Wear Resistance of Medium Carbon Steel with Different Microstructures

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material

2.2. Tribology Behavior

3. Results and Discussion

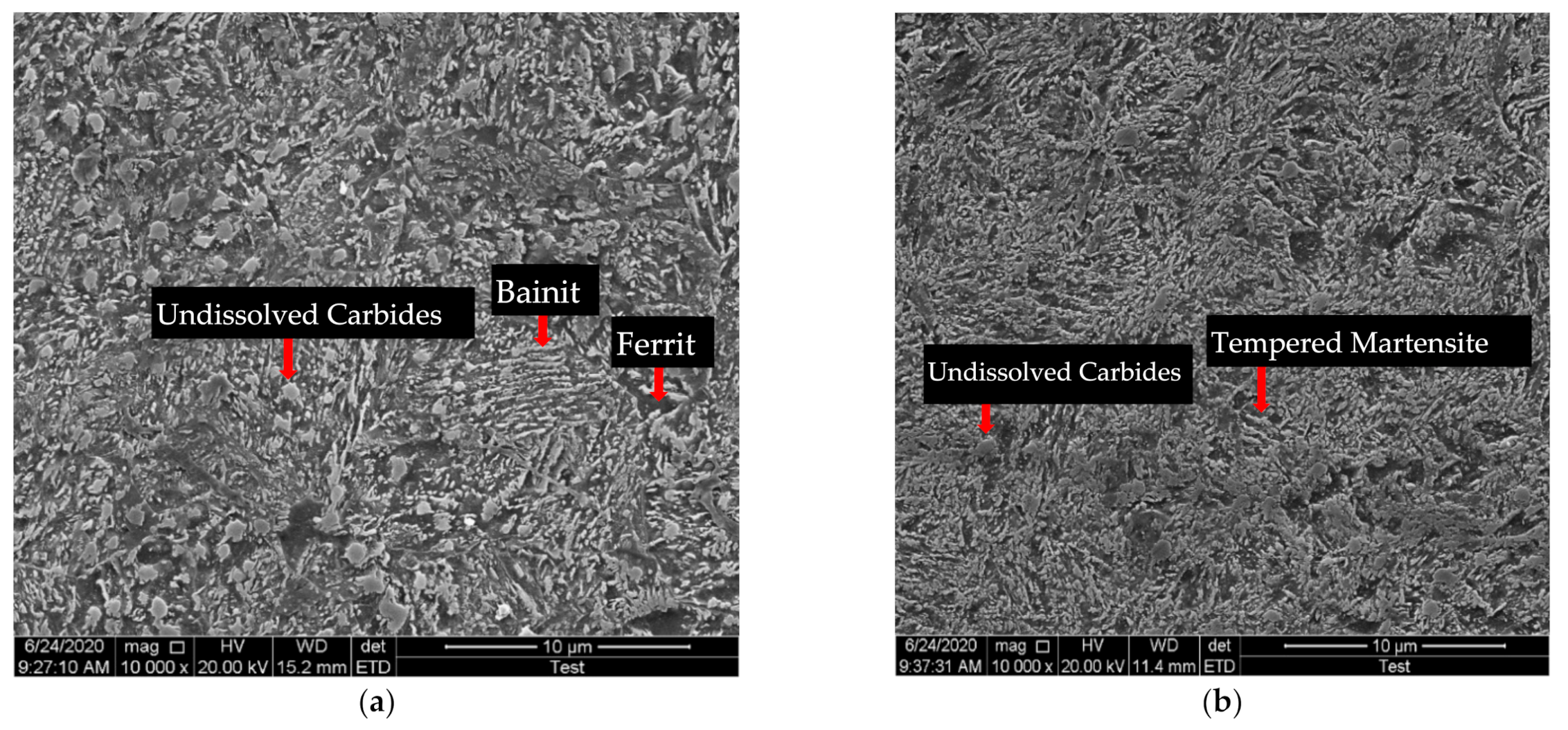

3.1. Microstructure and Characterization

3.2. The Volume Fraction of Retained Austenite

3.3. Hardness

3.4. Friction Performance

3.5. Wear Performance

3.6. Pile Up

3.7. Ball Surface

3.8. SEM Observations

3.9. Optical Observations

4. Discussion

5. Conclusions

- 1.

- The tempered martensite microstructure resulted in more plastic deformation and more cracks, due to lower fracture toughness, as compared to the bainite microstructure. This resulted in more debris being produced on the surfaces of samples with tempered martensite microstructure than with the bainite microstructure. Therefore, the tempered martensite microstructure results in higher wear loss than the bainite microstructure.

- 2.

- Severe smearing wear was observed on the top surfaces of 343 °C austempered disks and 585 °C quenched-tempered disks. This is because these two disks contain a more ferritic microstructure with low dislocation density which is soft and rather deformable as compared to the other disk specimens which were tested. Therefore, these two disks produced a higher coefficient of friction than the other disks.

- 3.

- Less debris was generated on the harder disks resulting in only mild abrasive wear. However, more debris was smeared on the softer disks and third body wear particles were produced resulting in relatively high wear of the softer disks.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Institutional Review Board Statement

Conflicts of Interest

References

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction. Wiley: Hoboken, NJ, USA, 2020. [Google Scholar]

- Clarke, A.J.; Miller, M.; Field, R.; Coughlin, D.; Gibbs, P.; Clarke, K.D.; Alexander, D.; Powers, K.; Papin, A.P.; Krauss, G. Atomic and nanoscale chemical and structural changes in quenched and tempered 4340 steel. Acta Materialia 2014, 77, 17–27. [Google Scholar] [CrossRef]

- Zhang, J.-C.; Zhang, T.; Yang, Y.-T. Microstructure and properties evolution of Nb-bearing medium Cr wear-resistant cast steel during heat treatment. J. Iron Steel Res. Int. 2020, 1–13. [Google Scholar] [CrossRef]

- Keough, J.R.; Hayrynen, K.L. Carbidic Austempered Ductile Iron (CADI). Ductile Iron News 2000, 3, 840–845. [Google Scholar]

- Bayati, H.; Elliott, R. Effect of Microstructural Features on the Austempering Heat Treatment Processing Window. In Materials Science Forum; Trans Tech Publications Ltd.: Bach, Switzerland, 2000; pp. 73–78. [Google Scholar] [CrossRef]

- Shen, F.S.; Krauss, G. The effect of phosphorous content and proeutectoid carbide distribution on the fracture behavior of 52100 steel. J. Heat Treat. 1982, 2, 238–249. [Google Scholar] [CrossRef]

- Jia, S.-J.; Li, B.; Liu, Q.-Y.; Ren, Y.; Zhang, S.; Gao, H. Effects of continuous cooling rate on morphology of granular bainite in pipeline steels. J. Iron Steel Res. Int. 2020, 27, 681–690. [Google Scholar] [CrossRef]

- Aglan, H.; Liu, Z.; Hassan, M.; Fateh, M. Mechanical and fracture behavior of bainitic rail steel. J. Mater. Process. Technol. 2004, 151, 268–274. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Z.; Rong, Y.; Thrush, S.J.; Barber, G.C.; Yang, H.; Qiu, F. Bainite kinetic transformation of austempered AISI 6150 steel. J. Mater. Res. Technol. 2020, 9, 1357–1364. [Google Scholar] [CrossRef]

- Lee, W.-S.; Su, T.-T. Mechanical properties and microstructural features of AISI 4340 high-strength alloy steel under quenched and tempered conditions. J. Mater. Process. Technol. 1999, 87, 198–206. [Google Scholar] [CrossRef]

- Huang, D.; Thomas, G. Structure and mechanical properties of tempered martensite and lower bainite in Fe−Ni−Mn−C steels. Metall. Trans. 1971, 2, 1587–1598. [Google Scholar] [CrossRef]

- Shashidhara, Y.M.; Jayaram, S.R. Tribological Studies on AISI 1040 with Raw and Modified Versions of Pongam and Jatropha Vegetable Oils as Lubricants. Adv. Tribol. 2012, 2012, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Litoria, A.K.; Joshi, A.A.; Joshi, M.D.; Dixit, G.; Singh, D.; Hosmani, S.S. Wear behaviour of boronized and duplex-treated AISI 4140 steel against DLC-coated boronized AISI 4140 disc. Surf. Eng. 2018, 35, 370–377. [Google Scholar] [CrossRef]

- Singh, D.; Mondal, D.P. Effect of Quenching and Tempering Processes and shot peening intensity on wear behaviour of SAE-6150 steel. IJEMS 2014, 21, 168–178. [Google Scholar]

- Han, X.; Zhang, Z.; Hou, J.; Barber, G.C.; Qiu, F. Tribological behavior of shot peened/austempered AISI 5160 steel. Tribol. Int. 2020, 145, 106197. [Google Scholar] [CrossRef]

- Chattopadhyay, C.; Sangal, S.; Mondal, K.; Garg, A. Improved wear resistance of medium carbon microalloyed bainitic steels. Wear 2012, 289, 168–179. [Google Scholar] [CrossRef]

- Kar, R.J.; Horn, R.M.; Zackay, V.F. The effect of heat treatment on microstructure and mechanical properties in 52100 steel. Met. Mater. Trans. A 1979, 10, 1711–1717. [Google Scholar] [CrossRef]

- Saleski, W.J.; Fisher, R.M.; Ritchie, R.O.; Thomas, G. Ludema, K.C., Ed.; The Nature and Origin of Sliding Wear Debris from Steels. In Materials & Molecular Research Division, Proceedings of the Conference on Wear of Materials, Reston, VA, USA, 11–14 April 1983; Ludema, K.C., Ed.; ASME: New York, NY, USA, 1983; Volume 83, pp. 434–445. [Google Scholar]

| C | Cr | V | Mn | P | Si | S | Fe |

|---|---|---|---|---|---|---|---|

| 0.51 | 0.95 | 0.15 | 0.80 | 0.035 | 0.22 | 0.04 | Balance |

| Austempered Temperature (°C) | Hardness | Quenched-Tempered Temperature (°C) | Hardness |

|---|---|---|---|

| As received | 85.2 HRB | As received | 85.2 HRB |

| 288 | 47.7 HRC | 380 | 48.2 HRC |

| 316 | 45.6 HRC | 455 | 43.8 HRC |

| 343 | 38.7 HRC | 585 | 38.3 HRC |

| Austempered Temperature (°C) | Austempered Retained Austenite (%) | Quenched-Tempered Temperature (°C) | Quenched-Tempered Retained Austenite (%) |

|---|---|---|---|

| 288 | 3.10 | 380 | 0.87 |

| 316 | 2.60 | 455 | 0.64 |

| 343 | 0.61 | 585 | 0.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Zhang, Z.; Barber, G.C.; Thrush, S.J.; Li, X. Wear Resistance of Medium Carbon Steel with Different Microstructures. Materials 2021, 14, 2015. https://doi.org/10.3390/ma14082015

Han X, Zhang Z, Barber GC, Thrush SJ, Li X. Wear Resistance of Medium Carbon Steel with Different Microstructures. Materials. 2021; 14(8):2015. https://doi.org/10.3390/ma14082015

Chicago/Turabian StyleHan, Xue, Zhenpu Zhang, Gary C. Barber, Steven J. Thrush, and Xin Li. 2021. "Wear Resistance of Medium Carbon Steel with Different Microstructures" Materials 14, no. 8: 2015. https://doi.org/10.3390/ma14082015

APA StyleHan, X., Zhang, Z., Barber, G. C., Thrush, S. J., & Li, X. (2021). Wear Resistance of Medium Carbon Steel with Different Microstructures. Materials, 14(8), 2015. https://doi.org/10.3390/ma14082015