Mechanical Behavior of Titanium Based Metal Matrix Composites Reinforced with TiC or TiB Particles under Quasi-Static and High Strain-Rate Compression

Abstract

1. Introduction

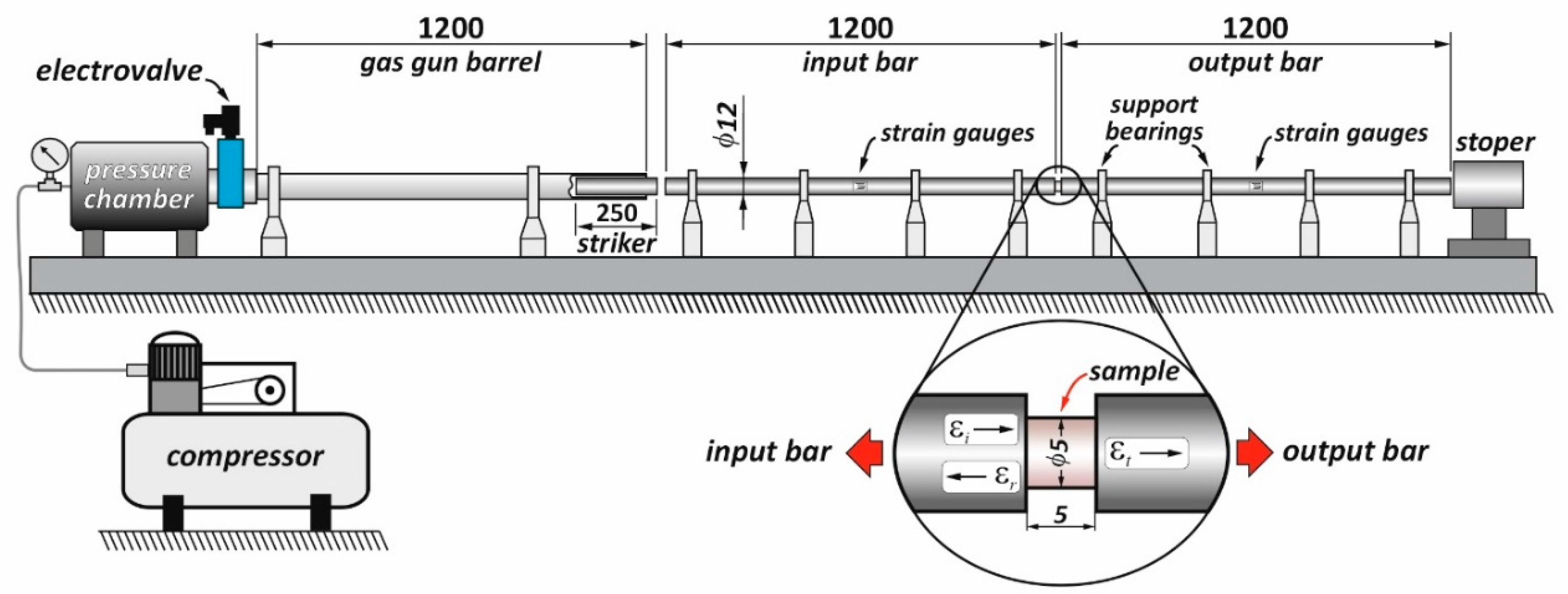

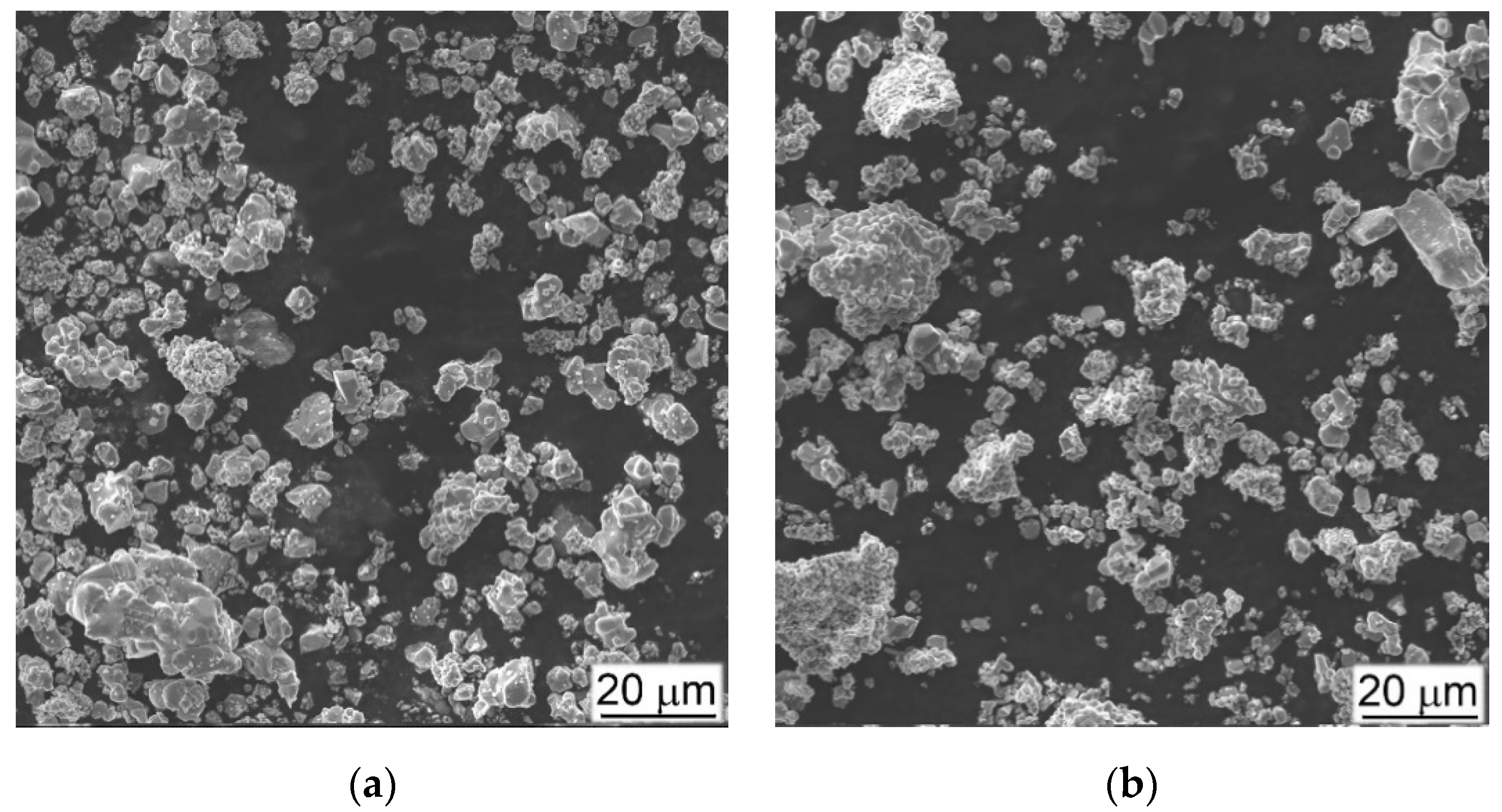

2. Materials and Methods

3. Results

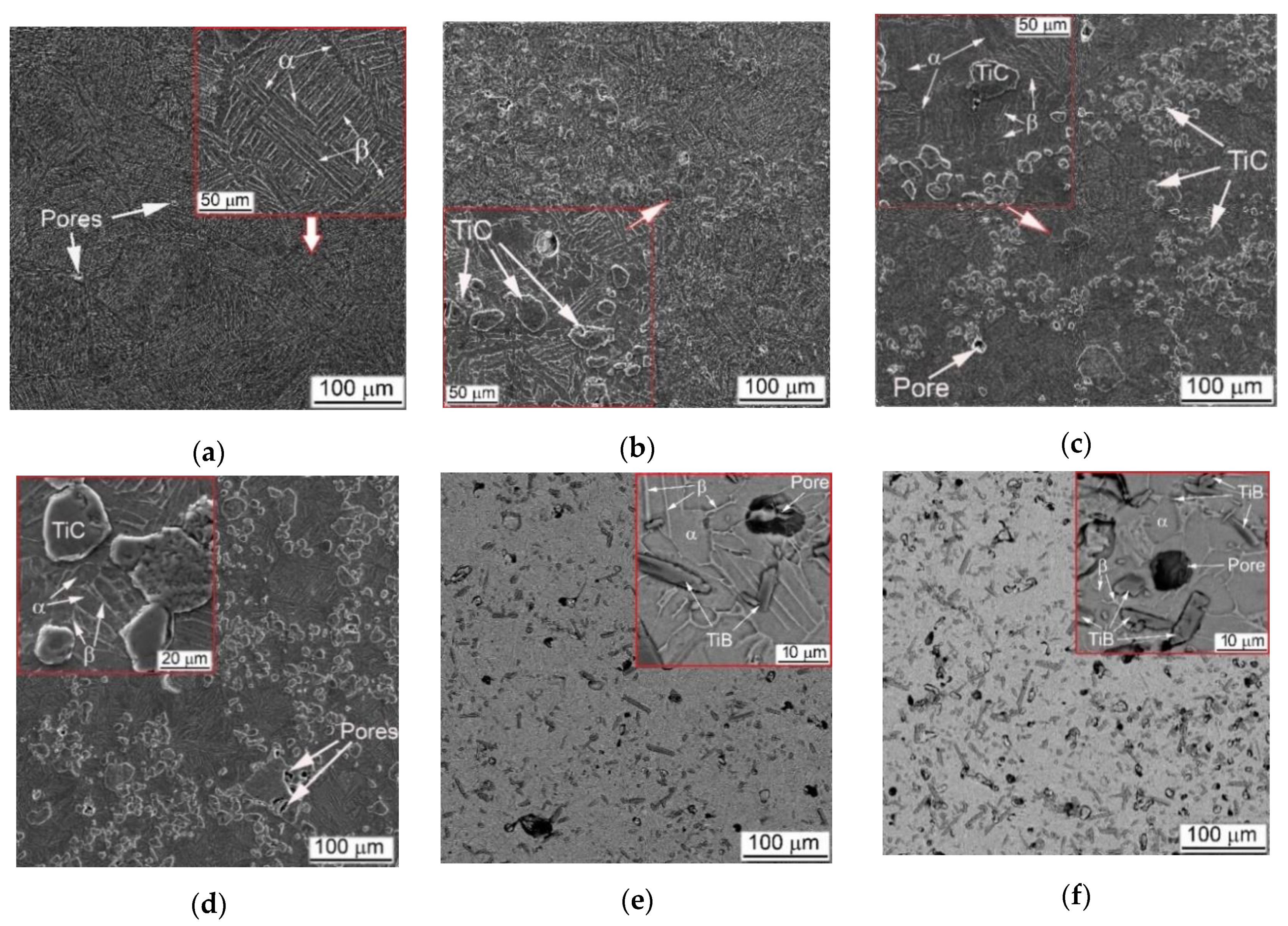

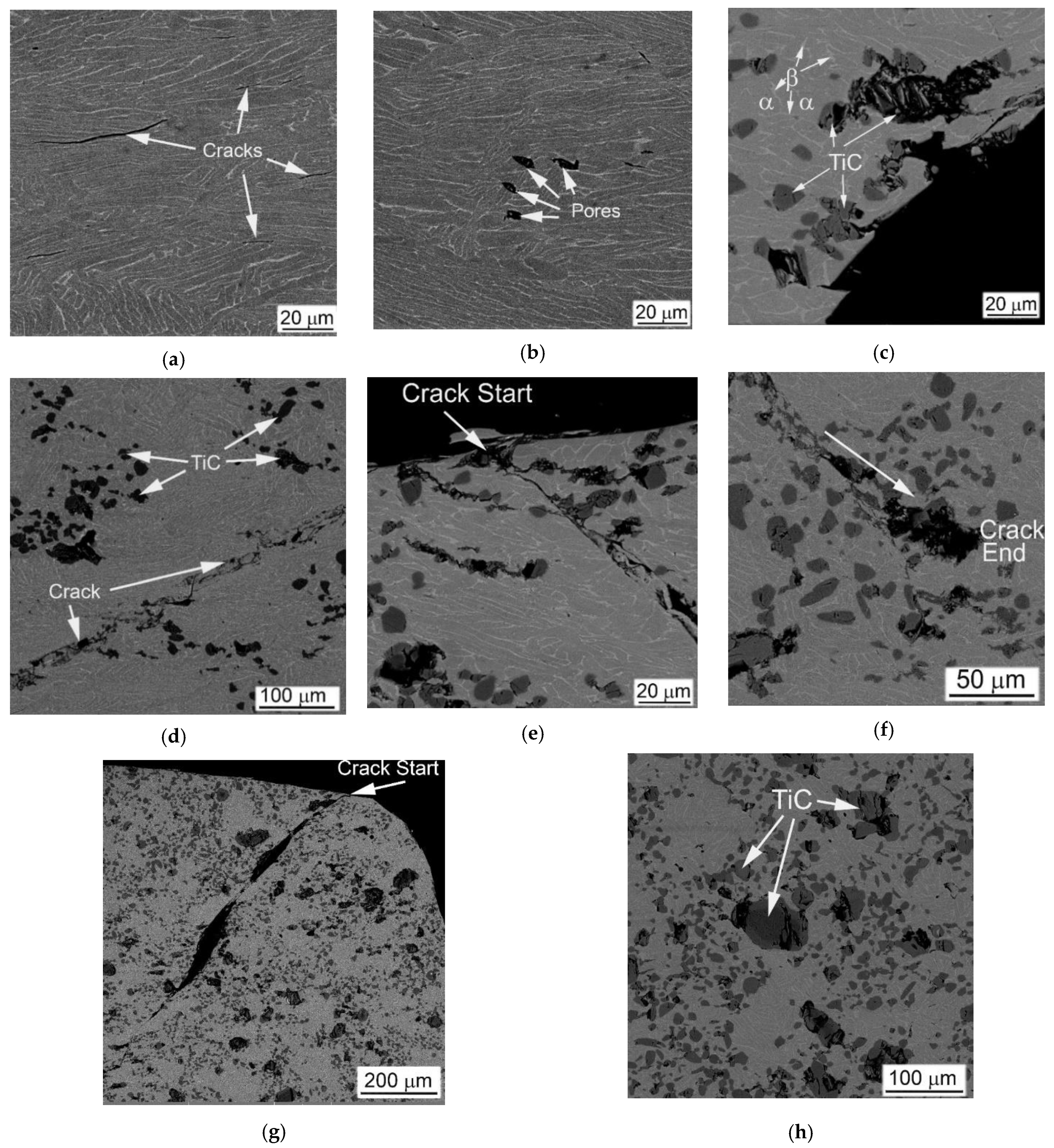

3.1. Characteristics of the Original Structures

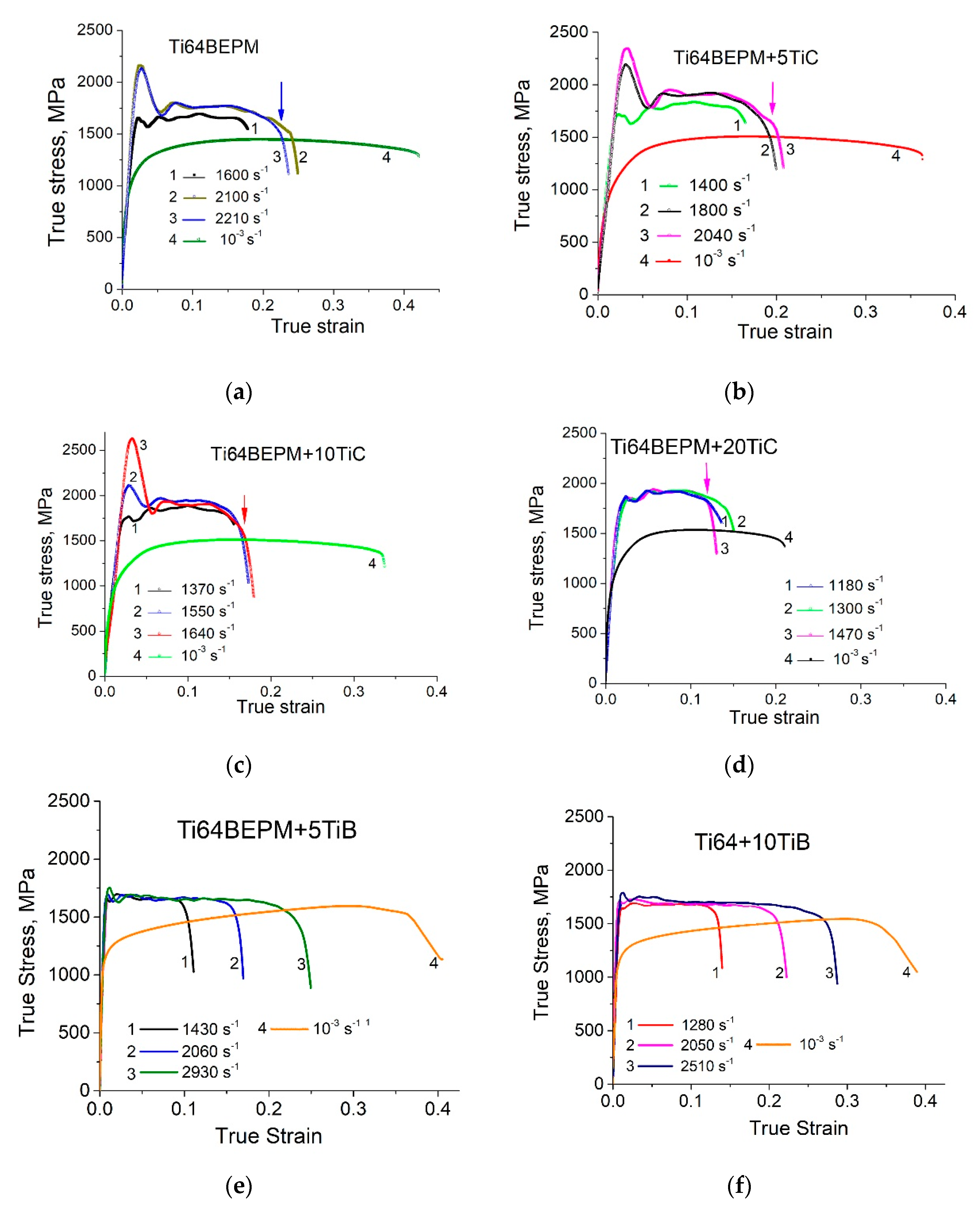

3.2. Compression Tests

4. Discussions

4.1. Strain Energy

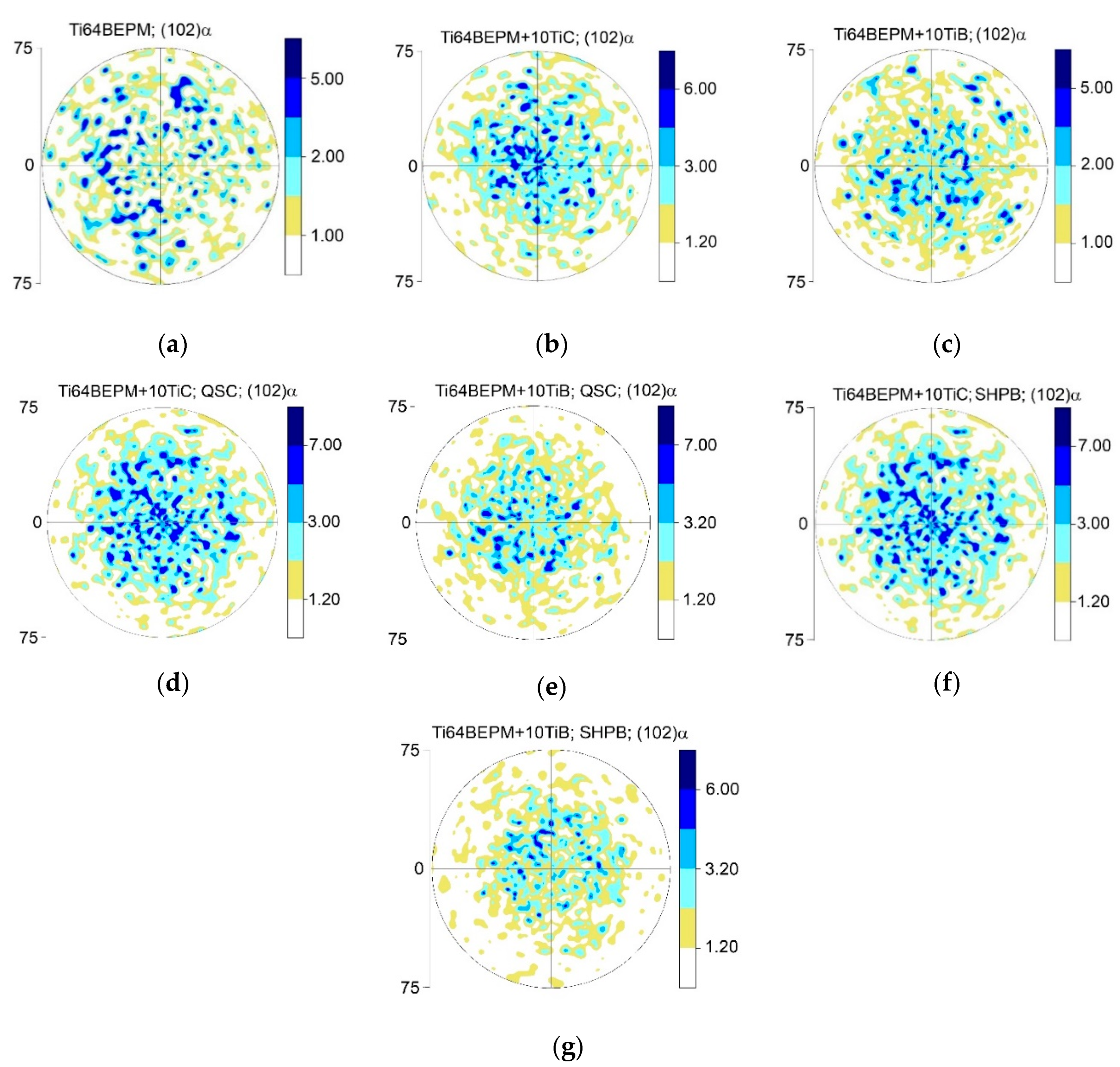

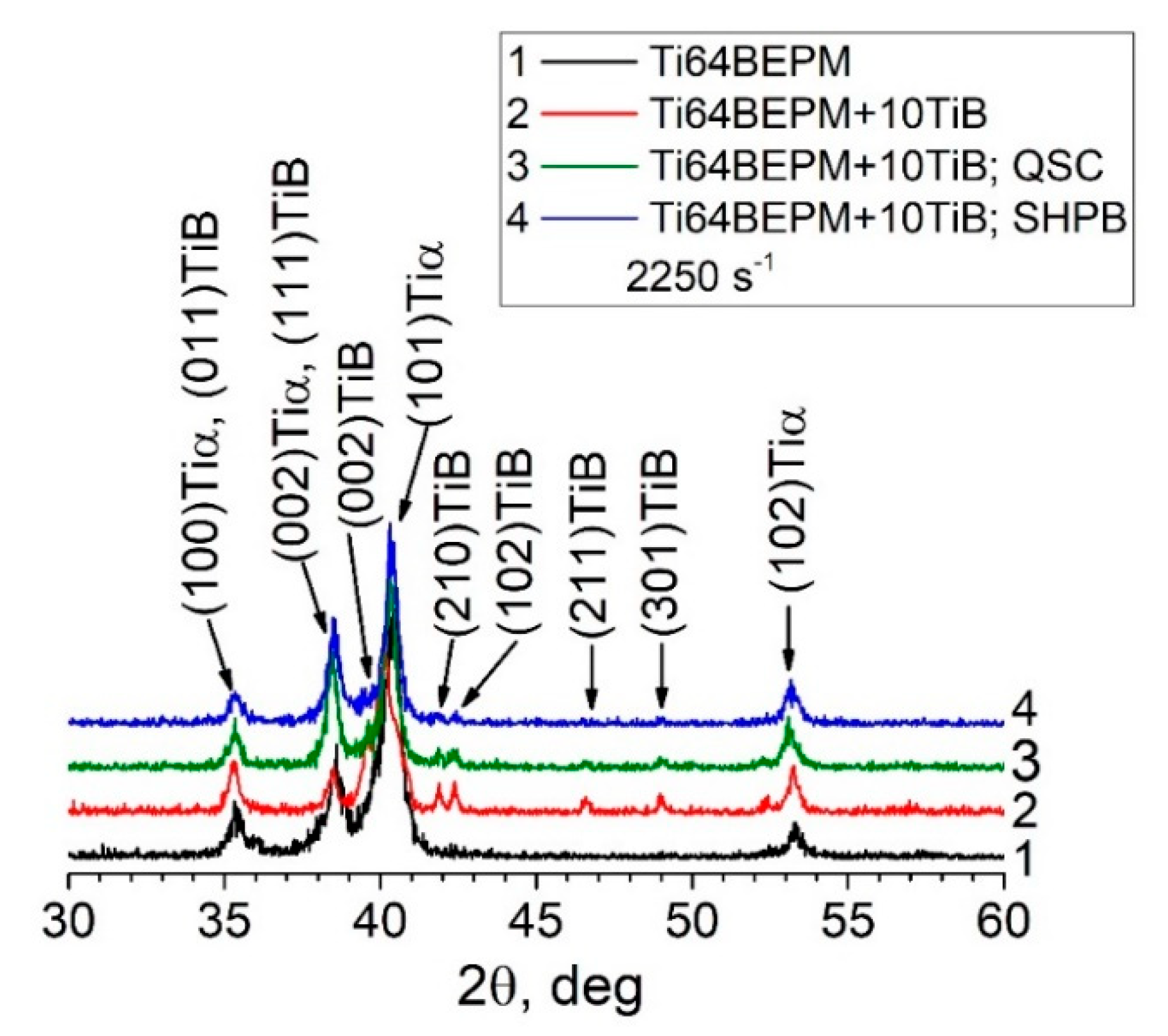

4.2. Changes in Phase Composition, Microstructure and Micro-Texture

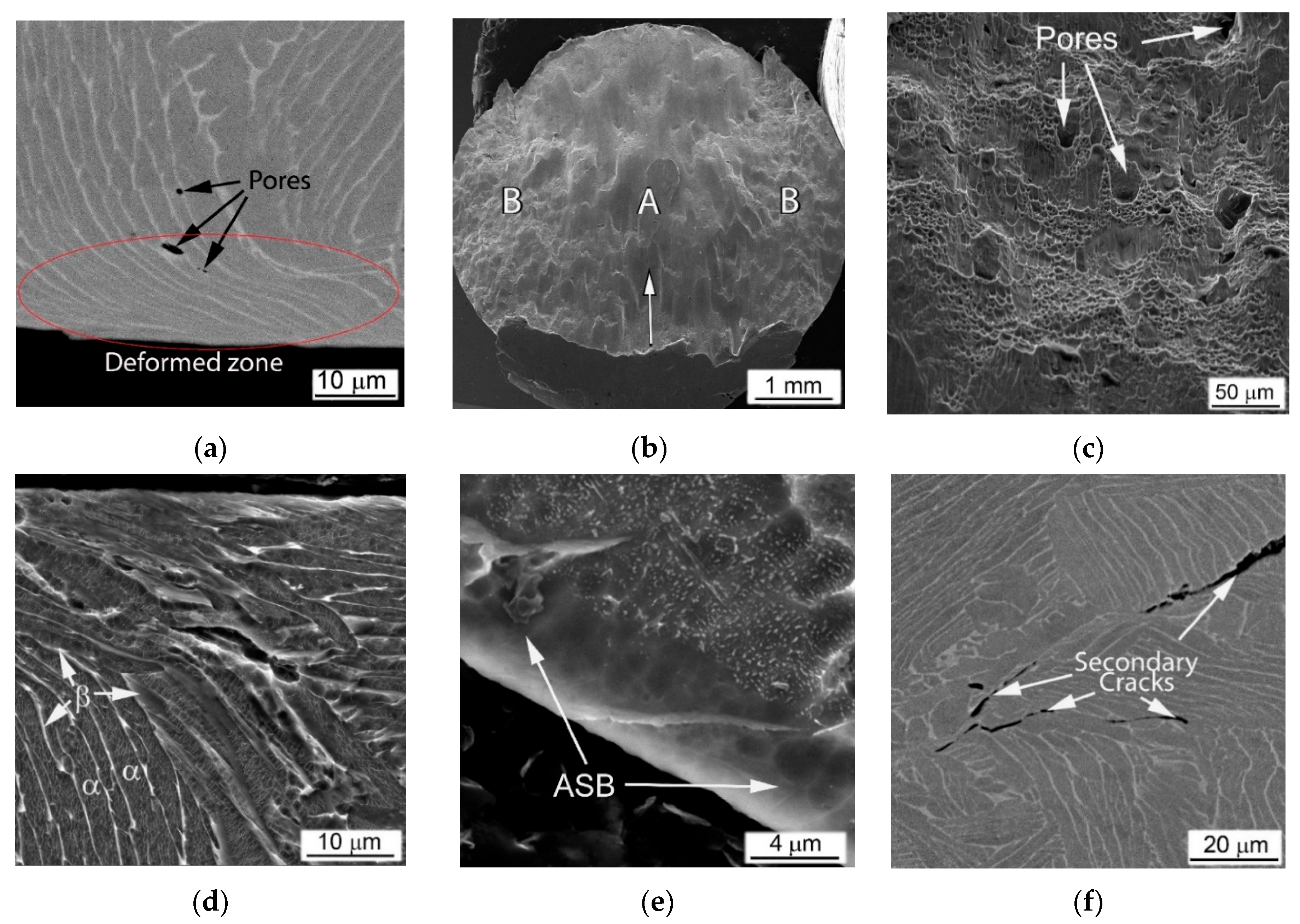

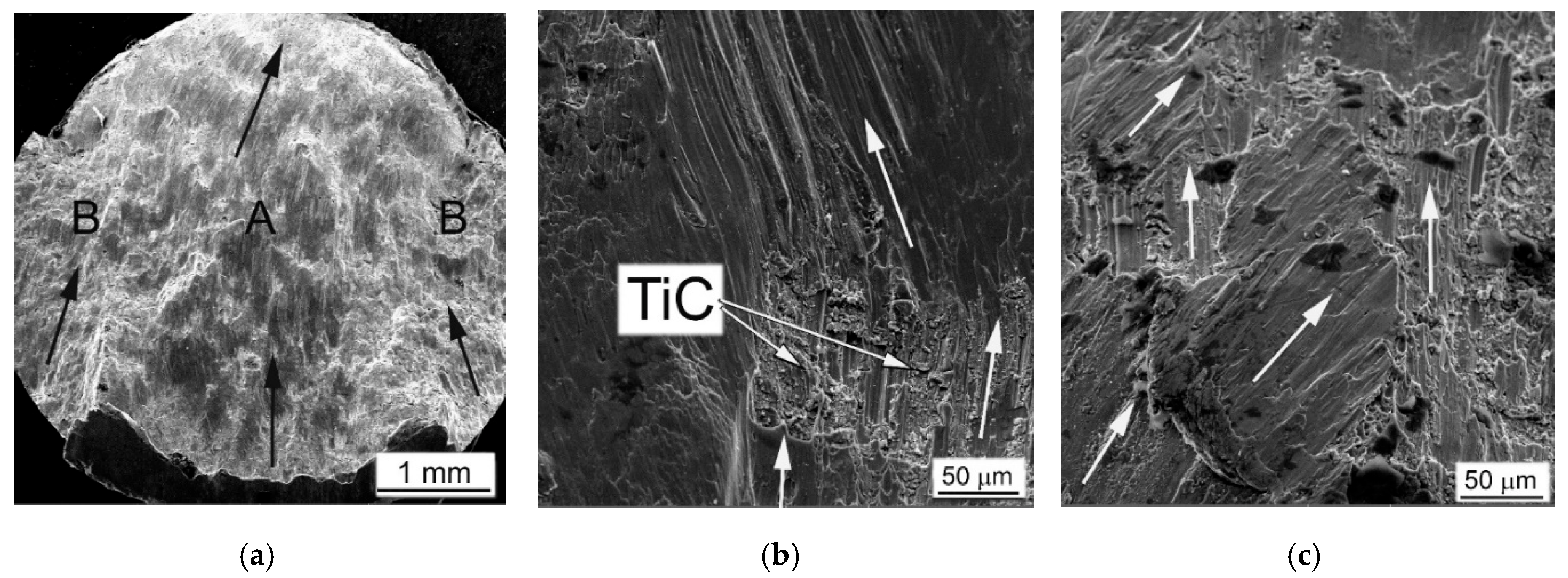

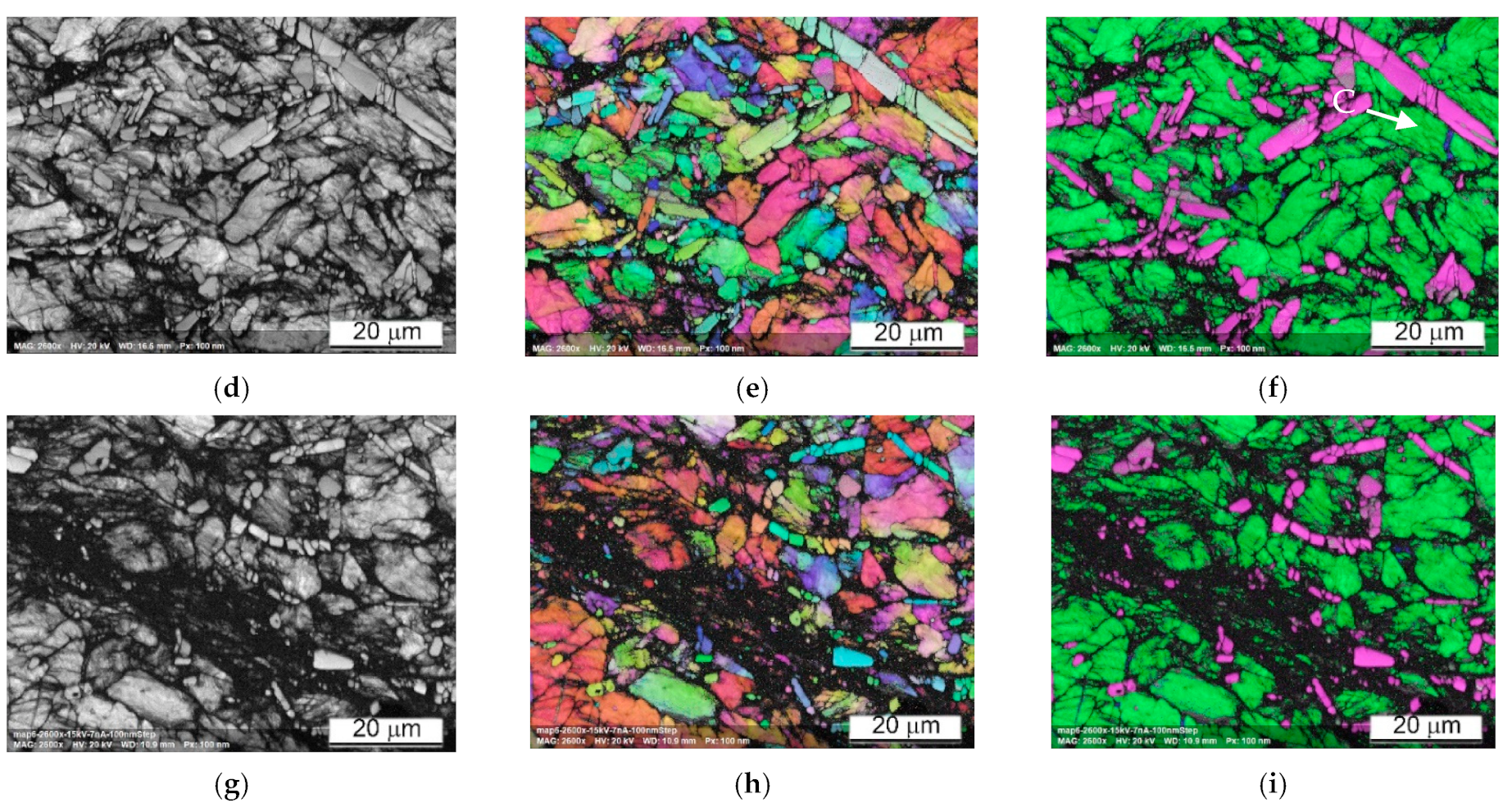

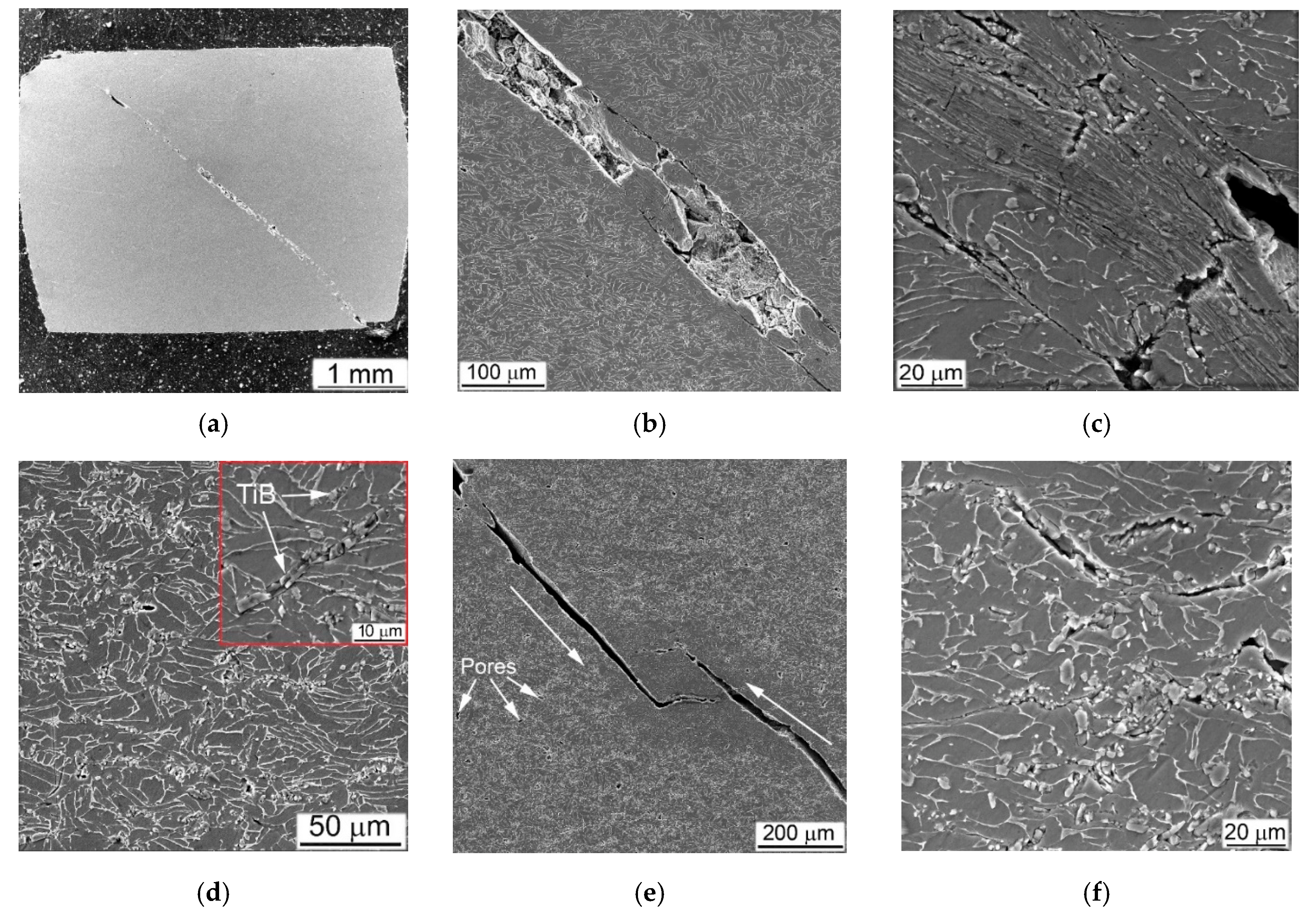

4.2.1. MMC Reinforced with TiC

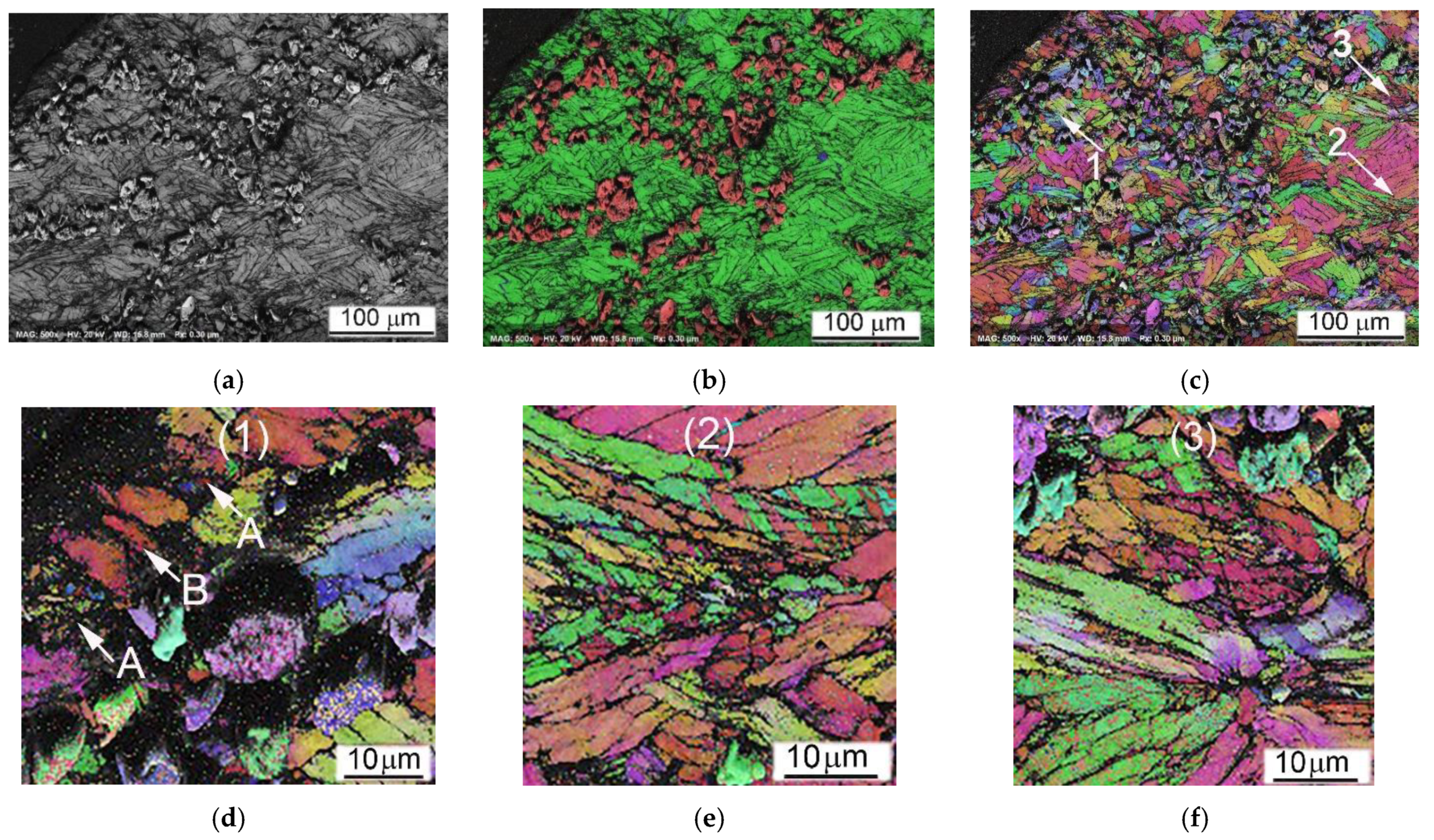

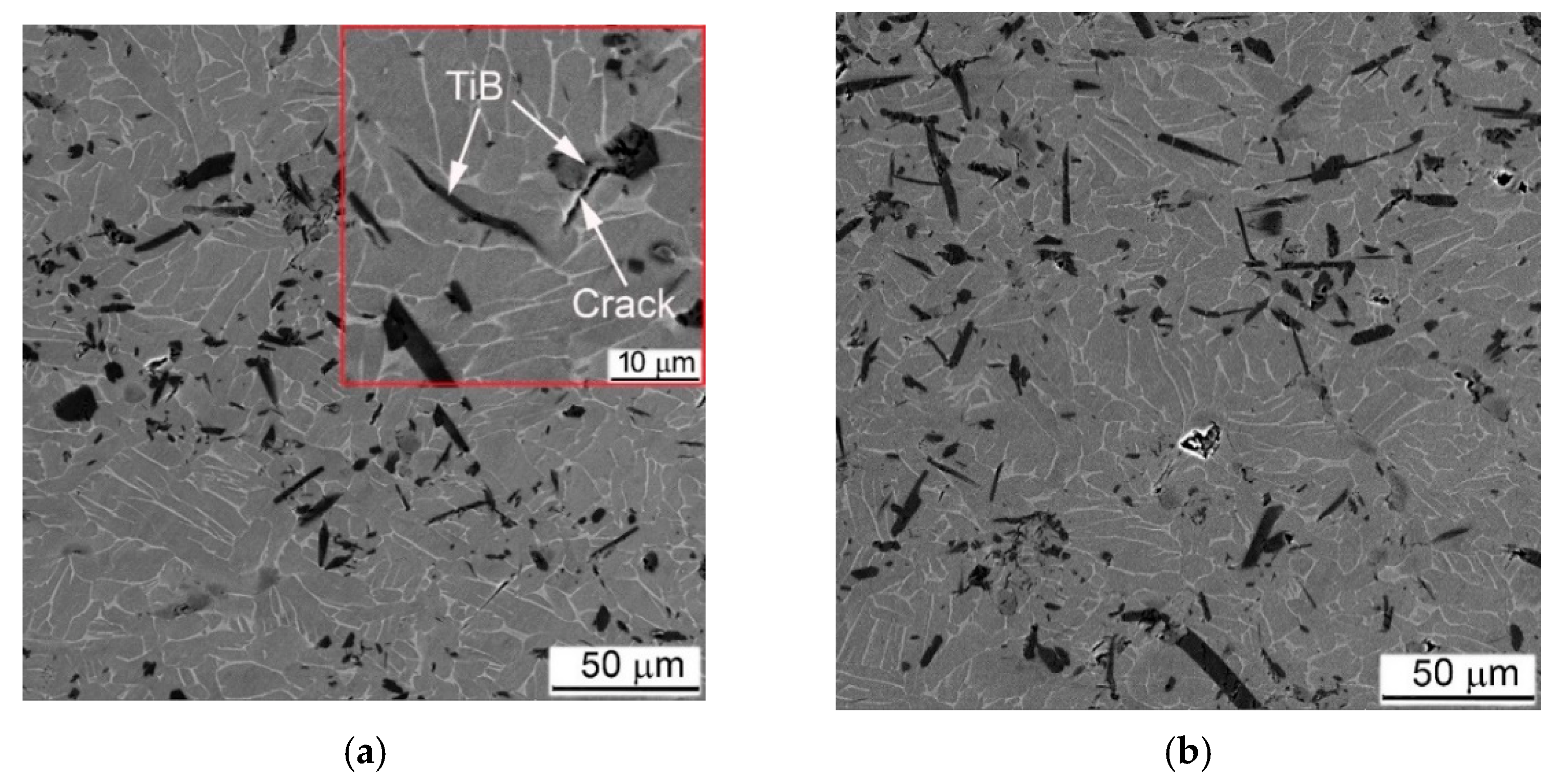

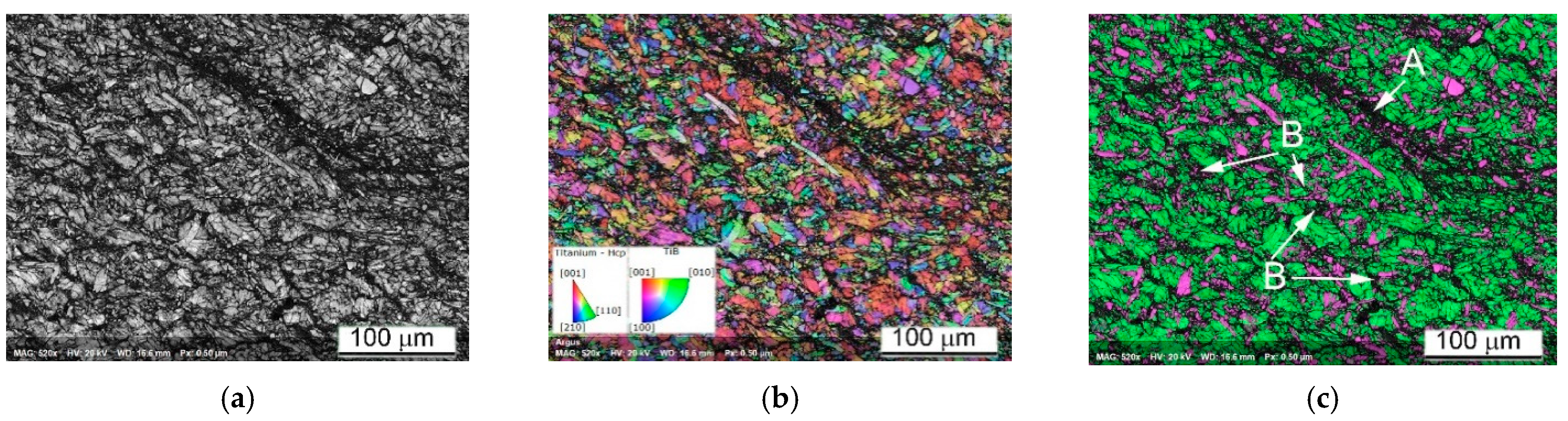

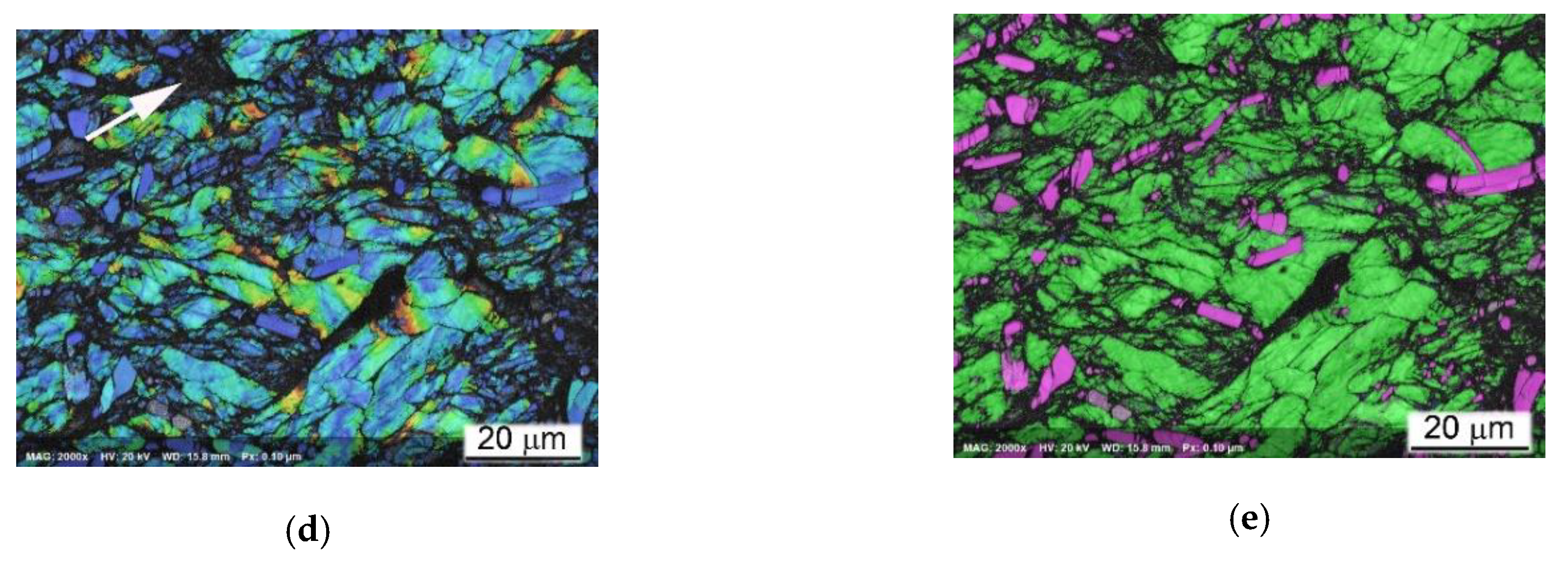

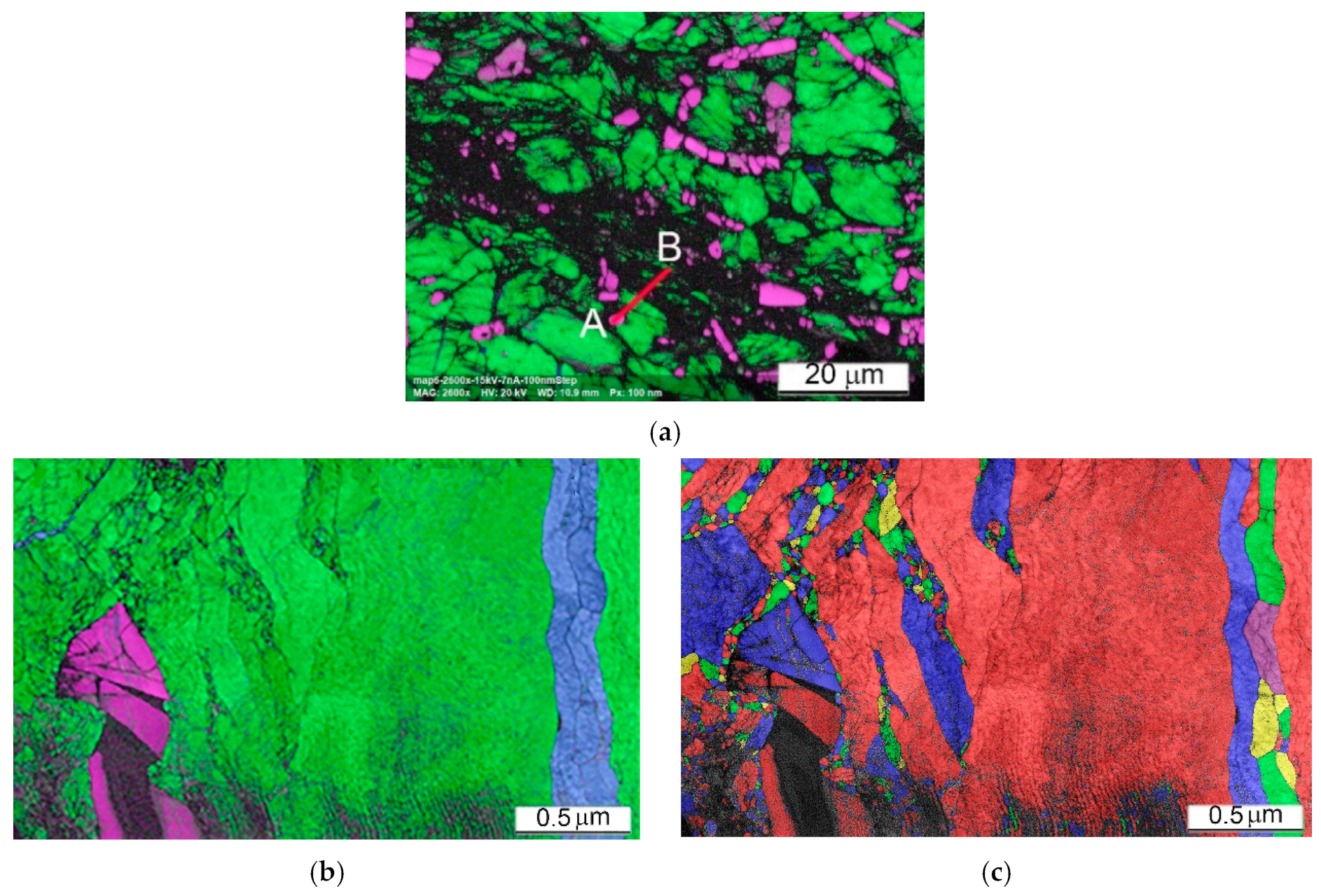

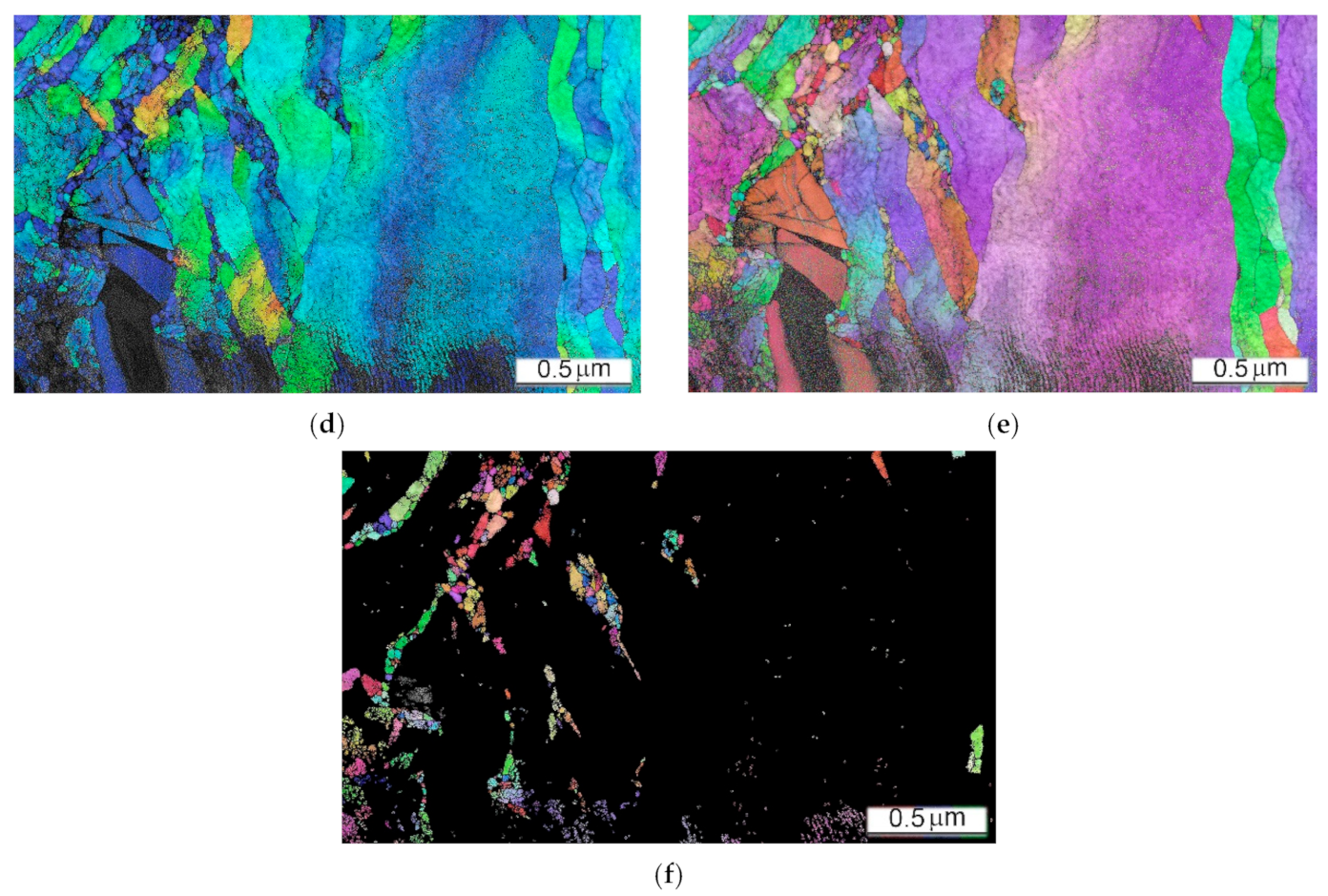

4.2.2. MMC Reinforced with TiB

- (1)

- TiB particle (magenta);

- (2)

- Relatively preserved, but most likely plastically deformed α-grains (green);

- (3)

- ASB I is a region that is not resolved by conventional EBSD due to extremely high fragmentation of the initial α-grains and/or high dislocation density reducing pattern quality, as well as a region of possible recrystallization;

- (4)

- ASB II is a region of a less deformed initial α-grains structure or possibly a region with a relatively larger recrystallized α-grains.

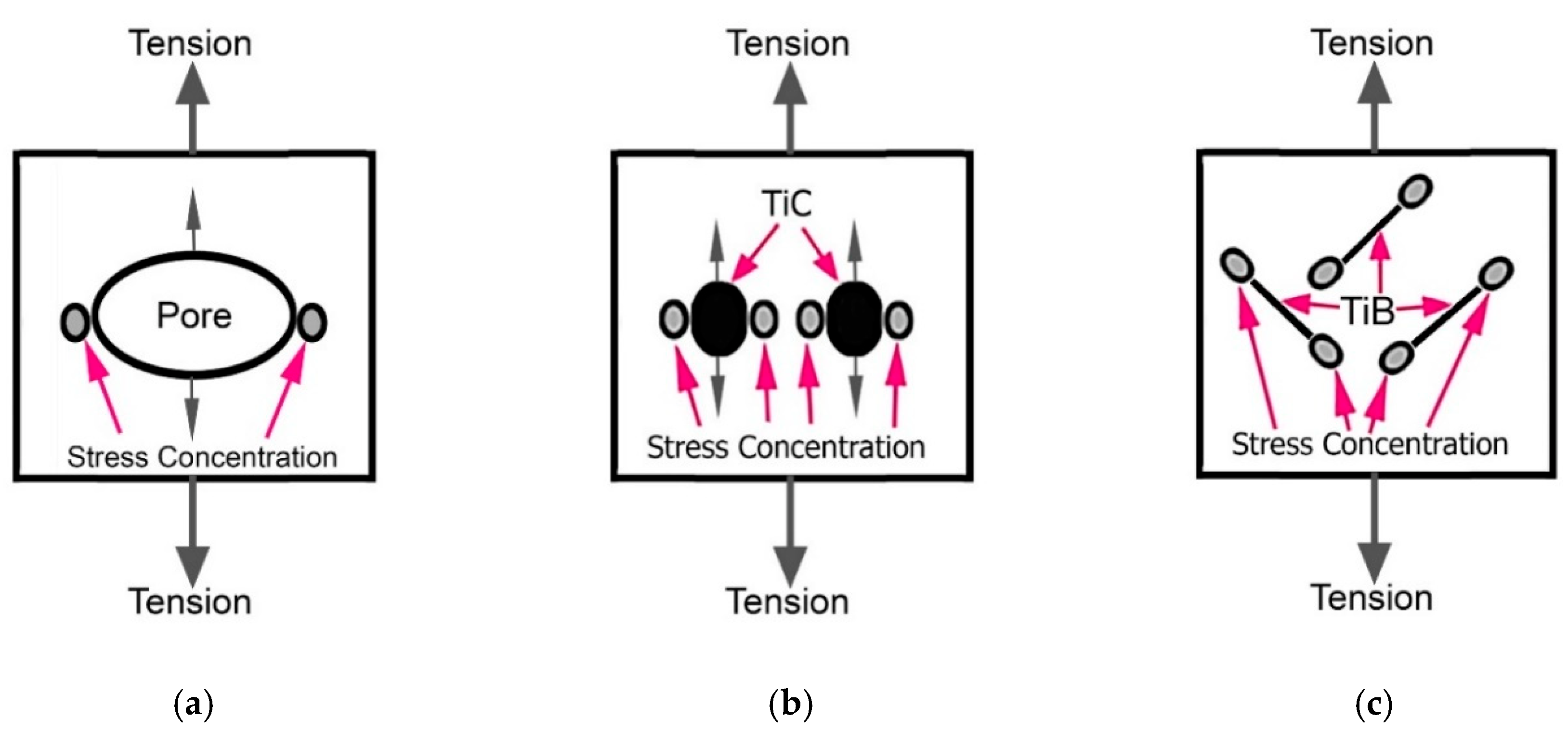

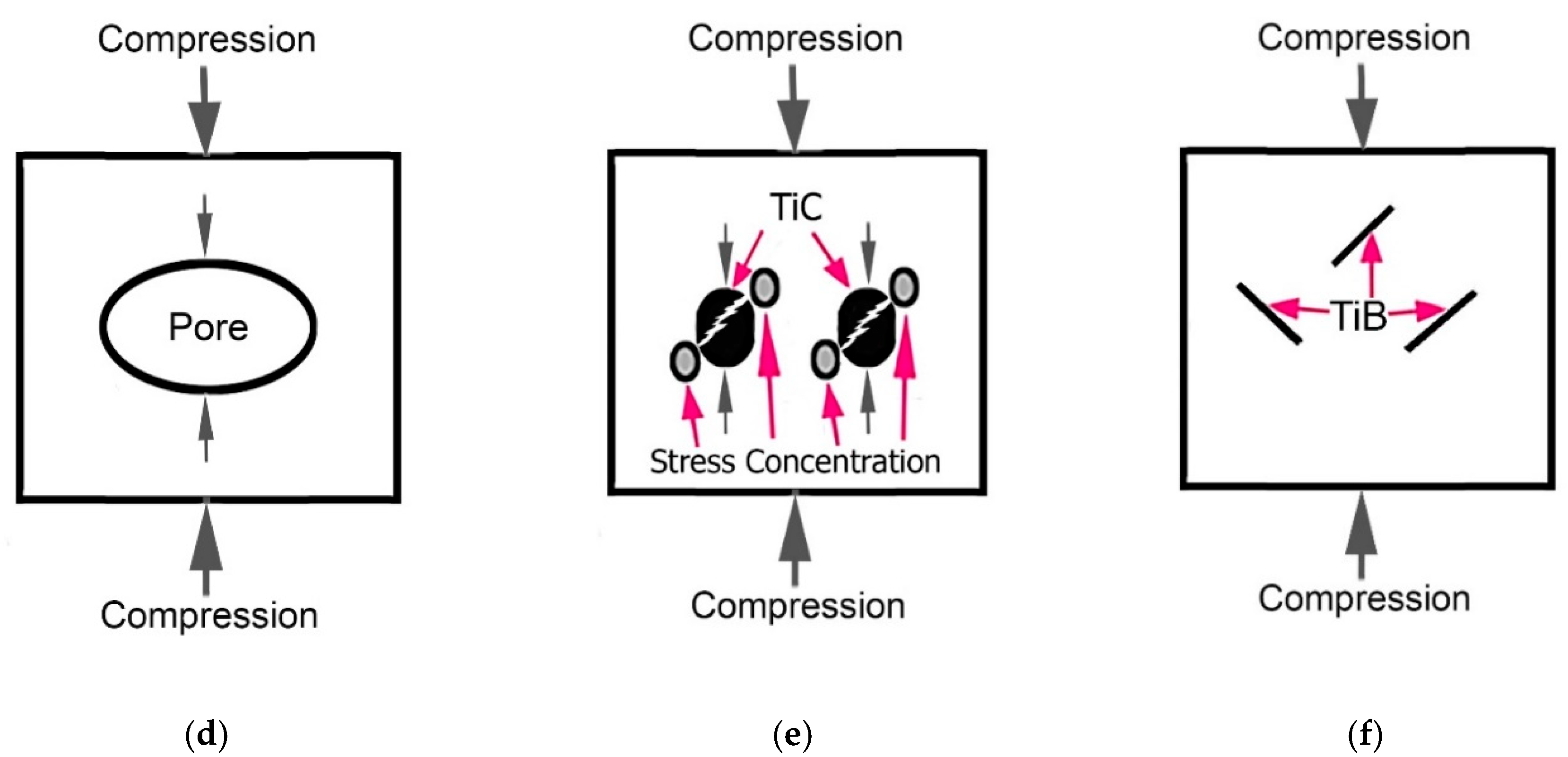

4.3. The Effect of Type of Reinforcing Particles and Their Volume Fraction on Deformation Mechanism and Deformation Energy

5. Conclusions

- The mechanical behavior of the alloy Ti64 based composites made using BEPM with different amounts of reinforcing particles: 5, 10, and 20% of TiC or 5, 10% (vol.) of TiB was analyzed taking into account the Strain Energy, phase composition, microstructure, and textures formed under dynamic and quasi static compression using strain rates in the range 10−3−103·s−1.

- All materials tested under dynamic conditions using SPB show high localization of plastic deformation in matrix alloy, mainly near reinforcement particles. Such localization was absent in materials tested under QSC.

- The measured Strain Energy and Maximal Strain Rates demonstrate the highest values for the cast and wrought alloy Ti64, followed by Ti64BEPM + 5TiC and Ti64BEPM + 10TiB, and then Ti64BEPM free of reinforcing particles.

- At high-strain SHPB tests, Ti64BEPM + XTiC composites have higher strength then a conventional cast and wrought Ti64 alloy if the content of TiC particles does not exceed 5% (vol.) and the strain rate does not exceed 1800 s−1. SE for Ti64BEPM + 5TiC and Ti64BEPM + 10TiC gradually increases with the strain rates reaching a maximum at 1800 s−1 and 1640 s−1, respectively, and then drops sharply as a result of brittle fracture. Ti64BEPM + 20TiC fractures at progressively lower strain rates, less than 1470 s−1, and due to a significant decrease in strength and ductility, its SE level is lower than that of Ti64BEPM + 5TiC. At lower strain rates, SE of Ti64BEPM + XTiB composites is lower compared to Ti64BEPM + XTiC equally reinforced, but due to higher plasticity of the composites Ti64BEPM + XTiB they exceed Ti64BEPM + XTiC in SE at strain rates above 2200 s−1.

- For Ti64BEPM alloy that does not contain reinforcing particles, the deformation localization mechanism changes from macro to micro level when the strain rate increases above 1800–2000 s−1. The localization of the macro level is characterized by plastic flow affects multiple grains forming the adiabatic shear bands. The plastic flow at the micro level is limited to separate α-phase lamellae. In Ti64BEPM +XTiC, the presence of particles gives emphasis to the localization of plastic deformation at the micro level. This is due to appearance of interfacial boundaries TiC/α and TiC/β, in addition to the interfacial boundaries α/β available in Ti64BEPM and the cast and wrought Ti64. With a higher content of TiC (20 vol.%), carbide particles became the weakest microstructure elements, which led to the brittleness of MMC and its fracture at relatively low rates (less than 1500 s−1) due to the simultaneous crushing of carbide particles and the formation of cracks inside the matrix.

- The negative effect of TiC is related to the high brittleness of particles or their conglomerates, which can cause the MMC to fracture under compression with relatively low strain rates. Stress concentration is formed at the interface between the carbide fragments and the matrix. Stress concentration effect under compression is less pronounced for MMC with TiB particles, which leads to an improvement in mechanical behavior of MMC composites at a higher deformation rate.

- Localization of plastic deformation at a high strain-rates compression of MMCs with TiB, causes intense local overheating at the interface between the alloy matrix and the particles of TiB. As a result, rapid dynamic recrystallization of matrix phases can occur locally to form grains with a size of not more than 10 nm.

- The damping ability of materials, which is analogous to the absorption of strain energy, was measured by the analysis of resonance-frequency-damping capacity. It shows that MMCs containing TiC or TiB particles absorb sound waves better in comparison with Ti64BEPM alloy free from particles. It was explained by the presence of interphases of TiC(TiB)/α, and TiC(TiB)/β in MMCs in addition to α/β interphases in the matrix alloy. The extra interfaces additionally inhibit the dislocation motion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Acronyms

| Acronym | Term |

| Ti64 | Commercial titanium alloy containing 6 (wt.)% Al and 4% V |

| Ti64GL | Ti-6Al-4V alloy with globular microstructure |

| BEPM | Blended Elemental Powder Metallurgy |

| Ti64BEPM | Titanium based alloy Ti-6(wt.)%Al-4V produced using BEPM |

| MMC | Metal Matrix Composite |

| Ti64BEPM + (X)TiC | MMC on the base of Ti-6Al-4V alloy containing X(vol.%) of Titanium Carbide (TiC) produced using BEPM |

| Ti64BEPM + (X)TiB | MMC on the base of Ti-6Al-4V alloy containing X(vol.%) of Titanium Boride (TiB) produced using BEPM |

| SE | Strain Energy |

| QSC | Quasi-Static compression |

| QST | Quasi-Static tension |

| SHPB | Split Hopkinson Pressure Bar |

| SEM | Scanning Electron Microscopy |

| SE | Secondary Electrons |

| BSE | Back Scattered Electrons |

| EBSD | Electron Backscatter Diffraction |

| ASB | Adiabatic Shear Band |

| GAM | Grain Average Misorientation |

| IPFz | Inverted Pole Figure in “z” axis |

| TKD | Transmission Kikuchi Diffraction |

| max | Maximal Strain Rate for which specimens were not fractured during the SHPB tests |

| Cr | Critical Strain Rate for which specimens became fractured during SHPB tests first time |

| εupper | Maximum strain at fracture, or for the non-cracked specimens, equal to strain at the moment of the specimen unloading |

| SEmax | Maximal Strain Energy value obtained on SHPB impact tests at Maximal Strain Rate |

| YS | Yield Strength (on Tension) |

| UTS | Ultimate Tensile Strength (on Tension) |

| El | Relative elongation (on Tension) |

| RA | Reduction in Area (on Tension) |

References

- Lutjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2007. [Google Scholar] [CrossRef]

- Boyer, R.R.; Briggs, R.D. The Use of β Titanium Alloys in the Aerospace Industry. J. Mater. Eng. Perform. 2005, 14, 681. [Google Scholar] [CrossRef]

- Niinomi, M. Recent metallic materials for biomedical applications. Metall. Mater. Trans. 2002, 33A, 477. [Google Scholar] [CrossRef]

- Fanning, J. Military Application for b Titanium Alloys. J. Mater. Eng. Perform. 2005, 14, 686–690. [Google Scholar] [CrossRef]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Sivakumar, B.; Kumar, S.; Sankara Narayanan, T.S.N. Comparison of fretting corrosion behaviour of Ti–6Al–4V alloy and CP-Ti in Ringer’s solution. Tribol. Mater. Surf. Interfaces 2011, 5, 158–164. [Google Scholar] [CrossRef]

- Poondla, N.; Srivatsan, T.S.; Patnaik, A.; Petraroli, M. A study of the microstructure and hardness of two titanium alloys: Commercially pure and Ti–6Al–4V. J. Alloy. Compd. 2009, 486, 162–167. [Google Scholar] [CrossRef]

- Eriksson, M.; Salamon, D.; Nygren, M.; Shen, Z. Spark plasma sintering and deformation of Ti–TiB2 composites. Mater. Sci. Eng. A 2007, 475, 101–104. [Google Scholar] [CrossRef]

- Fan, Z.; Guo, Z.X.; Cantor, B. The kinetics and mechanism of interfacial reaction in sigma fibre-reinforced Ti MMCs. Compos. Part A Appl. Sci. Manuf. 1997, 28, 131–140. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Markovsky, P.E.; Savvakin, D.G.; Stasiuk, O.O.; Norouzi Rad, M.; Prikhodko, S.V. Multi-layered structures of Ti-6Al-4V alloy and TiC and TiB composites on its base fabricated using blended elemental powder metallurgy. J. Mater. Process. Technol. 2019, 269, 172–181. [Google Scholar] [CrossRef]

- Stefansson, N.; Weiss, I.; Hutt, A.J. Titanium’95: Science and Technology; Blenkinsop, P.A., Evans, W.J., Flower, H.M., Eds.; The University Press: Cambridge, UK, 1996; Volume 2, pp. 980–987. [Google Scholar]

- Bhattacharjee, A.; Ghosal, P.; Gogia, A.K.; Bhargava, S.; Kamat, S.V. Room temperature plastic flow behaviour of Ti–6.8Mo–4.5Fe–1.5Al and Ti–10V–4.5Fe–1.5Al: Effect of grain size and strain rate. Mat. Sci. Eng. A 2007, 452–453, 219–227. [Google Scholar] [CrossRef]

- Markovsky, P.E.; Matviychuk, Y.U.V.; Bondarchuk, V.I. Influence of grain size and crystallographic texture on mechanical behavior of TIMETAL-LCB in metastable β-condition. Mater. Sci. Eng. A 2013, 559, 782–789. [Google Scholar] [CrossRef]

- Markovsky, P.E.; Bondarchuk, V.I.; Herasymchuk, O.M. Influence of Grain Size, Aging Conditions and Tension Rate on Mechanical Behavior of Titanium Low-Cost Metastable Beta-Alloy in Thermally Hardened Condition. Mater. Sci. Eng. 2015, A645, 150–162. [Google Scholar] [CrossRef]

- Markovsky, P.E.; Bondarchuk, V.I.; Shepotinnyk, O.V.; Gavrysh, I.M. Influence of phase composition and microstructure on mechanical behavior of Ti-3Al-4.5Fe-7.2Cr and VT22 titanium metastable β alloys on tension with different rates. Metallofiz. Noveyshye Tekhnologii 2016, 38, 935–952. [Google Scholar] [CrossRef]

- Markovsky, P.E.; Bondarchuk, V.I. Influence of strain rate, microstructure, chemical and phase composition on mechanical behavior of different titanium alloys. J. Mater. Eng. Perform. 2017, 26, 3431–3449. [Google Scholar] [CrossRef]

- Markovsky, P.E. Mechanical Behavior of Titanium Alloys under Different Conditions of Loading. Mater. Sci. Forum THERMEC-2018 2018, 941, 839–844. [Google Scholar] [CrossRef]

- Peirs, J.; Verleysen, P.; Degrieck, J.; Coghe, F. The use of hat-shaped specimens to study the high strain rate shear behavior of Ti–6Al–4V. Int. J. Impact Eng. 2010, 37, 703–714. [Google Scholar] [CrossRef]

- Meyer, H.W., Jr.; Kleponis, D.S. Modeling the high strain rate behavior of titanium undergoing ballistic impact and penetration. Int. J. Impact Eng. 2001, 26, 509–521. [Google Scholar] [CrossRef]

- Zheng, C.; Wang, F.; Cheng, X.; Liu, J.; Fu, K.; Liu, T.; Zhu, Z.; Yang, K.; Peng, M.; Jin, D. Failure mechanisms in ballistic performance of Ti6Al4V targets having equiaxed and lamellar microstructures. Int. J. Impact Eng. 2015, 85, 161–169. [Google Scholar] [CrossRef]

- Tianfeng, Z.; Junjie, W.; Jiangtao, C.; Ying, W.; Xibin, W. Dynamic shear characteristics of titanium alloy Ti-6Al-4V at large strain rates by the split Hopkinson pressure bar test. Int. J. Impact Eng. 2017, 109, 167–177. [Google Scholar] [CrossRef]

- Markovsky, P.E.; Janiszewski, J.; Bondarchuk, V.I.; Stasyuk, O.O.; Skoryk, M.A.; Cieplak, K.; Dziewit, P.; Prikhodko, S. Effect of Strain Rate on Microstructure Evolution and Mechanical Behavior of Titanium-Based Materials. Metals 2020, 10, 1404. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Teliovych, R.V.; Ivanchenko, V.G.; Tamirisakandala, S.; Miracle, D.B. Processing, microstructure, texture, and tensile properties of the Ti-6Al-4V-1.55 B eutectic alloy. Metall. Mater. Trans. A 2008, 39, 402–426. [Google Scholar] [CrossRef]

- Markovsky, P.E.; Savvakin, D.G.; Ivasishin, O.M.; Bondarchuk, V.I.; Prikhodko, S.V. Mechanical Behavior of Titanium-Based Layered Structures Fabricated Using Blended Elemental Powder Metallurgy. J. Mater. Eng. Perform. 2019, 28, 5772–5792. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Anokhin, V.M.; Demidik, A.N.; Savvakin, D.G. Cost-Effective Blended Elemental Powder Metallurgy of Titanium Alloys for Transportation Application. Key Eng. Mater. 2000, 188, 55–62. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Moxson, V.S. Low cost titanium hydride powder metallurgy. In Titanium Powder Metallurgy, Science, Technology and Applications; Qian, M., Froes, S.H., Eds.; Elsevier: Amsterdam, The Netherlands; Boston, MA, USA; Heidelberg, Germany; London, UK; New York, NY, USA; Oxford, UK; Paris, France; San Diego, CA, USA; San Francisco, CA, USA; Singapore; Sydney, Australia; Tokyo, Japan, 2015; Chapter 8; pp. 117–148. [Google Scholar]

- Qian, M. Cold Compaction and Sintering of Titanium and its Alloys for Near-Net-Shape or Preform Fabrication. Int. J. Powder Metall. 2010, 46, 29–44. [Google Scholar]

- Lee, C.S.; Oh, J.C.; Lee, S. Improvement of Hardness and Wear Resistance of (TiC, TiB)/Ti-6Al-4V Surface-Alloyed Materials Fabricated by High-Energy Electron-Beam irradiation. Metall. Mater. Trans. A 2003, 34A, 1461–1471. [Google Scholar] [CrossRef][Green Version]

- Savvakin, D.G.; Prikhodko, S.V.; Stasyuk, O.O.; Markovsky, P.E. Influence of TiC content and Strengthening Heat Treatment on Microstructure and Hardness of Metal Matrix Composite Based on Ti-6Al-4V Alloy. In preparation.

- Kolsky, H. Stress waves in solids. J. Sound Vib. 1964, 1, 88–110. [Google Scholar] [CrossRef]

- Sreenivasan, P.R.; Ray, S.K. Mechanical Testing at High Strain Rates. In Encyclopedia of Materials: Science and Technology, 2nd ed.; Elsevier: Amsterdam, The Netherlands; Boston, MA, USA; Heidelberg, Germany; London, UK; New York, NY, USA; Oxford, UK; Paris, France; San Diego, CA, USA; San Francisco, CA, USA; Singapore; Sydney, Australia; Tokyo, Japan, 2001; pp. 5269–5271. [Google Scholar]

- Chen, W.; Song, B. Split Hopkinson (Kolsky) Bar: Design, Testing and Applications; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2011. [Google Scholar] [CrossRef]

- Semiatin, S.L. An Overview of the Thermomechanical Processing of α/β Titanium Alloys: Current Status and Future Research Opportunities. Metall. Mater. Trans. A 2020, 51, 2593–2625. [Google Scholar] [CrossRef]

- Zhong, Z.; Zhang, B.; Jin, Y.; Zhang, H.; Wang, Y.; Ye, J.; Liu, Q.; Hou, Z.; Zhang, Z.; Ye, F. Design and anti-penetration performance of TiB/Ti system functionally graded material armor fabricated by SPS combined with tape casting. Ceram. Int. 2020, 46 Pt A, 28244–28249. [Google Scholar] [CrossRef]

- Wanjara, P.; Drew, R.A.L.; Root, J.; Yue, S. Evidence for Stable Stoichiometric Ti2C at the Interface in TiC Particulate Reinforced Ti Alloy Composites. Acta Mater. 2000, 48, 1443–1450. [Google Scholar] [CrossRef]

- Roger, J.; Gardiola, B.; Andrieux, J.; Viala, J.-C.; Dezellus, O. Synthesis of Ti matrix composites reinforced with TiC particles: Thermodynamic equilibrium and change in microstructure. J. Mater. Sci. 2017, 52, 4129–4141. [Google Scholar] [CrossRef]

- Ohring, M. Materials Science of Thin Films, Deposition and Structure; Academic Press: Cambridge, MA, USA, 2002; 794p. [Google Scholar] [CrossRef]

- Kyogoku, H.; Komatsu, S.; Shinohara, K.; Jinushi, H.; Toda, T. Microstructures and Mechanical Properties of Sintered Ti-4% Fe Alloy Compacts by Injection Moldings. J. Jpn. Soc. Powder Powder Metall. 1994, 41, 1075–1079. [Google Scholar] [CrossRef]

- Krivoglaz, M.A. X-ray and Neutron Diffraction in Nonideal Crystals; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1996; 494p. [Google Scholar] [CrossRef]

- Biswas, N.; Ding, J.L. Numerical Study of the Deformation and Fracture Behavior of Porous Ti6Al4V Alloy under Static and Dynamic Loading. Int. J. Impact Eng. 2015, 82, 89–102. [Google Scholar] [CrossRef]

- Kumar, P.; Ravi Chandran, K.S.; Cao, F.; Koopman, M.; Zak Fang, Z. The Nature of Tensile Ductility as Controlled by Extreme-Sized Pores in Powder Metallurgy Ti-6Al-4V Alloy. Metall. Mater. Trans. A 2016, 47A, 2150–2161. [Google Scholar] [CrossRef]

- Markovsky, P.E. High-strength structural states in titanium alloys subjected to intense thermal action. Met. Adv. Technol. 2009, 31, 511–535. (In Russian) [Google Scholar]

- Bignona, M.; Bertrand, E.; Tancret, F.; Rivera-Díaz-del-Castillo, P.E.J. Modelling martensitic transformation in titanium alloys: The influence of temperature and deformation. Materialia 2019, 7, 100382. [Google Scholar] [CrossRef]

- Bignona, M.; Bertrand, E.; Rivera-Díaz-del-Castillo, P.E.J.; Tancret, F. Martensite formation in titanium alloys: Crystallographic and compositional effects. J. Alloy. Compd. 2021, 872, 159636. [Google Scholar] [CrossRef]

- Prikhodko, S.V.; Kakoulli, I. Electron microscopy in conservation. In The Encyclopedia of Archaeological Sciences; Varela, S.L.L., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Paramore, J.D.; Butler, B.G.; Dunstan, M.K.; Rhee, H.; El Kadiri, H.; Whittington, W.R.; Mujahid, S.H. The role of microstructure and strain rate on the mechanical behavior of Ti6Al-4V produced by powder metallurgy. Int. J. Refract. Met. Hard Mater. 2020, 92, 105268. [Google Scholar] [CrossRef]

- Roebben, G.; Bollen, B.; Brebels, A.; Van Humbeeck, J.; Van der Biest, O. Impulse excitation apparatus to measure resonant frequencies, elastic moduli, and internal friction at room and high temperature. Rev. Sci. Instrum. 1997, 68, 4511. [Google Scholar] [CrossRef]

- Clyne, T.W.; Campbell, J.E. Chapter 6—Compressive Testing. In Testing of the Plastic Deformation of Metals; Cambridge University Press: Cambridge, UK, 2021; pp. 107–122. [Google Scholar] [CrossRef]

- Collings, E.; Welsch, G. Materials Properties Handbook: Titanium Alloys; ASM International: Novelty, OH, USA, 1994; 1176p. [Google Scholar]

- Gui, G.; Gao, L.Y.G.; Shinohara, K.; Bollen, B.; Toda, T. Preparation, Mechanical Properties, and High-Temperature Wear Resistance of Ti–Al–B alloy. Materials 2019, 12, 3751. [Google Scholar] [CrossRef]

- Balasubramanian, G.; Puria, I.K. Heat conduction across a solid-solid interface: Understanding nanoscale interfacial effects on thermal resistance. Appl. Phys. Lett. 2011, 99, 013116. [Google Scholar] [CrossRef]

| ## | Alloying Elements and Impurities, wt.% | TiC, or TiB, vol.% | Ti | Residual Porosity, % | Phase Composition | ||||

|---|---|---|---|---|---|---|---|---|---|

| Al | V | Fe | O | N | |||||

| Ti64BEPM | |||||||||

| 1 | 5.94 | 4.06 | 0.16 | 0.19 | 0.007 | - | Balance | 1.5 | α + β |

| Ti64BEPM + 5TiC | |||||||||

| 2 | 6.02 | 3.9 | 0.14 | 0.2 | 0.009 | 5 | ÷ | 2.1 | α + β + TiC |

| Ti64BEPM + 10TiC | |||||||||

| 3 | 6.0 | 4.02 | 0.11 | 0.21 | 0.008 | 10 | ÷ | 2.4 | α + β + TiC |

| Ti64BEPM + 20TiC | |||||||||

| 4 | 6.04 | 4.07 | 0.17 | 0.18 | 0.007 | 20 | ÷ | 2.8 | α + β + TiC |

| Ti64BEPM + 5TiB | |||||||||

| 5 | 6.03 | 4.04 | 0.12 | 0.22 | 0.008 | 5 | ÷ | 3.1 | α + β + TiB |

| Ti64BEPM + 10TiB | |||||||||

| 6 | 6.02 | 4.01 | 0.13 | 0.21 | 0.009 | 10 | ÷ | 4.0 | α + β + TiB |

| ## | Tensile Properties (QST) (Rate 8·10−4 s−1) | 3-Point Flexure | Young Module, GPa | Damping | Sound Frequency, Hz | Vickers Hardness, HV | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| YS, MPa | UTS, MPa | El. % | RA, % | Strength, MPa | Strain, % | |||||

| Ti64BEPM | ||||||||||

| 1 | 932 | 1033 | 7.6 | 21.2 | 2088 | 16.3 | 123 | 0.000251 | 12,022 | 339 |

| Ti64BEPM + 5TiC | ||||||||||

| 2 | 708 | 708 | ≤0.1 | - | 1680 | 4.2 | 135.2 | 0.000266 | 13,551 | 380 |

| Ti64BEPM + 10TiC | ||||||||||

| 3 | 620 | 620 | ≤0.1 | - | 1350 | ≤0.1 | 137 | 0.000309 | 14,029 | 403 |

| Ti64BEPM + 20TiC | ||||||||||

| 4 | 567 | 567 | ≤0.1 | - | 180 | ≤0.1 | 140.4 | 0.000219 | 14,649 | 425 |

| Ti64BEPM + 5TiB | ||||||||||

| 5 | 844 | 844 | ≤0.1 | - | 980 | ≤0.1 | 134.5 | 0.000284 | 13,624 | 362 |

| Ti64BEPM + 10TiB | ||||||||||

| 6 | 522 | 552 | ≤0.1 | - | 645 | ≤0.1 | 138.2 | 0.000322 | 14,219 | 388 |

| Location (in Figure 11) | Chemical Composition, wt.% | ||||

|---|---|---|---|---|---|

| Al | V | Fe | Ti | Sum of Impurities | |

| 1 (11g) | 6.2 | 4.2 | 1.2 | Balance | <0.4 |

| 2 (11h) | 4.8 | 11.8 | 1.8 | Balance | <0.4 |

| ## | Spot # | Phase | Composition, % | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ti | Al | V | C/B | |||||||

| Atomic | Weight | Atomic | Weight | Atomic | Weight | Atomic | Weight | |||

| Ti64BEPM + 10TiC (Figure 22a) | ||||||||||

| MMC General Composition | 66.18 | 80.63 | 10.68 | 7.43 | 4.62 | 5.98 | 17.51 | 5.35 | ||

| 1 | 1 | TiC | 63.89 | 87.02 | 0.07 | 0.05 | - | - | 35.91 | 12.27 |

| 2 | 2 | TiC | 75.63 | 91.97 | 0.68 | 0.47 | - | - | 23.61 | 7.20 |

| 3 | 3 | TiC | 71.80 | 90.56 | 0.36 | 0.26 | - | - | 27.76 | 8.78 |

| 4 | 4 | TiC | 65.42 | 87.43 | 0.11 | 0.09 | - | - | 34.27 | 11.49 |

| 5 | 5 | TiC | 76.81 | 92.84 | 0.16 | 0.11 | - | - | 23.01 | 6.98 |

| 6 | 6 | α + β | 82.17 | 88.94 | 9.73 | 5.94 | 3.32 | 3.82 | 4.79 | 1.30 |

| 7 | 7 | α + β | 80.89 | 87.15 | 9.08 | 5.53 | 5.24 | 6.02 | 4.79 | 1.30 |

| Ti64BEPM + 10TiB (Figure 22b) | ||||||||||

| MMC General Composition | 63.21 | 82.32 | 11.68 | 8.03 | 5.15 | 6.24 | 19.17 | 6.01 | ||

| 8 | 1 | TiB | 63.01 | 87.38 | 0.10 | 0.08 | 0.85 | 1.26 | 36.04 | 11.28 |

| 9 | 2 | TiB | 63.80 | 87.22 | 0.78 | 0.60 | 0.09 | 1.59 | 34.32 | 10.59 |

| 10 | 3 | TiB | 58.50 | 83.99 | 0.80 | 0.65 | 1.80 | 2.75 | 38.89 | 12.61 |

| 11 | 4 | α + β | 76.65 | 83.14 | 5.44 | 3.33 | 8.79 | 10.15 | - | - |

| 12 | 5 | TiAl (?) | 82.58 | 92.12 | 9.14 | 5.74 | 0.02 | 0.03 | - | - |

| 13 | 6 | α + β | 77.66 | 85.88 | 6.09 | 7.16 | 5.67 | 3.53 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markovsky, P.E.; Janiszewski, J.; Stasyuk, O.O.; Bondarchuk, V.I.; Savvakin, D.G.; Cieplak, K.; Goran, D.; Soni, P.; Prikhodko, S.V. Mechanical Behavior of Titanium Based Metal Matrix Composites Reinforced with TiC or TiB Particles under Quasi-Static and High Strain-Rate Compression. Materials 2021, 14, 6837. https://doi.org/10.3390/ma14226837

Markovsky PE, Janiszewski J, Stasyuk OO, Bondarchuk VI, Savvakin DG, Cieplak K, Goran D, Soni P, Prikhodko SV. Mechanical Behavior of Titanium Based Metal Matrix Composites Reinforced with TiC or TiB Particles under Quasi-Static and High Strain-Rate Compression. Materials. 2021; 14(22):6837. https://doi.org/10.3390/ma14226837

Chicago/Turabian StyleMarkovsky, Pavlo E., Jacek Janiszewski, Oleksandr O. Stasyuk, Vadim I. Bondarchuk, Dmytro G. Savvakin, Kamil Cieplak, Daniel Goran, Purvesh Soni, and Sergey V. Prikhodko. 2021. "Mechanical Behavior of Titanium Based Metal Matrix Composites Reinforced with TiC or TiB Particles under Quasi-Static and High Strain-Rate Compression" Materials 14, no. 22: 6837. https://doi.org/10.3390/ma14226837

APA StyleMarkovsky, P. E., Janiszewski, J., Stasyuk, O. O., Bondarchuk, V. I., Savvakin, D. G., Cieplak, K., Goran, D., Soni, P., & Prikhodko, S. V. (2021). Mechanical Behavior of Titanium Based Metal Matrix Composites Reinforced with TiC or TiB Particles under Quasi-Static and High Strain-Rate Compression. Materials, 14(22), 6837. https://doi.org/10.3390/ma14226837