Mechanical and Microstructural Properties of Ordinary Concrete with High Additions of Crushed Glass

Abstract

1. Introduction

2. Materials and Methods

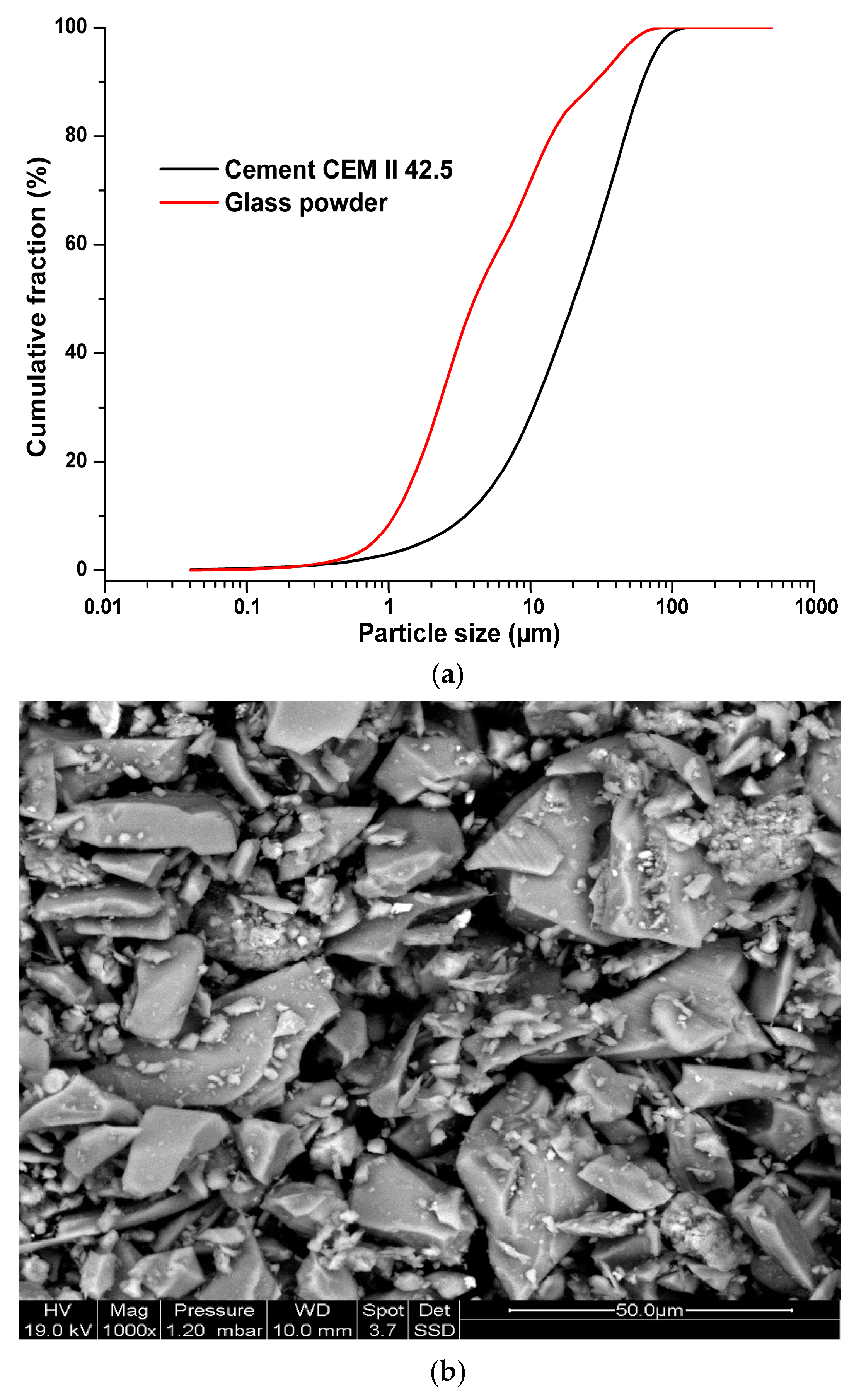

2.1. Materials and Mix Design

2.2. Experimental Methods

2.2.1. Slump Test

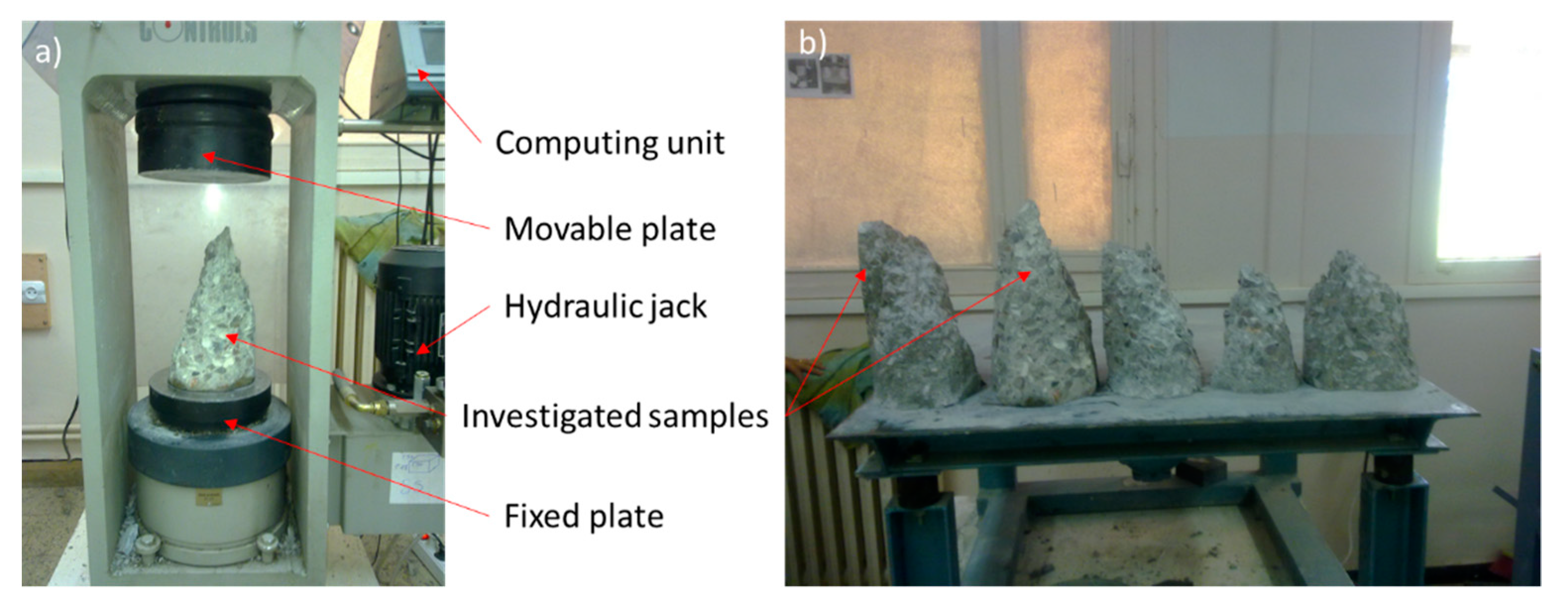

2.2.2. Mechanical Strength

- F: destructive force measured [kN];

- A: area of the sample [mm2].

2.2.3. Thermogravimetric Analysis (TGA)

- mel (t): the water mass related to the cement at the instant « t » [kg];

- mc: the anhydrous cement mass added to the sample [kg];

- Δm145°C→1100°C(t): sample mass loss between 145 °C and 1100 °C in [kg];

- Δm600°C→800°C(t): sample mass loss between 600 °C and 800 °C in [kg];

- md,145°C→1100°C(t): instrument drift between 145 °C and 1100 °C in [kg];

- mc: the anhydrous mass of cement introduced into the sample in [kg];

- LOI: ignition loss of the anhydrous cement in [%];

- msample: Initial mass of the sample in [kg];

- W/C: water/cement ratio [%];

- S/C: sand/cement ratio [%];

- A/C: mineral addition/cement ratio [%];

- Wel(∞): amount of water required for complete hydration of the cement [%]. This amount of water is estimated according to the composition of the cement by Bogue equations.

- Δm400°C→500°C(t): sample mass loss between 400 °C and 500 °C in [kg];

- md,400°C→500°C(t): instrument drift between 400 °C and 500 °C in [kg];

- : molar mass of Portlandite in [kg/mol];

- : molar mass of water in [kg/mol].

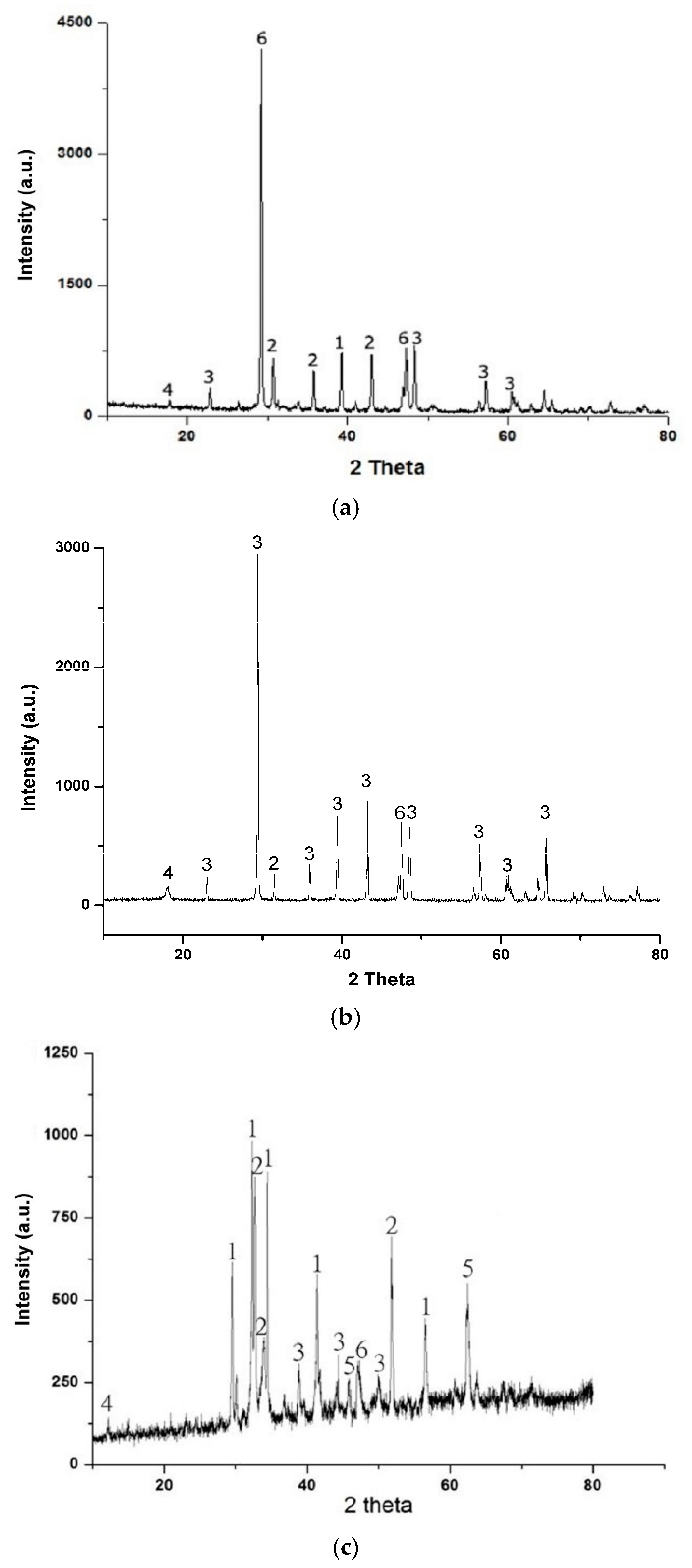

2.2.4. X-ray Diffraction (XRD) Analysis

2.2.5. Water Porosimetry

2.2.6. Porosimetry by Desorption Isotherms (Brunauer–Emmett–Teller (BET))

- d: the average pore diameter;

- R: the gas constant;

- V: nitrogen molar volume;

- T: nitrogen temperature;

- γ: the surface tension of nitrogen;

- θ: the contact angle.

- As: the specific surface area;

- nm: the number of moles of adsorbate in a monolayer;

- m: the sample mass in grams;

- a: the cross-sectional area of the adsorbate molecule of nitrogen;

- NA: Avogadro’s number.

3. Results and Discussion

3.1. Slump Tests of Fresh Concrete

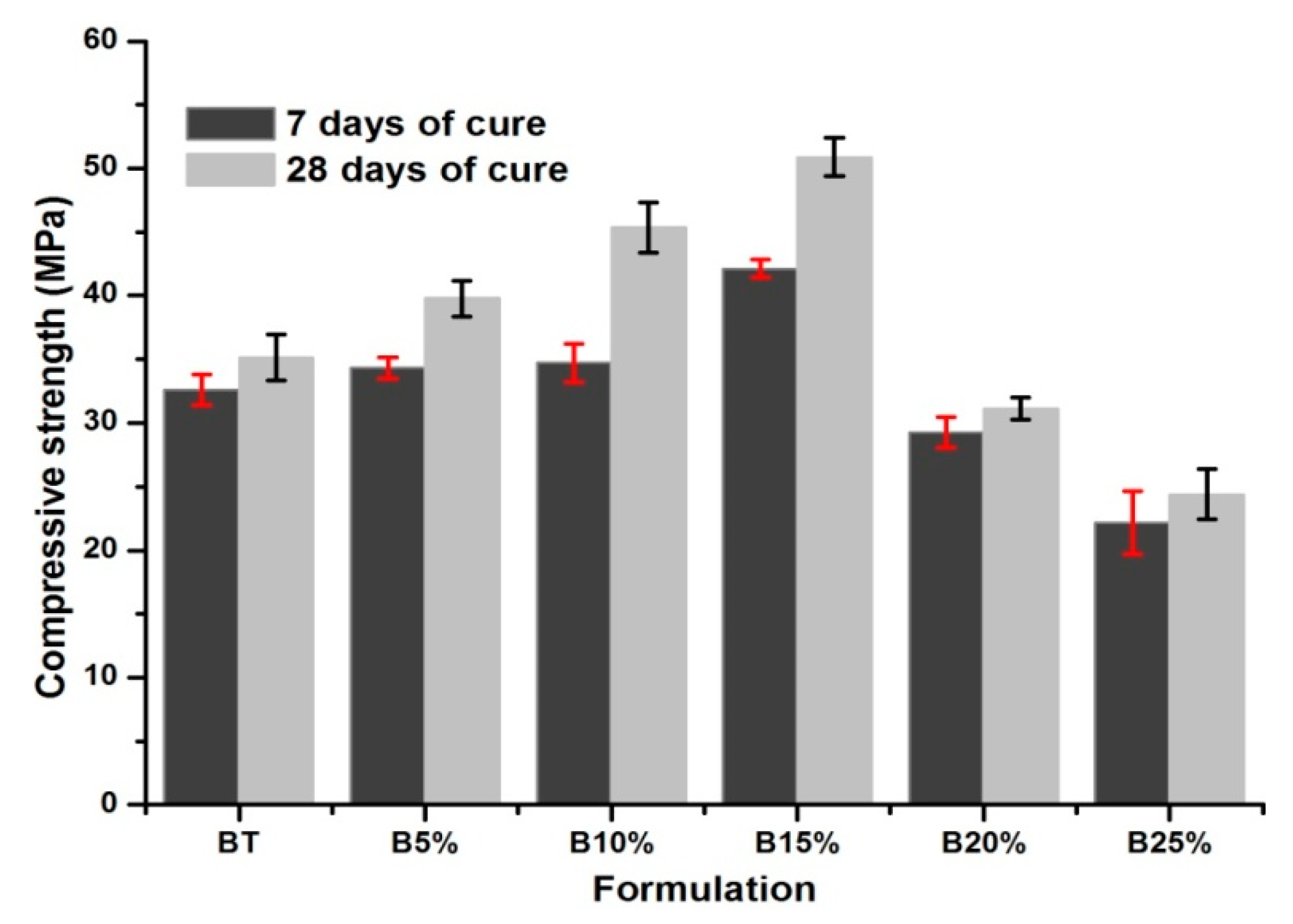

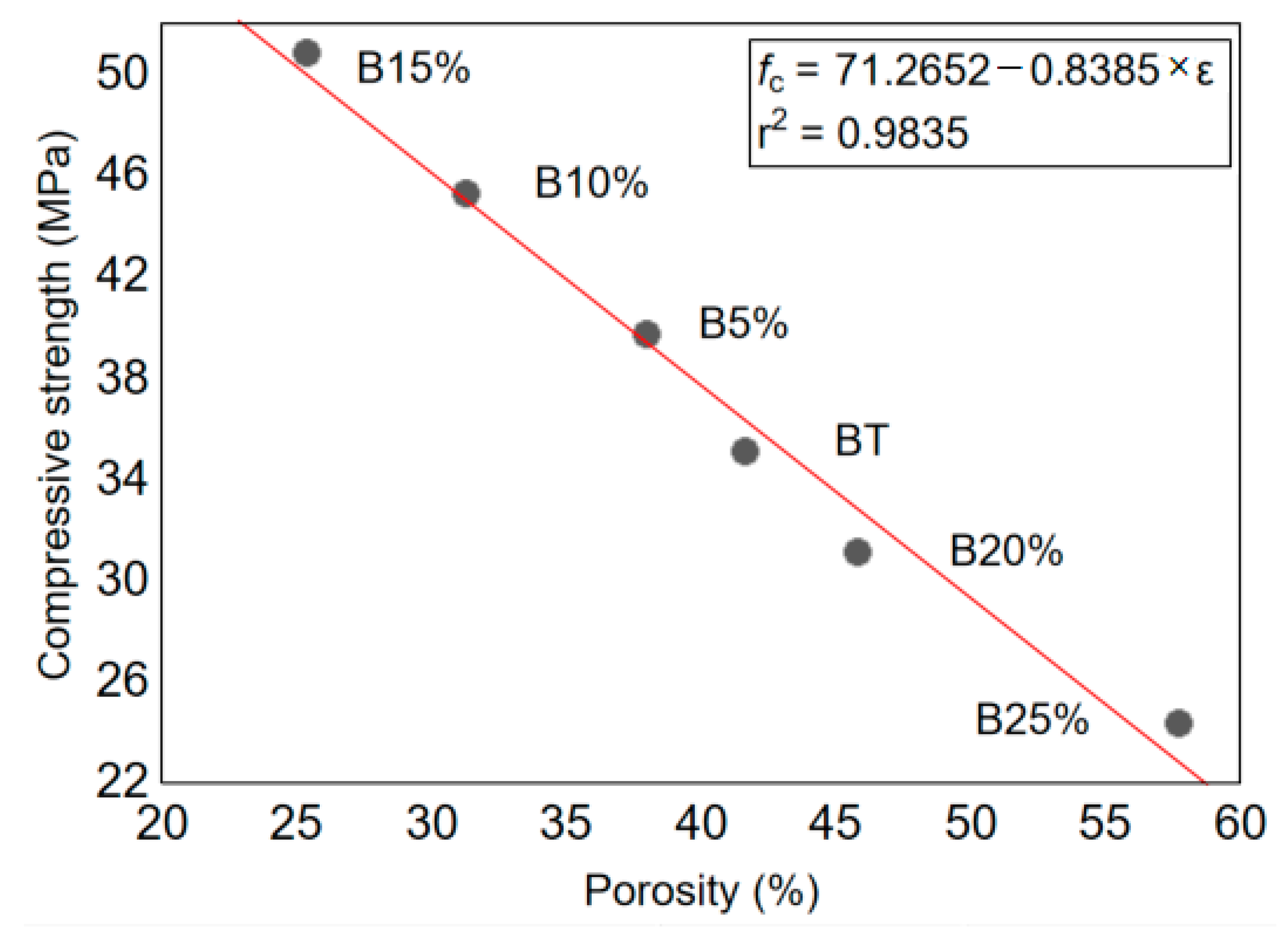

3.2. Compressive Strength of Hardened Concrete

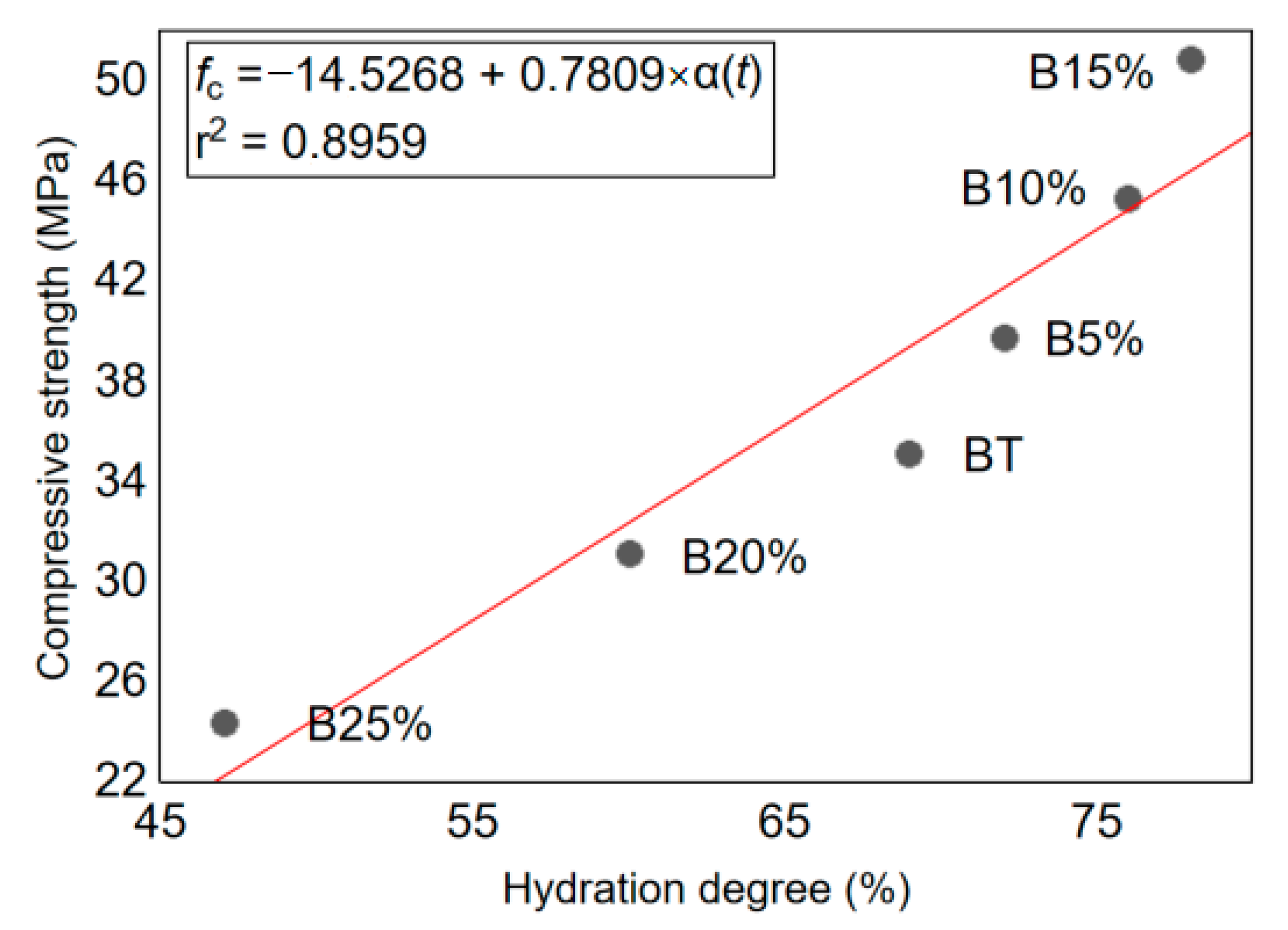

3.3. Hydration Degree

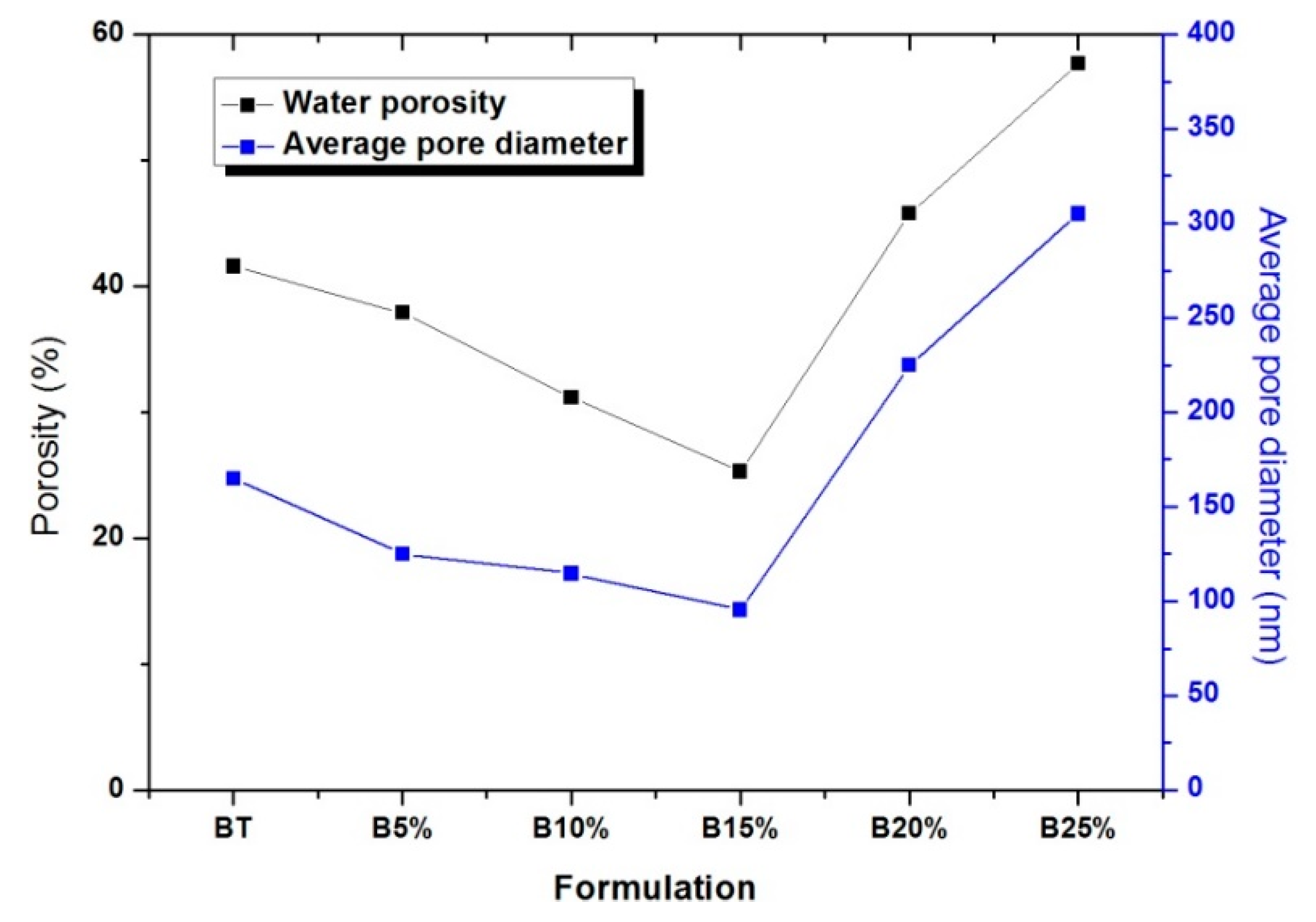

3.4. Evaluation of Porosity Accessible to Water and Average Pore Size

4. Ranking Method for Choosing the Most Effective Cementitious Composite Mixture

5. Conclusions

- The incorporation of glass powder directly influences the mechanical strength at 7 and 28 days of age. Replacing cement with dosage of 5%, 10% and 15% of cement by waste glass powder increases the value of compressive strength obtained at 7 and 28 days of age. Replacement of 15% cement by glass powder shows the highest compressive strength in comparison to the other substitution percentages. This is may have considered as the optimal dosage;

- TGA analysis shows that cement replacement by glass powder with dosage 15% and less increases the hydration degree of concrete. This is due to a small amount of chromium oxide contained in glass powder. These compounds accelerate the hydration reactions of cement particles. However, increasing the dosage of waste glass powder more than 15% has an opposite effect and the rapid decrease of the hydration degree was observed;

- XRD analysis of concrete mix design B15% highlighted the decrease of the intensities of portlandite peaks and confirmed the pozzolanic potential of glass powder that is considered as an advantage to limit the concrete degradation after its curing toward sulphate attacks and chloride;

- The results of BET analysis have shown that the cement replacement by glass powder up to 15% has reduced considerably the average pore diameter and therefore the concrete porosity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sheheryar, M.; Rehan, R.; Nehdi, M.L. Estimating CO2 Emission Savings from Ultrahigh Performance Concrete: A System Dynamics Approach. Materials 2021, 14, 995. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Chow, C.L.; Feo, L.; Penna, R.; Lau, D. Green Concrete: By-Products Utilization and Advanced Approaches. Sustainability 2019, 11, 5145. [Google Scholar] [CrossRef]

- Festa, J.; Dreux, G. Nouveau Guide du Béton et de Ses Constituants (New Guide of Concrete and Its Constituents); Eyrolles: Paris, France, 1998. (In French) [Google Scholar]

- Justnes, H.; Skocek, J.; Ostnor, T.A.; Engelsen, C.J.; Skjolsvold, O. Microstructural changes of hydrated cement blended with fly ash upon carbonation. Cem. Concr. Res. 2020, 137, 106192. [Google Scholar] [CrossRef]

- Nassar, R.U.D.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Islam, G.M.S.; Rahman, M.H.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Shen, J.; Xie, Z.; Griggs, D.; Shi, Y. Effects of kaolin on engineering properties of Portland cement concrete. Appl. Mech. Mater. 2012, 174–177, 76–81. [Google Scholar] [CrossRef]

- Weng, T.L.; Lin, W.T.; Cheng, A. Effect of metakaolin on strength and efflorescence quantity of cement-based composites. Sci. World J. 2013, 1–11. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Liu, R.; Zhang, B. Effect of fly ash and silica fume on hydration rate of cement pastes and strength of mortars. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 1225–1228. [Google Scholar] [CrossRef]

- Fontes, C.M.A.; Silva, R.B.; Lima, P.R.L. Characterization and Effect of Using Bottom and Fly Ashes from Co-combustion of Cocoa Waste as Mineral Addition in Concrete. Waste Biomass Valorization 2019, 10, 223–233. [Google Scholar] [CrossRef]

- Ali-Boucetta, T. Contribution du Laitier Granulé et de la Poudre de Verre Sur les Proprieties D’écoulement et de Durabilité des Béton Sautoplaçants et de Hautes Performances. (Contribution of Granulated Slag and Glass Powder on Flow and Durability Properties of Self-Compacting Concrete and High Performance Self-Compacting Concrete). Ph.D. Thesis, University of Annaba, Annaba, Algeria, 2014. [Google Scholar]

- Hendi, A.; Mostofinejad, D.; Sedaghatdoost, A.; Zohrabi, M.; Naeimi, N.; Tavakolinia, A. Mix design of the green self-consolidating concrete: Incorporating the waste glass powder. Constr. Build. Mater. 2019, 199, 369–384. [Google Scholar] [CrossRef]

- Coudray, C.; Amant, V.; Cantegrit, L.; Le Bocq, A.; Thery, F.; Denot, A.; Eisenlohr, L. Influence of Crushing Conditions on Recycled Concrete Aggregates (RCA) Leaching Behaviour. Waste Biomass Valorization 2017, 8, 2867–2880. [Google Scholar] [CrossRef]

- ToubalSeghir, N.; Benaimeche, O.; Krzywiński, K.; Sadowski, Ł. Ultrasonic Evaluation of Cement-Based Building Materials Modified Using Marble Powder Sourced from Industrial Wastes. Buildings 2020, 10, 38. [Google Scholar] [CrossRef]

- Jurczak, R.; Szmatuła, F.; Rudnicki, T.; Korentz, J. Effect of ground waste glass addition on the strength and durability of low strength concrete mixes. Materials 2021, 14, 190. [Google Scholar] [CrossRef]

- Schwarz, N.; Neithalath, N. Influence of a fine glass powder on cement hydration: Comparison to fly ash and modeling the degree of hydration. Cem. Concr. Res. 2008, 38, 429–436. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder-Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Mirzahosseini, M.; Riding, K.A. Effect of curing temperature and glass type on the pozzolanic reactivity of glass powder. Cem. Concr. Res. 2014, 58, 103–111. [Google Scholar] [CrossRef]

- Małek, M.; Łasica, W.; Jackowski, M.; Kadela, M. Effect of Waste Glass Addition as a Replacement for Fine Aggregate on Properties of Mortar. Materials 2020, 13, 3189. [Google Scholar] [CrossRef]

- Kim, I.S.; Choi, S.Y.; Yang, E.I. Evaluation of durability of concrete substituted heavyweight waste glass as fine aggregate. Constr. Build. Mater. 2018, 184, 269–277. [Google Scholar] [CrossRef]

- Chung, S.-Y.; Abd Elrahman, M.; Sikora, P.; Rucinska, T.; Horszczaruk, E.; Stephan, D. Evaluation of the Effects of Crushed and Expanded Waste Glass Aggregates on the Material Properties of Lightweight Concrete Using Image-Based Approaches. Materials 2017, 10, 1354. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd-Elmoaty, A.E.M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Kim, S.K.; Hong, W.K. High sulfate attack resistance of reinforced concrete flumes containing liquid crystal display (LCD) waste glass powder. Materials 2019, 12, 2031. [Google Scholar] [CrossRef]

- Yousefi, A.; Tang, W.; Khavarian, M.; Fang, C.; Wang, S. Thermal and Mechanical Properties of Cement Mortar Composite Containing Recycled Expanded Glass Aggregate and Nano Titanium Dioxide. Appl. Sci. 2020, 10, 2246. [Google Scholar] [CrossRef]

- Setina, J.; Gabrene, A.; Juhnevica, I. Effect of pozzolanic additives on structure and chemical durability of concrete. Procedia Eng. 2013, 57, 1005–1012. [Google Scholar] [CrossRef]

- EN 12350-2: Testing Fresh Concrete-Part 2: Slump Test; Association Française de Normalisation: Paris, France, 2014.

- AFNOR. NF EN206: Béton-Spécification, Performances, Production et Conformité; Association Française de NORmalisation: Paris, France, 2014. [Google Scholar]

- Mounanga, P. Étude Expérimentale du Comportement de Pâtes de Ciment au Trèsjeuneâge: Hydratation, Retraits, Propriétésthermophysiques, (Experimental Study of the Behaviour of Cement Pastes at Very Early Age: Hydration, Shrinkage, Thermophysical Properties). Ph.D. Thesis, University of Nantes, Nantes, France, 2003. [Google Scholar]

- Delmi, M.M.Y.; Aït-Mokhtar, A.; Amiri, O. Modelling the coupled evolution of hydration and porosity of cement-based materials. Constr. Build. Mater. 2006, 20, 504–514. [Google Scholar] [CrossRef]

- AFPC-AFREM. Détermination de la Masse Volumiqueapparente et de la Porosité Accessible à L’eau des Bétons–Méthodesrecommandées Pour la Mesure des Grandeurs Associées à la Durabilité. Compterendu des Journées Techniques; AFPC-AFREM: Toulouse, France, 1997. [Google Scholar]

- Johannesson, B.; Utgenannt, P. Microstructural changes caused by carbonation of cement mortar. Cem. Concr. Res. 2001, 31, 925–931. [Google Scholar] [CrossRef]

- Trabelsi, A.; Belarbi, R.; Turcry, P.; Aït-Mokhtar, A. Water vapor desorption variability of in situ concrete and effects on drying simulations. Mag. Concr. Res. 2015, 63, 333–342. [Google Scholar] [CrossRef]

- Richardson, I.G. The nature of C-S-H in hardened cement. Cem. Concr. Res. 1999, 29, 1131–1147. [Google Scholar] [CrossRef]

- Chen, Q.Y.; Hills, C.D.; Tyrer, M.; Slipper, I.; Shen, H.G.; Brough, A. Characterisation of products of tricalcium silicate hydration in the presence of heavy metals. J. Hazard. Mater. 2007, 47, 817–825. [Google Scholar] [CrossRef] [PubMed]

- Belebchouche, C.; Moussaceb, K.; Aït-Mokhtar, A. Evaluation of the encapsulation of nickel, chromium and lead-rich wastes in cement matrices by TCLP test. Eur. J. Environ. Civ. Eng. 2016, 20, 711–724. [Google Scholar] [CrossRef]

- Young, R.A. The Rietveld Method; OUP Oxford: Oxford, UK, 1995. [Google Scholar]

- Vaitkevičius, V.; Šerelis, E.; Hilbig, E. The effect of glass powder on the microstructure of ultra high performance concrete. Constr. Build. Mater. 2014, 68, 102–109. [Google Scholar] [CrossRef]

- Kara-Ali, R. Influence des Additions Minérales Sur le Besoineneau et les Résistancesmécaniques des Mélanges Cimentaires, (Influence of Mineral Additions on the Water Requirement and the Mechanical Strength of Cement Mixtures). Ph.D. Thesis, University of Cergy-Pontoise, Cergy, France, 2002. [Google Scholar]

- Planel, D. Les Effetscouplés de la Précipitation d’es Pèces Secondaires Sur le Comportement Mécanique et la Dégradation des Bétons, (The Coupled Effects of the Precipitation of Secondary Species on the Mechanical Behavior and Degradation of Concretes). Ph.D. Thesis, University of Marne La Vallée, Champs-sur-Marne, France, 2002. [Google Scholar]

- Alexander, M.G.; Bertron, A.; De-Belie, N. Performance of Cement-Based Materials in Aggressive Aqueous Environments; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Atahan, H.N.; Oktar, O.N.; Tasdemir, M.A. Effects of water-cement ratio and curing time on the critical pore width of hardened cement paste. Constr. Build. Mater. 2009, 23, 1196–1200. [Google Scholar] [CrossRef]

- Amiri, O.; Aït-Mokhtar, A.; Sarhani, M. Tri-dimensional modeling of cementitious materials permeability from polymodal pore size distribution obtained by mercury intrusion porosimetry tests. Adv. Cem. Res. 2005, 17, 39–45. [Google Scholar] [CrossRef]

| Authors | Mixture Content | Analysed Properties | Main Findings |

|---|---|---|---|

| Nassar et al. [6] | Milled waste glass as a 20% by weight replacement of cement, and 50% and 100% replacement of aggregate. Mixture type: Traditional concrete | Slump test, density, strength (compressive and flexural), sorption, | Higher water absorption, improvement in pore system characteristics, enhance durability such as sorption, chloride permeability, and freeze–thaw resistance |

| Islam et al. [7] | Glass powder as a 10–25% of cement replacement. Mixture type: Mortar | Flow test, compressive strength, cost analysis | Increase of strength, reducing costs. |

| Schwarz et al. [17] | Glass powder as 5%, 10% and 20% cement replacement by mass in mortar. Mixture type: Mortar | Strength activity index, effective conductivity, degree of hydration, | Increase of strength activity index, decrease of effective conductivity, decrease of hydration degree |

| Soliman et al. [18] | Glass powder as a replacement of cement in UHPC (from 0 to 50% of replacement by mass). Mixture type: Ultra High Performance Concrete | Compressive strength, heat flow, workability, hydration process | Increase of compressive strength, heat flow reduction, greater workability, slower hydration process |

| Mirzahosseini et al. [19] | Clear glass and green glass as a 25% replacement of cement Mixture type: Cement Paste | Chemical shrinkage, heat of hydration, absorption, compressive strength | Increase of chemical shrinkage, increase of heat of hydration, increase of compressive strength, |

| Małek et al. [20] | Glass cullet as a replacement of granite aggregate up to 20%. Cement content was not reduced. Mixture type: Lightweight concrete | Slump cone, porosity, pH values, bulk density, strength (compressive, flexural, split, tensile), elasticity of modulus, Poisson coefficient | Slump cone reduction, slight reduction of the density, increase of strength (compressive, flexural, split tensile strength) |

| Chung S-Y et al. [22] | Crushed glass or expanded glass as a full replacement of natural sand (0–4 mm). Cement content was not reduced Mixture type: Traditional concrete | Porosity, thermal conductivity, density, strength (compressive and flexural) | Thermal conductivity reduction, slight reduction of porosity, increase of strength (compressive and flexural) |

| Aliabdo et al. [23] | Glass powder as 5–25% cement replacement Mixture type: Traditional concrete | Thermo-gravimetric analysis, strength (compressive and tensile), slump test, density, sorption | Increase of compressive and tensile strength, decrease of absorption, Increase of density, |

| Kim et al. [24] | Glass powder as a 10% and 20% cement replacement Mixture type: Traditional concrete | Slump test, strength (compressive and flexural), porosity | Increase of compressive strength, porosity reduction, |

| Yousefi et al. [25] | Expanded glass as a 50% and 100% replacement of natural aggregate. Cement content was not reduced. Mixture type: Mortar | Flow test, density, water absorption, thermal insulation | Density reduction, increase of water absorption, compressive strength reduction, heat transferring rate reduction |

| Cement CEM II 42.5 | |||||||

| Compounds | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O |

| (%) | 19.83 ± 0.87 | 6.21 ± 0.24 | 3.12 ± 0.08 | 60.52 ± 1.31 | 0.94 ± 0.09 | 1.02 ± 0.06 | 0.01 ± 0.00 |

| Compounds | Cr2O3 | Na2O | Ignition loss = 2.41 according to NF EN 196-2 | ||||

| (%) | - | 0.05 ± 0.01 | SSA = 3310 cm2/g Density = 3.10 | ||||

| C3S = 49.41% | C2S = 19.85% | C3A = 11.18% | C4AF = 9.48% | ||||

| Glass Powder | |||||||

| Compounds | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O |

| (%) | 74.15 ± 0.93 | 2.12 ± 0.06 | 0.75 ± 0.09 | 5.63 ± 0.03 | 1.45 ± 0.14 | - | 0.15 ± 0.02 |

| Compounds | Cr2O3 | Na2O | Ignition loss = 0.85 | ||||

| (%) | 0.19 ± 0.03 | 8.44 ± 0.21 | SSA = 4530 cm2/g Density = 3.53 | ||||

| Element | O | Na | Mg | Al | Si | Cr | K | Ca | Fe | S |

|---|---|---|---|---|---|---|---|---|---|---|

| (%) | 45.45 ± 0.39 | 8.3 ± 0.2 | 2.04 ± 0.01 | 2.54 ± 0.09 | 31.85 ± 0.36 | 0.03 ± 0.02 | 0.65 ± 0.06 | 7.22 ± 0.36 | 1.87 ± 0.12 | 0.02 ± 0.01 |

| Designation | Cement | Glass Powder | Water | Sand 0/3 | Gravel 3/8 | Gravel 8/16 |

|---|---|---|---|---|---|---|

| BT | 350 | 0 | 175 | 713 | 314 | 628 |

| B5% | 332.5 | 17.5 | 175 | 714 | 314 | 629 |

| B10% | 315 | 35 | 175 | 715 | 315 | 629 |

| B15% | 297.5 | 52.5 | 175 | 716 | 315 | 630 |

| B20% | 280 | 70 | 175 | 716 | 315 | 630 |

| B25% | 262.5 | 87.5 | 175 | 717 | 316 | 631 |

| Designation | BT | B5% | B10% | B15% | B20% | B25% |

|---|---|---|---|---|---|---|

| Slump (mm) | 115 | 105 | 90 | 85 | 70 | 65 |

| Legend | Compound Name | Reference Pattern |

|---|---|---|

| 1 | Calcium silicate | 00-042-0551 |

| 2 | Larnite | 00-033-0302 |

| 3 | Calcite | 00-005-0586 |

| 4 | Ettringite | 00-041-1451 |

| 5 | Tricalcium aluminate | 00-038-1429 |

| 6 | Portlandite | 00-004-0733 |

| Mixture | Cement | Glass Powder | Cost | Cost Rank | Compressive Strength | Compressive Strength Rank | Total Rank |

|---|---|---|---|---|---|---|---|

| [-] | [kg] | [kg] | [Euro/m3] | [-] | [MPa] | [-] | [-] |

| BT | 350 | 0 | 100 | 6 | 35.16 | 4 | 10 |

| B5% | 332.5 | 17.5 | 98.8 | 5 | 39.80 | 3 | 8 |

| B10% | 315 | 35 | 97.6 | 4 | 45.35 | 2 | 6 |

| B15% | 297.5 | 52.5 | 96.4 | 3 | 50.89 | 1 | 4 |

| B20% | 280 | 70 | 95.2 | 2 | 31.15 | 5 | 7 |

| B25% | 262.5 | 87.5 | 94 | 1 | 24.41 | 6 | 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belebchouche, C.; Moussaceb, K.; Bensebti, S.-E.; Aït-Mokhtar, A.; Hammoudi, A.; Czarnecki, S. Mechanical and Microstructural Properties of Ordinary Concrete with High Additions of Crushed Glass. Materials 2021, 14, 1872. https://doi.org/10.3390/ma14081872

Belebchouche C, Moussaceb K, Bensebti S-E, Aït-Mokhtar A, Hammoudi A, Czarnecki S. Mechanical and Microstructural Properties of Ordinary Concrete with High Additions of Crushed Glass. Materials. 2021; 14(8):1872. https://doi.org/10.3390/ma14081872

Chicago/Turabian StyleBelebchouche, Cherif, Karim Moussaceb, Salah-Eddine Bensebti, Abdelkarim Aït-Mokhtar, Abdelkader Hammoudi, and Slawomir Czarnecki. 2021. "Mechanical and Microstructural Properties of Ordinary Concrete with High Additions of Crushed Glass" Materials 14, no. 8: 1872. https://doi.org/10.3390/ma14081872

APA StyleBelebchouche, C., Moussaceb, K., Bensebti, S.-E., Aït-Mokhtar, A., Hammoudi, A., & Czarnecki, S. (2021). Mechanical and Microstructural Properties of Ordinary Concrete with High Additions of Crushed Glass. Materials, 14(8), 1872. https://doi.org/10.3390/ma14081872