Dynamic Behavior of Aviation Polymer Composites at Various Weight Fractions of Physical Modifier

Abstract

:1. Introduction

- -

- The composition of composites by:

- Modification of the polymer matrix.

- The use of additives:

- (a)

- Without applied improvements;

- (b)

- After chemical improvement of their surface;

- (c)

- After physical improvement of their surface;

- (d)

- After biological improvement of their surface;

- (e)

- After mixed surface improvement.

- -

- Processing through the introduction of additional technological operations resulting in changes:

- To the physical properties of the composite produced;

- To the chemical composition of the composite produced;

- To the biological properties of the composite produced;

- In the form of a combination of these changes.

2. Experimental Investigation

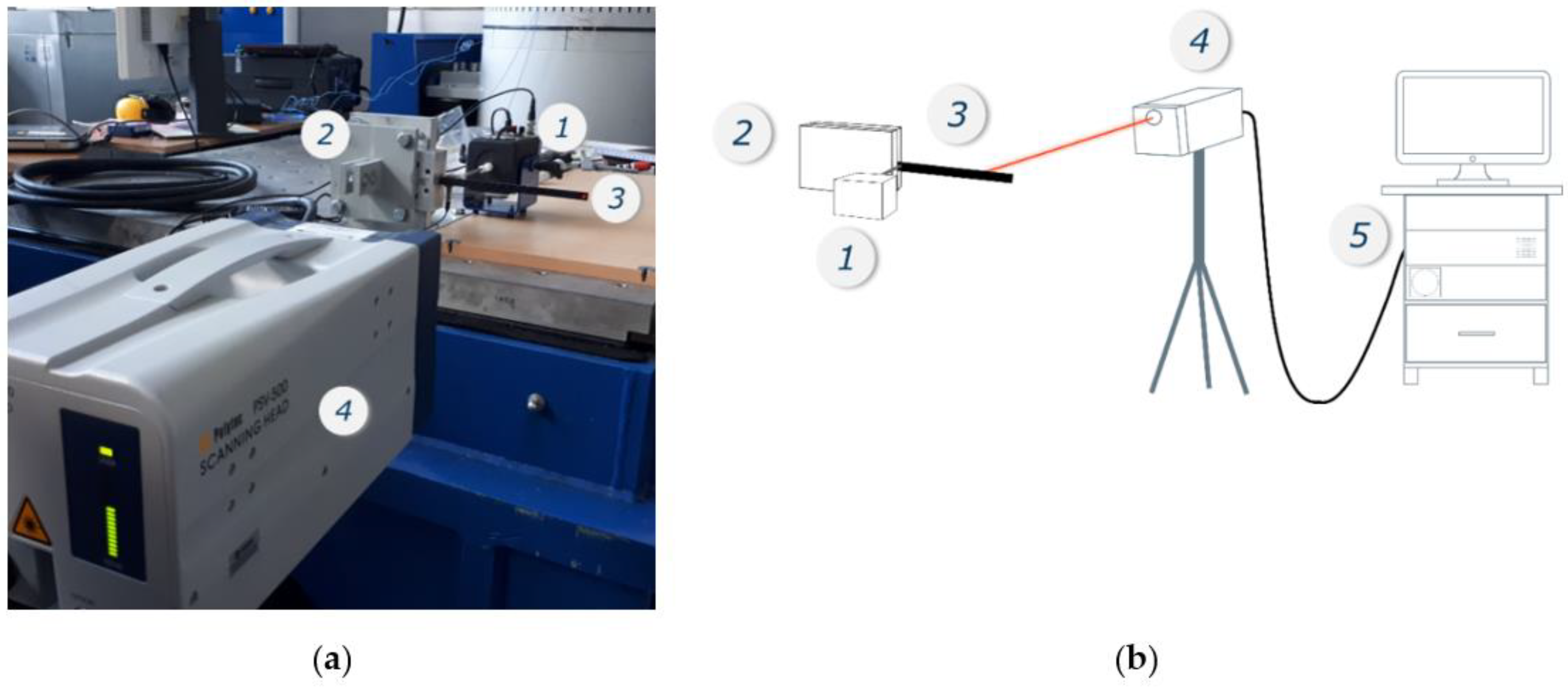

3. Measurement Approach

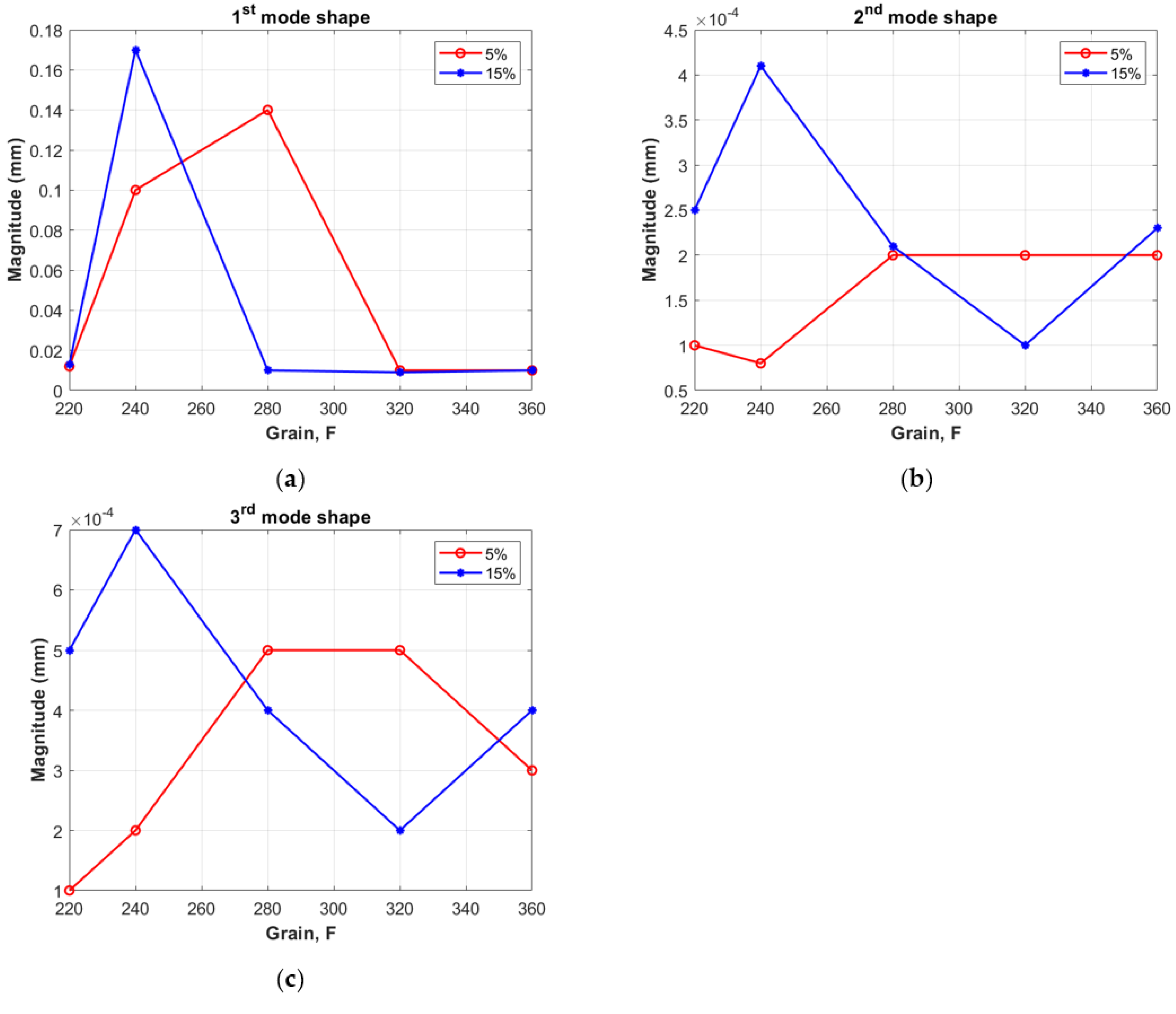

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Krzyzak, A.; Bemowski, G.; Szczepaniak, R.; Grzesik, N.; Gil, L. Evaluation of the Reliability of Composite Materials Used in Aviation. In Proceedings of the Safety and Realiability—Safe Society in a Changing World, Proceedings of ESREL, Trondheim, Norway, 17–21 June 2018; Haugen, S., Barros, A., van Gulijk, C., Kongsvik, T., Vinnem, J.E., Eds.; Taylor & Francis Group: London, UK, 2018; pp. 2093–2098. [Google Scholar]

- Mrówka, M.; Woźniak, A.; Prężyna, S.; Sławski, S. The Influence of Zinc Waste Filler on the Tribological and Mechanical Properties of Silicone-Based Composites. Polymers 2021, 13, 585. [Google Scholar] [CrossRef] [PubMed]

- Sławski, S.; Szymiczek, M.; Kaczmarczyk, J.; Domin, J.; Świtoński, E. Low Velocity Impact Response and Tensile Strength of Epoxy Composites with Different Reinforcing Materials. Materials 2020, 13, 3059. [Google Scholar] [CrossRef]

- Krzyzak, A.; Kosicka, E.; Szczepaniak, R.; Szymczak, T. Evaluation of the properties of polymer composites with carbon nanotubes in the aspect of their abrasive wear. J. Achiev. Mater. Manuf. Eng. 2019, 1, 5–12. [Google Scholar] [CrossRef]

- Mrówka, M.; Szymiczek, M.; Machoczek, T.; Lenża, J.; Matusik, J.; Sakiewicz, P.; Skonieczna, M. The influence of halloysite on the physicochemical, mechanical and biological properties of polyurethane based nanocomposites. Polimery 2020, 65, 784–791. [Google Scholar] [CrossRef]

- Mrówka, M.; Szymiczek, M.; Machoczek, T.; Pawlyta, M. Influence of the Halloysite Nanotube (HNT) Addition on Selected Mechanical and Biological Properties of Thermoplastic Polyurethane. Materials 2021, 14, 3625. [Google Scholar] [CrossRef]

- Mrówka, M.; Machoczek, T.; Jureczko, P.; Joszko, K.; Gzik, M.; Wolański, W.; Wilk, K. Mechanical, Chemical, and Processing Properties of Specimens Manufactured from Poly-Ether-Ether-Ketone (PEEK) Using 3D Printing. Materials 2021, 14, 2717. [Google Scholar] [CrossRef] [PubMed]

- Mucha, M.; Sterzynski, T.; Krzyzak, A. The effect of the heat treatment on the crosslinking of epoxy resin for aviation applications. Polimery 2020, 65, 776–783. [Google Scholar] [CrossRef]

- Rusu, B.; Blindu, S.B.; Micu, A.; Soare, V. Guidelines for Aircraft Composite Panels. INCAS Bull. 2020, 12, 217–228. [Google Scholar] [CrossRef]

- Gong, Y.; Shao, H.; Luo, J.; Li, Z. A deep transfer learning model for inclusion defect detection of aeronautics composite materials. Compos. Struct. 2020, 252, 112681. [Google Scholar] [CrossRef]

- Zimmermann, N.; Wang, P.H. A review of failure modes and fracture analysis of aircraft composite materials. Eng. Fail. Anal. 2020, 115, 104692. [Google Scholar] [CrossRef]

- Genena, F.A.; Jamal, D.A.; Ahmed, W.K.; Almarzooqi, L.A.; Almazrouei, A.S.; Al-Naqbi, A.H. Implementing green solutions to recycle UAE domestic waste: Aircraft composite materials. In Proceedings of the 2018 5th International Conference on Renewable Energy: Generation and Applications (ICREGA), Al Ain, United Arab Emirates, 25–28 February 2018; pp. 30–33. [Google Scholar] [CrossRef]

- Min, K.J.; Lee, H.S. Composite Materials Characterization for Aircraft Application. Mater. Sci. Forum 2016, 857, 169–173. [Google Scholar]

- Vlasova, V. Using composite materials in aircraft. AIP Conf. Proc. 2019, 2171, 3002. [Google Scholar] [CrossRef]

- Tcherdyntsev, V.V. Reinforced Polymer Composites. Polymers 2021, 13, 564. [Google Scholar] [CrossRef]

- Pinto, A.; Magalhães, F. Graphene-Polymer Composites. Polymers 2021, 13, 685. [Google Scholar] [CrossRef] [PubMed]

- Islam, S.; Islam, M. Sustainable reinforcers for polymer composites. Adv. Sustain. Polym. Compos. 2021, 59–88. [Google Scholar] [CrossRef]

- Komorek, A.; Komorek, Z.; Krzyzak, A.; Przybylek, P.; Szczepaniak, R. Impact of Frequency of Load Changes in Fatigue Tests on the Temperature of the Modified Polymer. Int. J. Thermophys. 2017, 38, 128. [Google Scholar] [CrossRef] [Green Version]

- Terpiłowski, J.; Rudzki, R.; Szczepaniak, R.; Woroniak, G. Thermal diffusivity investigation of Fe61Ni39, Fe52Ni48 and Fe40Ni60 binary iron–nickel alloys using the modified pulse method. J. Alloys Compd. 2016, 657, 748–754. [Google Scholar] [CrossRef]

- Hu, X.; Chen, Z.; Cao, Y.; Chen, Z.; Zhang, S.; Song, W. The Effect of Modifier on Properties of Bamboo Powder/High-Density Polyethylene Composites. For. Prod. J. 2019, 69, 313–321. [Google Scholar] [CrossRef]

- Kucharek, M.; MacRae, W.; Yang, L. Investigation of the effects of silica aerogel particles on thermal and mechanical properties of epoxy composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106108. [Google Scholar] [CrossRef]

- Szczepaniak, R.; Kozun, G.; Przybylek, P.; Komorek, A.; Krzyzak, A.; Woroniak, G. The effect of the application of a powder additive of a phase change material on the ablative properties of a hybrid composite. Compos. Struct. 2020, 256, 113041. [Google Scholar] [CrossRef]

- Rzeczkowski, J.; Samborski, S.; De Moura, M. Experimental Investigation of Delamination in Composite Continuous Fiber-Reinforced Plastic Laminates with Elastic Couplings. Materials 2020, 13, 5146. [Google Scholar] [CrossRef]

- Samborski, S. Analysis of the end-notched flexure test configuration applicability for mechanically coupled fiber reinforced composite laminates. Compos. Struct. 2017, 163, 342–349. [Google Scholar] [CrossRef]

- Rusinek, R.; Lajmert, P. Chatter Detection in Milling of Carbon Fiber-Reinforced Composites by Improved Hilbert–Huang Transform and Recurrence Quantification Analysis. Materials 2020, 13, 4105. [Google Scholar] [CrossRef] [PubMed]

- Komorek, A.; Przybyłek, P.; Kucharczyk, W. Effect of Sea Water and Natural Ageing on Residual Strength of Epoxy Laminates, Reinforced with Glass and Carbon Woven Fabrics. Adv. Mater. Sci. Eng. 2016, 2016, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Bełzowski, A.; Rechul, Z.; Stasieńko, J. Impact-related damage in glass roving reinforced laminate. Compos. Part B Eng. 2002, 5, 394–399. [Google Scholar]

- Goertzen, W.; Kessler, M. Dynamic mechanical analysis of carbon/epoxy composites for structural pipeline repair. Compos. Part B Eng. 2007, 38, 1–9. [Google Scholar] [CrossRef]

- Bashir, M. Use of Dynamic Mechanical Analysis (DMA) for Characterizing Interfacial Interactions in Filled Polymers. Solids 2021, 2, 108–120. [Google Scholar] [CrossRef]

- Gupta, M. Natural Fibre Reinforced Polymer Composites: A Review on Dynamic Mechanical Properties. Curr. Trends Fash. Technol. Text. Eng. 2017, 1, 555563. [Google Scholar] [CrossRef] [Green Version]

- Sethuraman, B.; Subramani, S.P.; Palaniappan, S.K.; Mylsamy, B.; Aruchamy, K. Experimental investigation on dynamic mechanical and thermal characteristics of Coccinia Indica fiber reinforced polyester composites. J. Eng. Fibers Fabr. 2020, 15, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Pak, S.; Park, S.; Song, Y.S.; Lee, D. Micromechanical and dynamic mechanical analyses for characterizing improved interfacial strength of maleic anhydride compatibilized basalt fiber/polypropylene composites. Compos. Struct. 2018, 193, 73–79. [Google Scholar] [CrossRef]

- Lavoratti, A.; Scienza, L.C.; Zattera, A.J. Dynamic-mechanical and thermomechanical properties of cellulose nanofiber/polyester resin composites. Carbohydr. Polym. 2016, 136, 955–963. [Google Scholar] [CrossRef]

- Costa, C.S.M.F.; Fonseca, A.C.; Serra, A.C.; Coelho, J.F.J. Dynamic Mechanical Thermal Analysis of Polymer Composites Reinforced with Natural Fibers. Polym. Rev. 2016, 56, 362–383. [Google Scholar] [CrossRef]

- Coiro, D.P.; de Marco, A.; Nicolosi, F.; Genito, N.; Figliolia, S. Design of a Low-Cost Easy-to-Fly STOL Ultralight Aircraft in Composite Material. Acta Polytech. 2005, 45, 73–80. [Google Scholar] [CrossRef]

- Stamos, M.; Nicoleau, C.; Toral, R.; Tudor, J.; Harris, N.R.; Niewiadomski, M.; Beeby, S.P. Screen-printed piezoelectric generator for helicopter health and usage monitoring systems. In Proceedings of the 8th International Workshop on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (Power MEMS 2008), Sendai, Japan, 9–12 November 2008. [Google Scholar]

- Krzyzak, A.; Kosicka, E.; Borowiec, M.; Szczepaniak, R. Selected Tribological Properties and Vibrations in the Base Resonance Zone of the Polymer Composite Used in the Aviation Industry. Materials 2020, 13, 1364. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kosicka, E.; Borowiec, M.; Kowalczuk, M.; Krzyzak, A.; Szczepaniak, R. Influence of the Selected Physical Modifier on the Dynamical Behavior of the Polymer Composites Used in the Aviation Industry. Materials 2020, 13, 5479. [Google Scholar] [CrossRef] [PubMed]

- Araumi, N.; Yabuno, H. Cubic–quintic nonlinear parametric resonance of a simply supported beam. Nonlinear Dyn. 2017, 90, 549–560. [Google Scholar] [CrossRef]

- Rincón-Casado, A.; González-Carbajal, J.; García-Vallejo, D.; Domínguez, J. Analytical and numerical study of the influence of different support types in the nonlinear vibrations of beams. Eur. J. Mech. A/Solids 2021, 85, 104113. [Google Scholar] [CrossRef]

- Borowiec, M.; Gawryluk, J.; Bochenski, M. Influence of Mechanical Couplings on the Dynamical Behavior and Energy Harvesting of a Composite Structure. Polymers 2020, 13, 66. [Google Scholar] [CrossRef]

- Shahab, S.; Erturk, A. Coupling of experimentally validated electroelastic dynamics and mixing rules formulation for macro-fiber composite piezoelectric structures. J. Intell. Mater. Syst. Struct. 2016, 28, 1575–1588. [Google Scholar] [CrossRef] [Green Version]

- Havel Composites CZ Sp.z. o. o. Available online: http://www.havel-composites.pl/files/doc/glowny_katalog.pdf (accessed on 1 July 2021).

- iAbrasive. FEPA 42-2:2006. Microgrits F230~F2000 Specifications; FEPA Standard: Courbevoie, France, 2006; Available online: http://www.iabrasive.com/articles/microgrits-f230-f2000-specifications-fepa-42-2-2006 (accessed on 1 July 2021).

- ISO 1183-1:2019 Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method. Available online: https://www.iso.org/standard/74990.html (accessed on 1 July 2021).

- Latalski, J.; Kowalczuk, M. Experimental vs. Analytical Modal Analysis of a Composite Circumferentially Asymmetric Stiffness Box Beam. AIP Conf. Proc. 2018, 1922, 100018. [Google Scholar] [CrossRef]

| Modified Properties | Modifier | Specification |

|---|---|---|

| mechanical | 18-acyl-dopamine | The results of the research conducted showed that the addition of 18-acyl-dopamine can be used as an effective modifier of composites based on a matrix of high-density polyethylene additionally reinforced with bamboo powder. When the modifier increased, the hardness of the composite deteriorated, while strength and stiffness improved. SEM analysis showed that the bond between the bamboo powder and the plastic matrix was strongest when the modifier 18-acyl-dopamine was 1.25% by mass [20]. |

| heat | aerogel | An epoxy resin filled with aerogel particles was tested for the effect of resin viscosity on pore infiltration and density of the resulting composites. Furthermore, the effects of aerogel content and particle size on the thermal conductivity and compressive properties of epoxy composites are presented. The study was conducted on a resin that is a mixture of bisphenol-A epoxy resin and epichlorohydrin-formaldehyde-phenol polymer, and a cycloaliphatic amine-based hardener was used as the curing agent. The introduction of silica aerogel particles into the resin led to a significant reduction in both the density of the resin and its thermal conductivity [21]. |

| ablative | PCM (phase-change material) | The use of an additive in the form of PCM (Phase Change Materials) causes some of the energy supplied to the system to be ‘consumed’ by the phase change energy of the PCM material. This improves the thermo-protective properties of the composite—it significantly reduces the ablative weight loss by about 30% and the temperature on the back surface of the tested composite by about 50% [22]. |

| Indication of the grain size of the alumina used | F220 | F240 | F280 | F320 | F360 |

| Grain size according to FEPA 42-2:2006 [µm] | 53 | 44.5 | 36.5 | 29.2 | 22.8 |

| Epoxy Resin | Hardening Agent | Carbon Fabric | Physical Modifier | Granularity | Mass Percentage of Modifier | Designation of the Composite |

|---|---|---|---|---|---|---|

| L285 | H286 | GG 280T | - | - | - | GG 280T/EA/0/0 |

| ALUMINA (EA) | F220 | 5% | GG 280T/EA/F220/5 | |||

| 15% | GG 280T/EA/F220/15 | |||||

| F240 | 5% | GG 280T/EA/F240/5 | ||||

| 15% | GG 280T/EA/F240/15 | |||||

| F280 | 5% | GG 280T/EA/F280/5 | ||||

| 15% | GG 280T/EA/F280/15 | |||||

| F320 | 5% | GG 280T/EA/F320/5 | ||||

| 15% | GG 280T/EA/F320/15 | |||||

| F360 | 5% | GG 280T/EA/F360/5 | ||||

| 15% | GG 280T/EA/F360/15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosicka, E.; Borowiec, M.; Kowalczuk, M.; Krzyzak, A. Dynamic Behavior of Aviation Polymer Composites at Various Weight Fractions of Physical Modifier. Materials 2021, 14, 6897. https://doi.org/10.3390/ma14226897

Kosicka E, Borowiec M, Kowalczuk M, Krzyzak A. Dynamic Behavior of Aviation Polymer Composites at Various Weight Fractions of Physical Modifier. Materials. 2021; 14(22):6897. https://doi.org/10.3390/ma14226897

Chicago/Turabian StyleKosicka, Ewelina, Marek Borowiec, Marcin Kowalczuk, and Aneta Krzyzak. 2021. "Dynamic Behavior of Aviation Polymer Composites at Various Weight Fractions of Physical Modifier" Materials 14, no. 22: 6897. https://doi.org/10.3390/ma14226897

APA StyleKosicka, E., Borowiec, M., Kowalczuk, M., & Krzyzak, A. (2021). Dynamic Behavior of Aviation Polymer Composites at Various Weight Fractions of Physical Modifier. Materials, 14(22), 6897. https://doi.org/10.3390/ma14226897