Long-Term Compressive Strength Development of Steel Fiber Shotcrete from Cores Based on Accelerator Types at Tunnel Site

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement

2.1.2. Aggregate

2.1.3. Accelerators

2.1.4. Steel Fibers

2.2. Mix Design

2.3. Specimen Preparation

2.4. Core Compressive Strength Test

3. Results and Analysis

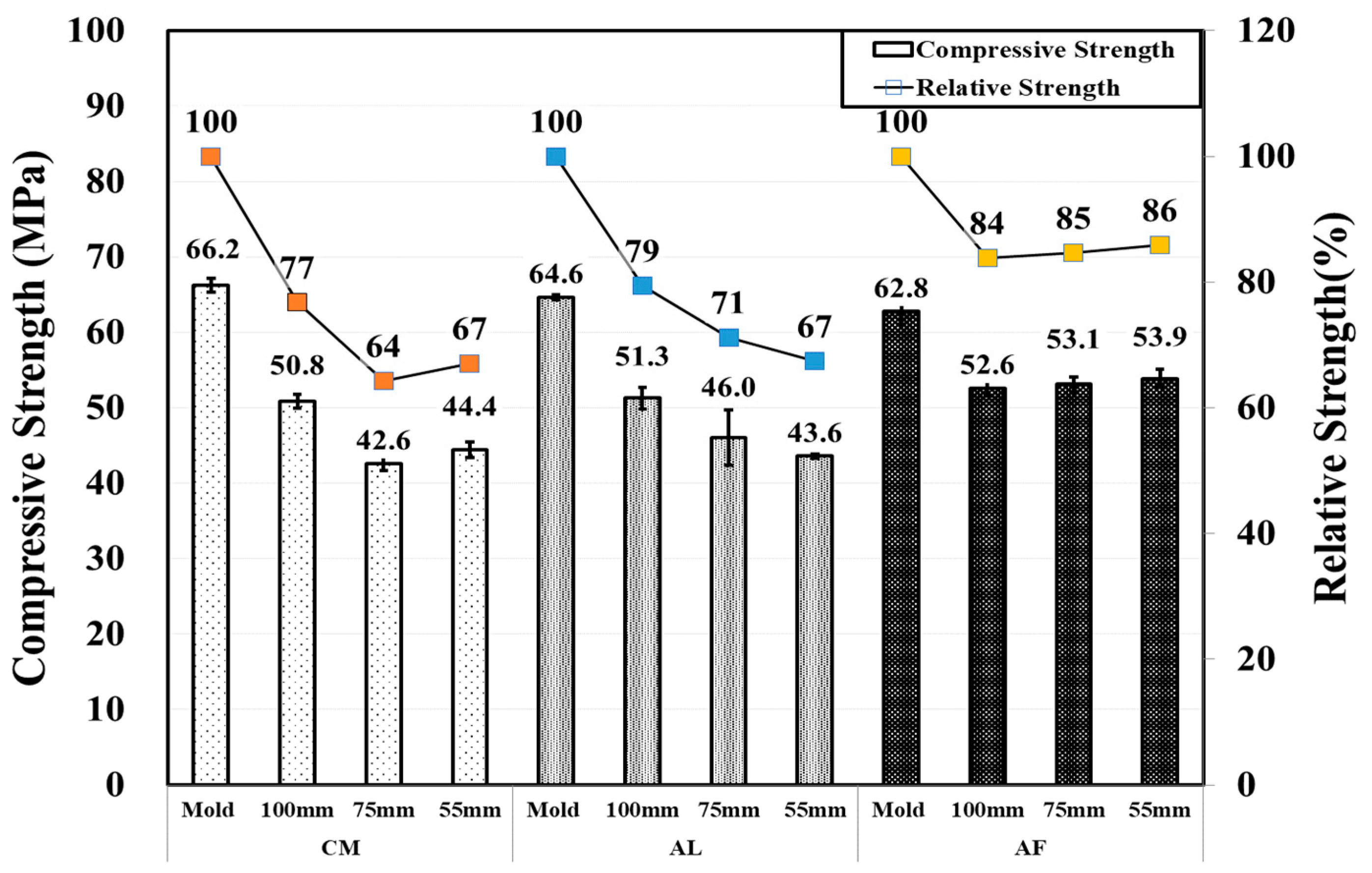

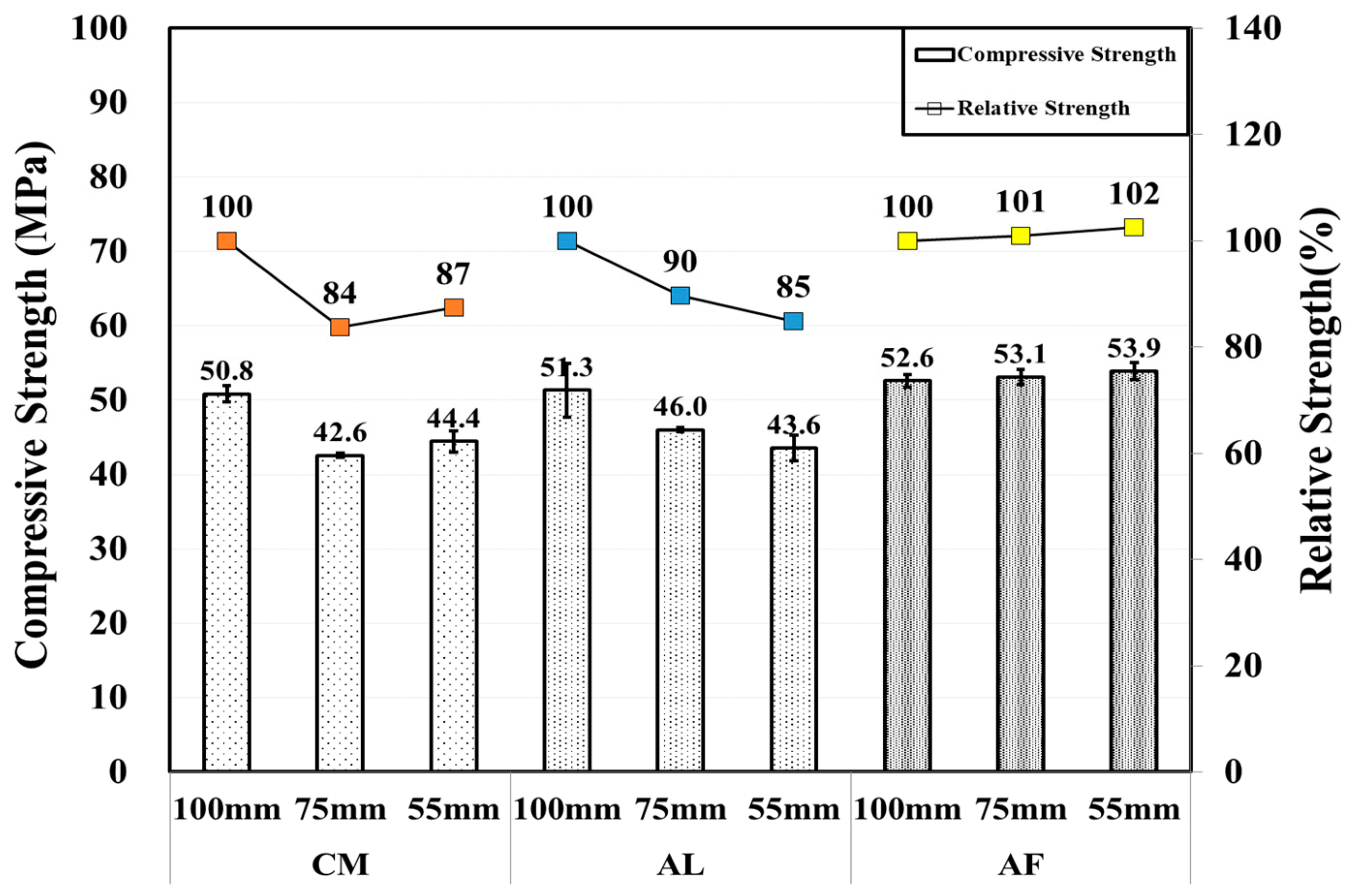

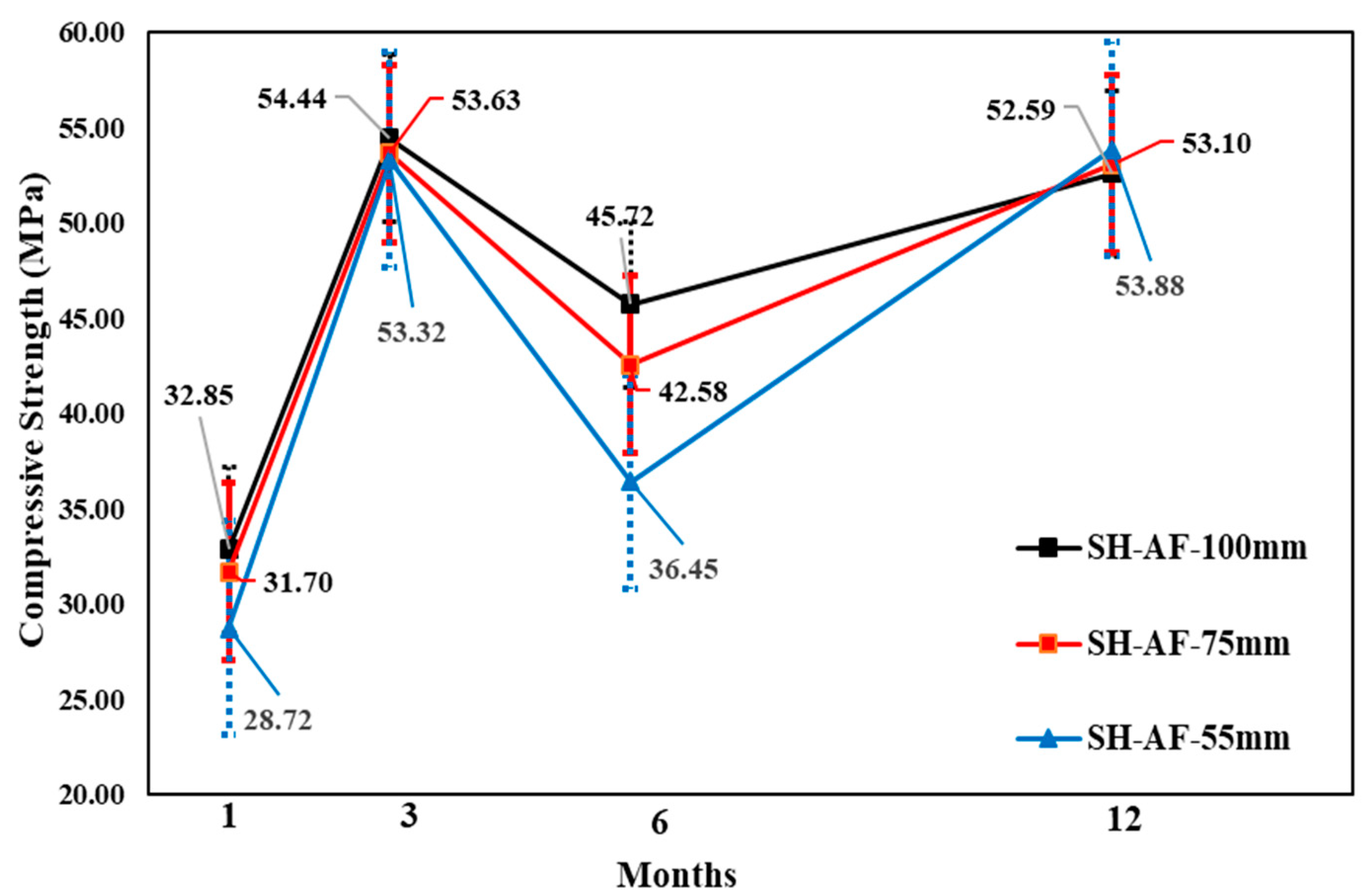

3.1. Effects of Accelerators on the Core Compressive Strength Test Result

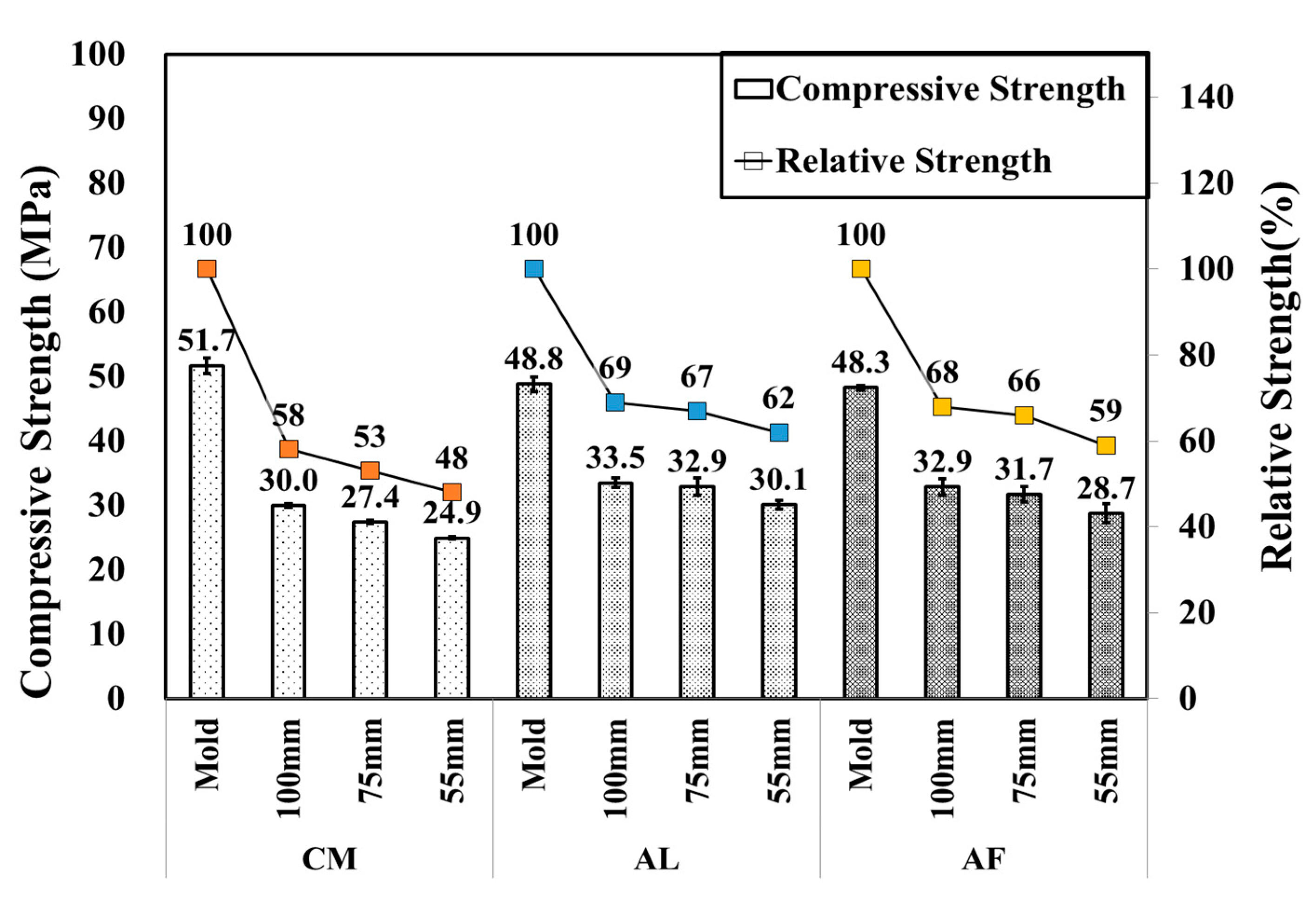

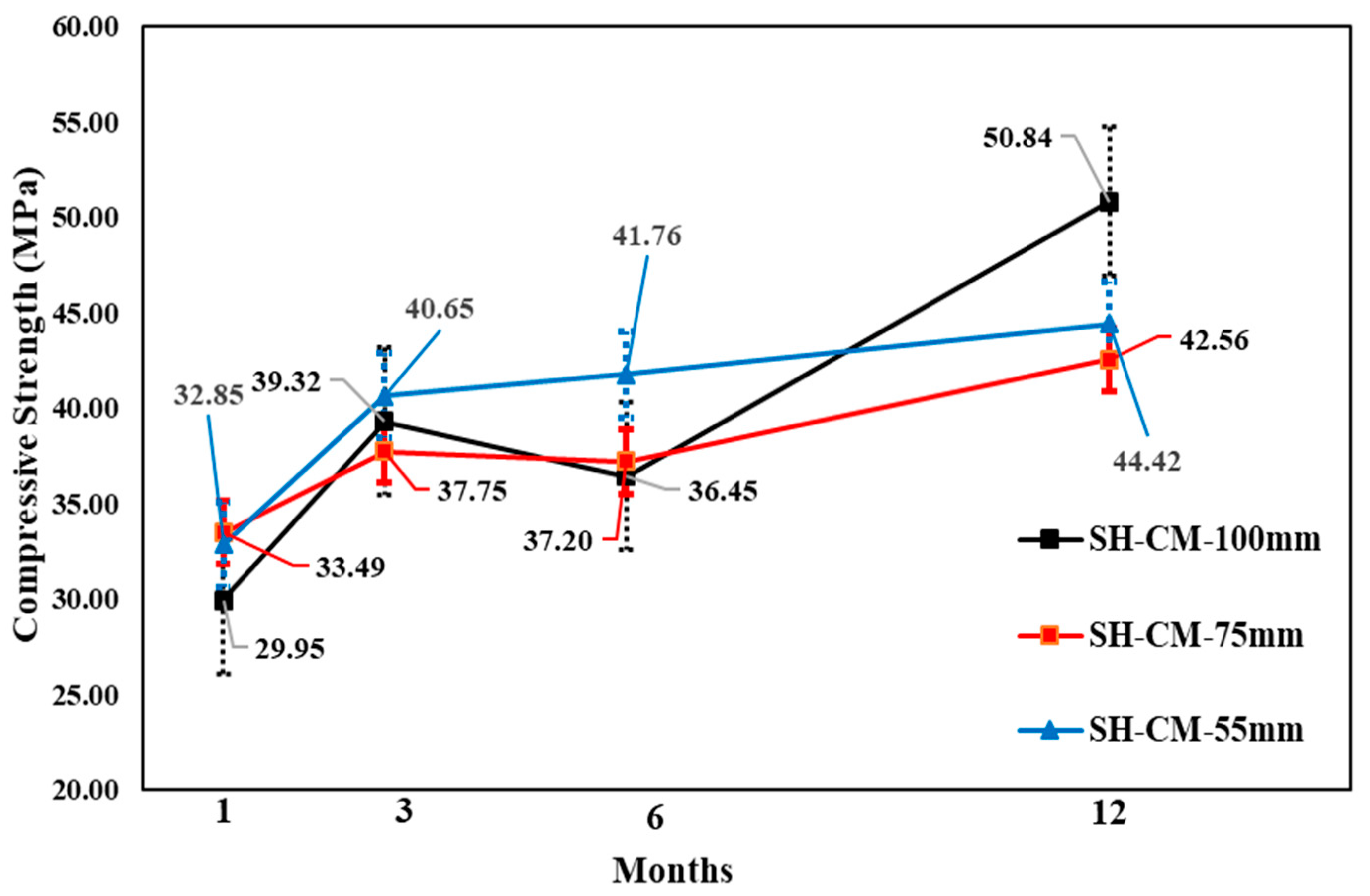

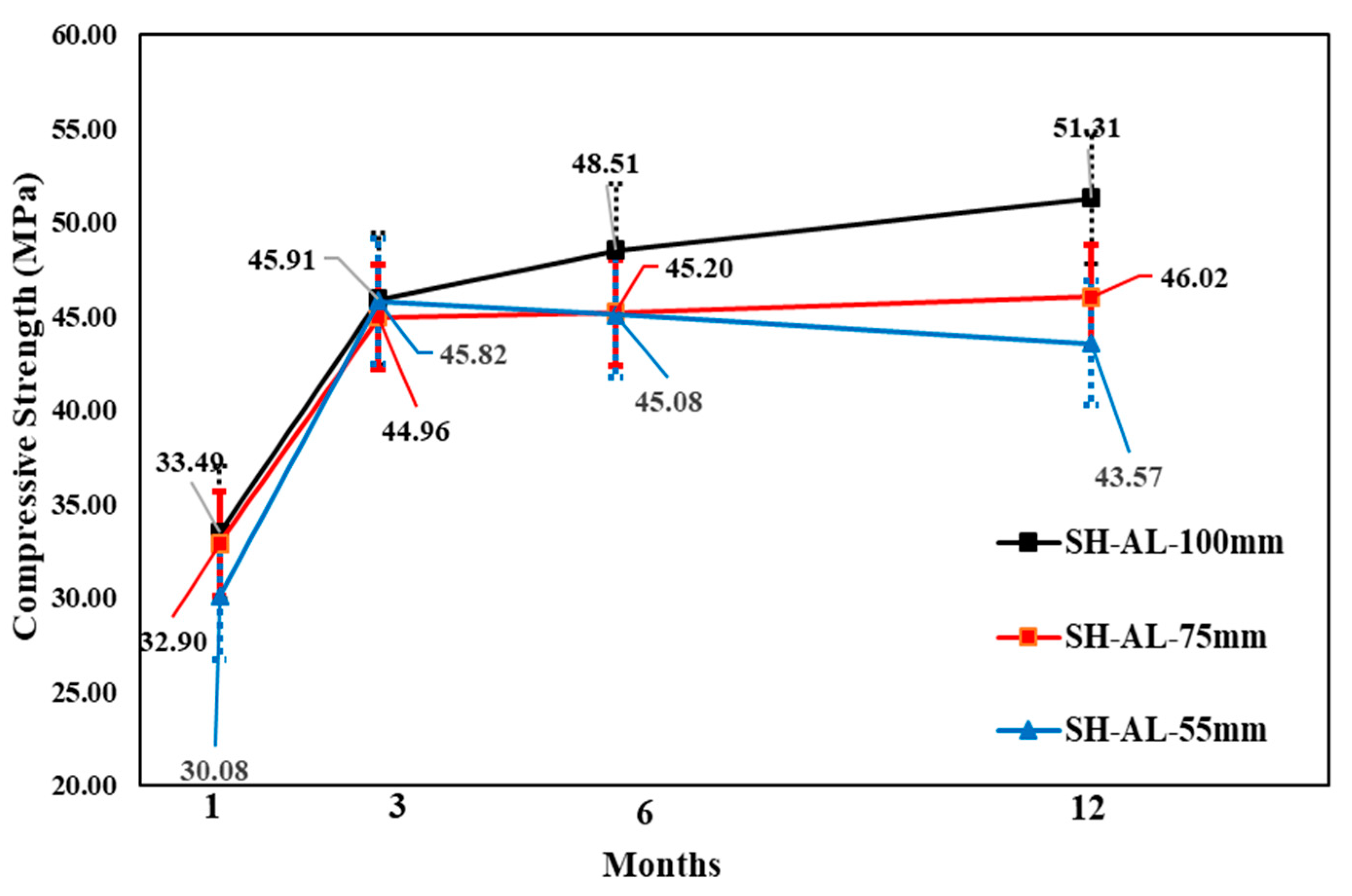

3.1.1. One-Month Core Compressive Strength Result

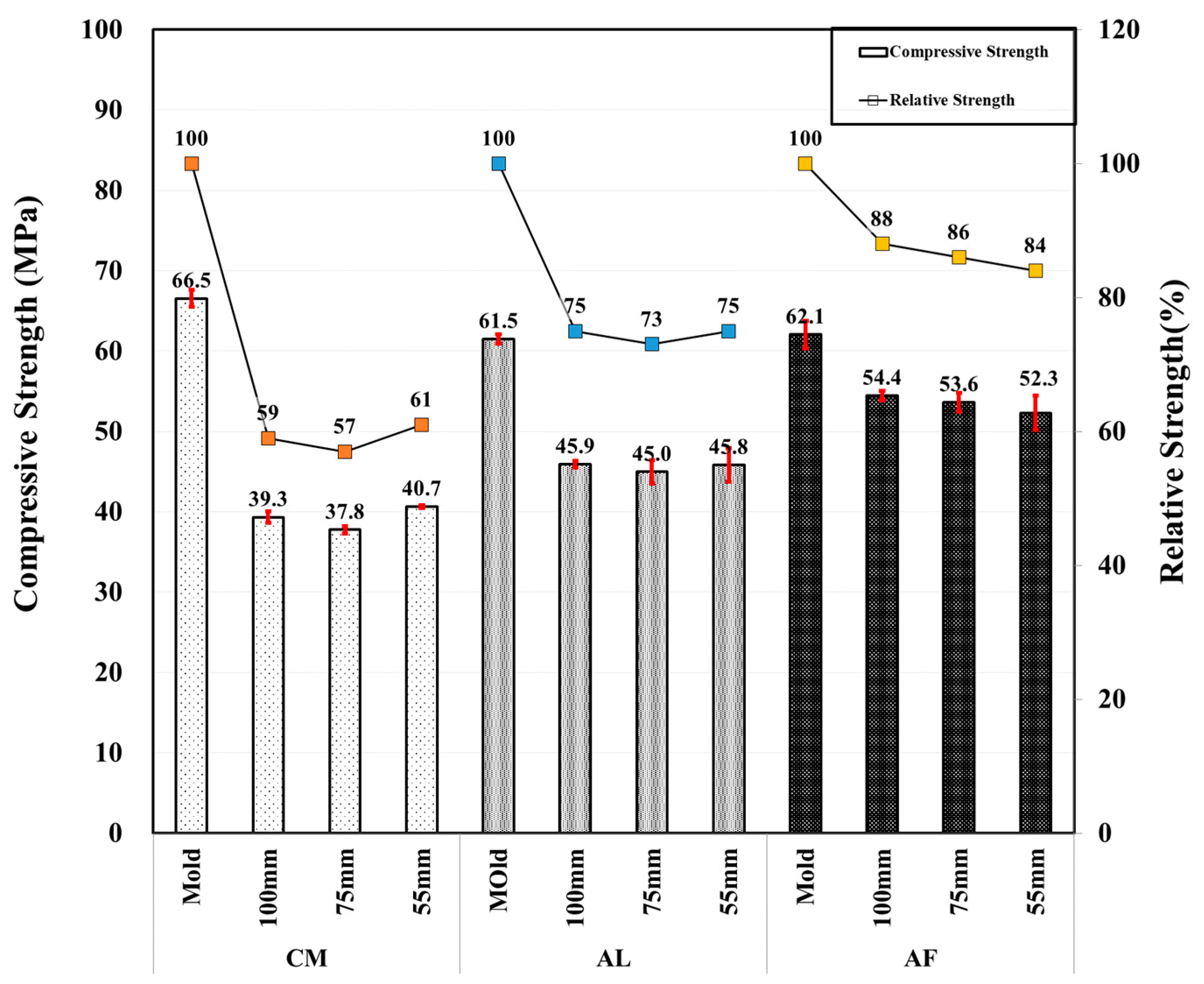

3.1.2. Three-Month-Old Core Compressive Strength Test Result

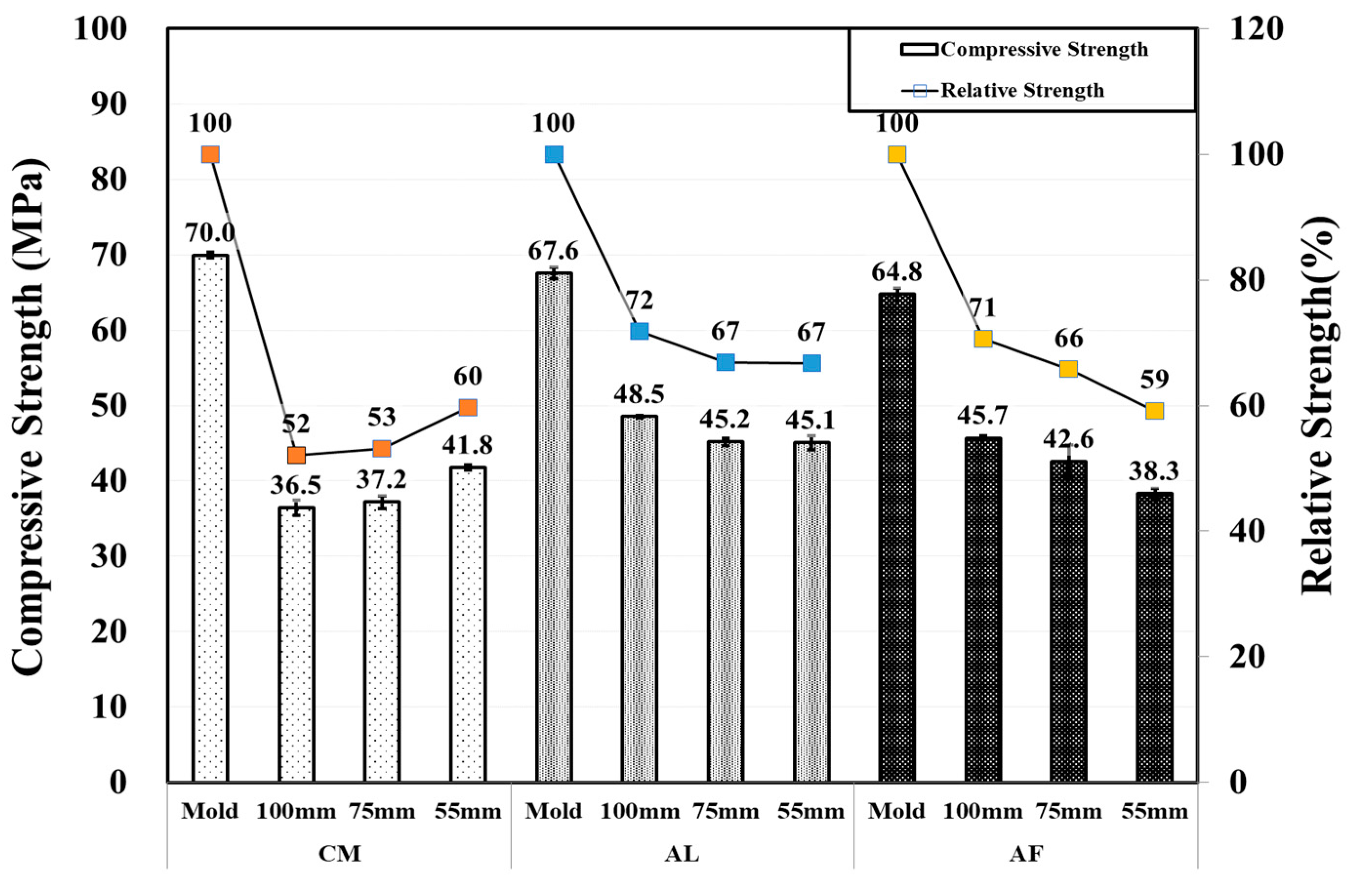

3.1.3. Six-Month Core Compressive Strength Test Result

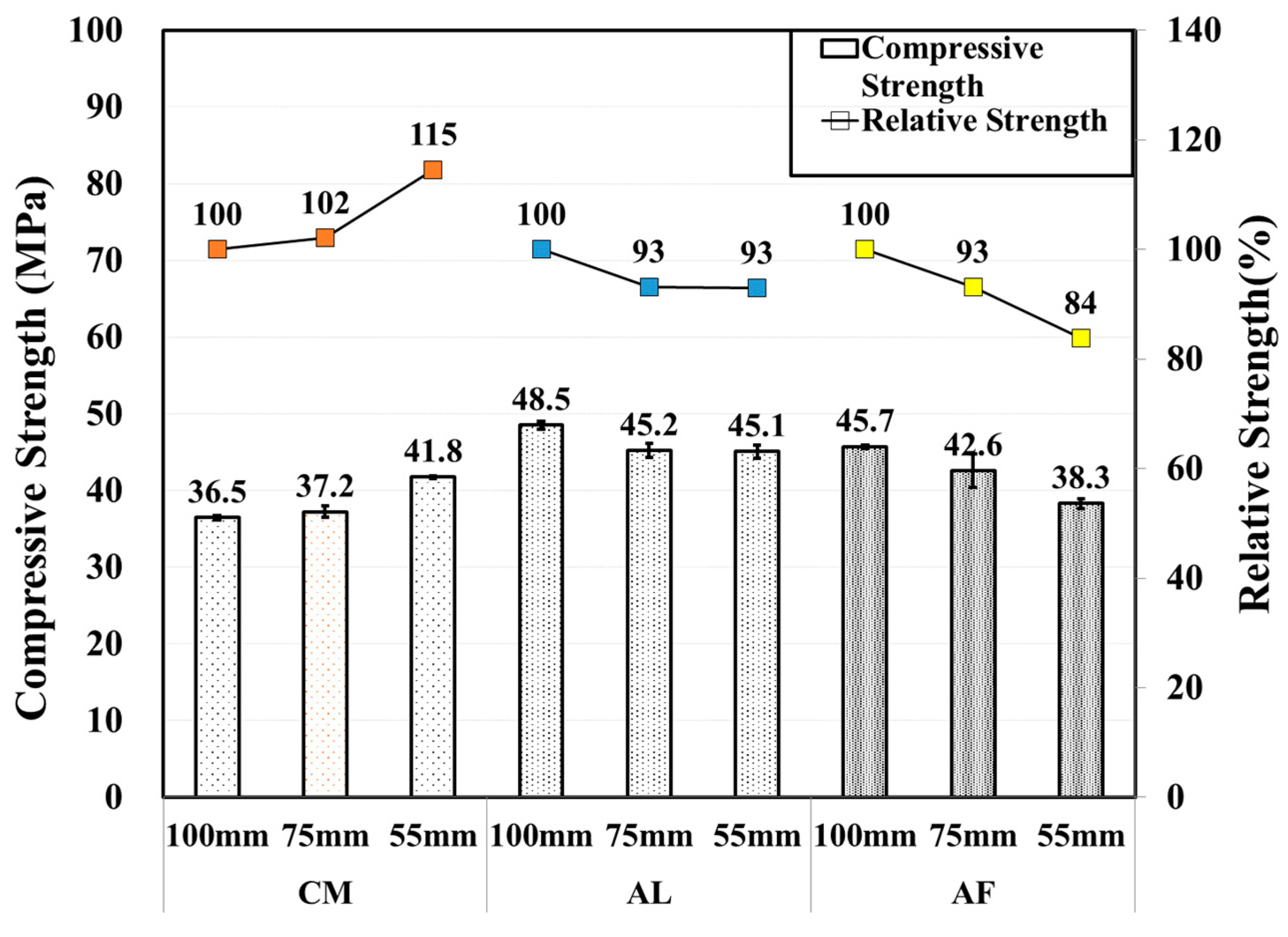

3.1.4. Twelve-Month Core Compressive Strength Test Result

3.2. Core Comprehensive Review of Shotcrete Long-Term Performance Test Results

4. Conclusions

- Three types of accelerating agents were used for experimental purposes: CM, AL, and AF. Steel fiber (37 kg) was incorporated into the CM and AL mix, and 40 kg of steel fiber was incorporated into the AF mix. Moreover, 1, 3, 6, and 12 month spec mens were applied to evaluate the long-term performance of shotcrete at a tunnel site.

- This study mainly focused on the core compressive strength for identifying the performance of the shotcrete. As a result, the CO (Φ100 mm) and SH specimens with Φ 100, Φ 75, and Φ 55 mm diameters with a length/diameter ratio of 2 in all specimens was shown.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bolduc, L.S.; Jolin, M.; Bissonnette, B. Evaluating the service life of shotcrete. Shotcrete Elem. Syst. 2010, 57–64. [Google Scholar]

- Malmgren, L.; Nordlund, E. Interaction of shotcrete with rock and rock bolts—A numerical study. Int. J. Rock Mech. Min. Sci. 2008, 45, 538–553. [Google Scholar] [CrossRef]

- Chapman, D.N.; Metje, N.; Stark, A. Introduction to Tunnel Construction; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Salvador, R.P.; Cavalaro, S.H.; Cincotto, M.A.; de Figueiredo, A.D. Parameters controlling early age hydration of cement pastes containing accelerators for sprayed concrete. Cem. Concr. Res. 2016, 89, 230–248. [Google Scholar] [CrossRef]

- De Belie, N.; Grosse, C.U.; Kurz, J.; Reinhardt, H.W. Ultrasound monitoring of the influence of different accelerating admixtures and cement types for shotcrete on setting and hardening behaviour. Cem. Concr. Res. 2005, 35, 2087–2094. [Google Scholar] [CrossRef] [Green Version]

- Won, J.P.; Hwang, U.J.; Kim, C.K.; Lee, S.J. Mechanical performance of shotcrete made with a high-strength cement-based mineral accelerator. Constr. Build. Mater. 2013, 49, 175–183. [Google Scholar] [CrossRef]

- Zhang, X.; Zeng, L.; Qiao, M.; Wang, W.; Chen, J.; Hong, J.; Ran, Q. Optimizing the setting behavior of cement paste with poly (AANa-co-DMAA) in the presence of alkali-free accelerator. Adv. Cem. Res. 2020, 1–28. [Google Scholar]

- Galobardes, I.; Picolo, R.; de Figueiredo, A.D.; Cavalaro, S.H.; Rueda, Á. Wet mix sprayed concrete set accelerating admixtures: Comparison between traditional aluminate based accelerators and new formulations of alkali free accelerators. In Proceedings of the 56 Congresso Brasileiro do Concreto, Natal, Brasil, 7–10 October 2014. [Google Scholar]

- Paglia, C.; Wombacher, F.; Böhni, H. The influence of alkali-free and alkaline shotcrete accelerators within cement systems: Influence of the temperature on the sulfate attack mechanisms and damage. Adv. Cem. Res. 2003, 33, 387–395. [Google Scholar]

- Wang, J.; Xie, Y.; Zhong, X.; Li, L. Test and simulation of cement hydration degree for shotcrete with alkaline and alkali-free accelerators. Cem. Concr. Compos. 2020, 112, 103684. [Google Scholar] [CrossRef]

- Won, J.P.; Hwang, U.J.; Lee, S.J. Enhanced long-term strength and durability of shotcrete with high-strength C12A7 mineral-based accelerator. Adv. Cem. Res. 2015, 76, 121–129. [Google Scholar]

- Jadhav, H.S.; Koli, M.D. Flexural Behavior of Hybrid Fiber Reinforced Concrete Beams. Int. J. Struct. Civ. Eng. Res. 2013, 2, 210–218. [Google Scholar]

- ASTM, A820/A820M-16. Standard Specification for Steel Fibers for Fiber-Reinforced Concrete. Available online: https://www.durocem.ir/images/standards/ASTM_A820_-_2011.pdf (accessed on 26 January 2021).

- KS F 2781. Steel Fiber ReinforcedWet-Mix Shotcrete. 2007. Available online: http://www.ks.or.kr/library/search/stddetail.do?itemNo=K001010114416&itemCd=K00101# (accessed on 1 October 2020).

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Chang, J.; Cui, K.; Zhang, Y. Effect of hybrid steel fibers on the mechanical performances and microstructure of sulphoaluminate cement-based reactive powder concrete. Constr. Build. Mater. 2020, 261, 120502. [Google Scholar] [CrossRef]

- Pyo, S.; Koh, T.; Tafesse, M.; Kim, H.K. Chloride-induced corrosion of steel fiber near the surface of ultra-high performance concrete and its effect on flexural behavior with various thickness. Constr. Build. Mater. 2019, 224, 206–213. [Google Scholar] [CrossRef]

- Babaie, R.; Abolfazli, M.; Fahimifar, A. Mechanical properties of steel and polymer fiber reinforced concrete. J. Mech. Behav. Mater. 2019, 28, 119–134. [Google Scholar] [CrossRef]

- Masi, A.; Chiauzzi, L.; Manfredi, V. Criteria for identifying concrete homogeneous areas for the estimation of in-situ strength in RC buildings. Constr. Build. Mater. 2016, 121, 576–587. [Google Scholar] [CrossRef]

- British Standard. Testing Hardened Concrete. In Compressive Strength of Test Specimens, BS EN; BSI: London, UK, 2009; pp. 12390–12393. [Google Scholar]

- Del Viso, J.R.; Carmona, J.R.; Ruiz, G. Shape and size effects on the compressive strength of high-strength concrete. Cem. Concr. Res. 2008, 38, 386–395. [Google Scholar] [CrossRef]

- Bungey, J.H. Determining concrete strength by using small-diameter cores. Mag. Concr. Res. 1979, 31, 91–98. [Google Scholar] [CrossRef]

- Madandoust, R.; Bungey, J.H.; Ghavidel, R. Prediction of the concrete compressive strength by means of core testing using GMDH-type neural network and ANFIS models. Comput. Mater. Sci. 2012, 51, 261–272. [Google Scholar] [CrossRef]

- Arioz, O.; Ramyar, K.; Tuncan, M.; Tuncan, A.; Cil, I. Some factors influencing effect of core diameter on measured concrete compressive strength. ACI Mater. J. 2007, 104, 291. [Google Scholar]

- Suzuki, S.; Kage, T.; Seko, S. Influence that ratio of length to diameter of high-strength concrete core to compressive strength of concrete. In Proceedings of the International Conference on Durability of Building Materials and Components, XII DBMC, Porto, Portugal, 12–15 April 2011. [Google Scholar]

- Hoang, A.T.; Le, A.T. A core correlation of spray characteristics, deposit formation, and combustion of a high-speed diesel engine fueled with Jatropha oil and diesel fuel. Fuel 2019, 244, 159–175. [Google Scholar] [CrossRef]

- Ju, M.; Park, K.; Oh, H. Estimation of compressive strength of high strength concrete using non-destructive technique and concrete core strength. Appl. Sci. 2017, 7, 1249. [Google Scholar] [CrossRef] [Green Version]

- Tuncan, M.; Arioz, O.; Ramyar, K.; Karasu, B. Assessing concrete strength by means of small diameter cores. Constr. Build. Mater. 2008, 22, 981–988. [Google Scholar] [CrossRef]

- Ollivier, J.P.; Maso, J.C.; Bourdette, B. Interfacial transition zone in concrete. Adv. Cem. Based Mater. 1995, 2, 30–38. [Google Scholar] [CrossRef]

- He, W.; Kong, X.; Fu, Y.; Zhou, C.; Zheng, Z. Experimental investigation on the mechanical properties and microstructure of hybrid fiber reinforced recycled aggregate concrete. Constr. Build. Mater. 2020, 261, 120488. [Google Scholar] [CrossRef]

- Yun, K.K.; Seunghak, C.; Taeho, H.; Hossain, M.S.; Han, S. Comparison of Long-Term Strength Development of Steel Fiber Shotcrete with Cast Concrete Based on Accelerator Type. Materials 2020, 13, 5599. [Google Scholar] [CrossRef]

- Cihangir, F.; Ercikdi, B.; Kesimal, A.; Turan, A.; Deveci, H. Utilisation of alkali-activated blast furnace slag in paste backfill of high-sulphide mill tailings: Effect of binder type and dosage. Miner. Eng. 2012, 30, 33–43. [Google Scholar] [CrossRef]

- Myrdal, R. Accelerating Admixtures for Concrete. State of the Art; SINTEF: Trondheim, Norway, 2007. [Google Scholar]

- Abdulla, K.F.; Cunningham, L.S.; Gillie, M. Experimental Study on the Mechanical Properties of Straw Fiber–Reinforced Adobe Masonry. J. Mater. Civ. Eng. 2020, 32, 04020322. [Google Scholar] [CrossRef]

- Mohajerani, A.; Hui, S.Q.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Abdul Kadir, A.; Rahman, M.T.; Maghool, F. Amazing Types, Properties, and Applications of Fibres in Construction Materials. Materials 2019, 12, 2513. [Google Scholar] [CrossRef] [Green Version]

| Test | Aggregate | Density (g/cm3) | Fineness Modulus | Division | Standard |

|---|---|---|---|---|---|

| Cement mineral mix | Fine | 2.61 | 3.86 | Aggregate for shotcrete | Mixed aggregate |

| Coarse | 2.70 | ||||

| Aluminate mix | Fine | 2.61 | 3.84 | ||

| Coarse | 2.70 | ||||

| Alkali mix | Fine | 2.61 | 3.78 | ||

| Coarse | 2.70 |

| Accelerator | Type | Specific Gravity | pH | Solid Content | Chemical Components | Function |

|---|---|---|---|---|---|---|

| Cement mineral | Powder | 2.76 | 10–12 | 99.2 | C12A7 | Easily combined in shotcrete with water |

| Aluminate | Liquid | 1.45 | 13 ± 2 | 45.7 | NaAlO2 and KAlO2 | High early strength |

| Alkali-free | Liquid | 1.36 | 2.6 | 42.0 | (%Na2O + 0.658 ∗ %K2O | Avoid skin burns, loss of eyesight, respiratory health problems, reduce rebound, strength gain |

| Accelerator | Gmax (mm) | Slump (mm) | W/C | S/a (%) | Unit Content (kg/m3) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Water | Cement | Sand | Gravel | High-Range Water-Reducing Agent | Steel Fiber (kg/m3) | |||||

| CM | 10 | 100 | 0.44 | 65 | 210 | 480 | 1047 | 568 | 4.80 (1.0%) | 37 |

| AL | 0.43 | 64.7 | 213 | 492 | 1074 | 608 | 3.936(0.8%) | 37 | ||

| AF | 0.44 | 62.1 | 206 | 465 | 1011 | 622 | 4.65 (1.0%) | 40 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, K.K.; Choi, S.; Ha, T.; Kim, S.K.; Hossain, M.S.; Han, S. Long-Term Compressive Strength Development of Steel Fiber Shotcrete from Cores Based on Accelerator Types at Tunnel Site. Materials 2021, 14, 580. https://doi.org/10.3390/ma14030580

Yun KK, Choi S, Ha T, Kim SK, Hossain MS, Han S. Long-Term Compressive Strength Development of Steel Fiber Shotcrete from Cores Based on Accelerator Types at Tunnel Site. Materials. 2021; 14(3):580. https://doi.org/10.3390/ma14030580

Chicago/Turabian StyleYun, Kyong Ku, Seunghak Choi, Taeho Ha, Seong Kwon Kim, Mohammad Shakhawat Hossain, and Seungyeon Han. 2021. "Long-Term Compressive Strength Development of Steel Fiber Shotcrete from Cores Based on Accelerator Types at Tunnel Site" Materials 14, no. 3: 580. https://doi.org/10.3390/ma14030580

APA StyleYun, K. K., Choi, S., Ha, T., Kim, S. K., Hossain, M. S., & Han, S. (2021). Long-Term Compressive Strength Development of Steel Fiber Shotcrete from Cores Based on Accelerator Types at Tunnel Site. Materials, 14(3), 580. https://doi.org/10.3390/ma14030580