Improvement in Hardness and Wear Behaviour of Iron-Based Mn–Cu–Sn Matrix for Sintered Diamond Tools by Dispersion Strengthening

Abstract

1. Introduction

2. Materials and Methods

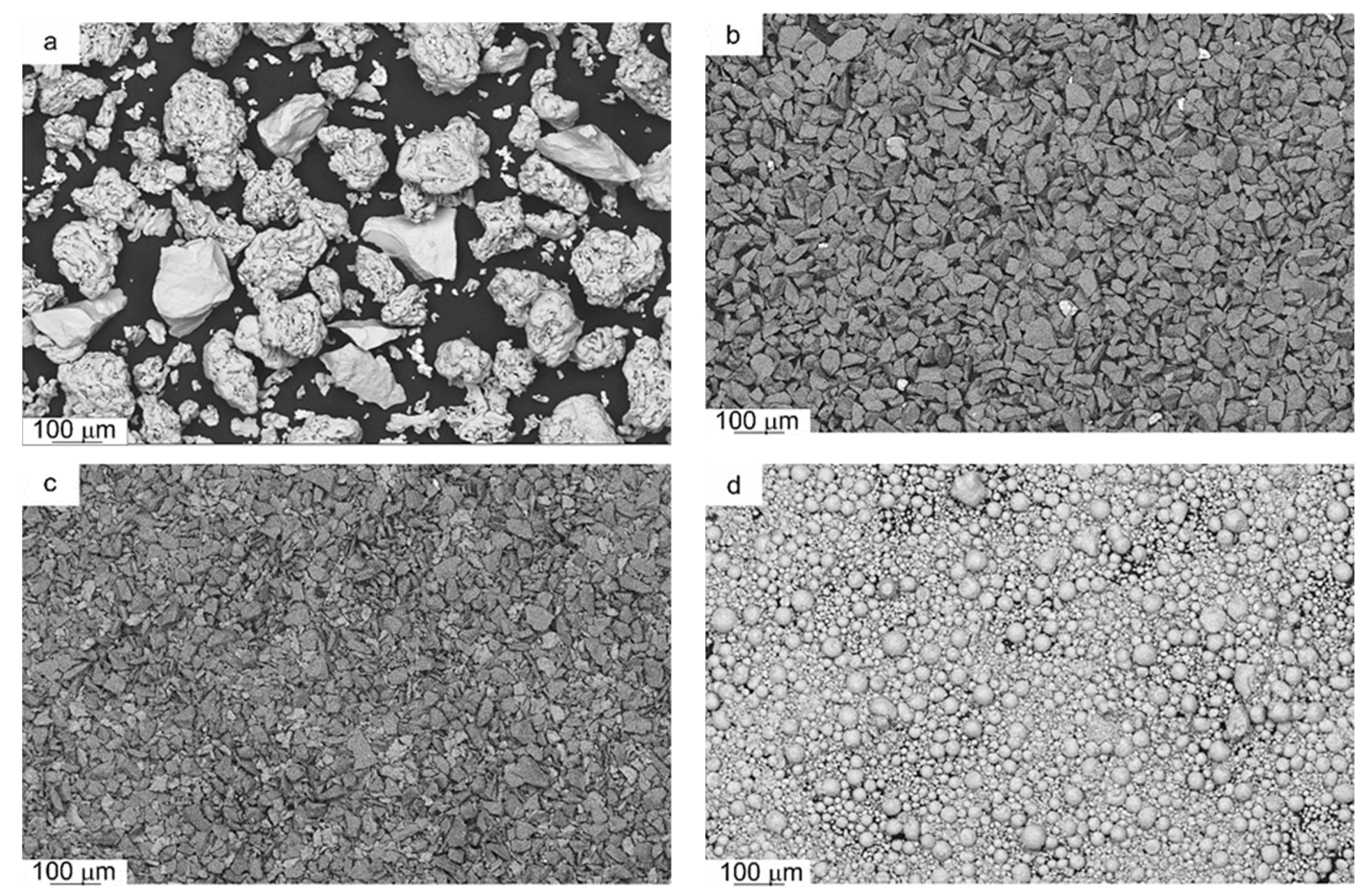

2.1. Materials

- Base (Fe–Mn–Cu–Sn–C);

- Base (Fe–Mn–Cu–Sn–C) with the addition of 5, 10, and 20 wt.% of SiC;

- Base (Fe–Mn–Cu–Sn–C) with the addition of 5, 10, and 20 wt.% of Al2O3;

- Base (Fe–Mn–Cu–Sn–C) with the addition of 5, 10, and 20 wt.% of the ZrO2.

- Premixing of base powders from the Fe–Mn–Cu–Sn–C system for 1 h in a chaotic motion Turbula Type T2C Shaker Mixer, WAB, Muttenz, Switzerland;

- Addition of the ceramic phase in an amount of 5 wt.%, 10 wt.%, and 20 wt.% to the base mixture (Fe–Mn–Cu–Sn–C);

- Premixing of base powders (Fe–Mn–Cu–Sn–C) and ceramic phase for 1 h in a chaotic motion Turbula-type mixer;

- Ball milling in air, at 70% of the critical speed, for 8 h, with about 50 vol.% of the milling vial filled with 12 mm 100Cr6 steel balls and 10:1 ball:powder weight ratio.

2.2. Spark Plasma Sintering (SPS)

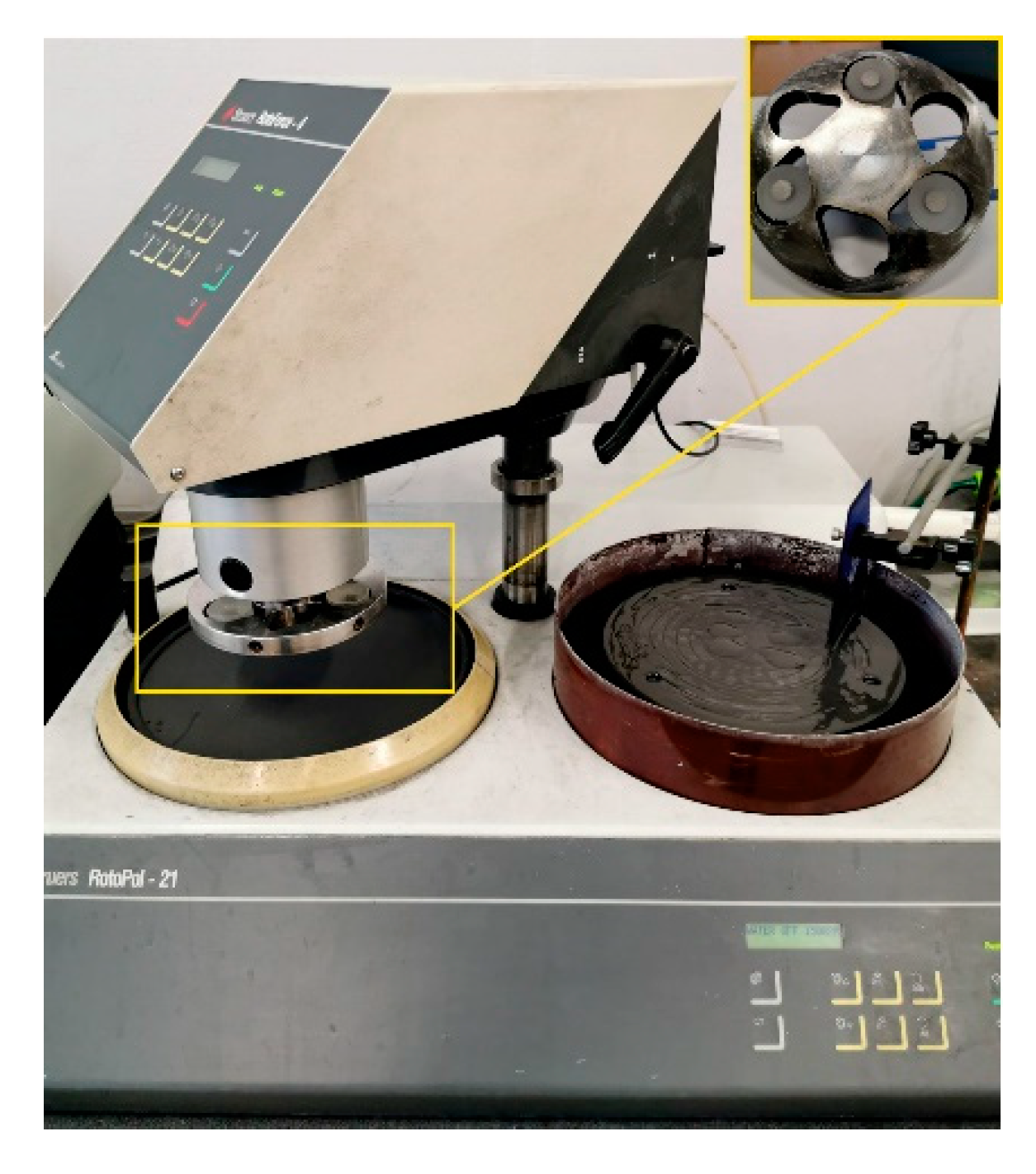

2.3. Characterization of Sintered Specimens

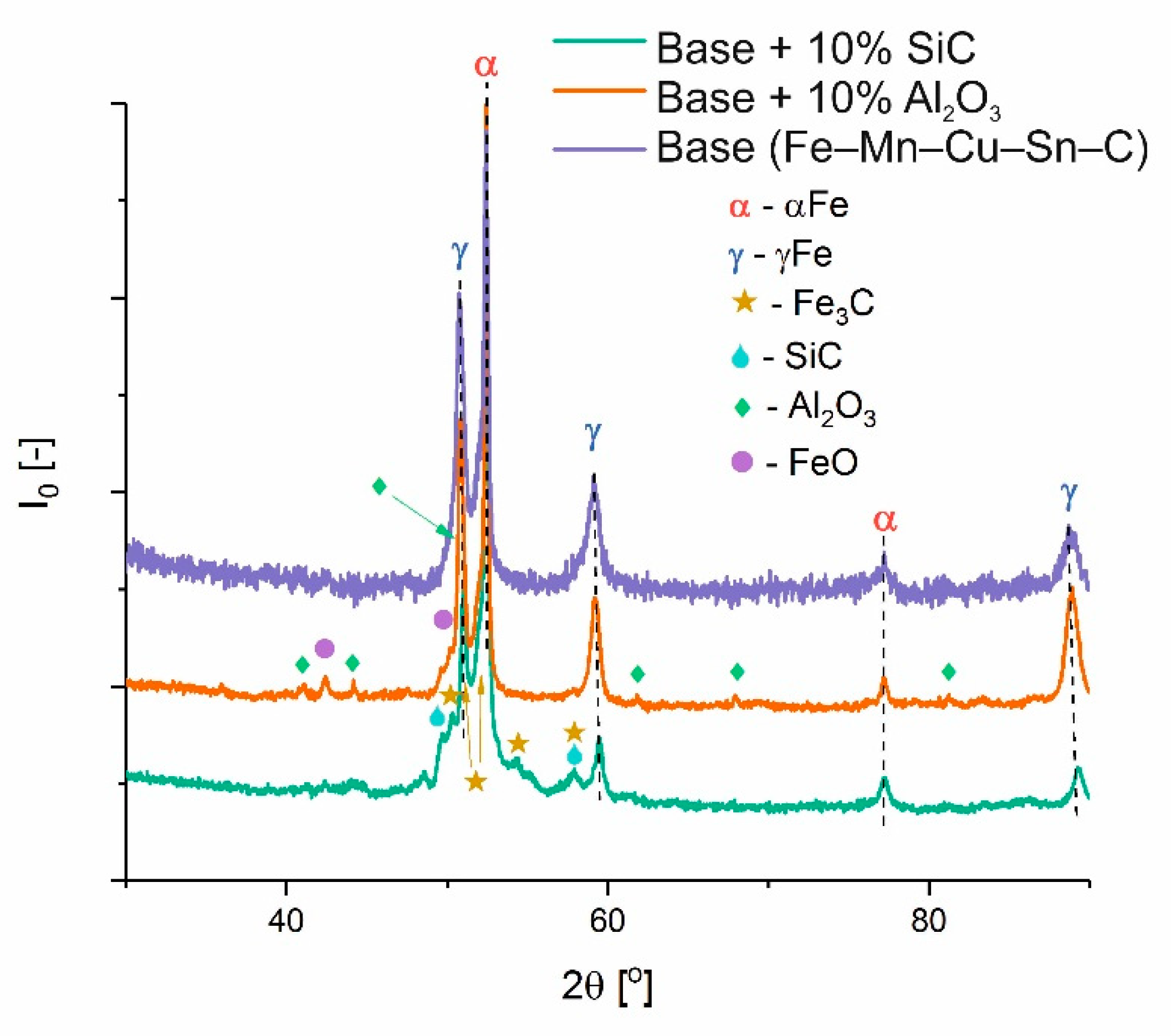

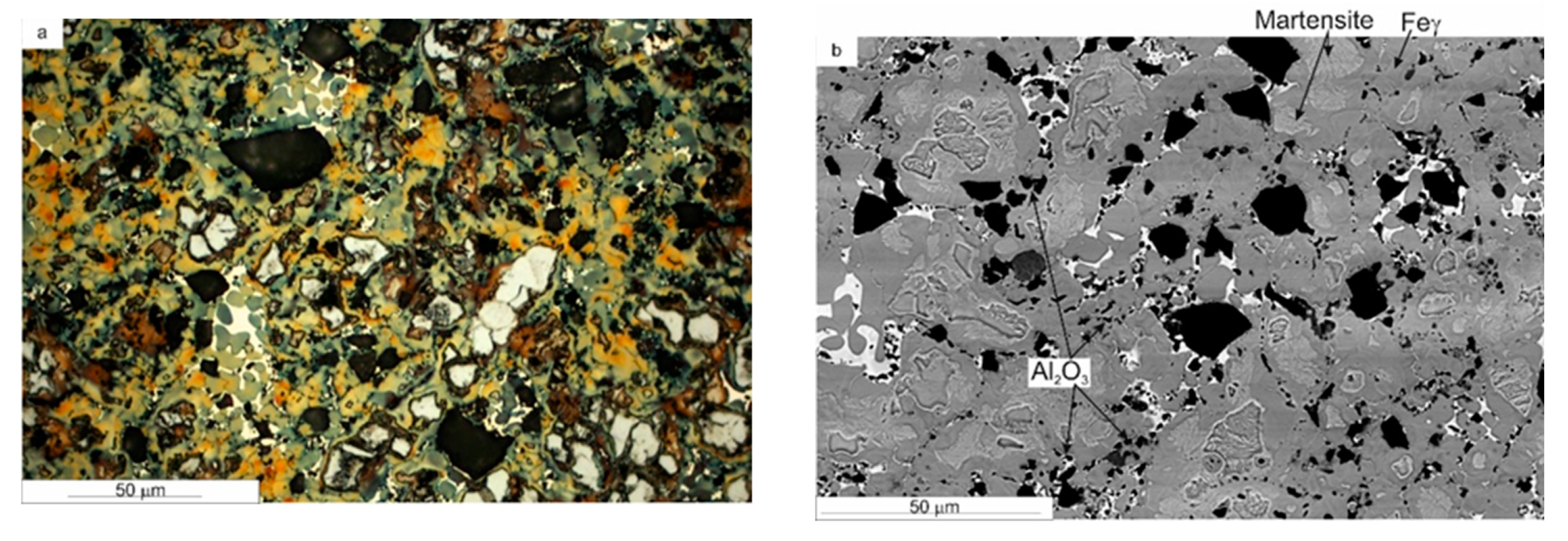

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Clark, I.E.; Kamphuis, B.J. Cobalite HDR—A new prealloyed matrix powder for diamond construction tools. Ind. Diam. Rev. 2002, 62, 177–182. [Google Scholar]

- Kamphuis, B.; Serneels, A. Cobalt and nickel free bond powder for diamond tools: Cobalite CNF. Ind. Diam. Rev. 2004, 64, 26–32. [Google Scholar]

- Bonneau, M.; Moltenni, M. Wire manufacturing and free sintering with NEXT. Ind. Diam. Rev. 2002, 4, 263–265. [Google Scholar]

- Keen—a new concept in prealloyed powders. Ind. Diam. Rev. 2005, 3, 45–47.

- Kamphuis, B.J.; Peersman, J. Pre−Alloyed Bond Powders. US Patent 7077883, 18 July 2006. [Google Scholar]

- Żak-Szwed, M.; Konstanty, J.; Zielińska-Lipiec, A. Iron-base PM matrix alloys for diamond impregnated tools. Int. J. Powder Met. 2009, 45, 36. [Google Scholar]

- Konstanty, J.; Stephenson, T.F.; Tyrała, D. Novel Fe−Ni−Cu−Sn matrix materials for the manufacture of diamond-impregnated tools. Diam. Tool. J. 2011, 2, 26–29. [Google Scholar]

- Romanski, A.; Tokarski, T.; Tyrala, D. Sintered Fe-Ni-Cu-Sn-C Alloys Made of Ball-Milled Powders. Arch. Metall. Mater. 2014, 59, 947–950. [Google Scholar] [CrossRef]

- Song, J.I.; Lee, G.Y.; Lee, C.S.; Lee, J.S. Fabrication of a diamond impregnated tool using iron nanopowder binder. J. Ceram. Process. Res. 2018, 19, 265–271. [Google Scholar]

- Zaitsev, A.A.; Sidorenko, D.A.; Levashov, E.A.; Kurbatkina, V.V.; Rupasov, S.I.; Andreev, V.A.; Sevast’yanov, P.V. Development and Application of the Cu–Ni–Fe–SnBased DispersionHardened Bond for Cutting Tools of Superhard Materials. J. Superhard Mater. 2012, 34, 270–280. [Google Scholar] [CrossRef]

- de Oliveira, L.J.; Bobrovnitchii, G.S.; Filgueira, M. Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix. Int. J. Refract. Hard Mater. 2007, 25, 328–335. [Google Scholar] [CrossRef]

- Tyrala, D.; Romanski, A.; Konstanty, J. The Effects of Powder Composition on Microstructure and Properties of Hot-Pressed Matrix Materials for Sintered Diamond Tools. J. Mater. Eng. Perform. 2020, 29, 1467–1472. [Google Scholar] [CrossRef]

- Loginov, P.A.; Sidorenko, D.A.; Shvyndian, N.V.; Sviridova, T.A.; Churyumov, A.Y.; Levashov, E.A. Effect of Ti and TiH2 doping on mechanical and adhesive properties of Fe-Co-Ni binder to diamond in cutting tools. Int. J. Refract. Met. Hard Mater. 2019, 79, 69–78. [Google Scholar] [CrossRef]

- Chen, F.; Yan, Z.; Liu, Z.; Long, Y.; Fu, N.; Zhang, F.; Liu, B.; Liu, Y. Preparation and properties of Al2O3-reinforced Cu-Ni-Sn metallic matrix for applications in diamond-cutting tools. Diam. Relat. Mater. 2020, 109, 108025. [Google Scholar] [CrossRef]

- Bączek, E.; Konstanty, J.; Romański, A.; Podsiadło, M.; Cyboroń, J. Processing and Characterization of Fe-Mn-Cu-Sn-C Alloys Prepared by Ball Milling and Spark Plasma Sintering. J. Mater. Eng. Perform. 2018, 29, 1–9. [Google Scholar] [CrossRef]

- Konstanty, J.; Bączek, E.; Romański, A.; Tyrała, D. Wear-resistant iron-based Mn-Cu-Sn matrix for sintered diamond tools. Powder Metall. 2018, 61, 43–49. [Google Scholar] [CrossRef]

- Fundal, E. The Struers Micro Wear Test. Structure 1989, 3, 3,4,23. [Google Scholar]

- Konstanty, J.; Tyrała, D. Wear Mechanism of Iron-Base Diamond Impregnated Tool Composites. Wear 2013, 303, 533–540. [Google Scholar] [CrossRef]

- Kim, J.K.T.W.; Kim, S.B. Resistance to Abrasive Wear of Materials Used as Metallic Matrices in Diamond Impregnated Tools. Mater. Sci. Forum 2007, 534–536, 1125–1128. [Google Scholar]

- Konstanty, J. Testing Resistance to Abrasive Wear of Iron-Base Materials Used as Metallic Matrices in Diamond Impregnated Tool Components; Final Report, February 2007; EHWA Diamond Ind. Co Ltd.: Osan, Korea, 2007; Unpublished work. [Google Scholar]

| Powder | Bulk Density (g/cm3) | Subsieve Auto Sizer | Laser Diffraction (µm) 1 | ||

|---|---|---|---|---|---|

| Mean Particle Size (µm) | D3 | D50 | D94 | ||

| Base (Fe–Mn–Cu–Sn–C) | 3.57 | 86 | – | ||

| SiC F320 | 1.50 | 31 | 48.98 | 29.97 | 16.53 |

| Al2O3 EF320 | 1.64 | 21 | 36.3 | 29.1 | 22.6 |

| ZrO2 Grade 16 | 1.89 | 43 | – | 0.069 | 0.20 |

| Material Composition (wt.%) | Density (Relative Density) (g/cm3) | Young’s Modulus (GPa) | HRB | HV1 | µm/20m | µm/20m |

|---|---|---|---|---|---|---|

| Base (Fe–Mn–Cu–Sn–C) | 7.75 ± 0.01 (>99%) | 197 ± 2 | 103 ± 1 | 299 ± 7 | 24.6 ± 2.72 | 138.7 ± 1.18 |

| Base + 10% SiC | 7.27 ± 0.01 (>99%) | 174 ± 2 | 114 ± 1 | 425 ± 26 | 13.6 ± 2.05 | 104.9 ± 10.62 |

| Base + 20% SiC | 6.85 ± 0.01 (>99%) | 162 ± 1 | 117 ± 1 | 459 ± 31 | 15.5 ± 1.85 | 119.9 ± 10.3 |

| Base + 10% Al2O3 | 7.28 ± 0.01 (99%) | 194 ± 2 | 106 ± 1 | 320 ± 15 | 11.0 ± 2.27 | 49.9 ± 11.75 |

| Base + 20% Al2O3 | 6.77 ± 0.01 (97%) | 187 ± 2 | 109 ± 1 | 350 ± 10 | 11.0 ± 3.56 | 40.5 ± 6.4 |

| Base + 10% ZrO2 | 7.24 ± 0.01 (96%) | 172 ± 2 | 107 ± 1 | 324 ± 9 | 23.6± 1.35 | 188.9 ± 10.8 |

| Base + 20% ZrO2 | 6.44 ± 0.01 (87%) | 116 ± 1 | 101 ± 1 | 354 ± 29 | 28.5 ± 4.37 | 159.7 ± 14.8 |

| Co-20% WC | 9.26 ± 0.01 (>99%) | 225 ± 3 | 113 ± 2 | 374 ± 17 | 48.8 ± 5.99 | 177.1 ± 9.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cygan-Bączek, E.; Wyżga, P.; Cygan, S.; Bała, P.; Romański, A. Improvement in Hardness and Wear Behaviour of Iron-Based Mn–Cu–Sn Matrix for Sintered Diamond Tools by Dispersion Strengthening. Materials 2021, 14, 1774. https://doi.org/10.3390/ma14071774

Cygan-Bączek E, Wyżga P, Cygan S, Bała P, Romański A. Improvement in Hardness and Wear Behaviour of Iron-Based Mn–Cu–Sn Matrix for Sintered Diamond Tools by Dispersion Strengthening. Materials. 2021; 14(7):1774. https://doi.org/10.3390/ma14071774

Chicago/Turabian StyleCygan-Bączek, Elżbieta, Piotr Wyżga, Sławomir Cygan, Piotr Bała, and Andrzej Romański. 2021. "Improvement in Hardness and Wear Behaviour of Iron-Based Mn–Cu–Sn Matrix for Sintered Diamond Tools by Dispersion Strengthening" Materials 14, no. 7: 1774. https://doi.org/10.3390/ma14071774

APA StyleCygan-Bączek, E., Wyżga, P., Cygan, S., Bała, P., & Romański, A. (2021). Improvement in Hardness and Wear Behaviour of Iron-Based Mn–Cu–Sn Matrix for Sintered Diamond Tools by Dispersion Strengthening. Materials, 14(7), 1774. https://doi.org/10.3390/ma14071774