Influence of Wood Fly Ash on Concrete Properties through Filling Effect Mechanism

Abstract

:1. Introduction

2. Materials and Methods

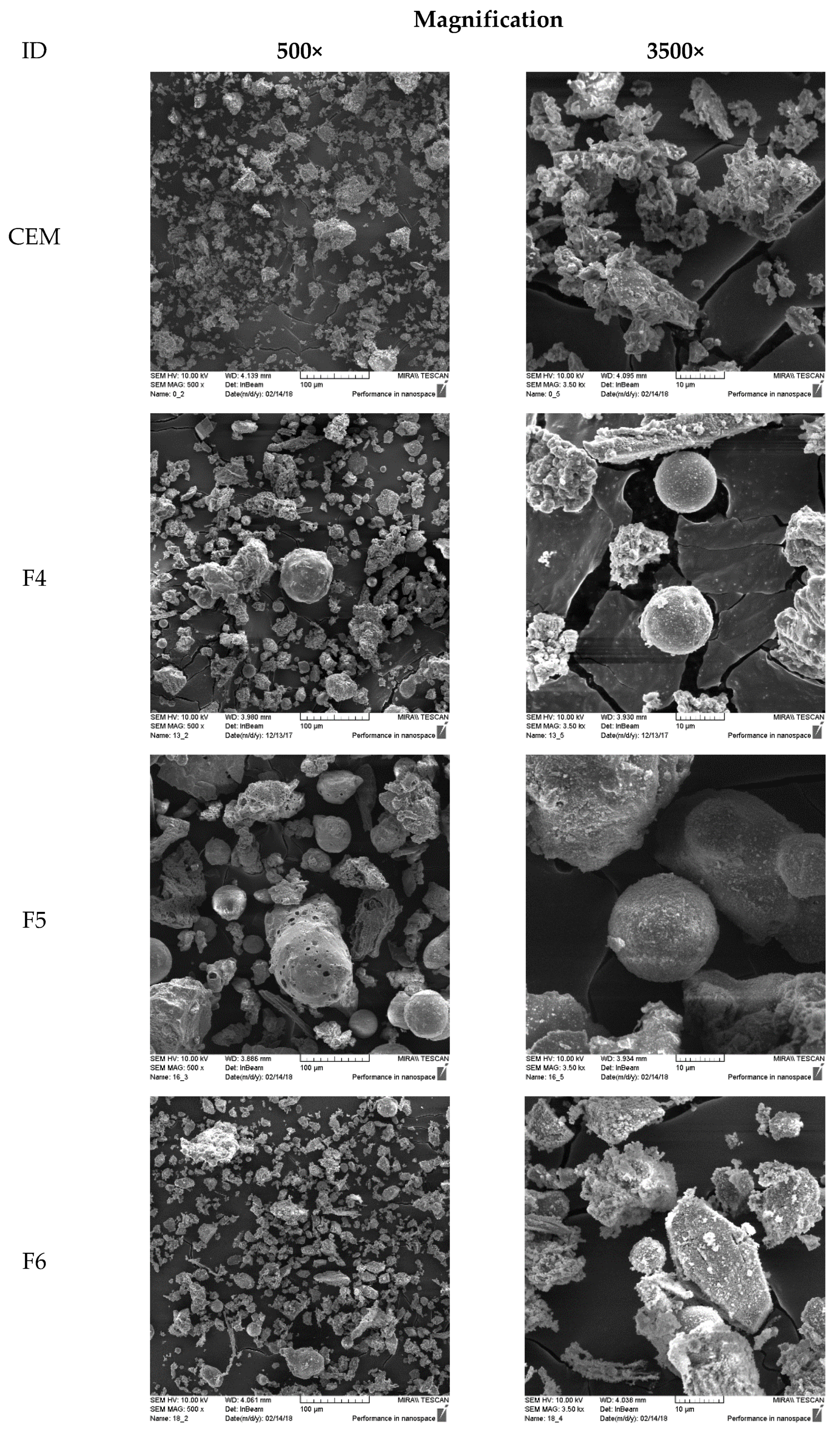

2.1. Characterisation of Fly Ash and Cement

2.2. Concrete Mix Design

2.3. Testing Methods

3. Results and Discussion

3.1. Fresh Concrete Properties

- Reduced interparticle friction during flow caused by the spherical shape and plain surface of admixture particles—ball-bearing effect [60].

- Adsorption of admixture particles on the surface of the cement particles due to electrical charges, which deflocculates the cement particles and increases mobility [59].

- Replacement with a filler containing large particles (>45 µm) [60].

3.2. Heat Generation

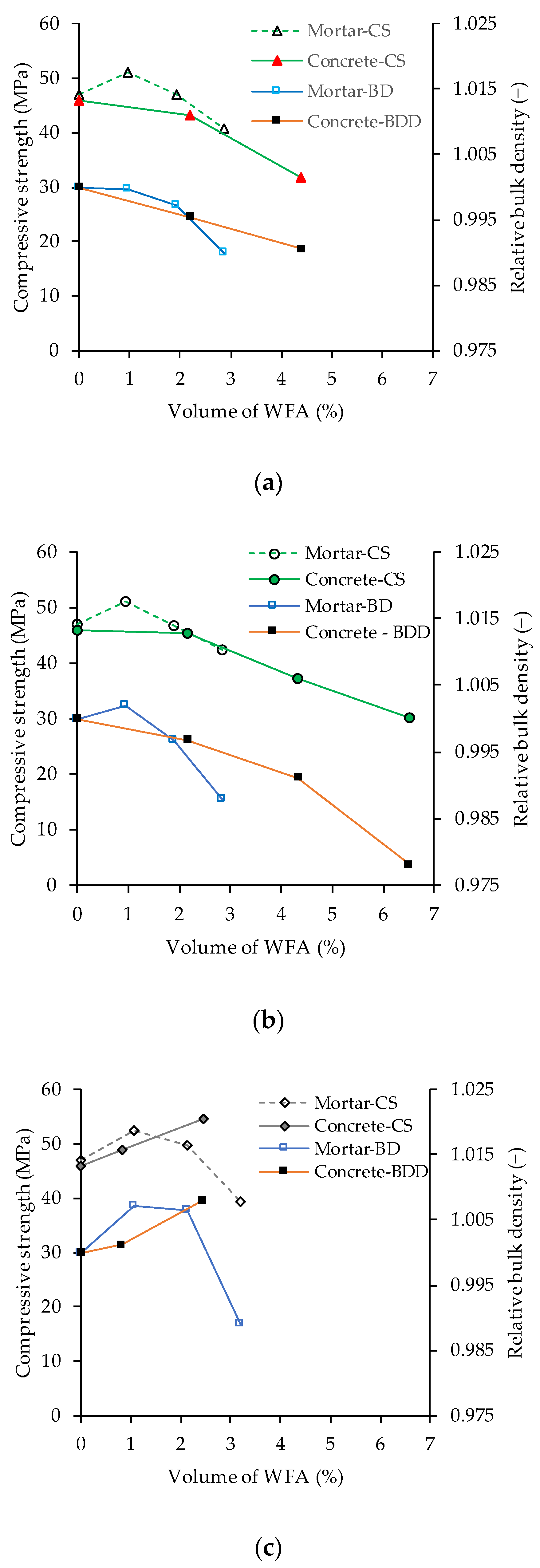

3.3. Compressive Strength

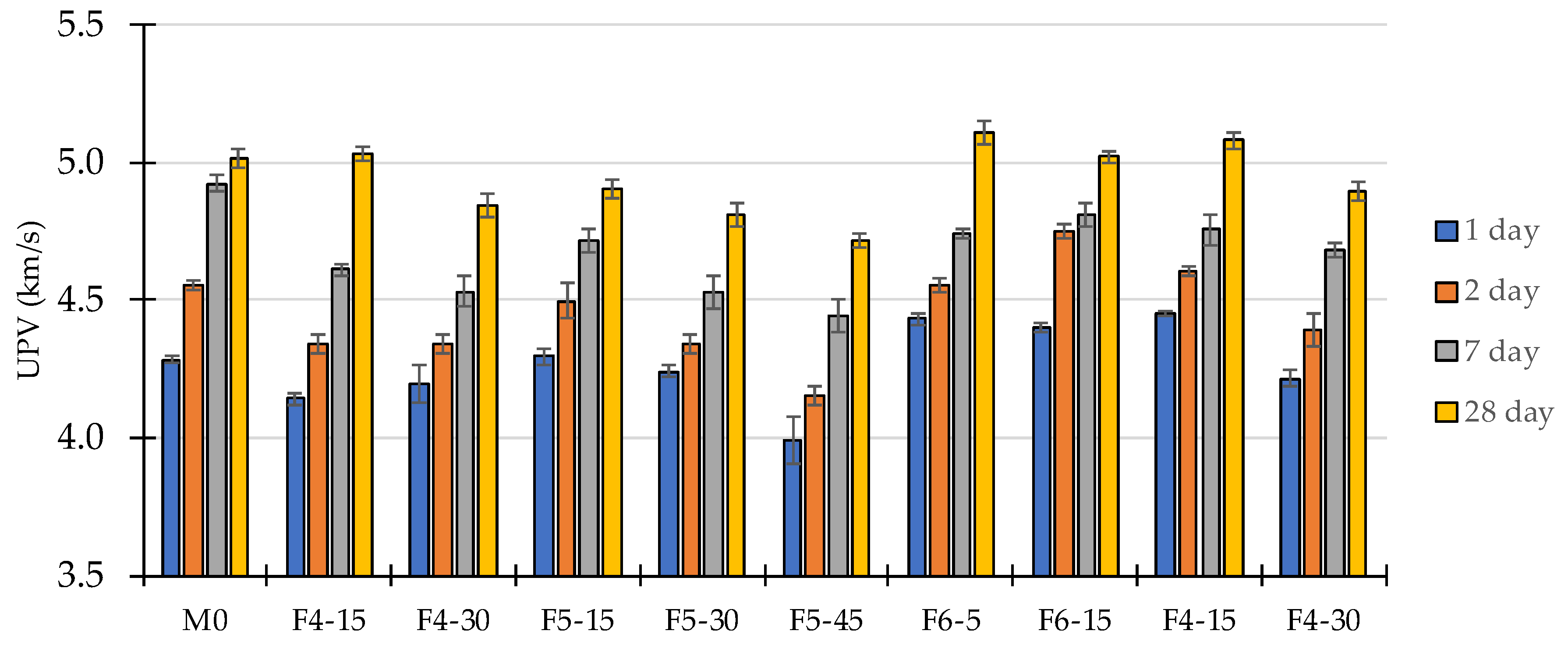

3.4. Stiffness Development

3.5. Apparent Porosity and Capillary Absorption

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scarlat, N.; Dallemand, J.; Taylor, N.; Banja, M. Brief on Biomass for Energy in the European Union; Sanchez Lopez, J., Av-raamides, M., Eds.; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Directorate-General for Energy (European Commission), Navigant. Technical Assistance in Realisation of the 5th Report on Progress of Renewable Energy in the EU. Analysis of Bioenergy Supply and Demand in the EU (Task 3): Final Report; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Carević, I.; Serdar, M.; Štirmer, N.; Ukrainczyk, N. Preliminary screening of wood biomass ashes for partial resources replacements in cementitious materials. J. Clean. Prod. 2019, 229, 1045–1064. [Google Scholar] [CrossRef]

- World Bioenergy Association. Global Bioenergy Statistics 2020; World Bioenergy Association: Stockholm, Sweden, 2020. [Google Scholar]

- Obernberger, I.; Supancic, K. Possibilities of Ash Utilisation from Biomass Combustion Plants. In Proceedings of the 17th European Biomass Conference and Exhibition, Hamburg, Germany, 29 June–3 July 2009; pp. 2372–2384. [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash: Part 2. Potential utilisation, technological and ecological advantages and challenges. Fuel 2013, 105, 19–39. [Google Scholar] [CrossRef]

- Knapp, B.A.; Insam, H. Recycling of Biomass Ashes: Current Technologies and Future Research Needs. In Recycling of Biomass Ashes; Springer: Singapore, 2011; pp. 1–16. [Google Scholar]

- Cheah, C.B.; Ramli, M. Mechanical strength, durability and drying shrinkage of structural mortar containing HCWA as partial replacement of cement. Constr. Build. Mater. 2012, 30, 320–329. [Google Scholar] [CrossRef]

- Maresca, A.; Hyks, J.; Astrup, T. Recirculation of biomass ashes onto forest soils: Ash composition, mineralogy and leaching properties. Waste Manag. 2017, 70, 127–138. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Agrela, F.; Cabrera, M.; Morales, M.M.; Zamorano, M.; Alshaaer, M. Biomass fly ash and biomass bottom ash. In New Trends in Eco-Efficient and Recycled Concrete; Woodhead Publishing: Sawston, UK, 2018; pp. 23–58. ISBN 9780081024805. [Google Scholar]

- Pettersson, M.; Björnsson, L.; Börjesson, P. Recycling of ash from co-incineration of waste wood and forest fuels: An overlooked challenge in a circular bioenergy system. Biomass Bioenergy 2020, 142, 105713. [Google Scholar] [CrossRef]

- Karltun, E.; Saarsalmi, A.; Ingerslev, M.; Mandre, M.; Andersson, S.; Gaitnieks, T.; Ozolinčius, R.; Varnagiryte-Kabasinskiene, I. Wood Ash Recycling—Possibilities and Risks. In Compatible Forest Management; Springer: Singapore, 2008; pp. 79–108. [Google Scholar]

- Cheah, C.B.; Ramli, M. The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: An overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Teixeira, E.; Camões, A.; Branco, F. Valorisation of wood fly ash on concrete. Resour. Conserv. Recycl. 2019, 145, 292–310. [Google Scholar] [CrossRef]

- Rozhina, E.; Ishmukhametov, I.; Nigamatzyanova, L.; Akhatova, F.; Batasheva, S.; Taskaev, S.; Montes, C.; Lvov, Y.; Fakhrullin, R. Comparative Toxicity of Fly Ash: An In Vitro Study. Molrecules 2021, 26, 1926. [Google Scholar] [CrossRef] [PubMed]

- Milovanović, B.; Štirmer, N.; Carević, I.; Baričević, A. Wood biomass ash as a raw material in concrete industry. J. Croat. Assoc. Civ. Eng. 2019, 71, 505–514. [Google Scholar] [CrossRef]

- James, A.K.; Thring, R.W.; Helle, S.; Ghuman, H.S. Ash Management Review—Applications of Biomass Bottom Ash. Energies 2012, 5, 3856–3873. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Mateus, R.; Camões, A.; Bragança, L.; Branco, F.G. Comparative environmental life-cycle analysis of concretes using biomass and coal fly ashes as partial cement replacement material. J. Clean. Prod. 2016, 112, 2221–2230. [Google Scholar] [CrossRef] [Green Version]

- Gupt, C.B.; Bordoloi, S.; Sekharan, S.; Sarmah, A.K. A feasibility study of Indian fly ash-bentonite as an alternative adsorbent composite to sand-bentonite mixes in landfill liner. Environ. Pollut. 2020, 265, 114811. [Google Scholar] [CrossRef]

- Kuźnia, M.; Magiera, A.; Zygmunt-Kowalska, B.; Kaczorek-Chrobak, K.; Pielichowska, K.; Szatkowski, P.; Benko, A.; Ziąbka, M.; Jerzak, W. Fly Ash as an Eco-Friendly Filler for Rigid Polyurethane Foams Modification. Mateials 2021, 14, 6604. [Google Scholar] [CrossRef] [PubMed]

- Fusade, L.; Viles, H.; Wood, C.; Burns, C. The effect of wood ash on the properties and durability of lime mortar for repointing damp historic buildings. Constr. Build. Mater. 2019, 212, 500–513. [Google Scholar] [CrossRef]

- Ekinci, A.; Hanafi, M.; Aydin, E. Strength, Stiffness, and Microstructure of Wood-Ash Stabilized Marine Clay. Minerals 2020, 10, 796. [Google Scholar] [CrossRef]

- Longo, F.; Cascardi, A.; Lassandro, P.; Aiello, M. A New Fabric Reinforced Geopolymer Mortar (FRGM) with Mechanical and Energy Benefits. Fibers 2020, 8, 49. [Google Scholar] [CrossRef]

- Longo, F.; Cascardi, A.; Lassandro, P.; Aiello, M.A. Energy and seismic drawbacks of masonry: A unified retrofitting solution. J. Build. Pathol. Rehabil. 2021, 6, 1–24. [Google Scholar] [CrossRef]

- Rajabipour, F.; Zahedi, M.; Kaladharan, G. Evaluating the Performance and Feasibility of Using Recovered Fly Ash and Fluidized Bed Combustion (FBC) Fly Ash as Concrete Pozzolan; Final Project Report; The Pennsylvania State University: University Park, PA, USA, 2020. [Google Scholar]

- Thy, P.; Jenkins, B.; Grundvig, S.; Shiraki, R.; Lesher, C. High temperature elemental losses and mineralogical changes in common biomass ashes. Fuel 2006, 85, 783–795. [Google Scholar] [CrossRef]

- Li, X.-G.; Chen, Q.-B.; Huang, K.-Z.; Ma, B.-G.; Wu, B. Cementitious properties and hydration mechanism of circulating fluidized bed combustion (CFBC) desulfurization ashes. Constr. Build. Mater. 2012, 36, 182–187. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash. Part 1. Phase–mineral and chemical composition and classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Ukrainczyk, N.; Vrbos, N.; Koenders, E.A.B. Reuse of Woody Biomass Ash Waste in Cementitious Materials. Chem. Biochem. Eng. Q. 2016, 30, 137–148. [Google Scholar] [CrossRef]

- Wang, S.; Miller, A.; Llamazos, E.; Fonseca, F.; Baxter, L. Biomass fly ash in concrete: Mixture proportioning and mechanical properties. Fuel 2008, 87, 365–371. [Google Scholar] [CrossRef]

- EN 450-1. Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria; European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- Maschio, S.; Tonello, G.; Piani, L.; Furlani, E. Fly and bottom ashes from biomass combustion as cement replacing components in mortars production: Rheological behaviour of the pastes and materials compression strength. Chemosphere 2011, 85, 666–671. [Google Scholar] [CrossRef] [PubMed]

- Rissanen, J.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Partial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly Ash. J. Mater. Civ. Eng. 2017, 29, 04017061. [Google Scholar] [CrossRef] [Green Version]

- Carević, I.; Baričević, A.; Štirmer, N.; Šantek Bajto, J. Correlation between physical and chemical properties of wood biomass ash and cement composites performances. Constr. Build. Mater. 2020, 256, 119450. [Google Scholar] [CrossRef]

- Rajamma, R.; Senff, L.; Ribeiro, M.; Labrincha, J.; Ball, R.; Allen, G.; Ferreira, V. Biomass fly ash effect on fresh and hardened state properties of cement based materials. Compos. Part B Eng. 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of woody biomass fly ash in cement-based materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- Lazik, P.R.; Bošnjak, J.; Cetin, E.; Kücük, A. Application of wood ash as a substitute for fly ash and investigation of concrete properties. Otto Graf J. 2020, 19, 103–118. [Google Scholar]

- Tulashie, S.K.; Dapaah, S.; Mensah, D.; Appiah, N. Palm fiber ash as a supplementary cementitious material for the production of mortar prism. Innov. Infrastruct. Solutions 2021, 7, 1–10. [Google Scholar] [CrossRef]

- Carević, I.; Štirmer, N.; Serdar, M.; Ukrainczyk, N. Effect of Wood Biomass Ash Storage on the Properties of Cement Composites. Materials 2021, 14, 1632. [Google Scholar] [CrossRef]

- Šantek Bajto, J.; Štirmer, N.; Cerković, S.; Carević, I.; Kostanić Jurić, K. Pilot Scale Production of Precast Concrete Elements with Wood Biomass Ash. Materials 2021, 14, 6578. [Google Scholar] [CrossRef]

- Kaminskas, R.; Cesnauskas, V. Influence of activated biomass fly ash on portland cement hydration. Ceram. Silik. 2014, 58, 260–268. [Google Scholar]

- Van Loo, S.; Koppejan, J. (Eds.) The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2008. [Google Scholar]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- ASTM C618-19. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ISO/TS 16996 Solid Biofuels—Determination of Elemental Composition by X-Ray Fluorescence; International Organization for Standardization (ISO): Geneva, Switzerland, 2015.

- ASTM D7348-13. Standard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM C188-17. Standard Test Method for Density of Hydraulic Cement; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- EN 12176. Characterization of Sludge—Determination of pH-Value; European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- EN 197-1. Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements; European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- EN 480-1. Admixtures for Concrete, Mortar and Grout—Test Methods—Part 1: Reference Concrete and Reference Mortar for Testing; European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- EN 12350-2. Testing Fresh Concrete—Part 2: Slump-Test; European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12350-6. Testing Fresh Concrete—Part 6: Density; European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12350-7. Testing Fresh Concrete—Part 7: Air Content—Pressure Methods; European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12390-3. Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- Mehta, P.K.; Monteiro, P.J.M. Concrete Microstructure, Properties, and Materials, 3rd ed.; The McGraw-Hill Companies: New York, NY, USA, 2006. [Google Scholar]

- Yang, Z.; Huddleston, J.; Brown, H. Effects of wood ash on properties of concrete and flowable fill. J. Mater. Sci. Chem. Eng. 2016, 4, 101–114. [Google Scholar] [CrossRef] [Green Version]

- Elinwa, A.U.; Mahmood, Y.A. Ash from timber waste as cement replacement material. Cem. Concr. Compos. 2002, 24, 219–222. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, Fourth and Final Edition; Pearson Education Limited: Essex, UK, 2004. [Google Scholar]

- Ramachandran, V.S. (Ed.) Concrete Admixtures Handbook: Properties, Science and Technology, 2nd ed.; Noyes Publication: Saddle River, NJ, USA, 1995. [Google Scholar]

- Wesche, K. (Ed.) Report of Technical Committee 67-FAB Use of Fly Ash in Building RILEM, Fly Ash in Concrete Properties and Performance; E&FN SPON: London, UK, 1991. [Google Scholar]

- Sakai, E.; Masuda, K.; Kakinuma, Y.; Aikawa, Y. Effects of Shape and Packing Density of Powder Particles on the Fluidity of Cement Pastes with Limestone Powder. J. Adv. Concr. Technol. 2009, 7, 347–354. [Google Scholar] [CrossRef] [Green Version]

- Oey, T.; Kumar, A.; Bullard, J.W.; Neithalath, N.; Sant, G. The Filler Effect: The Influence of Filler Content and Surface Area on Cementitious Reaction Rates. J. Am. Ceram. Soc. 2013, 96, 1978–1990. [Google Scholar] [CrossRef]

- Garboczi, E.; Bullard, J. Shape analysis of a reference cement. Cem. Concr. Res. 2004, 34, 1933–1937. [Google Scholar] [CrossRef]

- Chen-Tan, N.W.; Van Riessen, A.; Ly, C.V.; Southam, D.C. Determining the Reactivity of a Fly Ash for Production of Geopolymer. J. Am. Ceram. Soc. 2009, 92, 881–887. [Google Scholar] [CrossRef]

- Skripkiūnas, G.; Macijauskas, M.; Nagrockienė, D.; Daugėla, A. The Influence of Biomass Fly Ash on the Plasticizing Effects in Cement Pastes. Procedia Eng. 2017, 172, 1015–1022. [Google Scholar] [CrossRef]

- Lea’s Chemistry of Cement and Concrete, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2003.

- Jakob, C.; Jansen, D.; Ukrainczyk, N.; Koenders, E.; Pott, U.; Stephan, D.; Neubauer, J. Relating Ettringite Formation and Rheological Changes during the Initial Cement Hydration: A Comparative Study Applying XRD Analysis, Rheological Measurements and Modeling. Materials 2019, 12, 2957. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Winnefeld, F.; Zingg, A.; Holzer, L.; Pakusch, J.; Becker, S. The Ettringite-Superplasticizer Interaction and Its Impact on the Ettringite Distribution in Cement Suspensions. 2009. Available online: https://www.dora.lib4ri.ch/empa/islandora/object/empa:8767 (accessed on 10 October 2021).

- Illikainen, M.; Tanskanen, P.; Kinnunen, P.; Körkkö, M.; Peltosaari, O.; Wigren, V.; Österbacka, J.; Talling, B.; Niinimäki, J. Reactivity and self-hardening of fly ash from the fluidized bed combustion of wood and peat. Fuel 2014, 135, 69–75. [Google Scholar] [CrossRef]

- Ohenoja, K.; Tanskanen, P.; Wigren, V.; Kinnunen, P.; Körkkö, M.; Peltosaari, O.; Österbacka, J.; Illikainen, M. Self-hardening of fly ashes from a bubbling fluidized bed combustion of peat, forest industry residuals, and wastes. Fuel 2016, 165, 440–446. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.; Tarelho, L.A.D.C.; Allen, G.C.; Labrincha, J.; Ferreira, V.M. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef] [PubMed]

- Oey, T.; Timmons, J.; Stutzman, P.; Bullard, J.W.; Balonis, M.; Bauchy, M.; Sant, G. An improved basis for characterizing the suitability of fly ash as a cement replacement agent. J. Am. Ceram. Soc. 2017, 100, 4785–4800. [Google Scholar] [CrossRef]

- Roszczynialski, W.; Nocuń-Wczelik, W. Studies of cementitious systems with new generation by-products from fluidised bed combustion. J. Therm. Anal. Calorim. 2004, 77, 151–158. [Google Scholar] [CrossRef]

- Moosberg-Bustnes, H.; Lagerblad, B.; Forssberg, E. The function of fillers in concrete. Mater. Struct. 2004, 37, 74–81. [Google Scholar] [CrossRef]

- Wadsö, L.; Winnefeld, F.; Riding, K.; Sandberg, P. Calorimetry. In A Practical Guide to Microstructural Analysis of Cementitious Materials; Scrivener, K., Snellings, R., Lothenbach, B., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 37–74. [Google Scholar]

- Ataie, F.F.; Riding, K.A. Influence of agricultural residue ash on early cement hydration and chemical admixtures adsorption. Constr. Build. Mater. 2016, 106, 274–281. [Google Scholar] [CrossRef] [Green Version]

- Ohenoja, K.; Tanskanen, P.; Peltosaari, O.; Wigren, V.; Österbacka, J.; Illikainen, M. Effect of particle size distribution on the self-hardening property of biomass-peat fly ash from a bubbling fluidized bed combustion. Fuel Process. Technol. 2016, 148, 60–66. [Google Scholar] [CrossRef]

- Grau, F.; Choo, H.; Hu, J.W.; Jung, J. Engineering Behavior and Characteristics of Wood Ash and Sugarcane Bagasse Ash. Mater. 2015, 8, 6962–6977. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Udoeyo, F.F.; Inyang, H.; Young, D.T.; Oparadu, E.E. Potential of Wood Waste Ash as an Additive in Concrete. J. Mater. Civ. Eng. 2006, 18, 605–611. [Google Scholar] [CrossRef]

- Lawrence, P.; Cyr, M.; Ringot, E. Mineral admixtures in mortars effect of type, amount and fineness of fine constituents on compressive strength. Cem. Concr. Res. 2005, 35, 1092–1105. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Kirkelund, G.M.; Jensen, P.E.; Geiker, M.R.; Ottosen, L.M. Impact of production parameters on physiochemical characteristics of wood ash for possible utilisation in cement-based materials. Resour. Conserv. Recycl. 2019, 145, 230–240. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifschitz, E.M. Theory of Elasticity, Vol. 7 of Course of Theoretical Physics, 3rd ed.; Pergamon Press: Oxford, UK, 1986. [Google Scholar]

- Gabrijel, I.; Staquet, S.; Krüger, M.; Carette, J.; Grosse, C.U.; Trtnik, G. Ultrasonic Techniques for Determination and Monitoring Various Properties of Cementitious Materials at Early Ages. In Seismic Structural Health Monitoring; Springer: Singapore, 2020; pp. 23–68. [Google Scholar]

- Šiler, P.; Bayer, P.; Sehnal, T.; Kolářová, I.; Opravil, T.; Šoukal, F. Effects of high-temperature fly ash and fluidized bed combustion ash on the hydration of Portland cement. Constr. Build. Mater. 2015, 78, 181–188. [Google Scholar] [CrossRef]

- Safiuddin, M.; Hearn, N. Comparison of ASTM saturation techniques for measuring the permeable porosity of concrete. Cem. Concr. Res. 2005, 35, 1008–1013. [Google Scholar] [CrossRef]

- Tkaczewska, E.; Małolepszy, J. Hydration of coal–biomass fly ash cement. Constr. Build. Mater. 2009, 23, 2694–2700. [Google Scholar] [CrossRef]

| CEM | F4 | F5 | F6 | |

|---|---|---|---|---|

| Combustion technology | Grate combustor | Grate combustor | Bubbling fluidized bed | |

| Incineration temperature (°C) | - | 700–950 | up to 800 | up to 850 |

| Additive used | - | - | Quartz sand | |

| Type of wood | beech, oak, fir, spruce | beech, oak, hornbeam | beech, oak, hornbeam, poplar | |

| P2O5 | 0.22 | 1.82 | 1.35 | 4.03 |

| Na2O | 0.85 | 0.65 | 1.32 | 0.63 |

| K2O | 1.25 | 6.05 | 4.77 | 6.21 |

| CaO | 59.80 | 46.75 | 16.25 | 47.35 |

| MgO | 2.01 | 8.26 | 4.30 | 4.71 |

| Al2O3 | 4.94 | 6.16 | 10.50 | 3.56 |

| TiO2 | 0.23 | 0.34 | 1.17 | 0.25 |

| Fe2O3 | 3.15 | 2.85 | 4.23 | 1.69 |

| SiO2 | 21.88 | 19.80 | 39.95 | 14.45 |

| SO3 | 3.33 | 2.73 | 0.60 | 3.95 |

| CaCO3 | 6.56 | 8.13 | 7.12 | 26.94 |

| Pozzolanic oxides (SiO2 + Al2O3 + Fe2O3) | 29.97 | 28.81 | 54.68 | 19.70 |

| Alkalies (Na2O + 0.658 K2O) | 1.67 | 4.63 | 4.59 | 4.72 |

| LOI (at 950 °C) | 3.60 | 3.80 | 8.30 | 12.70 |

| pH | 12.86 | 13.15 | 12.97 | 13.22 |

| d50 (µm) | 9.4 | 71.9 | 120.7 | 17.8 |

| SSA 1 (kg/m2) | 796 | 223 | 180 | 627 |

| Density (g/cm3) | 3.10 | 2.59 | 2.63 | 2.33 |

| Bulk density (g/cm3) | - | 0.91 | 0.61 | 0.55 |

| Mix Designation | M0 | F4-15 | F4-30 | F5-15 | F5-30 | F5-45 | F6-5 | F6-15 |

|---|---|---|---|---|---|---|---|---|

| Cement (kg) | 380 | 323 | 266 | 323 | 266 | 209 | 361 | 323 |

| WFA cement replacement (%) | 0 | 15 | 30 | 15 | 30 | 45 | 5 | 15 |

| WFA content (kg) | 0 | 57 | 114 | 57 | 114 | 171 | 19 | 57 |

| Cement + WFA (kg) | 380 | |||||||

| w/(cem. + WFA) ratio | 0.5 | |||||||

| Water (kg) | 190 | |||||||

| Aggregate (kg) | 1821 | 1811 | 1801 | 1811 | 1801 | 1791 | 1816 | 1805 |

| Fine aggregate (kg) | 648 | 645 | 641 | 645 | 641 | 638 | 646 | 643 |

| Coarse aggregate (kg) | 1173 | 1167 | 1160 | 1167 | 1160 | 1154 | 1169 | 1162 |

| Mix Designation | M0 | F4-15 | F4-30 | F5-15 | F5-30 | F5-45 | F6-5 | F6-15 |

|---|---|---|---|---|---|---|---|---|

| Fresh density (kg/m3) | 2470 | 2470 | 2460 | 2470 | 2450 | 2440 | 2480 | 2500 |

| Initial temperature (°C) | 22.2 | 23.6 | 25.1 | 23.2 | 23.3 | 23.3 | 24.4 | 22.2 |

| Air content (%) | 1.0 | 0.9 | 1.1 | 1.4 | 0.7 | 0.3 | 0.3 | 1.6 |

| Slump (mm) | 90 | 100 | 40 | 85 | 90 | 90 | 110 | 5 |

| Bulk dry density (kg/m3) | 2371 | 2360 | 2348 | 2363 | 2350 | 2319 | 2373 | 2390 |

| (±8) | (±16) | (±13) | (±13) | (±15) | (±20) | (±24) | (±8) | |

| Bulk saturated density (kg/m3) | 2506 | 2499 | 2484 | 2500 | 2485 | 2464 | 2503 | 2514 |

| (±6) | (±12) | (±10) | (±15) | (±10) | (±12) | (±17) | (±6) | |

| Apparent solid density (kg/m3) | 2743 | 2742 | 2718 | 2739 | 2719 | 2713 | 2726 | 2728 |

| (±4) | (±4) | (±6) | (±22) | (±5) | (±3) | (±8) | (±2) | |

| Apparent porosity (%) | 13.57 | 13.93 | 13.60 | 13.73 | 13.57 | 14.52 | 12.94 | 12.40 |

| (±0.17) | (±0.48) | (±0.30) | (±0.21) | (±0.49) | (±0.85) | (±0.64) | (±0.27) | |

| Compressive strength (MPa) | 45.9 (±0.9) | 43.2 (±0.3) | 31.9 (±1.4) | 45.3 (±0.6) | 37.3 (±1.5) | 30.1 (±0.8) | 48.9 (±1.2) | 54.5 (±0.9) |

| Capillary absorption coefficient (kg/(m2h0.5)) | 1.28 (±0.07) | 1.22 (±0.11) | 1.24 (±0.04) | 1.30 (±0.11) | 1.35 (±0.13) | 1.30 (±0.18) | 0.99 (±0.20) | 1.02 (±0.07) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabrijel, I.; Jelčić Rukavina, M.; Štirmer, N. Influence of Wood Fly Ash on Concrete Properties through Filling Effect Mechanism. Materials 2021, 14, 7164. https://doi.org/10.3390/ma14237164

Gabrijel I, Jelčić Rukavina M, Štirmer N. Influence of Wood Fly Ash on Concrete Properties through Filling Effect Mechanism. Materials. 2021; 14(23):7164. https://doi.org/10.3390/ma14237164

Chicago/Turabian StyleGabrijel, Ivan, Marija Jelčić Rukavina, and Nina Štirmer. 2021. "Influence of Wood Fly Ash on Concrete Properties through Filling Effect Mechanism" Materials 14, no. 23: 7164. https://doi.org/10.3390/ma14237164

APA StyleGabrijel, I., Jelčić Rukavina, M., & Štirmer, N. (2021). Influence of Wood Fly Ash on Concrete Properties through Filling Effect Mechanism. Materials, 14(23), 7164. https://doi.org/10.3390/ma14237164