Characteristics, Mechanism and Criterion of Channel Segregation in NbTi Alloy via Numerical Simulations and Experimental Characterizations

Abstract

:1. Introduction

2. Materials and Experimental Methods

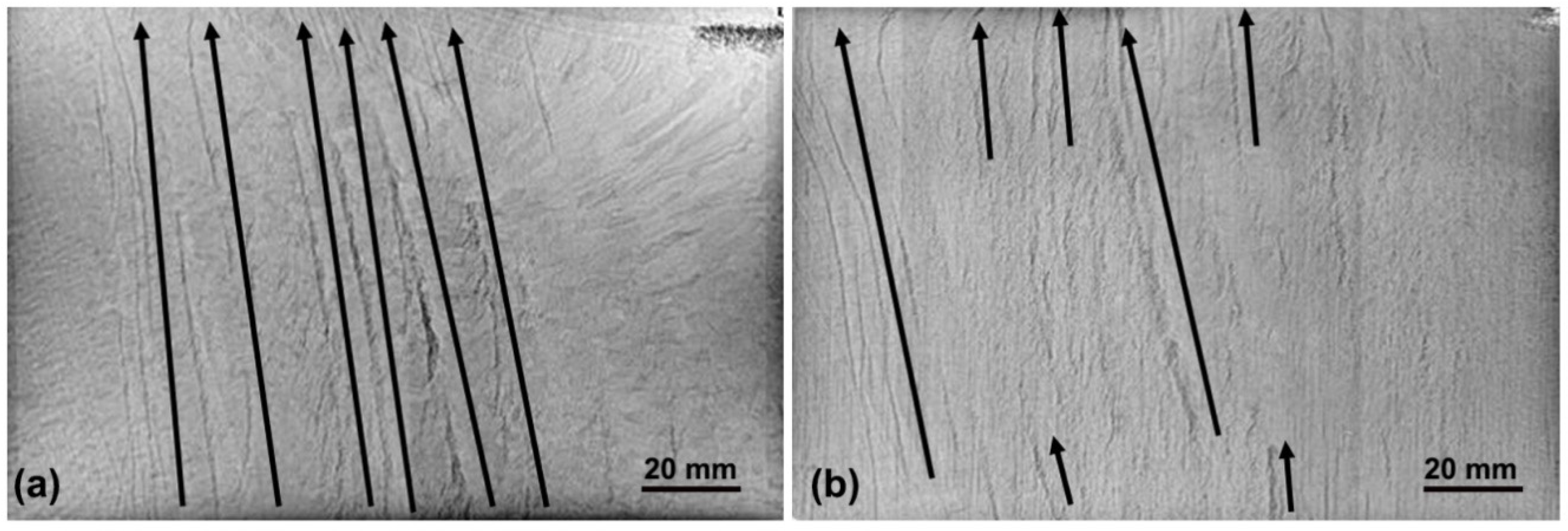

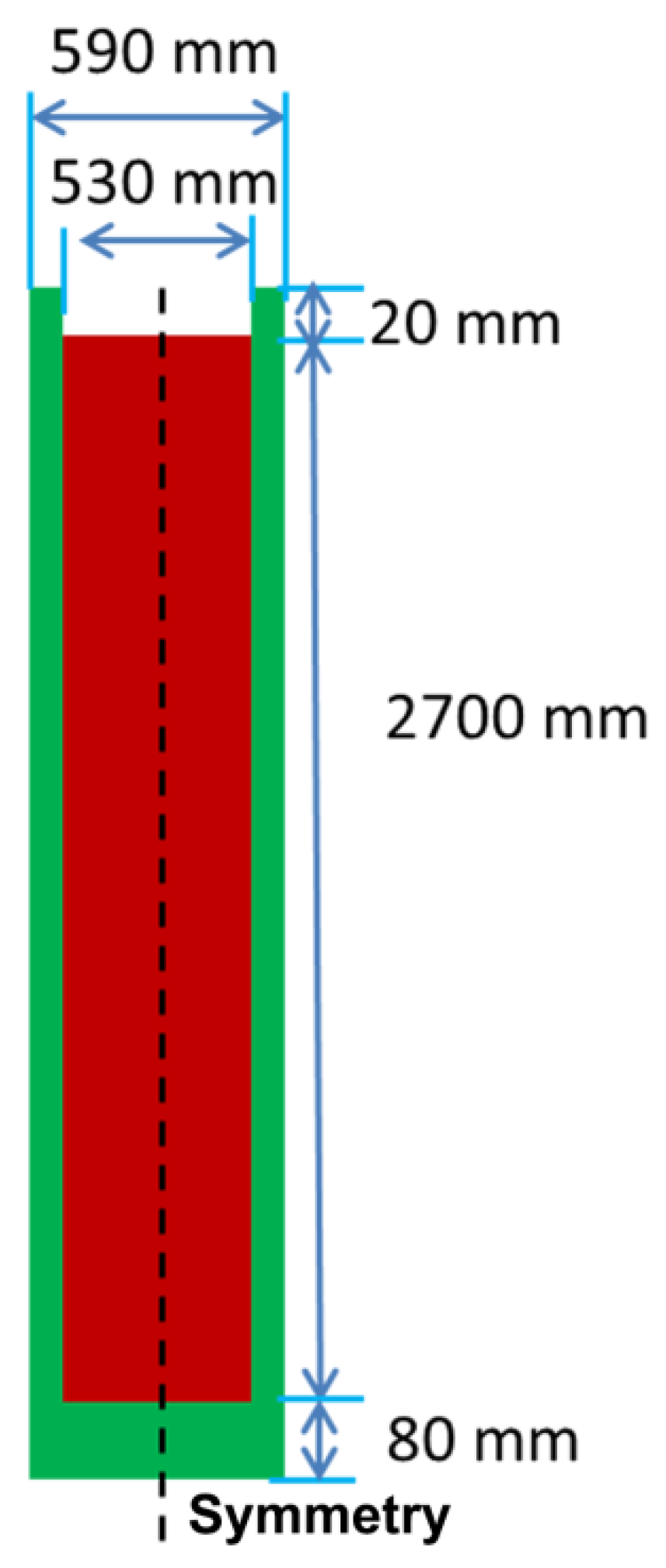

2.1. Ingot Production and Industrial X-ray Transmission Observation

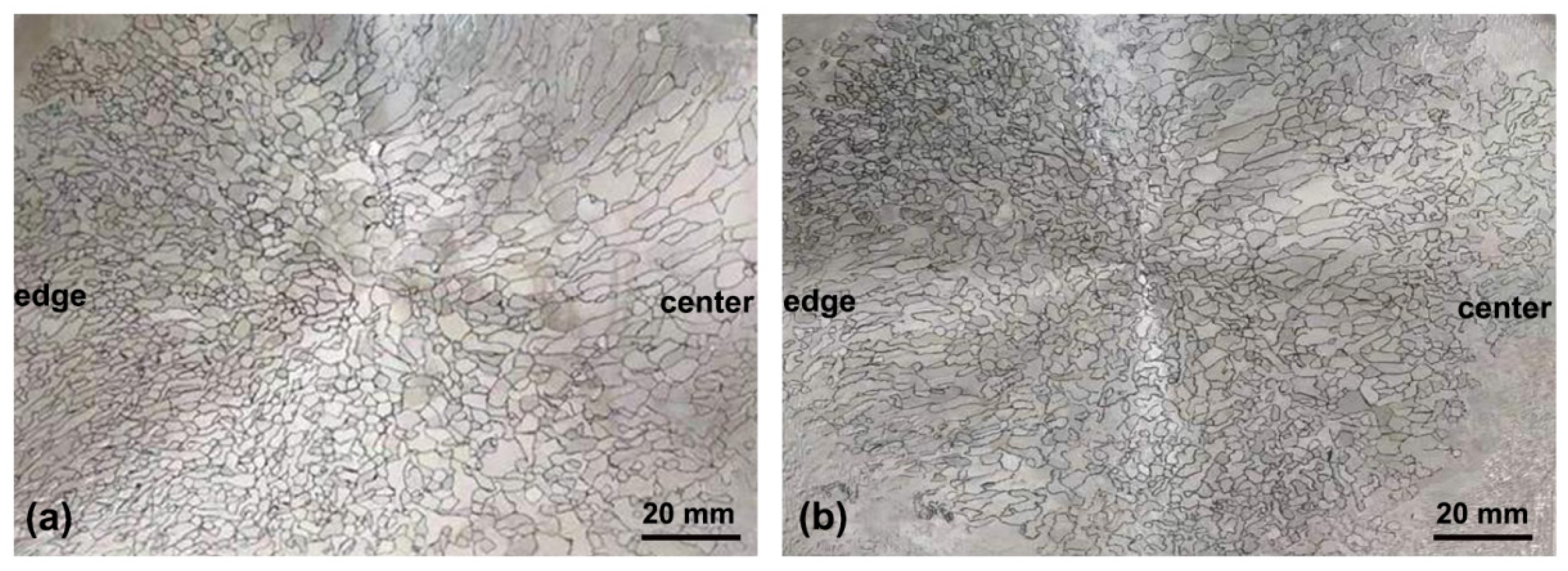

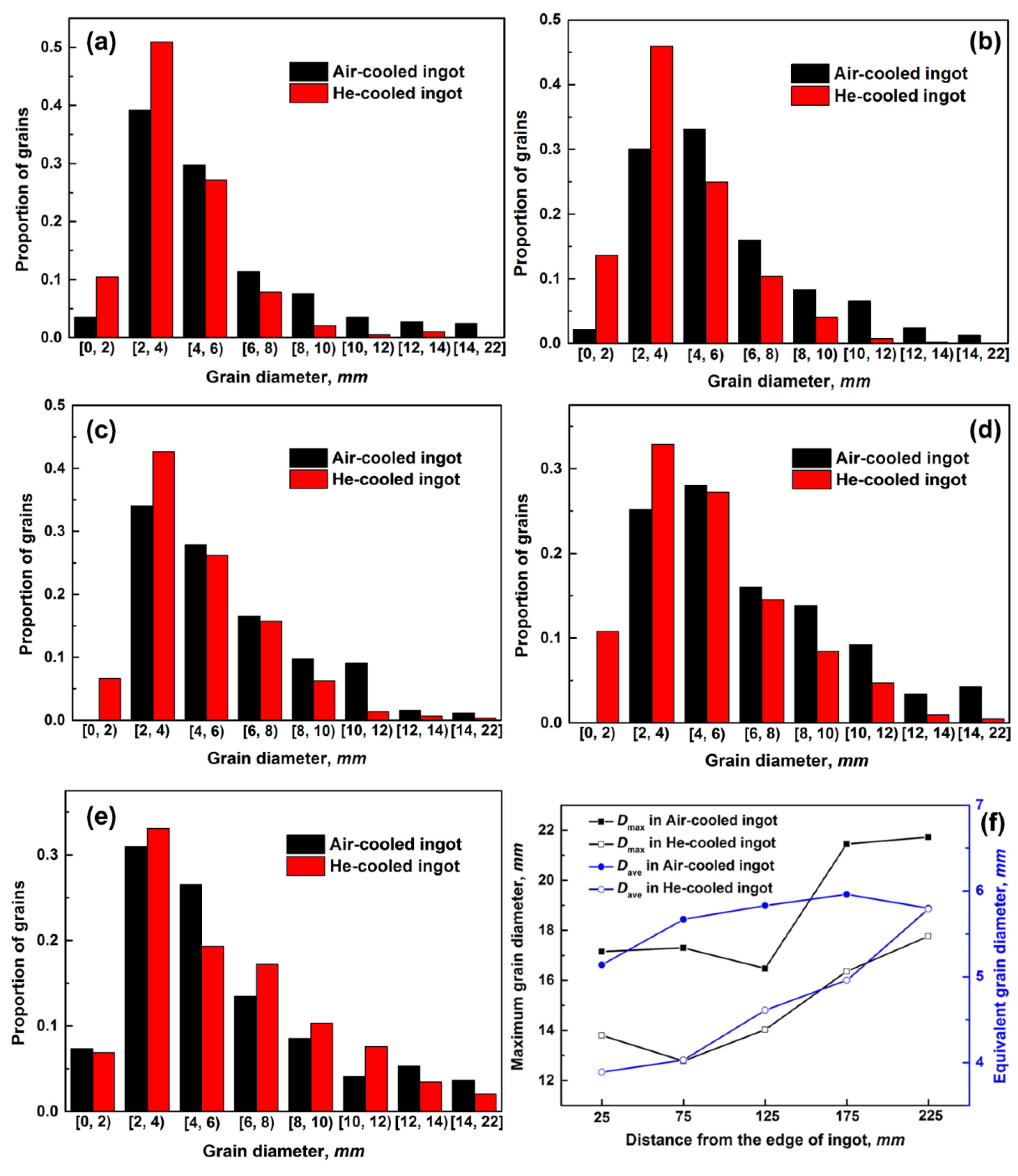

2.2. Acid Etching and Grain Size Distribution

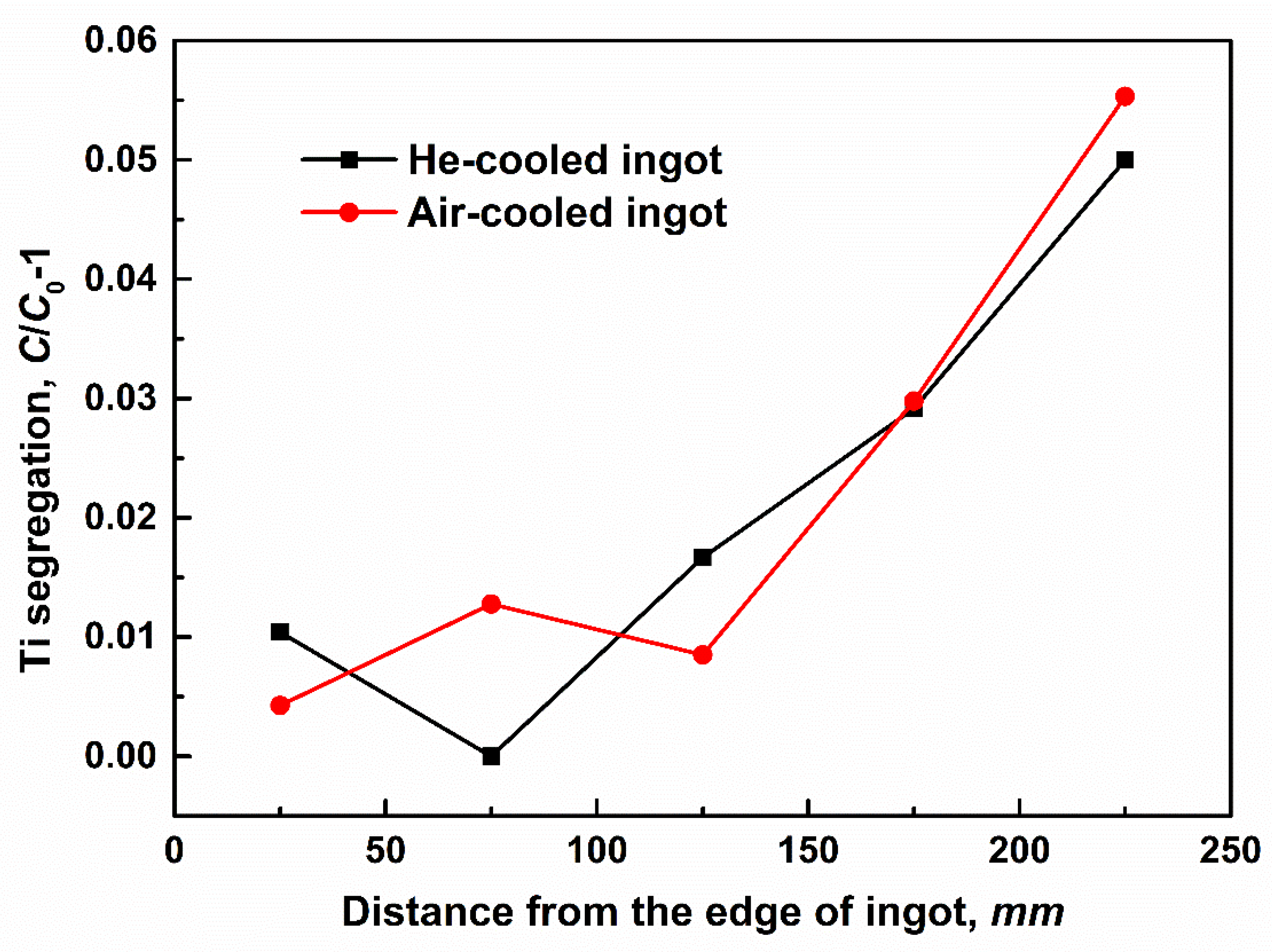

2.3. Chemical Analysis and Segregation Determination

2.4. 3D Microtomography

3. Experimental Results

4. Simulation Method and Model

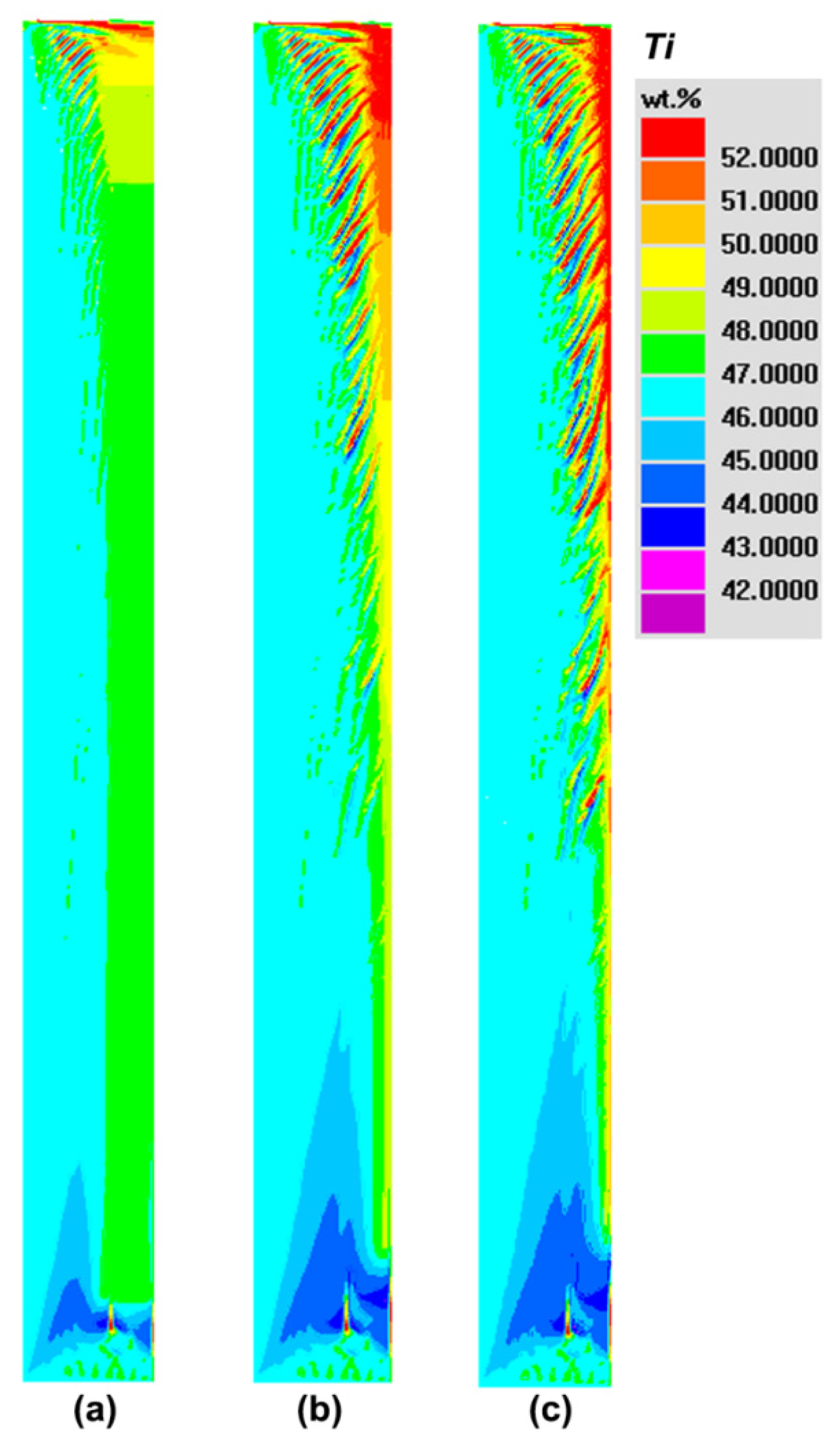

5. Simulation Results and Discussion

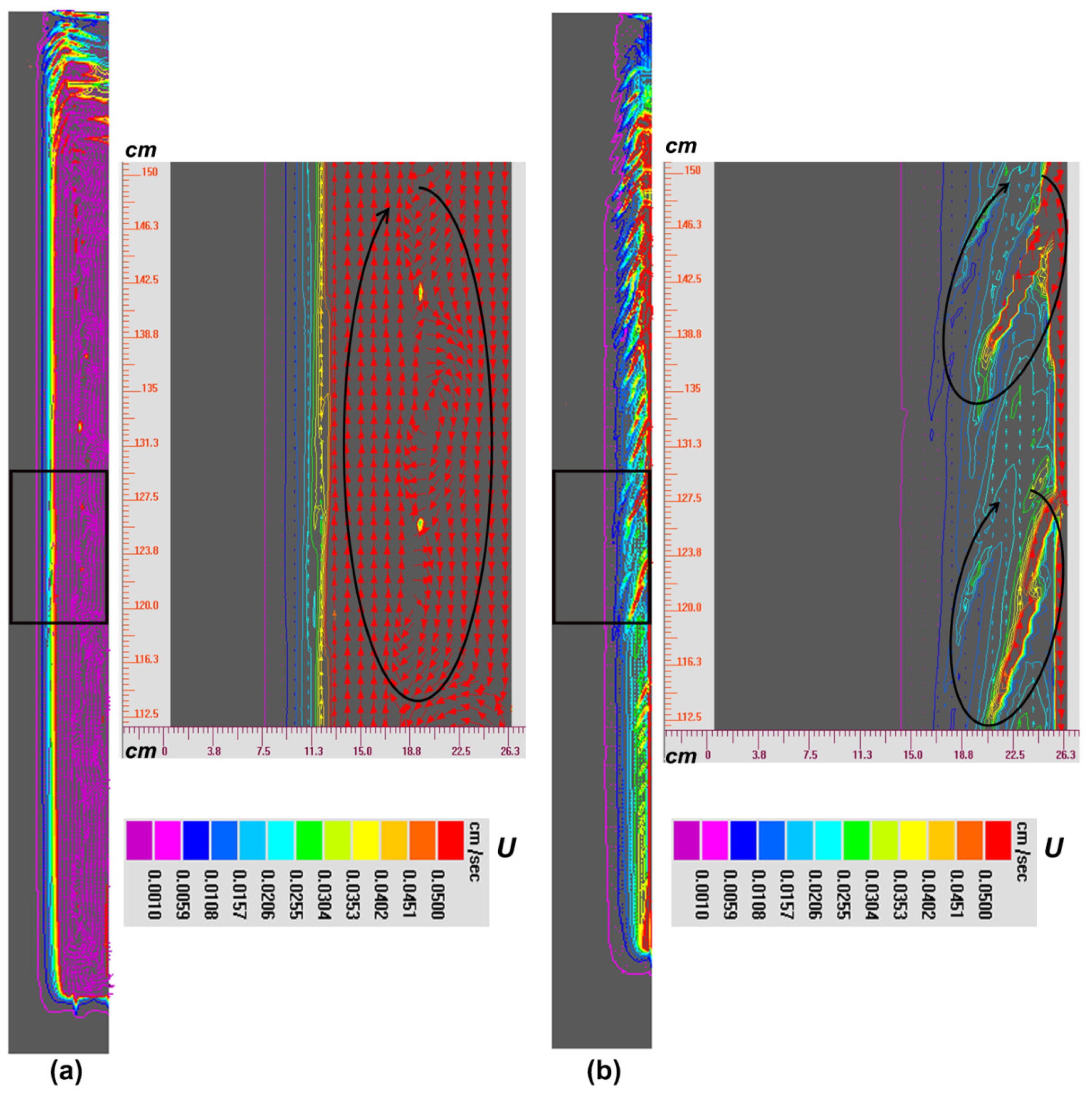

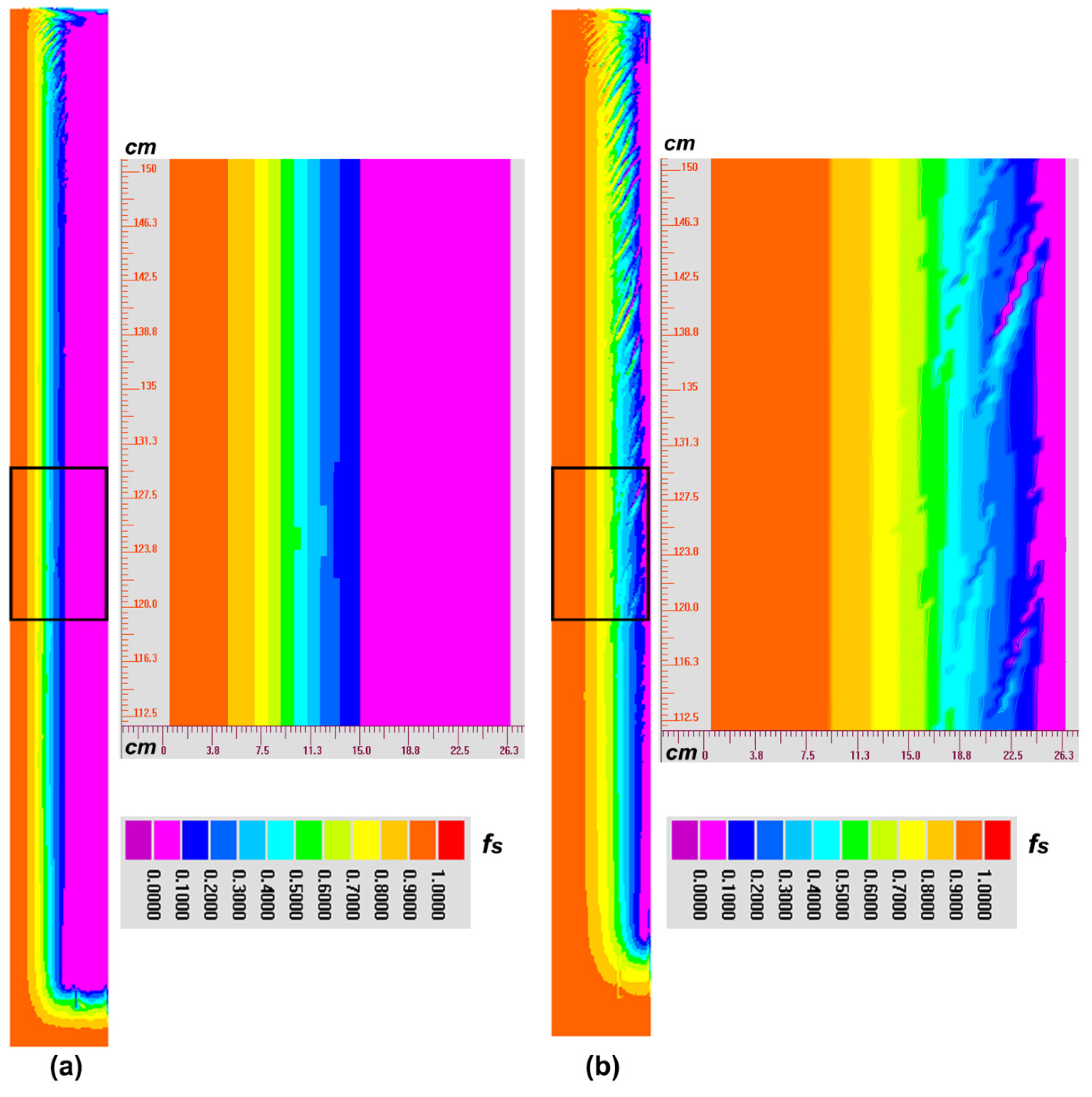

5.1. Formation Mechanism of CS in NbTi Alloy

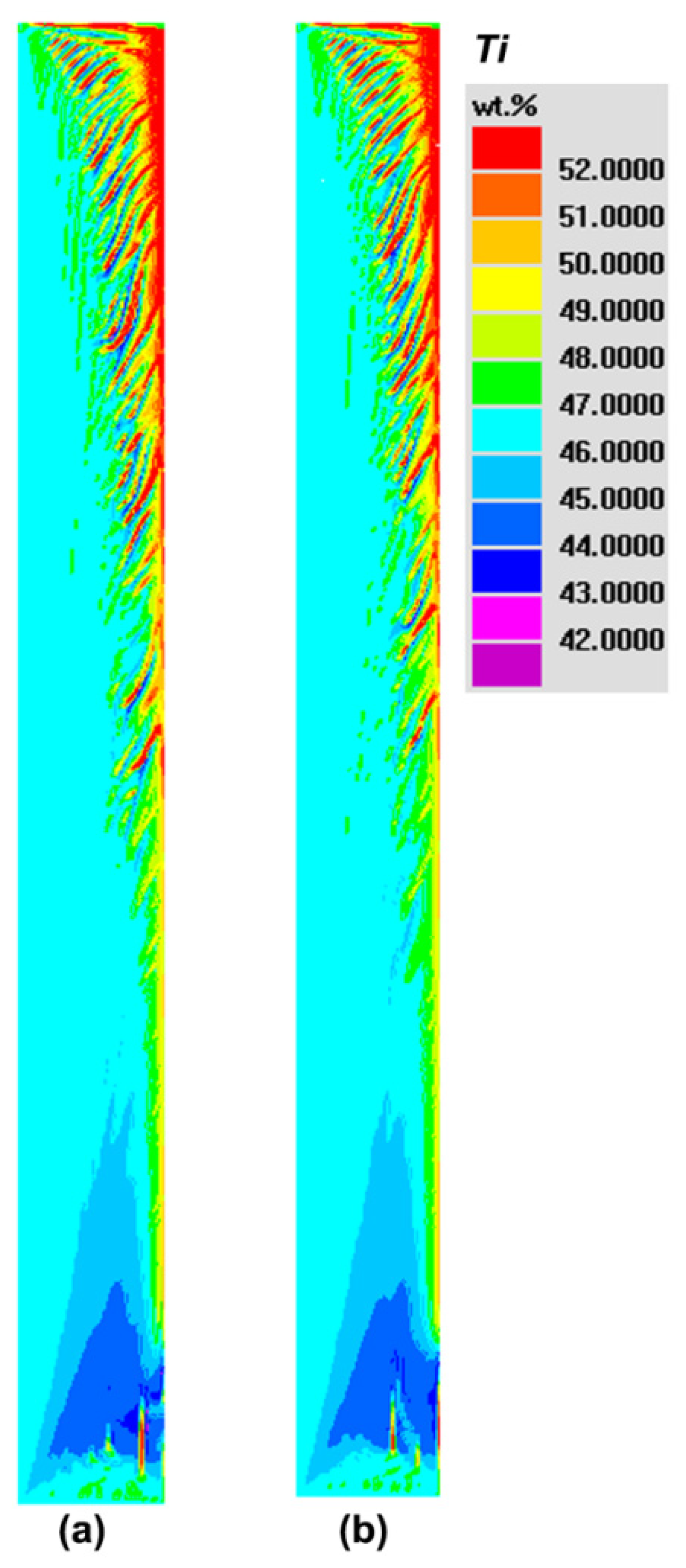

5.2. Effect of Cooling Rate on the Final Macrosegregation in NbTi Alloy

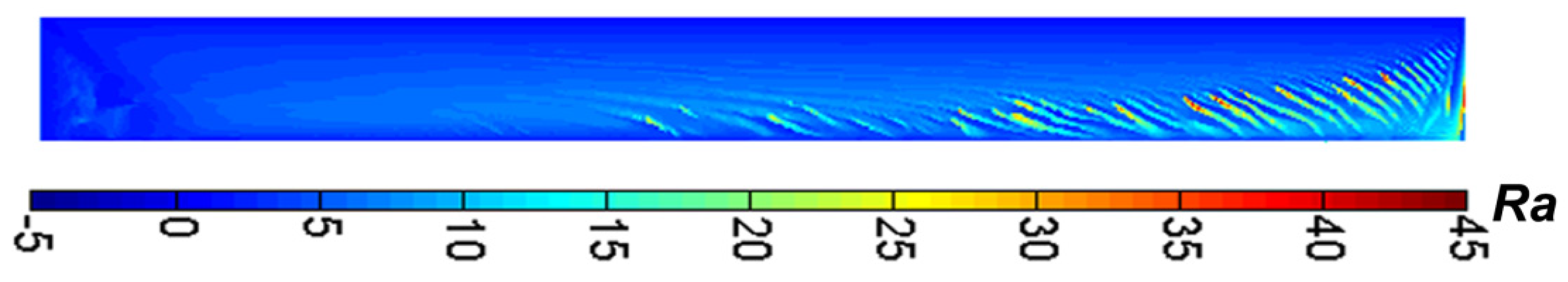

5.3. Rayleigh Number Criterion of CS Initiation in NbTi Alloy

6. Conclusions

- By comparing the macrostructure, grain size, compositional segregation and 3D details of channel segregation in He- and air-cooled ingots, it can be found that severer segregation in the air-cooled ingot is caused by coarser grains and the resulting stronger natural convection during solidification. After increasing cooling by He treatment, it reduces the interdendritic flow velocity, consequently lowering the positive, global and channel-type segregations. The key effect of the cooling capacity of the mold on macrosegregation including CS was sufficiently proven by the numerous simulations.

- Macrosegregation simulations show that the formation of CS in NbTi alloy includes two stages of channel initiation and growth. CS initiation is triggered by the flow instability and mush destabilization caused by the large density contrast and the strong thermo-solutal convection. Under the interaction of solidification and flow, the micro channel can continue to grow into a macro channel.

- Based on the Rayleigh number distribution and the final CS sites, the critical Ra criterion of 15 is successfully proposed in NbTi alloy for the first time. When the Rayleigh number is lower than the critical value, CS disappears. It provides a significant tool to predict CS and fabricate the homogenized NbTi ingot in engineering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kizu, K.; Tsuchiya, K.; Obana, T.; Takahata, K.; Hoshi, R.; Hamaguchi, S.; Nunoya, Y.; Yoshida, K.; Matsukawa, M.; Yanagi, N. Critical current measurement of prototype NbTi cable-in-conduit conductor for JT-60SA. Fusion Eng. Des. 2009, 84, 1058–1062. [Google Scholar] [CrossRef]

- Litaudon, X.; Abduallev, S.; Abhangi, M.; Abreu, P.; Afzal, M.; Aggarwal, K.M.; Ahlgren, T.; Ahn, J.; Aho-Mantila, L.; Aiba, N.; et al. Overview of the JET results in support to ITER. Nucl. Fusion 2017, 57, 102001. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Matsumoto, S.; Choi, S.; Teranishi, R.; Kiyoshi, T. A new structure for a magnetic field concentrator using NbTi sheet superconductors. Physica C 2011, 471, 1547–1549. [Google Scholar] [CrossRef]

- Shin, H.S.; Oh, S.Y.; Ha, D.W.; Oh, S.S. RRR behavior in NbTi superconducting cable due to fatigue damage. Physica C 2002, 378–381, 1148–1153. [Google Scholar] [CrossRef]

- Li, J.F.; Zhang, P.X.; Liu, X.H.; Li, J.S.; Feng, Y.; Wang, T.C.; Du, S.J.; Liu, W.T.; Grunblatt, G.; Verwaerde, C. Microstructure and properties of NbTi superconducting composite wire for ITER. Rare Metal Mat. Eng. 2009, 38, 263–265. [Google Scholar]

- Combeau, H.; Zaloznik, M.; Hans, S.; Richy, P.E. Prediction of macrosegregation in steel ingots: Influence of the motion and the morphology of equiaxed grains. Metall. Mater. Trans. B 2009, 40, 289–304. [Google Scholar] [CrossRef]

- Guillemot, G.; Gandin, C.A.; Bellet, M. Interaction between single grain solidification and macrosegregation: Application of a cellular automaton-finite element model. J. Cryst. Growth 2007, 303, 58–68. [Google Scholar] [CrossRef]

- Schneider, M.C.; Gu, J.P.; Beckermann, C.; Boettinger, W.J.; Kattner, U.R. Modeling of micro- and macrosegregation and freckle formation in single-crystal nickel-base superalloy directional solidification. Metall. Mater. Trans. A 1997, 28, 1517–1531. [Google Scholar] [CrossRef]

- Založnik, M.; Kumar, A.; Combeau, H. An operator splitting scheme for coupling macroscopic transport and grain growth in a two-phase multiscale solidification model: Part II—Application of the model. Comp. Mater. Sci. 2010, 48, 11–21. [Google Scholar] [CrossRef]

- Sawada, T.; Oikawa, K.; Anzai, K. Three-dimensional numerical simulation of channel segregation in directionally solidified Sn-20 mass% Bi ingot. Tetsu-to-Hagane 2013, 99, 135–140. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.; Ludwig, A. A three-phase model for mixed columnar-equiaxed solidification. Metall. Mater. Trans. A 2006, 37, 1613–1631. [Google Scholar] [CrossRef]

- Gu, J.P.; Beckermann, C. Simulation of convection and macrosegregation in a large steel ingot. Metall. Mater. Trans. A 1999, 30, 1357–1366. [Google Scholar] [CrossRef] [Green Version]

- Li, W.S.; Shen, H.F.; Zhang, X.; Liu, B.C. Modeling of Species Transport and Macrosegregation in Heavy Steel Ingots. Metall. Mater. Trans. B 2014, 45, 464–471. [Google Scholar] [CrossRef]

- Vreeman, C.J.; Incropera, F.P. The effect of free-floating dendrites and convection on macrosegregation in direct chill cast aluminum alloys Part II: Predictions for Al-Cu and Al-Mg alloys. Int. J. Heat Mass Transf. 2000, 43, 687–704. [Google Scholar] [CrossRef]

- Kumar, A.; Založnik, M.; Combeau, H.; Lesoult, G.; Kumar, A. Channel segregation during columnar solidification: Relation between mushy zone instability and mush permeability. Int. J. Heat Mass Transf. 2021, 164, 120602. [Google Scholar] [CrossRef]

- Plotkowski, A.; Krane, M.J.M. On the numerical prediction of channel segregation. Int. J. Heat Mass Transf. 2016, 100, 11–23. [Google Scholar] [CrossRef]

- Anderson, D.M.; Guba, P. Convective Phenomena in Mushy Layers. Annu. Rev. Fluid Mech. 2020, 52, 93–119. [Google Scholar] [CrossRef]

- Flemings, M.C. MIT studies on dendritic solidification from 1950 to 1970. J. Cryst. Growth 2020, 530, 125246. [Google Scholar] [CrossRef]

- Flemings, M.C. Our understanding of macrosegregation: Past and present. ISIJ Int. 2000, 40, 833–841. [Google Scholar] [CrossRef]

- Beckermann, C. Modelling of macrosegregation: Applications and future needs. Int. Mater. Rev. 2002, 47, 243–261. [Google Scholar] [CrossRef]

- Lesoult, G. Macrosegregation in steel strands and ingots: Characterisation, formation and consequences. Mater. Sci. Eng. A 2005, 413–414, 19–29. [Google Scholar] [CrossRef]

- Pickering, E.J. Macrosegregation in steel ingots: The applicability of modelling and characterisation techniques. ISIJ Int. 2013, 53, 935–949. [Google Scholar] [CrossRef] [Green Version]

- Ludwig, A.; Wu, M.; Kharicha, A. On macrosegregation. Metall. Mater. Trans. A 2015, 46, 4854–4867. [Google Scholar] [CrossRef]

- Cao, Y.F.; Chen, Y.; Li, D.Z. Formation mechanism of channel segregation in carbon steels by inclusion flotation: Microtomography characterization and multi-phase flow modeling. Acta Mater. 2016, 107, 325–336. [Google Scholar] [CrossRef]

- Cao, Y.F.; Chen, Y.; Li, D.Z.; Liu, H.W.; Fu, P.X. Comparison of channel segregation formation in model alloys and steels via numerical simulations, Metall. Mater. Trans. A 2016, 47, 2927–2939. [Google Scholar] [CrossRef]

- Auburtin, P.; Wang, T.; Cockcroft, S.L.; Mitchell, A. Freckle formation and freckle criterion in superalloy castings. Metall. Mater. Trans. B 2000, 31, 801–811. [Google Scholar] [CrossRef]

- Yuan, L.; Lee, P.D. A new mechanism for freckle initiation based on microstructural level simulation. Acta Mater. 2012, 60, 4917–4926. [Google Scholar] [CrossRef]

- Beckermann, C.; Gu, J.P.; Boettinger, W.J. Development of a freckle predictor via rayleigh number method for single-crystal nickel-base superalloy castings. Metall. Mater. Trans. A 2000, 31, 2545–2557. [Google Scholar] [CrossRef]

- Ramirez, J.C.; Beckermann, C. Evaluation of a rayleigh-number-based freckle criterion for Pb-Sn alloys and Ni-base superalloys. Metall. Mater. Trans. A 2003, 34, 1525–1536. [Google Scholar] [CrossRef]

- Valdes, J.; King, P.; Liu, X. On the formulation of a freckling criterion for Ni-based superalloy vacuum arc remelting ingots. Metall. Mater. Trans. A 2010, 41, 2408–2416. [Google Scholar] [CrossRef]

- Torabi Rad, M.; Kotas, P.; Beckermann, C. Rayleigh number criterion for formation of A-segregates in steel castings and ingots. Metall. Mater. Trans. A 2013, 44, 4266–4281. [Google Scholar]

- Pickering, E.J.; Al-Bermani, S.S.; Talamantes-Silva, J. Application of criterion for A-segregation in steel ingots. Mater. Sci. Tech. 2015, 31, 1313–1319. [Google Scholar] [CrossRef]

- Cao, Y.F.; Chen, Y.; Fu, P.X.; Liu, H.W.; Li, D.Z. The experimental characterization and numerical simulation of A-segregates in 27SiMn steel. Metall. Mater. Trans. A 2017, 48, 2260–2273. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Solutal expansion coefficient | βC | 0.8 × 10−2 (wt.%)−1 |

| Thermal expansion coefficient | βT | 1.87 × 10−5 K−1 |

| Liquidus slope | ml | −11.4 K (wt.%)−1 |

| Secondary dendritic arm spacing | ds | 200 μm |

| Dynamic viscosity | μl | 0.0042 Pa·s |

| Specific heat capacity | cp | 2000 J kg−1 K−1 |

| Latent heat | ∆H | 150,000 J kg−1 |

| Heat conductivity | λ | 30 W m−1 K−1 |

| Density | ρ | 5460 kg m−3 |

| Melting point of pure Nb | Tm | 2750.15 K |

| Equivalent partition coefficient | k | 0.75 |

| ρ, kg m−3 | Cp, J kg−1 K−1 | λ, W m−1 K−1 | T0, K | |

|---|---|---|---|---|

| Mold | 8900 | 385 | 380 | 323.15 |

| Interface heat-transfer coefficient hi, W m−2 K−1 | Liquid–top surface: 50 Mold–top surface: 50 Liquid–mold: 2000 Mold–air: 200 + 4 × 5.67 × 10−8 × 0.9 × T3 | |||

| Interface Heat-Transfer Coefficient, W m−2 K−1 | Average Interdendritic Flow Velocity 1, mm/s | Max. Interdendritic Flow Velocity 1, mm/s | Max. Ti Content 2, wt.% | GM 2 | Max. Ti Content in CS 2, wt.% | Max. Length of CS, mm2 | Number of CS 2 |

|---|---|---|---|---|---|---|---|

| 2000 | 0.105 | 0.944 | 63.66 | 0.0412 | 58.49 | 19.76 | 24 |

| 2500 | 0.104 | 0.924 | 63.39 | 0.0406 | 58.31 | 17.89 | 21 |

| 3000 | 0.103 | 0.794 | 63.29 | 0.0397 | 58.17 | 15.81 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, B.; Chen, Z.; Cao, Y.; Liu, Y.; Kang, X.; Chen, Y.; Liu, H.; Fu, P.; Luan, Y.; Li, D. Characteristics, Mechanism and Criterion of Channel Segregation in NbTi Alloy via Numerical Simulations and Experimental Characterizations. Materials 2021, 14, 796. https://doi.org/10.3390/ma14040796

Zhu B, Chen Z, Cao Y, Liu Y, Kang X, Chen Y, Liu H, Fu P, Luan Y, Li D. Characteristics, Mechanism and Criterion of Channel Segregation in NbTi Alloy via Numerical Simulations and Experimental Characterizations. Materials. 2021; 14(4):796. https://doi.org/10.3390/ma14040796

Chicago/Turabian StyleZhu, Baohui, Zhenzhen Chen, Yanfei Cao, Yanchang Liu, Xiuhong Kang, Yun Chen, Hongwei Liu, Paixian Fu, Yikun Luan, and Dianzhong Li. 2021. "Characteristics, Mechanism and Criterion of Channel Segregation in NbTi Alloy via Numerical Simulations and Experimental Characterizations" Materials 14, no. 4: 796. https://doi.org/10.3390/ma14040796

APA StyleZhu, B., Chen, Z., Cao, Y., Liu, Y., Kang, X., Chen, Y., Liu, H., Fu, P., Luan, Y., & Li, D. (2021). Characteristics, Mechanism and Criterion of Channel Segregation in NbTi Alloy via Numerical Simulations and Experimental Characterizations. Materials, 14(4), 796. https://doi.org/10.3390/ma14040796