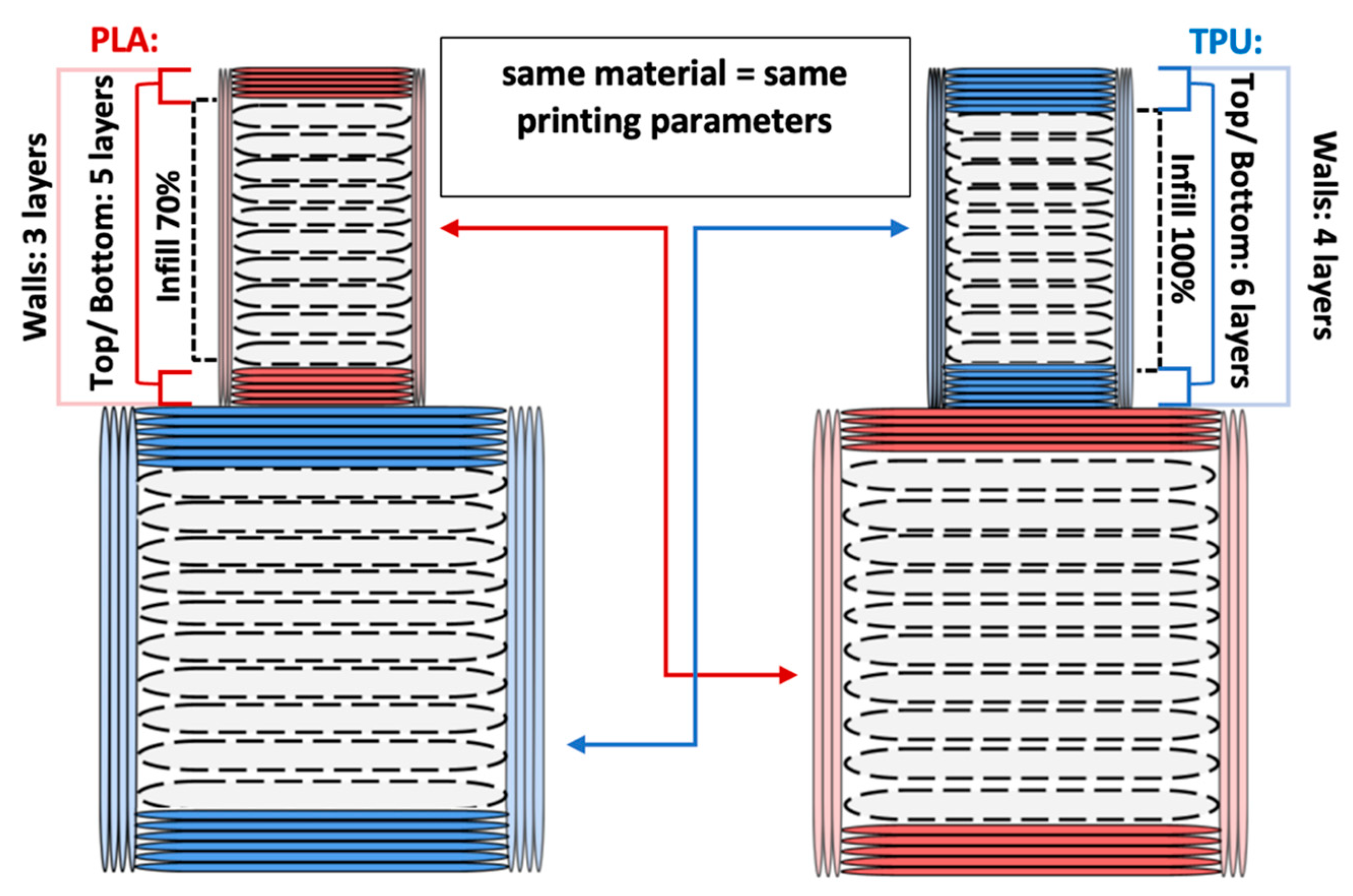

2.3. Printing Parameters

2.4. Adhesion

2.5. Roughness

3. Results

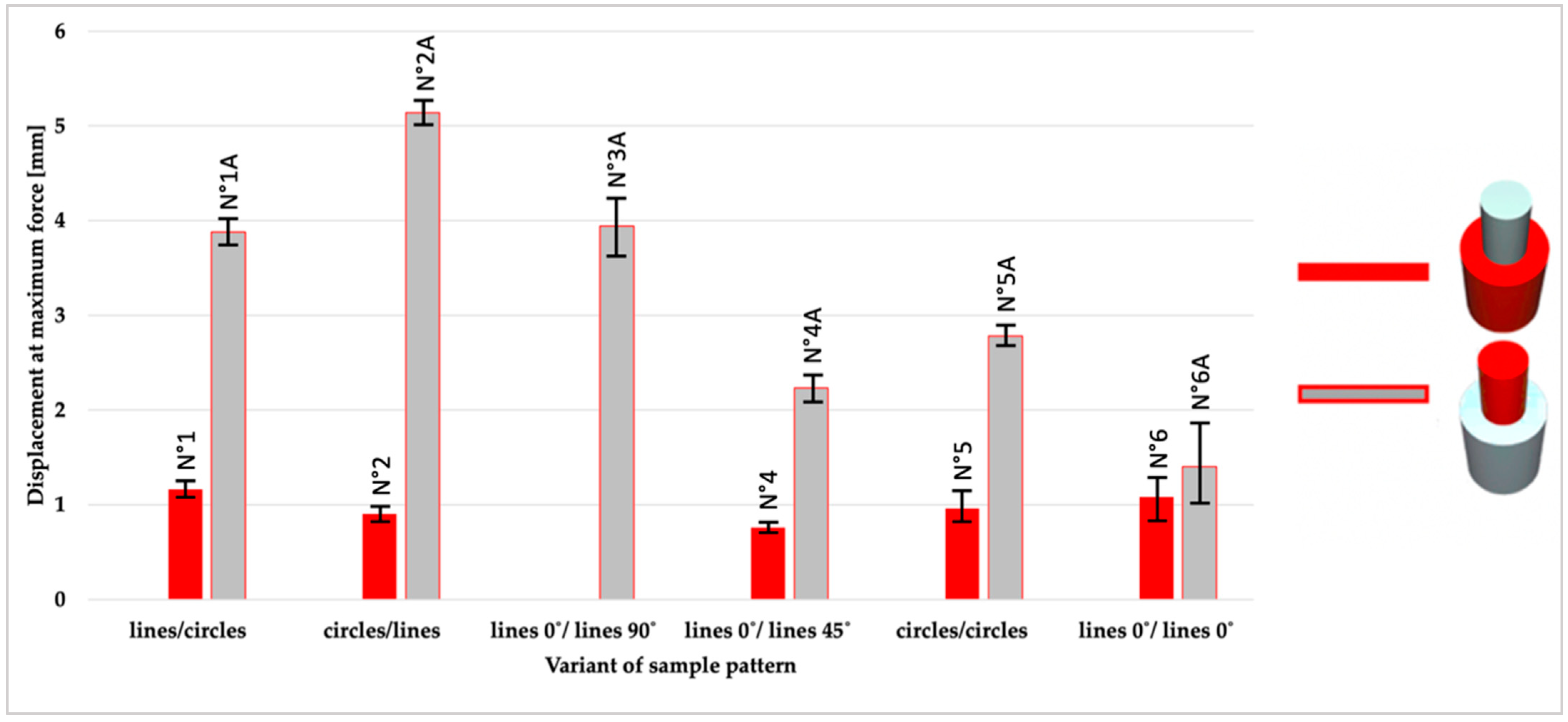

3.1. Adhesion

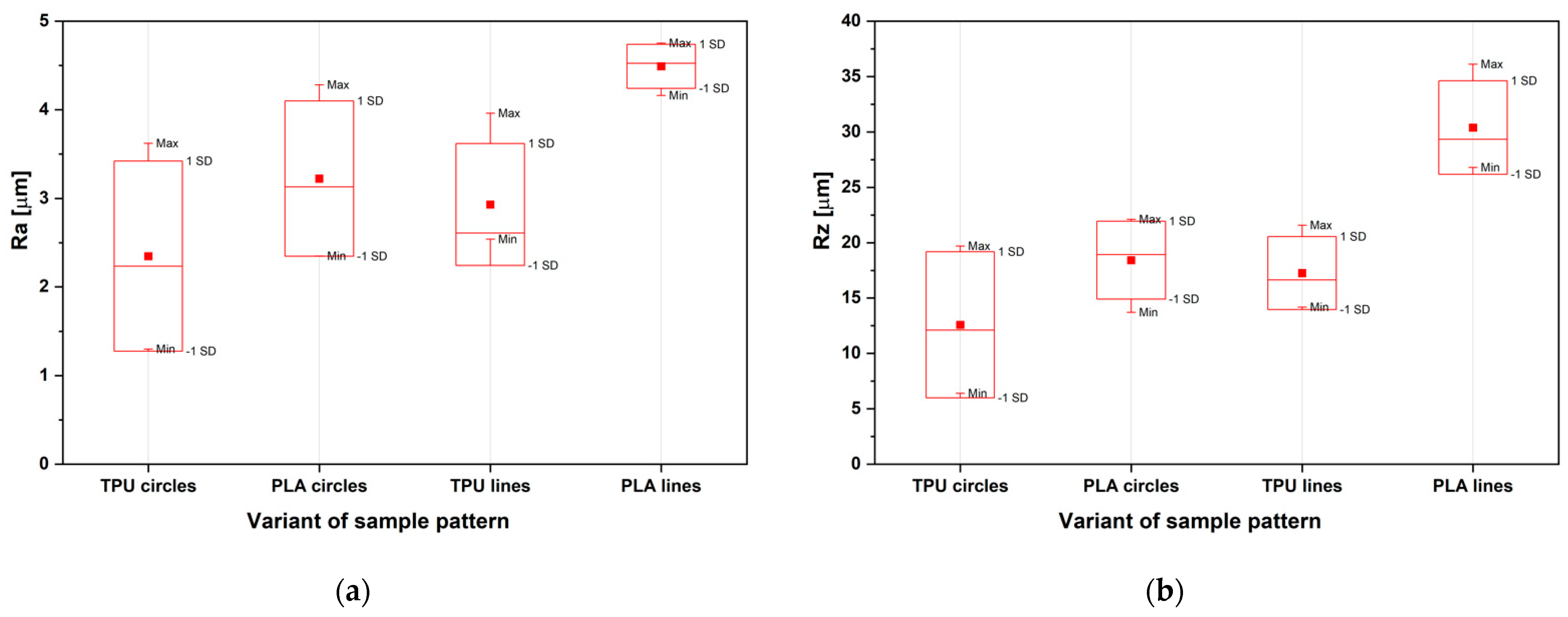

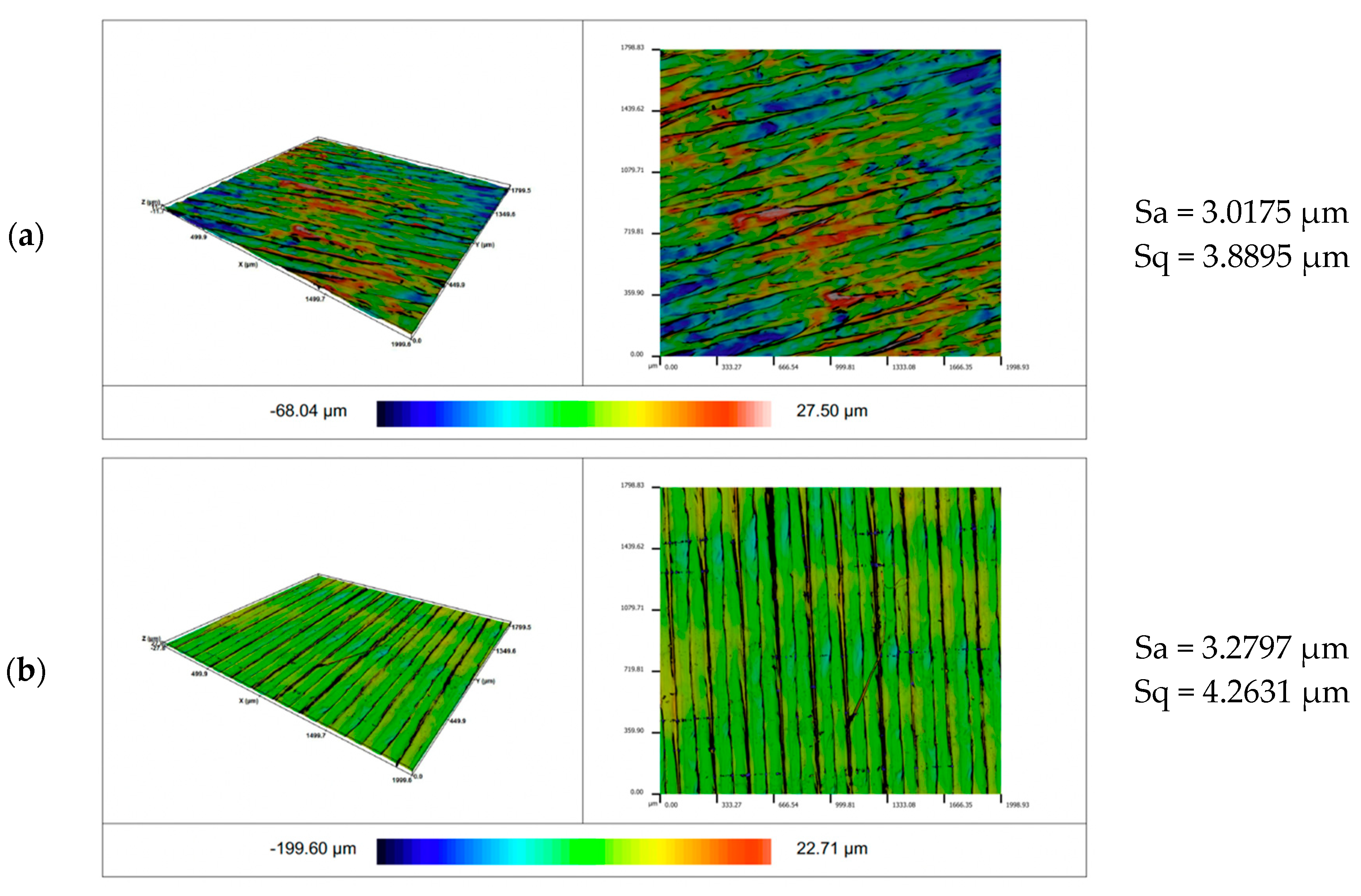

3.2. Roughness

3.3. Roughness and Adhesion Summarised

4. Discussion

- No5A: TPU with a Concentric pattern—PLA with Concentric pattern

- No4A: TPU with a Lines 0° pattern—PLA with Lines 45° pattern

- No5: PLA with a Concentric pattern—TPU with Concentric pattern

- No1: PLA with a Line pattern—TPU with Concentric pattern

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Chen, J.; Shang, E.; Chen, Y. Process based modeling of energy consumption for multi-material FDM 3D printing. Chin. J. Mech. Eng. 2020, 20. [Google Scholar] [CrossRef]

- Yadav, D.; Chhabra, D.; Garg, R.K.; Ahlawat, A.; Phogat, A. Optimization of FDM 3D printing process parameters for multi-material using artificial neural network. Mater. Today Proc. 2020, 9, 1583–1591. [Google Scholar] [CrossRef]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical parameters influencing the quality of prototypes in fused deposition modelling. J. Mater. Process. Technol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Garcia-Gonzalez, D.; Jérusalem, A.; Arias, A. Design of FDM 3D printed polymers: An experimental-modelling methodology for the prediction of mechanical properties. Mater. Des. 2020, 188, 108414. [Google Scholar] [CrossRef]

- Citarella, R.; Giannella, V. Additive Manufacturing in Industry. Appl. Sci. 2021, 11, 840. [Google Scholar] [CrossRef]

- Budzik, G.; Woźniak, J.; Paszkiewicz, A.; Przeszłowski, Ł.; Dziubek, T.; Dębski, M. Methodology for the Quality Control Process of Additive Manufacturing Products Made of Polymer Materials. Materials 2021, 14, 2202. [Google Scholar] [CrossRef]

- Kusoglu, I.; Doñate-Buendía, C.; Barcikowski, S.; Gökce, B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials 2021, 14, 1169. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Haghsefat, K.; Eng, M.; Tingting, L. FDM 3D Printing Technology and Its Fundemental Properties. In Proceedings of the International Conference on Innovation and Research in Engineering Sciences, Tbilisi, Georgia, 30 June 2020. [Google Scholar]

- Bergonzi, L.; Vettori, M.; Stefanini, L.; D’Alcamo, L. Different infill geometry influence on mechanical properties of FDM produced PLA. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 49th AIAS Conference (AIAS 2020), Genova, Italy, 2–5 September 2020; IOP Publishing: Bristol, UK, 2021. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Bagheri, A.; Domínguez-Fernández, A.; Casado-López, R. Influence of infill and nozzle diameter on porosity of FDM printed parts with rectilinear grid pattern. Procedia Manuf. 2019, 41, 288–295. [Google Scholar] [CrossRef]

- Yahamed, A.; Ikonomov, P.; Fleming, P.D.; Pekarovicova, A.; Gustafson, P.; Alden, A.Q.; Alrafeek, S. Mechanical properties of 3D printed polymers. J. Print Media Technol. Res. 2016, 5, 273–289. [Google Scholar]

- Taczała, J.; Czepułkowska, W.; Konieczny, B.; Sokołowski, J.; Kozakiewicz, M.; Szymor, P. Comparison of 3D printing MJP and FDM technology in dentistry. Arch. Mater. Sci. Eng. 2020, 1, 32–40. [Google Scholar] [CrossRef]

- Lüchtenborg, J.; Burkhardt, F.; Nold, J.; Rothlauf, S.; Wesemann, C.; Pieralli, S.; Wemken, G.; Witkowski, S.; Spies, B. Implementation of Fused Filament Fabrication in Dentistry. Appl. Sci. 2021, 11, 6444. [Google Scholar] [CrossRef]

- Jeon, B.; Han, J.W.; Lee, K.S.; Cha, S.W. Improvement of the Mechanical Properties of Biodegradable Polymers Using a Microcellular Foaming Process and Natural By-Products. Polym. Technol. Eng. 2012, 51, 401–406. [Google Scholar] [CrossRef]

- Tao, Y.; Shao, J.; Li, P.; Shi, S.Q. Application of a thermoplastic polyurethane/polylactic acid composite filament for 3D-printed personalized orthosis. Mater. Teh. 2019, 53, 71–76. [Google Scholar] [CrossRef]

- Mamiński, M.; Novák, I.; Mičušík, M.; Małolepszy, A.; Toczyłowska-Mamińska, R. Discharge Plasma Treatment as an Efficient Tool for Improved Poly(lactide) Adhesive–Wood Interactions. Materials 2021, 14, 3672. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Kang, B.-K.; Kim, H.-D.; Yoo, H.-J.; Kim, J.-S.; Huh, J.-H.; Jung, Y.-J.; Lee, D.-J. Effect of hot pressing/melt mixing on the properties of thermoplastic polyurethane. Macromol. Res. 2009, 17, 616–622. [Google Scholar] [CrossRef]

- Tabuani, D.; Bellucci, F.; Terenzi, A.; Camino, G. Flame retarded Thermoplastic Polyurethane (TPU) for cable jacketing application. Polym. Degrad. Stab. 2012, 97, 2594–2601. [Google Scholar] [CrossRef]

- Mrówka, M.; Szymiczek, M.; Machoczek, T.; Pawlyta, M. Influence of the Halloysite Nanotube (HNT) Addition on Selected Mechanical and Biological Properties of Thermoplastic Polyurethane. Materials 2021, 14, 3625. [Google Scholar] [CrossRef]

- He, X.; Zhou, J.; Jin, L.; Long, X.; Wu, H.; Xu, L.; Gong, Y.; Zhou, W. Improved Dielectric Properties of Thermoplastic Polyurethane Elastomer Filled with Core–Shell Structured PDA@TiC Particles. Materials 2020, 13, 3341. [Google Scholar] [CrossRef]

- Lee, H.; Eom, R.-I.; Lee, Y. Evaluation of the Mechanical Properties of Porous Thermoplastic Polyurethane Obtained by 3D Printing for Protective Gear. Adv. Mater. Sci. Eng. 2019, 2019, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Sambruno, A.; Bañon, F.; Salguero, J.; Simonet, B.; Batista, M. Kerf Taper Defect Minimization Based on Abrasive Waterjet Machining of Low Thickness Thermoplastic Carbon Fiber Composites C/TPU. Materials 2019, 12, 4192. [Google Scholar] [CrossRef] [Green Version]

- Ji, X.; Gao, F.; Geng, Z.; Li, D. Fabrication of thermoplastic polyurethane/polylactide shape-memory blends with tunable optical and mechanical properties via a bilayer structure design. Polym. Test. 2021, 97, 107135. [Google Scholar] [CrossRef]

- Lis-Bartos, A.; Smieszek, A.; Frańczyk, K.; Marycz, K. Fabrication, Characterization, and Cytotoxicity of Thermoplastic Polyurethane/Poly(lactic acid) Material Using Human Adipose Derived Mesenchymal Stromal Stem Cells (hASCs). Polymers 2018, 10, 1073. [Google Scholar] [CrossRef] [Green Version]

- Hu, Q.; Suihong, L.; Yan, G.; Zhicheng, S. Topological Structure Design and Fabrication of Biocompatible PLA/TPU/ADM Mesh with Appropriate Elasticity for Hernia Repair. Macromol. Biosci. 2021, 21, 2000423. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, L.; Heng, P.; Xiao, J.; Lv, J.; Zhang, Q.; Hickey, M.E.; Tu, Q.; Wang, J. Lecithin doped electrospun poly(lactic acid)-thermoplastic polyurethane fibers for hepatocyte viability improvement. Colloids Surf. B Biointerfaces 2018, 175, 264–271. [Google Scholar] [CrossRef]

- Han, Y.; Kim, J. A Study on the Mechanical Properties of Knit Fabric Using 3D Printing—Focused on PLA, TPU Filament. J. Fash. Bus. 2018, 22, 93–105. [Google Scholar] [CrossRef]

- Lopes, L.; Silva, A.; Carneiro, O. Multi-material 3D printing: The relevance of materials affinity on the boundary interface performance. Addit. Manuf. 2018, 23, 45–52. [Google Scholar] [CrossRef]

- Schwartz, J.J.; Boydston, A.J. Multimaterial actinic spatial control 3D and 4D printing. Nat. Commun. 2019, 10, 791. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Tatineni, J.; Cadd, B.; Peart, G.; Gibson, I. Advanced auricular prosthesis development by 3D modelling and multi-material printing. In Proceedings of the International Conference on Design and Technology (DesTech 2016), Geelong, Australia, 5–8 December 2016; Volume 7. Available online: https://dro.deakin.edu.au/eserv/DU:30091544/gibson-advancedauricular-2017.pdf (accessed on 8 September 2021).

- Yin, J.; Li, M.; Dai, G.; Zhou, H.; Ma, L.; Zheng, Y. 3D Printed Multi-material Medical Phantoms for Needle-tissue Interaction Modelling of Heterogeneous Structures. J. Bionic Eng. 2021, 18, 346–360. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef] [Green Version]

- Tamburrino, F.; Graziosi, S.; Bordegoni, M. The influence of slicing parameters on the multi-material adhesion mechanisms of FDM printed parts: An exploratory study. Virtual Phys. Prototyp. 2019, 14, 316–332. [Google Scholar] [CrossRef]

- Rahmati, S.; Vahabli, E. Evaluation of analytical modeling for improvement of surface roughness of FDM test part using measurement results. Int. J. Adv. Manuf. Technol. 2015, 79, 823–829. [Google Scholar] [CrossRef]

- Garg, A.; Bhattacharya, A.; Batish, A. On Surface Finish and Dimensional Accuracy of FDM Parts after Cold Vapor Treatment. Mater. Manuf. Process. 2016, 31, 522–529. [Google Scholar] [CrossRef]

- Ahn, D.; Kweon, J.-H.; Kwon, S.; Song, J.; Lee, S. Representation of surface roughness in fused deposition modeling. J. Mater. Process. Technol. 2009, 209, 5593–5600. [Google Scholar] [CrossRef]

- Bouzouita, A.; Notta-Cuvier, D.; Raquez, J.-M.; Lauro, F.; Dubois, P. Poly(lactic acid)-Based Materials for Automotive Applications. In Industrial Applications of Poly(lactic acid). Advances in Polymer Science; Di Lorenzo, M., Androsch, R., Eds.; Springer: Cham, Switzerland, 2017; Volume 282. [Google Scholar] [CrossRef]

- Bouzouita, A. Elaboration of Polylactide-Based Materials for Automotive Application: Study of Structure-Process-Properties Interactions Amani Bouzouita. Ph.D. Thesis, Université de Valenciennes et du Hainaut-Cambresis, Valenciennes, France, Université de Mons, Mons, Belgium, 2016. [Google Scholar]

- Fort, T.; Bruns, K.; Bichel, A.; Miller, J.; Vanstrom, J.R.; Koziel, J.A. Puncture and Cut Resistant Glove Testing; TSM 416 Technology Capstone Projects. 31; Iowa State University Digital Repository: Ames, IA, USA, 2018. [Google Scholar] [CrossRef]

- Higher Dimension Materials, Inc. Cut, Abrasion and/or Puncture Resistant Knitted Gloves. U.S. Patent 20170055608, 2 March 2017.

- Chari, S.; Haines, T.; Varghese, P.; Economidis, A. Are non-slip socks really ’non-slip’? An analysis of slip resistance. BMC Geriatr. 2009, 9, 39. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Filamentum, Flexfill TPU 98A, TDS. Available online: http://www.fillamentumautomotive.com/wp-content/uploads/2020/10/Technical-Data-Sheet_Flexfill-TPU-98A_26082019.pdf (accessed on 16 August 2021).

- Ultimaker PLA, TDS. Available online: https://support.ultimaker.com/hc/en-us/articles/360011962720 (accessed on 16 August 2021).

- Taczała, J.; Rak, K.; Sawicki, J.; Krasowski, M. Numerical Analysis of the Bond Strength between Two Methacrylic Polymers by Surface Modification. Materials 2021, 14, 3927. [Google Scholar] [CrossRef]

- Surface Texture from Ra to Rz. Available online: https://www.mmsonline.com/columns/surface-texture-from-ra-to-rz (accessed on 16 August 2021).

| Mechanical Properties | Material | Typical Value | Test Method |

|---|---|---|---|

| Hardness | PLA | 83 (Shore D) | Durometer |

| Tensile modulus | PLA | 2.346 MPa | ISO 527 (1 mm/min) |

| Elongation at break | PLA | 5.2% | ISO 527 (50 mm/min) |

| Hardness | TPU | 60 (Shore D) | ISO 7619–1 |

| Tensile strength | TPU | 53.7 MPa | DIN 53504 (200 mm/min) |

| Elongation at break | TPU | 318% | DIN 53504 (200 mm/min) |

| Print Setting | Extruder 1: PLA | Extruder 2: TPU |

|---|---|---|

| Layer Height | 0.2 mm | 0.2 mm |

| Top/Bottom Line Width | 0.35 mm | 0.35 mm |

| Wall Line Court | 3 | 4 |

| Top/Bottom Layers | 5 | 6 |

| Infill Density | 70% | 100% |

| Infill Pattern | Triangles | Grid |

| Printing Temperature | 200 °C | 210 °C |

| Print Speed | 70 mm/s | 30 mm/s |

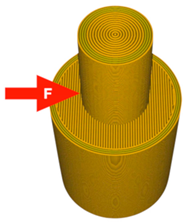

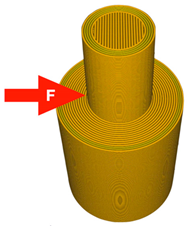

| A 3D Model with A Visible Pattern | Pattern Configuration | Material Configuration/N° | |

|---|---|---|---|

| Bottom: PLA Top: TPU | Bottom: TPU Top: PLA | ||

| Bottom part: Lines Top part: Concentric |  N°−1 |  N°−1A |

| Bottom part: Concentric Top part: Lines |  N°−2 |  N°−2A |

| Bottom part: Lines (Line direction: 0°) Top part: Lines (Line direction: 90°) | Failure N°−3 |  N°−3A |

| Bottom part: Lines (Line direction: 0°) Top part: Lines (Line direction: 45°) |  N°−4 |  N°−4A |

| Bottom part: Concentric Top part: Concentric |  N°−5 |  N°−5A |

| Bottom part: Lines 0° Top part: Lines 0° |  N°−6 |  N°−6A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brancewicz-Steinmetz, E.; Sawicki, J.; Byczkowska, P. The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU). Materials 2021, 14, 6464. https://doi.org/10.3390/ma14216464

Brancewicz-Steinmetz E, Sawicki J, Byczkowska P. The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU). Materials. 2021; 14(21):6464. https://doi.org/10.3390/ma14216464

Chicago/Turabian StyleBrancewicz-Steinmetz, Emila, Jacek Sawicki, and Paulina Byczkowska. 2021. "The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU)" Materials 14, no. 21: 6464. https://doi.org/10.3390/ma14216464

APA StyleBrancewicz-Steinmetz, E., Sawicki, J., & Byczkowska, P. (2021). The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU). Materials, 14(21), 6464. https://doi.org/10.3390/ma14216464