Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices

Abstract

:1. Introduction

2. Approach and Bibliometric Method

3. Material Properties of Polymer Powder Feedstocks

3.1. General Properties and Material Type

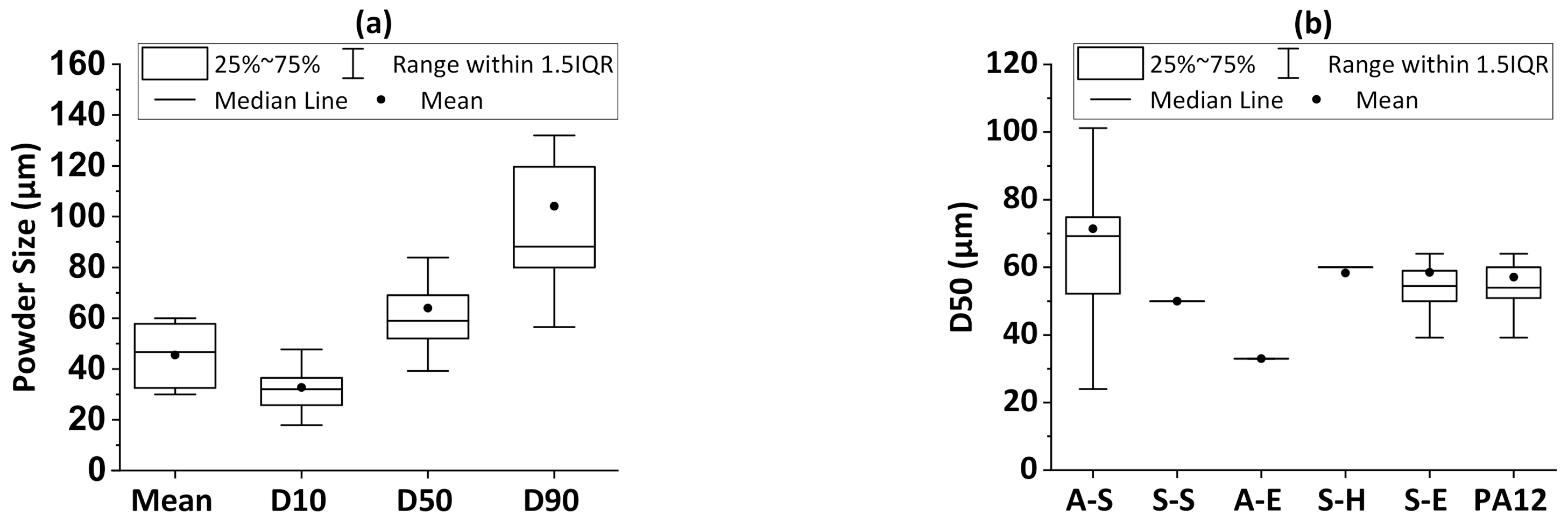

3.2. Powder Size

3.3. Flowability and Processing Window

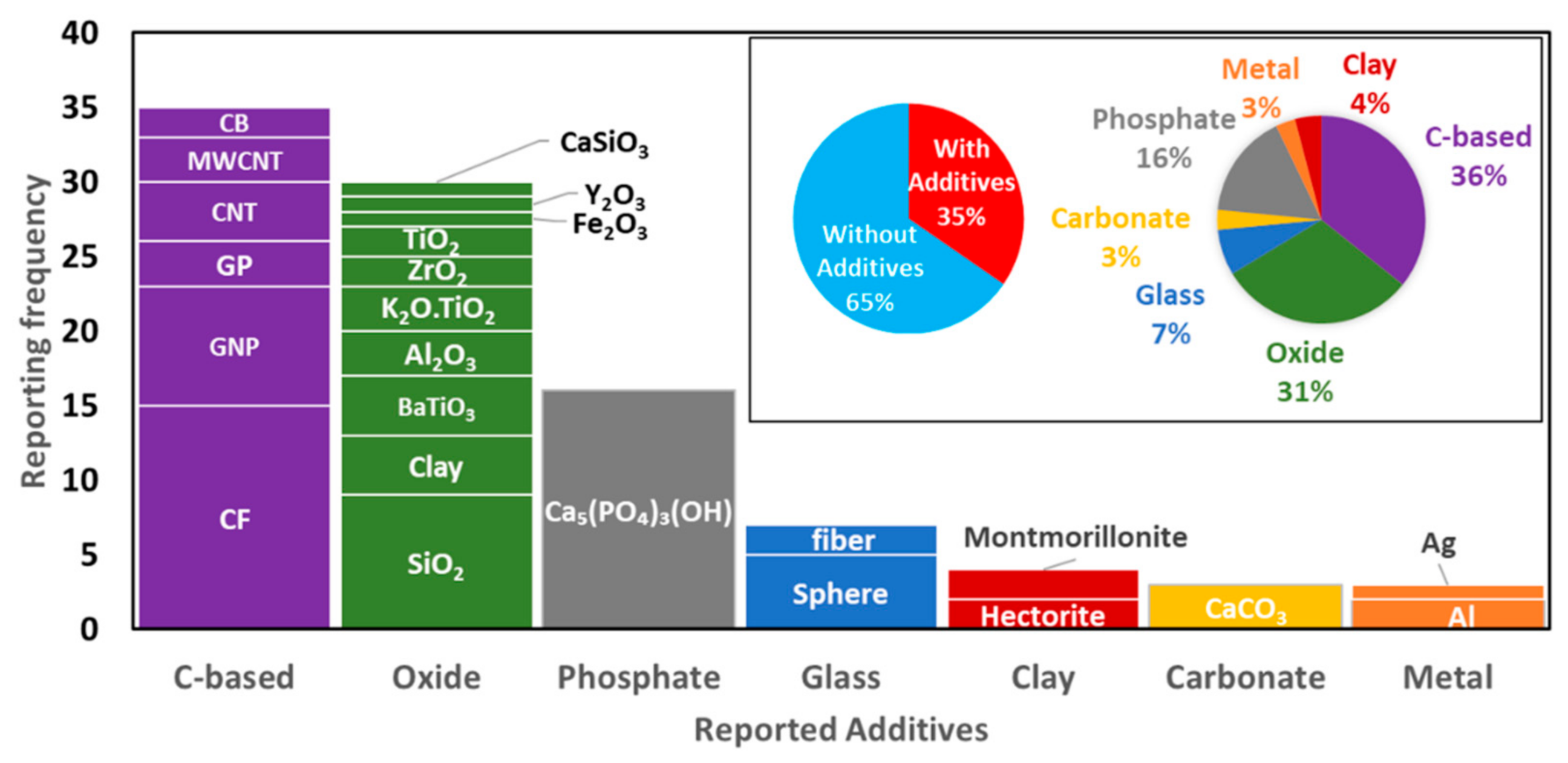

3.4. Additives

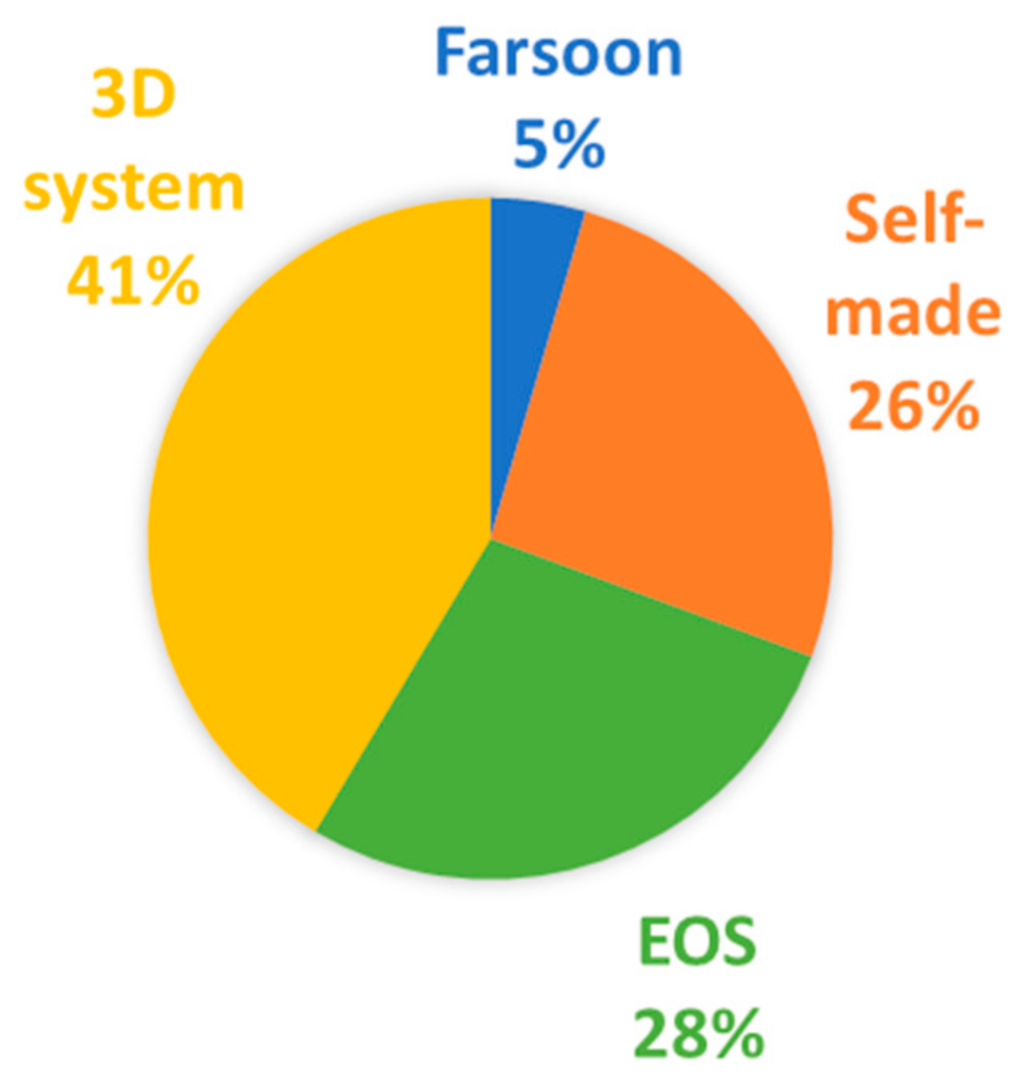

4. L-PBF Machine and Process Parameters

5. As-Built Part Properties of Polymer Powder Feedstocks

6. Quantification of Cross-Correlations by Principle Component Analysis of the Most Reported Material, Process, and as-Built Part Properties

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Campbell, I.; Diegel, O.; Kowen, J.; Wohlers, T. Wohlers Report. 3D Printing and Additive Manufacturing State of the Industry; Wohlers Associates: Fort Collins, CO, USA, 2019. [Google Scholar]

- Kusoglu, I.M.; Gökce, B.; Barcikowski, S. Research trends in laser powder bed fusion of Al alloys within the last decade. Addit. Manuf. 2020, 36, 101489. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part. B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Ligon, S.M.; Samuel, C.; Liska, R.; Stampfl, J.; Gurr, M.; Malhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [Green Version]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric composites for powder-based additive manufacturing: Materials and applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- EOS 3D Printing Materials, Plastics for Additive Manufacturing, SLS Materials and Processes. Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-plastic/sls-polymer-materials (accessed on 26 February 2021).

- Eshkalak, S.K.; Ghomi, E.R.; Dai, Y.; Choudhury, D.; Ramakrishna, S. The role of three-dimensional printing in healthcare and medicine. Mater. Des. 2020, 194, 1–15. [Google Scholar] [CrossRef]

- Schmid, M.; Wegener, K. Additive Manufacturing: Polymers Applicable for Laser Sintering (LS). Procedia Eng. 2016, 149, 457–464. [Google Scholar] [CrossRef] [Green Version]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- ISO/ASTM 52910:2018—Additive Manufacturing—Design—Requirements, Guidelines and Recommendations. Available online: https://www.iso.org/standard/67289.html (accessed on 14 February 2020).

- Duan, B.; Wang, M.; Zhou, W.Y.; Cheung, W.L.; Li, Z.Y.; Lu, W.W. Three-dimensional nanocomposite scaffolds fabricated via selective laser sintering for bone tissue engineering. Acta Biomater. 2010, 6, 4495–4505. [Google Scholar] [CrossRef]

- Duan, B.; Wang, M. Customized Ca–P/PHBV nanocomposite scaffolds for bone tissue engineering: Design, fabrication, surface modification and sustained release of growth factor. J. R. Soc. Interface 2010, 7, S615–S629. [Google Scholar] [CrossRef] [Green Version]

- Goodridge, R.; Shofner, M.; Hague, R.; McClelland, M.; Schlea, M.; Johnson, R.; Tuck, C. Processing of a Polyamide-12/carbon nanofibre composite by laser sintering. Polym. Test. 2011, 30, 94–100. [Google Scholar] [CrossRef]

- Van Hooreweder, B.; Moens, D.; Boonen, R.; Kruth, J.-P.; Sas, P. On the difference in material structure and fatigue properties of nylon specimens produced by injection molding and selective laser sintering. Polym. Test. 2013, 32, 972–981. [Google Scholar] [CrossRef]

- Athreya, S.R.; Kalaitzidou, K.; Das, S. Processing and characterization of a carbon black-filled electrically conductive Nylon-12 nanocomposite produced by selective laser sintering. Mater. Sci. Eng. A 2010, 527, 2637–2642. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Xu, L.; Shi, Y. Preparation, characterization and processing of carbon fibre/polyamide-12 composites for selective laser sintering. Compos. Sci. Technol. 2011, 71, 1834–1841. [Google Scholar] [CrossRef]

- Zhao, M.; Wudy, K.; Drummer, D. Crystallization kinetics of polyamide 12 during selective laser sintering. Polymers 2018, 168, 1–14. [Google Scholar]

- Athreya, S.R.; Kalaitzidou, K.; Das, S. Mechanical and microstructural properties of Nylon-12/carbon black composites: Selective laser sintering versus melt compounding and injection molding. Compos. Sci. Technol. 2011, 71, 506–510. [Google Scholar] [CrossRef]

- Verbelen, L.; Dadbakhsh, S.; van den Eynde, M.; Kruth, J.P.; Goderis, B.; van Puyvelde, P. Characterization of polyamide powders for determination of laser sintering processability. Eur. Polym. J. 2016, 75, 163–174. [Google Scholar] [CrossRef]

- Ziegelmeier, S.; Christou, P.; Wöllecke, F.; Tuck, C.; Goodridge, R.; Hague, R.; Krampe, E.; Wintermantel, E. An experimental study into the effects of bulk and flow behaviour oflaser sintering polymer powders on resulting part properties. J. Mater. Process. Technol. 2015, 215, 239–250. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Paggi, R.A.; Lago, A.; Beal, V.E. Microstructural and mechanical characterization of PA12/MWCNTs nanocomposite manufactured by selective laser sintering. Polym. Test. 2011, 30, 611–615. [Google Scholar] [CrossRef] [Green Version]

- Bai, J.; Goodridge, R.D.; Hague, R.J.; Song, M.; Okamoto, M. Influence of carbon nanotubes on the rheology and dynamic mechanical properties of polyamide-12 for laser sintering. Polym. Test. 2014, 36, 95–100. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, J.; Sachs, M.; Blümel, C.; Winzer, B.; Toni, F.; Wirth, K.-E.; Peukert, W. A Novel Process Chain for the Production of Spherical SLS Polymer Powders with Good Flowability. Procedia Eng. 2015, 102, 550–556. [Google Scholar] [CrossRef] [Green Version]

- Hupfeld, T.; Laumer, T.; Stichel, T.; Schuffenhauer, T.; Heberle, J.; Schmidt, M.; Barcikowski, S.; Gökce, B. A new approach to coat PA12 powders with laser-generated nanoparticles for selective laser sintering. Procedia CIRP 2018, 74, 244–248. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Pande, S.; Bobade, S.M.; Kumar, S. A Targeted Functional Value Based Nanoclay/PA12 Composite Material Development for Selective Laser Sintering Process. Procedia Manuf. 2018, 21, 630–637. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Hague, R.J.M.; Song, M. Improving the Mechanical Properties of Laser-Sintered Polyamide 12 through Incorporation of Carbon Nanotubes. Polym. Eng. Sci. 2013, 53, 1937–1946. [Google Scholar] [CrossRef]

- Chunze, S.; Yusheng, Y.; Jinsong, L.; Jinhui, A. Nanosilica/Nylon-12 composite powder for Selective Laser Sintering. J. Reinf. Plast. Compos. 2009, 28, 2889–2901. [Google Scholar] [CrossRef]

- Kim, H.C.; Hahn, H.T.; Yang, Y.S. Synthesis of PA12/functionalized GNP nanocomposite powders for the selective laser sintering process. J. Compos. Mater. 2012, 47, 501–509. [Google Scholar] [CrossRef]

- Jing, W.; Hui, C.; Qiong, W.; Hongbo, L.; Zhanjun, L. Surface modification of carbon fibers and the selective laser sintering of modified carbon fiber/nylon 12 composite powder. Mater. Des. 2017, 116, 253–260. [Google Scholar] [CrossRef]

- Yuan, S.; Zheng, Y.; Chua, C.K.; Yan, Q.; Zhou, K. Electrical and thermal conductivities of MWCNT/polymer composites fabricated by selective laser sintering. Compos. Part. A Appl. Sci. Manuf. 2018, 105, 203–213. [Google Scholar] [CrossRef]

- Jain, P.K.; Pandey, P.M.; Rao, P. Selective laser sintering of clay-reinforced polyamide. Polym. Compos. 2009, 31, 732–743. [Google Scholar] [CrossRef]

- Wudy, K.; Lanzl, L.; Drummer, D. Selective laser sintering of filled polymer systems: Bulk properties and laser beam material interection. Phys. Procedia 2016, 83, 991–1002. [Google Scholar] [CrossRef] [Green Version]

- Wegner, A.; Witt, G. Adjustment of isotropic part properties in laser sintering based on adapted double laser exposure strategies. Opt. Laser Technol. 2019, 109, 381–388. [Google Scholar] [CrossRef]

- Verbelen, L.; Dadbakhsh, S.; Eynde, M.V.D.; Strobbe, D.; Kruth, J.-P.; Goderis, B.; Van Puyvelde, P. Analysis of the material properties involved in laser sintering of thermoplastic polyurethane. Addit. Manuf. 2017, 15, 12–19. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Verbelen, L.; Vandeputte, T.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.-P. Effect of Powder Size and Shape on the SLS Processability and Mechanical Properties of a TPU Elastomer. Phys. Procedia 2016, 83, 971–980. [Google Scholar] [CrossRef] [Green Version]

- Wahap, M.S.; Dalgamo, K.W.; Cochrane, R.F.; Hassan, S. Development of Polymer Nanocomposites for Rapid Prototyping Process. Proc. World Congr. Eng. 2009, 2, 1–6. [Google Scholar]

- Drummer, D.; Drexler, M.; Wudy, K. Impact of Heating Rate During Exposure of Laser Molten Parts on the Processing Window of PA12 Powder. Phys. Procedia 2014, 56, 184–192. [Google Scholar] [CrossRef] [Green Version]

- Athreya, S.R.; Kalaitzidou, K.; Das, S. Microstructure, thermomechanical properties, and electrical conductivity of carbon black-filled nylon-12 nanocomposites prepared by selective laser sintering. Polym. Eng. Sci. 2011, 52, 12–20. [Google Scholar] [CrossRef]

- Flodberg, G.; Pettersson, H.; Yang, L. Pore analysis and mechanical performance of selective laser sintered objects. Addit. Manuf. 2018, 24, 307–315. [Google Scholar] [CrossRef]

- Wudy, K.; Drummer, D. Aging effects of polyamide 12 in selective laser sintering: Molecular weight distribution and thermal properties. Addit. Manuf. 2019, 25, 1–9. [Google Scholar] [CrossRef]

- Eynde, M.V.D.; Verbelen, L.; Van Puyvelde, P. Assessing polymer powder flow for the application of laser sintering. Powder Technol. 2015, 286, 151–155. [Google Scholar] [CrossRef] [Green Version]

- Pavan, M.; Craeghs, T.; Verhelst, R.; Ducatteeuw, O.; Kruth, J.P.; Dewulf, W. CT-based quality control of Laser Sintering of Polymers. Case Stud. Nondestruct. Test. Eval. 2016, 6, 62–68. [Google Scholar] [CrossRef] [Green Version]

- Dechet, M.A.; Goblirsch, A.; Romeis, S.; Zhao, M.; Lanyi, F.J.; Kaschta, J.; Schubert, D.W.; Drummer, D.; Peukert, W.; Schmidt, J. Production of polyamide 11 microparticles for Additive Manufacturing by liquid-liquid phase separation and precipitation. Chem. Eng. Sci. 2019, 197, 11–25. [Google Scholar] [CrossRef]

- Drummer, D.; Rietzel, D.; Kühnlein, F. Development of a characterization approach for the sintering behavior of new thermoplastics for selective laser sintering. Phys. Procedia 2010, 5, 533–542. [Google Scholar] [CrossRef] [Green Version]

- Shen, F.; Yuan, S.; Chua, C.K.; Zhou, K. Development of process efficiency maps for selective laser sintering of polymeric composite powders: Modeling and experimental testing. J. Mater. Process. Technol. 2018, 254, 52–59. [Google Scholar] [CrossRef]

- Wegner, A.; Oehler, M.; Ünlü, T. Development of a new polybutylene terephthalate material for laser sintering process. Procedia CIRP 2018, 74, 254–258. [Google Scholar] [CrossRef]

- Yan, M.; Tian, X.; Peng, G.; Li, D.; Zhang, X. High temperature rheological behavior and sintering kinetics of CF/PEEK composites during selective laser sintering. Compos. Sci. Technol. 2018, 165, 140–147. [Google Scholar] [CrossRef]

- Salazar, A.; Rico, A.; Rodriguez, J.; Escudero, J.S.; Seltzer, R.; Cutillas, F.M.D.L.E. Fatigue crack growth of SLS polyamide 12: Effect of reinforcement and temperature. Compos. Part B Eng. 2014, 59, 285–292. [Google Scholar] [CrossRef]

- Lindberg, A.; Alfthan, J.; Pettersson, H.; Flodberg, G.; Yang, L. Mechanical performance of polymer powder bed fused objects—FEM simulation and verification. Addit. Manuf. 2018, 24, 577–586. [Google Scholar] [CrossRef]

- Berretta, S.; Ghita, O.; Evans, K. Morphology of polymeric powders in Laser Sintering (LS): From Polyamide to new PEEK powders. Eur. Polym. J. 2014, 59, 218–229. [Google Scholar] [CrossRef]

- Wegner, A. New Polymer Materials for the Laser Sintering Process: Polypropylene and Others. Phys. Procedia 2016, 83, 1003–1012. [Google Scholar] [CrossRef] [Green Version]

- Drummer, D.; Medina-Hernández, M.; Drexler, M.; Wudy, K. Polymer Powder Production for Laser Melting Through Immiscible Blends. Procedia Eng. 2015, 102, 1918–1925. [Google Scholar] [CrossRef] [Green Version]

- Franco, A.; Lanzetta, M.; Romoli, L. Experimental analysis of selective laser sintering of polyamide powders: An energy perspective. J. Clean. Prod. 2010, 18, 1722–1730. [Google Scholar] [CrossRef] [Green Version]

- Laumer, T.; Stichel, T.; Nagulin, K.; Schmidt, M. Optical analysis of polymer powder materials for Se-lective Laser Sintering. Polym. Test. 2016, 56, 207–213. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Verbelen, L.; Verkinderen, O.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.-P. Effect of PA12 powder reuse on coalescence behaviour and microstructure of SLS parts. Eur. Polym. J. 2017, 92, 250–262. [Google Scholar] [CrossRef]

- Peyre, P.; Rouchausse, Y.; Defauchy, D.; Régnier, G. Experimental and numerical analysis of the selective laser sintering (SLS) of PA12 and PEKK semi-crystalline polymers. J. Mater. Process. Technol. 2015, 225, 326–336. [Google Scholar] [CrossRef]

- Greiner, S.; Wudy, K.; Wörz, A.; Drummer, D. Thermographic investigation of laser-induced temperature fields in selective laser beam melting of polymers. Opt. Laser Technol. 2019, 109, 569–576. [Google Scholar] [CrossRef]

- Greiner, S.; Wudy, K.; Lanzl, L.; Drummer, D. Selective laser sintering of polymer blends: Bulk properties and process behavior. Polym. Test. 2017, 64, 136–144. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Scherbakov, V. Selective Laser Sintering of Biopolymers with Micro and Nano Ceramic Additives for Medicine. Phys. Procedia 2012, 39, 491–499. [Google Scholar] [CrossRef] [Green Version]

- Drexler, M.; Lexow, M.; Drummer, D. Selective Laser Melting of Polymer Powder—Part Mechanics as Function of Exposure Speed. Phys. Procedia 2015, 78, 328–336. [Google Scholar] [CrossRef] [Green Version]

- Tian, X.; Peng, G.; Yan, M.; He, S.; Yao, R. Process prediction of selective laser sintering based on heat transfer analysis for polyamide composite powders. Int. J. Heat Mass Transf. 2018, 120, 379–386. [Google Scholar] [CrossRef]

- Mokrane, A.; Boutaous, M.; Xin, S. Process of selective laser sintering of polymer powders: Modeling, simulation, and validation. CR Mecanique 2018, 346, 1087–1103. [Google Scholar] [CrossRef]

- Bourell, D.L.; Watt, T.J.; Leigh, D.K.; Fulcher, B. Performance Limitations in Polymer Laser Sintering. Phys. Procedia 2014, 56, 147–156. [Google Scholar] [CrossRef] [Green Version]

- Drummer, D.; Wudy, K.; Kühnlein, F.; Drexler, M. Polymer blends for Selective Laser Sintering: Material and process requirements. Phys. Procedia 2012, 39, 509–517. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Rouholamin, D.; Davies, R.; Ghita, O.R. Powder characteristics, microstructure and properties of graphite platelet reinforced Poly Ether Ether Ketone composites in High Temperature Laser Sinter-ing (HT-LS). Mater. Des. 2015, 88, 1310–1320. [Google Scholar] [CrossRef] [Green Version]

- Berretta, S.; Evans, K.E.; Ghita, O.R. Predicting processing parameters in high temperature laser sintering (HT-LS) from powder properties. Mater. Des. 2016, 105, 301–314. [Google Scholar] [CrossRef] [Green Version]

- Qi, F.; Chen, N.; Wang, Q. Preparation of PA11/BaTiO3 nanocomposite powders with improved processability, dielectric and piezoelectric properties for use in selective laser sintering. Mater. Des. 2017, 131, 135–143. [Google Scholar] [CrossRef]

- Wang, G.; Wang, P.; Zhen, Z.; Zhang, W.; Ji, J. Preparation of PA12 microspheres with tunable morphology and size for use in SLS processing. Mater. Des. 2015, 87, 656–662. [Google Scholar] [CrossRef]

- Wudy, K.; Greiner, S.; Zhao, M.; Drummer, D. Selective laser beam melting of polymers: In situ and offline measurements for process adapted thermal characterization. Procedia CIRP 2018, 74, 238–243. [Google Scholar] [CrossRef]

- Vasquez, M.; Haworth, B.; Hopkinson, N. Methods for quantifying the stable sintering region in laser sintered polyamide-12. Polym. Eng. Sci. 2013, 53, 1230–1240. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.; Wu, H.; Zhu, W.; Yang, L.; Li, Z.; Yan, C.; Wen, S.; Shi, Y. Investigation into the processability, recyclability and crystalline structure of selective laser sintered Polyamide 6 in comparison with Polyamide 12. Polym. Test. 2018, 69, 366–374. [Google Scholar] [CrossRef]

- Lanzl, L.; Wudy, K.; Drexler, M.; Drummer, D. Laser-High-Speed-DSC: Process-oriented thermal analysis of PA12 in Selective Laser Sinering. Phys. Procedia 2016, 83, 981–990. [Google Scholar] [CrossRef] [Green Version]

- Schmid, M.; Kleijnen, R.; Vetterli, M.; Wegener, K. Influence of the Origin of Polyamide 12 Powder on the Laser Sintering Process and Laser Sintered Parts. Appl. Sci. 2017, 7, 462. [Google Scholar] [CrossRef] [Green Version]

- Eosoly, S.; Vrana, N.E.; Lohfeld, S.; Hindie, M.; Looney, L. Interaction of cell culture with composition effects on the mechanical properties of polycaprolactone-hydroxyapatite scaffolds fabricated via selective laser sintering (SLS). Mater. Sci. Eng. C 2012, 32, 2250–2257. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Leite, J.L.; Vieira, L.; Pires, A.T.N.; Roesler, C. Mechanical properties of PA6/PA12 blend specimens prepared by selective laser sintering. Polym. Test. 2012, 31, 411–416. [Google Scholar] [CrossRef] [Green Version]

- Beitz, S.; Uerlich, R.; Bokelmann, T.; Diener, A.; Vietor, T.; Kwade, A. Influence of Powder Deposition on Powder Bed and Specimen Properties. Materials 2019, 12, 297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, B.; Berretta, S.; Evans, K.; Smith, K.; Ghita, O. A primary study into graphene/polyether ether ketone (PEEK) nanocomposite for laser sintering. Appl. Surf. Sci. 2018, 428, 1018–1028. [Google Scholar] [CrossRef] [Green Version]

- Blümel, C.; Sachs, M.; Laumer, T.; Winzer, B.; Schmidt, J.; Schmidt, M.; Peukert, W.; Wirth, K.-E. In-creasing flowability and bulk density of PE-HD powders by a dry particle coating process and impact on LBM processes. Rapid Prototyp. J. 2015, 6, 697–704. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Zhang, Z.; Kruth, J.-P.; Vleugels, J. Additive manufacturing of zirconia parts by indirect selective laser sintering. J. Eur. Ceram. Soc. 2014, 34, 81–89. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Kruth, J.-P.; Vleugels, J. Additive manufacturing of alumina parts by indirect selective laser sintering and post processing. J. Mater. Process. Technol. 2013, 213, 1484–1494. [Google Scholar] [CrossRef]

- Xia, Y.; Zhou, P.; Cheng, X.; Xie, Y.; Liang, C.; Li, C.; Xu, S. Selective laser sintering fabrication of nano-hydroxyapatite/poly-ε-caprolactone scaffolds for bone tissue engineering applications. Int. J. Nanomed. 2013, 8, 4197–4213. [Google Scholar]

- Duan, B.; Cheung, W.L.; Wang, M. Optimized fabrication of Ca–P/PHBV nanocomposite scaffolds via selective laser sintering for bone tissue engineering. Biofabrication 2011, 3, 015001. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Boury, S.; Neirinck, B.; Kruth, J.-P.; Vleugels, J. Preparation and indirect selective laser sintering of alumina/PA microspheres. Ceram. Int. 2012, 38, 1241–1247. [Google Scholar] [CrossRef]

- Dupin, S.; Lame, O.; Barrès, C.; Charmeau, J.-Y. Microstructural origin of physical and mechanical properties of polyamide 12 processed by laser sintering. Eur. Polym. J. 2012, 48, 1611–1621. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, A.; Wegener, K. Materials perspective of polymers for additive manufacturing with selective laser sintering. J. Mater. Res. 2014, 29, 1824–1832. [Google Scholar] [CrossRef] [Green Version]

- Maskery, I.; Sturm, L.; Aremu, A.O.; Panesar, A.; Williams, C.B.; Tuck, C.J.; Wildman, R.D.; Ash-croft, I.A.; Hague, R.J.M. Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Beal, V.E.; Paggi, R.A.; Salmoria, G.V.; Lago, A. Statistical evaluation of laser energy density effect on mechanical properties of polyamide parts manufactured by selective laser sintering. J. Appl. Polym. Sci. 2009, 113, 2910–2919. [Google Scholar] [CrossRef]

- Jain, P.K.; Pandey, P.M.; Rao, P.V.M. Effect of delay time on part strength in selective laser sintering. Int. J. Adv. Manuf. Technol. 2009, 43, 117–126. [Google Scholar] [CrossRef]

- Bai, J.; Yuan, S.; Shen, F.; Zhang, B.; Chua, C.K.; Zhou, K.; Wei, J. Toughening of polyamide 11 with carbon nanotubes for additive manufacturing. Virtual Phys. Prototyp. 2017, 12, 1–6. [Google Scholar] [CrossRef]

- Türk, D.-A.; Brenni, F.; Zogg, M.; Meboldt, M. Mechanical characterization of 3D printed polymers for fiber reinforced polymers processing. Mater. Des. 2017, 118, 256–265. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Klauss, P.; Paggi, R.A.; Kanis, L.A.; Lago, A. Structure and mechanical properties of cellulose based scaffolds fabricated by selective laser sintering. Polym. Test. 2009, 28, 648–652. [Google Scholar] [CrossRef]

- Van Hooreweder, B.; De Coninck, F.; Moens, D.; Boonen, R.; Sas, P. Microstructural characterization of SLS-PA12 specimens under dynamic tension/compression excitation. Polym. Test. 2010, 29, 319–326. [Google Scholar] [CrossRef]

- Vasquez, M.; Haworth, B.; Hopkinson, N. Optimum sintering region for laser sintered nylon-12. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2011, 225, 2240–2248. [Google Scholar] [CrossRef] [Green Version]

- Kenzari, S.; Bonina, D.; Dubois, J.; Fournée, V. Quasicrystal–polymer composites for selective laser sintering technology. Mater. Des. 2012, 35, 691–695. [Google Scholar] [CrossRef]

- Vesenjak, M.; Krstulovi-Opara, L.; Ren, Z.; Domazet, Z. Cell shape effect evaluation of polyamide cel-lular structures. Polym. Test. 2010, 29, 991–994. [Google Scholar] [CrossRef]

- Ghita, O.; James, E.; Trimble, R.; Evans, K.E. Physico-chemical behaviour of Poly (Ether Ketone) (PEK) in High Temperature Laser Sintering (HT-LS). J. Mater. Process. Technol. 2014, 214, 969–978. [Google Scholar] [CrossRef] [Green Version]

- Duan, B.; Wang, M. Encapsulation and release of biomolecules from Ca-P/PHBV nanocomposite microspheres and three-dimensional scaffolds fabricated by selective laser sintering. Polym. Degrad. Stab. 2010, 95, 1655–1664. [Google Scholar] [CrossRef]

- Lindner, M.; Hoeges, S.; Meiners, W.; Wissenbach, K.; Smeets, R.; Telle, R.; Poprawe, R.; Fischer, H. Manufacturing of individual biodegradable bone substitute implants using selective laser melting tech-nique. J. Biomed. Mater. Res. A 2011, 97, 466–471. [Google Scholar] [CrossRef]

- Van Bael, S.; Desmet, T.; Chai, Y.C.; Pyka, G.; Dubruel, P.; Kruth, J.-P.; Schrooten, J. In vitro cell-biological performance and structural characterization of selective laser sintered and plasma surface functionalized polycaprolactone scaffolds for bone regeneration. Mater. Sci. Eng. C 2013, 33, 3404–3412. [Google Scholar] [CrossRef]

- Cooke, W.; Tomlinson, R.A.; Burguete, R.; Johns, D.; Vanard, G. Anisotropy, homogeneity and ageing in an SLS polymer. Rapid Prototyp. J. 2011, 17, 269–279. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Yuan, S.; Zhou, K.; Chua, C.K.; Wei, J. Thermal Influence of CNT on the Polyamide 12 Nanocomposite for Selective Laser Sintering. Molecules 2015, 20, 19041–19050. [Google Scholar] [CrossRef]

- Savalani, M.M.; Hao, L.; Dickens, P.M.; Zhang, Y.; Tanner, K.E. The effects and interactions of fabrication parameters on the properties of selective laser sintered hydroxyapatite polyamide composite bio-materials. Rapid Prototyp. J. 2012, 18, 16–27. [Google Scholar] [CrossRef]

- Griessbach, S.; Lach, R.; Grellmann, W. Structure–property correlations of laser sintered nylon 12 for dynamic dye testing of plastic parts. Polym. Test. 2010, 29, 1026–1030. [Google Scholar] [CrossRef]

- Bai, J.; Zhang, B.; Song, J.; Bi, G.; Wang, P.; Wie, J. The effect of processing conditions on the mechanical properties of polyethylene produced by selective laser sintering. Polym. Test. 2016, 52, 89–93. [Google Scholar] [CrossRef]

- Qi, F.; Chen, N.; Wang, Q. Dielectric and piezoelectric properties in selective laser sintered polyamide11/BaTiO3/CNT ternary nanocomposites. Mater. Des. 2018, 143, 72–80. [Google Scholar] [CrossRef]

- Schmidt, J.; Sachs, M.; Fanselow, S.; Zhao, M.; Romeis, S.; Drummer, D.; Wirth, K.-E.; Peukert, W. Optimized polybutylenetere phthalate powders for selective laser beam melting. Chem. Eng. Sci. 2016, 156, 1–10. [Google Scholar] [CrossRef]

- Shuai, C.; Yang, B.; Peng, S.; Li, Z. Development of composite porous scaffolds based on poly(lactide-co-glycolide)/nano-hydroxyapatite via selective laser sintering. Int. J. Adv. Manuf. Technol. 2013, 69, 51–57. [Google Scholar] [CrossRef]

- Franco, A.; Romoli, L. Characterization of laser energy consumption in sintering of polymer based powders. J. Mater. Process. Technol. 2012, 212, 917–926. [Google Scholar] [CrossRef]

- Goodridge, R.; Hague, R.; Tuck, C. Effect of long-term ageing on the tensile properties of a polyamide 12 laser sintering material. Polym. Test. 2010, 29, 483–493. [Google Scholar] [CrossRef]

- Yang, J.; Shi, Y.; Yan, C. Selective laser sintering of polyamide 12/potassium titanium whisker composites. J. Appl. Polym. Sci. 2010, 117, 2196–2204. [Google Scholar] [CrossRef]

- Majewski, C.; Hopkinson, N. Effect of section thickness and build orientation on tensile properties and material characteristics of laser sintered nylon-12 parts. Rapid Prototyp. J. 2011, 17, 176–180. [Google Scholar] [CrossRef]

- Meyer, K.; Zimmermann, I. Effect of glidants in binary powder mixtures. Powder Technol. 2004, 139, 40–54. [Google Scholar] [CrossRef]

- Hupfeld, T.; Sommereyns, A.; Schuffenhauer, T.; Zhuravlev, E.; Krebs, M.; Gann, S.; Keßler, O.; Schmidt, M.; Gökce, B.; Barcikowski, S. How colloidal surface additivation of polyamide 12 powders with well-dispersed silver nanoparticles influences the crystallization already at low 0.01 vol%. Addit. Manuf. 2020, 36, 101419. [Google Scholar] [CrossRef]

- Hupfeld, T.; Salamon, S.; Landers, J.; Sommereyns, A.; Doñate-Buendía, C.; Schmidt, J.; Wende, H.; Schmidt, M.; Barcikowski, S.; Gökce, B. 3D printing of magnetic parts by laser powder bed fusion of iron oxide nanoparticle functionalized polyamide powders. J. Mater. Chem. C 2020, C 8, 12204–12217. [Google Scholar] [CrossRef]

- Hupfeld, T.; Sommereyns, A.; Riahi, F.; Doñate-Buendía, C.; Gann, S.; Schmidt, M.; Gökce, B.; Barcikowski, S. Analysis of the nanoparticle dispersion and its effect on the crystalline microstructure in carbon-additivated PA12 feedstock material for laser powder bed fusion. Materials 2020, 13, 3312. [Google Scholar] [CrossRef] [PubMed]

- Hupfeld, T.; Wegner, A.; Blanke, M.; Doñate-Buendía, C.; Sharov, V.; Nieskens, S.; Piechotta, M.; Giese, M.; Barcikowski, S.; Gökce, B. Plasmonic seasoning: Giving color to desktop laser 3D printed polymers by highly dispersed nanoparticles. Adv. Opt. Mater. 2020, 8, 2070060. [Google Scholar] [CrossRef]

- Moylan, S.; Brown, C.; Slotwinski, J. Recommended Protocol for Round-Robin Studies in Additive Manufacturing. J. Test. Eval. 2016, 44, 1009–1018. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brown, C.U.; Jacob, G.; Stoudt, M.; Moylan, S.; Slotwinski, J.; Donmez, A. Interlaboratory Study for Nickel Alloy 625 Made by Laser Powder Bed Fusion to Quantify Mechanical Property Variability. J. Mater. Eng. Perform. 2016, 25, 3390–3397. [Google Scholar] [CrossRef] [PubMed]

- Ahuja, B.; Schaub, A.; Junker, D.; Tenner, F.; Plettke, R.; Merklein, M.; Schmidt, M.; Karg, M. A Round Robin Study for Laser Beam Melting in Metal Powder Bed. S. Afr. J. Ind. Eng. 2016, 27, 30–42. [Google Scholar] [CrossRef] [Green Version]

- Bourell, D.; Coholich, J.; Chalancon, A.; Bhat, A. Evaluation of energy density measures and validation for powder bed fusion of polyamide. CIRP Ann. Manuf. Technol. 2017, 66, 210–220. [Google Scholar] [CrossRef]

- Jansson, A.; Pejryd, L. Characterisation of carbon fibre-reinforced polyamide manufactured by selective laser sintering. Addit. Manuf. 2016, 9, 7–13. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Review of the mechanical properties of carbon nanofiber/polymer composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2126–2142. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, B.; Davies, R.; Liu, Y.; Yi, N.; Qiang, D.; Zhu, Y.; Ghita, O. Laser sintering of graphene nano-platelets encapsulated polyamide powders. Addit. Manuf. 2020, 35, 101363. [Google Scholar]

- Sommereyns, A.; Hupfeld, T.; Gann, S.; Wang, T.; Wu, C.; Zhuravlev, E.; Lüddecke, A.; Baumann, S.; Rudloff, J.; Lang, M.; et al. Influence of sub-monolayer quantities of carbon nanoparticles on the melting and crystallization behavior of polyamide 12 powders for additive manufacturing. Mater. Des. 2021, 201. [Google Scholar] [CrossRef]

- Sanguansat, P. (Ed.) Principal Component Analysis—Engineering Applications; InTech: Rijeka, Croatia, 2012; ISBN 978-953-51-0182-6. [Google Scholar]

- Naik, G.R. (Ed.) Advances in Principal Component Analysis—Research and Development; Springer: Singapore, 2018. [Google Scholar]

| Powder Size | VED | AED | Laser Power | Scanning Speed | Layer Thickness | Hatch Spacing | UTS | Elongation | |

|---|---|---|---|---|---|---|---|---|---|

| Powder Size | 1 | 0.09922 | −0.03446 | 0.39481 | −0.23362 | −0.14307 | 0.02324 | −0.54097 | 0.28128 |

| VED | 0.09922 | 1 | 0.98235 | −0.72197 | −0.84689 | 0.94208 | −0.49303 | 0.67412 | −0.26240 |

| AED | −0.03446 | 0.98235 | 1 | −0.81100 | −0.78176 | 0.98819 | −0.38709 | 0.78199 | −0.30151 |

| Laser Power | 0.39481 | −0.72197 | −0.81100 | 1 | 0.63875 | −0.86263 | 0.22207 | −0.74786 | −0.02901 |

| Scanning Speed | −0.23362 | −0.84689 | −0.78176 | 0.63875 | 1 | −0.70787 | 0.71575 | −0.31273 | −0.17942 |

| Layer Thickness | −0.14307 | 0.94208 | 0.98819 | −0.86263 | −0.70787 | 1 | −0.29013 | 0.84981 | −0.32563 |

| Hatch Spacing | 0.02324 | −0.49303 | −0.38709 | 0.22207 | 0.71575 | −0.29013 | 1 | −0.10027 | −0.00206 |

| UTS | −0.54097 | 0.67412 | 0.78199 | −0.74786 | −0.31273 | 0.84981 | −0.10027 | 1 | −0.61968 |

| Elongation | 0.28128 | −0.26240 | −0.30151 | −0.02901 | −0.17942 | −0.32563 | −0.00206 | −0.61968 | 1 |

| Ref. | Polymer Type | Additives | D50 (μm) | VED (J/mm³) | AED (J/mm²) | Laser Power (W) | Scanning Speed (mm/s) | Layer Thickness (µm) | Hatch Spacing (µm) | UTS (MPa) | Elongation (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [71] | aged PA12 | 53 | 0.15 | 0.02 | 18 | 4000 | 100 | 300 | 48 | 47 | |

| [70] | PA12 | 56 | 0.36 | 0.04 | 18 | 2500 | 100 | 200 | 50 | 18 | |

| [35] | TPU | 63 | 0.67 | 0.07 | 10 | 1000 | 100 | 150 | 18 | 559 | |

| [27] | PA12 | 37 | 0.90 | 0.09 | 18 | 2000 | 100 | 100 | 38 | 21 | |

| [27] | PA12 | silica | 37 | 1.00 | 0.1 | 20 | 2000 | 100 | 100 | 46 | 20 |

| [35] | TPU | 200 | 1.60 | 0.16 | 24 | 1000 | 100 | 150 | 4 | 208 | |

| [21] | PA12 | 58 | 3.41 | 0.68 | 4 | 45 | 200 | 125 | 86 | 11 | |

| [21] | PA12 | MWCNT | 58 | 3.41 | 0.68 | 4 | 45 | 200 | 125 | 94 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kusoglu, I.M.; Doñate-Buendía, C.; Barcikowski, S.; Gökce, B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials 2021, 14, 1169. https://doi.org/10.3390/ma14051169

Kusoglu IM, Doñate-Buendía C, Barcikowski S, Gökce B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials. 2021; 14(5):1169. https://doi.org/10.3390/ma14051169

Chicago/Turabian StyleKusoglu, Ihsan Murat, Carlos Doñate-Buendía, Stephan Barcikowski, and Bilal Gökce. 2021. "Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices" Materials 14, no. 5: 1169. https://doi.org/10.3390/ma14051169

APA StyleKusoglu, I. M., Doñate-Buendía, C., Barcikowski, S., & Gökce, B. (2021). Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials, 14(5), 1169. https://doi.org/10.3390/ma14051169