Tribological Behavior and Microstructural Analysis of Atmospheric Plasma Spray Deposited Thin Coatings on Cardan Cross Spindles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Coating Deposition

2.2.2. Microhardness Measurements and Scratch Tests

2.2.3. Morphological and Structural Analyses

2.2.4. Surface Topography Measurement

2.2.5. Friction and Wear Tests

3. Results and Discussions

3.1. Hardness and Elasticity Modulus

3.2. Surface Topography

3.3. Microstructural Characterization of the Coatings by SEM Analysis

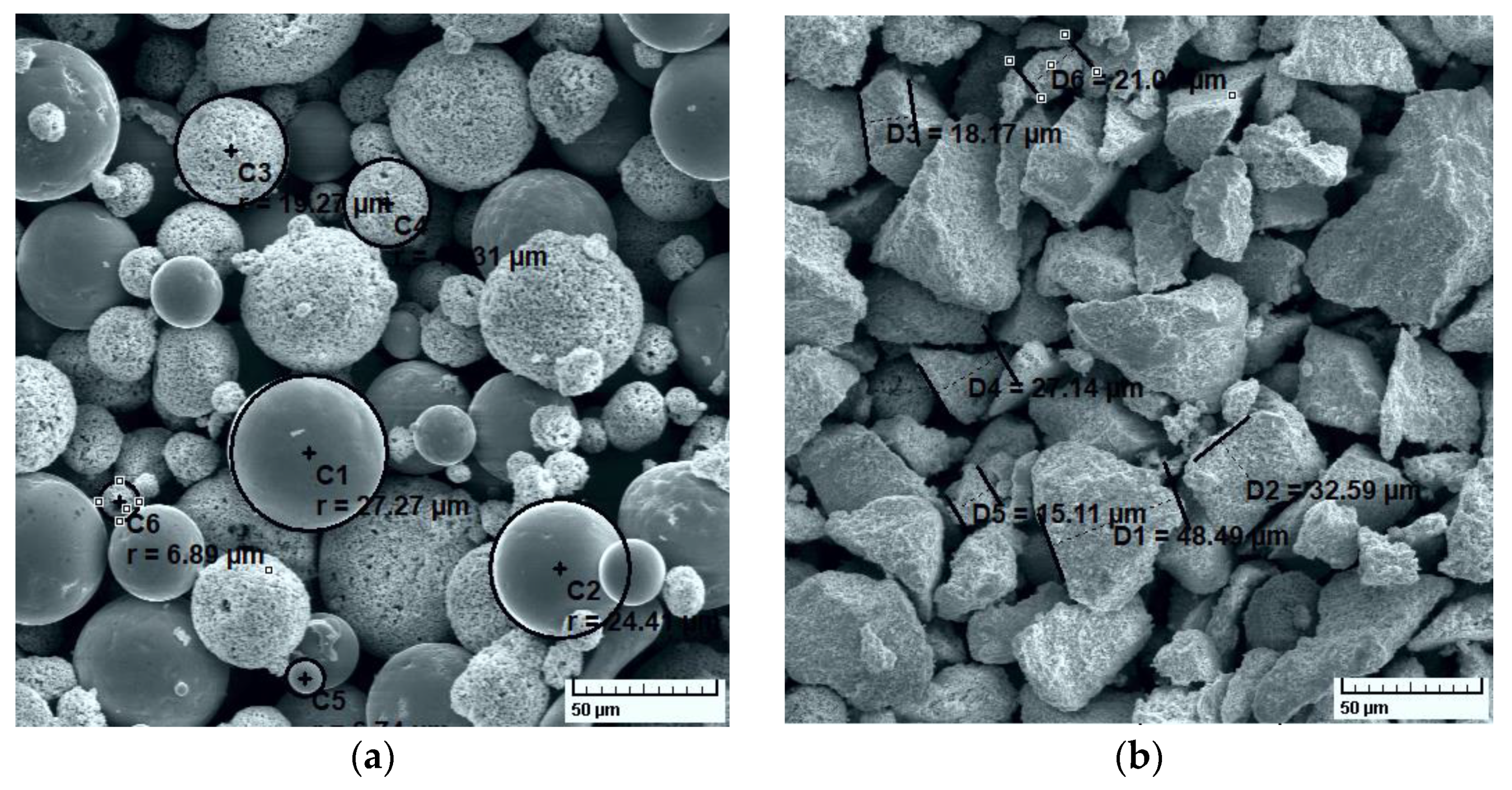

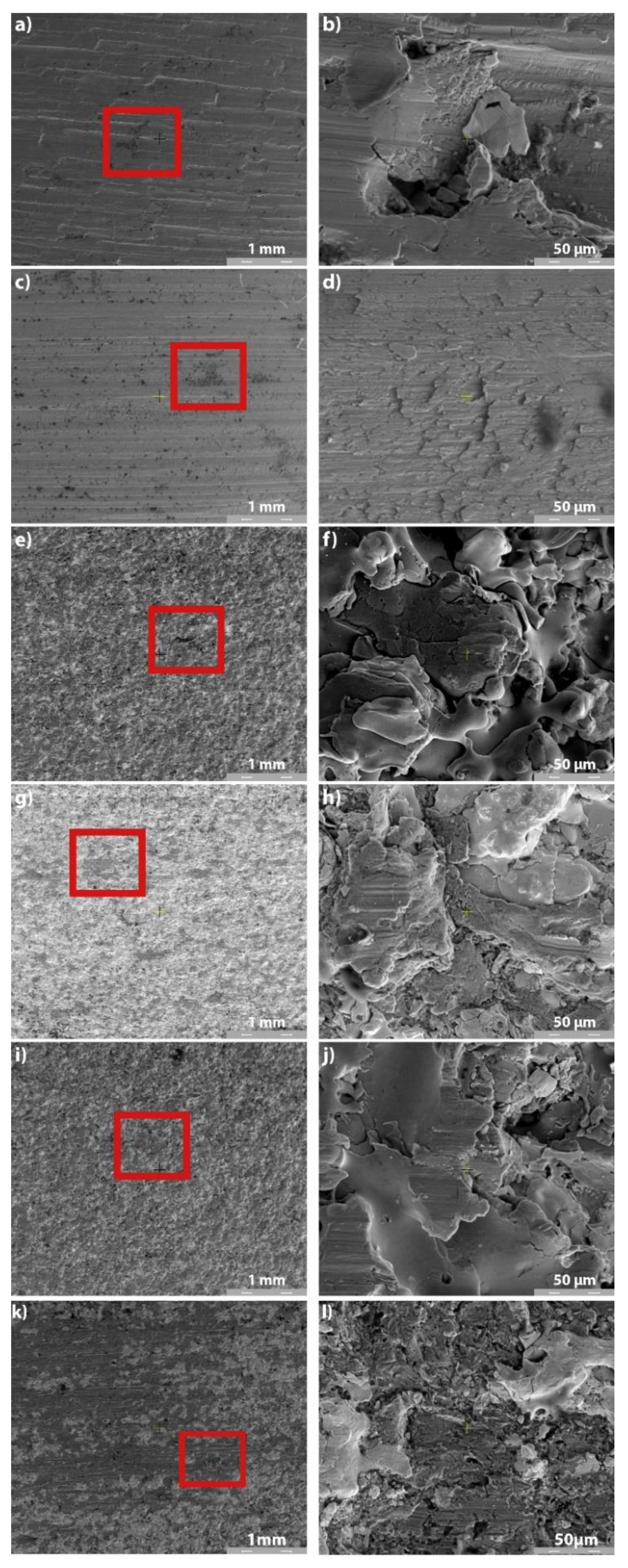

3.3.1. Surface SEM Analysis

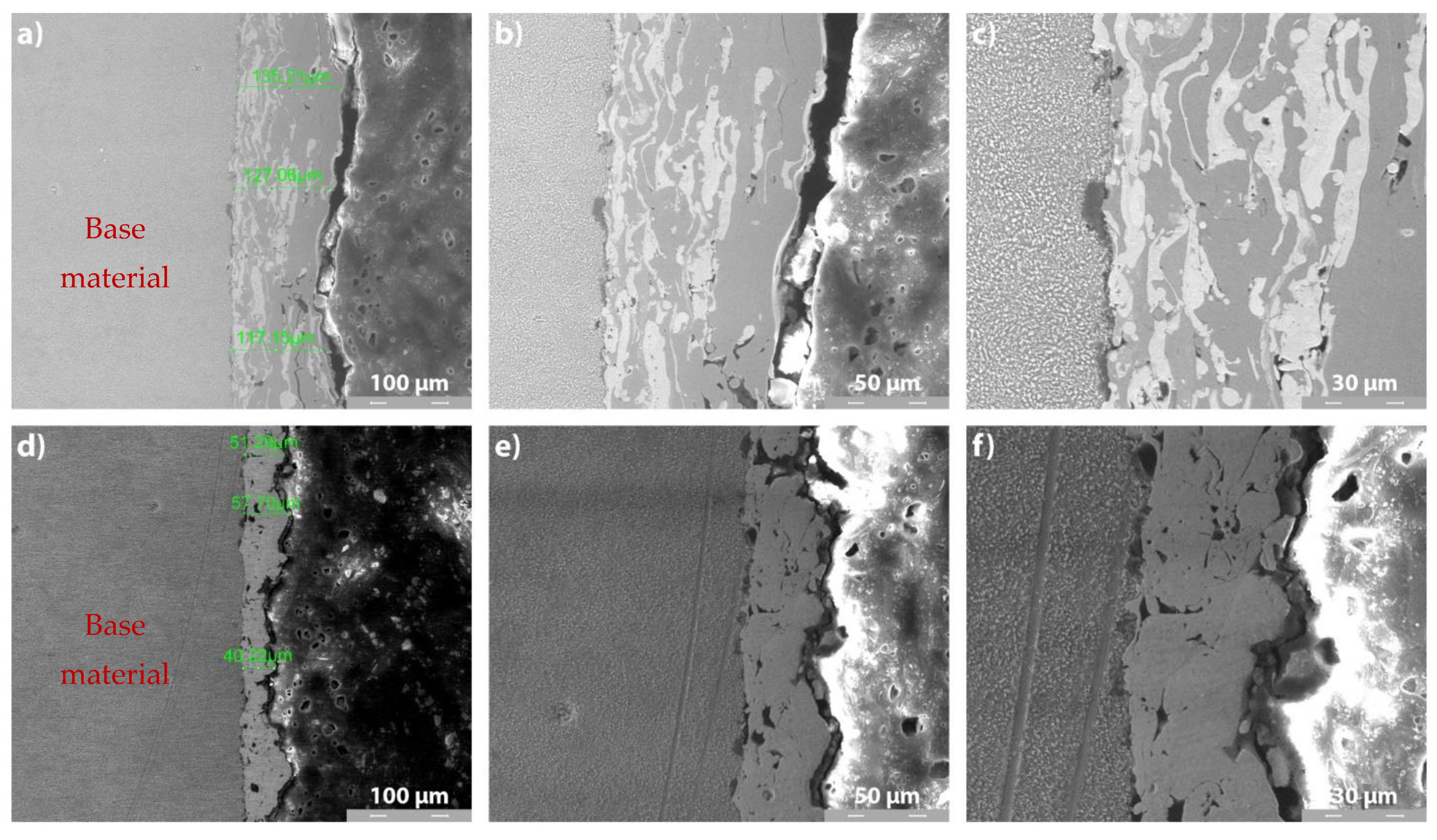

3.3.2. Cross-Section SEM Analysis of Metco 32 and Metco 72 Coatings on 40Cr10 Substrate

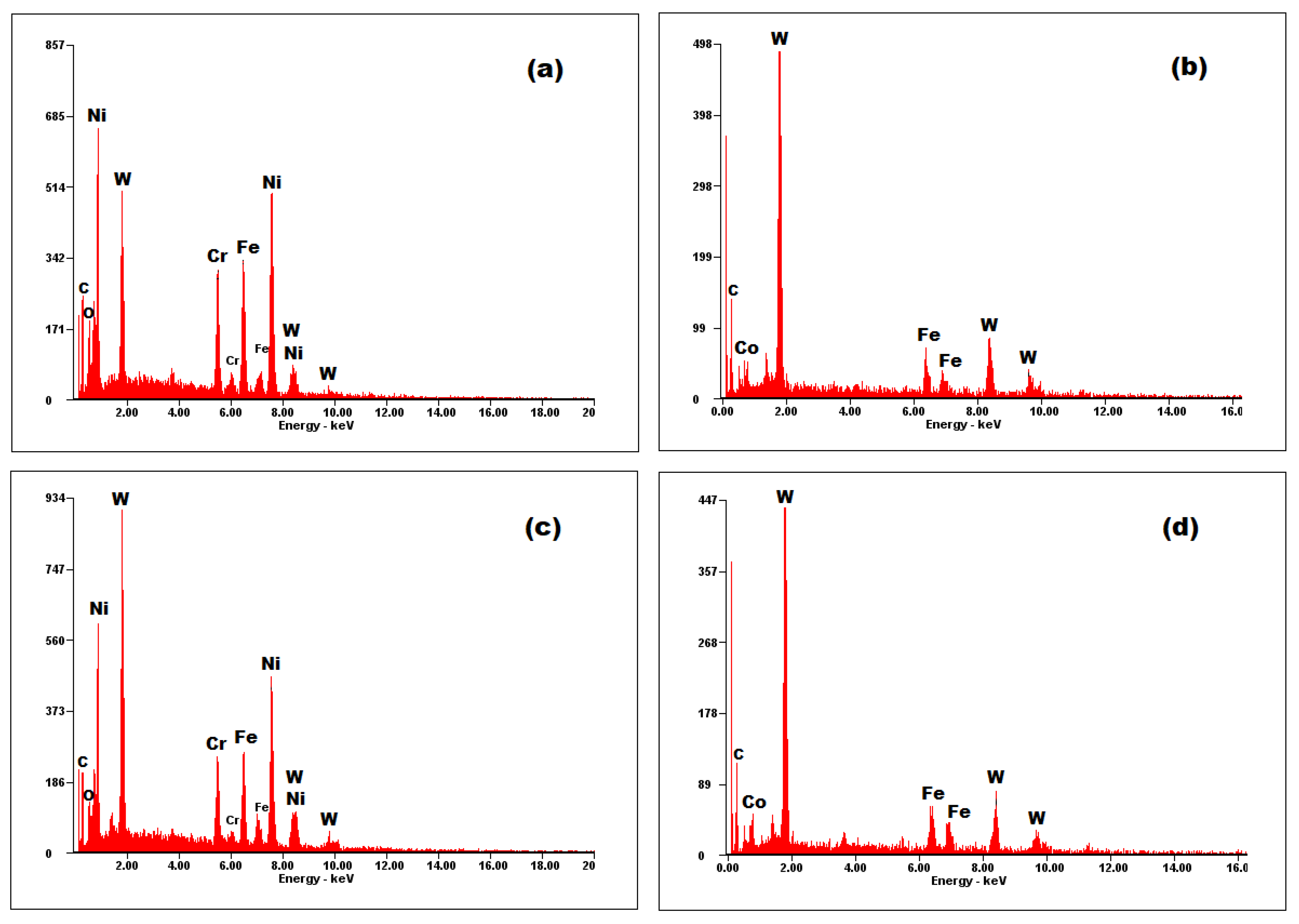

3.4. EDS Analysis

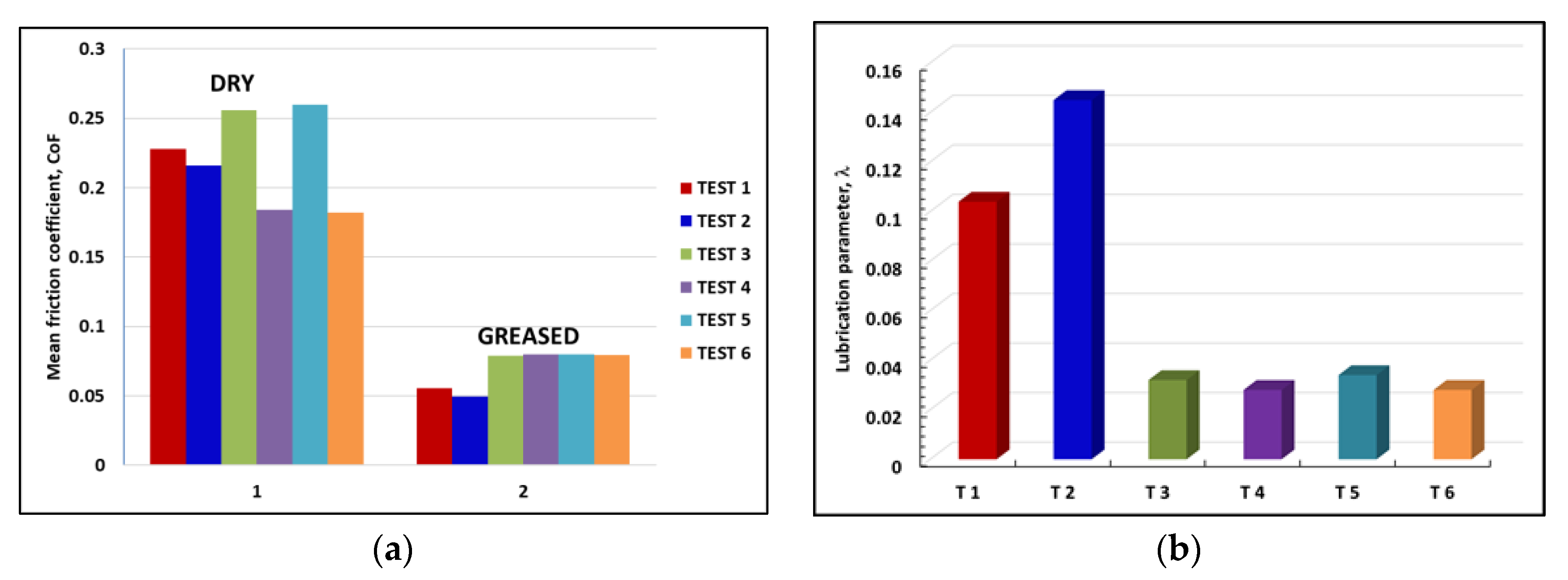

3.5. Friction and Wear Results

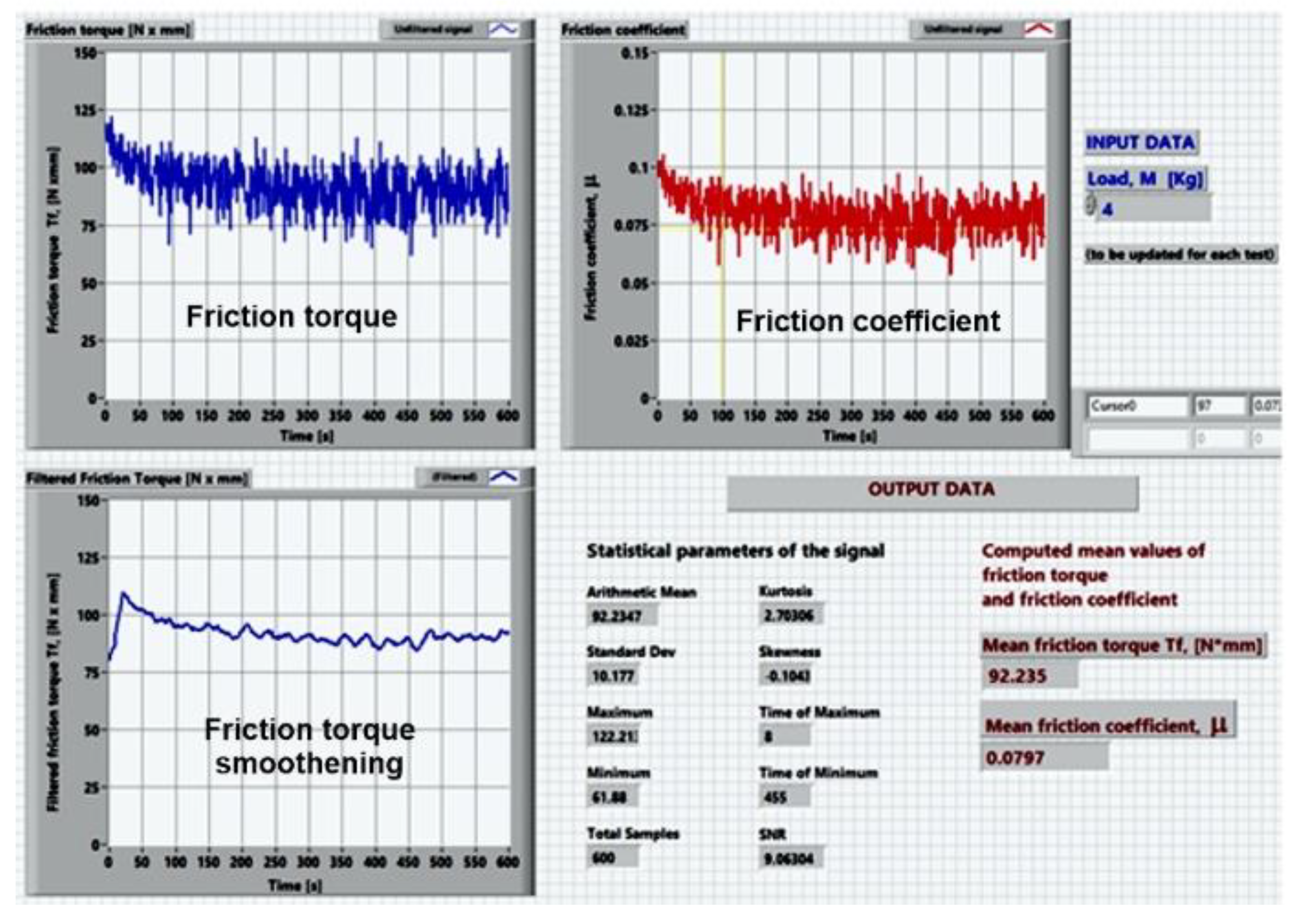

3.5.1. Friction Results

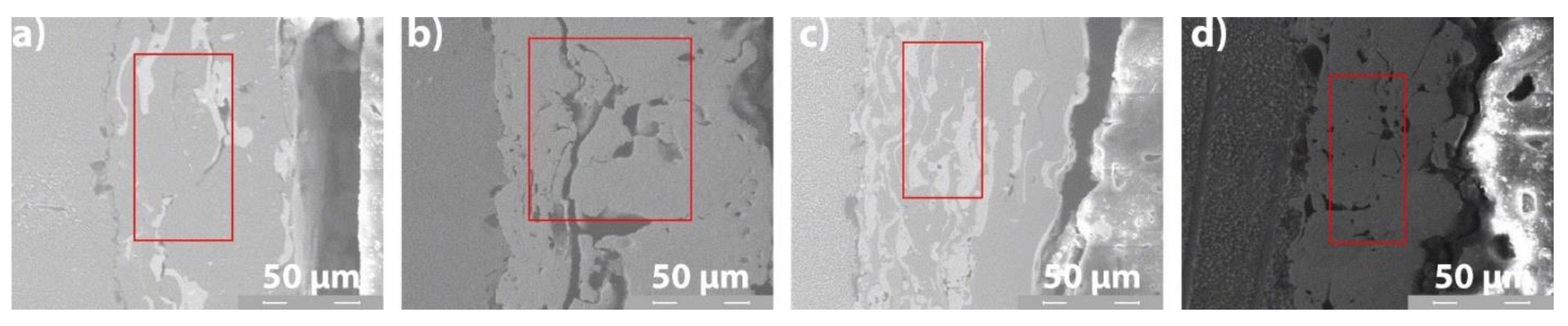

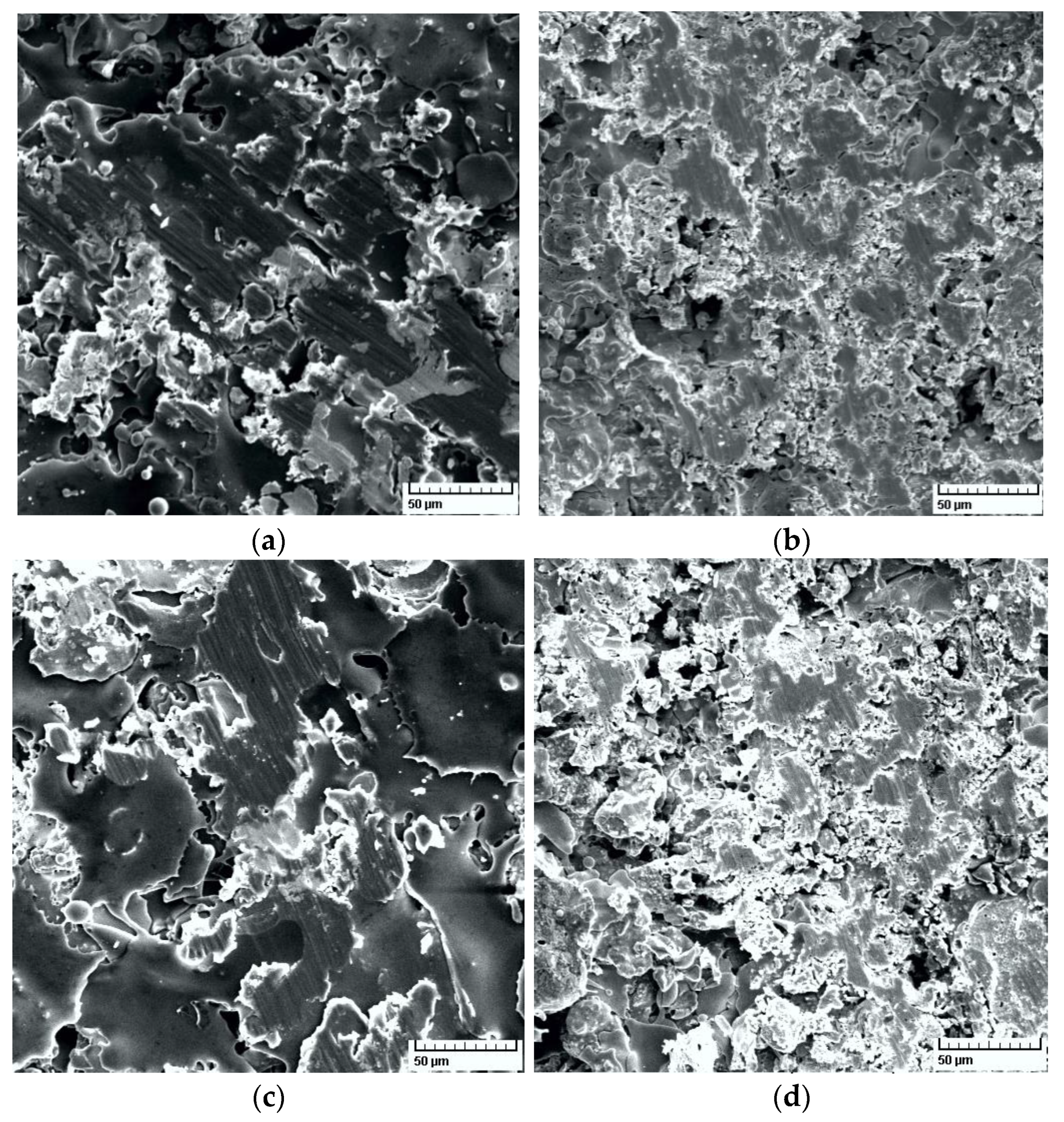

3.5.2. Wear Mechanism

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Krause, H.; Hammel, C. The wear behaviour of copper alloy-steel and polyamide-steel sliding pairs for heavily loaded cardan joints. Wear 1984, 93, 127–143. [Google Scholar] [CrossRef]

- Bulut, G.; Parlar, Z. Dynamic stability of a shaft system connected through a Hooke’s joint. Mech. Mach. Theory 2011, 46, 1689–1695. [Google Scholar] [CrossRef]

- Chaban, A.; Łukasik, Z.; Popenda, A.; Szafraniec, A. Mathematical Modelling of Transient Processes in an Asynchronous Drive with a Long Shaft Including Cardan Joints. Energies 2021, 14, 5692. [Google Scholar] [CrossRef]

- Bulut, G. Dynamic stability analysis of torsional vibrations of a shaft system connected by a Hooke’s joint through a continuous system model. J. Sound Vib. 2014, 333, 3691–3701. [Google Scholar] [CrossRef]

- Xia, Y.; Pang, J.; Yang, L.; Zhao, Q.; Yang, X. Nonlinear numerical and experimental study on the second-order torsional and lateral vibration of driveline system connected by cardan joint. J. Vib. Control 2020, 26, 540–551. [Google Scholar] [CrossRef]

- Song, M.-H.; Nam, T.-K.; Lee, J.-U. Self-Excited Torsional Vibration in the Flexible Coupling of a Marine Propulsion Shafting System Employing Cardan Shafts. J. Mar. Sci. Eng. 2020, 8, 348. [Google Scholar] [CrossRef]

- Vesali, F.; Rezvani, M.A.; Kashfi, M. Dynamics of universal joints, its failures and some propositions for practically improving its performance and life expectancy. J. Mech. Sci. Technol. 2012, 26, 2439–2449. [Google Scholar] [CrossRef]

- Stamenić, Z.; Tasic, M.B.; Mitrović, R. Influence of the Geometry Parameters of Cardan Joint Rolling Parts on the Load Distribution. FME Trans. 2012, 40, 135–143. [Google Scholar]

- Wang, G.; Qi, Z. Approximate determination of the joint reaction forces in the drive system with double universal joints. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 232, 1191–1207. [Google Scholar] [CrossRef]

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; Wiley: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Niranatlumpong, P.; Koiprasert, H. The effect of Mo content in plasma-sprayed Mo-NiCrBSi coating on the tribological behavior. Surf. Coat. Technol. 2010, 205, 483–489. [Google Scholar] [CrossRef]

- Kowalski, S. Influence of diamond-like carbon coatings on the wear of the press joint components. Wear 2021, 486–487, 204076. [Google Scholar] [CrossRef]

- Cimpoeșu, R.; Vizureanu, P.; Știrbu, I.; Sodor, A.; Zegan, G.; Prelipceanu, M.; Cimpoeșu, N.; Ioanid, N. Corrosion-Resistance Analysis of HA Layer Deposited through Electrophoresis on Ti4Al4Zr Metallic Substrate. Appl. Sci. 2021, 11, 4198. [Google Scholar] [CrossRef]

- Bita, A.I.; Stan, G.E.; Niculescu, M.; Ciuca, I.; Vasile, E.; Antoniac, I. Adhesion evaluation of different bioceramic coatings on Mg-Ca alloys for biomedical applications. J. Adhes. Sci. Technol. 2016, 30, 1968–1983. [Google Scholar] [CrossRef]

- Pogrebnyak, A.D.; Bratushka, S.N.; Ilyashenko, M.V.; Makhmudov, N.A.; Kolisnichenko, O.V.; Tyurin, Y.N.; Uglov, V.V.; Pshik, A.V.; Kaverin, M.V. Tribological and physical-mechanical properties of protective coatings from Ni-Cr-B-Si-Fe/WC-Co-Cr before and after fission with a plasma jet. J. Frict. Wear 2011, 32, 84–90. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Popovich, V.; Matos, M.; Senos, A.M.R.; Vieira, M.T. Carbide phases formed in WC–M (M = Fe/Ni/Cr) systems. Ceram. Int. 2009, 35, 369–372. [Google Scholar] [CrossRef]

- Ndumia, J.N.; Kang, M.; Gbenontin, B.V.; Lin, J.; Nyambura, S.M. A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings. Nanomaterials 2021, 11, 2527. [Google Scholar] [CrossRef]

- Boas, M.; Bamberger, M.; Revez, G. Laser-alloying of a plasma-sprayed WC/Co layer to enhance wear properties. Surf. Coat. Technol. 1990, 42, 175–186. [Google Scholar] [CrossRef]

- Guilemany, J.M.; Miguel, J.M.; Vizcaino, S.; Climent, F. Role of three-body abrasion wear in the sliding wear behaviour of WC–Co coatings obtained by thermal spraying. Surf. Coat. Technol. 2001, 140, 141–146. [Google Scholar] [CrossRef]

- Bolleddu, V.; Racherla, V.; Bandyopadhyay, P.P. Comparative study of air plasma sprayed and high velocity oxy-fuel sprayed nanostructured WC-17wt.%Co coatings. Int. J. Adv. Manuf. Technol. 2015, 84, 1601–1613. [Google Scholar] [CrossRef]

- Rayón, E.; Bonache, V.; Salvador, M.D.; Roa, J.J.; Sánchez, E. Hardness and Young’s modulus distributions in atmospheric plasma sprayed WC–Co coatings using nanoindentation. Surf. Coat. Technol. 2011, 205, 4192–4197. [Google Scholar] [CrossRef]

- Rahbar-kelishami, A.; Abdollah-zadeh, A.; Hadavi, M.M.; Banerji, A.; Alpas, A.; Gerlich, A.P. Effects of friction stir processing on wear properties of WC–12%Co sprayed on 52100 steel. Mater. Des. 2015, 86, 98–104. [Google Scholar] [CrossRef]

- Simunovic, K.; Havrlisan, S.; Saric, T.; Vukelic, D. Modeling and Optimization in Investigating Thermally Sprayed Ni-Based Self-Fluxing Alloy Coatings: A Review. Materials 2020, 13, 4584. [Google Scholar] [CrossRef] [PubMed]

- Khanna, A.S.; Kumari, S.; Kanungo, S.; Gasser, A. Hard coatings based on thermal spray and laser cladding. Int. J. Refract. Met. Hard Mater. 2009, 27, 485–491. [Google Scholar] [CrossRef]

- Kazamer, N.; Pascal, D.T.; Marginean, G.; Şerban, V.A.; Codrean, C.; Uţu, I.D. A Comparison between Hardness, Corrosion and Wear Performance of APS Sprayed WC-CoMo and WC-Co Coatings. Solid State Phenom. 2016, 254, 71–76. [Google Scholar] [CrossRef]

- Bolelli, G.; Bonferroni, B.; Laurila, J.; Lusvarghi, L.; Milanti, A.; Niemi, K.; Vuoristo, P. Micromechanical properties and sliding wear behaviour of HVOF-sprayed Fe-based alloy coatings. Wear 2012, 276–277, 29–47. [Google Scholar] [CrossRef]

- Bolelli, G.; Börner, T.; Milanti, A.; Lusvarghi, L.; Laurila, J.; Koivuluoto, H.; Vuoristo, P. Tribological behavior of HVOF- and HVAF-sprayed composite coatings based on Fe-Alloy + WC–12%Co. Surf. Coat. Technol. 2014, 248, 104–112. [Google Scholar] [CrossRef]

- Paleu, C.C.; Munteanu, C.; Istrate, B.; Bhaumik, S.; Vizureanu, P.; Bălţatu, M.S.; Paleu, V. Microstructural Analysis and Tribological Behavior of AMDRY 1371 (Mo–NiCrFeBSiC) Atmospheric Plasma Spray Deposited Thin Coatings. Coatings 2020, 10, 1186. [Google Scholar] [CrossRef]

- Paleu, V.; Cîrlan Paleu, C.; Istrate, B.; Bhaumik, S.; Munteanu, C. Friction and wear resistance of Al2O3 40TiO2 (AMDRY 6250) coating of a pump shaft sleeve bearing. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Cluj-Napoca, Romania, 19–21 September 2019; IOP Publishing: Bristol, UK, 2020; Volume 724, p. 012064. [Google Scholar] [CrossRef]

- Dascălu, A.; Istrate, B.; Munteanu, C.; Paleu Cîrlan, C.; Paleu, V. Morphological and tribological studies of thermal plasma jet deposited coatings used in cardan joints. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Iași, Romania, 4–5 June 2020; IOP Publishing: Bristol, UK, 2020; Volume 997, p. 012022. [Google Scholar] [CrossRef]

- Istrate, B.; Rau, J.V.; Munteanu, C.; Antoniac, I.V.; Saceleanu, V. Properties and in vitro assessment of ZrO2-based coatings obtained by atmospheric plasma jet spraying on biodegradable Mg–Ca and Mg–Ca–Zr alloys. Ceram. Int. 2020, 46, 15897–15906. [Google Scholar] [CrossRef]

- Doxey, R.C. Use of an AMSLER Wear Testing Machine to Investigate the Wear of Steel. Master’s Thesis, United States Naval Postgraduate School, Monterey, CA, USA, 1956. Available online: https://core.ac.uk/download/pdf/36708066.pdf (accessed on 27 October 2020).

- Paleu, V.; Georgescu, S.; Baciu, C.; Istrate, B.; Baciu, E.R. Preliminary experimental research on friction characteristics of a thick gravitational casted babbit layer on steel substrate. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Iasi, Romania, 9–10 June 2016; IOP Publishing: Bristol, UK, 2016; Volume 147, p. 012028. [Google Scholar] [CrossRef] [Green Version]

- Paulin, C.; Chicet, D.; Paleu, V.; Benchea, M.; Lupescu, Ş.; Munteanu, C. Dry friction aspects of Ni-based self-fluxing flame sprayed coatings. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Sibiu, Romania, 14–17 June 2017; IOP Publishing: Bristol, UK, 2017; Volume 227, p. 012091. [Google Scholar] [CrossRef] [Green Version]

- Paleu, C.C.; Paleu, V.; Istrate, B.; Cimpoesu, N.; Munteanu, C. Thin coatings for pumping station mechanical components. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Iasi, Romania, 19–22 June 2019; IOP Publishing: Bristol, UK, 2019; Volume 591, p. 012007. [Google Scholar] [CrossRef] [Green Version]

- Mrdak, M.; Vencl, A.; Ćosić, M. Microstructure and mechanical properties of the Mo–NiCrBSi coating deposited by atmospheric plasma spraying. FME Trans. 2009, 37, 27–32. [Google Scholar]

- Vashishtha, N.; Khatirkar, R.K.; Sapate, S.G. Tribological behaviour of HVOF sprayed WC-12Co, WC-10Co-4Cr and Cr3C2−25NiCr coatings. Tribol. Int. 2017, 105, 55–68. [Google Scholar] [CrossRef]

- Total Materia Database. Available online: https://portal.totalmateria.com (accessed on 29 October 2021).

- Zhang, X.C.; Xu, B.S.; Xuan, F.Z.; Tu, S.T.; Wang, H.D.; Wu, Y.X. Porosity and effective mechanical properties of plasma-sprayed Ni-based alloy coatings. Appl. Surf. Sci. 2009, 255, 4362–4371. [Google Scholar] [CrossRef]

- Neikov, O.D.; Naboychenko, S.S.; Murashova, I.B. Production of Nickel and Nickel-Alloy Powders. In Handbook of Non-Ferrous Metal. Powders, 2nd ed.; Neikov, O.D., Naboychenko, S.S., Dowson, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 633–668. [Google Scholar] [CrossRef]

- Longo, F.N. Coating Processing. In Handbook of Thermal Spray Technology; Davis, J.R., Ed.; ASM International: Materials Park, OH, USA, 2004; pp. 108–119. [Google Scholar]

- Yan, Y. Tribology and tribocorrosion testing and analysis of metallic biomaterials. In Metals for Biomedical Devices, 2nd ed.; Niinomi, M., Ed.; Elsevier: Amsterdam, The Netherlands; Woodhead Publishing: Duxford, UK, 2019; pp. 218–234. [Google Scholar] [CrossRef]

- Bhaumik, S.; Kamaraj, M.; Paleu, V. Tribological analyses of a new optimized gearbox biodegradable lubricant blended with reduced graphene oxide nanoparticles. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 901–915. [Google Scholar] [CrossRef]

| Test Number | Lower Disk | Upper Disk | |

|---|---|---|---|

| Substrate | Coating | ||

| TEST 1 | AISI52100 | 40Cr10 | without |

| TEST 2 | AISI52100 | RUL2 | without |

| TEST 3 | AISI52100 | 40Cr10 | Metco 32 |

| TEST 4 | AISI52100 | 40Cr10 | Metco 72 |

| TEST 5 | AISI52100 | RUL2 | Metco 32 |

| TEST 6 | AISI52100 | RUL2 | Metco 72 |

| Parameter | Metco 32/40Cr10 | Metco 72/40Cr10 | Metco 32/RUL2 | Metco 72/RUL2 | 40Cr10 | RUL2 |

|---|---|---|---|---|---|---|

| Microhardness, HR0.5 [GPa] (and confidence limits) | 2.42 (−0.37; +0.48) | 0.93 (±0.08) | 1.56 (−0.28; +0.31) | 0.88 (−0.15; +0.3) | 1.22 (±0.3) | 0.98 (±0.2) |

| Young modulus, E [GPa] (and confidence limits) | 81.8 (−7.51; +11.43) | 40.88 (±3.25) | 64.21 (−8.68; +4.80) | 54.34 (−6.93; +7.18) | 216.33 (±5.11) | 215.93 (±1.04) |

| Coating thickness, hc [μm] (and confidence limits) | 59.64 (−4.47; +2.52) | 91.70 (−5.05; +8.94) | 126.47 (−8.74; +9.32) | 49.74 (−7.96; +9.52) | 0 - | 0 - |

| Sample | Testing Conditions | |

|---|---|---|

| Dry | Grease Lubricated | |

| Roughness Ra, [μm] | Roughness Ra, [μm] | |

| 40Cr10 (no coating) | 1.96 ± 0.11 | 1.04 ± 0.07 |

| RUL 2 (no coating) | 0.37 ± 0.04 | 0.28 ± 0.03 |

| Metco 32/40Cr10 | 7.54 ± 0.29 | 4.61 ± 0.14 |

| Metco 72/40Cr10 | 5.97 ± 0.26 | 5.22 ± 0.21 |

| Metco 32/RUL2 | 5.55 ± 0.24 | 4.31 ± 0.17 |

| Metco 72/RUL2 | 4.44 ± 0.19 | 5.19 ± 0.24 |

| Test No. 1 | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 | Test 6 |

|---|---|---|---|---|---|---|

| Dry CoF (and confidence limits) | 0.228 (±0.021) | 0.216 (±0.019) | 0.256 (±0.027) | 0.184 (±0.016) | 0.260 (±0.03) | 0.182 (±0.019) |

| Greased CoF (and confidence limits) | 0.0556 (±0.0041) | 0.0496 (±0.0037) | 0.079 (±0.0057) | 0.0801 (±0.0062) | 0.0797 (±0.0059) | 0.0795 (±0.0054) |

| Test No. 1 | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 | Test 6 |

|---|---|---|---|---|---|---|

| λ parameter | 0.104 | 0.145 | 0.032 | 0.028 | 0.034 | 0.028 |

| Lubrication regime | Mixed | Boundary | ||||

| Coating/ Substrate | Metco 32/ 40Cr10 | Metco 72/ 40Cr10 | Metco 32/ RUL2 | Metco 72/ RUL2 |

|---|---|---|---|---|

| Average dry CoF Standard deviation | 0.481 0.190 | 0.550 0.205 | 0.604 0.240 | 0.626 0.225 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munteanu, C.; Paleu, V.; Istrate, B.; Dascălu, A.; Cîrlan Paleu, C.; Bhaumik, S.; Ancaş, A.D. Tribological Behavior and Microstructural Analysis of Atmospheric Plasma Spray Deposited Thin Coatings on Cardan Cross Spindles. Materials 2021, 14, 7322. https://doi.org/10.3390/ma14237322

Munteanu C, Paleu V, Istrate B, Dascălu A, Cîrlan Paleu C, Bhaumik S, Ancaş AD. Tribological Behavior and Microstructural Analysis of Atmospheric Plasma Spray Deposited Thin Coatings on Cardan Cross Spindles. Materials. 2021; 14(23):7322. https://doi.org/10.3390/ma14237322

Chicago/Turabian StyleMunteanu, Corneliu, Viorel Paleu, Bogdan Istrate, Anişoara Dascălu, Cornelia Cîrlan Paleu, Shubrajit Bhaumik, and Ana Diana Ancaş. 2021. "Tribological Behavior and Microstructural Analysis of Atmospheric Plasma Spray Deposited Thin Coatings on Cardan Cross Spindles" Materials 14, no. 23: 7322. https://doi.org/10.3390/ma14237322

APA StyleMunteanu, C., Paleu, V., Istrate, B., Dascălu, A., Cîrlan Paleu, C., Bhaumik, S., & Ancaş, A. D. (2021). Tribological Behavior and Microstructural Analysis of Atmospheric Plasma Spray Deposited Thin Coatings on Cardan Cross Spindles. Materials, 14(23), 7322. https://doi.org/10.3390/ma14237322