Ductile-to-Brittle Transition and Brittle Fracture Stress of Ultrafine-Grained Low-Carbon Steel

Abstract

1. Introduction

2. Experimental Procedure

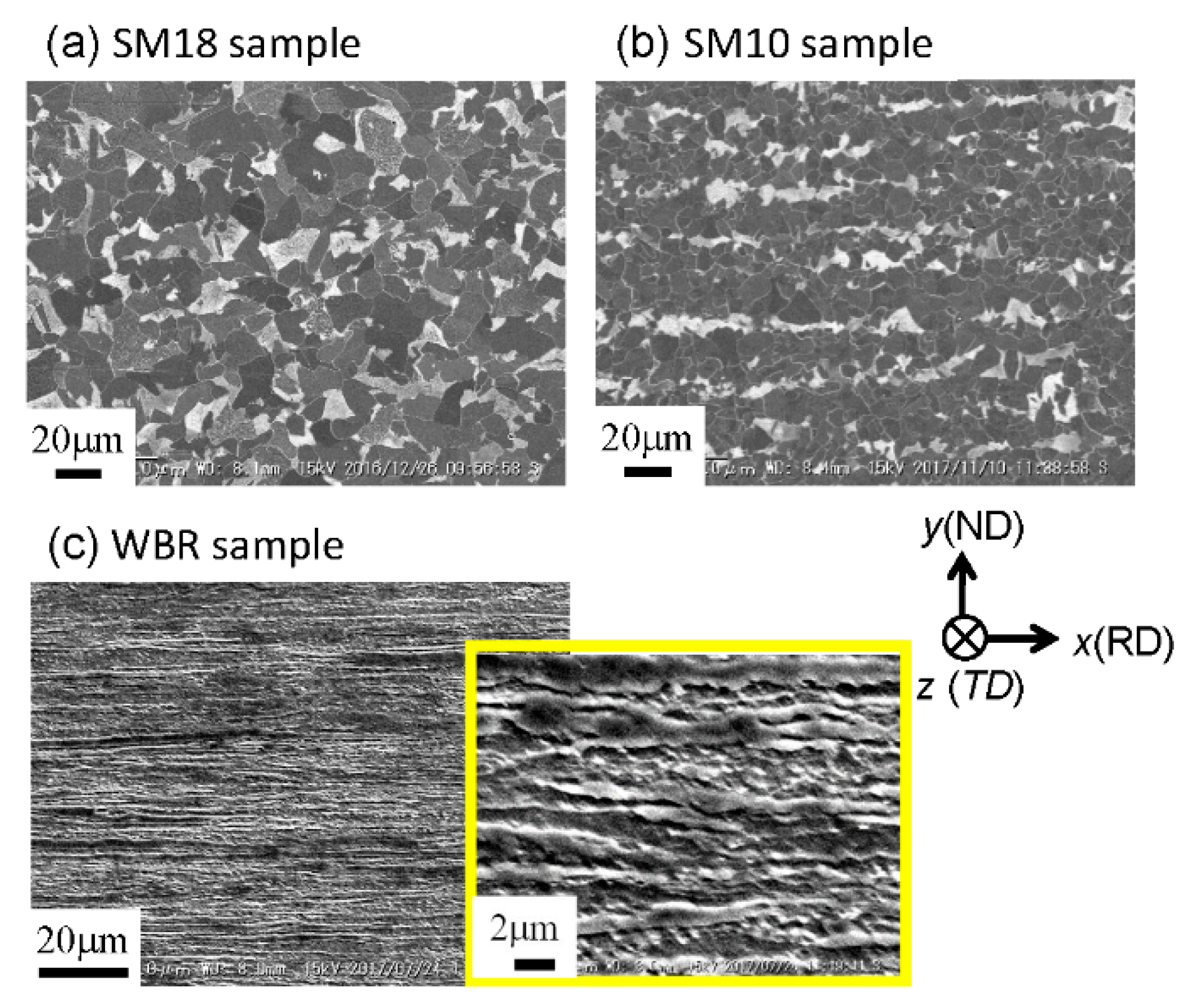

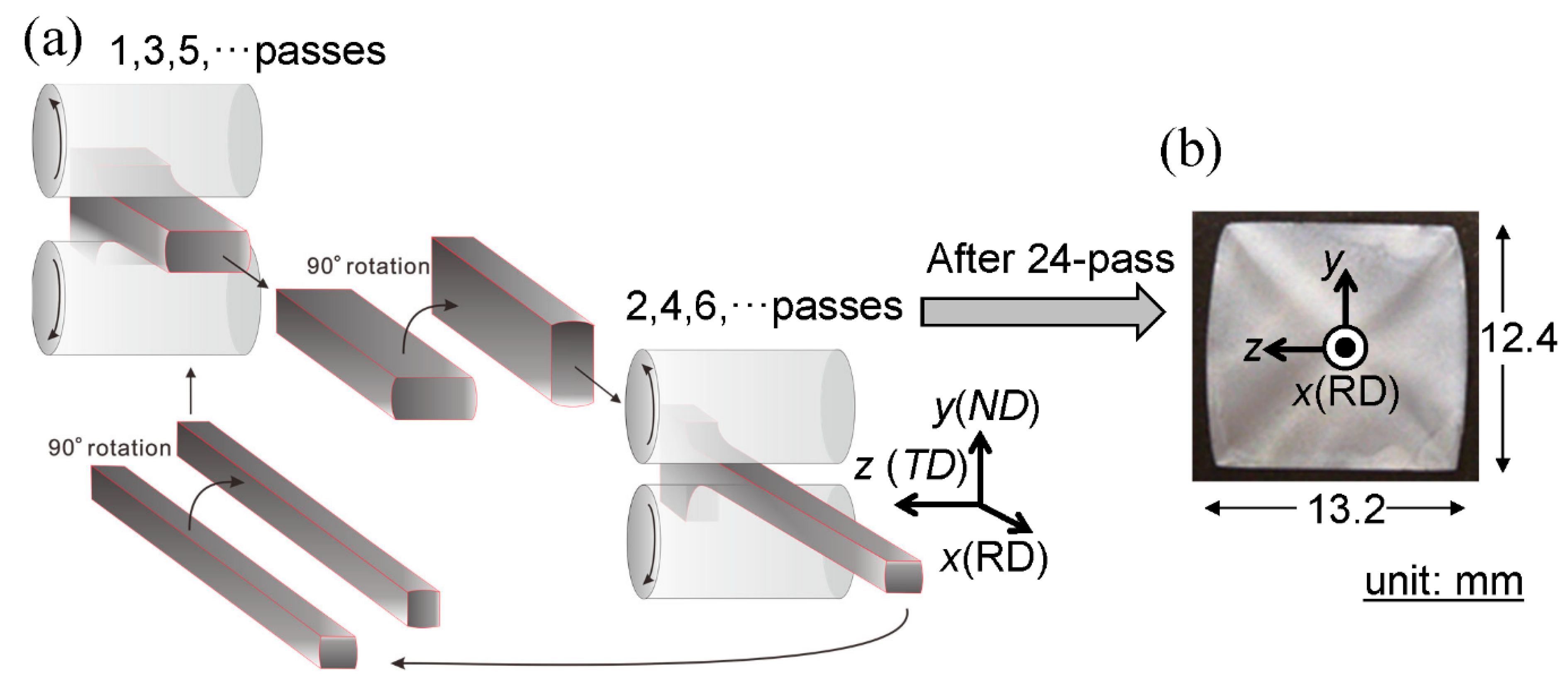

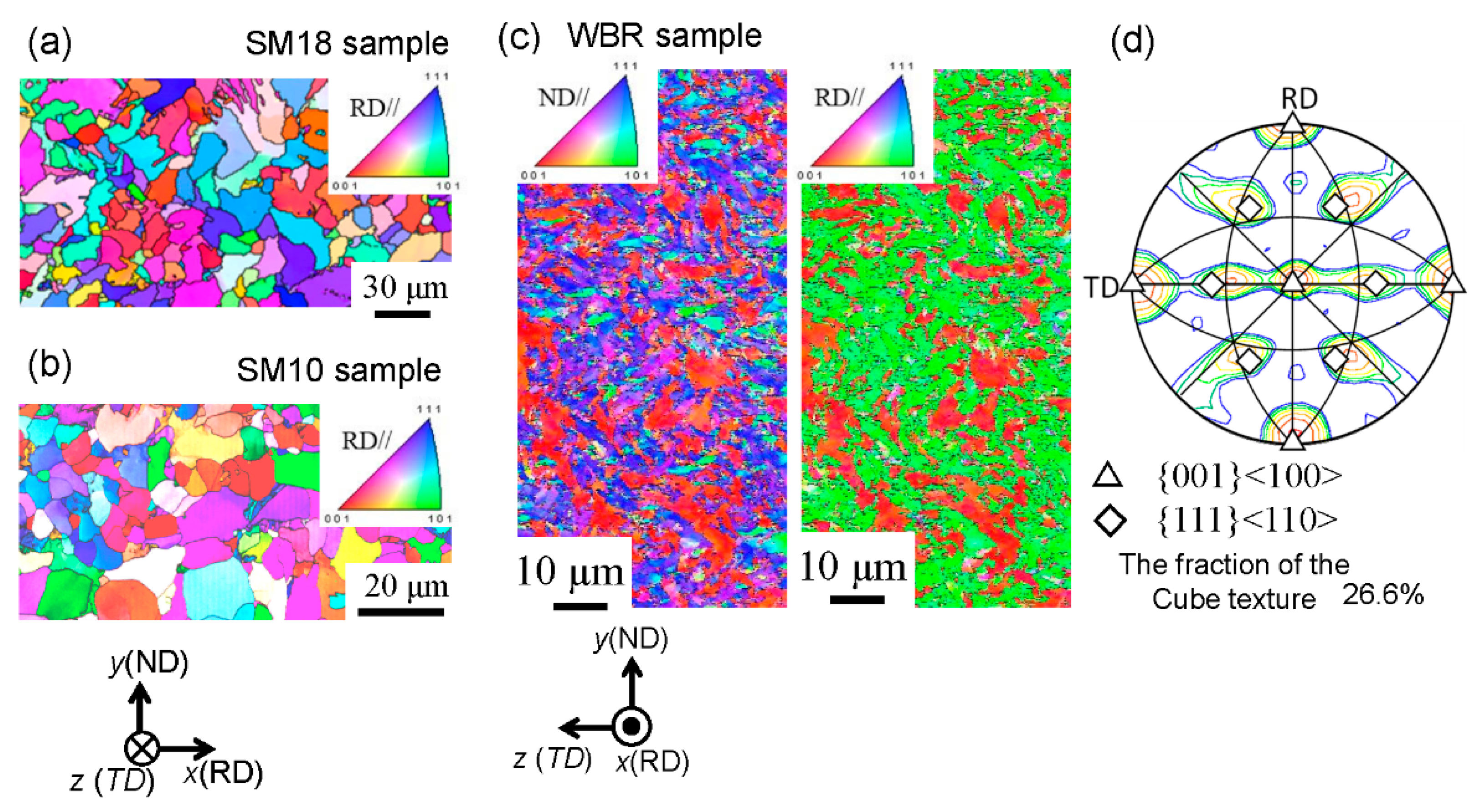

2.1. Specimen Preparation

2.2. Mechanical Properties and Microstructure

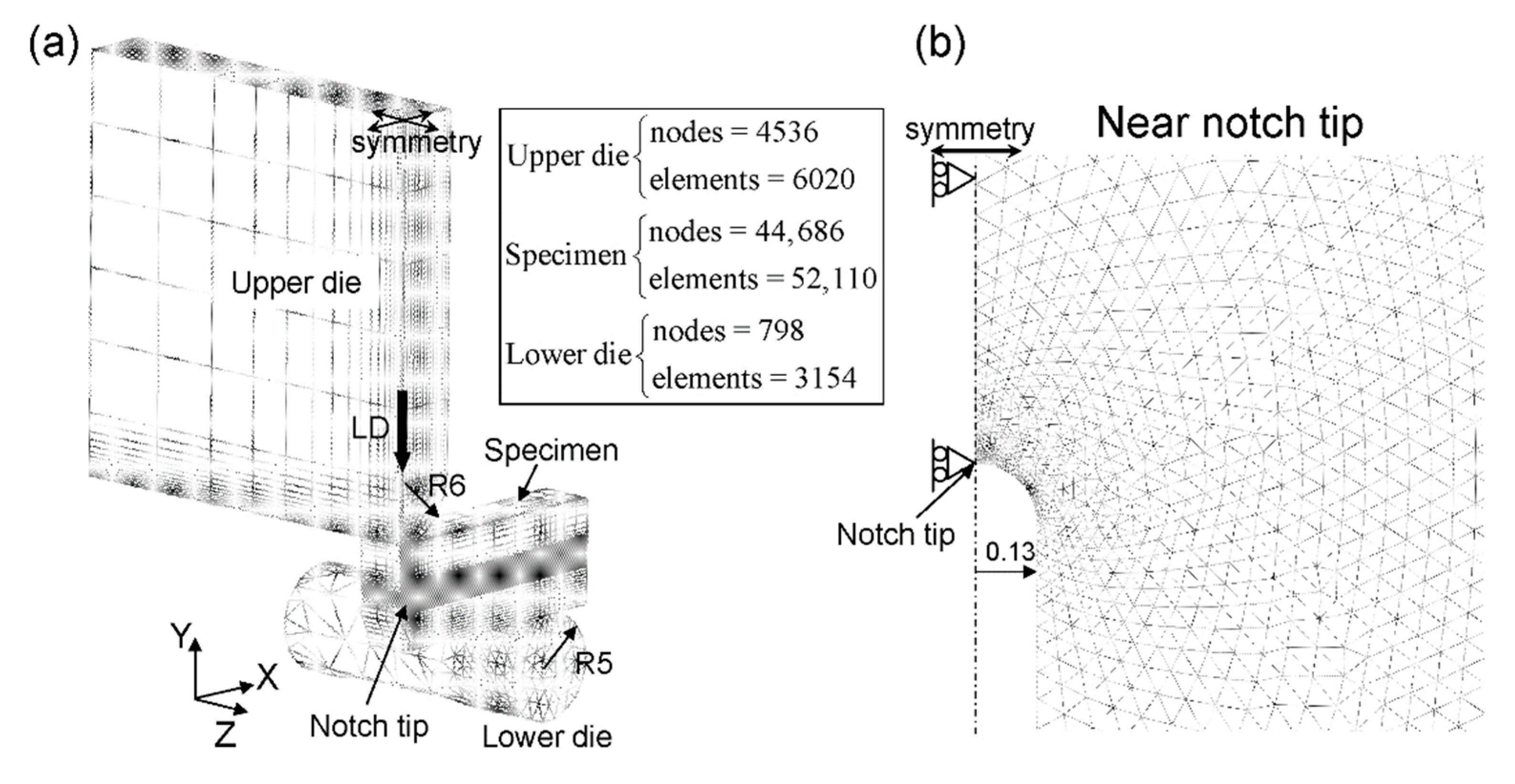

3. Numerical Procedure

4. Results

4.1. Microstructure Evolution

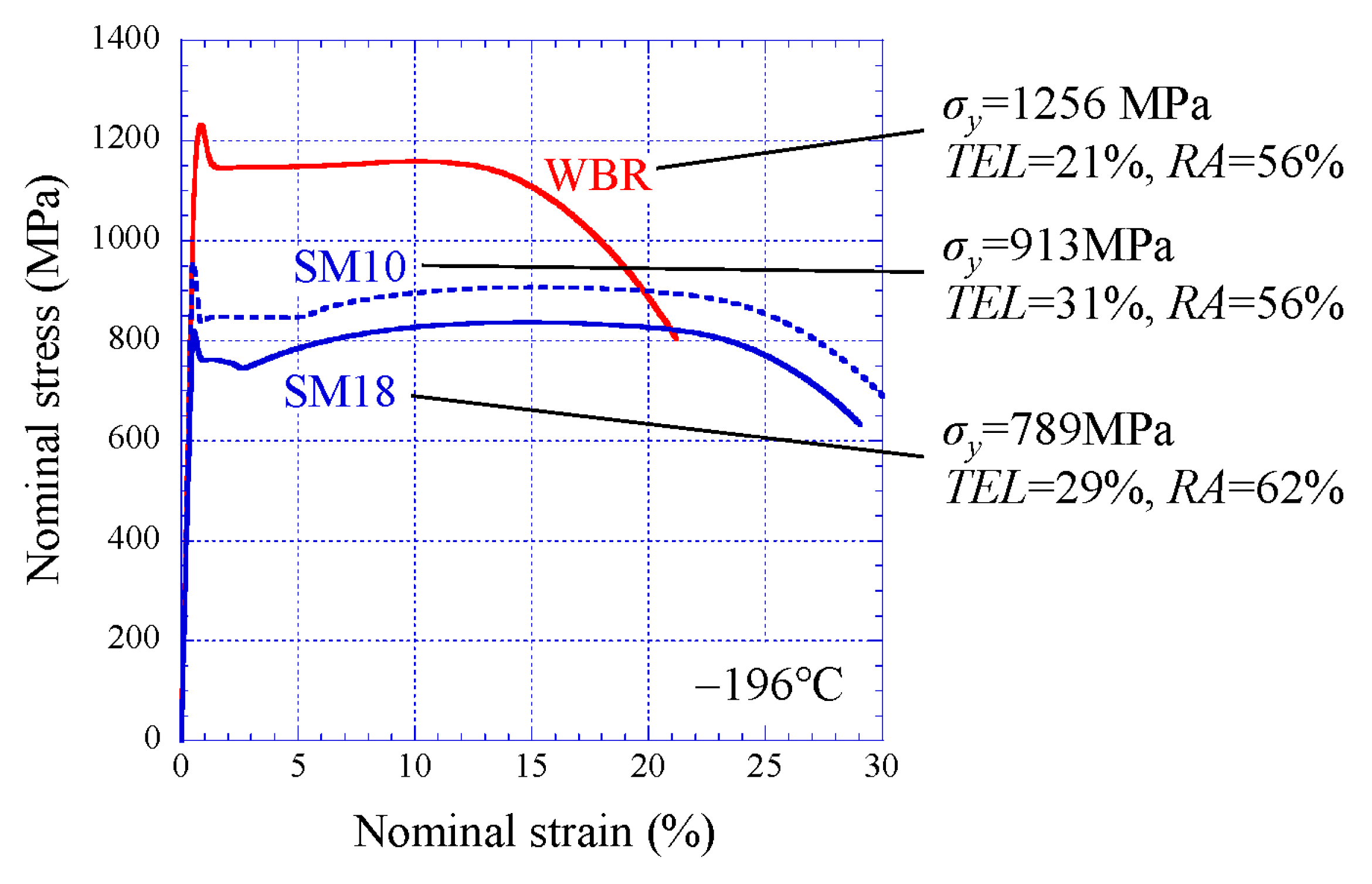

4.2. Tensile Properties

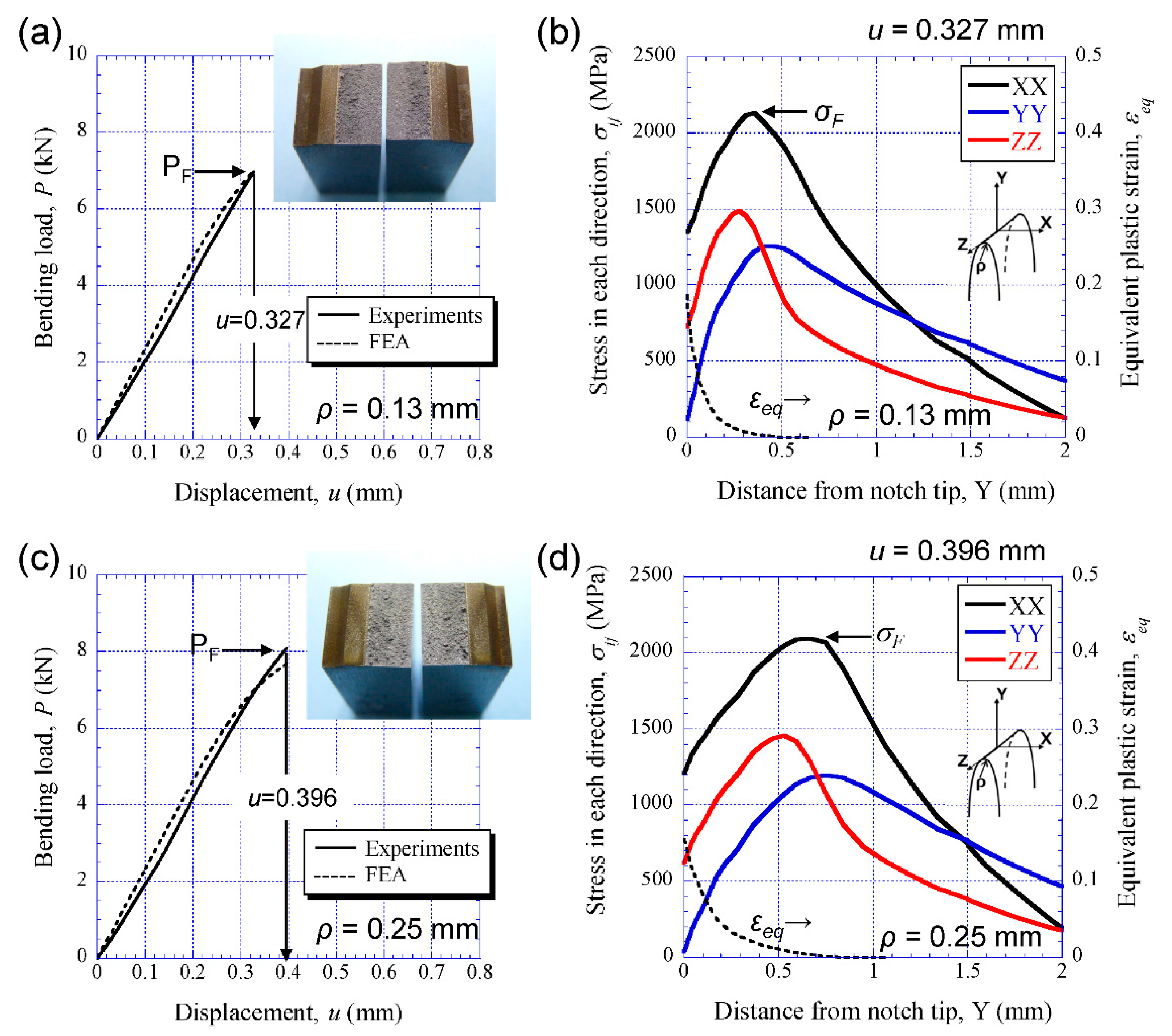

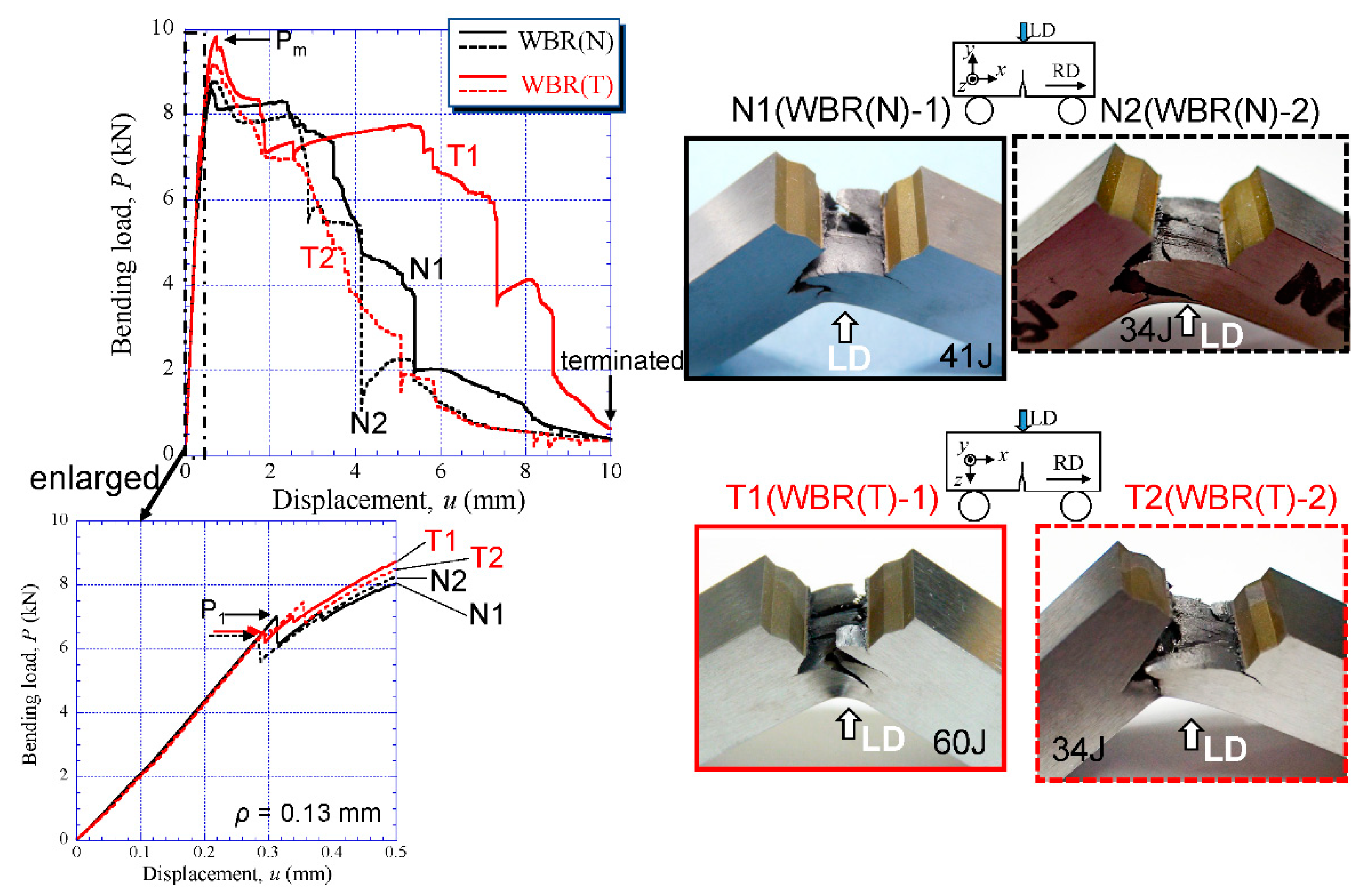

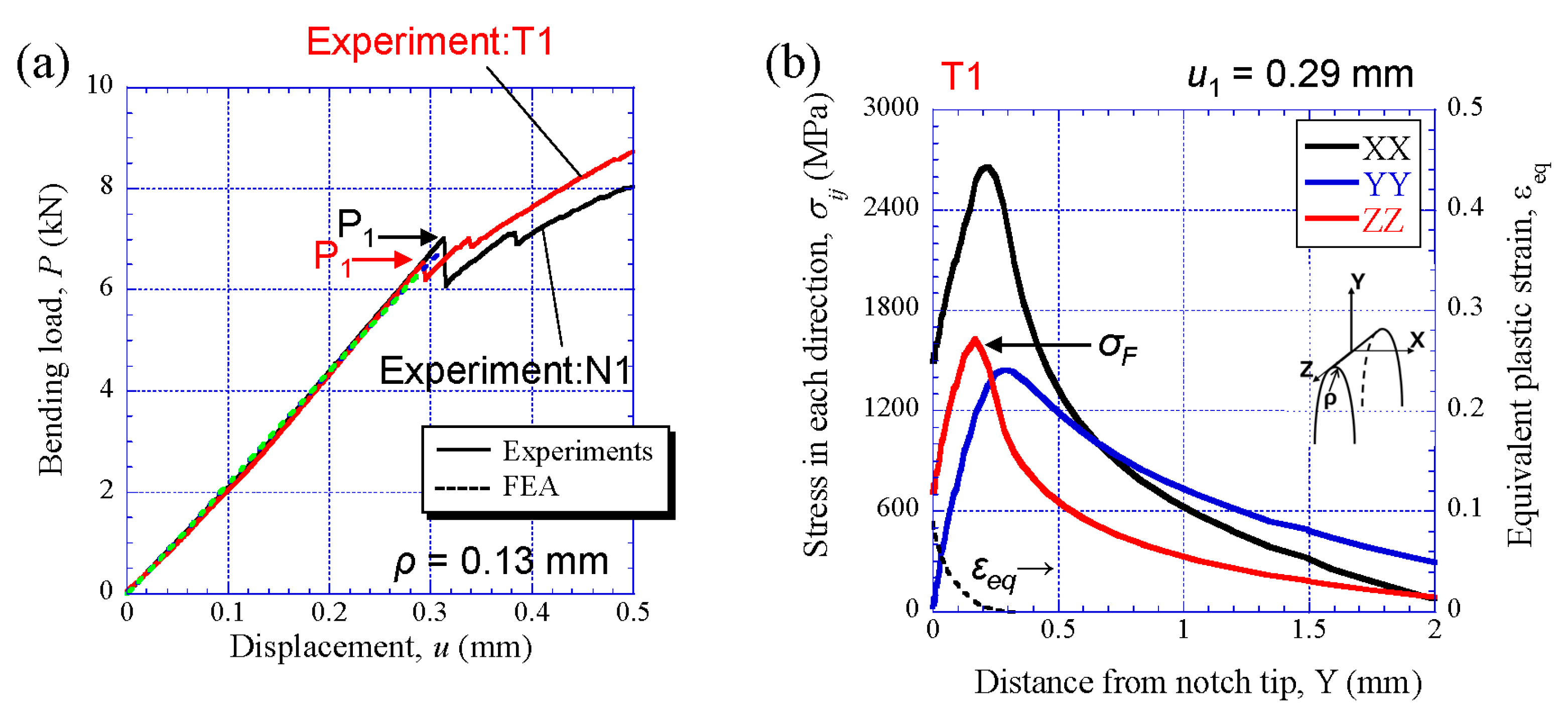

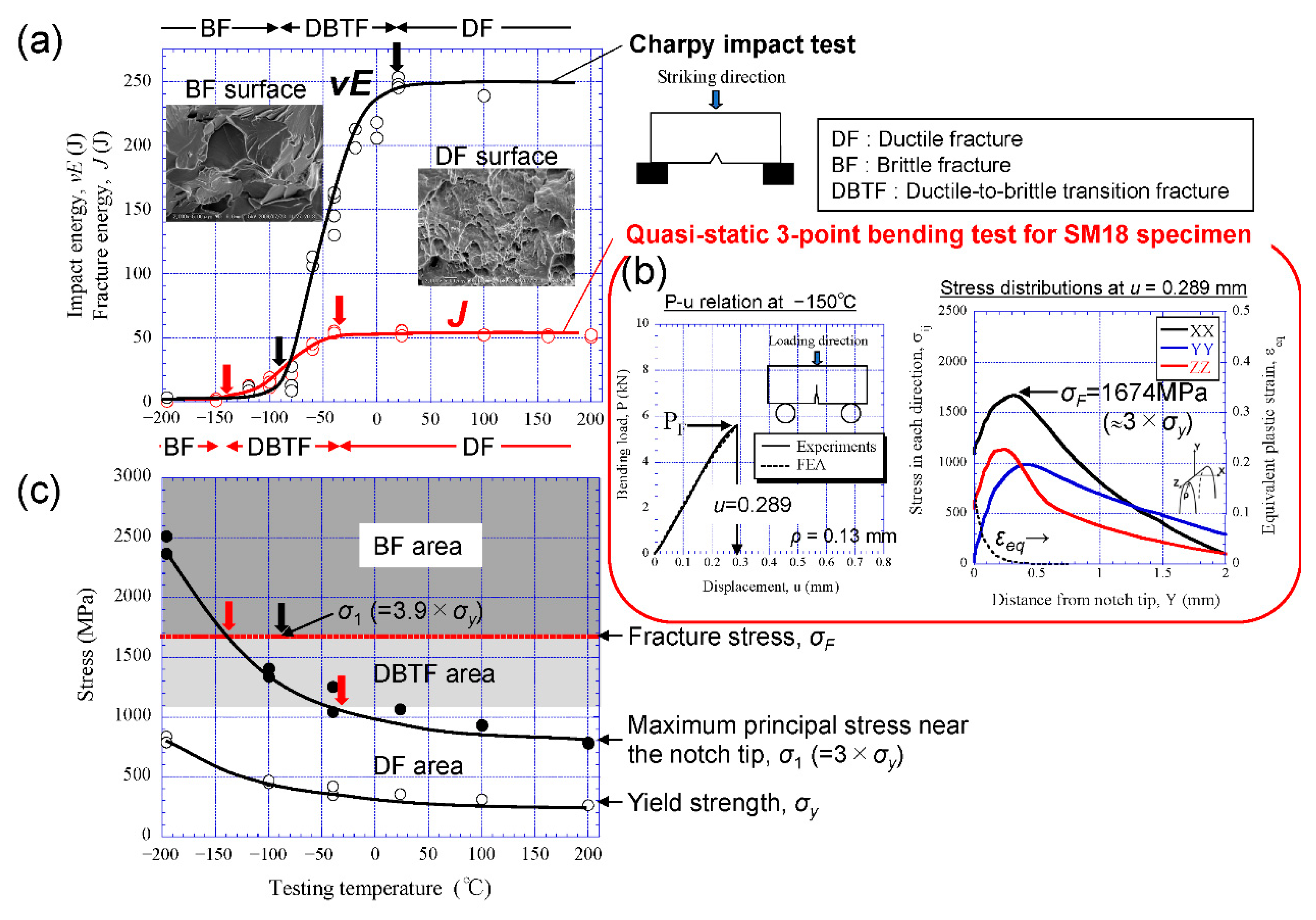

4.3. Three-Point Bending Properties and Fracture Stress

5. Discussion

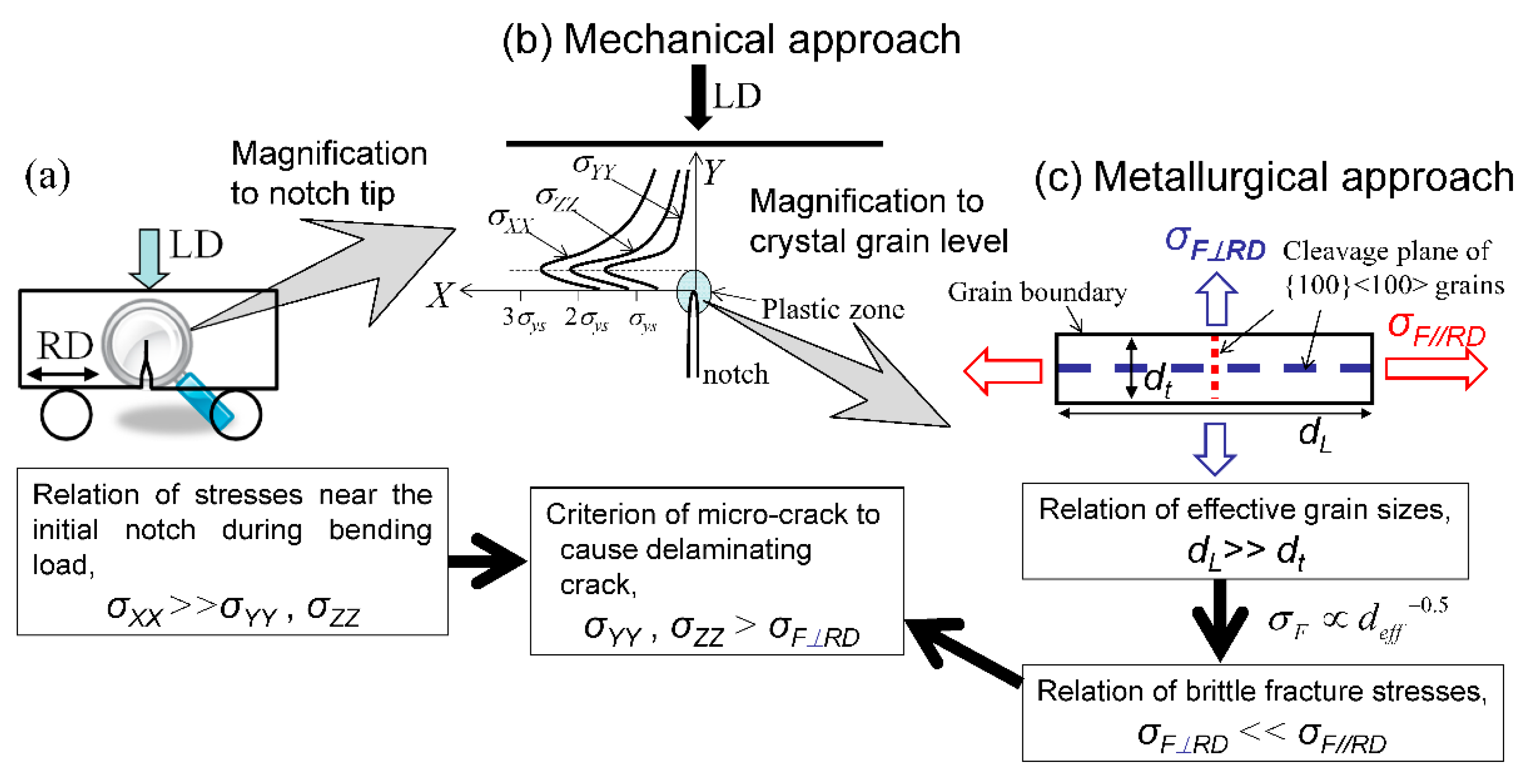

5.1. Delaminating Crack

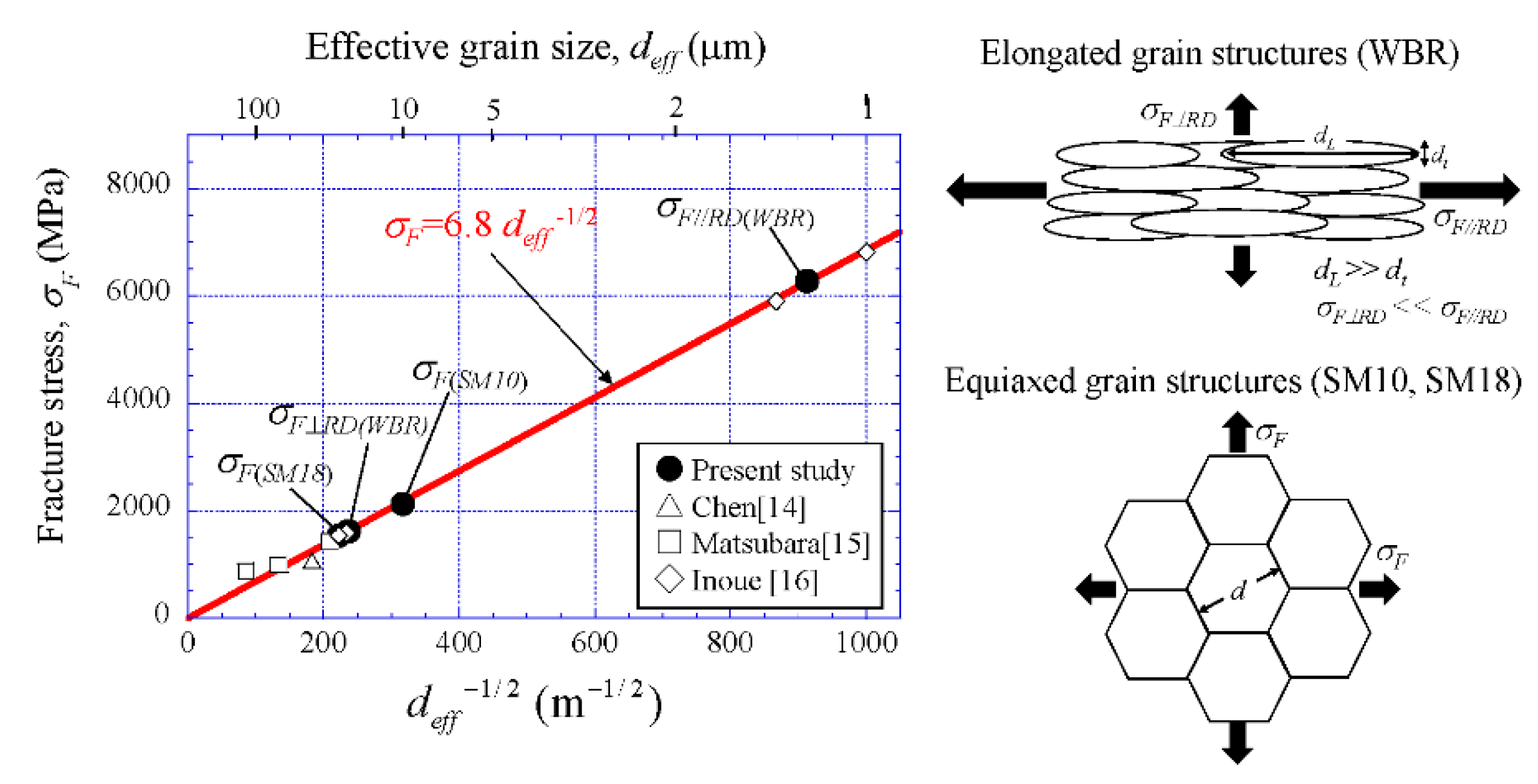

5.2. Brittle Fracture Stress vs. Grain Size

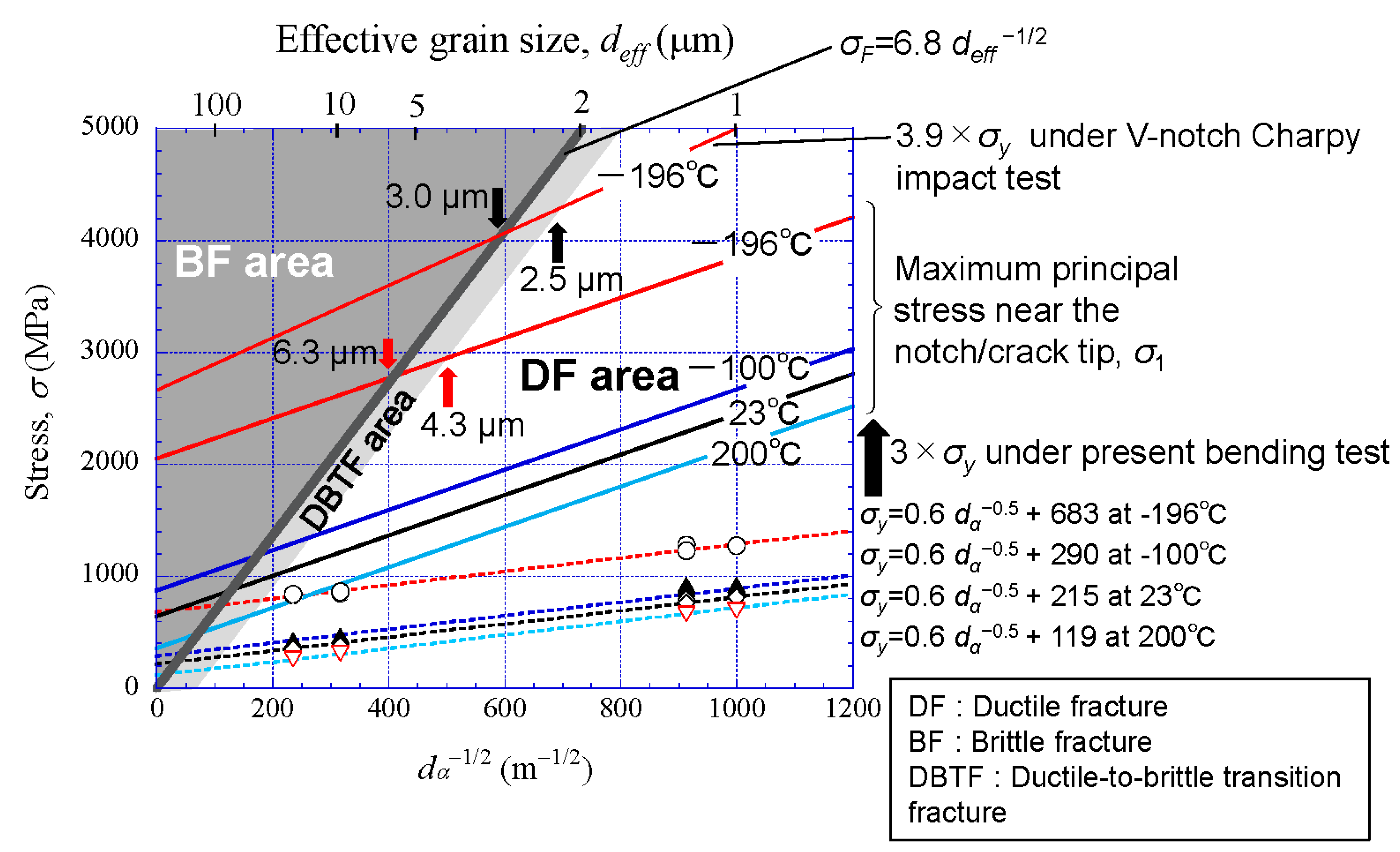

5.3. Condition for Brittle Fracture

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nishioka, K.; Ichikawa, K. Progress in thermomechanical control of steel plates and their commercialization. Sci. Technol. Adv. Mater. 2012, 13, 023001. [Google Scholar] [CrossRef] [PubMed]

- Shenawy, E.E.; Reda, R. Optimization of TMCP strategy for microstructure refinement and flow-productivity characteristics enhancement of low carbon steel. J. Mater. Res. Technol. 2019, 8, 2819–2831. [Google Scholar] [CrossRef]

- Morrison, W.B. The effect of grain size on the stress-strain relationship in low-carbon steel. Trans. ASME 1966, 59, 824–846. [Google Scholar]

- Inoue, T.; Yin, F.; Kimura, Y.; Tsuzaki, K.; Ochiai, S. Delamination effect on impact properties of ultrafine-grained low-carbon steel processed by warm caliber rolling. Metall. Mater. Trans. A 2010, 41, 341–355. [Google Scholar] [CrossRef]

- Tsuchida, N.; Inoue, T.; Nakano, H.; Okamoto, T. Enhanced true stress–true strain relationships due to grain refinement of a low-carbon ferrite–pearlite steel. Mater. Lett. 2015, 160, 117–119. [Google Scholar] [CrossRef]

- Pickering, F.B.; Gladman, T. Metallurgical Developments in Carbon Steel. Iron Steel Inst. Spec. Rep. 1963, 10–20. [Google Scholar]

- Bourell, D.L. Cleavage delamination in impact tested warm-rolled steel. Metall. Trans. A 1983, 14, 2487–2496. [Google Scholar] [CrossRef]

- Takagi, S.; Kawasaki, K.; Kimura, Y. Mechanical properties of ultra fine grained steels. J. Mater. Process. Technol. 2001, 117, 359–363. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. Manuf. Technol. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Torizuka, S.; Ohmori, A.; Murty, N.; Nagai, K. Effect of strain on the microstructure and mechanical properties of multi-pass warm caliber rolled low carbon steel. Scr. Mater. 2006, 54, 563–568. [Google Scholar] [CrossRef]

- Inoue, T.; Ueji, R. Improvement of strength, toughness and ductility in ultrafine-grained low-carbon steel processed by warm bi-axial rolling. Mater. Sci. Eng. A 2020, 786, 139415. [Google Scholar] [CrossRef]

- Morris, J.W., Jr. Materials science. Stronger, tougher steels. Science 2008, 320, 1022–1023. [Google Scholar] [CrossRef]

- Gilbert, A.; Hahn, G.T.; Reid, C.N.; Wilcox, B.A. Annihilation of vacancies at stacking faults in f.c.c. metals. Acta Mater. 1964, 12, 754–755. [Google Scholar] [CrossRef]

- Chen, J.K. Physical models for cleavage fracture at various temperatures—Bases for local approach to fracture of HSLA steel. Mater. Sci. Eng. A 2008, 486, 369–375. [Google Scholar] [CrossRef]

- Matsubara, M.; Aihara, S. Effect of microstructure on local fracture stress of ferrite/cementite steels. CAMP-ISIJ 2009, 22, 1323. [Google Scholar]

- Inoue, T. Brittle fracture stress of ultrafine-grained low-carbon steel. Mater. Trans. 2017, 58, 1505–1508. [Google Scholar] [CrossRef]

- Inoue, T.; Yin, F.; Kimura, Y. Strain distribution and microstructural evolution in multi-pass warm caliber rolling. Mater. Sci. Eng. A 2007, 466, 114–122. [Google Scholar] [CrossRef]

- Inoue, T.; Ueji, R.; Kimura, Y. Improvement of toughness and strength balance in low-carbon steel bars with cube texture processed by warm bi-axial rolling. Mater. Lett. 2019, 240, 172–175. [Google Scholar] [CrossRef]

- Inoue, T.; Ueji, R. Effect of strain and deformation mode on cube texture formation in warm bi-axial rolled low-carbon steel. Finite Elem. Anal. Des. 2021, 183–184, 103491. [Google Scholar] [CrossRef]

- Inoue, T. Toughening of low-alloy steel by ultrafine-grained structure (Development of fracture control from microstructure design). In Fracture Mechanics—Properties, Patterns and Behaviours; Alves, L.M., Ed.; InTech: Rijeka, Croatia, 2016; pp. 103–120. [Google Scholar] [CrossRef]

- Takeuchi, Y.; Noda, N.; Komori, S.; Yamoto, T. Temperature dependence of elastic moduli of several steels at low temperature range. J. Soc. Mater. Sci. (Jpn.) 1979, 28, 852–856. [Google Scholar] [CrossRef]

- Tsuchida, N.; Inoue, T.; Nakano, H. Effect of ferrite grain size on the estimated true stress–true strain relationship up to the plastic deformation limit in low carbon ferrite–cementite steels. J. Mater. Res. 2013, 28, 2171–2179. [Google Scholar] [CrossRef]

- Tsuchida, N.; Tomota, Y.; Nagai, K. Tensile Properties Obtained by Static Tensile Tests in Ultrafine-grained Ferrite—Cementite Steels. Tetsu-to-Hagane 2003, 89, 1170–1177. [Google Scholar] [CrossRef]

- Dieter, G.E. Mechanical Metallurgy; SI Metric Edition; McGraw-Hill Book Co.: Singapore, 1988; p. 248. [Google Scholar]

- Okamura, H. Introduction to Linear Fracture Mechanics; Baifukan: Tokyo, Japan, 1995; p. 218. (In Japanese) [Google Scholar]

- Schino, A.D.; Guarnacshelli, C. Microstructure and cleavage resistance of high strength steels. Mater. Sci. Forum 2010, 638–642, 3188–3193. [Google Scholar] [CrossRef]

- Tanguy, B.; Besson, J.; Piques, R.; Pineau, A. Ductile to brittle transition of an A508 steel characterized by Charpy impact test Part II: Modeling of the Charpy transition curve. Eng. Fract. Mech. 2005, 72, 413–414. [Google Scholar] [CrossRef]

- Takashima, Y.; Minami, F. Prediction of Charpy absorbed energy of steel for welded structure in ductile-to-brittle fracture transition temperature range. Q. J. Jpn. Weld. Soc. 2020, 38–42, 103–107. [Google Scholar] [CrossRef]

- Ma, H. The Effect of Stress Triaxiality on the Local Cleavage Fracture Stress in a Granular Bainitic Weld Metal. Int. J. Fract. 1998, 89, 143–158. [Google Scholar] [CrossRef]

- Inoue, T.; Kimura, Y. Effect of initial notch orientation on fracture toughness in fail-safe steel. J. Mater. Sci. 2013, 48, 4766–4772. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Inoue, T.; Qiu, H.; Ueji, R.; Kimura, Y. Ductile-to-Brittle Transition and Brittle Fracture Stress of Ultrafine-Grained Low-Carbon Steel. Materials 2021, 14, 1634. https://doi.org/10.3390/ma14071634

Inoue T, Qiu H, Ueji R, Kimura Y. Ductile-to-Brittle Transition and Brittle Fracture Stress of Ultrafine-Grained Low-Carbon Steel. Materials. 2021; 14(7):1634. https://doi.org/10.3390/ma14071634

Chicago/Turabian StyleInoue, Tadanobu, Hai Qiu, Rintaro Ueji, and Yuuji Kimura. 2021. "Ductile-to-Brittle Transition and Brittle Fracture Stress of Ultrafine-Grained Low-Carbon Steel" Materials 14, no. 7: 1634. https://doi.org/10.3390/ma14071634

APA StyleInoue, T., Qiu, H., Ueji, R., & Kimura, Y. (2021). Ductile-to-Brittle Transition and Brittle Fracture Stress of Ultrafine-Grained Low-Carbon Steel. Materials, 14(7), 1634. https://doi.org/10.3390/ma14071634