Fly Ash with Ammonia: Properties and Emission of Ammonia from Cement Composites

Abstract

1. Introduction

- loss on ignition

- fineness and water requirement

- properties of fresh mortar

- setting time

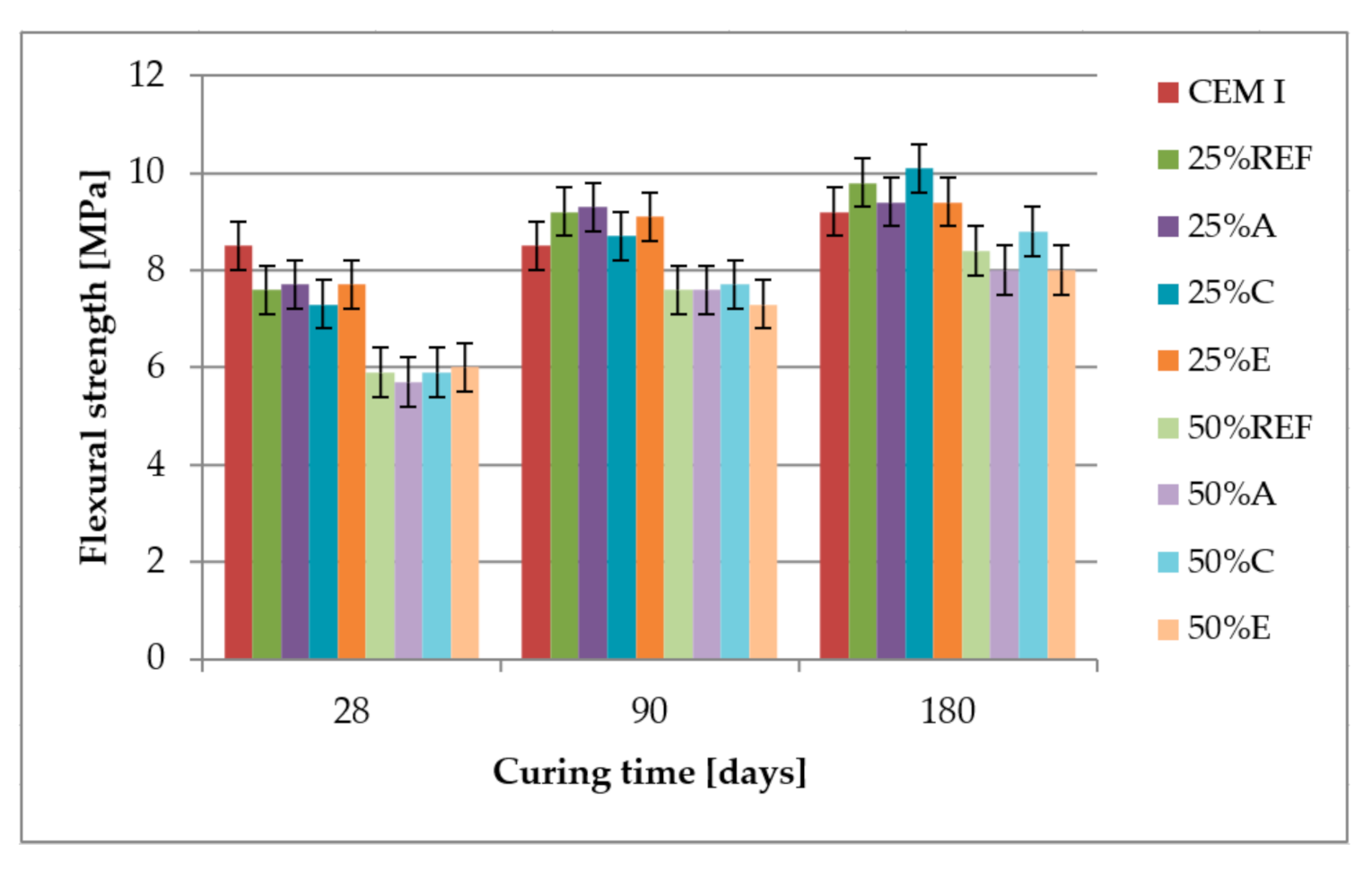

- compressive and bending strength

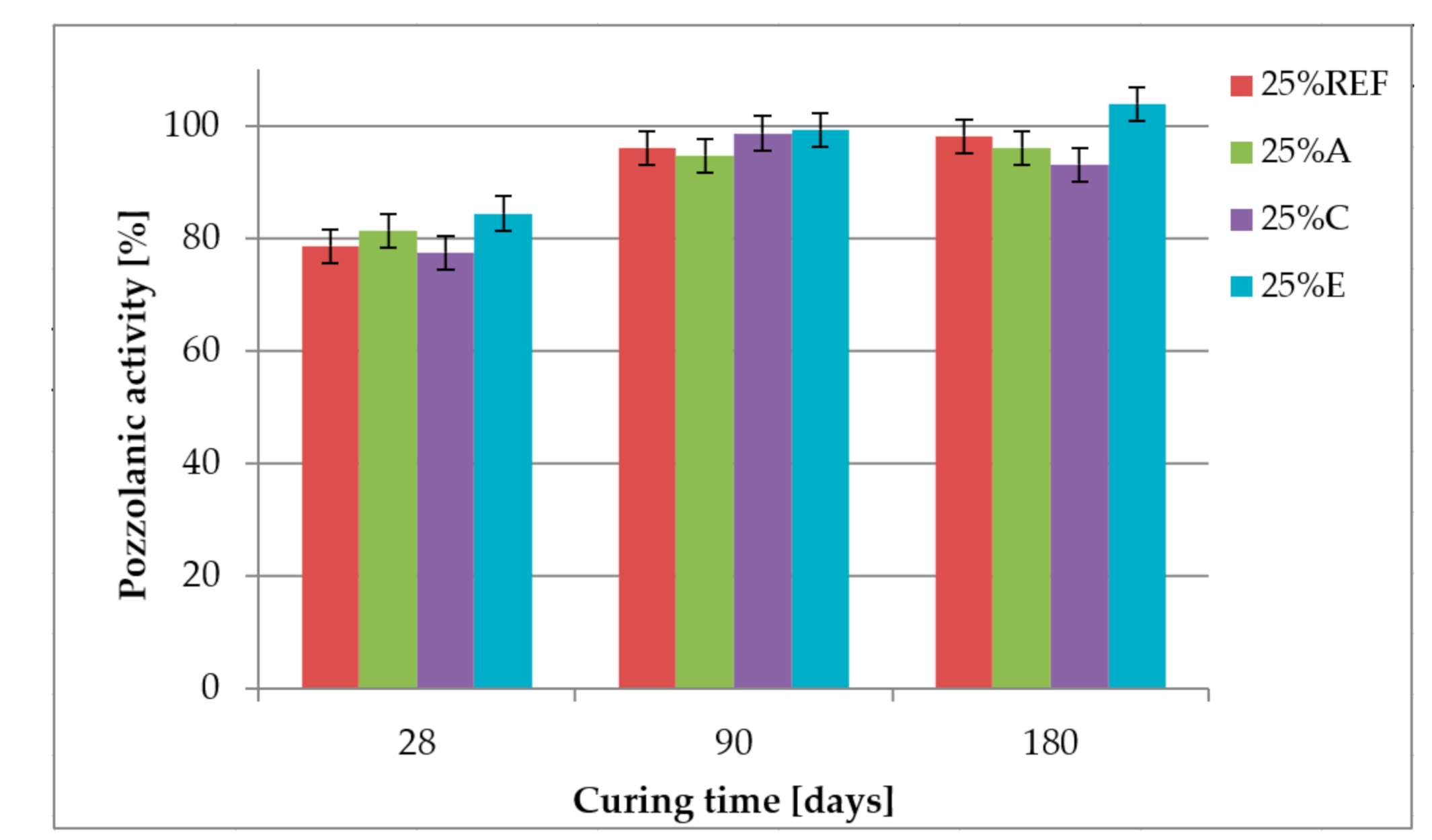

- pozzolanic activity

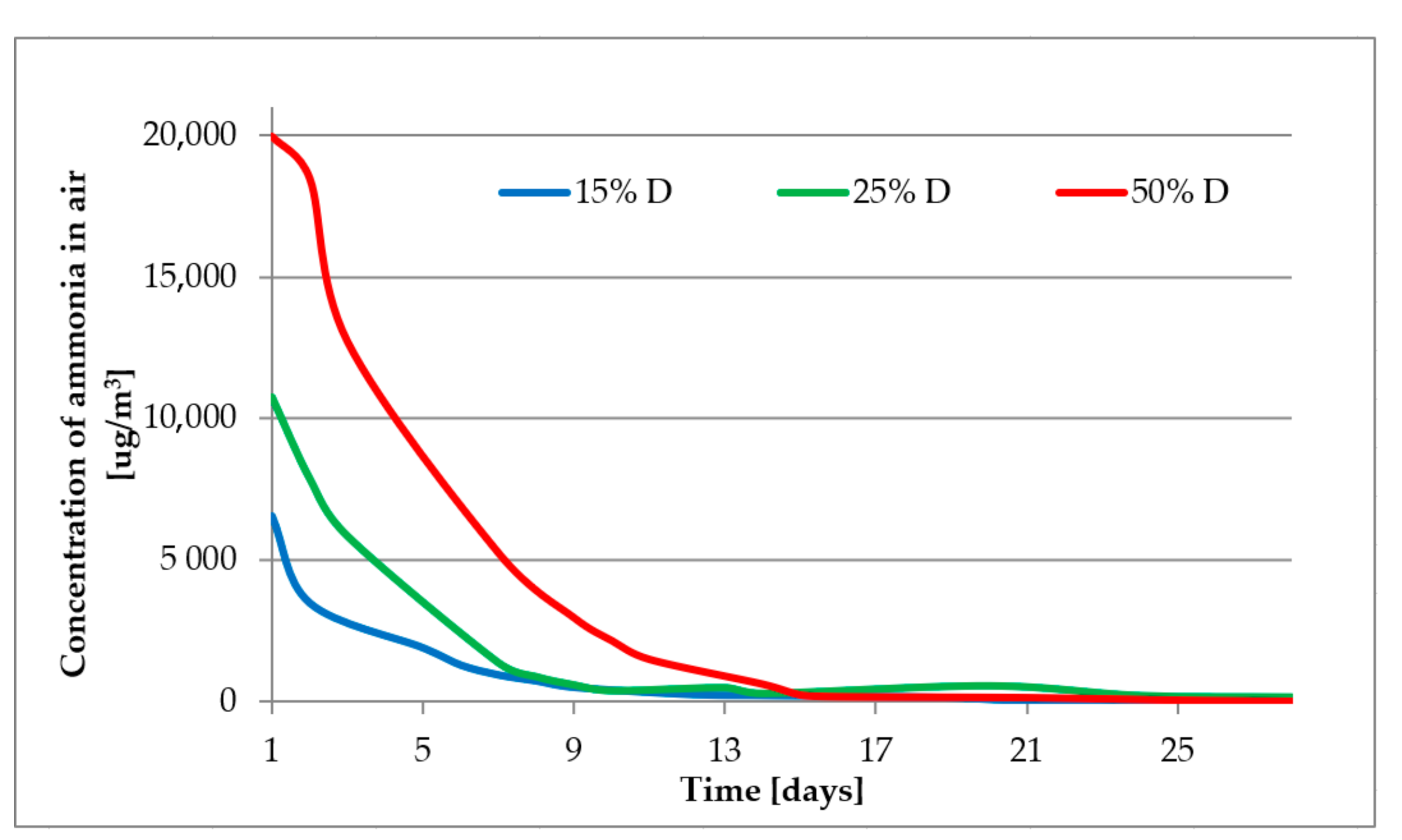

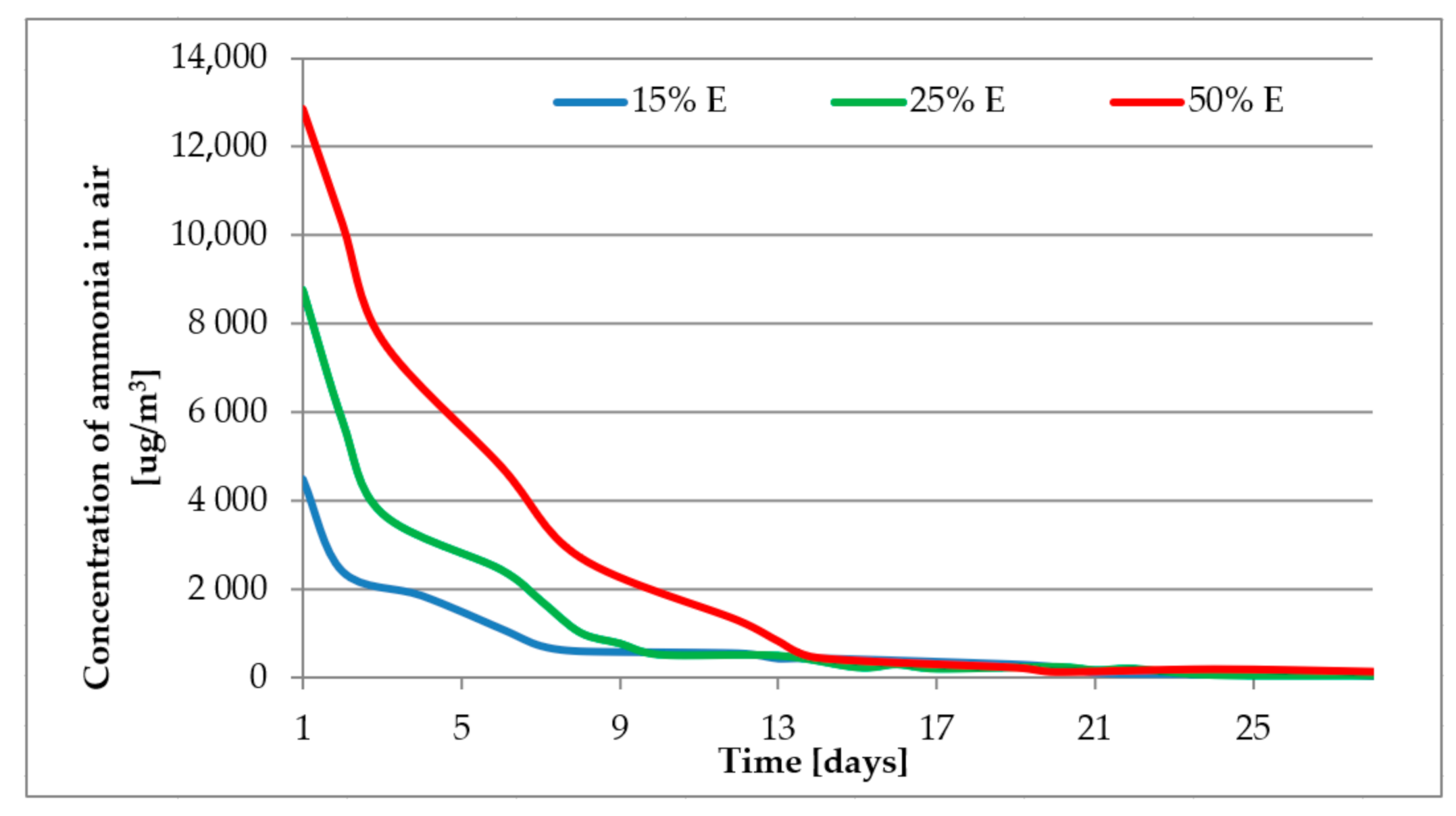

- emission of ammonia from mortars

2. Materials and Methods

2.1. Fly Ash and Cement

2.2. Loss on Ignition, Fineness and Water Requirement

2.3. Properties of Fresh Mortar

2.4. Setting Time

2.5. Compressive and Bending Strength

2.6. Pozzolanic Activity

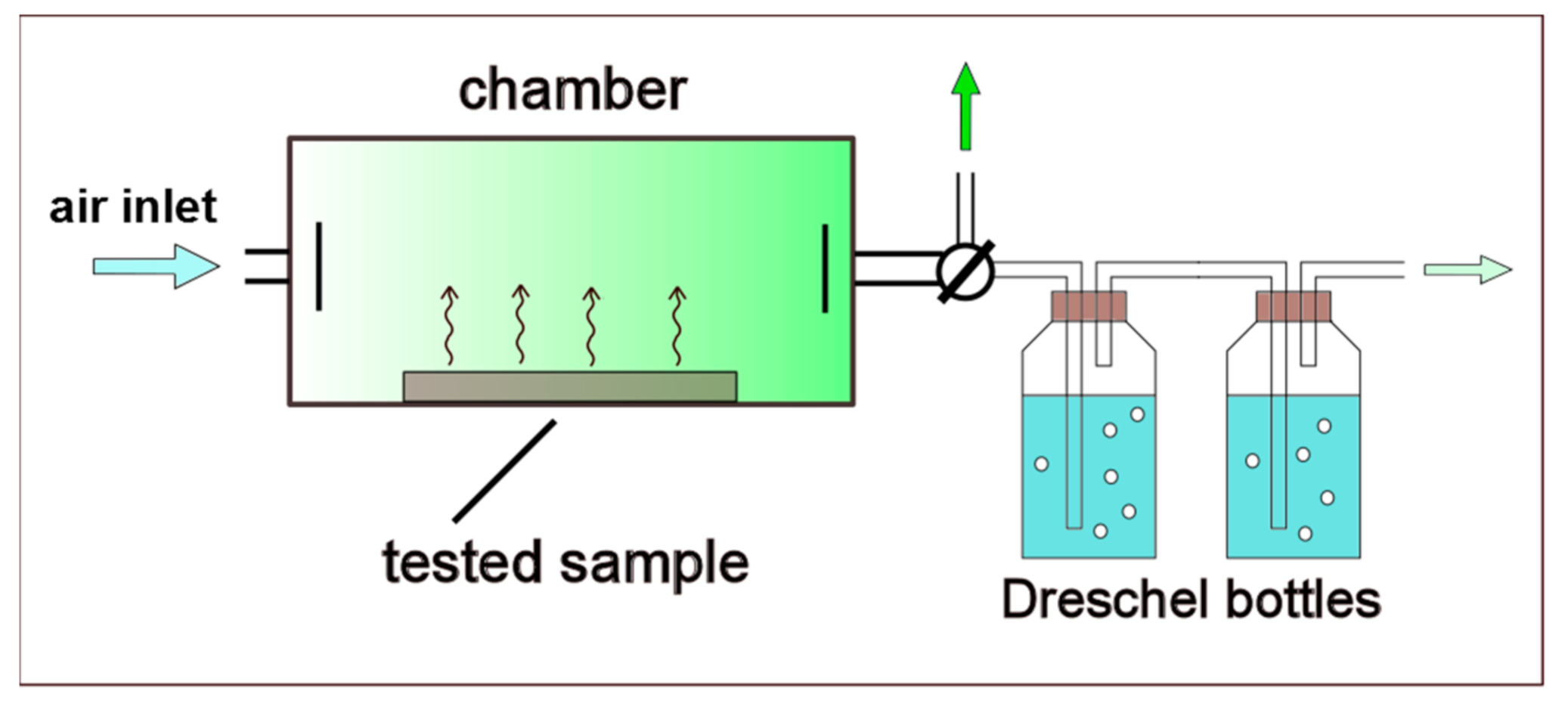

2.7. Emission of Ammonia from Mortars

- height 2.5 m

- floor (and ceiling) 3 m × 4 m

- one door with dimensions 0.8 m × 2 m

- one window with a surface of 2 m2

- 1.0 m2/m3 for the wall emission

- 0.4 m2/m3 for the floor or ceiling emissions

- 1.8 m2/m3 for the emission from walls, floor and ceiling

3. Results and Discussion

3.1. Loss on Ignition, Fineness and Water Requirement

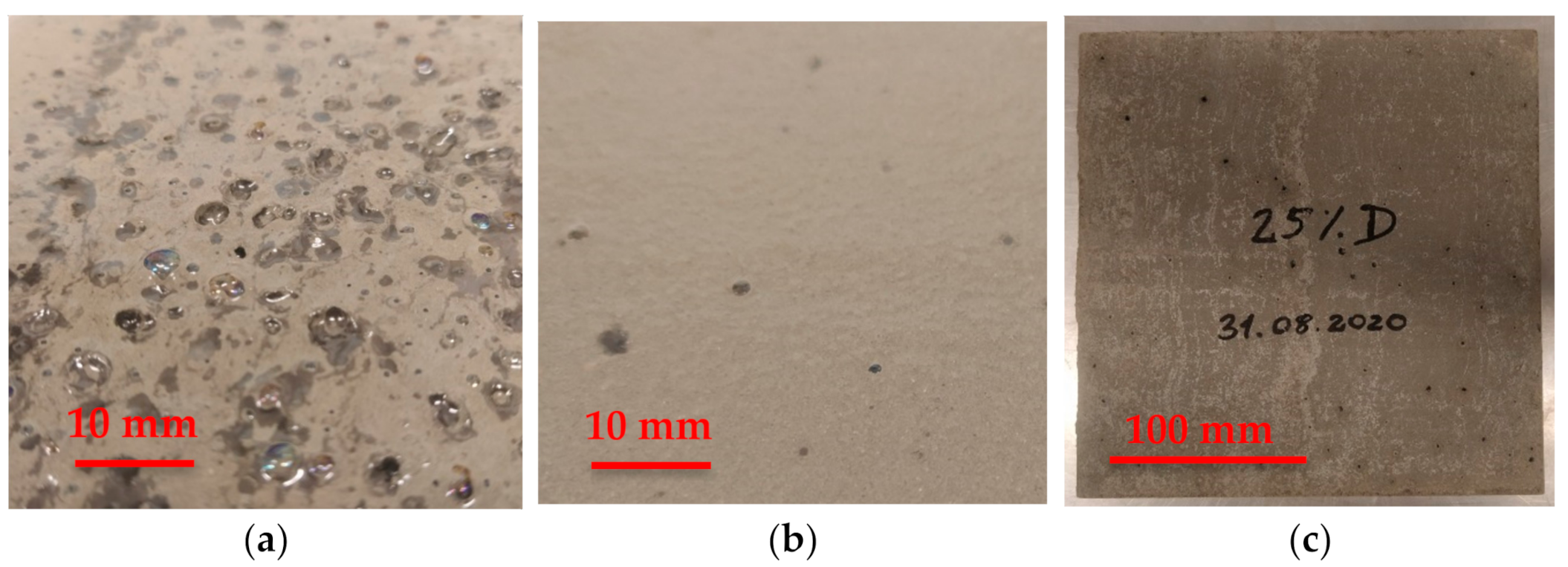

3.2. Properties of Fresh Mortar

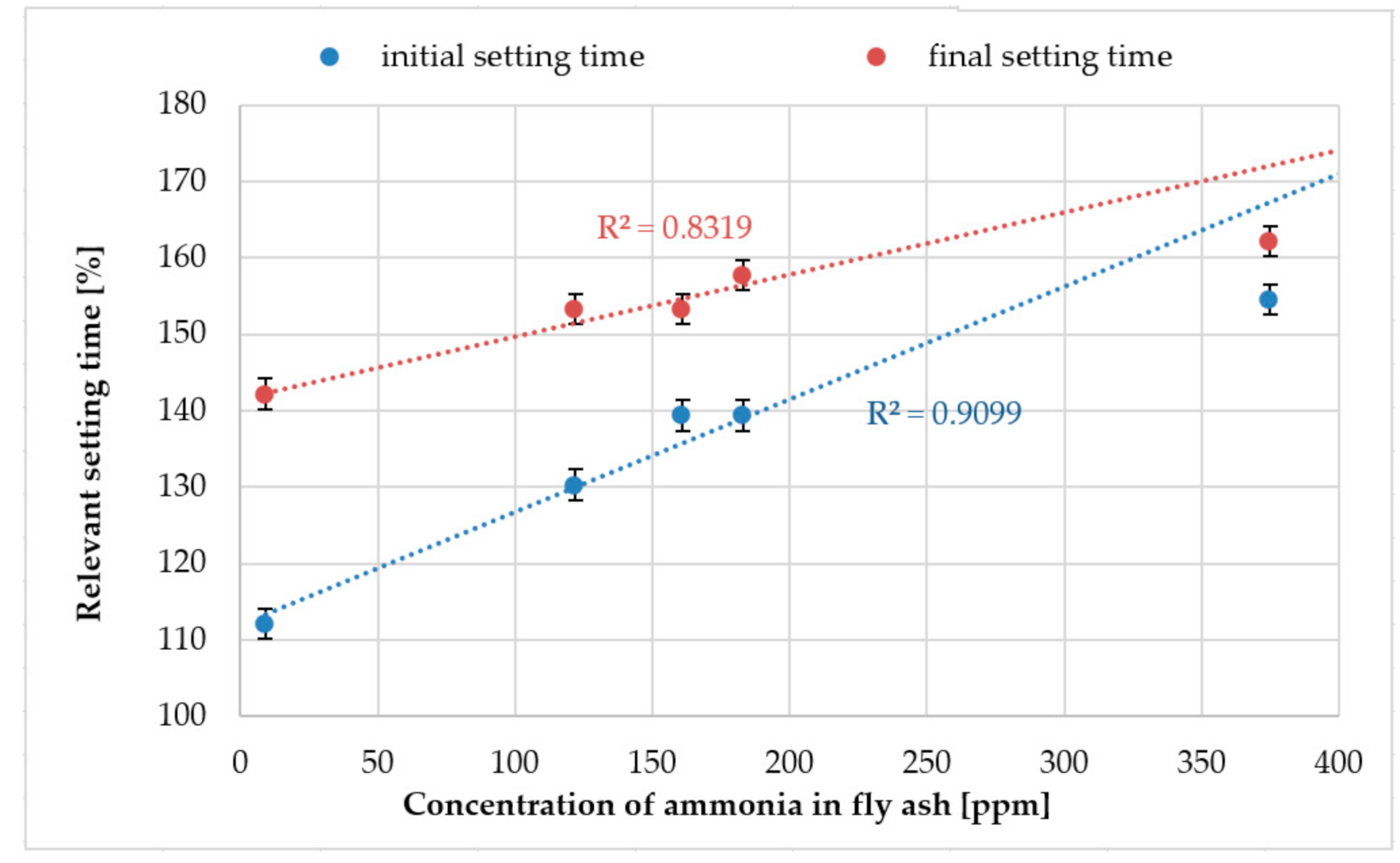

3.3. Setting Time

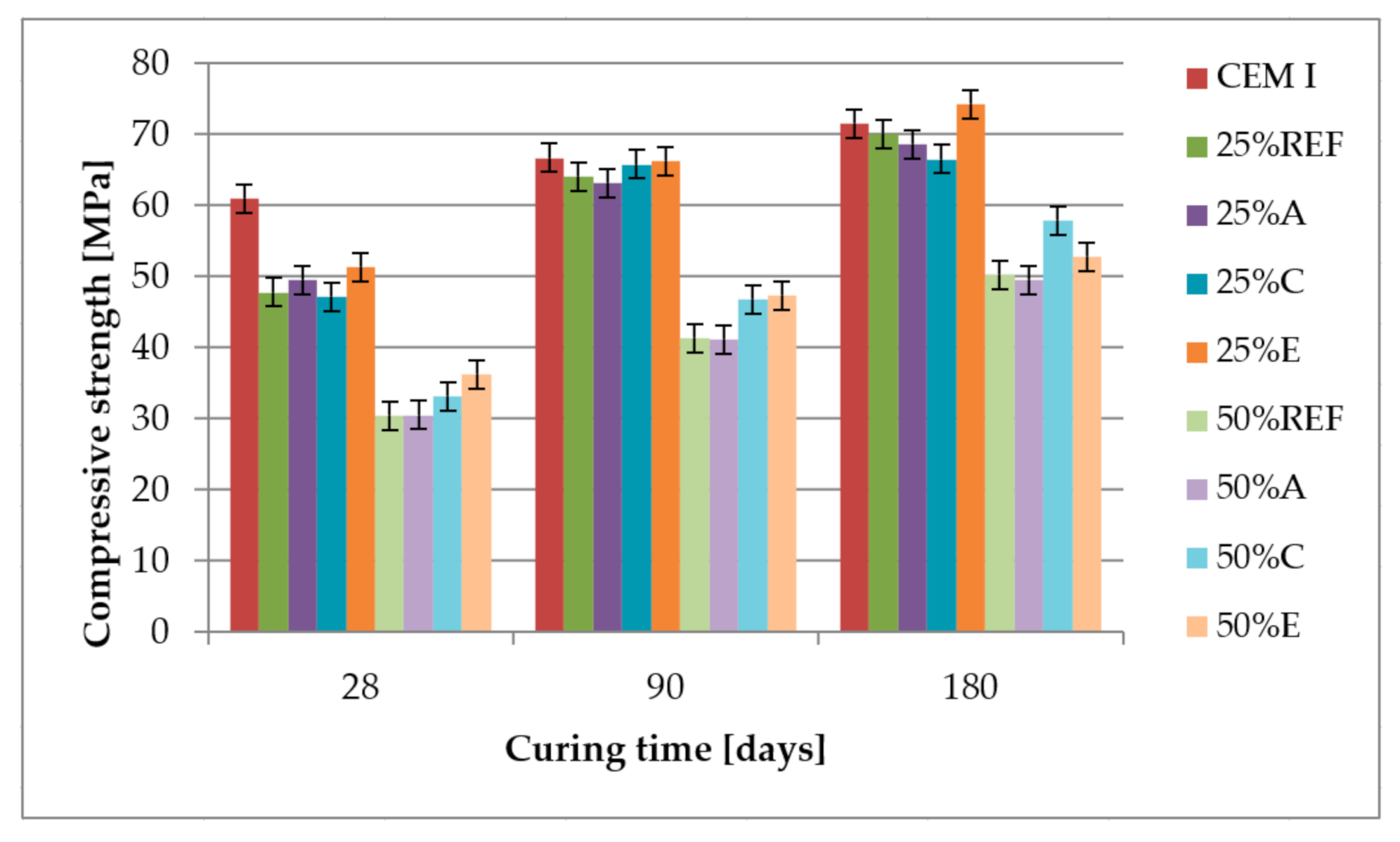

3.4. Compressive Strength, Bending Strength and Pozzolanic Activity

3.5. Emission of Ammonia from Mortars

4. Conclusions

- no correlation between the ammonia content and loss on ignition and the fineness of fly ash was found

- no significant effect of ammonia on mortar density and consistency was found

- no significant effect of ammonia on compressive strength and pozzolanic activity was found

- no significant influence of ammonia on water requirement was found

- intense release of ammonia gas was observed when the ash came into contact with a strongly alkaline cement grout, which might also cause the observed increase of the air content in fresh mortar

- ammonia in fly ash increases the initial and final setting times of the grouts within the limits permitted by the PN-EN 450-1 standard [1]. It was estimated, however, that ash containing more than 600 ppm of ammonia might extend the initial setting time not fulfilling the requirements of the standard

- ammonia present in the tested fly ash significantly affects the emission of this gas from mortars. It was observed that the amount of ammonia emission increases with the increase of ammonia concentration in the ash and the amount of added ash to the mortar. After 28 days, however, when the cement composites reach their declared parameters, the emission of ammonia is negligible

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hill, R.L.; Folliard, K.J. The Impact of Fly Ash on Air-Entrained Concrete. Concr. InFocus 2006, 5, 71–72. [Google Scholar]

- Czarnecki, L.; Garbacz, A.; Sokołowska, J.J. Fly Ash Polymer Concretes. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28 June 2010; pp. 127–138. [Google Scholar]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Czarnecki, L.; Woyciechowski, P.; Adamczewski, G. Risk of concrete carbonation with mineral industrial by-products. KSCE J. Civ. Eng. 2017, 22, 755–764. [Google Scholar] [CrossRef]

- Karim, M.R.; Hossain, M.; Khan, M.N.N.; Zain, M.F.M.; Jamil, M.; Lai, F.C. On the utilization of pozzolanic wastes as an alternative resource of cement. Materials 2014, 7, 7809–7827. [Google Scholar] [CrossRef] [PubMed]

- Chyliński, F.; Bobrowicz, J.; Łukowski, P. Undissolved Ilmenite Mud from TiO2 Production—Waste or a Valuable Addition to Portland Cement Composites? Materials 2020, 13, 3555. [Google Scholar] [CrossRef]

- Harasymiuk, J.; Rudziński, A. Old Dumped Fly Ash as a Sand Replacement in Cement Composites. Buildings 2020, 10, 67. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. EN 197-1:2012 Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- The European Parliament and the Council of the European Union. EN 450-1:2012 Fly Ash for concrete—Part 1: Definition, Specifications and Conformity Criteria; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- Paul, S.C.; van Rooyen, A.S.; van Zijl, G.P.A.G.; Petrik, L.F. Properties of cement-based composites using nanoparticles: A comprehensive review. Constr. Build. Mater. 2018, 189, 1019–1034. [Google Scholar] [CrossRef]

- ASTM International. ASTM C618-19 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Kołodyńska, D.; Franus, W. Chitosan-zeolite composites obtained from fly ashes for heavy metal ions removal. Miner. Energy Econ. Res. Inst. Polish Acad. Sci. 2016, 95, 145–156. [Google Scholar]

- European Parliament and Council Directive. 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control) Text with EEA Relevance; European Parliament and Council: Brussels, Belgium, 2010. [Google Scholar]

- Liu, Y.; Zhao, J.; Lee, J.-M. Conventional and New Materials for Selective Catalytic Reduction (SCR) of NOx. Chem. Cat. Chem. 2018, 10, 1499–1511. [Google Scholar] [CrossRef]

- Zhang, X.; lv, S. Low-Temperature Selective Catalytic Reduction of NO with NH3 over Manganese Oxides Supported on Fly Ash-Palygorskite. J. Thermodyn. Catal. 2015, 6, 3. [Google Scholar] [CrossRef]

- Bittner, J.; Gasiorowski, S.; Hrach, F. Removing Ammonia from Fly Ash. Int. Ash Util. Symp. 2001, 781, 12–14. [Google Scholar]

- Ling, Q.; Xiaojian, G.; Qiyan, L. Influences of coal fly ash containing ammonium salts on properties of cement paste. J. Environ. Manag. 2019, 249, 109374. [Google Scholar] [CrossRef]

- Michalik, A.; Babińska, J.; Chyliński, F.; Piekarczuk, A. Ammonia in fly ashes from flue gas denitrification process and its impact on the properties of cement composites. Buildings 2019, 9, 225. [Google Scholar] [CrossRef]

- Mazur, M.; Janda, T.; Żukowski, W. Chemical and thermal methods for removing ammonia from fly ashes. Czas. Tech. 2017, 6, 31–50. [Google Scholar] [CrossRef]

- Brendel, J.G.F.; Bonetti, J.E.; Rathbone, R.F.; Frey, R.N. Investigation of Ammonia Adsorption on Fly Ash due to Instalation of Celective Catalytic Reduction System; Technical Report; West Virginia University Research Corporation: Pittsburg, PA, USA, 1 November 2000. [Google Scholar]

- Maj, I.; Kalisz, S.; Gądek, W. Ammonia desorption from fly ash. E3S Web Conf. 2019, 82, 01012. [Google Scholar] [CrossRef]

- Jang, H.; So, H.; So, S. Emission characteristic of ammonia in cement mortars using different sand from area of production. Environ. Eng. Res. 2016, 21, 241–246. [Google Scholar] [CrossRef]

- ATSDR. Toxicological Profile for Ammonia; Agency for Toxic Substances and Disease Registry, ATSDR: Atlanta, GA, USA, 2004; pp. 15–16. [Google Scholar]

- U.S. National Agency. Occupational Safety and Health Guideline for Ammonia. In Occupational Safety and Health Guidelines; National Institute of Occupational Safety and Health: Washington, DC, USA, 1992; pp. 1–7. [Google Scholar]

- Health and Safety Executive. EH40 Workplace Exposure Limits; Health and Safety Executive: Norwich, UK, 2011. [Google Scholar]

- U.S. Environmental Protection Agency. EPA Air Pollution Cost Manual—EPA Document; EPA/452/B-02-001; United States Environmental Protection Agency Office of Air Quality Planning and Standards: Washington, DC, USA, 2002. [Google Scholar]

- M1 Classification of Indoor Environment 2018 and Updated Criteria of RTS Environmental Classification. September 2019. Available online: http://cer.rts.fi/en/m1-emission-class-for-building-material/m1-criteria-2/ (accessed on 31 December 2020).

- Proposal for a Regulation of the Minister of Health on the Permissible Concentrations and Intensities of Factors Harmful to Health Emitted by Building Materials, Devices and Equipment in Rooms Intended for Human Residence, 2020. Available online: http://legislacja.gov.pl/projekt/12339600/katalog/12731109#12731109 (accessed on 31 December 2020). (In Polish)

- The European Parliament and the Council of the European Union. Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), Establishing a European Chemicals Agency, Amending Directive 1999/45; European Parliament and Council: Brussels, Belgium, 2020. [Google Scholar]

- Bai, Z.; Dong, Y.; Wang, Z.; Zhu, T. Emission of ammonia from indoor concrete wall and assessment of human exposure. Environ. Int. 2006, 32, 303–311. [Google Scholar] [CrossRef]

- Shou, L.; Hayes, J.; Cheng, W.; Wu, C.-Y.; Townsend, T.; Vinson, T.; Schert, J. Characterization of ammonia gas release from concrete added with ammoniated fly ash. Air Qual. Atmos. Heal. 2014, 7, 505–513. [Google Scholar] [CrossRef]

- Bentur, A.; Larianovsky, P. Use of Ammonia Containing Fly Ash in Concrete. Isr. Natl. Coal Ash Board 2016, 11, 2001–2002. [Google Scholar]

- Polish Committee for Standardization. EN 12457-4:2003 Characterisation of Waste—Leaching; Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 4: One Stage Batch Test at a Liquid to Solid Ratio of 10 L/kg for Materials with Particle Size below 10 mm (without or with Limited Size Reduction); Polish Committee for Standardization: Warsaw, Poland, 2003. [Google Scholar]

- European Committee for Standardization. EN 196-2:2013-11 Method of Testing Cement—Part 2: Chemical Analysis of Cement; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- Polish Committee for Standardization. EN 451-2:2017 Method of Testing Fly Ash—Part 2: Determination of Fineness by Wet Sieving; Polish Committee for Standardization: Warsaw, Poland, 2017. [Google Scholar]

- European Committee for Standardization. EN 1015-7:1998 Methods of Test for Mortar for Masonry—Part 7: Determination of Air Content of Fresh Mortar; European Committee for Standardization: Brussels, Belgium, 1998. [Google Scholar]

- Polski Komitet Normalizacyjny. PN-EN 1015-7:2000 Methods of Test for Mortar for Masonry—Part 7: Determination of Air Content of Fresh Mortar; European Committee for Standardization: Brussels, Belgium, 2000. [Google Scholar]

- Polish Committee for Standardization. EN 1015-6:1998/A1:2006 Methods of Test for Mortar for Masonry—Part 6: Determination of Bulk Density of Fresh Mortar; Polish Committee for Standardization: Warsaw, Poland, 2006. [Google Scholar]

- Polish Committee for Standardization. EN 1015-3:1999 Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); Polish Committee for Standardization: Warsaw, Poland, 1999. [Google Scholar]

- Polish Committee for Standardization. EN 196-3:2016 Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- European Committee for Standardization. EN 196-1:2016-07 Methods of testing cement—Part 1: Determination of Strength; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- European Committee for Standardization. EN 206+A1:2016-12 Concrete—Specification, Performance, Production and Conformity; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Polish Committee for Standardization. EN 16516:2017 Construction Products: Assessment of Release of Dangerous Substances—Determination of Emissions into Indoor Air; Polish Committee for Standardization: Warsaw, Poland, 2017. [Google Scholar]

- Jolicoeur, C.; To, T.C.; Benoît, É.; Hill, R.; Zhang, Z.; Pagé, M. Fly ash-carbon effects on concrete air entrainment: Fundamental studies on their origin and chemical mitigation. In Proceedings of the 2009 World of Coal Ash (WOCA) Conference, Lexington, KY, USA, 4–7 May 2009; pp. 1–23. [Google Scholar]

- Chyliński, F.; Kuczyński, K.; Łukowski, P. Application of Ilmenite Mud Waste as an Addition to Concrete. Materials 2020, 13, 866. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology, 2nd ed.; Pearson Education Ltd.: Harlow, UK, 2010. [Google Scholar]

- Kim, J.K.; Cho, S.D.; Lee, H.D.; Kim, S.C. Effect of ammonia concentration on the utilization of AGFA (Ammonia Contaminated Fly Ash) as an additive in mortar and concrete mixture. J. Ind. Eng. Chem. 2007, 13, 932–938. [Google Scholar]

- Fawzi, N.M.; Kareem, S.L. Effect of incorporating ammonia solution on Some Mechanical Properties of Concrete. In Proceedings of the International Culture, Art & Islamic Architecture Conference, Kish Island, Iran, 30 September 2016. [Google Scholar]

- Tyra, M.; Robl, T.; Drive, P. Research in Ammonia Diffusivity in Portland Cement Based Mixes. In Proceedings of the 2001 International Ash Utilization Symposium, Kentucky, KY, USA, 5 May 2001. [Google Scholar]

| Sample | Concentration in Water Solution (mg/L) | Concentration in Fly Ash (mg/kg) |

|---|---|---|

| REF | 0.9 | 9 |

| A | 12.2 | 122 |

| B | 18.3 | 183 |

| C | 16.1 | 161 |

| D | 42.8 | 428 |

| E | 37.5 | 375 |

| Property | Value |

|---|---|

| compressive strength (MPa) | |

| - 2 days | 32.2 |

| - 28 days | 59.0 |

| flexural strength (MPa) | |

| - 2 days | 5.7 |

| - 28 days | 9.6 |

| setting time (min) | 170 |

| end of setting time (min) | 225 |

| soundness expansion (mm) | 0 |

| loss on ignition (%) | 3.30 |

| insoluble residue (%) | 0.90 |

| specific surface area 1 (cm2/g) | 3620 |

| density (g/cm3) | 3.10 |

| Constituent | SO3 | Cl | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | Na2Oeq | C3A |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 2.82 | 0.052 | 19.96 | 5.00 | 2.47 | 64.37 | 1.27 | 0.70 | 0.13 | 0.59 | 9.07 |

| Sample | Cement (g) | Fly Ash | Water (g) | Standard Consistency (%) | Standard Consistency (mm) | |

|---|---|---|---|---|---|---|

| (g) | Type | |||||

| CEM I | 500 | 0 | /– | 128 | 25.5 | 5 |

| 25% REF | 375 | 125 | /Ref | 127 | 25.5 | 4 |

| 25% A | 375 | 125 | /A | 131 | 26.0 | 7 |

| 25% B | 375 | 125 | /B | 131 | 26.0 | 6 |

| 25% C | 375 | 125 | /C | 125 | 25.0 | 8 |

| 25% D | 375 | 125 | /D | 126 | 25.0 | 5 |

| 25% E | 375 | 125 | /E | 128 | 25.5 | 8 |

| Sample | Cement (g) | Fly Ash (g)/Type | Water (g) | Sand (g) | |

|---|---|---|---|---|---|

| CEM I | 450.0 | 0.0 | /– | 225 | 1350 |

| 25% REF | 337.5 | 112.5 | /Ref | ||

| 25% A | 337.5 | 112.5 | /A | ||

| 25% C | 337.5 | 112.5 | /C | ||

| 25% E | 337.5 | 112.5 | /E | ||

| 50% REF | 225.0 | 225.0 | /Ref | ||

| 50% A | 225.0 | 225.0 | /A | ||

| 50% C | 225.0 | 225.0 | /C | ||

| 50% E | 225.0 | 225.0 | /E | ||

| Sample | Cement (g) | Fly Ash (g)/Type | Water (g) | Sand (g) | |

|---|---|---|---|---|---|

| 15% D | 382.5 | 67.5 | /D | 225 | 1.350 |

| 25% D | 337.5 | 112.5 | /D | 225 | 1.350 |

| 50% D | 225.0 | 225.0 | /D | 225 | 1.350 |

| 15% E | 382.5 | 67.5 | /E | 225 | 1.350 |

| 25% E | 337.5 | 112.5 | /E | 225 | 1.350 |

| 50% E | 225.0 | 225.0 | /E | 225 | 1.350 |

| Sample | Loss on Ignition (%) | Fineness (%) | Water Demand (%) |

|---|---|---|---|

| REF | 1.43 | 34.2 | 99 |

| A | 4.02 | 36.2 | 101 |

| B | 4.47 | 32.2 | 101 |

| C | 2.43 | 29.6 | 100 |

| D | 3.36 | 26.4 | 100 |

| E | 3.47 | 25.8 | 100 |

| Sample | Density (kg/m3) | Air Content (%) | Consistency (mm) |

|---|---|---|---|

| 100% CEM I | 2.190 | 5.0 | 171 |

| 25% Ref | 2.210 | 2.5 | 197 |

| 25% A | 2.190 | 3.0 | 176 |

| 25% C | 2.200 | 3.5 | 209 |

| 25% E | 2.190 | 4.0 | 197 |

| 50% Ref | 2.180 | 2.5 | 221 |

| 50% A | 2.160 | 3.5 | 171 |

| 50% C | 2.190 | 3.0 | 215 |

| 50% E | 2.130 | 6.0 | 213 |

| Sample | Initial Setting Time | Final Setting Time | ||

|---|---|---|---|---|

| (min) | (%) | (min) | (%) | |

| CEM I | 165 | 100 | 225 | 100 |

| 25% Ref | 185 | 112 | 320 | 142 |

| 25% A | 215 | 130 | 345 | 153 |

| 25% B | 230 | 139 | 355 | 158 |

| 25% C | 230 | 139 | 345 | 153 |

| 25% D | 305 | 185 | 415 | 184 |

| 25% E | 255 | 155 | 365 | 162 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chyliński, F.; Goljan, A.; Michalik, A. Fly Ash with Ammonia: Properties and Emission of Ammonia from Cement Composites. Materials 2021, 14, 707. https://doi.org/10.3390/ma14040707

Chyliński F, Goljan A, Michalik A. Fly Ash with Ammonia: Properties and Emission of Ammonia from Cement Composites. Materials. 2021; 14(4):707. https://doi.org/10.3390/ma14040707

Chicago/Turabian StyleChyliński, Filip, Anna Goljan, and Agnieszka Michalik. 2021. "Fly Ash with Ammonia: Properties and Emission of Ammonia from Cement Composites" Materials 14, no. 4: 707. https://doi.org/10.3390/ma14040707

APA StyleChyliński, F., Goljan, A., & Michalik, A. (2021). Fly Ash with Ammonia: Properties and Emission of Ammonia from Cement Composites. Materials, 14(4), 707. https://doi.org/10.3390/ma14040707