Effect of Nano-Filled Protective Coating and Different pH Enviroment on Wear Resistance of New Glass Hybrid Restorative Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Exposure of Samples to Solutions of Different pH Values

2.3. Mass Recordings and Determining Wear Resistance

2.4. Statistical Analysis

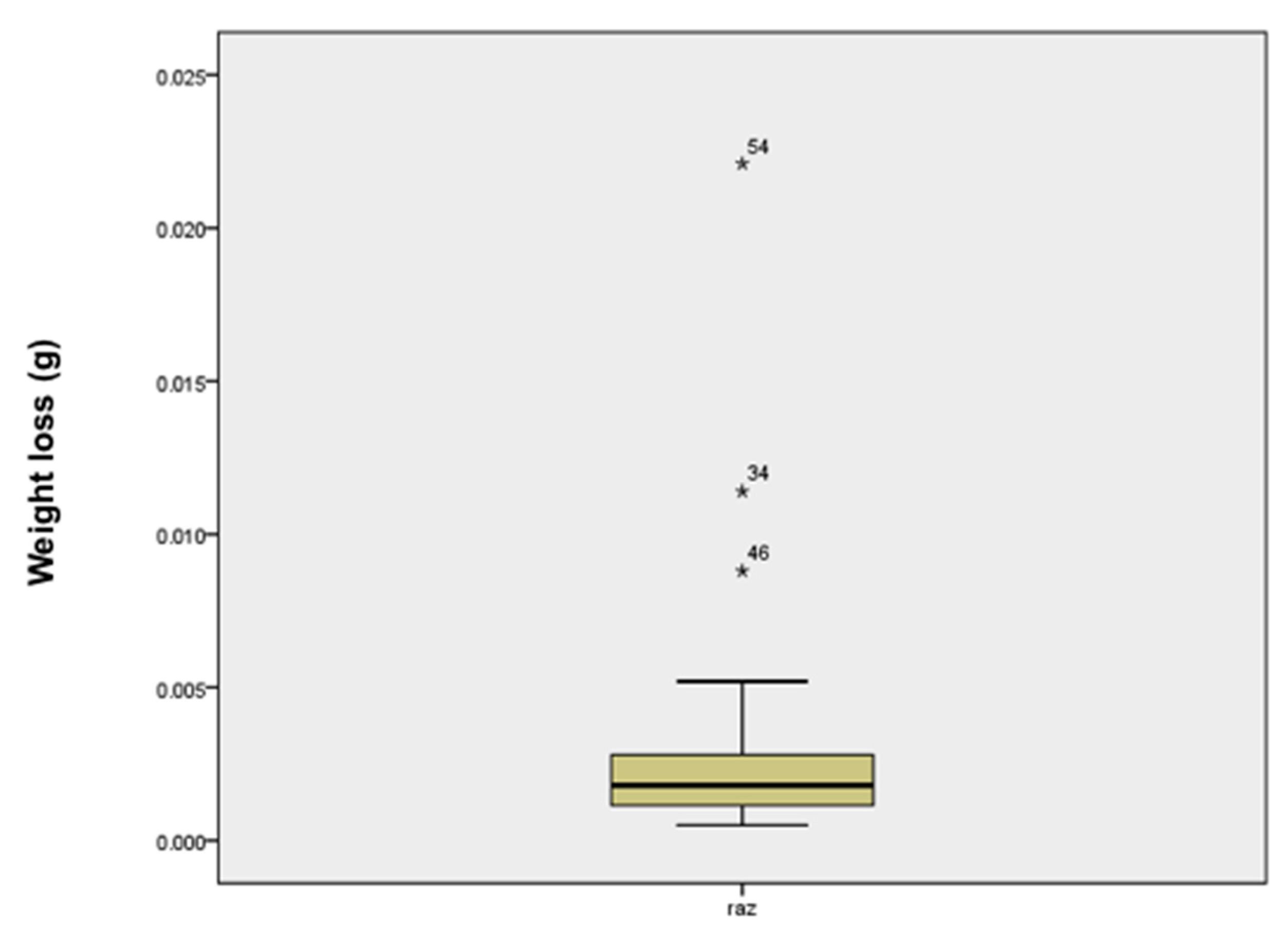

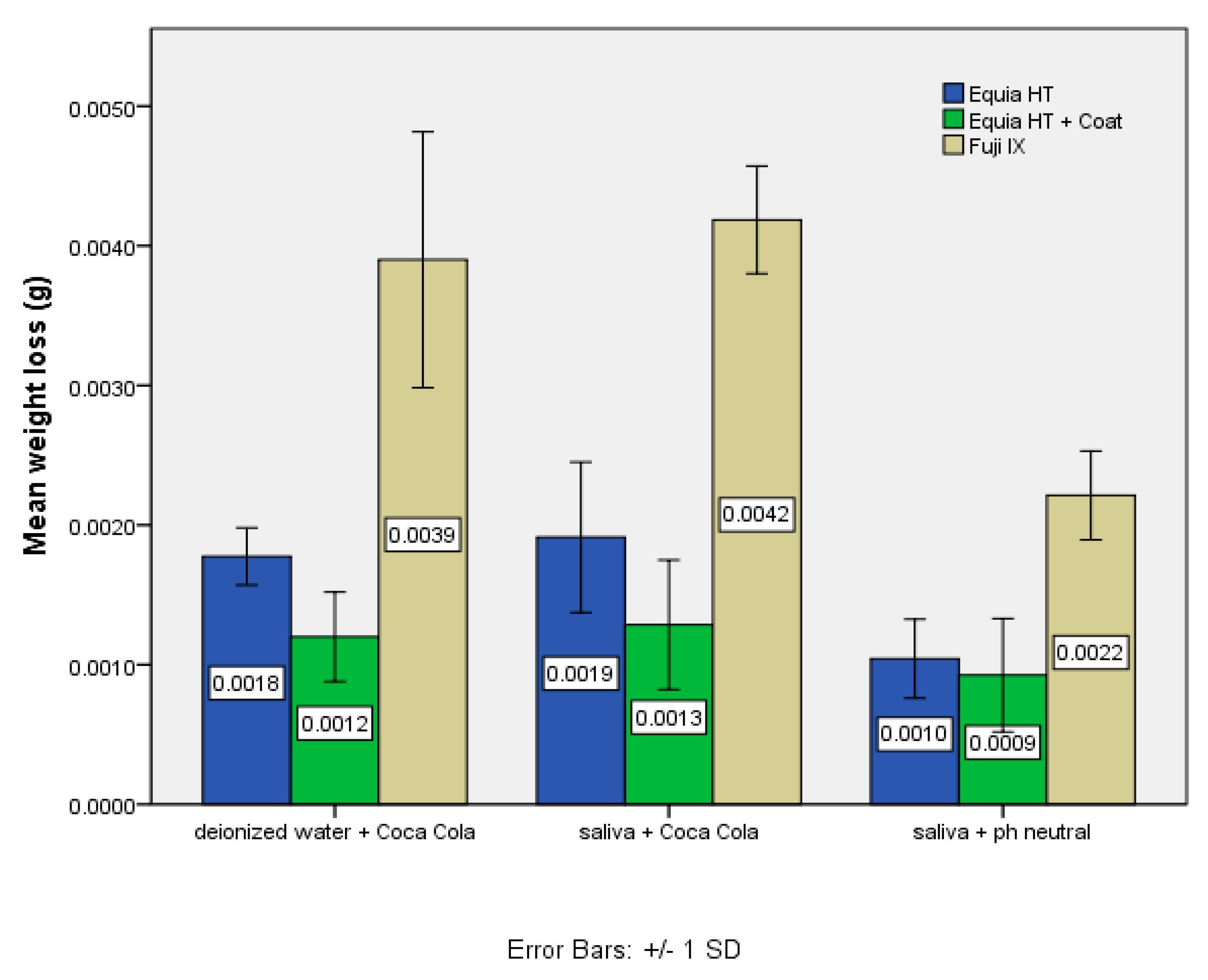

3. Results

4. Discussion

5. Conclusions

- The glass hybrid material Equia Forte Fil HT is more resistant to wear than the high-viscosity GIC Fuji IX GP in all storage conditions and acid load.

- Equia Forte Fil HT samples coated with Equia Forte Coat are more resistant to brush-induced wear compared to samples not coated with Coat, but not significantly.

- The storage medium (distilled water or artificial saliva) does not significantly affect the wear of the Fuji IX GP and Equia Forte HT Fil materials.

- The wear of material is significantly higher with periodic exposure to a low pH solution, independent of the storage medium.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wilson, A.D.; Kent, B.E. A new translucent cement for dentistry. The glass ionomer cement. Br. Dent. J. 1972, 132, 133–135. [Google Scholar] [CrossRef] [PubMed]

- Nicholson, J.W. Glass-ionomer cements for clinical dentistry. Mater. Technol. 2010, 25, 8–13. [Google Scholar] [CrossRef]

- Barra, D. Composition Structure Property: Relationships in Glass Ionomer Cements. Ph.D. Thesis, University of Limerick, Limerick, Ireland, 1997. [Google Scholar]

- McCabe, J.F.; Walls, A.W. Glass Ionomer Restorative Materials (Polyalkenoates). In Applied Dental Materials, 9th ed.; Blackwell Publishing Ltd: Oxford, UK, 2008; pp. 245–257. [Google Scholar]

- Sidhu, S.K.; Nicholson, J.W. A Review of Glass-Ionomer Cements for Clinical Dentistry. J. Funct. Biomater. 2016, 7, 16. [Google Scholar] [CrossRef] [PubMed]

- Knight, G.M. The Benefits and Limitations of Glass-Ionomer Cements and Their Use in Contemporary Dentistry. In Glass-Ionomers in Dentistry, 1st ed.; Sharanbir, K.S., Ed.; Springer International Publishing: Cham, Switzerland, 2016; Volume 3, pp. 57–79. [Google Scholar]

- Da Silva, R.C.; Zuanon, A.C.C. Surface roughness of glass ionomer cements indicated for atraumatic restorative treatment (ART). Braz. Dent. J. 2006, 17, 106–109. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodrigues, D.S.; Buciumeanu, M.; Martinelli, A.E.; Nascimento, R.M.; Henriques, B.; Silva, F.S.; Souza, J.C.M. Mechanical Strength and Wear of Dental Glass-Ionomer and Resin Composites Affected by Porosity and Chemical Composition. J. Bio- Tribo-Corros. 2015, 1, 24. [Google Scholar] [CrossRef] [Green Version]

- Cho, S.Y.; Cheng, A.C. A review of glass ionomer restorations in the primary dentition. J. Can. Dent. Assoc. 1999, 65, 491–495. [Google Scholar] [PubMed]

- De Amorim, R.G.; Leal, S.C.; Frencken, J.E. Survival of atraumatic restorative treatment (ART) sealants and restorations: A meta-analysis. Clin. Oral. Investig. 2012, 16, 429–441. [Google Scholar] [CrossRef] [Green Version]

- Capparè, P.; Tetè, G.; Sberna, M.T.; Panina-Bordignon, P. The Emerging Role of Stem Cells in Regenerative Dentistry. Curr. Gene Ther. 2020, 20, 259–268. [Google Scholar] [CrossRef]

- Tetè, G.; Capparé, P.; Gherlone, E. New Application of Osteogenic Differentiation from HiPS Stem Cells for Evaluating the Osteogenic Potential of Nanomaterials in Dentistry. Int. J. Environ. Res. Public Health 2020, 17, 1947. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gurgan, S.; Kutuk, Z.B.; Cakir, F.Y.; Ergin, E. A randomized controlled 10 years follow up of a glass ionomer restorative material in class I and class II cavities. J. Dent. 2020, 94, 103175. [Google Scholar] [CrossRef] [PubMed]

- Gurgan, S.; Kutuk, Z.B.; Ergin, E.; Oztas, S.S.; Cakir, F.Y. Clinical performance of a glass ionomer restorative system: A 6-year evaluation. Clin. Oral Investig. 2016, 21, 2335–2343. [Google Scholar] [CrossRef] [PubMed]

- Najeeb, S.; Khurshid, Z.; Zafar, M.S.; Khan, A.S.; Zohaib, S.; Martí, J.M.N.; Sauro, S.; Matinlinna, J.P.; Rehman, I.U. Modifications in Glass Ionomer Cements: Nano-Sized Fillers and Bioactive Nanoceramics. Int. J. Mol. Sci. 2016, 17, 1134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Šalinović, I.; Stunja, M.; Schauperl, Z.; Verzak, Ž.; Malčić, A.I.; Rajić, V.B. Mechanical Properties of High Viscosity Glass Ionomer and Glass Hybrid Restorative Materials. Acta Stomatol. Croat. 2019, 53, 125–131. [Google Scholar] [CrossRef]

- Mickenautsch, S. High-viscosity glass-ionomer cements for direct posterior tooth restorations in permanent teeth: The evidence in brief. J. Dent. 2016, 55, 121–123. [Google Scholar] [CrossRef] [PubMed]

- Kutuk, Z.B.; Ozturk, C.; Cakir, F.Y.; Gurgan, S. Mechanical performance of a newly developed glass hybrid restorative in the restoration of large MO Class 2 cavities. Niger. J. Clin. Pr. 2019, 22, 833–841. [Google Scholar] [CrossRef] [PubMed]

- Xie, D.; Brantley, W.A.; Culbertson, B.M.; Wang, G. Mechanical properties and of glass-ionomer cements. Dent. Mater. 2000, 16, 129–138. [Google Scholar] [CrossRef]

- Litonjua, L.A.; Andreana, S.; Bush, P.J.; Cohen, R.E. Tooth wear: Attrition, erosion, and abrasion. Quintessence Int. 2003, 34, 435–446. [Google Scholar] [PubMed]

- Gao, S.; Gao, S.; Xu, B.; Yu, H. Effects of Different pH-Values on the Nanomechanical Surface Properties of PEEK and CFR-PEEK Compared to Dental Resin-Based Materials. Materials 2015, 27, 4751–4767. [Google Scholar] [CrossRef] [PubMed]

- Tkalec, A. Analysis of Wear of the Sliding Tribo Pair Tooth-Dental Splint. Bachelor’s Thesis, Faculty of Mechanical Engineering and Naval Architecture, Zagreb, Croatia, 2011. (In Croatian). [Google Scholar]

- Kawai, K.; Iwami, Y.; Ebisu, S. Effect of resin monomer composition on toothbrush wear resistance. J. Oral Rehabil. 1998, 25, 264–268. [Google Scholar] [CrossRef] [PubMed]

- Winkler, S.; Monasky, G.E.; Kwok, J. Laboratory wear investigation of resin posterior denture teeth. J. Prosthet. Dent. 1992, 67, 812–814. [Google Scholar] [CrossRef]

- Eneren, E.S.; Imazato, S.; Kaneshiro, A.V.; Iwami, Y.; Ebusi, S.; Gurgan, S. Resistance of surface coating resins against tooth brushing abrasion. Am. J. Dent. 2010, 23, 70–74. [Google Scholar]

- Yap, A.U.; Teoh, S.H.; Hasting, G.W.; Lu, C.S. Comparative wear ranking of dental restorative materials utilizing different wear simulation models. J. Oral Rehabil. 1997, 24, 574–580. [Google Scholar] [CrossRef] [PubMed]

- Kanter, J.; Koski, R.E.; Martin, D. The relationship of weight loss to surface roughness of composite resins from simulated toothbrushing. J. Prosthet. Dent. 1982, 47, 505–513. [Google Scholar] [CrossRef]

- Gando, I.; Ariyoshi, M.; Ikeda, M.; Sadr, A.; Nikaido, T.; Tagami, J. Resistance of dentin coating materials against abrasion by tooth- brush. Dent. Mater. 2013, 32, 68–74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Belli, R.; Pelka, M.A.; Petschelt, A.; Lohbauer, U. In vitro wear gap formation of self-adhesive resin cements: A CLSM evaluation. J. Dent. 2009, 37, 984–993. [Google Scholar] [CrossRef] [PubMed]

- Jankauskas, V.; Skirkus, R. Steel abrasive wear forecasting by wearing surfaces microgeometric parameters. Mechanika 2013, 19, 486–490. [Google Scholar] [CrossRef] [Green Version]

- Kessler, R. The Minamata Convention on Mercury: A First Step toward Protecting Future Generations. Environ. Health Perspect. 2013, 121, A304–A309. [Google Scholar] [CrossRef] [PubMed]

- Cosgun, A.; Bolgul, B.; Duran, N. In vitro investigation of antimicrobial effects, nanohardness, and cytotoxicity of different glass ionomer restorative materials in dentistry. Niger. J. Clin. Pr. 2019, 22, 422–431. [Google Scholar]

- Moshaverinia, M.; Navas, A.; Jahedmanesh, N.; Shah, K.C.; Moshaverinia, A.; Ansari, S. Comparative evaluation of the physical properties of a reinforced glass ionomer dental restorative material. J. Prosthet. Dent. 2019, 122, 154–159. [Google Scholar] [CrossRef] [PubMed]

- Bonifacio, C.C.; Kleverlaan, C.; Raggio, D.P.; Werner, A.; De Carvalho, R.; Van Amerongen, W. Physical-mechanical properties of glass ionomer cements indicated for atraumatic restorative treatment. Aust. Dent. J. 2009, 54, 233–237. [Google Scholar] [CrossRef]

- Al Jamhan, A.S. In Vitro Wear and Hardness if New Conventional Glass Ionomer Cement Coated with Nano-Filled Resin. Ph.D. Thesis, Indiana University School of Dentistry, Indianapolis, IN, USA, 2011. [Google Scholar]

- Faraji, F.; Heshmat, H.; Banava, S. Effect of protective coating on microhardness of a new glass ionomer cement: Nanofilled coating versus unfilled resin. J. Conserv. Dent. 2017, 20, 260–263. [Google Scholar] [CrossRef] [PubMed]

- Lohbauer, U.; Krämer, N.; Siedschlag, G.; Schubert, E.W.; Lauerer, B.; Müller, F.A.; Petschelt, A.; Ebert, J. Strength and wear resistance of a dental glass-ionomer cement with a novel nanofilled resin coating. Am. J. Dent. 2011, 24, 124–128. [Google Scholar] [PubMed]

- Kanik, Ö.; Türkün, L.; Dasch, W. In vitro abrasion of resin-coated highly viscous glass ionomer cements: A confocal laser scanning microscopy study. Clin. Oral Investig. 2016, 21, 821–829. [Google Scholar] [CrossRef] [PubMed]

- Brzović Rajić, V.; Ivanišević Malčić, A.; Bilge Kütük, Z.; Gurgan, S.; Jukić, S.; Miletić, I. Compressive Strength of New Glass Ionomer Cement Technology based Restorative Materials after Thermocycling and Cyclic Loading. Acta Stomatol. Croat. 2019, 53, 318–325. [Google Scholar] [CrossRef] [PubMed]

- Diem, V.T.K.; Tyas, M.J.; Ngo, H.C.; Phuong, L.H.; Khanh, N.D. The effect of a nano-filled resin coating on the 3-year clinical performance of a conventional high-viscosity glass-ionomer cement. Clin. Oral Investig. 2013, 18, 753–759. [Google Scholar] [CrossRef]

- Wang, X.Y.; Yap, A.U.J.; Ngo, H.C. Effect of Early Water Exposure on the Strength of Glass Ionomer Restoratives. Oper. Dent. 2006, 31, 584–589. [Google Scholar] [CrossRef] [PubMed]

- Ferracane, J.L. Hygroscopic and hydrolytic effects in dental polymer networks. Dent. Mater. 2006, 22, 211–222. [Google Scholar] [CrossRef] [PubMed]

- Poornima, P.; Koley, P.; Kenchappa, M.; Nagaveni, N.B.; Bharath, K.P.; Neena, I.E. Comparative evaluation of compressive strength and surface microhardness of EQUIA Forte, resin-modified glass-ionomer cement with conventional glass-ionomer cement. J. Indian Soc. Pedod. Prev. Dent. 2019, 37, 265–270. [Google Scholar] [CrossRef]

- Jafarpour, D.; Mese, A.; Ferooz, M.; Bagheri, R. The effects of nanofilled resin-based coatings on the physical properties of glass ionomer cement restorative materials. J. Dent. 2019, 89, 103177. [Google Scholar] [CrossRef]

- Mohamed-Tahir, M.A.; Yap, A.U.J. Effects of pH on the surface texture of glass ionomer based/containing restorative materials. Oper. Dent. 2004, 29, 586–591. [Google Scholar] [PubMed]

- Gal, J.Y.; Fovet, Y.; Adib-Yadzi, M. About a synthetic saliva for in vitro studies. Talanta 2001, 53, 1103–1115. [Google Scholar] [CrossRef]

- Perera, D.; Yu, S.C.H.; Zeng, H.; Meyers, I.A.; Walsh, L.J. Acid Resistance of Glass Ionomer Cement Restorative Materials. Bioengineering 2020, 7, 150. [Google Scholar] [CrossRef] [PubMed]

| Experimental Subgroups | Storage Conditions and Exposure to a Low pH Solution |

|---|---|

| Subgroup 1 | The samples were stored for 7 days in artificial saliva. |

| Subgroup 2 | The samples were stored for 7 days in artificial saliva and exposed to acidic environment five times for 5 minutes per day. |

| Subgroup 3 | The samples were stored for 7 days in distilled water and exposed to acidic environment five times for 5 minutes per day. |

| Source | Type III Sum of Squares | Df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 8.737 × 10−5 a | 8 | 1.092 × 10−5 | 48.748 | <0.00005 |

| Intercept | <0.00005 | 1 | <0.00005 | 1287.735 | <0.00005 |

| Acid | 1.498 × 10−5 | 2 | 7.492 × 10−6 | 33.440 | <0.00005 |

| Material | 6.803 × 10−5 | 2 | 3.402 × 10−5 | 151.836 | <0.00005 |

| Acid * material | 6.243 × 10−6 | 4 | 1.561 × 10−6 | 6.966 | <0.00005 |

| Error | 1.344 × 10−5 | 60 | 2.240 × 10−7 | ||

| Total | <0.00005 | 69 | |||

| Corrected Total | <0.00005 | 68 |

| (I) Materialb | (J) Materialb | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| Equia HT | Equia HT + Coat | 0.5750 | 0.0002865 | 0.158 | −0.000179 | 0.001329 |

| Fuji IX | −0.0021250 * | 0.0002865 | 0.000 | −0.002879 | −0.001371 | |

| Equia HT + Coat | Equia HT | −0.0005750 | 0.0002865 | 0.158 | −0.001329 | 0.000179 |

| Fuji IX | −0.0027000 * | 0.0002865 | 0.000 | −0.003454 | −0.001946 | |

| Fuji IX | Equia HT | 0.0021250 * | 0.0002865 | 0.000 | 0.001371 | 0.002879 |

| Equia HT + Coat | 0.0027000 * | 0.0002865 | 0.000 | 0.001946 | 0.003454 | |

| (I) Materialb | (J) Materialb | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| Equia HT | Equia HT + Coat | 0.0001179 | 0.0001771 | 0.803 | −0.000350 | 0.000586 |

| Fuji IX | −0.0011696 * | 0.0001771 | 0.000 | −0.001638 | −0.000702 | |

| Equia HT + Coat | Equia HT | −0.0001179 | 0.0001771 | 0.803 | −0.000586 | 0.000350 |

| Fuji IX | −0.0012875 * | 0.0001711 | 0.000 | −0.001740 | −0.000835 | |

| Fuji IX | Equia HT | 0.0011696 * | 0.0001771 | 0.000 | 0.000702 | 0.001638 |

| Equia HT + Coat | 0.0012875 * | 0.0001711 | 0.000 | 0.000835 | 0.001740 | |

| (I) Acid Load | (J) Acid Load | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | ||

|---|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | ||||||

| Scheffe | deionized water + acid solution | Saliva + acid solution | −0.000145 | 0.0001397 | 0.588 | −0.000495 | 0.000206 |

| saliva-pH neutral | 0.000883 * | 0.0001381 | 0.000 | 0.000536 | 0.001230 | ||

| saliva + acid solution | deionized water + acid solution | 0.000145 | 0.0001397 | 0.588 | −0.000206 | 0.000495 | |

| saliva-pH neutral | 0.001028 * | 0.0001412 | 0.000 | 0.000673 | 0.001382 | ||

| saliva-ph neutral | deionized water + acid solution | −0.000883 * | 0.0001381 | 0.000 | −0.001230 | −0.000536 | |

| saliva+acid solution | −0.001028 * | 0.0001412 | 0.000 | −0.001382 | −0.000673 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brkanović, S.; Ivanišević, A.; Miletić, I.; Mezdić, D.; Jukić Krmek, S. Effect of Nano-Filled Protective Coating and Different pH Enviroment on Wear Resistance of New Glass Hybrid Restorative Material. Materials 2021, 14, 755. https://doi.org/10.3390/ma14040755

Brkanović S, Ivanišević A, Miletić I, Mezdić D, Jukić Krmek S. Effect of Nano-Filled Protective Coating and Different pH Enviroment on Wear Resistance of New Glass Hybrid Restorative Material. Materials. 2021; 14(4):755. https://doi.org/10.3390/ma14040755

Chicago/Turabian StyleBrkanović, Sandra, Ana Ivanišević, Ivana Miletić, Dražen Mezdić, and Silvana Jukić Krmek. 2021. "Effect of Nano-Filled Protective Coating and Different pH Enviroment on Wear Resistance of New Glass Hybrid Restorative Material" Materials 14, no. 4: 755. https://doi.org/10.3390/ma14040755

APA StyleBrkanović, S., Ivanišević, A., Miletić, I., Mezdić, D., & Jukić Krmek, S. (2021). Effect of Nano-Filled Protective Coating and Different pH Enviroment on Wear Resistance of New Glass Hybrid Restorative Material. Materials, 14(4), 755. https://doi.org/10.3390/ma14040755