A State of the Art of the Overall Energy Efficiency of Wood Buildings—An Overview and Future Possibilities

Abstract

:1. Introduction

1.1. Building Services

1.2. Building Design under Specific Weather Conditions

1.3. Building Characteristics

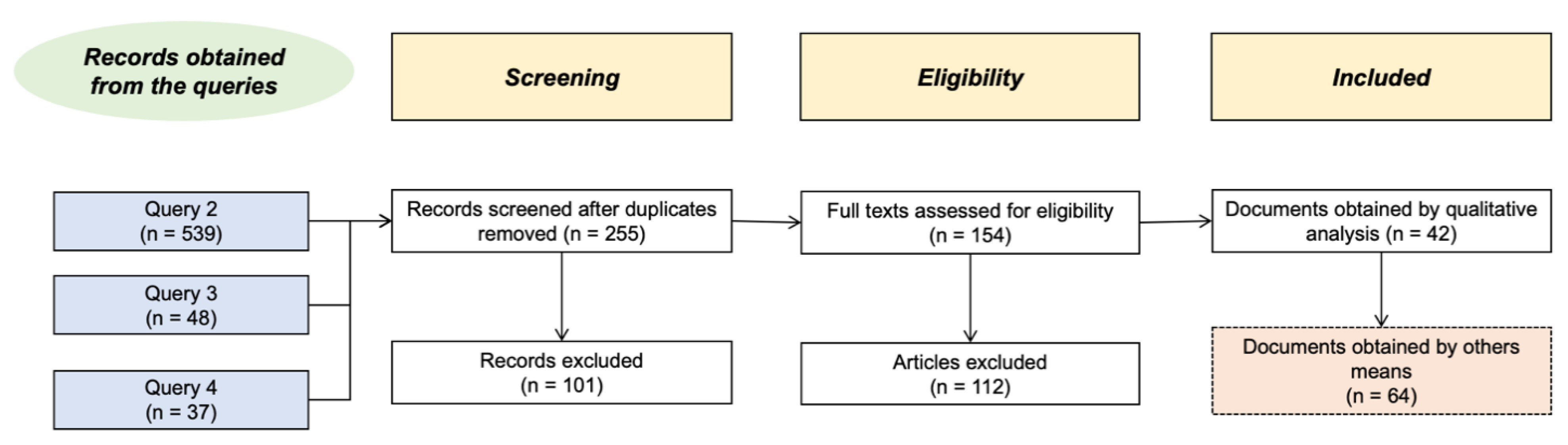

2. Materials and Methods

- ((“wood frame” AND (“building” OR “construction”)) OR “mass timber”);

- AND (“materials” or “building materials”);

- AND (“embodied energy” or “energy efficiency”) AND “energy”;

- AND “efficiency”.

3. Materials’ Influence on Building Energy Efficiency

- Fibrous: This group refers to fibers that are small in size to provide air space in the material. This type of insulation is produced with organic or inorganic fibers (e.g., glass wool, rock wool, slag wool, wood wool, cellulose) that are normally bound together with an adhesive [75];

- Granular: This group refers to nodules containing voids or hollow spaces. These materials are also considered open-cell materials due to the gases that can be transferred between the individual spaces [75];

- Cellular: The materials in this group are made of individual cells that are either interconnected with or sealed from each other. Glass, plastics and rubber may comprise the base material, and various foaming agents are used. Cellular insulation is often further classified as either open-cell (when cells are interconnected) or closed-cell (when cells are sealed from each other) [75];

- Reflective and treatments: This group includes materials that are added to surfaces to lower long-wave emittance, thereby reducing radiant heat transfer from the surface, such as low-emittance jackets and facing [75].

4. Wood and Building Energy Efficiency

4.1. Wood Frame Buildings

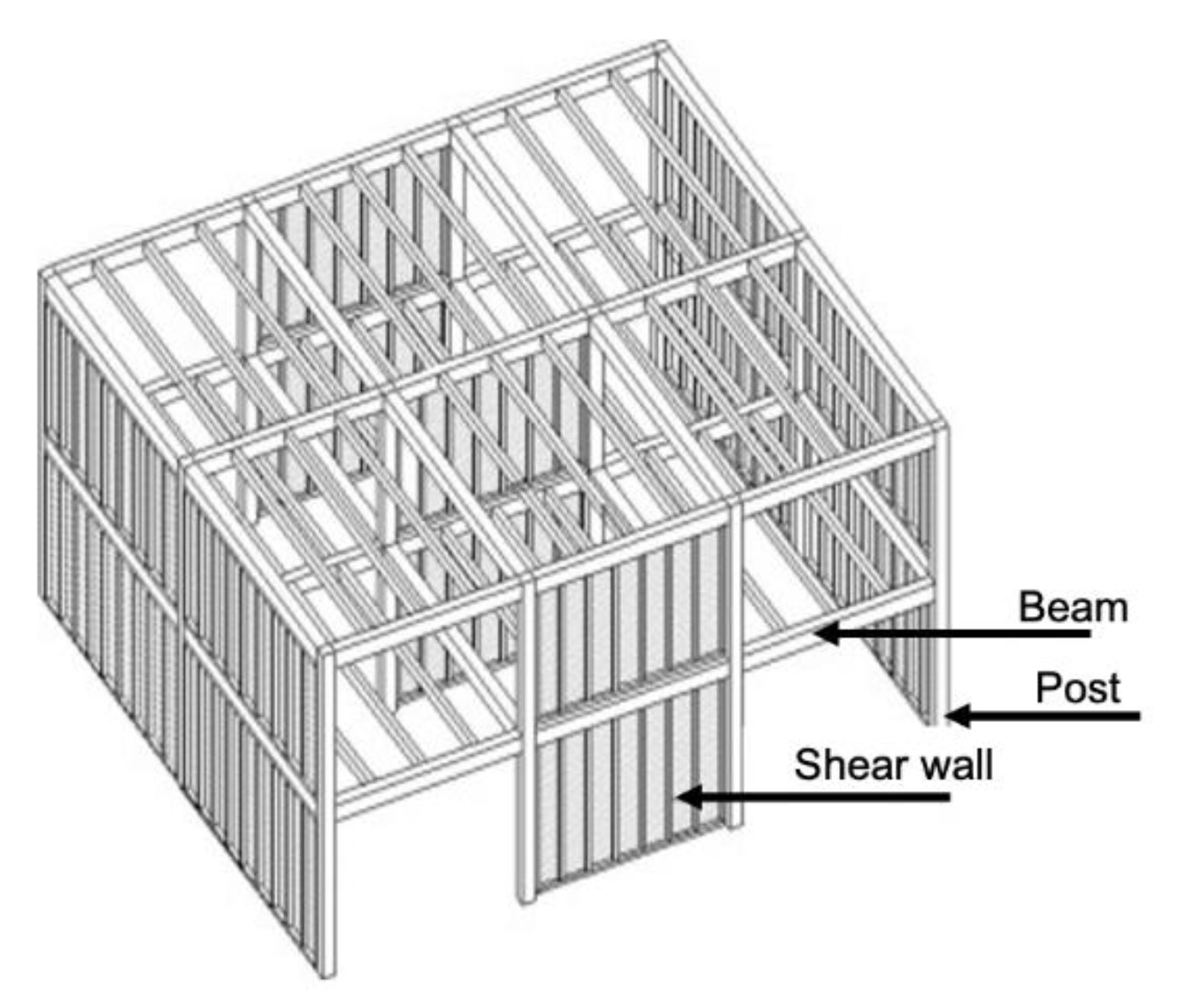

4.2. Post-and-Beam Buildings

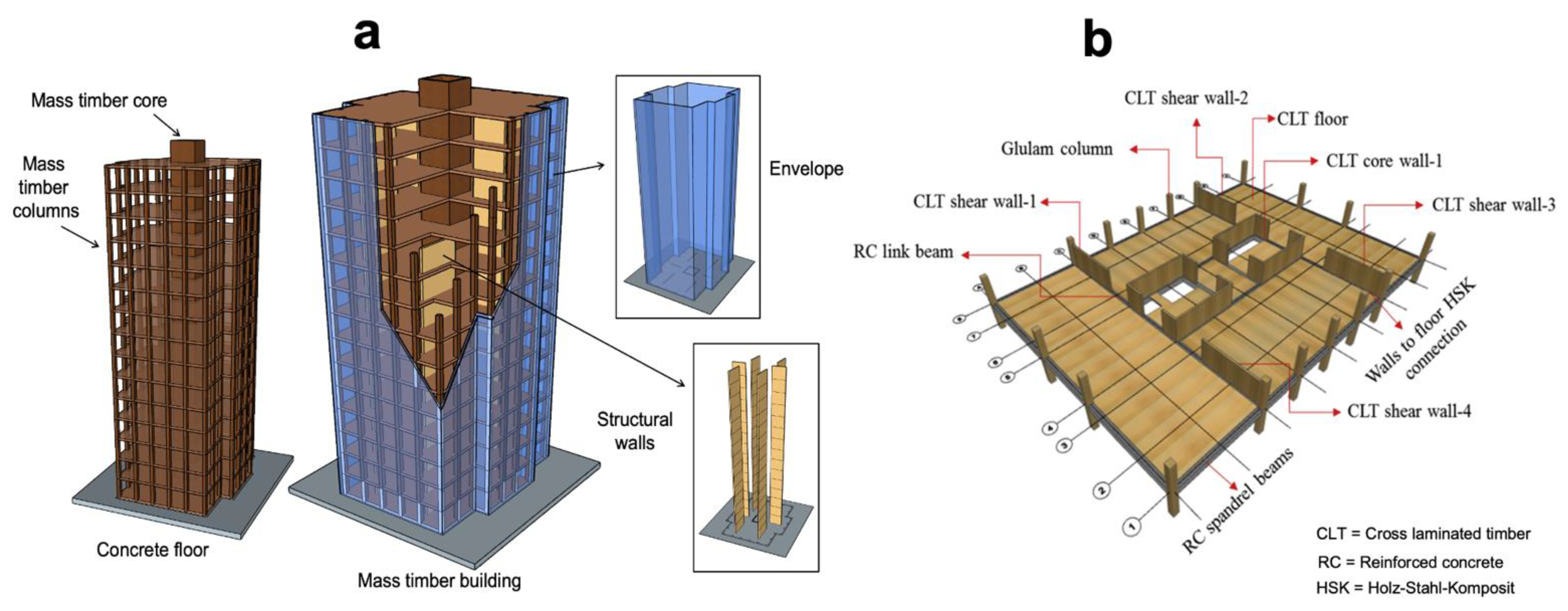

4.3. Mass Timber Buildings

4.4. Hybrid Buildings

5. Strategies to Improve Building Energy Efficiency

- Insulation materials: As mentioned in previous sections, for wood building systems, such as wood-frame, post-and-beam, mass timber and hybrid constructions, insulators played an important role in reducing thermal losses and keeping buildings heated in winter and cooled in summer. A wood-frame envelope (building) with appropriate insulation can provide an environment that is 5°C warmer in winter and 10°C cooler in summer [35]. Many types of insulation materials are available, including ones made of inorganic materials, such as ceramic materials, glass wool, rock wool and slag wool, and ones made of organic materials, including cane, cellulose, cotton, kenaf and wood particles, among others [183] (see Table 3). XI et al. [184] developed a binderless insulator board using kenaf fibers that have thermal conductivity properties similar to those of traditional insulation material (rock wool). Zhou et al. developed cotton stalk insulation boards (without binders) that are potential candidates to replace perlite and vermiculite insulators [185]. In North America, for example, the insulation materials most commonly used for wood-frame and post-and-beam buildings are glass wool, followed by expanded polystyrene (EPS), which accounts for 44.3% and 23.5% by volume, respectively [186,187].

- Reflective surfaces: This strategy makes the building (façade) capable of reflecting sunlight. Thus, infrared, visible, and ultraviolet light are all important when considering reflective surfaces. Reflective surfaces are an interesting strategy to improve the energy efficiency of all types of wood building systems. A study carried out in the United States on residential and commercial buildings showed that the surface temperature of buildings could be reduced by about 10 °C by using this strategy [188]. In addition, the use of reflective surfaces on wood-frame buildings results in energy savings of 4% to 9% (4% to 6% in cold climates) [189].

- Building airtightness: this approach plays a critical role for the buildings for energy-efficiency buildings as the energy performance can be significantly reduced by poor airtightness [190]. Such a topic has aroused in the 1970s but still continues as an important strategy. According to Cooper et al. [191], many researchers have pointed out that proper airtightness is a requirement for buildings’ energy efficiency since the consumption caused by unintended building air leakage can account for 13–50% and 4–20% of the overall heating and cooling demand, respectively [192,193,194,195].

- Cool roofs: These roofs are used for radiation heat transfer, providing space for cooling in the buildings. It reduces surface temperature by reflecting more solar radiation into the sky comparing to conventional roofs and consequently reduces heat flow from the roof to the building. These roofs could be recommended to reduce building air conditioning loads for wooden buildings. According to Dehwah and Krarti [196], for the wood-frame constructions, cool roofs reduced annual energy use for space cooling by about 44% and that for space heating by up to 17%. For warm regions, the use of cool roofs has been shown to reduce peak demand and cooling energy by 10% to 30% [197]. According to Boixo et al. [198], cool roofs in Andalucía (Spain) can provide energy savings of about 295,000 kWh per year, which represents 2% of overall residential electricity demand for flat-roofed buildings. Moreover, these savings avoid 136,000 tons of CO2 per year from being produced from electricity production.

- Green roofs: These are referring to totally or partly green spaces covering buildings. Green roofs are systems that make plants grow in the roof. This type of roof prevents heat from entering the building using water evaporation while protecting the roof from sunlight and energy loss [35]. According to Coma et al. [59], green roofs could reduce building energy consumption by about 16.7% in warm regions. A green roof reduced the flow of heat by 70% to 90% in summer and by 10% to 30% in winter compared to a traditional roof [199]. Green roofs are also an interesting strategy to protect wood structures from igniting [200,201].

- Glazed windows: This type of window refers to the glass panes incorporated in a window frame (also called an insulating glass unit or IGU). In this system, the air sealed in between the panes acts as an insulating layer [35]. A large number of techniques can be used in all types of wood buildings to improve the thermal efficiency of IGUs, such as the use of coated glass [58], multi-layer glass [202], vacuum glass [203] or smart glass [204], and incorporating materials (e.g., gas or aerogel) in the cavity between the panes of glass [57]. Fasi et al. showed that double-paned clear-glass windows could annually reduce lighting, cooling and total energy consumption by 70%, 8% and 14%, respectively [205].

- Window shade: This strategy involves using a window shade to prevent direct sun exposure inside the building either continuously or at specific times of day [35]. Tzempelikos et al. [206] stated that this method could reduce the secondary (lighting, heating and cooling) energy consumption of a building in Montreal (Canada) by 31%. Liu et al. studied the use of shading devices on opaque facades to reduce energy demand. This work was carried out in near-extreme summer conditions using energy simulations of typical buildings in Hong Kong [207]. The results showed that with an optimal configuration, the highest energy savings for the smallest total area of shade panels were observed at different tilt angles. The findings also showed potential energy savings of more than 8% for shading panels used on flats with west-facing façades. Given this scope, the use of window shading could be an approach to consider for low- and mid-rise (wood-frame and post-and-beam) buildings.

- Low-conductivity window frames: Materials such as extruded vinyl, glass fiber reinforced polyester (GFRP), polyvinyl chloride (PVC) and unplasticized polyvinyl chloride (uPVC) are used to produce the frame. Low-conductivity window frames can reduce heat loss by 25% to 40% for typical building assemblies. Windows with polyurethane, urethane, glass wool and vermiculite flakes in the window frame cavity have also been studied. It has been found that the lower the thermal conductivity of the insulation, the lower the heat transfer coefficient, consequently, the greater the thermal efficiency of the window system. Furthermore, a new strategy used in wood-frame building systems in Canada [50] is to fill window frame cavities with aerogels (having a thermal conductivity of about 0.02 W/mK), which results in a reduction in heat transfer of up to 29% for IGUs.

- Building information modeling (BIM): Berardi and Jafarpur [3] state that improvements in the shape, envelope and operating systems of buildings represent the largest research opportunity to reduce the energy consumption of future constructions in North America. According to Won and Cheng [208], the implementation of building information modeling (BIM) is a very promising approach to overcome this challenge, especially for wood buildings. BIM is used to develop a digital representation of a building’s components. By allowing users to extract geometric information from the project, these data can be used to manage and improve the technical aspects of the building before its construction phase. Furthermore, from an energy savings perspective, using Autodesk Revit BIM software (Version 2018, Autodesk, Inc., United States ) and an energy assessment tool FirstRate5 (Nationwide House Energy Rating Scheme, Australia) is a potential solution to systematically study variations in energy use during the operational phase considering geographic location, climatic conditions, shape, form and material variations. On the other hand, as indicated in a very recent study by Tushar et al. [209], little attention is paid to energy savings and environmental impacts concurrently with these design parameters. Moreover, as indicated in [209], energy data from the operational phase is important for all building processes to assess the influence of its corresponding EE.

- Phase changing materials (PCMs): Improving the energy efficiency of buildings through energy storage is a very interesting approach for a less energy-consuming electricity system. Consequently, the use of PCMs is one way to regulate indoor temperature by shifting the peak load to off-peak hours and reducing the need for heating and cooling energy [210]. PCMs can store a large amount of latent heat by undergoing a phase change (typically from solid to liquid), which adds thermal mass to the building envelope and thus reduces the energy demand of wood building envelopes [211]. The literature shows that the use of PCMs in well-insulated residential buildings can reduce energy use for heating or cooling by up to 25% [212,213,214]. Gypsum plasterboard with incorporated PCMs (capric and stearic acid) was studied by Sari et al. [215]. The authors argued that the plasterboard absorbed 25 wt% of the PCM and showed no leakage signs after 5000 thermal cycling tests (melting/freezing cycling). In addition, the plasterboard’s thermal performance improved, reducing the indoor temperature by 1.3 °C. Mathis et al. [49] investigated MDF panels with plastic and PCMs, and HDF on top to enclose the PCM pouches. For this experiment, the following PCM mixtures were used: a blend of capric and lauric acids and two commercial products (PureTemp®20 and PureTemp®23 (PureTemp, Park Glen Rd, MN, United States). The results revealed that the latent panel was stable, making the materials suitable for building applications. The panel made with Puretemp®23 embodied much energy, up to 57.1 Jg−1 with a melting point of 22.2 °C. These results show that the use of PCMs in the envelope of wood building systems could be an interesting strategy to improve the energy efficiency of buildings.

- Nano-insulation materials (NIMs): Another strategy to improve the energy performance of wood buildings is the use of nanotechnology-based insulation materials or NIMs. These materials are homogeneous composites consisting of open or closed nanopore particles in the range of 0.1 nm–100 nm in size with low thermal conductivity (less than 0.04 W/mK) in perfect conditions [216]. According to Gao et al., NIMs have a thermal conductivity of about 0.02 W/mK on account of the predominantly size-dependent thermal conduction that occurs at the nanometer scale. Figure 7 compares the structure of VIPs and NIMs. Although it is mentioned in previous sections, it is important to also stress here that not all types of strategies reviewed have been the subject of the same amount of research and development efforts and available literature. There is a vast amount of literature on topics dealing with green roofs, organic and inorganic PCMs and insulation materials, whereas other areas, such as window shades and NIMs, have gaps in the literature and provide very interesting research opportunities for future studies.

6. Concluding Remarks and Future Research Opportunities

- The literature has shown that although on-site mid-rise construction has well-established methods and products in the industry, there is a lack of research into the use of advanced construction technologies. Usage examples include incorporating prefabricated systems in wood-frame and post-and-beam buildings and emphasizing the potential environmental benefits (energy savings, GHG emission reductions, etc.) that these technologies might bring to the industry. Given the fact that most of the studies found focus particularly on materials and not on the building system as a whole, including BIM during pre-project development, taking energy savings into account could be an area for consideration. Moreover, the literature review identified that in post-and-beam studies, limited research has been done on energy use.

- Mass timber and hybrid systems offer innovative solutions for the construction industry. From an energy efficiency perspective, it was found that CLT can achieve energy savings of about 40% compared to traditional building systems such as concrete and light steel frame. It was also found that although hybrid buildings are an emerging technology to date, little attention has been given to their environmental and energy impacts. Furthermore, although not directly related to the energy efficiency of construction, an important point that was identified by this review and deserves to be highlighted is the lack of development of design codes and specifications for the use of mass timber materials. Those that focus on well-established concepts for concrete and steel structures, such as structural robustness—which, according to the Voulpiotis et al. [178], is still not well comprehended because of the complexity of wood properties and the challenge of testing large assemblies—therefore, represent a research opportunity to be seized. In addition, as is the case for wood-frame structures, studies of the potential environmental benefits of mass timber and hybrid systems as a whole are still a research gap.

- Choosing the most appropriate building shape and correct orientation could reduce energy consumption by 30–40% [220]. However, to date, studies concentrating on such topics and the energy savings of wood buildings generally overlook architectural variability and architectural features related to the functional needs of the building. Therefore, improving the envelope, operating systems and shape of wood-frame buildings, especially in North America, still represents the largest opportunity to reduce building energy consumption [3].

- Phase changing materials (PCMs) and nano-insulating materials (NIMs) represent energy-saving potential for wood buildings. However, it was found that most of the studies pertaining to them were based on prototype elements and that there was little practical application of these technologies. Thus, full-scale testing, with practical application, is a noteworthy field to explore, especially using such technologies in wood-frame and mass timber buildings. In addition, practical cases must be considered to evaluate the thermal and energy performance and life cycle analysis (LCA) of using such elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Selby, J.D.; Desouza, K.C. Fragile cities in the developed world: A conceptual framework. Cities 2019, 91, 180–192. [Google Scholar] [CrossRef]

- International Energy Agency. Global Energy & CO2 Status Report 2019—Analysis; IEA: Paris, France, 2019. [Google Scholar]

- Berardi, U.; Jafarpur, P. Assessing the impact of climate change on building heating and cooling energy demand in Canada. Renew. Sustain. Energy Rev. 2020, 121, 109681. [Google Scholar] [CrossRef]

- Delzendeh, E.; Wu, S.; Lee, A.; Zhou, Y. The impact of occupants’ behaviours on building energy analysis: A research review. Renew. Sustain. Energy Rev. 2017, 80, 1061–1071. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. International Energy Outlook 2016; EIA: Washington, DC, USA, 2016.

- Energy Star®. What Is Energy Star. Available online: https://www.energystar.gov/about (accessed on 3 April 2021).

- Sabapathy, A.; Ragavan, S.K.V.; Vijendra, M.; Nataraja, A.G. Energy efficiency benchmarks and the performance of LEED rated buildings for Information Technology facilities in Bangalore, India. Energy Build. 2010, 42, 2206–2212. [Google Scholar] [CrossRef]

- Scofield, J.H.; Doane, J. Energy performance of LEED—Certified buildings from 2015 Chicago benchmarking data. Energy Build. 2018, 174, 402–413. [Google Scholar] [CrossRef]

- BREEAM. BREEAM: The World’s Leading Sustainability Assessment Method for Masterplanning Projects, Infrastructure and Buildings. Available online: https://www.breeam.com/ (accessed on 3 April 2021).

- Patterson, M.G. What is energy efficiency?: Concepts, indicators and methodological issues. Energy Policy 1996, 24, 377–390. [Google Scholar] [CrossRef]

- Dixit, M.K.; Culp, C.H.; Fernandez-Solis, J.L. Embodied energy of construction materials: Integrating human and capital energy into an IO-based hybrid model. Environ. Sci. Technol. 2015, 49, 1936–1945. [Google Scholar] [CrossRef] [PubMed]

- Dixit, M.K. Life cycle recurrent embodied energy calculation of buildings: A review. J. Clean. Prod. 2019, 209, 731–754. [Google Scholar] [CrossRef]

- Stephan, A.; Stephan, L. Life cycle energy and cost analysis of embodied, operational and user-transport energy reduction measures for residential buildings. Appl. Energy 2016, 161, 445–464. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle embodied energy analysis of residential buildings: A review of literature to investigate embodied energy parameters. Renew. Sustain. Energy Rev. 2017, 79, 390–413. [Google Scholar] [CrossRef]

- Energy Star®. The Difference between Source and Site Energy||ENERGY STAR. Available online: https://www.energystar.gov/buildings/facility-owners-and-managers/existing-buildings/use-portfolio-manager/understand-metrics/difference (accessed on 3 April 2021).

- Takano, A.; Pal, S.K.; Kuittinen, M.; Alanne, K. Life cycle energy balance of residential buildings: A case study on hypothetical building models in Finland. Energy Build. 2015, 105, 154–164. [Google Scholar] [CrossRef]

- Chen, T.; Burnett, J.; Chau, C. Analysis of embodied energy use in the residential building of Hong Kong. Energy 2001, 26, 323–340. [Google Scholar] [CrossRef]

- Koezjakov, A.; Urge-Vorsatz, D.; Crijns-Graus, W.; van den Broek, M. The relationship between operational energy demand and embodied energy in Dutch residential buildings. Energy Build. 2018, 165, 233–245. [Google Scholar] [CrossRef]

- Reddy, B.V.; Jagadish, K. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A. Life cycle primary energy analysis of residential buildings. Energy Build. 2010, 42, 210–220. [Google Scholar] [CrossRef]

- Citherlet, S.; Defaux, T. Energy and environmental comparison of three variants of a family house during its whole life span. Build. Environ. 2007, 42, 591–598. [Google Scholar] [CrossRef]

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, C.H. Identification of parameters for embodied energy measurement: A literature review. Energy Build. 2010, 42, 1238–1247. [Google Scholar] [CrossRef]

- Cherian, P.; Palaniappan, S.; Menon, D.; Anumolu, M.P. Comparative study of embodied energy of affordable houses made using GFRG and conventional building technologies in India. Energy Build. 2020, 223, 110138. [Google Scholar] [CrossRef]

- Monteiro, H.; Fernández, J.E.; Freire, F. Comparative life-cycle energy analysis of a new and an existing house: The significance of occupant’s habits, building systems and embodied energy. Sustain. Cities Soc. 2016, 26, 507–518. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H.; de Myttenaere, K. A comprehensive assessment of the life cycle energy demand of passive houses. Appl. Energy 2013, 112, 23–34. [Google Scholar] [CrossRef] [Green Version]

- Lessard, Y.; Anand, C.; Blanchet, P.; Frenette, C.; Amor, B.; Ben Amor, M. LEED v4: Where Are We Now? Critical Assessment through the LCA of an Office Building Using a Low Impact Energy Consumption Mix. J. Ind. Ecol. 2018, 22, 1105–1116. [Google Scholar] [CrossRef]

- Li, T.; Alavy, M.; Siegel, J.A. Measurement of residential HVAC system runtime. Build. Environ. 2019, 150, 99–107. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration (EIA). Heating and Cooling No Longer Majority of U.S. Home Energy Use. Available online: https://www.eia.gov/todayinenergy/detail.php?id=10271 (accessed on 13 May 2020).

- Stopps, H.; Touchie, M.F. Managing thermal comfort in contemporary high-rise residential buildings: Using smart thermostats and surveys to identify energy efficiency and comfort opportunities. Build. Environ. 2020, 173, 106748. [Google Scholar] [CrossRef]

- Gärtner, J.A.; Gray, F.M.; Auer, T. Assessment of the impact of HVAC system configuration and control zoning on thermal comfort and energy efficiency in flexible office spaces. Energy Build. 2020, 212, 109785. [Google Scholar] [CrossRef]

- Tian, Z.; Si, B.; Shi, X.; Fang, Z. An application of Bayesian Network approach for selecting energy efficient HVAC systems. J. Build. Eng. 2019, 25, 100796. [Google Scholar] [CrossRef]

- Cuce, P.M.; Riffat, S. A comprehensive review of heat recovery systems for building applications. Renew. Sustain. Energy Rev. 2015, 47, 665–682. [Google Scholar] [CrossRef]

- Mardiana-Idayu, A.; Riffat, S.B. An experimental study on the performance of enthalpy recovery system for building applications. Energy Build. 2011, 43, 2533–2538. [Google Scholar] [CrossRef]

- Kneifel, J.; Webb, D. Predicting energy performance of a net-zero energy building: A statistical approach. Appl. Energy 2016, 178, 468–483. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aslani, A.; Bakhtiar, A.; Akbarzadeh, M.H. Energy-efficiency technologies in the building envelope: Life cycle and adaptation assessment. J. Build. Eng. 2019, 21, 55–63. [Google Scholar] [CrossRef]

- Rouleau, J.; Gosselin, L.; Blanchet, P. Understanding energy consumption in high-performance social housing buildings: A case study from Canada. Energy 2018, 145, 677–690. [Google Scholar] [CrossRef]

- Lee, J.; Wi, S.; Chang, S.J.; Choi, J.; Kim, S. Prediction evaluating of moisture problems in light-weight wood structure: Perspectives on regional climates and building materials. Build. Environ. 2020, 168, 106521. [Google Scholar] [CrossRef]

- Hua, Y.; Oswald, A.; Yang, X. Effectiveness of daylighting design and occupant visual satisfaction in a LEED Gold laboratory building. Build. Environ. 2011, 46, 54–64. [Google Scholar] [CrossRef]

- Hwang, T.; Kim, J.T. Effects of Indoor Lighting on Occupants’ Visual Comfort and Eye Health in a Green Building. Indoor Built Environ. 2011, 20, 75–90. [Google Scholar] [CrossRef]

- Aries, M.B.; Veitch, J.A.; Newsham, G.R. Windows, view, and office characteristics predict physical and psychological discomfort. J. Environ. Psychol. 2010, 30, 533–541. [Google Scholar] [CrossRef]

- Wang, J.; Wei, M.; Ruan, X. Characterization of the acceptable daylight quality in typical residential buildings in Hong Kong. Build. Environ. 2020, 182, 107094. [Google Scholar] [CrossRef]

- Premrov, M.; Žigart, M.; Leskovar, V.Ž. Influence of the building shape on the energy performance of timber-glass buildings located in warm climatic regions. Energy 2018, 149, 496–504. [Google Scholar] [CrossRef]

- Kheiri, F. A review on optimization methods applied in energy-efficient building geometry and envelope design. Renew. Sustain. Energy Rev. 2018, 92, 897–920. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, G.; Xia, X.; Setunge, S.; Shi, L. A review of internal and external influencing factors on energy efficiency design of buildings. Energy Build. 2020, 216, 109944. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M. Evaluation of the efficiency and sustainability of timber-based construction. J. Clean. Prod. 2020, 259, 120835. [Google Scholar] [CrossRef]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F. Introduction to the environmental impact of construction and building materials. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Elsevier Inc.: Amsterdam, The Netherlands, 2014; pp. 1–10. ISBN 9780857097675. [Google Scholar]

- Jelle, B.P.; Gustavsen, A.; Baetens, R. The path to the high performance thermal building insulation materials and solutions of tomorrow. J. Build. Phys. 2010, 34, 99–123. [Google Scholar] [CrossRef] [Green Version]

- Mathis, D.; Blanchet, P.; Landry, V.; Lagière, P. Thermal characterization of bio-based phase changing materials in decorative wood-based panels for thermal energy storage. Green Energy Environ. 2019, 4, 56–65. [Google Scholar] [CrossRef]

- Paulos, J.; Berardi, U. Optimizing the thermal performance of window frames through aerogel-enhancements. Appl. Energy 2020, 266, 114776. [Google Scholar] [CrossRef]

- Yoonus, H.; Al-Ghamdi, S.G. Environmental performance of building integrated grey water reuse systems based on Life-Cycle Assessment: A systematic and bibliographic analysis. Sci. Total Environ. 2020, 712, 136535. [Google Scholar] [CrossRef]

- Nußholz, J.L.K.; Rasmussen, F.N.; Whalen, K.; Plepys, A. Material reuse in buildings: Implications of a circular business model for sustainable value creation. J. Clean. Prod. 2020, 245, 118546. [Google Scholar] [CrossRef]

- Palmieri, S.; Cipolletta, G.; Pastore, C.; Giosuè, C.; Akyol, Ç.; Eusebi, A.L.; Frison, N.; Tittarelli, F.; Fatone, F. Pilot scale cellulose recovery from sewage sludge and reuse in building and construction material. Waste Manag. 2019, 100, 208–218. [Google Scholar] [CrossRef] [PubMed]

- Cabeza, L.F.; Boquera, L.; Chàfer, M.; Vérez, D. Embodied energy and embodied carbon of structural building materials: Worldwide progress and barriers through literature map analysis. Energy Build. 2020, 231, 110612. [Google Scholar] [CrossRef]

- Pomponi, F.; Piroozfar, P.A.; Southall, R.; Ashton, P.; Farr, E.R. Life cycle energy and carbon assessment of double skin façades for office refurbishments. Energy Build. 2015, 109, 143–156. [Google Scholar] [CrossRef] [Green Version]

- Monahan, J.; Powell, J.C. An embodied carbon and energy analysis of modern methods of construction in housing: A case study using a lifecycle assessment framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Arıcı, M.; Kan, M. An investigation of flow and conjugate heat transfer in multiple pane windows with respect to gap width, emissivity and gas filling. Renew. Energy 2015, 75, 249–256. [Google Scholar] [CrossRef]

- Young, C.-H.; Chen, Y.-L.; Chen, P.-C. Heat insulation solar glass and application on energy efficiency buildings. Energy Build. 2014, 78, 66–78. [Google Scholar] [CrossRef]

- Coma, J.; Pérez, G.; Solé, C.; Castell, A.; Cabeza, L.F. Thermal assessment of extensive green roofs as passive tool for energy savings in buildings. Renew. Energy 2016, 85, 1106–1115. [Google Scholar] [CrossRef] [Green Version]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Kosny, J.; Asiz, A.; Smith, I.; Shrestha, S.; Fallahi, A. A review of high R-value wood framed and composite wood wall technologies using advanced insulation techniques. Energy Build. 2014, 72, 441–456. [Google Scholar] [CrossRef]

- Nunes, G.; de Melo Moura, J.D.; Güths, S.; Atem, C.; Giglio, T. Thermo-energetic performance of wooden dwellings: Benefits of cross-laminated timber in Brazilian climates. J. Build. Eng. 2020, 32, 101468. [Google Scholar] [CrossRef]

- Ceccotti, A.; Sandhaas, C.; Okabe, M.; Yasumura, M.; Minowa, C.; Kawai, N. SOFIE project—3D shaking table test on a seven-storey full-scale cross-laminated timber building. Earthq. Eng. Struct. Dyn. 2013, 42, 2003–2021. [Google Scholar] [CrossRef]

- FPInnovations. Guide for Designing Energy-Efficient Building Enclosures; FPInnovations: Pointe-Claire, QC, Canada, 2013. [Google Scholar]

- Pan, Y.; Ventura, C.E.; Tannert, T. Damage index fragility assessment of low-rise light-frame wood buildings under long duration subduction earthquakes. Struct. Saf. 2020, 84, 101940. [Google Scholar] [CrossRef]

- Salehi, H.; Burgueño, R. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar] [CrossRef]

- Krippendorff, K. Content Analysis: An Introduction to Its Methodology, 2nd ed.; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2004. [Google Scholar]

- Tang, L.Y.; Shen, Q.; Cheng, E.W.L. A review of studies on Public–Private Partnership projects in the construction industry. Int. J. Proj. Manag. 2010, 28, 683–694. [Google Scholar] [CrossRef] [Green Version]

- Breton, C.; Blanchet, P.; Amor, B.; Beauregard, R.; Chang, W.-S. Assessing the Climate Change Impacts of Biogenic Carbon in Buildings: A Critical Review of Two Main Dynamic Approaches. Sustainability 2018, 10, 2020. [Google Scholar] [CrossRef] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Atatement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goubran, S.; Masson, T.; Walker, T. Diagnosing the local suitability of high-rise timber construction. Build. Res. Inf. 2020, 48, 101–123. [Google Scholar] [CrossRef]

- Azari, R.; Abbasabadi, N. Embodied energy of buildings: A review of data, methods, challenges, and research trends. Energy Build. 2018, 168, 225–235. [Google Scholar] [CrossRef]

- Mithraratne, N.; Vale, B. Life cycle analysis model for New Zealand houses. Build. Environ. 2004, 39, 483–492. [Google Scholar] [CrossRef]

- Praseeda, K.; Reddy, B.V.; Mani, M. Embodied energy assessment of building materials in India using process and input–output analysis. Energy Build. 2015, 86, 677–686. [Google Scholar] [CrossRef]

- ASHRAE. Insulation for Mechanical Systems. In Handbook—Fundamentals; ASHRAE: Peachtree Corners, GA, USA, 2013. [Google Scholar]

- Al-Homoud, M.S. Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Czajkowski, Ł.; Olek, W.; Weres, J.; Guzenda, R. Thermal properties of wood-based panels: Specific heat determination. Wood Sci. Technol. 2016, 50, 537–545. [Google Scholar] [CrossRef] [Green Version]

- Tavares, V.; Lacerda, N.; Freire, F. Embodied energy and greenhouse gas emissions analysis of a prefabricated modular house: The “Moby” case study. J. Clean. Prod. 2019, 212, 1044–1053. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Inventory of Carbon & Energy (ICE); Version 1.6a; University of Bath: Bath, UK, 2008. [Google Scholar]

- Biswas, K.; Desjarlais, A.; Smith, D.; Letts, J.; Yao, J.; Jiang, T. Development and thermal performance verification of composite insulation boards containing foam-encapsulated vacuum insulation panels. Appl. Energy 2018, 228, 1159–1172. [Google Scholar] [CrossRef]

- Ozalp, C.; Saydam, D.; Çerçi, K.; Hürdoğan, E.; Moran, H. Evaluation of a sample building with different type building elements in an energetic and environmental perspective. Renew. Sustain. Energy Rev. 2019, 115, 109386. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Doniavi, A. Thermal Conductivity of Low-Density Polyethylene Foams Part II: Deep Investigation using Response Surface Methodology. J. Therm. Sci. 2020, 29, 159–168. [Google Scholar] [CrossRef]

- Fallah, M.; Medghalchi, Z. Proposal of a new approach for avoiding anti-insulation in residential buildings by considering occupant’s comfort condition. Therm. Sci. Eng. Prog. 2020, 20, 100721. [Google Scholar] [CrossRef]

- Lenzen, M.; Treloar, G. Embodied energy in buildings: Wood versus concrete—Reply to Börjesson and Gustavsson. Energy Policy 2002, 30, 249–255. [Google Scholar] [CrossRef]

- Gonçalves, M.; Simões, N.; Serra, C.; Flores-Colen, I. A review of the challenges posed by the use of vacuum panels in external insulation finishing systems. Appl. Energy 2020, 257, 114028. [Google Scholar] [CrossRef]

- Gouvernement du Canada. Panneaux Lamellés-Croisés|Ressources Naturelles Canada. Available online: https://www.rncan.gc.ca/nos-ressources-naturelles/industrie-commerce-forestiere/demandes-en-produits-forestiers/taxonomie-des-produits-du-bois/panneaux-lamelles-croises/15830 (accessed on 13 November 2019).

- Jayalath, A.; Navaratnam, S.; Ngo, T.; Mendis, P.; Hewson, N.; Aye, L. Life cycle performance of Cross Laminated Timber mid-rise residential buildings in Australia. Energy Build. 2020, 223, 110091. [Google Scholar] [CrossRef]

- Dimoudi, A.; Tompa, C. Energy and environmental indicators related to construction of office buildings. Resour. Conserv. Recycl. 2008, 53, 86–95. [Google Scholar] [CrossRef]

- Nässén, J.; Hedenus, F.; Karlsson, S.; Holmberg, J. Concrete vs. wood in buildings—An energy system approach. Build. Environ. 2012, 51, 361–369. [Google Scholar] [CrossRef]

- Gerilla, G.; Teknomo, K.; Hokao, K. An environmental assessment of wood and steel reinforced concrete housing construction. Build. Environ. 2007, 42, 2778–2784. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Xiao, J. Estimation and minimization of embodied carbon of buildings: A review. Buildings 2017, 7, 5. [Google Scholar] [CrossRef]

- Buchanan, A.H.; Levine, S. Wood-based building materials and atmospheric carbon emissions. Environ. Sci. Policy 1999, 2, 427–437. [Google Scholar] [CrossRef]

- EN ISO 10456 Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; ISO: Geneva, Switzerland, 2007.

- Alsayegh, G.; Mukhopadhyaya, P.; Wang, J.; Zalok, E.; van Reenen, D. Preliminary Characterization of Physical Properties of Cross-Laminated-Timber (CLT) Panels for Hygrothermal Modelling. Adv. Civ. Eng. Mater. 2013, 2, 472–484. [Google Scholar] [CrossRef]

- APA—The Engineered Wood Association Plywood. Available online: https://www.apawood.org/plywood (accessed on 20 May 2020).

- Think Wood Cross-Laminated Timber. Available online: https://www.thinkwood.com/products-and-systems/mass-timber/cross-laminated-timber-clt-handbook (accessed on 20 May 2020).

- Lawson, B. BDP Environment Design Guide—Embodied Energy of Building Materials; Royal Australian Institute of Architects: Melbourne, Australia, 2006. [Google Scholar]

- Cardarelli, F. Materials Handbook—A concise desktop reference. Mater. Des. 2001, 22, 237. [Google Scholar] [CrossRef]

- May, B.; England, J.R.; Raison, R.J.; Paul, K.I. Cradle-to-gate inventory of wood production from Australian softwood plantations and native hardwood forests: Embodied energy, water use and other inputs. For. Ecol. Manag. 2012, 264, 37–50. [Google Scholar] [CrossRef]

- APA—The Engineered Wood Association Oriented Strand Board (OSB). Available online: https://www.apawood.org/osb (accessed on 20 May 2020).

- Haseli, M.; Layeghi, M.; Hosseinabadi, H.Z. Characterization of blockboard and battenboard sandwich panels from date palm waste trunks. Measurement 2018, 124, 329–337. [Google Scholar] [CrossRef]

- Zhang, X.; Kim, Y.; Eberhardt, T.L.; Shmulsky, R. Lab-scale structural insulated panels with lignin-incorporated rigid polyurethane foams as core. Ind. Crop. Prod. 2019, 132, 292–300. [Google Scholar] [CrossRef]

- Chang, S.J.; Wi, S.; Kim, S. Thermal bridging analysis of connections in cross-laminated timber buildings based on ISO 10211. Constr. Build. Mater. 2019, 213, 709–722. [Google Scholar] [CrossRef]

- Think Wood Glue-Laminated Timber (Glulam) Structures. Available online: https://www.thinkwood.com/products-and-systems/mass-timber/glue-laminated-timber-glulam (accessed on 20 May 2020).

- Zeitz, A.; Griffin, C.; Dusicka, P. Comparing the embodied carbon and energy of a mass timber structure system to typical steel and concrete alternatives for parking garages. Energy Build. 2019, 199, 126–133. [Google Scholar] [CrossRef]

- Hasslacher Norica Timber. Single and Multiple Family Houses. Multi-Storey Residential and Office Buildings. Public and Administrative Buildings. Agricultural Facilities. Industrial and Production Halls. Recreational and Sport-Hall Facilities. 2020. Available online: https://www.hasslacher.com/data/_dateimanager/broschuere/HNT-Brettschichtholz-EN.pdf (accessed on 3 April 2021).

- Standards Council of Canada. CAN/CSA-A82.31-M91; Standards Council of Canada: Ottawa, ON, Canada, 1991. [Google Scholar]

- CGC, Inc. Drywall and Veneer Plaster Products. 2020. Available online: https://www.usg.com/content/dam/USG_Marketing_Communications/canada/product_promotional_materials/finished_assets/cgc-construction-handbook-ch01-drywall-and-veneer-plaster-products-can-en.pdf (accessed on 16 December 2020).

- Kyriakidis, A.; Michael, A.; Illampas, R.; Charmpis, D.C.; Ioannou, I. Thermal performance and embodied energy of standard and retrofitted wall systems encountered in Southern Europe. Energy 2018, 161, 1016–1027. [Google Scholar] [CrossRef]

- Goggins, J.; Keane, T.; Kelly, A. The assessment of embodied energy in typical reinforced concrete building structures in Ireland. Energy Build. 2010, 42, 735–744. [Google Scholar] [CrossRef] [Green Version]

- Asadi, I.; Shafigh, P.; Bin Abu Hassan, Z.F.; Mahyuddin, N.B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Himes, A.; Busby, G. Wood buildings as a climate solution. Dev. Built Environ. 2020, 4, 100030. [Google Scholar] [CrossRef]

- Cabral, M.R.; Nakanishi, E.Y.; Santos, S.F.; Christoforo, A.L.; Fiorelli, J. Orientation effect on the physical and mechanical properties of strand cement boards. Constr. Build. Mater. 2021, 275, 122121. [Google Scholar] [CrossRef]

- Canadian Wood Council. Wood-Frame Housing—A North American Marvel; Canadian Wood Council: Ottawa, ON, Canada, 2002. [Google Scholar]

- Canada Mortgage and Housing Corporation. Canadian Wood-Frame House Construction; CMHC: Ottawa, ON, Canada, 2013; ISBN 0-660-19535-6. [Google Scholar]

- Gouvernement du Québec Directives and Explanatory Guide; Gouvernement du Québec: Quebec City, QC, Canada, 2015.

- Structurlam Mass Timber Design Guide CrossLam® CLT|GlulamPLUS®|Mass Timber Building Systems. 2019. Available online: https://www.structurlam.com/wp-content/uploads/2019/04/Structurlam-Design-Guide_FINAL_Spreads.pdf (accessed on 17 December 2020).

- Breyer, D.E.; Fridle, K.J.; Cobeen, K.E.; Pollock, D.G. Design of Wood Structures; McGraw-Hill Education: New York, NY, USA, 2006. [Google Scholar]

- American Wood Council. Details for Conventional Wood Frame Construction; American Wood Council: Leesburg, VA, USA, 2001. [Google Scholar]

- Riggio, M.; Dilmaghani, M. Structural health monitoring of timber buildings: A literature survey. Build. Res. Inf. 2019, 48, 1–21. [Google Scholar] [CrossRef]

- Barkokebas, R.D.; Chen, Y.; Yu, H.; Al-Hussein, M. Achieving housing energy-efficiency requirements: Methodologies and impacts on housing construction cost and energy performance. J. Build. Eng. 2019, 26, 100874. [Google Scholar] [CrossRef]

- Capozzoli, A.; Gorrino, A.; Corrado, V. A building thermal bridges sensitivity analysis. Appl. Energy 2013, 107, 229–243. [Google Scholar] [CrossRef]

- François, A.; Ibos, L.; Feuillet, V.; Meulemans, J. In situ measurement method for the quantification of the thermal transmittance of a non-homogeneous wall or a thermal bridge using an inverse technique and active infrared thermography. Energy Build. 2021, 233, 110633. [Google Scholar] [CrossRef]

- Wang, J.; DeMartino, C.; Xiao, Y.; Li, Y. Thermal insulation performance of bamboo- and wood-based shear walls in light-frame buildings. Energy Build. 2018, 168, 167–179. [Google Scholar] [CrossRef]

- Chang, Y.; Ries, R.J.; Wang, Y. The quantification of the embodied impacts of construction projects on energy, environment, and society based on I–O LCA. Energy Policy 2011, 39, 6321–6330. [Google Scholar] [CrossRef]

- Bowley, W.; Evins, R. Assessing energy and emissions savings for space conditioning, materials and transportation for a high-density mixed-use building. J. Build. Eng. 2020, 31, 101386. [Google Scholar] [CrossRef]

- Liu, H.; Singh, G.; Lu, M.; Bouferguene, A.; Al-Hussein, M. BIM-based automated design and planning for boarding of light-frame residential buildings. Autom. Constr. 2018, 89, 235–249. [Google Scholar] [CrossRef]

- Jiang, R.; Mao, C.; Hou, L.; Wu, C.; Tan, J. A SWOT analysis for promoting off-site construction under the backdrop of China’s new urbanisation. J. Clean. Prod. 2018, 173, 225–234. [Google Scholar] [CrossRef]

- Yu, T.; Man, Q.; Wang, Y.; Shen, G.Q.; Hong, J.; Zhang, J.; Zhong, J. Evaluating different stakeholder impacts on the occurrence of quality defects in offsite construction projects: A Bayesian-network-based model. J. Clean. Prod. 2019, 241, 118390. [Google Scholar] [CrossRef]

- Zhang, Y.; Lei, Z.; Han, S.; Bouferguene, A.; Al-Hussein, M. Process-Oriented Framework to Improve Modular and Offsite Construction Manufacturing Performance. J. Constr. Eng. Manag. 2020, 146, 04020116. [Google Scholar] [CrossRef]

- Lu, W.; Chen, K.; Xue, F.; Pan, W. Searching for an optimal level of prefabrication in construction: An analytical framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- Richard, R.-B. Industrialised building systems: Reproduction before automation and robotics. Autom. Constr. 2005, 14, 442–451. [Google Scholar] [CrossRef]

- Chen, Z.; Popovski, M.; Ni, C. A novel floor-isolated re-centering system for prefabricated modular mass timber construction—Concept development and preliminary evaluation. Eng. Struct. 2020, 222, 111168. [Google Scholar] [CrossRef]

- Awad, H.; Gül, M.; Zaman, H.; Yu, H.; Al-Hussein, M. Evaluation of the thermal and structural performance of potential energy efficient wall systems for mid-rise wood-frame buildings. Energy Build. 2014, 82, 416–427. [Google Scholar] [CrossRef]

- Li, M.; Lam, F.; Foschi, R.O.; Nakajima, S.; Nakagawa, T. Seismic performance of post and beam timber buildings I: Model development and verification. J. Wood Sci. 2012, 58, 20–30. [Google Scholar] [CrossRef]

- Cecobois. Guide Technique sur la Conception de Poutres et Colonnes en Gros Bois; Cecobois: Québec, QC, Canada, 2015. [Google Scholar]

- Gattesco, N.; Boem, I. Seismic performances and behavior factor of post-and-beam timber buildings braced with nailed shear walls. Eng. Struct. 2015, 100, 674–685. [Google Scholar] [CrossRef]

- Kim, H.-B.; Park, J.-S.; Hong, J.-P.; Oh, J.-K.; Lee, J.-J. Air Tightness Performance of Residential Timber Frame Buildings. J. Korean Wood Sci. Technol. 2014, 42, 89–100. [Google Scholar] [CrossRef] [Green Version]

- Cornaro, C.; Zanella, V.; Robazza, P.; Belloni, E.; Buratti, C. An innovative straw bale wall package for sustainable buildings: Experimental characterization, energy and environmental performance assessment. Energy Build. 2020, 208, 109636. [Google Scholar] [CrossRef]

- Richard, R.-B. Industrialized building system categorization. In Offsite Architecture; Routledge: London, UK, 2017; pp. 3–20. [Google Scholar]

- Harte, A.M. Mass timber—The emergence of a modern construction material. J. Struct. Integr. Maint. 2017, 2, 121–132. [Google Scholar] [CrossRef]

- Kordziel, S.; Pei, S.; Glass, S.V.; Zelinka, S.; Tabares-Velasco, P.C. Structure Moisture Monitoring of an 8-Story Mass Timber Building in the Pacific Northwest. J. Arch. Eng. 2019, 25, 04019019. [Google Scholar] [CrossRef]

- Smith, R.E.; Quale, J.D. Offsite Architecture: Constructing the Future; Routledge: London, UK, 2017; ISBN 9781317588825. [Google Scholar]

- Chen, Z.; Popovski, M.; Iqbal, A. Structural Performance of Post-Tensioned CLT Shear Walls with Energy Dissipators. J. Struct. Eng. 2020, 146, 04020035. [Google Scholar] [CrossRef]

- Carvalho, L.F.; Jorge, L.F.C.; Jerónimo, R. Plug-and-Play Multistory Mass Timber Buildings: Achievements and Potentials. J. Arch. Eng. 2020, 26, 04020011. [Google Scholar] [CrossRef]

- Cover, J. Mass timber: The new sustainable choice for tall buildings. Int. J. High-Rise Build. 2020, 9, 87–93. [Google Scholar] [CrossRef]

- Bolvardi, V.; Pei, S.; van de Lindt, J.W.; Dolan, J.D. Direct displacement design of tall cross laminated timber platform buildings with inter-story isolation. Eng. Struct. 2018, 167, 740–749. [Google Scholar] [CrossRef]

- Bezabeh, M.; Bitsuamlak, G.; Popovski, M.; Tesfamariam, S. Probabilistic serviceability-performance assessment of tall mass-timber buildings subjected to stochastic wind loads: Part I—Structural design and wind tunnel testing. J. Wind Eng. Ind. Aerodyn. 2018, 181, 85–103. [Google Scholar] [CrossRef]

- Pei, S.; Van De Lindt, J.W.; Popovski, M.; Berman, J.W.; Dolan, J.D.; Ricles, J.M.; Sause, R.; Blomgren, H.; Rammer, D. Cross-Laminated Timber for Seismic Regions: Progress and Challenges for Research and Implementation. J. Struct. Eng. 2016, 142, E2514001. [Google Scholar] [CrossRef]

- Guo, H.; Liu, Y.; Meng, Y.; Huang, H.; Sun, C.; Shao, Y. A Comparison of the Energy Saving and Carbon Reduction Performance between Reinforced Concrete and Cross-Laminated Timber Structures in Residential Buildings in the Severe Cold Region of China. Sustainability 2017, 9, 1426. [Google Scholar] [CrossRef] [Green Version]

- Setter, L.; Smoorenburg, E.; Wijesuriya, S.; Tabares-Velasco, P.C. Energy and hygrothermal performance of cross laminated timber single-family homes subjected to constant and variable electric rates. J. Build. Eng. 2019, 25, 100784. [Google Scholar] [CrossRef]

- Tettey, U.Y.A.; Dodoo, A.; Gustavsson, L. Effect of different frame materials on the primary energy use of a multi storey residential building in a life cycle perspective. Energy Build. 2019, 185, 259–271. [Google Scholar] [CrossRef]

- Gasparri, E.; Lucchini, A.; Mantegazza, G.; Mazzucchelli, E.S. Construction management for tall CLT buildings: From partial to total prefabrication of façade elements. Wood Mater. Sci. Eng. 2015, 10, 256–275. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2020, 286, 125443. [Google Scholar] [CrossRef]

- The Canadian Wood Council. Brock Commons Tallwood House: University of British Columbia Vancouver Campus—The Advent of Tall Wood Sructures in Canada: A Case Study. Available online: https://cwc.ca/wp-content/uploads/2019/03/CS-BrockCommon.Study_.23.pdf (accessed on 21 April 2020).

- Pullen, T.; Hall, D.; Lessing, J. A Preliminary Overview of Emerging Trends for Industrialized Construction in the United States: White Paper; ETH Zürich: Zürich, Switzerland, 2019. [Google Scholar]

- The Council on Tall Buildings and Urban Habitat. Tall Building Criteria. Available online: https://www.ctbuh.org/resource/height (accessed on 5 February 2021).

- Programme for the Endorsement of Forest Certification. William Perkin Church of England High School. Available online: https://www.pefc.org/resources/case-stories/william-perkin-church-of-england-high-school (accessed on 30 December 2020).

- Architect Magazine. Dalston Works, the Largest CLT Building in the World. Available online: https://www.architectmagazine.com/technology/detail/dalston-works-the-largest-clt-building-in-the-world_o (accessed on 5 February 2021).

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA based comparative case study in the U.S. Pacific Northwest. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Yin, L.; Lee, B. Simulation-based building performance comparison between CLT-concrete hybrid, CLT, and reinforced concrete structures in Canada. In Proceedings of the 2019 CSCE Annual Conference, Laval, QC, Canada, 12–15 June 2019. [Google Scholar]

- Loss, C.; Piazza, M.; Zandonini, R. Connections for steel–timber hybrid prefabricated buildings. Part I: Experimental tests. Constr. Build. Mater. 2016, 122, 781–795. [Google Scholar] [CrossRef]

- Dickof, C.; Stiemer, S.F.; Bezabeh, M.A.; Tesfamariam, S. CLT–Steel Hybrid System: Ductility and Overstrength Values Based on Static Pushover Analysis. J. Perform. Constr. Facil. 2014, 28, A4014012. [Google Scholar] [CrossRef]

- Asiz, A.; Smith, I. Connection System of Massive Timber Elements Used in Horizontal Slabs of Hybrid Tall Buildings. J. Struct. Eng. 2011, 137, 1390–1393. [Google Scholar] [CrossRef]

- Tesfamariam, S.; Stiemer, S.F.; Dickof, C.; Bezabeh, M.A. Seismic Vulnerability Assessment of Hybrid Steel-Timber Structure: Steel Moment-Resisting Frames with CLT Infill. J. Earthq. Eng. 2014, 18, 929–944. [Google Scholar] [CrossRef]

- Foster, R.M.; Ramage, M.H. Tall timber. In Nonconventional and Vernacular Construction Materials: Characterisation, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 467–490. [Google Scholar]

- Abrahamsen, R.B.; Arne Malo, K. Structural design and assembly of “treet”—A 14-storey timber residential building in norway. In Proceedings of the World Conference on Timber Engineering, Quebec City, QC, Canada, 10–14 August 2014. [Google Scholar]

- Malo, K.A.; Abrahamsen, R.B.; Bjertnæs, M.A. Some structural design issues of the 14-storey timber framed building “Treet” in Norway. Eur. J. Wood Prod. 2016, 74, 407–424. [Google Scholar] [CrossRef] [Green Version]

- Abrahamsen, R. Mjøstårnet—Construction of an 81 m Tall Timber Building. Internationales Holzbau-Forum IHF 2017. Available online: https://www.forum-holzbau.com/pdf/31_IHF2017_Abrahamsen.pdf (accessed on 21 April 2020).

- Lehmann, S. Low carbon construction systems using prefabricated engineered solid wood panels for urban infill to significantly reduce greenhouse gas emissions. Sustain. Cities Soc. 2013, 6, 57–67. [Google Scholar] [CrossRef]

- Think Wood. Demonstrating the Viability of Mass Wood Structures. Available online: https://www.thinkwood.com/our-projects/brock-commons-tallwood-house (accessed on 21 April 2020).

- The Canadian Wood Council. Wood Innovation and Design Centre. Prince George, BC. A Technical Case Study. 2015. Available online: https://wood-works.ca/wp-content/uploads/151203-WoodWorks-WIDC-Case-Study-WEB.pdf (accessed on 21 April 2020).

- Nordic Structures. Origine, 13-Storey Building. Available online: https://www.nordic.ca/en/projects/structures/origine (accessed on 21 April 2020).

- Li, Y.; Chen, L. A study on database of modular façade retrofitting building envelope. Energy Build. 2020, 214, 109826. [Google Scholar] [CrossRef]

- Ahmed, S.; Arocho, I. Analysis of cost comparison and effects of change orders during construction: Study of a mass timber and a concrete building project. J. Build. Eng. 2021, 33, 101856. [Google Scholar] [CrossRef]

- Mallo, M.F.L.; Espinoza, O. Awareness, perceptions and willingness to adopt Cross-Laminated Timber by the architecture community in the United States. J. Clean. Prod. 2015, 94, 198–210. [Google Scholar] [CrossRef]

- Ahmed, S.; Arocho, I. Mass timber building material in the U.S. construction industry: Determining the existing awareness level, construction-related challenges, and recommendations to increase its current acceptance level. Clean. Eng. Technol. 2020, 1, 100007. [Google Scholar] [CrossRef]

- Voulpiotis, K.; Köhler, J.; Jockwer, R.; Frangi, A. A holistic framework for designing for structural robustness in tall timber buildings. Eng. Struct. 2021, 227, 111432. [Google Scholar] [CrossRef]

- Li, J.; Rismanchi, B.; Ngo, T. Feasibility study to estimate the environmental benefits of utilising timber to construct high-rise buildings in Australia. Build. Environ. 2019, 147, 108–120. [Google Scholar] [CrossRef]

- Reddy, B.V. Sustainable materials for low carbon buildings. Int. J. Low-Carbon Technol. 2009, 4, 175–181. [Google Scholar] [CrossRef] [Green Version]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A Comparative Cradle-to-Gate Life Cycle Assessment of Mid-Rise Office Building Construction Alternatives: Laminated Timber or Reinforced Concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Zeng, R.; Chini, A. A review of research on embodied energy of buildings using bibliometric analysis. Energy Build. 2017, 155, 172–184. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Xu, J.; Sugawara, R.; Widyorini, R.; Han, G.; Kawai, S. Manufacture and properties of low-density binderless particleboard from kenaf core. J. Wood Sci. 2004, 50, 62–67. [Google Scholar] [CrossRef]

- Zhou, X.-Y.; Zheng, F.; Li, H.-G.; Lu, C.-L. An environment-friendly thermal insulation material from cotton stalk fibers. Energy Build. 2010, 42, 1070–1074. [Google Scholar] [CrossRef]

- Lafond, C.; Blanchet, P. Technical Performance Overview of Bio-Based Insulation Materials Compared to Expanded Polystyrene. Buildings 2020, 10, 81. [Google Scholar] [CrossRef]

- Grand View Research. North America Building Thermal Insulation Market|Industry Report 2025. 2016. Available online: https://www.grandviewresearch.com/industry-analysis/north-america-building-thermal-insulation-market (accessed on 24 May 2020).

- Akbari, H.; Konopacki, S.; Pomerantz, M. Cooling energy savings potential of reflective roofs for residential and commercial buildings in the United States. Energy 1999, 24, 391–407. [Google Scholar] [CrossRef]

- Petrie, T.W.; Atchley, J.A.; Childs, P.W.; Desjarlais, A.O. Energy Savings for Stucco Walls Coated with Cool Colors. In Proceedings of the Thermal Performance of Exterior Envelopes of Whole Buildings X, Clear Water Beach, FL, USA, 2–7 December 2007. [Google Scholar]

- Hsu, Y.-S.; Zheng, X.; Cooper, E.; Gillott, M.; Wood, C.J. Evaluation of the indoor pressure distribution during building airtightness tests using the pulse and blower door methods. Build. Environ. 2021, 195, 107742. [Google Scholar] [CrossRef]

- Cooper, E.; Zheng, X.; Wood, C.J. Numerical and experimental validations of the theoretical basis for a nozzle based pulse technique for determining building airtightness. Build. Environ. 2021, 188, 107459. [Google Scholar] [CrossRef]

- Jokisalo, J.; Kurnitski, J.; Korpi, M.; Kalamees, T.; Vinha, J. Building leakage, infiltration, and energy performance analyses for Finnish detached houses. Build. Environ. 2009, 44, 377–387. [Google Scholar] [CrossRef]

- Keast, D.N.; Beranek, T. The Use of Sound to Locate Infiltration Openings in Buildings; Newman, Inc.: Cambridge, MA, USA, 1979. [Google Scholar]

- International Energy Agency. Energy Conservation in Buildings and Community Systems Programme. Air Infiltration Calculation Techniques: An Applications Guide. Sir William Lyons R o ~ d Cavsntw CV4 7EZ. Available online: https://www.iea-ebc.org/Data/publications/EBC_Annex_31_tsr.pdf (accessed on 3 April 2021).

- Persily, A.K.; Emmerich, S.J. Energy Impacts of Infiltration and Ventilation in U.S. Office Buildings Using Multizone Airflow Simulation. Available online: https://www.nist.gov/publications/energy-impacts-infiltration-and-ventilation-us-office-buildings-using-multizone-airflow (accessed on 3 April 2021).

- Dehwah, A.H.; Krarti, M. Impact of switchable roof insulation on energy performance of US residential buildings. Build. Environ. 2020, 177, 106882. [Google Scholar] [CrossRef]

- Konopacki, S.; Gartland, L.; Akbari, H.; Rainer, L. Demonstration of Energy Savings of Cool Roofs; Ernest Orlando Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1998. [CrossRef] [Green Version]

- Boixo, S.; Diaz-Vicente, M.; Colmenar, A.; Castro, M.A. Potential energy savings from cool roofs in Spain and Andalusia. Energy 2012, 38, 425–438. [Google Scholar] [CrossRef]

- Liu, K.; Minor, J.; Liu, K.; Minor, J. Performance Evaluation of an Extensive Green Roof. 2005. Available online: https://sustainabletechnologies.ca/app/uploads/2013/03/NRC_EastviewGRrept.pdf (accessed on 25 May 2020).

- Gerzhova, N.; Blanchet, P.; Dagenais, C.; Côté, J.; Ménard, S. Côté Heat Transfer Behavior of Green Roof Systems Under Fire Condition: A Numerical Study. Buildings 2019, 9, 206. [Google Scholar] [CrossRef] [Green Version]

- Gerzhova, N.; Cote, J.; Blanchet, P.; Dagenais, C.; Menard, S. A conceptual framework for modelling the thermal conductivity of dry green roof substrates. BioResources 2019, 14, 8573–8599. [Google Scholar] [CrossRef]

- Kirankumar, G.; Saboor, S.; Vali, S.S.; Mahapatra, D.; Setty, A.B.T.P.; Kim, K.-H. Thermal and cost analysis of various air filled double glazed reflective windows for energy efficient buildings. J. Build. Eng. 2020, 28, 101055. [Google Scholar] [CrossRef]

- Fang, Y.; Arya, F.; Hyde, T.J.; Hewitt, N. A novel building component hybrid vacuum glazing—A modelling and experimental validation. ASHRAE Trans. 2013, 119, 430–440. [Google Scholar]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef] [Green Version]

- Fasi, M.A.; Budaiwi, I.M. Energy performance of windows in office buildings considering daylight integration and visual comfort in hot climates. Energy Build. 2015, 108, 307–316. [Google Scholar] [CrossRef]

- Tzempelikos, A.; Athienitis, A.K. The impact of shading design and control on building cooling and lighting demand. Sol. Energy 2007, 81, 369–382. [Google Scholar] [CrossRef]

- Liu, S.; Kwok, Y.T.; Lau, K.K.-L.; Chan, P.W.; Ng, E. Investigating the energy saving potential of applying shading panels on opaque façades: A case study for residential buildings in Hong Kong. Energy Build. 2019, 193, 78–91. [Google Scholar] [CrossRef]

- Won, J.; Cheng, J.C. Identifying potential opportunities of building information modeling for construction and demolition waste management and minimization. Autom. Constr. 2017, 79, 3–18. [Google Scholar] [CrossRef]

- Tushar, Q.; Bhuiyan, M.A.; Zhang, G.; Maqsood, T. An integrated approach of BIM-enabled LCA and energy simulation: The optimized solution towards sustainable development. J. Clean. Prod. 2021, 289, 125622. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Use of phase change materials for thermal energy storage in concrete: An overview. Constr. Build. Mater. 2013, 46, 55–62. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B.; Cetin, K.S. Freeze-thaw performance of phase change material (PCM) incorporated pavement subgrade soil. Constr. Build. Mater. 2019, 202, 449–464. [Google Scholar] [CrossRef]

- Guarino, F.; Athienitis, A.; Cellura, M.; Bastien, D. PCM thermal storage design in buildings: Experimental studies and applications to solaria in cold climates. Appl. Energy 2017, 185, 95–106. [Google Scholar] [CrossRef]

- Memon, S.A. Phase change materials integrated in building walls: A state of the art review. Renew. Sustain. Energy Rev. 2014, 31, 870–906. [Google Scholar] [CrossRef]

- Mathis, D.; Blanchet, P.; Lagière, P.; Landry, V. Performance of Wood-Based Panels Integrated with a Bio-Based Phase Change Material: A Full-Scale Experiment in a Cold Climate with Timber-Frame Huts. Energies 2018, 11, 3093. [Google Scholar] [CrossRef] [Green Version]

- Sarı, A.; Karaipekli, A.; Kaygusuz, K. Capric acid and stearic acid mixture impregnated with gypsum wallboard for low-temperature latent heat thermal energy storage. Int. J. Energy Res. 2008, 32, 154–160. [Google Scholar] [CrossRef]

- Kalhor, K.; Ememinejad, N. Qualitative and quantitative optimization of thermal insulation materials: Insights from the market and energy codes. J. Build. Eng. 2020, 30, 101275. [Google Scholar] [CrossRef]

- Mofid, S.A.; Jelle, B.P.; Zhao, X.; Gao, T.; Grandcolas, M.; Cunningham, B.; Ng, S.; Yang, R. Utilization of size-tunable hollow silica nanospheres for building thermal insulation applications. J. Build. Eng. 2020, 31, 101336. [Google Scholar] [CrossRef]

- Gao, T.; Sandberg, L.I.C.; Jelle, B.P. Nano Insulation Materials: Synthesis and Life Cycle Assessment. Procedia CIRP 2014, 15, 490–495. [Google Scholar] [CrossRef] [Green Version]

- Baetens, R.; Jelle, B.P.; Thue, J.V.; Tenpierik, M.J.; Grynning, S.; Uvsløkk, S.; Gustavsen, A. Vacuum insulation panels for building applications: A review and beyond. Energy Build. 2010, 42, 147–172. [Google Scholar] [CrossRef] [Green Version]

- Heiselberg, P.; Brohus, H.; Hesselholt, A.; Rasmussen, H.; Seinre, E.; Thomas, S. Application of sensitivity analysis in design of sustainable buildings. Renew. Energy 2009, 34, 2030–2036. [Google Scholar] [CrossRef] [Green Version]

| Primary Keyword | Buildings * | Materials * | Energy * |

|---|---|---|---|

| Secondary keyword | Wood buildings | Wood | Embodied energy * |

| Wood frame * | Bio-based | Energy efficiency * | |

| Mass timber * | Building materials * | Energy improvement | |

| Constructions * | Sustainable materials |

| Form | Material | Density (kg/m3) | Thermal Conductivity (W/mK) | Typical Applications | Embodied Energy (MJ/kg) | References |

|---|---|---|---|---|---|---|

| Sprayed-in-place | Cellulose | 24–36 | 0.054–0.046 | Attic retrofitting, frame sidewalls. | 0.94–3.30 | [76,79,80] |

| Foamed-in-place | Polyurethane | 40–55 | 0.024–0.023 | Roofs, cavities, irregular and rough surfaces. | 72.10–102.10 | |

| Blankets: batts or rolls | Fiberglass | 12–56 | 0.040–0.030 | Walls, ceilings, partitions, prefabricated houses, irregular surfaces. | 11.00–41.81 | [76,79,81,82] |

| Rock wool | 40–200 | 0.037–0.040 | 11.30–16.80 | |||

| Polyethylene | 35–40 | 0.041–0.029 | Ceilings, hangers, wrapping, carpet underlay, expansion joints. | 51.00–103.00 | ||

| Poured-in | Fiberglass | 10–48 | 0.038–0.030 | Cavities, around obstructions. | 11.00–41.81 | [76,79,83,84] |

| Rock wool | — | 0.042–0.040 | Cavities. | 11.30–16.80 | ||

| Cellulose | 24–36 | 0.054–0.046 | Small cavities. | 0.94–3.30 | ||

| Perlite | 32–176 | 0.060–0.040 | Fill or mixed with Portland cement. | 0.66–10.00 | ||

| Vermiculite | 64–130 | 0.068–0.063 | Ceilings, cavity walls, cores of hollow-core blocks. | 0.72–7.20 | ||

| Board | Fiberglass | 24–112 | 0.035–0.032 | Cavity walls, roofs, prefabricated houses. | 11.00–41.81 | [76,79,80,85] |

| Expanded polystyrene | 16–35 | 0.038–0.037 | Walls, roofs, floors, basements, foundations. Must be covered inside and outside (fire and weather protection). | 58.40–151.00 | ||

| Extruded polystyrene | 26–45 | 0.032–0.030 | 58.40–151.00 | |||

| Polyurethane | 40–55 | 0.024–0.023 | 65.20–110.00 | |||

| Vacuum Insulation Panels (VIP) | — | 0.004–0.003 | Walls, roofs, floors, perimeter, basements, foundations. | — | ||

| Reflective systems | Aluminized thin sheets | — | Reduces only radiant heat transfer | Ceilings, walls, floors. Most effective to reduce downward heat flow. | 115.00–157.10 | [76,79] |

| Material | Density (kg/m3) | Thermal Conductivity (W/m°C) | Typical Applications | Embodied Energy (MJ/kg) | References |

|---|---|---|---|---|---|

| Timber—softwood | 450 | 0.12–0.14 | Studs, trimmers, cripplers, other structural elements of wood frames | 0.30–13.00 | [93,94,95,96,97,98,99] |

| Timber—hardwood | 700 | 0.17–0.23 | 7.00–18.00 | ||

| Oriented strand boards (OSB) | 650 | 0.13–0.24 | Sub-flooring, single-layer flooring, wall and roof sheathing, ceilings/decks, structural insulated panels, webs for wood i-joists, industrial containers, mezzanines | 10.00–15.00 | [93,94,95,97,98,100,101,102] |

| Hardboard | 1000 | 0.12–0.29 | 16.00–35.00 | ||

| Particleboard | 600 | 0.12–0.17 | 4.00–15.00 | ||

| Medium density fiberboards (MDF) | 600 | 0.011–0.14 | 8.90–11.00 | ||

| Plywood | 700 | 0.12–0.15 | 10.00–20.00 | ||

| Cross laminated timber (CLT) | 485 | 0.13–0.10 | Floors, walls, roofing | 4.90–10.00 | [93,94,95,96,97,98,103,104,105,106] |

| Glulam | 600 | 0.12–0.13 | Beams, columns | 8.00–14.00 | |

| Gypsum board | 900 | 0.25–0.80 | Heavy-wear locations where durability and resistance to abrasions are required | 3.48–6.75 | [93,97,98,107,108,109] |

| Cement-bonded board | 1200 | 0.23–0.80 | Sub-flooring, single-layer flooring, walls, ceiling/deck sheathing | 4.80–6.75 | [93,97,98] |

| Concrete | 1600 | 0.40–0.57 | Sub-flooring, beams, columns | 1.70–23.90 | [93,97,98,107,110,111] |

| Steel | 7850 | 50.00–64.00 | — | 25.00–45.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabral, M.R.; Blanchet, P. A State of the Art of the Overall Energy Efficiency of Wood Buildings—An Overview and Future Possibilities. Materials 2021, 14, 1848. https://doi.org/10.3390/ma14081848

Cabral MR, Blanchet P. A State of the Art of the Overall Energy Efficiency of Wood Buildings—An Overview and Future Possibilities. Materials. 2021; 14(8):1848. https://doi.org/10.3390/ma14081848

Chicago/Turabian StyleCabral, Matheus Roberto, and Pierre Blanchet. 2021. "A State of the Art of the Overall Energy Efficiency of Wood Buildings—An Overview and Future Possibilities" Materials 14, no. 8: 1848. https://doi.org/10.3390/ma14081848

APA StyleCabral, M. R., & Blanchet, P. (2021). A State of the Art of the Overall Energy Efficiency of Wood Buildings—An Overview and Future Possibilities. Materials, 14(8), 1848. https://doi.org/10.3390/ma14081848