Mechanical Performance of Artificial Hip Stems Manufactured by Hot Forging and Selective Laser Melting Using Biocompatible Ti-15Zr-4Nb Alloy

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Test Specimens

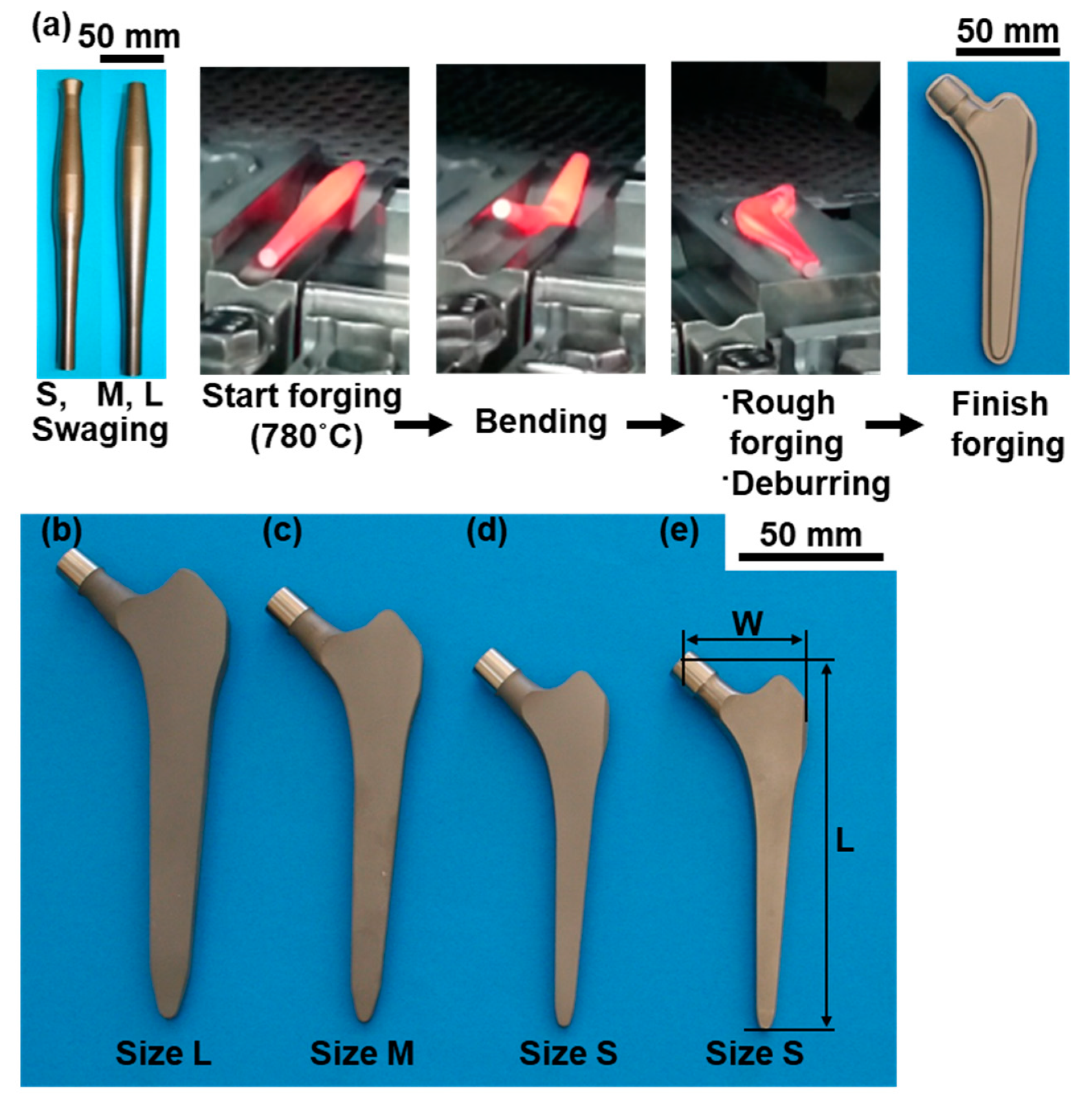

2.1.1. Hot Die Forging of Artificial Hip Stems

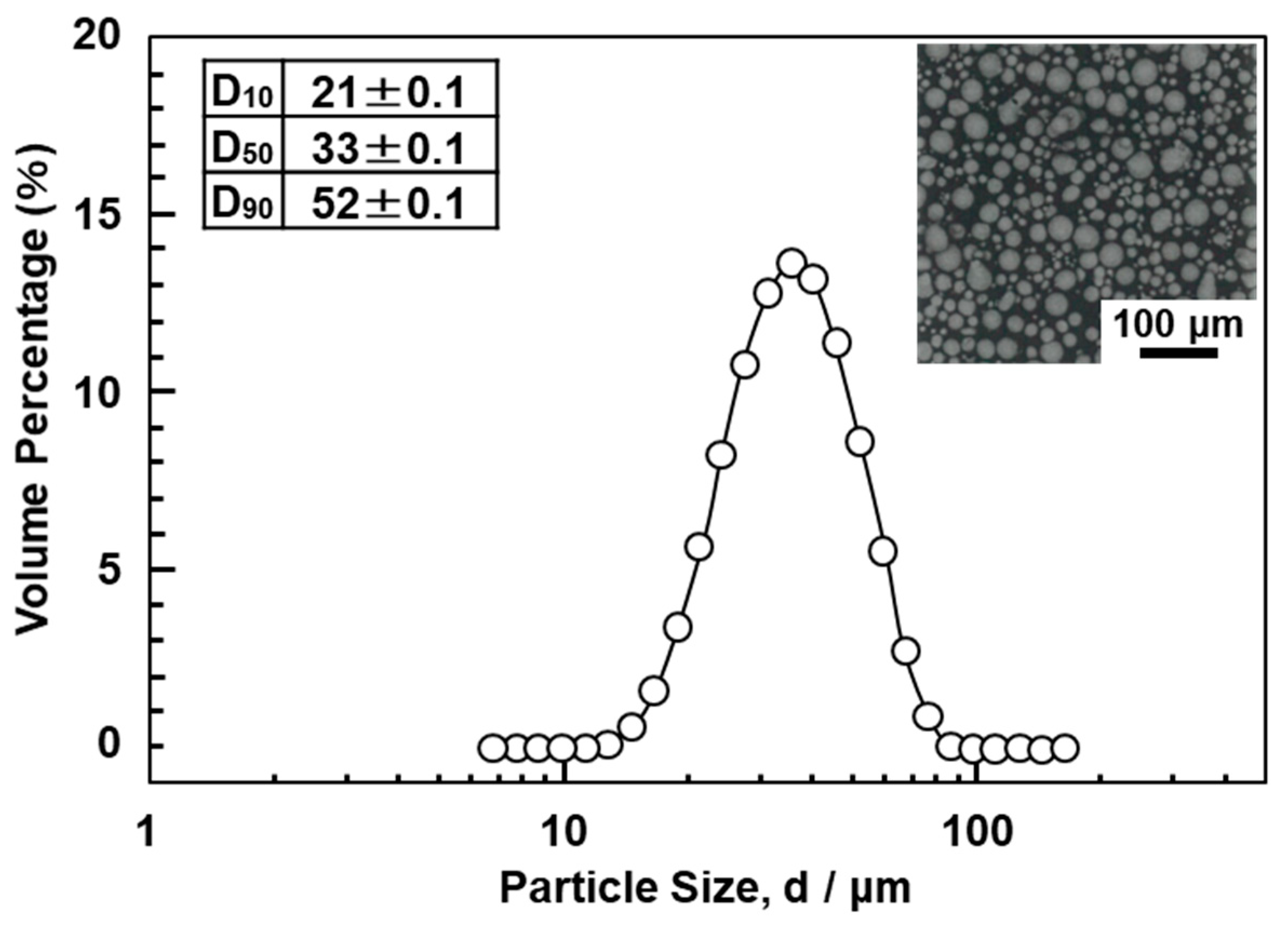

2.1.2. Selective Laser Melting of Artificial Hip Stems and Rod Specimens

2.1.3. Chemical Analyses of Test Specimens

2.2. Microstructural Observation

2.3. Evaluation of Mechanical Properties

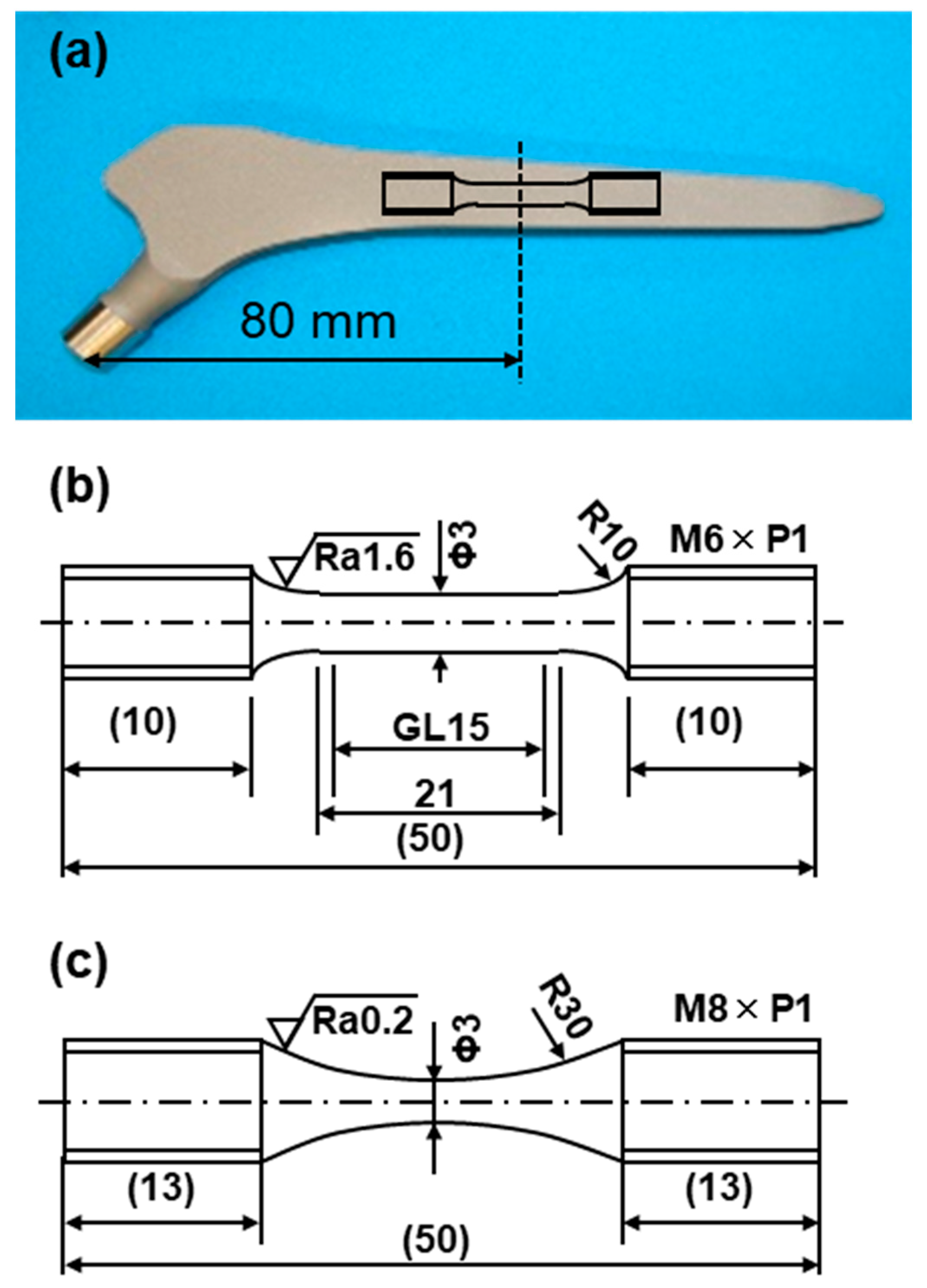

2.3.1. Room Temperature Tensile Tests

2.3.2. Fatigue Tests

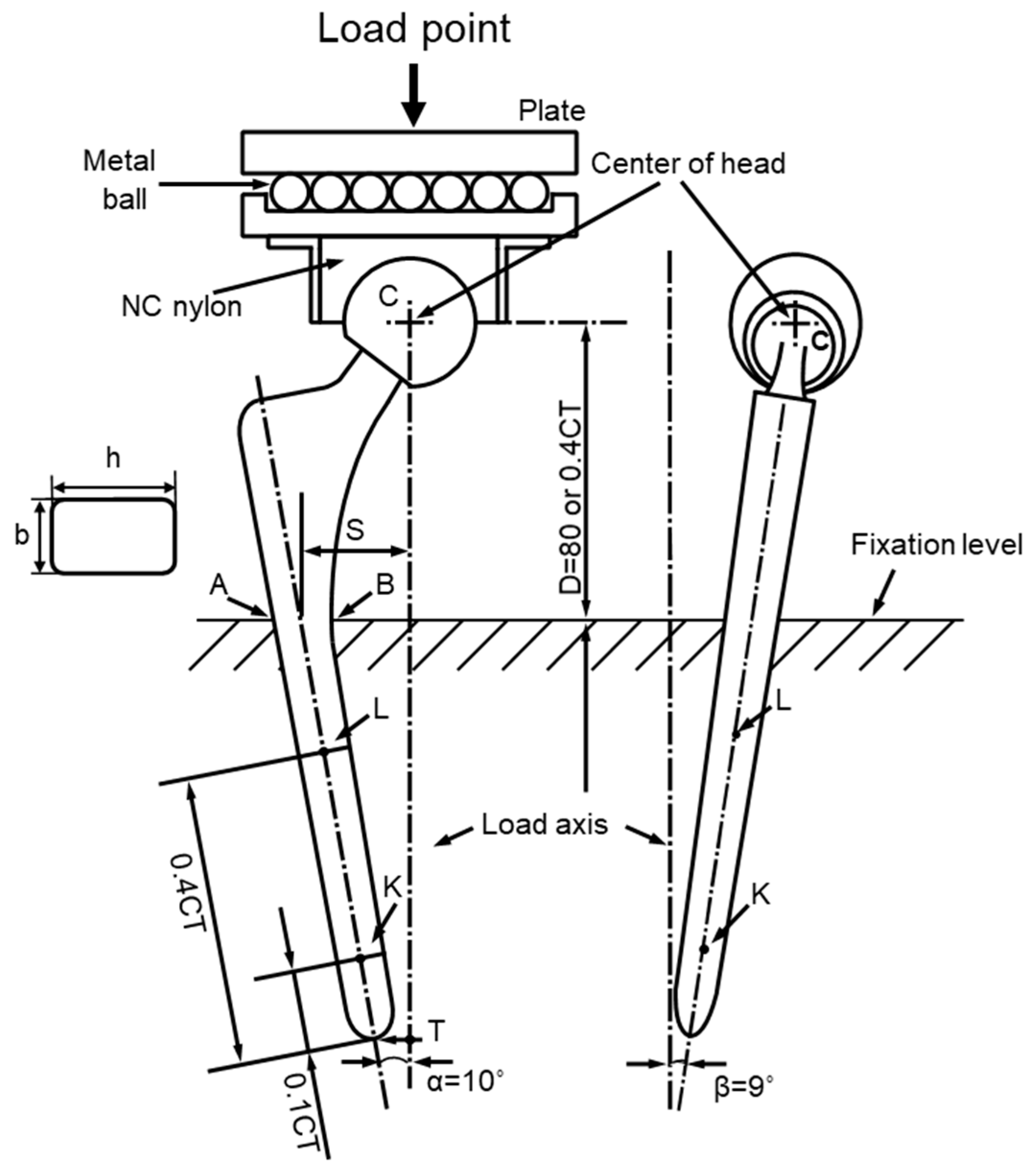

2.3.3. Durability Tests of Artificial Hip Stems

2.4. Static Immersion Test

2.5. Statistical Analysis

3. Results and Discussion

3.1. Microstructures and Mechanical Properties of Hot-Forged Artificial Hip Stems

3.1.1. Microstructures of Hot-Forged Artificial Hip Stems

3.1.2. Mechanical Properties of Hot-Forged Artificial Hip Stems

3.2. Microstructures and Mechanical Properties of Selective-Laser-Melted Ti Alloy Hip Stems and Rod Specimens

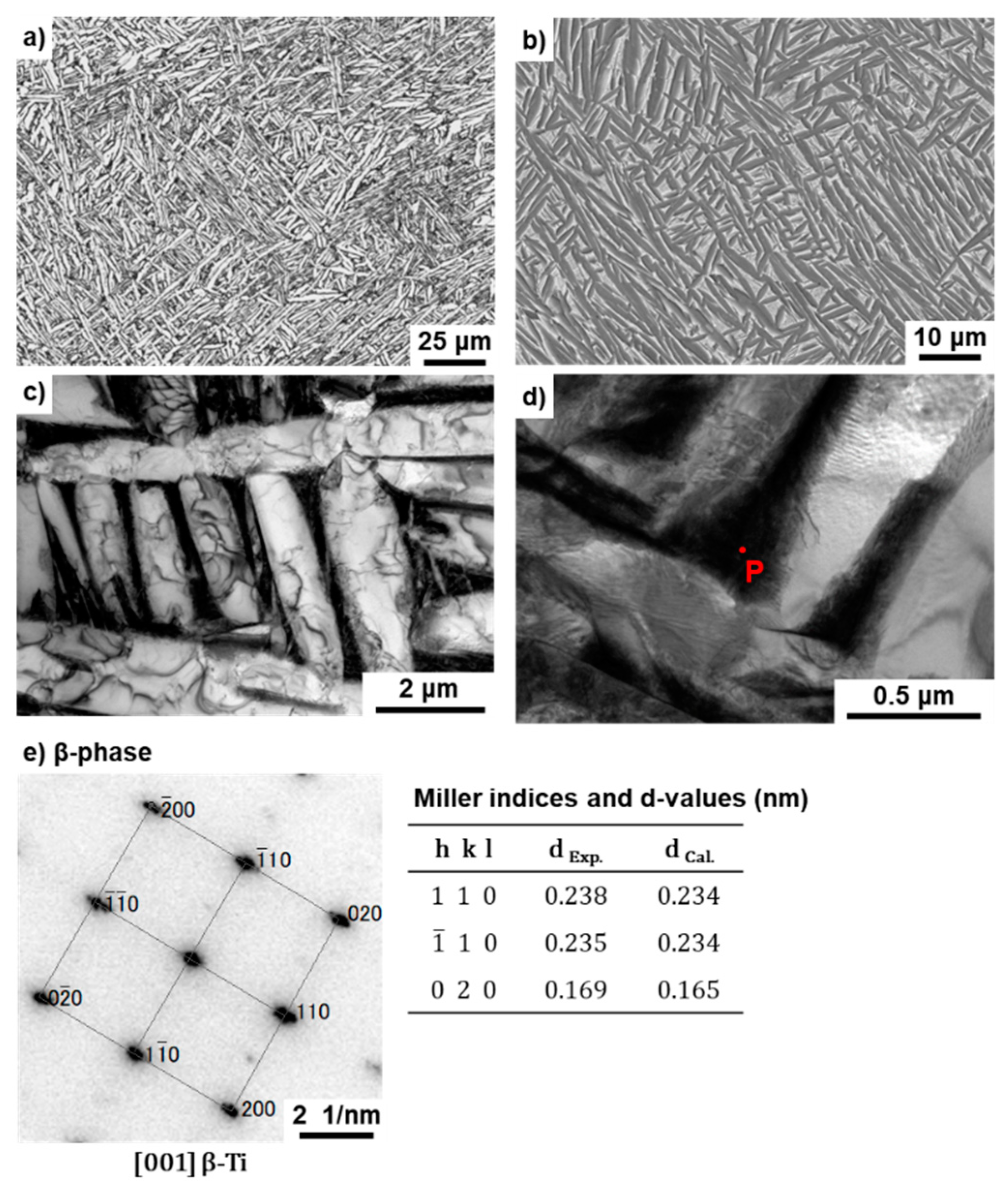

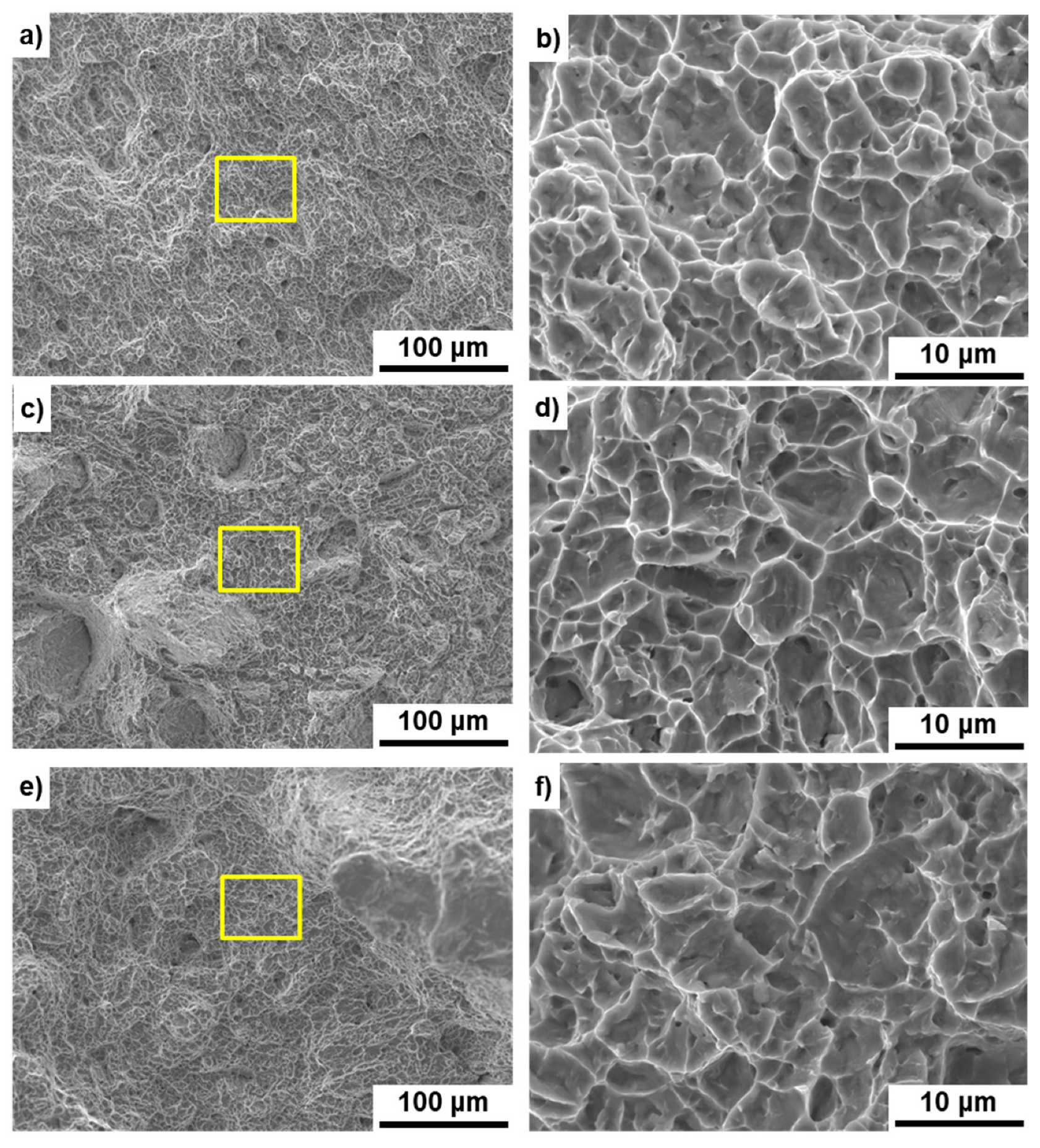

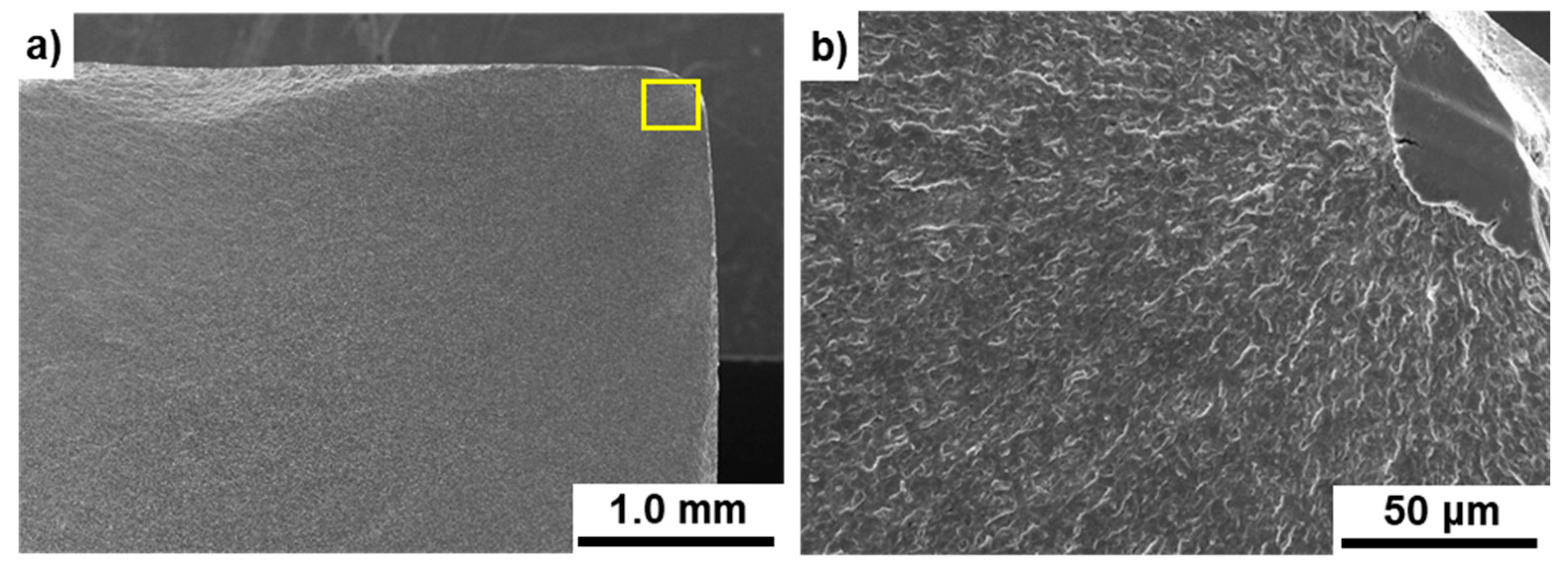

3.2.1. Microstructures of Selective-Laser-Melted Stems and Rod Specimens

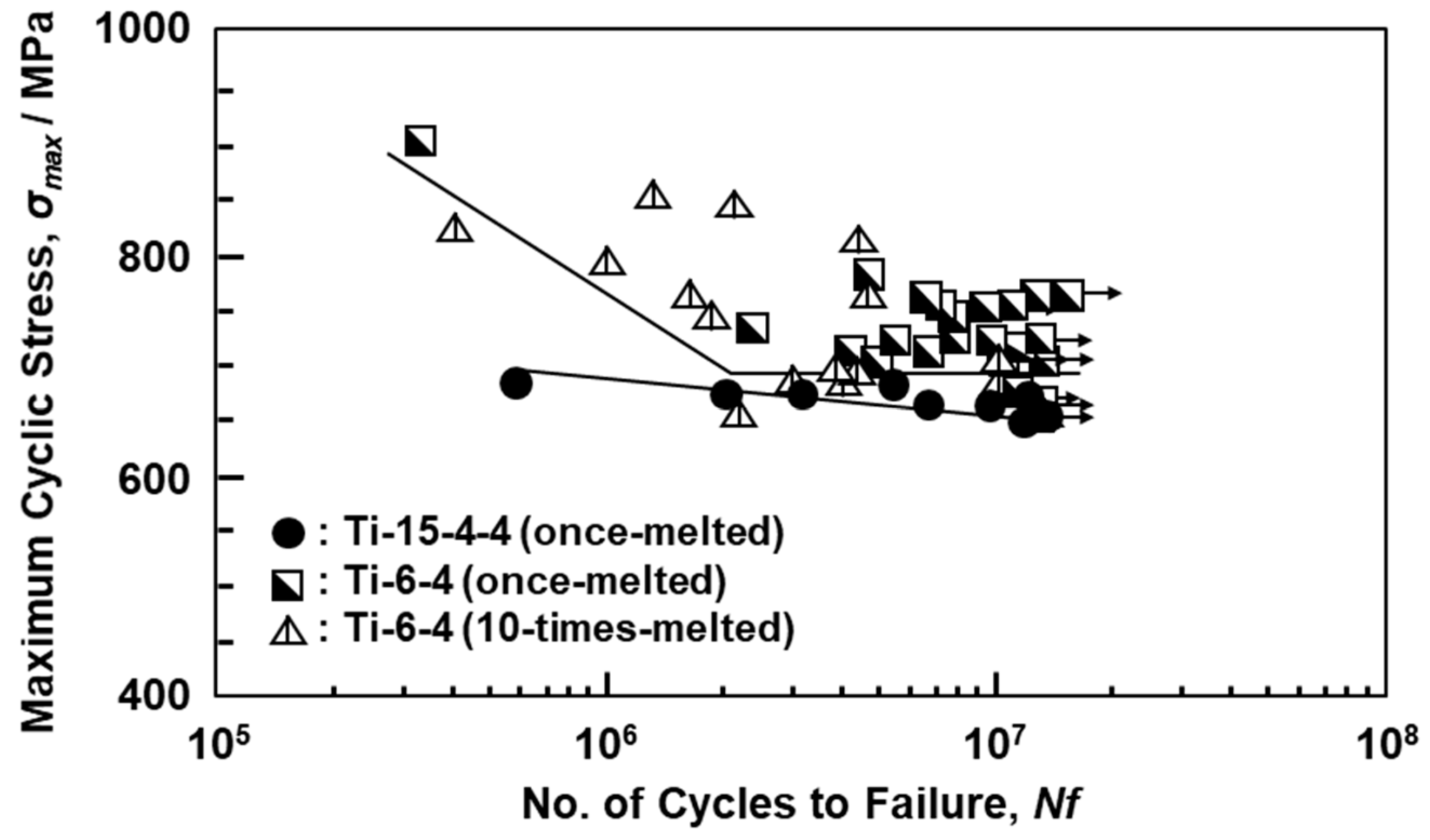

3.2.2. Mechanical Properties of Selective-Laser-Melted Stems and Rod Specimens

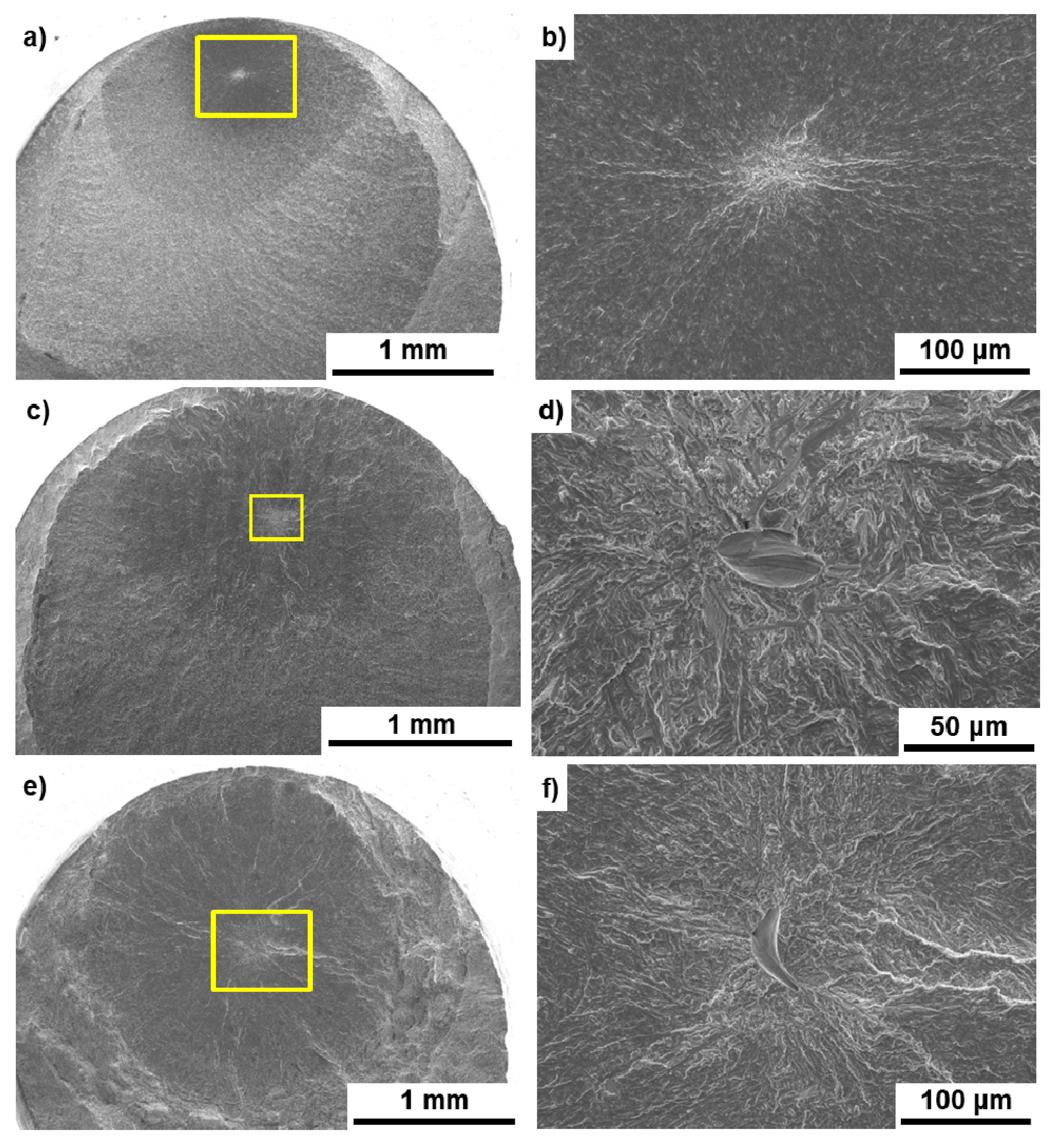

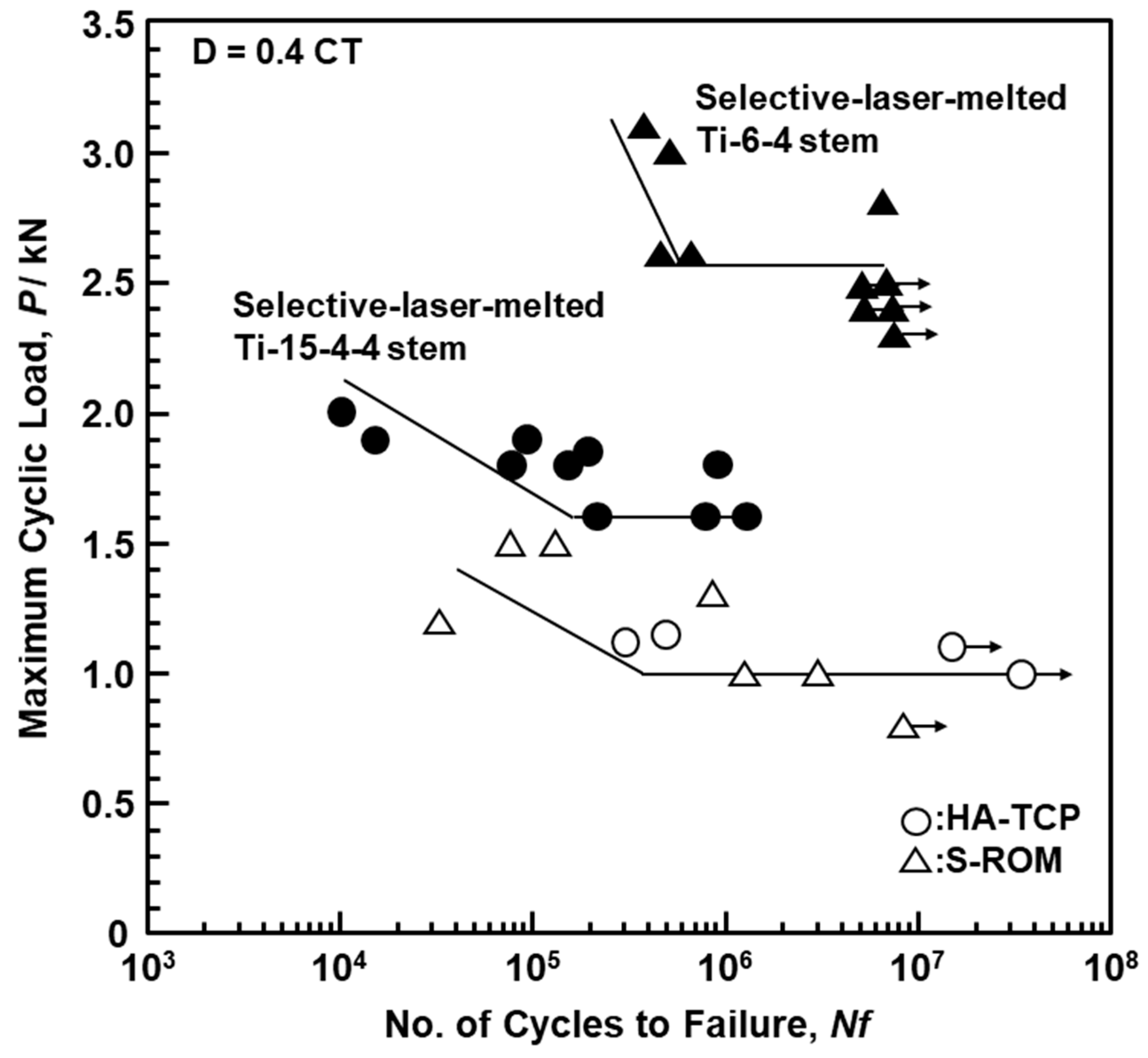

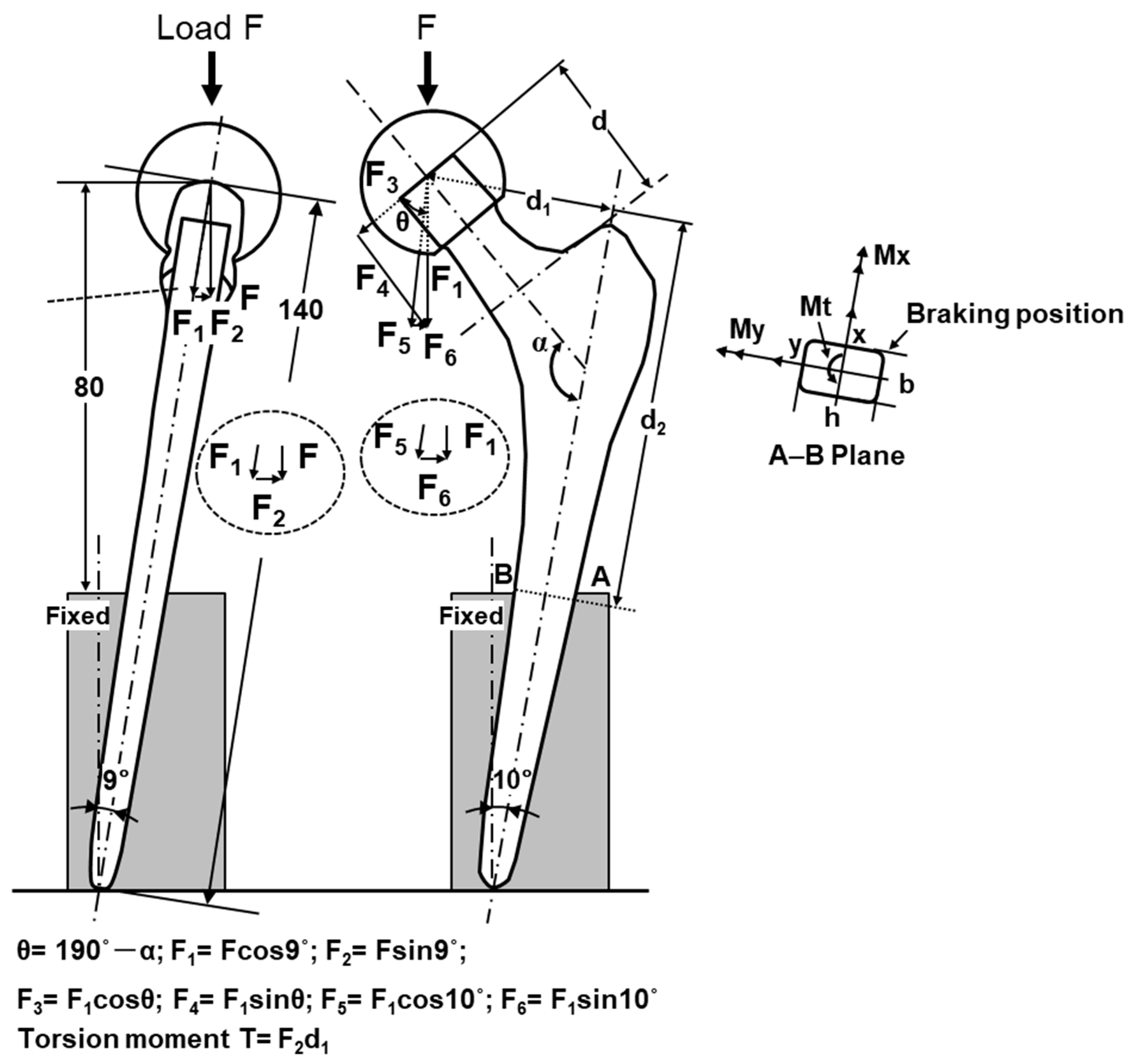

3.3. Stress Analysis of Artificial Hip Stem

3.4. Immersion Properties of Once-Laser-Melted Ti-15-4-4 and Wrought Ti-15-4 Plates

4. Conclusions

- For the hot-forged Ti-15-4 stem, it was found that the β-phase precipitated in the grain boundaries of the α (hcp) matrix was produced by hot forging. The microstructures were finer than that of the Alloclassic SL stem (Ti-6-7).

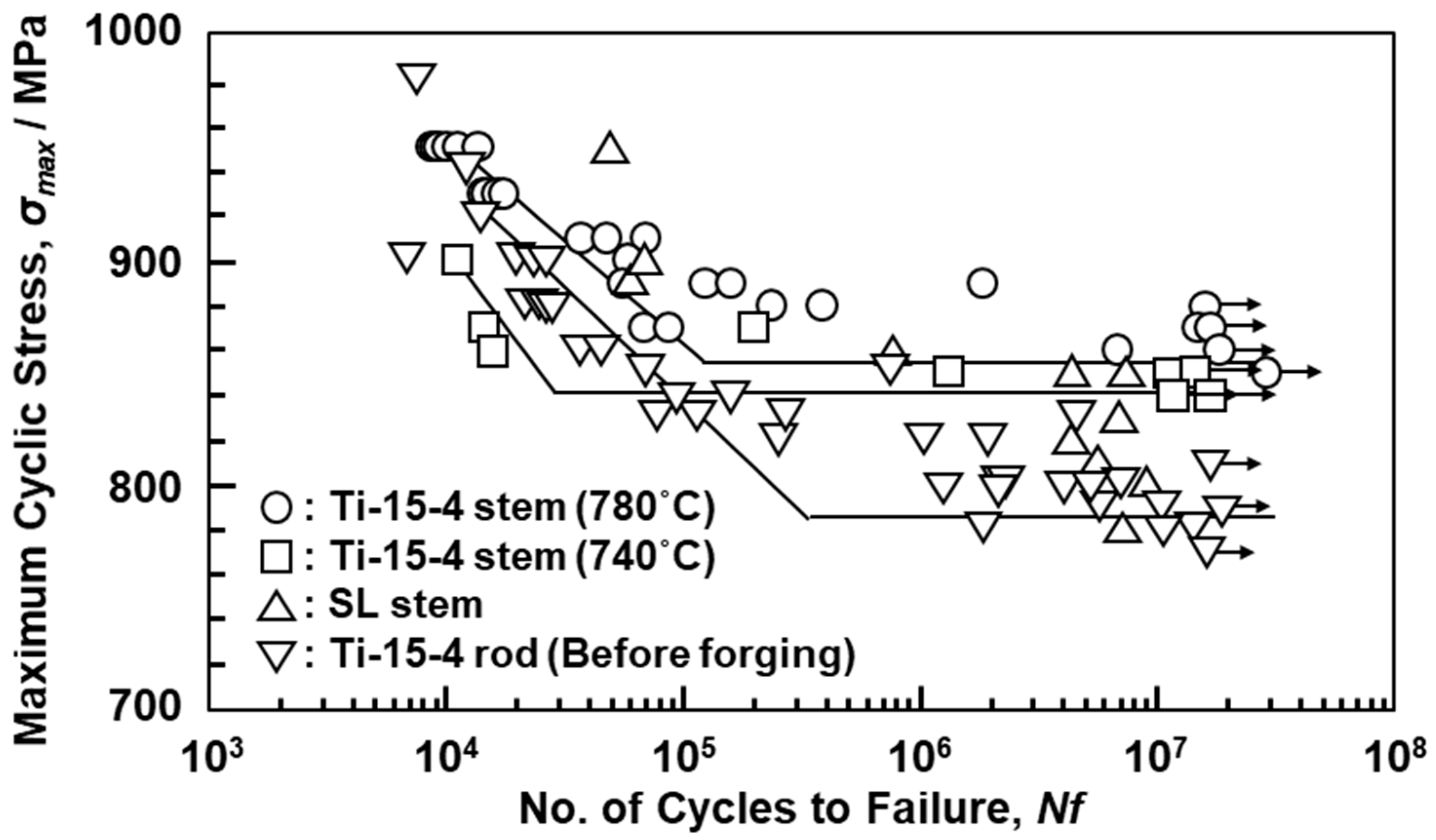

- The tensile strength of the Ti-15-4 stem hot-forged at 780 °C was close to that of the Alloclassic SL stem. The fatigue strength of the Ti-15-4 stem hot-forged at 780 °C was ~855 MPa, which was higher than that of the Alloclassic SL stem. The σFS/σUTS (0.85) value of the hot-forged Ti-15-4 stem was slightly higher than that of the Alloclassic SL stem (0.78).

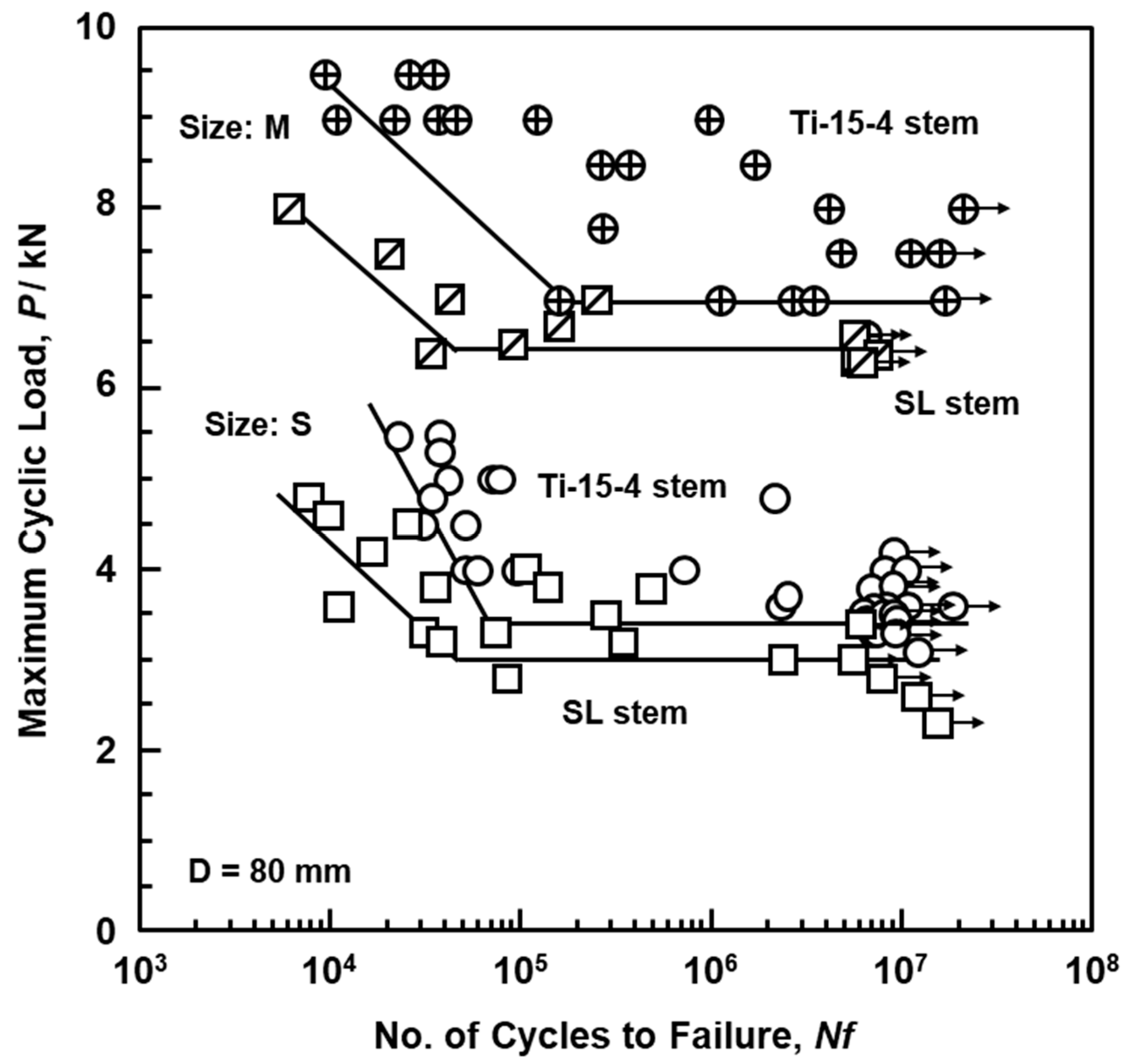

- The durabilities after 5 million cycles were 3400 ± 495 N for an S stem and 6800 ± 606 N for an M stem. The durabilities of the Alloclassic SL stem were 3000 ± 512 N for an S stem and 6400 ± 463 N for an M stem. The stress analysis of the durability test results of stems was performed using the fatigue strength (σFS). The equivalent stress (σeq) obtained by stress analysis was close to σFS obtained by fatigue tests of specimens cut from S stems.

- The selective-laser-melted Ti-15-4-4 and Ti-6-4 rods had an acicular structure. TEM images of the laser-melted Ti-15-44 and Ti-6l-4 rods showed a fine lath martensitic (α’) (hcp, a = b = 0.295, c = 0.468 nm) structure that precipitated with the fine β-phase (bcc, a = b = 0.331 nm) in the grain boundary of the α’ matrix. The durability limit of the laser-melted Ti-6-4 stem was ~2500, which was much higher than those of the approved product HA−TCP and S-ROM stems. It is considered that selective laser melting can also be applied to custom-made artificial hip stems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Okazaki, Y.; Katsuda, S. Biological safety evaluation and surface modification of biocompatible Ti-15Zr-4Nb Alloy. Materials 2021, in press. [Google Scholar]

- Okazaki, Y. Development of low-cost manufacturing process and effects of adding small amounts of Ta, O, and N on the physical and mechanical properties of highly biocompatible Ti alloys. Mater. Trans. 2019, 60, 1769–1778. [Google Scholar] [CrossRef]

- Titanium Materials for Surgical Implant Applications Part 4: Wrought Titanium 15-Zirconium 4-Niobium Alloy, JIS T 7401-4; Japanese Standards Association: Tokyo, Japan, 2021.

- Baleani, M.; Viceconti, M.; Muccini, M.; Ansaloni, M. Endurance verification of custom-made hip prostheses. Int. J. Fatigue 2000, 22, 865–871. [Google Scholar] [CrossRef]

- Bieger, R.; Ignatius, A.; Decking, R.; Claes, L.; Reichel, H.; Dürselen, L. Primary stability and strain distribution of cementless hip stems as a function of implant design. Clin. Biomech. 2012, 27, 158–164. [Google Scholar] [CrossRef] [PubMed]

- Shaik, S.A.; Bose, K.; Cherukuri, H.P. A study of durability of hip implants. Mater. Des. 2012, 42, 230–237. [Google Scholar] [CrossRef]

- Ploeg, H.-L.; Bürgi, M.; Wyss, U.P. Hip stem fatigue test prediction. Int. J. Fatigue 2009, 31, 894–905. [Google Scholar] [CrossRef]

- Chao, J. Is 7206 ISO standard enough to prove the endurance of femoral components of hip prostheses? Eng. Fail. Anal. 2008, 15, 83–89. [Google Scholar] [CrossRef]

- Simoneau, C.; Terriault, P.; Jetté, B.; Dumas, M.; Brailovski, V. Development of a porous metallic femoral stem: Design, manufacturing, simulation and mechanical testing. Mater. Des. 2017, 114, 546–556. [Google Scholar] [CrossRef]

- Raimondi, M.T.; Pietrabissa, R. Modelling evaluation of the testing condition influence on the maximum stress induced in a hip prosthesis during ISO 7206 fatigue testing. Med. Eng. Phys. 1999, 21, 353–359. [Google Scholar] [CrossRef]

- Baleani, M.; Cristofolini, L.; Viceconti, M. Endurance testing of hip prostheses: A comparison between the load fixed in ISO 7206 standard and the physiological loads. Clin. Biomech. 1999, 14, 339–345. [Google Scholar] [CrossRef]

- Pekedis, M.; Yildiz, H. Comparison of fatigue behaviour of eight different hip stem: A numerical and experimental study. J. Biomed. Sci. Eng. 2011, 4, 643–650. [Google Scholar] [CrossRef] [Green Version]

- Karande, S.; Shelge, S.V. Fatigue life prediction for hip stem using finite element analysis. Available online: https://ierjournal.org/index.php (accessed on 8 January 2021).

- Croitoru, A.S.M.; Pacioga, B.A.; Comsa, C.S. Personalized hip implants manufacturing and testing. Appl. Surf. Sci. 2017, 417, 256–261. [Google Scholar] [CrossRef]

- Dorn, U.; Neumann, D.; Frank, M. Corrosion behavior of tantalum-coated cobalt–chromium modular necks compared to titanium modular necks in a simulator test. J. Arthroplast. 2014, 29, 831–835. [Google Scholar] [CrossRef]

- Viceconti, M.; Baleani, M.; Squarzoni, S.; Toni, A. Fretting wear in a modular neck hip prosthesis. J. Biomed. Mater. Res. 1997, 35, 207–216. [Google Scholar] [CrossRef]

- Fiorentino, A.; Zarattini, G.; Pazzaglia, U.; Ceretti, E. Hip prosthesis design. Market analysis, new perspectives and an innovative solution. Procedia CIRP 2013, 5, 310–314. [Google Scholar] [CrossRef] [Green Version]

- Humphreys, P.K.; Orr, J.F.; Bahrani, A.S. Testing of total hip replacements: Endurance tests and stress measurements part 2: Stress measurements. Proc. Inst. Mech. Eng. 1990, 204, 35–41. [Google Scholar] [CrossRef] [PubMed]

- Griza, S.; dos Santos, S.V.; Ueki, M.M.; Bertoni, F.; Strohaecker, T.R. Case study and analysis of a fatigue failure in a THA stem. Eng. Fail. Anal. 2013, 28, 166–175. [Google Scholar] [CrossRef]

- Khanoki, S.A.; Pasini, D. Fatigue design of a mechanically biocompatible lattice for a proof-of-concept femoral stem. J. Mech. Behav. Biomed. Mater. 2013, 22, 65–83. [Google Scholar] [CrossRef] [Green Version]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Ram, G.D.J.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti–6Al–4V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Microstructure of Ti-6Al-4V produced by selective laser melting. J. Phys. Conf. Ser. 2012, 371, 012084. [Google Scholar] [CrossRef] [Green Version]

- Verma, P.K.; Warghane, S.; Nichul, U.; Kumar, P.; Dhole, A.; Hiwarkar, V. Effect of boron addition on microstructure, hardness and wear performance of Ti-6Al-4V alloy manufactured by laser powder bed fusion. Meter. Charact. 2021, 172, 110848. [Google Scholar] [CrossRef]

- Ter Haar, G.M.; Becker, H. Selective laser melting produced Ti-6Al-4V: Post-process heat treatments to achieve superior tensile properties. Materials 2018, 11, 146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Azarniya, A.; Colera, X.G.; Mirzaali, M.J.; Sovizi, S.; Bartolomeu, F.; Wits, W.W.; Yap, C.Y.; Ahn, J.; Miranda, G.; Silva, F.S.; et al. Additive manufacturing of Ti-6Al-4V parts through laser metal deposition (LMD): Process, microstructure, and mechanical properties. J. Alloys Compd. 2019, 804, 163–191. [Google Scholar] [CrossRef]

- Facchini, L.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting prealloyed powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M. Microstructure and tensile properties of selectively laser-melted and HIPed laser-melted Ti-6Al-4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Humbeeck, J.V. Heat treatment of Ti6Al4V produced by selective laser melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Okazaki, Y.; Ishino, A. Microstructures and mechanical properties of laser-sintered commercially pure Ti and Ti-6Al-4V alloy for dental applications. Materials 2020, 13, 609. [Google Scholar] [CrossRef] [Green Version]

- JIS. Titanium and Titanium Alloys–Determination of Hydrogen Content, JIS H 1619; Japanese Standards Association: Tokyo, Japan, 2012. [Google Scholar]

- JIS. Methods for Determination of Nitrogen in Titanium and Titanium Alloys, JIS H 1612; Japanese Standards Association: Tokyo, Japan, 1993. [Google Scholar]

- JIS. Methods for Determination of Oxygen in Titanium and Titanium Alloys, JIS H 1620; Japanese Standards Association: Tokyo, Japan, 1995. [Google Scholar]

- JIS. Methods for Determination of Carbon in Titanium and Titanium Alloys, JIS H 1617; Japanese Standards Association: Tokyo, Japan, 1995. [Google Scholar]

- ASTM. Standard Test Method for Analysis of Titanium and Titanium Alloys by Direct Current Plasma and Inductively Coupled Plasma Atomic Emission Spectrometry (Performance-Based Test Methodology); ASTM E2371; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- JIS. Metallic Materials–Tensile Testing–Method of Test at Room Temperature; JIS Z 2241; Japanese Standards Association: Tokyo, Japan, 2011. [Google Scholar]

- JIS. Test Method for Fatigue Properties of Metallic Biomaterials; JIS T 0309; Japanese Standards Association: Tokyo, Japan, 2009. [Google Scholar]

- ISO. Implants for Surgery–Partial and Total Hip Joint Prostheses–Part 4: Determination of Endurance Properties and Performance of Stemmed Femoral Components; ISO 7206-4; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- Gruen, T.A.; McNeice, G.M.; Amstutz, H.C. “Modes of failure” of cemented stem-type femoral components: A radiographic analysis of loosening. Clin. Orthop. Relat. Res. 1979, 141, 17–27. [Google Scholar] [CrossRef]

- Boyle, C.; Kim, I.Y. Comparison of different hip prosthesis shapes considering micro-level bone remodeling and stress-shielding criteria using three-dimensional design space topology optimization. J. Biomech. 2011, 44, 1722–1728. [Google Scholar] [CrossRef] [PubMed]

- Okazaki, Y.; Gotoh, E. Comparison of fatigue strengths of biocompatible Ti-15Zr-4Ta alloy and other titanium materials. Mater. Sci. Eng. C 2011, 31, 325–333. [Google Scholar] [CrossRef]

- ISO. Implants for Surgery–Test Solutions and Environmental Conditions for Static and Dynamic Corrosion Tests on Implantable Materials and Medical Devices; ISO 16428; International Organization for Standardization: Geneva, Switzerland, 2005. [Google Scholar]

- JIS. Testing Method for Metal Release from Metallic Biomaterials; JIS T 0304; Japanese Standards Association: Tokyo, Japan, 2002. [Google Scholar]

- JSMS. Standard Evaluation Method of Fatigue Reliability for Metallic Materials–Standard Regression Method of SN Curves; JSMS-SD-06-08; JSMS Committee on Fatigue and Reliability Engineering: Tokyo, Japan, 1981. [Google Scholar]

- DIN. Load Controlled Fatigue Testing–Execution and Evaluation of Cyclic Tests at Constant Load Amplitudes on Metallic Specimens and Components, English Translation of DIN 50100; DIN Deutsches Institute fur Normumg: Berlin, Germany, 2016. [Google Scholar]

- ASTM. Standard Practice for Statistical Analysis of Linear or Linearized Stress-Life (S–N) and Strain-Life (ε–N) Fatigue Data; ASTM E739; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Boyer, R.; Welsch, G.; Collings, E.W. (Eds.) ASM Materials Properties Handbook: Titanium Data Sheets; The Materials Information Society: Materials Park, OH, USA, 1994. [Google Scholar]

- ISO. Implants for Surgery–Metallic Materials–Part 3: Wrought Titanium 6-Aluminium 4-Vanadium Alloy; ISO5832–3; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Sangiorgio, S.N.; Ebramzadeh, E.; Borkowski, S.L.; Oakes, D.A.; Reid, J.J.; Bengs, B.C. Effect of proximal femoral bone support on the fixation of a press-fit noncemented total hip replacement femoral component. J. Appl. Biomater. Funct. Mater. 2013, 11, 26–34. [Google Scholar] [CrossRef]

- Flecher, X.; Pearce, O.; Parratte, S.; Aubaniac, J.-M.; Argenson, J.-N. Custom cementless stem improves hip function in young patients at 15-year followup. Clin. Orthop. Relat. Res. 2010, 468, 747–755. [Google Scholar] [CrossRef] [Green Version]

- Götze, C.; Rosenbaum, D.; Hoedemaker, J.; Bottner, F.; Steens, W. Is there a need of custom-made prostheses for total hip arthroplasty? Gait analysis, clinical and radiographic analysis of customized femoral components. Arch. Orthop. Trauma Surg. 2009, 129, 267–274. [Google Scholar] [CrossRef]

- Wettstein, M.; Mouhsine, E.; Argenson, J.-N.; Rubin, P.J.; Aubaniac, J.-M.; Leyvraz, P.-F. Three-dimensional computed cementless custom femoral stems in young patients. Clin. Orthop. Rel. Res. 2005, 437, 169–175. [Google Scholar] [CrossRef]

- Koulouvaris, P.; Stafylas, K.; Sculco, T.; Xenakis, T. Custom-design implants for severe distorted proximal anatomy of the femur in young adults followed for 4-8 years. Acta Orthop. 2008, 79, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Kawate, K.; Ohneda, Y.; Ohmura, T.; Yajima, H.; Sugimoto, K.; Takakura, Y. Computed tomography-based custom-made stem for dysplastic hips in Japanese patients. J. Arthroplast. 2009, 24, 65–70. [Google Scholar] [CrossRef] [PubMed]

- Traina, F.; de Clerico, M.; Biondi, F.; Pilla, F.; Tassinari, E.; Toni, A. Sex differences in hip morphology: Is stem modularity effective for total hip replacement? J. Bone Jt. Surg. Am. 2009, 91, 121–128. [Google Scholar] [CrossRef]

- Albanese, C.V.; Santori, F.S.; Pavan, L.; Learmonth, l.D.; Passariello, R. Periprosthetic DXA after total hip arthroplasty with short vs. ultra-shot custom-made femoral stems. Acta Orthop. 2009, 80, 291–297. [Google Scholar] [CrossRef] [PubMed]

| Stem Size | Swaged Rod | Rough/Finish Forging | Forged Stem | |||||

|---|---|---|---|---|---|---|---|---|

| Length mm | Max. Dia. mm | Starting Temp. °C | Length (L) mm | Width (W) mm | Number of Specimens | Ra μm | ||

| S | 215 | 22 | 740 | 780 | 135 | 45 | 100 | 3–4 |

| M | 220 | 25 | 740 | 780 | 160 | 50 | 100 | 3–4 |

| L | 220 | 25 | 780 | 170 | 55 | 40 | 3–4 | |

| Alloy | Zr | Nb | Ta | Pd | Fe | O | N | H | C | Ti |

| Hot-forged Ti-15-4 stem | 16.10 | 3.90 | 0.17 | <0.01 | 0.026 | 0.254 | 0.080 | 0.001 | 0.010 | Bal. |

| Ti-15-4-4 powder | 16.6 | 3.97 | 3.12 | <0.01 | 0.04 | 0.322 | 0.09 | 0.002 | 0.01 | Bal. |

| Laser-melted Ti-15-4-4 stem | 16.9 | 3.92 | 3.11 | <0.01 | 0.04 | 0.34 | 0.096 | 0.003 | 0.009 | Bal. |

| Alloy | Al | V | Fe | O | N | H | C | Ti | ||

| Ti-6-4 powder | 6.05 | 3.89 | 0.21 | 0.11 | 0.003 | 0.002 | 0.006 | Bal. | ||

| Laser-melted Ti-6-4 stem | 6.25 | 3.98 | 0.19 | 0.089 | 0.02 | 0.0015 | 0.012 | Bal. |

| Ti Alloy | σ0.2%PS /MPa | σUTS /MPa | TE (%) | RA (%) | σFS /MPa | σFS /σUTS |

|---|---|---|---|---|---|---|

| Hot-forged stems | ||||||

| Ti-15-4 rod (before forging) | 887 ± 5 | 942 ± 2 | 20 ± 1 | 60 ± 1 | 785 ± 17 | 0.83 |

| 780 °C forged Ti-15-4 stem | 919 ± 10 | 983 ± 9 | 21 ± 1 | 58 ± 2 | 855 ± 14 | 0.86 |

| 740 °C forged Ti-15-4 stem | 912 ± 6 | 979 ± 7 | 19 ± 2 | 55 ± 5 | 840 ± 5 | 0.85 |

| SL stem (Ti-6-7) | 949 ± 23 | 1034 ± 23 | 16 ± 1 | 54 ± 1 | 805 ± 26 | 0.78 |

| Ti Alloy | σ0.2%PS /MPa | σUTS /MPa | TE (%) | RA (%) | σFS /MPa | σFS/σUTS |

|---|---|---|---|---|---|---|

| Selective-laser-melted rods | ||||||

| Once-melted 0° Ti-15-4 | 880 ± 2 | 1032 ± 1 | 14 ± 1 | 31 ± 2 | ||

| Once-melted 90° Ti-15-4 | 860 ± 3 | 1022 ± 2 | 16 ± 1 | 36 ± 7 | 640 ± 11 | 0.63 |

| Once-melted 90° Ti-6-4 | 949 ± 3 | 1041 ± 2 | 15 ± 1 | 46 ± 2 | 680 ± 37 | 0.65 |

| 10-times-melted 90° Ti-6-4 | 946 ± 2 | 1036 ± 2 | 15 ± 1 | 47 ± 1 | 660 ± 14 | 0.64 |

| Specimen | σeq /MPa | x, y /mm | σFS /MPa | σeq/σFS |

|---|---|---|---|---|

| Hot-forged Ti-15-4 | 871 | (3.6, −5.5) | 855 | 1.02 |

| Alloclassic SL | 791 | (3.6, −5.5) | 805 | 0.98 |

| Laser-melted Ti-15-4-4 | 107 | (3.6, −5.5) | 640 | 0.17 |

| Laser-melted Ti-6-4 | 178 | (3.6, −5.5) | 680 | 0.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okazaki, Y.; Mori, J. Mechanical Performance of Artificial Hip Stems Manufactured by Hot Forging and Selective Laser Melting Using Biocompatible Ti-15Zr-4Nb Alloy. Materials 2021, 14, 732. https://doi.org/10.3390/ma14040732

Okazaki Y, Mori J. Mechanical Performance of Artificial Hip Stems Manufactured by Hot Forging and Selective Laser Melting Using Biocompatible Ti-15Zr-4Nb Alloy. Materials. 2021; 14(4):732. https://doi.org/10.3390/ma14040732

Chicago/Turabian StyleOkazaki, Yoshimitsu, and Jun Mori. 2021. "Mechanical Performance of Artificial Hip Stems Manufactured by Hot Forging and Selective Laser Melting Using Biocompatible Ti-15Zr-4Nb Alloy" Materials 14, no. 4: 732. https://doi.org/10.3390/ma14040732

APA StyleOkazaki, Y., & Mori, J. (2021). Mechanical Performance of Artificial Hip Stems Manufactured by Hot Forging and Selective Laser Melting Using Biocompatible Ti-15Zr-4Nb Alloy. Materials, 14(4), 732. https://doi.org/10.3390/ma14040732