A Study on Minimizing Welding Deformation of Joints for the Sealing of Emission After-Treatment Structure

Abstract

1. Introduction

2. Simulation to Minimize Welding Deformation Using Finite Element Method

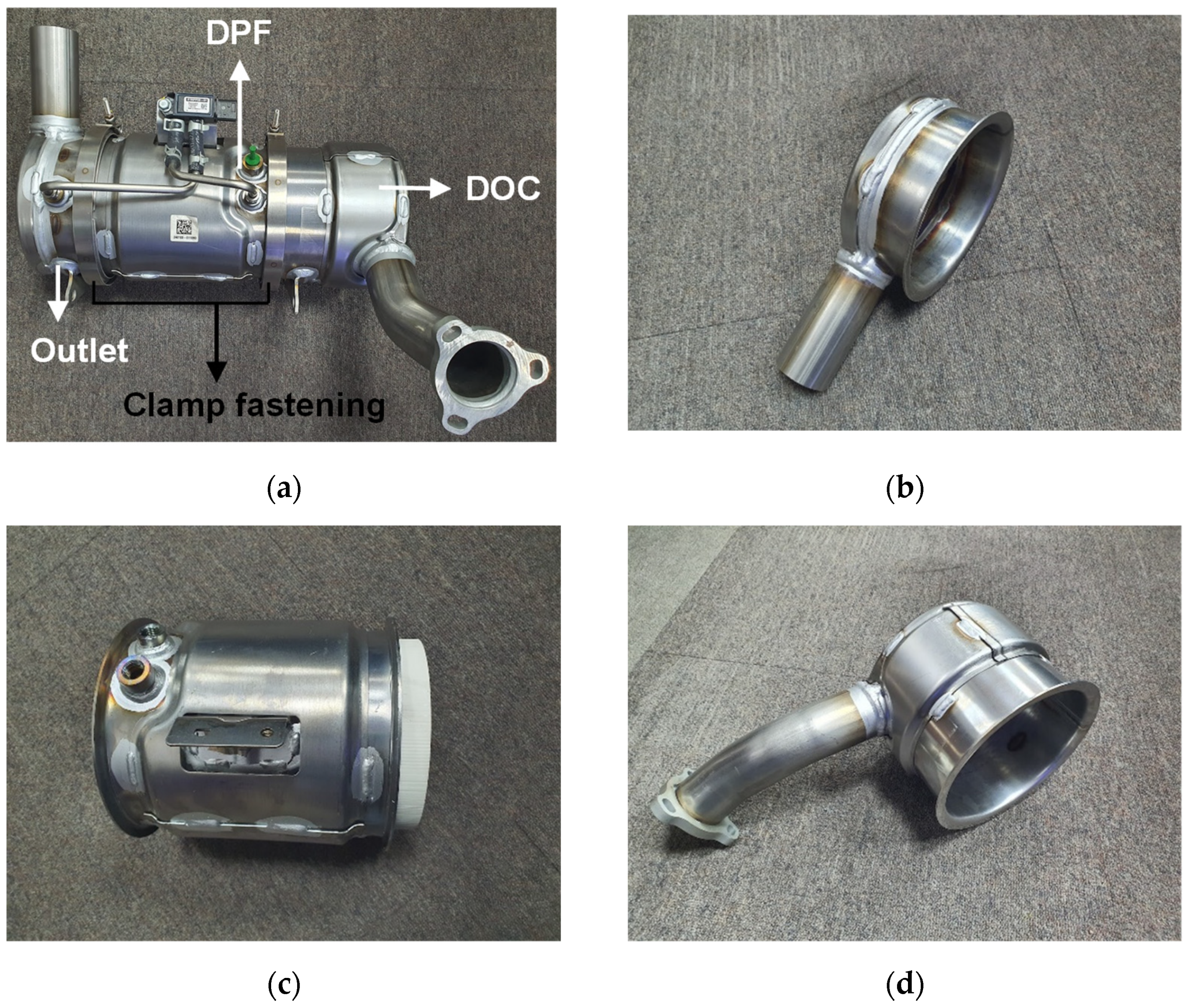

2.1. Muffler Structure Welding Experiments Condition and Welding Section

2.2. Methodology

2.3. Stage 1: Deriving the Welding Sequence to Minimize Thermal Deformation of Joints

2.4. Stage 1: Calculating the Effect of Welding Parts on Welding Deformation Using Thermoplastic Analysis

2.5. Stage 2: Calculating Welding Deformation at Joints by Considering Welding Sequence

3. Muffler Structure Welding Experiment Considering the Optimal Sequence

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, S.; Kim, J.; Kim, D.; Jang, Y.; Cho, J. Thermal Elasto-Plastic Analysis of Welding Sequence for Least Distortion of Overlay Welded Structure. In Proceedings of the Volume 3: Structures, Safety, and Reliability, American Society of Mechanical Engineers, Madrid, Spain, 17–22 June 2018; Volume 77546, pp. 1–9. [Google Scholar]

- Rong, Y.; Xu, J.; Huang, Y.; Zhang, G. Review on finite element analysis of welding deformation and residual stress. Sci. Technol. Weld. Join. 2017, 23, 198–208. [Google Scholar] [CrossRef]

- Narang, H.K.; Mahapatra, M.M.; Jha, P.K.; Sridhar, P.; Biswas, P. Experimental and Numerical Study on Effect of Weld Rein-forcement on Angular Distortion of SAW Square Butt Welded Plates. J. Weld. Join. 2018, 36, 48–59. [Google Scholar] [CrossRef]

- Deng, D.; Liang, W.; Murakawa, H. Determination of welding deformation in fillet-welded joint by means of numerical simu-lation and comparison with experimental results. J. Mater. Process. Technol. 2007, 183, 219–225. [Google Scholar] [CrossRef]

- Rong, Y.; Zhang, G.; Huang, Y. Study on deformation and residual stress of laser welding 316L T-joint using 3D/shell finite element analysis and experiment verification. Int. J. Adv. Manuf. Technol. 2017, 89, 2077–2085. [Google Scholar] [CrossRef]

- Rong, Y.; Zhang, G.; Huang, Y. Study of Welding Distortion and Residual Stress Considering Nonlinear Yield Stress Curves and Multi-constraint Equations. J. Mater. Eng. Perform. 2016, 25, 4484–4494. [Google Scholar] [CrossRef]

- Kim, J.W.; Jang, B.S.; Kang, S.W. A study on an efficient prediction of welding deformation for T-joint laser welding of sandwich panel Part II: Proposal of a method to use shell element model. Int. J. Nav. Arch. Ocean Eng. 2014, 6, 245–256. [Google Scholar] [CrossRef]

- Murakawa, H.; Oda, I.; Itoh, S.; Serizwa, H.; Shibahara, M.; Nishikawa, H. Iterative substructure method for fast FEM analysis of mechanical problems in welding. Prepr. Natl. Meet. JWS 2004, 75, 274–275. [Google Scholar]

- Huang, H.; Ma, N.; Hashimoto, T.; Murakawa, H. Welding deformation and residual stresses in arc welded lap joints by modified itera-tive analysis. Sci. Technol. Weld. Join. 2015, 20, 571–577. [Google Scholar] [CrossRef]

- Murakawa, H.; Ma, N.; Huang, H. Iterative substructure method employing concept of inherent strain for large-scale welding problems. Weld. World 2015, 59, 53–63. [Google Scholar] [CrossRef]

- Ikushima, K.; Shibahara, M. Prediction of residual stresses in multi-pass welded joint using Idealized Explicit FEM accelerated by a GPU. Comput. Mater. Sci. 2014, 93, 62–67. [Google Scholar] [CrossRef]

- Ikushima, K.; Itoh, S.; Shibahara, M. Development of idealized explicit FEM using GPU parallelization and its application to large-scale analysis of residual stress of multi-pass welded pipe joint. Weld. World 2015, 59, 589–595. [Google Scholar] [CrossRef]

- Ma, N. An accelerated explicit method with GPU parallel computing for thermal stress and welding deformation of large structure models. Int. J. Adv. Manuf. Technol. 2016, 87, 2195–2211. [Google Scholar] [CrossRef]

- Ma, N. An accelerated explicit method and GPU parallel computing for thermal stress and welding deformation of automo-tive parts. Int. J. Appl. Mech. 2016, 8, 1650023. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, J.; Kang, S. A Study on Welding Deformation Prediction for Ship Blocks Using the Equivalent Strain Method Based on Inherent Strain. Appl. Sci. 2019, 9, 4906. [Google Scholar] [CrossRef]

- Kang, S.; Kim, J.; Jang, Y.; Lee, K. Welding Deformation Analysis, Using an Inherent Strain Method for Friction Stir Welded Electric Vehicle Aluminum Battery Housing, Considering Productivity. Appl. Sci. 2019, 9, 3848. [Google Scholar] [CrossRef]

- Wu, C.; Wang, C.; Kim, J.-W. Welding Distortion Prediction for Multi-Seam Welded Pipe Structures using Equivalent Thermal Strain Method. J. Weld. Join. 2021, 39, 435–444. [Google Scholar] [CrossRef]

- Kim, T.-J.; Jang, B.-S.; Kang, S.-W. Welding deformation analysis based on improved equivalent strain method considering the effect of temperature gradients. Int. J. Nav. Archit. Ocean Eng. 2015, 7, 157–173. [Google Scholar] [CrossRef]

- Kim, T.J.; Jang, B.S.; Kang, S.W. Welding deformation analysis based on improved equivalent strain method to cover ex-ternal constraint during cooling stage. Int. J. Nav. Archit. Ocean Eng. 2015, 7, 805–816. [Google Scholar] [CrossRef]

- Lee, J.; Seo, H.; Chung, H. Efficient welding distortion analysis method for large welded structures. J. Mater. Process. Technol. 2018, 256, 36–50. [Google Scholar] [CrossRef]

- Rong, Y.; Wang, L.; Wu, R.; Xu, J. Visualization and simulation of 1700MS sheet laser welding based on three-dimensional geometries of weld pool and keyhole. Int. J. Therm. Sci. 2022, 171, 107257. [Google Scholar] [CrossRef]

- Gannon, L.; Liu, Y.; Pegg, N.; Smith, M. Effect of welding sequence on residual stress and distortion in flat-bar stiffened plates. Mar. Struct. 2010, 23, 385–404. [Google Scholar] [CrossRef]

- Tabar, R.S.; Wärmefjord, K.; Söderberg, R.; Lindkvist, L. A novel rule-based method for individualized spot welding se-quence optimization with respect to geometrical quality. J. Manuf. Sci. Eng. 2019, 141, 111013. [Google Scholar] [CrossRef]

- Huang, M.-W.; Hsieh, C.C.; Arora, J.S. A genetic algorithm for sequencing type problems in engineering design. Int. J. Numer. Methods Eng. 1997, 40, 3105–3115. [Google Scholar] [CrossRef]

- Romanin, L.; Ferro, P.; Berto, F. A simplified non-linear numerical method for the assessment of welding induced defor-mations. Mar. Struct. 2021, 78, 102982. [Google Scholar] [CrossRef]

- Kadivar, M.H.; Jafarpur, K.; Baradaran, G.H. Optimizing welding sequence with genetic algorithm. Comput. Mech. 2000, 26, 514–519. [Google Scholar] [CrossRef]

- Kang, M.; Seo, J.; Chung, H. Ship block assembly sequence planning considering productivity and welding deformation. Int. J. Nav. Arch. Ocean Eng. 2018, 10, 450–457. [Google Scholar] [CrossRef]

- Romero-Hdz, J.; Saha, B.N.; Tstutsumi, S.; Fincato, R. Incorporating domain knowledge into reinforcement learning to ex-pedite welding sequence optimization. Eng. Appl. Artif. Intell. 2020, 91, 103612. [Google Scholar] [CrossRef]

- Ha, Y. Analytical Methodology Obtaining an Optimal Welding Sequence for Least Distortion of Welded Structure. J. Weld. Join. 2013, 31, 54–59. [Google Scholar] [CrossRef][Green Version]

- Lee, S.; Kim, E.; Park, J.; Choi, J. MIG Welding Optimization of Muffler Manufacture by Microstructural Change and Ther-mal Deformation Analysis. J. Weld. Join. 2017, 35, 29–37. [Google Scholar] [CrossRef]

- Kim, H.; Lee, K.; Kim, J.; Lee, C.; Jung, Y.; Kang, S. A Study on the Friction Stir Welding Experiment and Simulation of the Fillet Joint of Extruded Aluminum Material of Electric Vehicle Frame. Appl. Sci. 2020, 10, 9103. [Google Scholar] [CrossRef]

| Component | Weight Percent (wt%) |

|---|---|

| Carbon | 0.12 |

| Chromium | 16.0–18.0 |

| Molybdenum | 0.75–1.25 |

| Manganese | 1.00 |

| Silicon | 1.00 |

| Phosphorus | 0.04 |

| Sulfur | 0.03 |

| Part 1 | Part 2 | Part 3 | |

|---|---|---|---|

| Result | 1.00 | 1.11 | 5.98 |

| Welding sequence by simulation result | 1 | 2 | 3 |

| Welding sequence considering the work process and simulation results | 1 | 2 | 3 |

| Part 1 | Part 2 | Part 3 | Part 4 | Part 5 | |

|---|---|---|---|---|---|

| Result | 4.70 | 15.43 | 1.85 | 1.00 | 3.33 |

| Welding sequence by simulation result | 6 | 8 | 2 | 1 | 4 |

| Welding sequence considering the work process and simulation results | 6 | 8 | 2 | 1 | 4 |

| Part 6 | Part 7 | Part 8 | Part 9 | Part 10 | |

| Result | 7.03 | 3.39 | 3.21 | 23.29 | 16.73 |

| Welding sequence by simulation result | 7 | 5 | 3 | 10 | 9 |

| Welding sequence considering the work process and simulation results | 7 | 5 | 3 | 10 | 9 |

| Part 1 | Part 2 | Part 3 | Part 4 | |

|---|---|---|---|---|

| Result | 2.98 | 20.39 | 1.00 | 7.38 |

| Welding sequence by simulation result | 2 | 7 | 1 | 5 |

| Welding sequence considering the work process and simulation results | 1 | 2 | 4 | 5 |

| Part 5 | Part 6 | Part 7 | Part 8 | |

| Result | 3.23 | 39.41 | 4.97 | 16.27 |

| Welding sequence by simulation result | 3 | 8 | 4 | 6 |

| Welding sequence considering the work process and simulation results | 3 | 8 | 7 | 6 |

| Outlet Assembly | DPF Assembly–Outlet Assembly | DPF Assembly–DOC Assembly | DOC Assembly | |

|---|---|---|---|---|

| Experimental [mm] | 0.28 | 0.36 | 0.17 | 0.071 |

| Simulation [mm] | 0.30 | 0.41 | 0.19 | 0.063 |

| Agreement [%] | 7.14 | 13.89 | 11.76 | 11.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.; Yun, W.; Kim, H.; Kim, J.; Ji, C.; Lee, K.; Kim, J.; Jang, H.-L.; Chun, K. A Study on Minimizing Welding Deformation of Joints for the Sealing of Emission After-Treatment Structure. Materials 2021, 14, 6982. https://doi.org/10.3390/ma14226982

Kang S, Yun W, Kim H, Kim J, Ji C, Lee K, Kim J, Jang H-L, Chun K. A Study on Minimizing Welding Deformation of Joints for the Sealing of Emission After-Treatment Structure. Materials. 2021; 14(22):6982. https://doi.org/10.3390/ma14226982

Chicago/Turabian StyleKang, Sungwook, Wangho Yun, Hwanjin Kim, Jaewoong Kim, Changwook Ji, Kwangjin Lee, Jaehwang Kim, Hong-Lae Jang, and Kwangsan Chun. 2021. "A Study on Minimizing Welding Deformation of Joints for the Sealing of Emission After-Treatment Structure" Materials 14, no. 22: 6982. https://doi.org/10.3390/ma14226982

APA StyleKang, S., Yun, W., Kim, H., Kim, J., Ji, C., Lee, K., Kim, J., Jang, H.-L., & Chun, K. (2021). A Study on Minimizing Welding Deformation of Joints for the Sealing of Emission After-Treatment Structure. Materials, 14(22), 6982. https://doi.org/10.3390/ma14226982