Elements of Pathway for Quick and Reliable Health Monitoring of Concrete Behavior in Cable Post-Tensioned Concrete Girders

Abstract

:1. Introduction

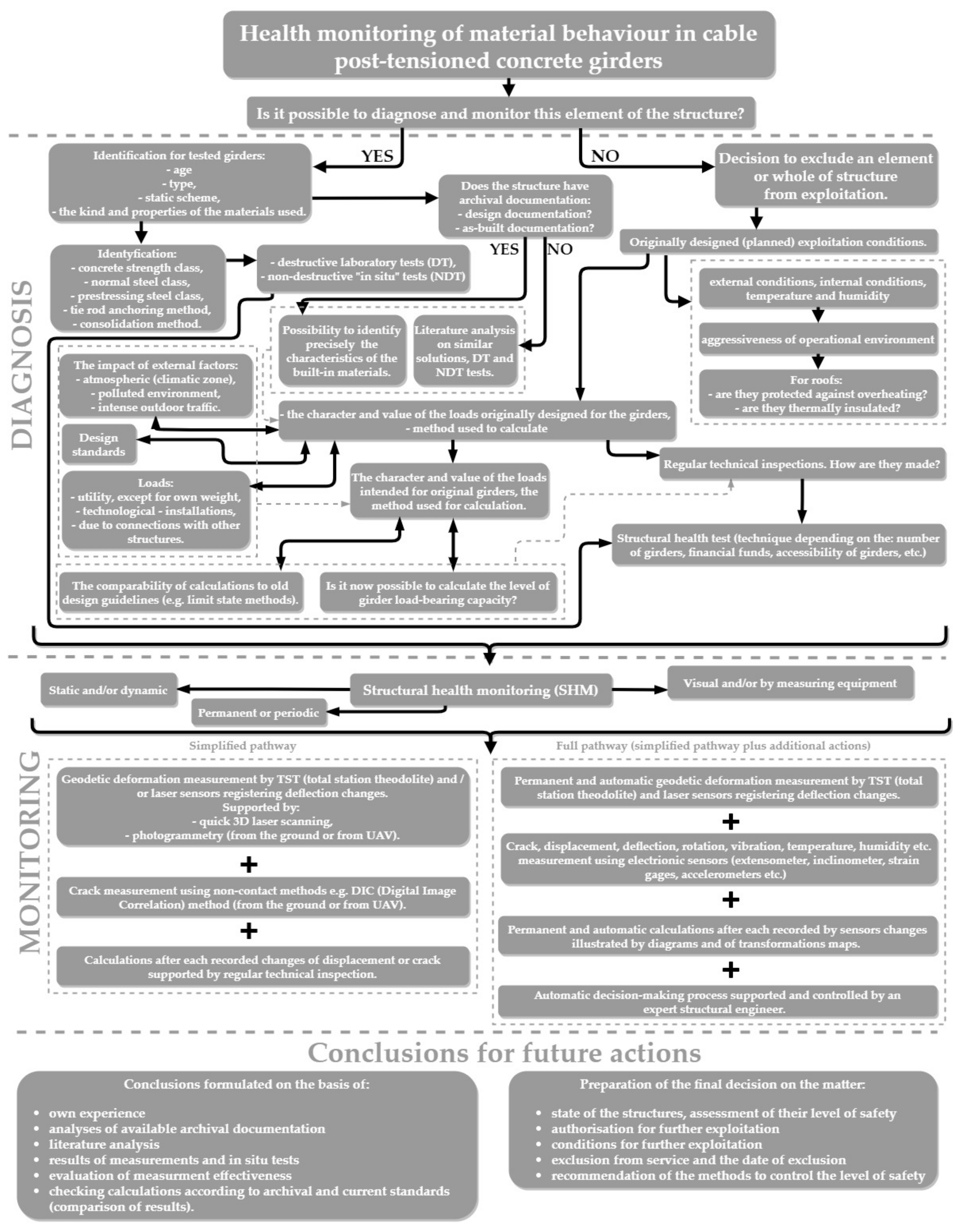

2. Materials and Methods

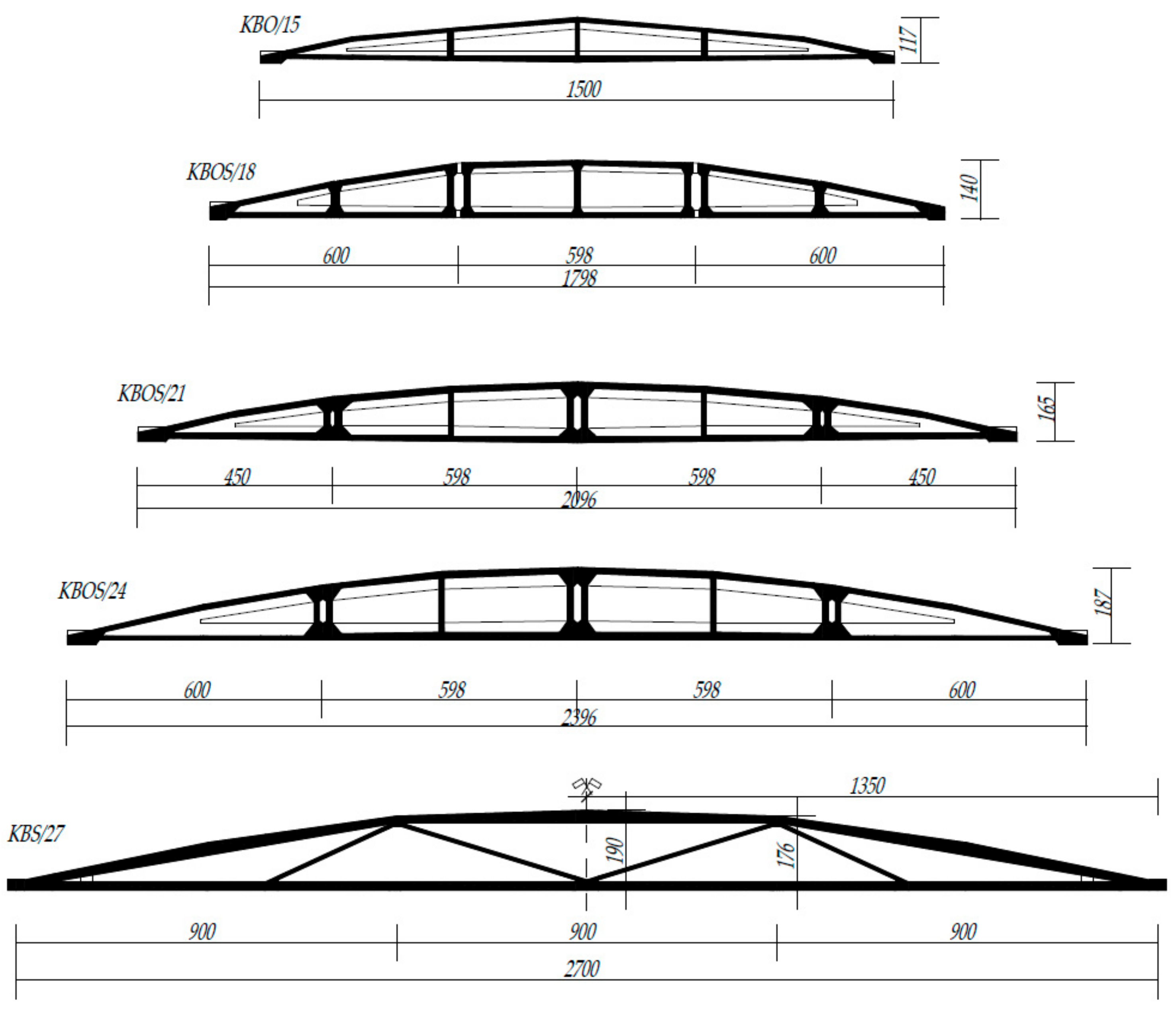

2.1. Description of Seleceted Cable Post-Tensioned Concrete Girders

2.2. Diagnostic Methods Description

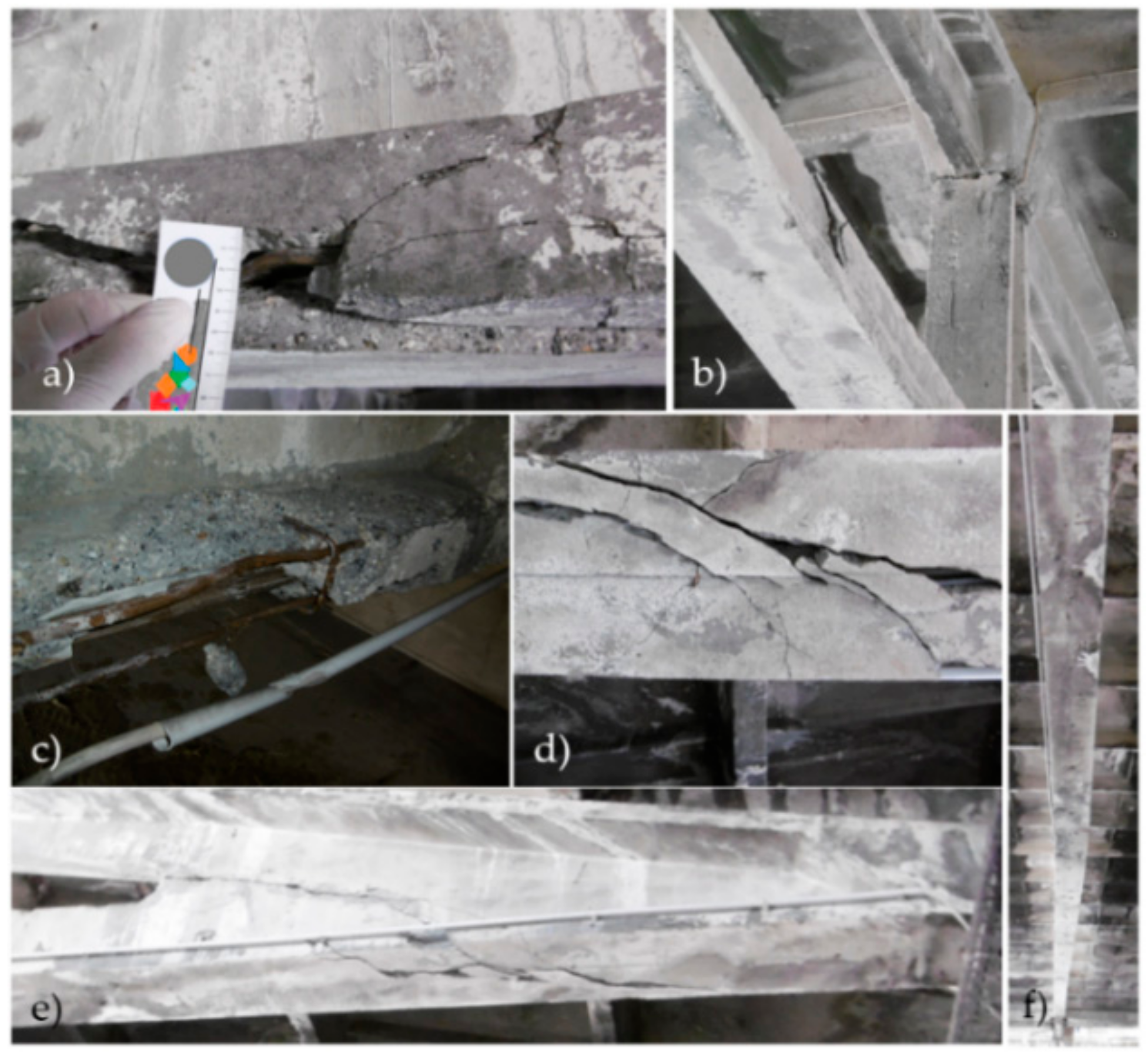

2.3. Visual Method

- cracking and deformation of prestressed structures in monolithic sections and assembly joints, as well as the state of supports,

- defects in the concrete in the prestressed structures themselves and in the elements joined to them as well as the corrosion of the connecting elements,

- scratches and deformation of roof slabs, especially on their undersides, near the ends of girders, as well as roof leaks, with particular attention paid to the location of cable anchorage zones,

- the accumulation of dirt (dust) on the elements and the extent and weight of suspended installations (including: the change of their location and weight, replacement, or extension), information boards and other loads,

- cracks and defects in the glazing of skylights or replacement of their constituent elements with heavier ones,

- use of the building in accordance with its original purpose,

- thermal and humidity parameters of the building envelope and thermal and humidity conditions of the internal environment,

- possible influence of dynamic loads on the whole structure of the building, e.g., connected with the production technology of the plant.

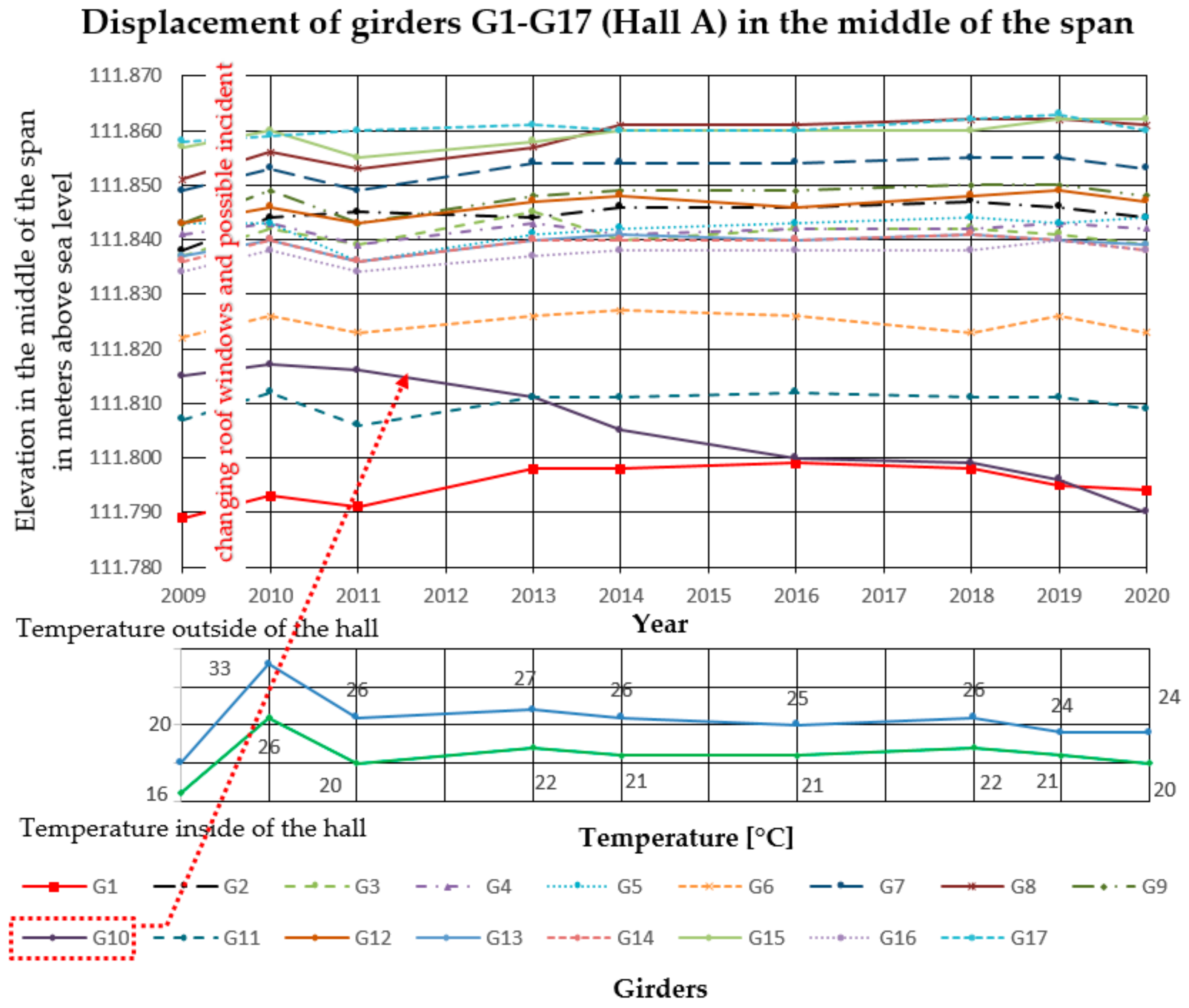

2.4. Deflection Measurements

- I—good condition,

- II—acceptable condition,

- III—poor condition,

- IV—very bad condition.

2.5. Concrete Testing Methods

- Demonstration of compliance of the compressive strength of concrete in a structure, that is, concrete already embedded in the structural element (e.g., precast concrete), but without the use of “standard” samples. The indirect methods are used here, that is, those that do not “destroy” the structure, and at the same time are cheaper than traditional sampling.

- Evaluation of the quality of concrete in the case of non-compliance of the compression strength conditions, which was carried out with the use of standard samples or when execution errors are found during the execution of work.

- Evaluation of the technical condition of existing structures when they are to be modernized or redesigned.

2.5.1. Non-Destructive Methods—Sclerometric and Ultrasonic Tests

2.5.2. Destructive Methods—Concrete Cores Test

3. Results

3.1. Visual Method Results

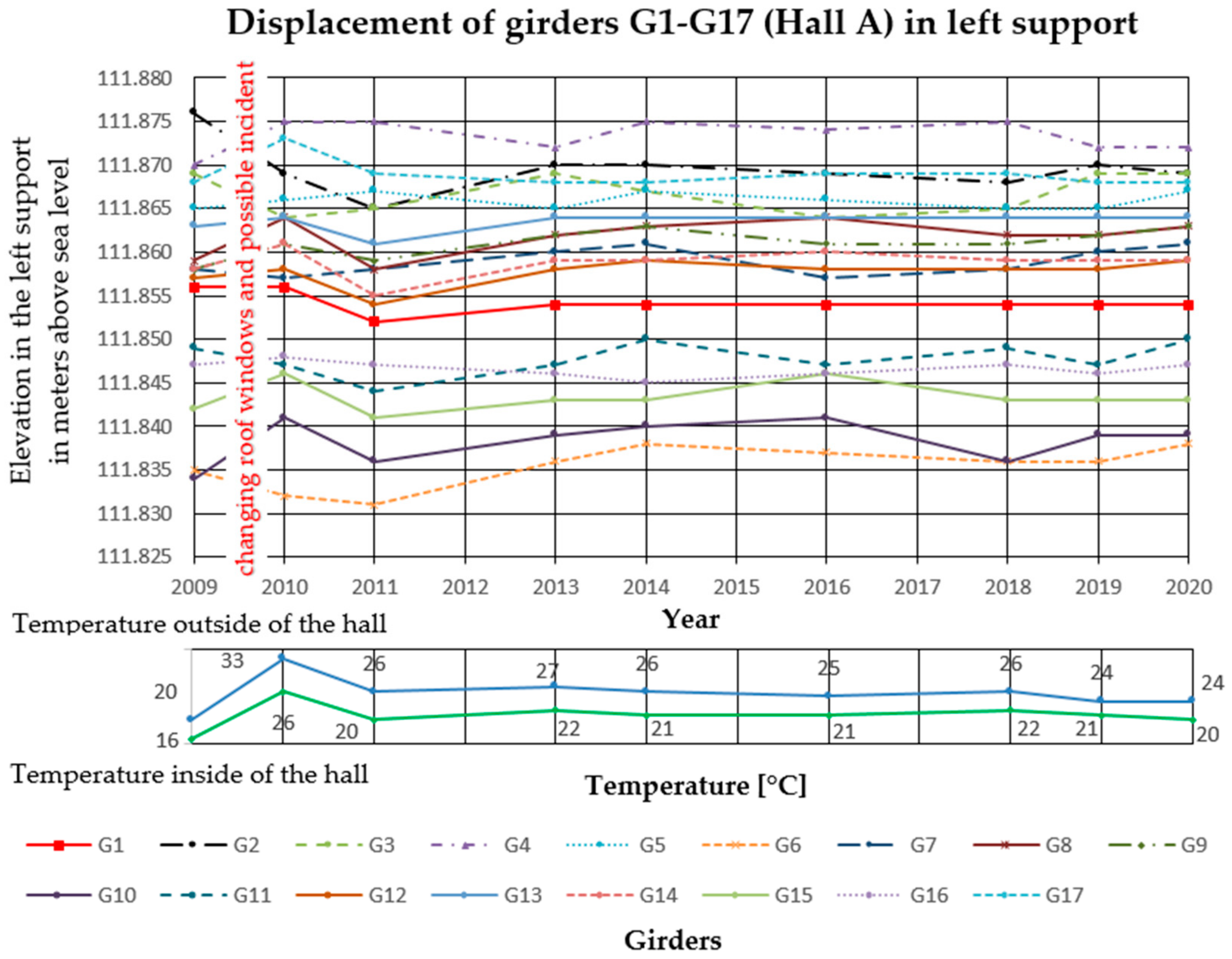

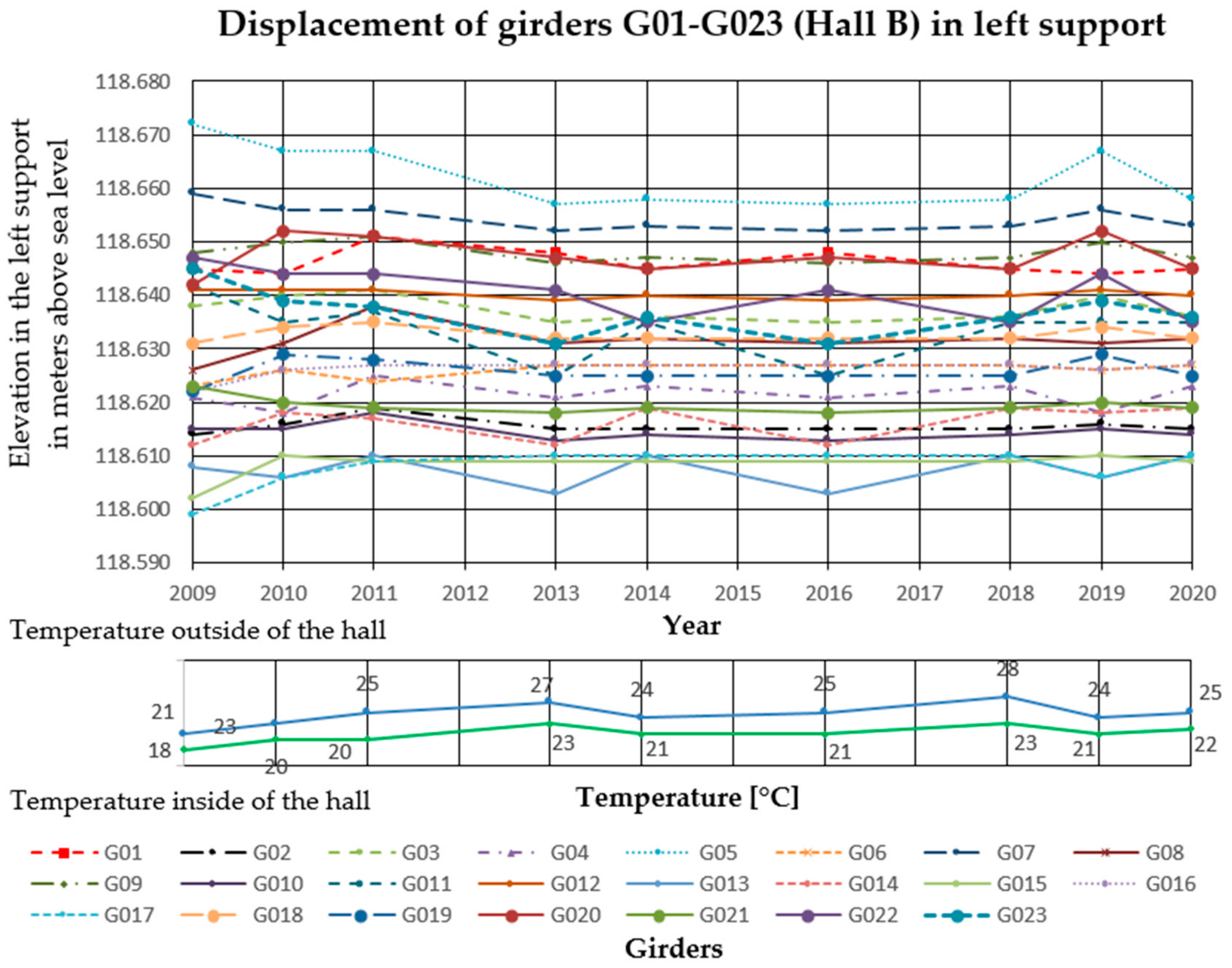

3.2. Deflection Measurements

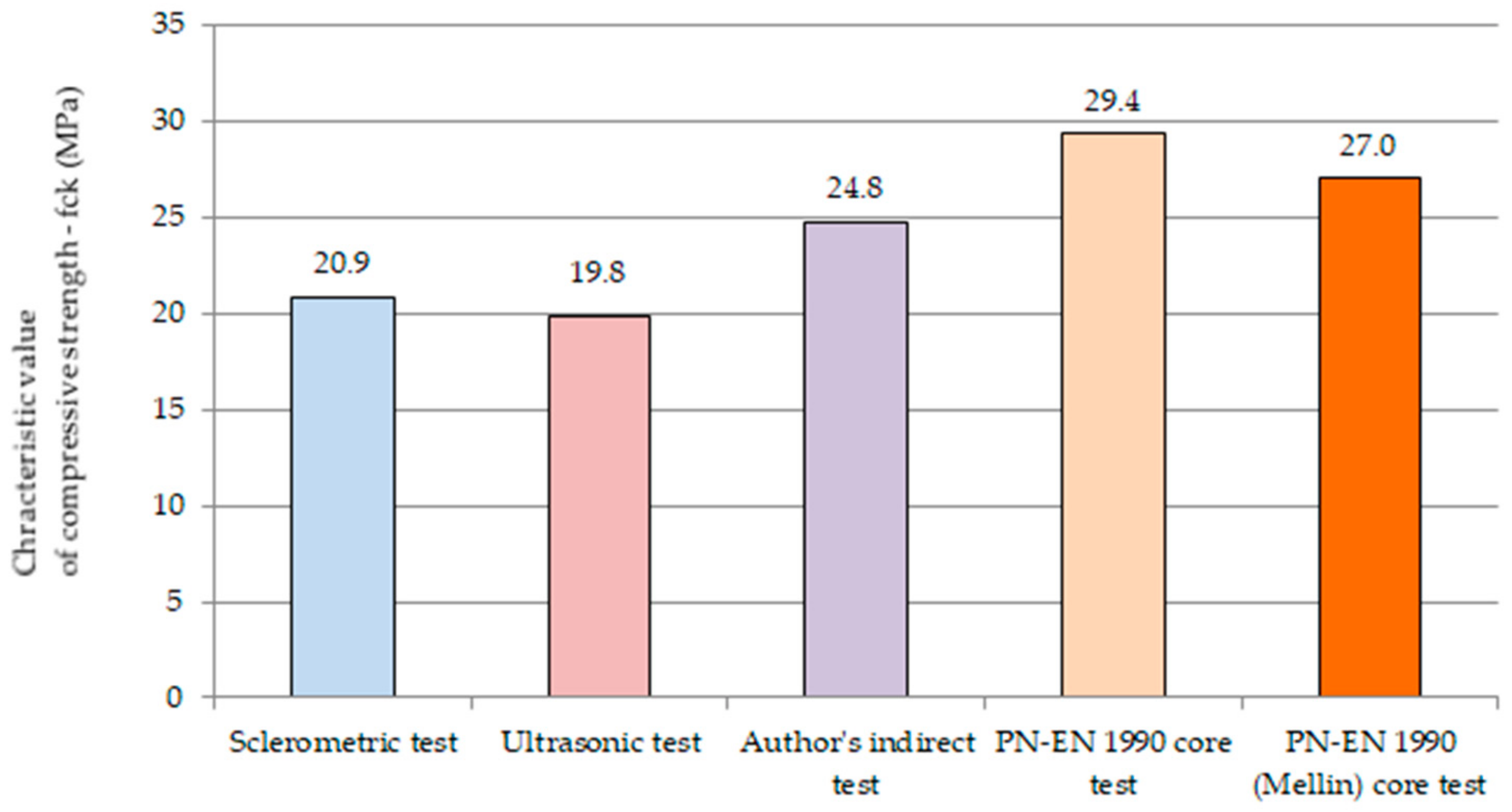

3.3. Sclerometric Test Results

- fc—compressive strength of concrete,

- L—number of rebound.

- 1st criterion: fi,min ≥ fck cube,

- 2nd criterion: fcm ≥ 1,2 fck cube,

- 3rd criterion: fcm ≥ fck cube + 1.64·s

- fck ≤ 32.4 MPa

- fck ≤ 36.0 MPa/1.2 = 30.0 MPa

- fck ≤ 36.0 MPa—1.64·1.92 MPa = 32.8 MPa.

3.4. Ultrasonic Tests Results

- vL—ultrasound wave speed (km/s).

- fck ≤ 30.2 MPa

- fck ≤ 34.2 MPa/1.2 = 28.5 MPa

- fck ≤ 34.2 MPa—1.64·2.11 MPa = 30.7 MPa.

3.5. Concrete Core Tests Results

- —the mean value of the difference of the compressive strength determined on the core bore samples and the strength determined from the base curve (Equation (6)),

- s—standard deviation of strength differences ,

- —coefficient taken from the standard table, for n ≥ 9.

- t—age of structure (days),

- sc—cement class.

- 1st criterion:

- 2nd criterion:

4. Discussion

4.1. Deflection Measurement Discussion

4.2. Concrete Test Discussion

- vk—coefficient of variation of the sample; vk = s/fcm

- kn—a factor that depends on the sample size and confidence level (at the minimum confidence level γ = 0.75 and n = 8 → kn = 5.07).

- —gamma function value,

- n—sample size,

- σ—population standard deviation.

5. Conclusions

- monitoring of existing building structures containing prestressed structures is essential for economic reasons, safety of use, durability, and determination of the moment until which they can be used;

- the methods proposed in this paper are useful or even necessary to determine and monitor the current technical condition of such objects “in situ”;

- the method of testing deformation and displacements of prestressed elements is the basic method, which makes it possible to assess the technical condition of prestressed elements, whereas non-destructive strength testing may be an auxiliary and supplementary method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yun, Y.M. Evaluation of Ultimate Strength of Post-Tensioned Anchorage Zones. J. Adv. Concr. Technol. 2005, 3, 149–159. [Google Scholar] [CrossRef]

- Im, S.B.; Hurlebaus, S. Non-destructive testing methods to identify voids in external post-tensioned tendons. KSCE J. Civ. Eng. 2012, 16, 388–397. [Google Scholar] [CrossRef]

- Mao, W.; Gou, H.; He, Y.; Pu, Q. Local Stress Behavior of Post-Tensioned Prestressed Anchorage Zones in Continuous Rigid Frame Arch Railway Bridge. Appl. Sci. 2018, 8, 1833. [Google Scholar] [CrossRef] [Green Version]

- Shin, K.-J.; Lee, S.-C.; Kim, Y.Y.; Kim, J.-M.; Park, S.; Lee, H. Construction Condition and Damage Monitoring of Post-Tensioned PSC Girders Using Embedded Sensors. Sensors 2017, 17, 1843. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oh, B.H.; Kim, K.S. Shear Behavior of Full-Scale Post-Tensioned Prestressed Concrete Bridge Girders. ACI Struct. J. 2004, 101, 176–182. [Google Scholar] [CrossRef]

- Gunter, B.; Galo, G.; Mercado, E.; Baibas, D. Post-Tensioned Concrete Girders. In Bridge Design Practice, 4th ed.; Bustamente, Y., Ed.; State of California Department of Transportation, Caltrans: Sacramento, CA, USA, 2015; Chapter 7. [Google Scholar]

- Calvi, G.M.; Moratti, M.; O’Reilly, G.J.; Scattarreggia, N.; Monteiro, R.; Malomo, D.; Calvi, P.M.; Pinho, R. Once upon a Time in Italy: The Tale of the Morandi Bridge. Struct. Eng. Int. 2019, 29, 198–217. [Google Scholar] [CrossRef]

- Rania, N.; Coppola, I.; Martorana, F.; Migliorini, L. The Collapse of the Morandi Bridge in Genoa on 14 August 2018: A Collective Traumatic Event and Its Emotional Impact Linked to the Place and Loss of a Symbol. Sustain. J. Rec. 2019, 11, 6822. [Google Scholar] [CrossRef] [Green Version]

- Invernizzi, S.; Montagnoli, F.; Carpinteri, A. Fatigue assessment of the collapsed XXth Century cable-stayed Polcevera Bridge in Genoa. Procedia Struct. Integr. 2019, 18, 237–244. [Google Scholar] [CrossRef]

- Nawy, E.G. Prestressed Concrete; Pearson Education: Sydney, Australia, 2011. [Google Scholar]

- Runkiewicz, L. Technical Condition Assessment of a Post-Tensioned Reinforced Concrete Girders; Instructions, Guidelines, Handbooks No. 353/2018; Building Research Institute: Warsaw, Poland, 2018.

- Breen, J.E. Anchorage Zone Reinforcement for Post-Tensioned Concrete Girders; American Association of State Highway and Transportation Officials, United States, Federal Highway Administration, National Research Council (U.S.), Transportation Research Board: Washington, DC, USA, 1994; Volume 356.

- Highway Structures and Bridges. Inspection and Assessment; CS 465 Management of Post-Tensioned Concrete Bridges (Formerly BD 54/15); Highways England: London, UK, 2020.

- Japan International Cooperation Agency. Quality Control Manual for Prestressed Concrete Girder; Ministry of Construction, the Republic of the Union of Myanmar, Japan International Cooperation Agency: Tokyo, Japan, 2019.

- Salas, R.M.; West, J.S.; Breen, J.E.; Kreger, M.E. Conclusions, Recommendations and Design Guidelines for Corrosion Protection of Post-Tensioned Bridges; Report No. FHWA/TX-04/0-1405-9; Texas Department of Transportation: Austin, TX, USA, 2004.

- Nowogońska, B.; Korentz, J. Value of Technical Wear and Costs of Restoring Performance Characteristics to Residential Buildings. Buildings 2020, 10, 9. [Google Scholar] [CrossRef] [Green Version]

- Bungey, J.H.; Grantham, M.G. Testing of Concrete in Structures; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Malhotra, V.; Carino, N.J. Handbook on Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Gorzelańczyk, T.; Schabowicz, K.; Szymków, M. Tests of Fiber Cement Materials Containing Recycled Cellulose Fibers. Materials 2020, 13, 2758. [Google Scholar] [CrossRef] [PubMed]

- Szymanowski, J. Evaluation of the Adhesion between Overlays and Substrates in Concrete Floors: Literature Survey, Recent Non-Destructive and Semi-Destructive Testing Methods, and Research Gaps. Buildings 2019, 9, 203. [Google Scholar] [CrossRef] [Green Version]

- Hooton, R.D. Future directions for design, specification, testing, and construction of durable concrete structures. Cem. Concr. Res. 2019, 124, 105827. [Google Scholar] [CrossRef]

- Schabowicz, K. Non-Destructive Testing of Materials in Civil Engineering. Materials 2019, 12, 3237. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hoła, J.; Schabowicz, K. State-of-the-art non-destructive methods for diagnostic testing of building structures – anticipated development trends. Arch. Civ. Mech. Eng. 2010, 10, 5–18. [Google Scholar] [CrossRef]

- Malek, J.; Kaouther, M. Destructive and non-destructive testing of concrete structures. Jordan J. Civ. Eng. 2014, 159, 1–10. [Google Scholar]

- McCann, D.; Forde, M. Review of NDT methods in the assessment of concrete and masonry structures. NDT E Int. 2001, 34, 71–84. [Google Scholar] [CrossRef]

- Sbartaï, Z.-M.; Breysse, D.; Larget, M.; Balayssac, J.-P. Combining NDT techniques for improved evaluation of concrete properties. Cem. Concr. Compos. 2012, 34, 725–733. [Google Scholar] [CrossRef]

- Bassil, A.; Chapeleau, X.; LeDuc, D.; Abraham, O. Concrete Crack Monitoring Using a Novel Strain Transfer Model for Distributed Fiber Optics Sensors. Sensors 2020, 20, 2220. [Google Scholar] [CrossRef] [Green Version]

- Runkiewicz, L. Application of non-destructive testing methods to assess properties of construction materials in building diagnostics. Archit. Civ. Eng. Environ. 2009, 2, 79–86. [Google Scholar]

- Hoła, A.; Sadowski, Ł. A method of the neural identification of the moisture content in brick walls of historic buildings on the basis of non-destructive tests. Autom. Constr. 2019, 106, 102850. [Google Scholar] [CrossRef]

- Gerwick, B.C., Jr. Construction of Prestressed Concrete Structures; John Wiley & Sons: Hoboken, NJ, USA, 1997. [Google Scholar]

- Naaman, A.E. Prestressed Concrete Analysis and Design: Fundamentals; Techno Press 3000: Sarasota, FL, USA, 2012. [Google Scholar]

- Guo, T.; Chen, Z.; Lu, S.; Yao, R. Monitoring and analysis of long-term prestress losses in post-tensioned concrete beams. Measurement 2018, 122, 573–581. [Google Scholar] [CrossRef]

- Han, K.; DeGol, J.; Golparvar-Fard, M. Geometry- and Appearance-Based Reasoning of Construction Progress Monitoring. J. Constr. Eng. Manag. 2018, 144, 04017110. [Google Scholar] [CrossRef] [Green Version]

- Bednarz, Ł.J.; Jasieńko, J.; Nowak, T.P. Test monitoring of the Centennial Hall’s dome, Wroclaw (Poland). In Optics for Arts, Architecture, and Archaeology V; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9527, p. 95270C. [Google Scholar] [CrossRef]

- Bednarz, Ł.J.; Jasieńko, J.; Rutkowski, M.; Nowak, T.P. Strengthening and long-term monitoring of the structure of an historical church presbytery. Eng. Struct. 2014, 81, 62–75. [Google Scholar] [CrossRef]

- Coronelli, D.; Castel, A.; Vu, N.A.; François, R. Corroded post-tensioned beams with bonded tendons and wire failure. Eng. Struct. 2009, 31, 1687–1697. [Google Scholar] [CrossRef]

- Terzioglu, T.; Karthik, M.M.; Hurlebaus, S.; Hueste, M.B.D.; Maack, S.; Woestmann, J.; Wiggenhauser, H.; Krause, M.; Miller, P.K.; Olson, L.D. Nondestructive evaluation of grout defects in internal tendons of post-tensioned girders. NDT E Int. 2018, 99, 23–35. [Google Scholar] [CrossRef]

- Ghaffary, A.; Moustafa, M.A. Synthesis of Repair Materials and Methods for Reinforced Concrete and Prestressed Bridge Girders. Materials 2020, 13, 4079. [Google Scholar] [CrossRef] [PubMed]

- Ghahari, S.; Assi, L.N.; Alsalman, A.; Alyamaç, K.E. Fracture Properties Evaluation of Cellulose Nanocrystals Cement Paste. Materials 2020, 13, 2507. [Google Scholar] [CrossRef] [PubMed]

- Al-Hamrani, A.; Kucukvar, M.; Alnahhal, W.; Mahdi, E.; Onat, N.C. Green Concrete for a Circular Economy: A Review on Sustainability, Durability, and Structural Properties. Materials 2021, 14, 351. [Google Scholar] [CrossRef] [PubMed]

- Pino, V.; Nanni, A.; Arboleda, D.; Roberts-Wollmann, C.; Cousins, T. Repair of Damaged Prestressed Concrete Girders with FRP and FRCM Composites. J. Compos. Constr. 2017, 21, 04016111. [Google Scholar] [CrossRef]

- Fang, H.; Bai, Y.; Liu, W.; Qi, Y.; Wang, J. Connections and structural applications of fibre reinforced polymer composites for civil infrastructure in aggressive environments. Compos. Part B Eng. 2019, 164, 129–143. [Google Scholar] [CrossRef]

- De Domenico, D.; Urso, S.; Borsellino, C.; Spinella, N.; Recupero, A. Bond behavior and ultimate capacity of notched concrete beams with externally-bonded FRP and PBO-FRCM systems under different environmental conditions. Constr. Build. Mater. 2020, 265, 121208. [Google Scholar] [CrossRef]

- Wałach, D. Analysis of Factors Affecting the Environmental Impact of Concrete Structures. Sustain. J. Rec. 2021, 13, 204. [Google Scholar] [CrossRef]

- Runkiewicz, L.; Sieczkowski, J. Research and assessment of reinforced concrete roof tensile girders in exploited facilities. Przegląd Bud. Buildging Rev. 2018, 89, 41–46. [Google Scholar]

- Hoła, J.; Runkiewicz, L. Methods and diagnostic techniques used to analyse the technical state of reinforced concrete structures. Struct. Environ. 2018, 4, 309–336. [Google Scholar] [CrossRef]

- Dang, J.; Haruta, D.; Shrestha, A.; Endo, H.; Matsunaga, S.; Kasai, A.; Wang, X. Arial patrol for bridge routine and post-earthquake emergency inspection using small aerial photography UAV. In Proceedings of the 5th International Symposium on Advances in Civil and Environmental Engineering Practises for Sustainable Development, Galle, Sri Lanka, 16 March 2017; Volume 2018, p. 21. [Google Scholar]

- Mrówczyńska, M.; Grzelak, B.; Sztubecki, J. Unmanned Aerial Vehicles as a Supporting Tool of Classic Land Surveying in Hard-to-Reach Areas. In International Scientific Siberian Transport Forum; Springer: Cham, Switzerland, 2019; pp. 717–729. [Google Scholar]

- Lacidogna, G.; Piana, G.; Accornero, F.; Carpinteri, A. Multi-technique damage monitoring of concrete beams: Acoustic Emission, Digital Image Correlation, Dynamic Identification. Constr. Build. Mater. 2020, 242, 118114. [Google Scholar] [CrossRef]

- Chen, G.; Liang, Q.; Zhong, W.; Gao, X.; Cui, F. Homography-based measurement of bridge vibration using UAV and DIC method. Measurement 2021, 170, 108683. [Google Scholar] [CrossRef]

- PN-EN 1992-1-1: 2008 Eurocode 2: Design of Concrete Structures; PKN: Warszawa, Poland, 2008.

- Bednarz, Ł. Flat roof structures monitoring—Requirements. Inżynier Budownictwa 2020, 2, 63–66. [Google Scholar]

- Gorzelańczyk, T.; Pachnicz, M.; Różański, A.; Schabowicz, K. Identification of microstructural anisotropy of cellulose cement boards by means of nanoindentation. Constr. Build. Mater. 2020, 257, 119515. [Google Scholar] [CrossRef]

- Skrzypczak, I.; Kokoszka, W.; Buda-Ożóg, L.; Kogut, J.; Słowik, M. Environmental Aspects and Renewable Energy Sources in the Production of Construction Aggregate. In Proceedings of the International Conference on Advances in Energy Systems and Environmental Engineering (ASEE17), Wrocław, Poland, 2–5 July 2017; EDP Sciences: Ulis, France, 2017; p. 00160. [Google Scholar]

- Al Ajmani, H.; Suleiman, F.; Abuzayed, I.; Tamimi, A. Evaluation of Concrete Strength Made with Recycled Aggregate. Buildings 2019, 9, 56. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Liu, G.; Li, K.; Wang, T.; Shrestha, A.; Martek, I.; Tao, X. Layout Optimization Model for the Production Planning of Precast Concrete Building Components. Sustain. J. Rec. 2018, 10, 1807. [Google Scholar] [CrossRef] [Green Version]

- Domagała, L. Size Effect in Compressive Strength Tests of Cored Specimens of Lightweight Aggregate Concrete. Materials 2020, 13, 1187. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Skrzypczak, I.; Kokoszka, W.; Zięba, J.; Leśniak, A.; Bajno, D.; Bednarz, L. A Proposal of a Method for Ready-Mixed Concrete Quality Assessment Based on Statistical-Fuzzy Approach. Materials 2020, 13, 5674. [Google Scholar] [CrossRef] [PubMed]

- PKN. PN-EN 13791: 2019-12 Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components; PKN: Warszawa, Poland, 2019.

- PKN. PN-EN 206: 2013+A1: 2016 Concrete—Specification, Performance, Production and Conformity; PKN: Warszawa, Poland, 2017.

- PKN. PN-EN 12504-1: 2019-08 Testing Concrete in Structures—Part 1: Cored Specimens—Taking, Examining and Testing in Compression; PKN: Warszawa, Poland, 2019.

- PKN. PN-EN 12504-2: 2012 Testing Concrete in Structures—Part 2: Non-Destructive Testing—Determination of Rebound Number; PKN: Warszawa, Poland, 2012.

- PKN. PN-EN 12504-3: 2006 Testing Concrete in Structures—Part 3: Determination of Pull-Out Force; PKN: Warszawa, Poland, 2006.

- PKN. PN-EN 12504-4: 2005 Testing Concrete in Structures—Part 4: Determination of Ultrasonic Pulse Velocity; PKN: Warszawa, Poland, 2005.

- Bergamo, O.; Campione, G. Experimental Investigation for Degradation Analysis of an RC Italian Viaduct and Retrofitting Design. Pr. Period. Struct. Des. Constr. 2020, 25, 05020010. [Google Scholar] [CrossRef]

- Stawiski, B.; Kania, T. Tests of Concrete Strength across the Thickness of Industrial Floor Using the Ultrasonic Method with Exponential Spot Heads. Materials 2020, 13, 2118. [Google Scholar] [CrossRef] [PubMed]

- Schickert, G. Critical reflections on non-destructive testing of concrete. Mater. Struct. 1984, 17, 217–223. [Google Scholar] [CrossRef]

- Panahandeh, M.; Hashemolhosseini, H.; Eftekhar, M.R.; Hashemolhosseini, A.H.; Baghbanan, A. Obtaining the strength parameters of concrete using drilling data. J. Build. Eng. 2021, 38, 102181. [Google Scholar] [CrossRef]

- Sathish, S.; Ramkumar, S.; Geetha, M. Drilling performances and wear characteristics of coated drill bits during drilling reinforced concrete. Int. J. Appl. Ceram. Technol. 2019, 16, 357–366. [Google Scholar] [CrossRef] [Green Version]

- PKN. PN-EN 12390-3: 2019-07 Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; PKN: Warszawa, Poland, 2019.

- PKNMiJ. PN-B-06250: 1988 Ordinary Concrete; PKNMiJ: Warszawa, Poland, 1988.

- ITB. Instructions for Using Schmidt Hammers for Non-Destructive Quality Control of Concrete; No. 510; ITB: Warszawa, Poland, 1977.

- ITB. Instructions for Using Ultrasonic Method for Non-Destructive Quality Control of Concrete in Structure; No. 209; ITB: Warszawa, Poland, 1977.

- Jaggerwal, H.; Bajpai, Y. Estimating the Quality of Concrete Bridge Girder Using Ultrasonic Pulse Velocity Test. Int. J. Comput. Eng. Res. (IJCER) 2014, 4, 2250–3005. [Google Scholar]

- PKN. PN-EN 1990. Eurocode: Basis of Structural Design; PKN: Warszawa, Poland, 2005.

- Concrete Society. Concrete Core Testing for Strength; Technical Report No 11; Concrete Society: London, UK, 1987. [Google Scholar]

| Group of Methods | Type of Method | Test Instruments | Tested Parameter | Specified Concrete Properties | Comments | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| Sclerometric methods | Impact methods | Poldi hammer, HPS hammer | imprint depth and diameter | hardness, compressive strength | historical methods, rarely used today | fixed interaction energy | necessity of measuring the imprint diameter increases the testing time |

| Rebound methods | Sclerometers (Schmidt hammer L, N, M, PT type) | number of rebounds of the impact mass acting on the component under test with constant energy | hardness, compressive strength | method often used today | fixed interaction energy, measurement speed | influence of concrete age on reflection number | |

| Acoustic methods | Ultrasonic method | ultrasonic pulse velocity testers, material samplers | speed of the ultrasonic wave that spreads in the test material | concrete compressive strength, concrete homogeneity, defect detection (defectoscopy) | two ultrasonic heads: transmitting and receiving | totally non-destructive method | influence of reinforcement on ultrasonic wave velocity measurement, discrepancies in results |

| Ultrasonic tomography method | ultrasonic tomographs | measurement of the propagation of elastic waves (ultrasonic) induced by a multi-head antenna | detection of various types of material imperfections, with one-sided access | multiple transmitter/ receiver heads | totally non-destructive method, high accuracy | high work intensity of the tests, discrepancies in results | |

| AE Acoustic Emission | AE instruments | energy and amplitude of the acoustic wave generated in a component as a result of its loading or deformation | defectoscopy | the method is mainly used for steel elements, less frequently for concrete elements | totally non-destructive method, high accuracy | high work intensity of the tests, discrepancies in results | |

| Echo method | Specialised measuring equipment | transition time of the pulse reflected from the opposite surface | defectoscopy | one transmitter/ receiver head | totally non-destructive method, high accuracy | high work intensity of the tests, discrepancies in results | |

| Hammer method | Specialised measuring equipment | velocity of the ultrasonic wave excited in the component under test | defectoscopy | acoustic impulse is generated by hitting the surface of the test piece using a hammer | totally non-destructive method, high accuracy | high work intensity of the tests, discrepancies in results | |

| Quasi-destructive metod | Methods of pulling out an anchor or bolt anchored in concrete | Equipment:

| pull-out force | compressive strength | there is local damage of approx. 5 cm depth from the surveyed surface | possibility of fixing anchors in concrete as well as in hardened concrete | high work intensity of fixing the anchors in hardened concrete |

| Borehole method | Drill rig with core bit, testing machine | destructive force of specimens recovered from structures by means of boreholes | compressive strength | need to collect concrete samples | high accuracy | high work intensity of the sampling |

| No. | Testing Angle α | Mean Rebound Value Lmv | Equivalent Mean Rebound Value Lmv(α–0) | Strength from the Curve fci | Corrected Strength fci′ = 0.6 · fci |

|---|---|---|---|---|---|

| 1 | 0 | 46.6 | 46.6 | 63.1 | 37.9 |

| 2 | 0 | 45.4 | 45.4 | 59.1 | 35.6 |

| 3 | 0 | 45.2 | 45.2 | 58.4 | 35.1 |

| 4 | 0 | 45.8 | 45.8 | 60.4 | 36.3 |

| 5 | 0 | 45.4 | 45.4 | 59.1 | 35.5 |

| 6 | 0 | 46.8 | 46.8 | 63.8 | 38.3 |

| 7 | 0 | 44.8 | 44.8 | 57.1 | 34.3 |

| 8 | 0 | 45.4 | 45.4 | 59.1 | 35.5 |

| 9 | 0 | 45.8 | 45.8 | 60.4 | 36.3 |

| 10 | +90° | 44.4 | 45.8 | 60.4 | 36.3 |

| 11 | +90° | 44.6 | 48.0 | 67.9 | 40.8 |

| 12 | +90° | 40.6 | 43.8 | 53.9 | 32.4 |

| 13 | 0 | 45.2 | 45.2 | 58.4 | 35.1 |

| 14 | 0 | 45.2 | 45.2 | 58.4 | 35.1 |

| 15 | 0 | 45.4 | 45.4 | 59.1 | 35.5 |

| Average compressive strength | fc mean = 36.0 MPa | ||||

| Standard deviation | s = 1.92 MPa | ||||

| Relative standard deviation | υk = 5.3% | ||||

| Girder | Homogeneity of Hardened Concrete According to [72] |

|---|---|

| G10—Hall A | k = 0.90 > 0.8; Very good |

| G11—Hall A | k = 0.91 > 0.8; Very good |

| G05—Hall B | k = 0.89 > 0.8; Very good |

| G018—Hall B | k = 0.92 > 0.8; Very good |

| No. | Length of the Measurement Path s (mm) | Pulse Transition Time t (μs) | Ultrasound Wave Speed vL (km/s) | Concrete Compressive Strength fc (Mpa) |

|---|---|---|---|---|

| 1 | 210 | 48.1 | 4.4 | 32.6 |

| 2 | 210 | 47.2 | 4.4 | 34.7 |

| 3 | 205 | 46.9 | 4.4 | 32.8 |

| 4 | 200 | 46.6 | 4.3 | 30.9 |

| 5 | 205 | 46.7 | 4.4 | 33.2 |

| 6 | 205 | 46.1 | 4.4 | 34.6 |

| 7 | 210 | 46.1 | 4.6 | 37.3 |

| 8 | 210 | 46.3 | 4.5 | 36.8 |

| 9 | 205 | 46.4 | 4.4 | 33.9 |

| 10 | 210 | 46.3 | 4.5 | 36.8 |

| 11 | 205 | 46.2 | 4.4 | 34.4 |

| 12 | 210 | 46.5 | 4.5 | 36.3 |

| 13 | 200 | 46.9 | 4.3 | 30.3 |

| 14 | 205 | 46.7 | 4.4 | 33.2 |

| 15 | 210 | 46.9 | 4.5 | 35.4 |

| Average compressive strength | fc mean = 42.0 Mpa | |||

| Standard deviation | s = 2.11 MPa | |||

| Relative standard deviation | υk = 6.2% | |||

| Girder | Homogeneity of Hardened Concrete According | |

|---|---|---|

| to [73] | to [74] | |

| G10—Hall A | k = 0.89 > 0.8; Very good | v = 4.0 m/s ∈ (3.5–4.5) m/s; Good |

| G11—Hall A | k = 0.90 > 0.8; Very good | v = 4.4 m/s ∈ (3.5–4.5) m/s; Good |

| G05—Hall B | k = 0.87 > 0.8; Very good | v = 3.8 m/s ∈ (3.5–4.5) m/s; Good |

| G018—Hall B | k = 0.92 > 0.8; Very good | v = 4.4 m/s ∈ (3.5–4.5) m/s; Good |

| Girder/Sample no. | Destructive Force F (kN) | Concrete Compressive Strength fc (MPa) |

|---|---|---|

| G10—Hall A/001 | 254.0 | 33.1 |

| G10—Hall A/002 | 248.0 | 32.7 |

| G11—Hall A/003 | 267.0 | 34.2 |

| G11—Hall A/004 | 260.0 | 33.1 |

| G05—Hall B/005 | 279.0 | 36.3 |

| G05—Hall B/006 | 264.0 | 33.6 |

| G018—Hall B/007 | 283.0 | 36.0 |

| G018—Hall B/008 | 286.6 | 36.4 |

| Average compressive strength of concrete | fcm = 34.4 MPa | |

| Standard deviation | s = 1.6 MPa | |

| Relative standard deviation | υk = 4.5% | |

| Girder/Sample no. | Compressive Strength | δf = fis − fL (MPa) | |

|---|---|---|---|

| Core with Correction Value 0.85 fis (MPa) | Basic Curve—Equation (5) fL (MPa) | ||

| G10—Hall A/001 | 38.9 | 22.8 | 6.1 |

| G10—Hall A/002 | 38.5 | 22.1 | 6.4 |

| G11—Hall A/003 | 40.2 | 24.7 | 5.1 |

| G11—Hall A/004 | 38.9 | 22.8 | 6.1 |

| G05—Hall B/005 | 42.7 | 28.3 | 3.3 |

| G05—Hall B/006 | 39.5 | 23.6 | 5.6 |

| G018—Hall B/007 | 42.4 | 27.8 | 3.6 |

| G018—Hall B/008 | 42.8 | 22.1 | 3.2 |

| Average value | δfm(8) = 4.9 MPa | ||

| Standard deviation is | s = 1.34 MPa < 3.0 MPa | ||

| and for calculation according to [44] | |||

| standard deviation can be use | s = 3.0 MPa | ||

| Girder/Sample No. | Core Vale fis (MPa) | Compressive Strength Determined from the Curve | |

|---|---|---|---|

| Basic Curve Equation (6) | Modified Equation (11) | ||

| G10—Hall A/001 | 38.9 | 46.1 | 41.2 |

| G10—Hall A/002 | 38.5 | 44.0 | 39.1 |

| G11—Hall A/003 | 40.2 | 43.7 | 38.8 |

| G11—Hall A/004 | 38.9 | 44.7 | 39.8 |

| G05—Hall B/005 | 42.7 | 44.0 | 39.1 |

| G05—Hall B/006 | 39.5 | 46.5 | 41.6 |

| G018—Hall B/007 | 42.4 | 43.0 | 38.1 |

| G018—Hall B/008 | 42.8 | 44.0 | 39.1 |

| Average value—fc(8) is, cube (MPa) | 40.5 | 44.5 | 39.6 |

| Lowest value—fclowest,cube (MPa) | 38.5 | 43.0 | 38.1 |

| Standard deviation s (MPa) | 1.8 | 1.2 | 1.2 |

| 3.0 MPa, and for calculation according to [44] standard deviation is s = 3.0 MPa | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bednarz, L.; Bajno, D.; Matkowski, Z.; Skrzypczak, I.; Leśniak, A. Elements of Pathway for Quick and Reliable Health Monitoring of Concrete Behavior in Cable Post-Tensioned Concrete Girders. Materials 2021, 14, 1503. https://doi.org/10.3390/ma14061503

Bednarz L, Bajno D, Matkowski Z, Skrzypczak I, Leśniak A. Elements of Pathway for Quick and Reliable Health Monitoring of Concrete Behavior in Cable Post-Tensioned Concrete Girders. Materials. 2021; 14(6):1503. https://doi.org/10.3390/ma14061503

Chicago/Turabian StyleBednarz, Lukasz, Dariusz Bajno, Zygmunt Matkowski, Izabela Skrzypczak, and Agnieszka Leśniak. 2021. "Elements of Pathway for Quick and Reliable Health Monitoring of Concrete Behavior in Cable Post-Tensioned Concrete Girders" Materials 14, no. 6: 1503. https://doi.org/10.3390/ma14061503

APA StyleBednarz, L., Bajno, D., Matkowski, Z., Skrzypczak, I., & Leśniak, A. (2021). Elements of Pathway for Quick and Reliable Health Monitoring of Concrete Behavior in Cable Post-Tensioned Concrete Girders. Materials, 14(6), 1503. https://doi.org/10.3390/ma14061503