Strength Characteristics and Microstructure of Cement Stabilized Soft Soil Admixed with Silica Fume

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Methods and Sample Preparation

3. Results

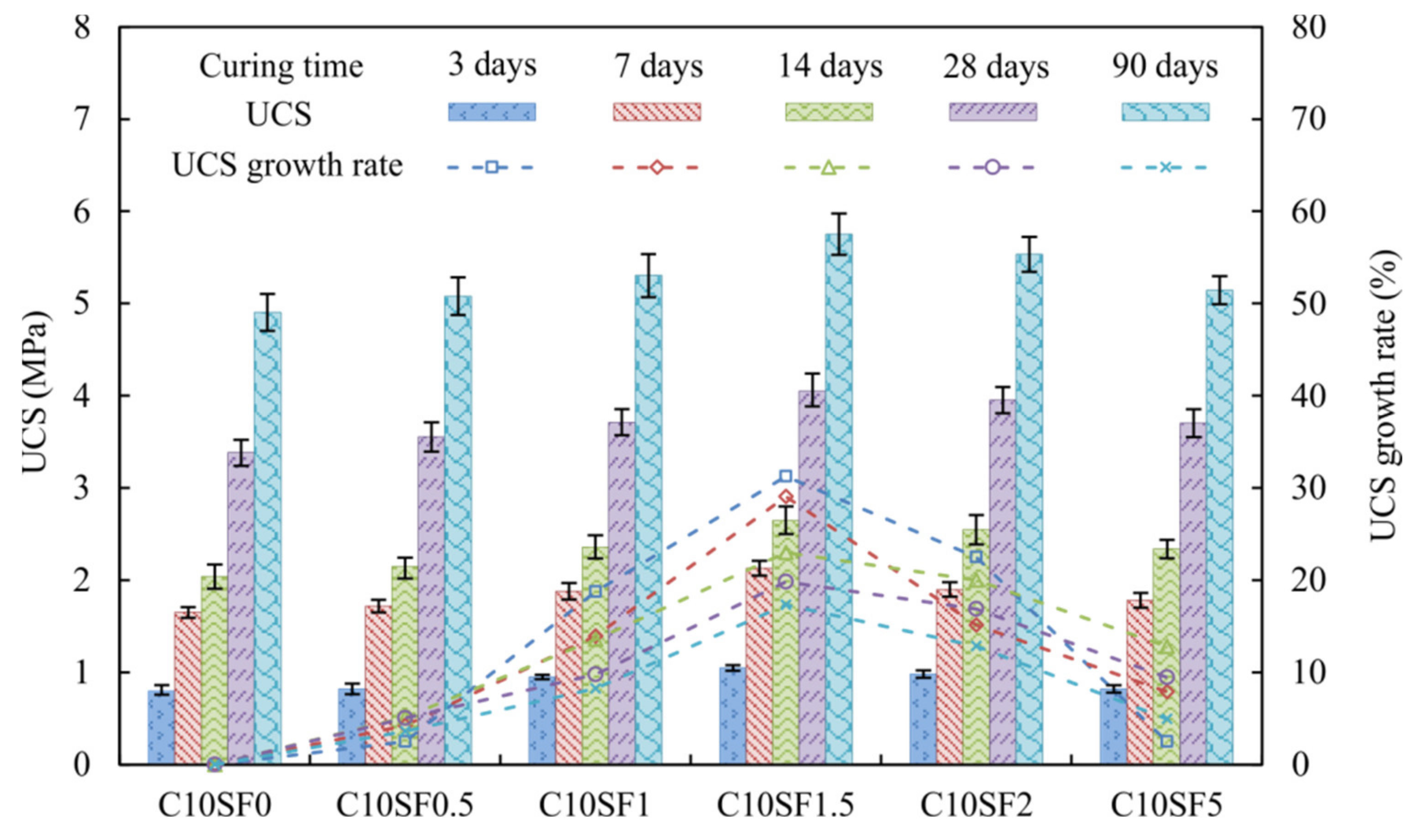

3.1. Strength of Cement Stabilized Soil admixed with Silica Fume

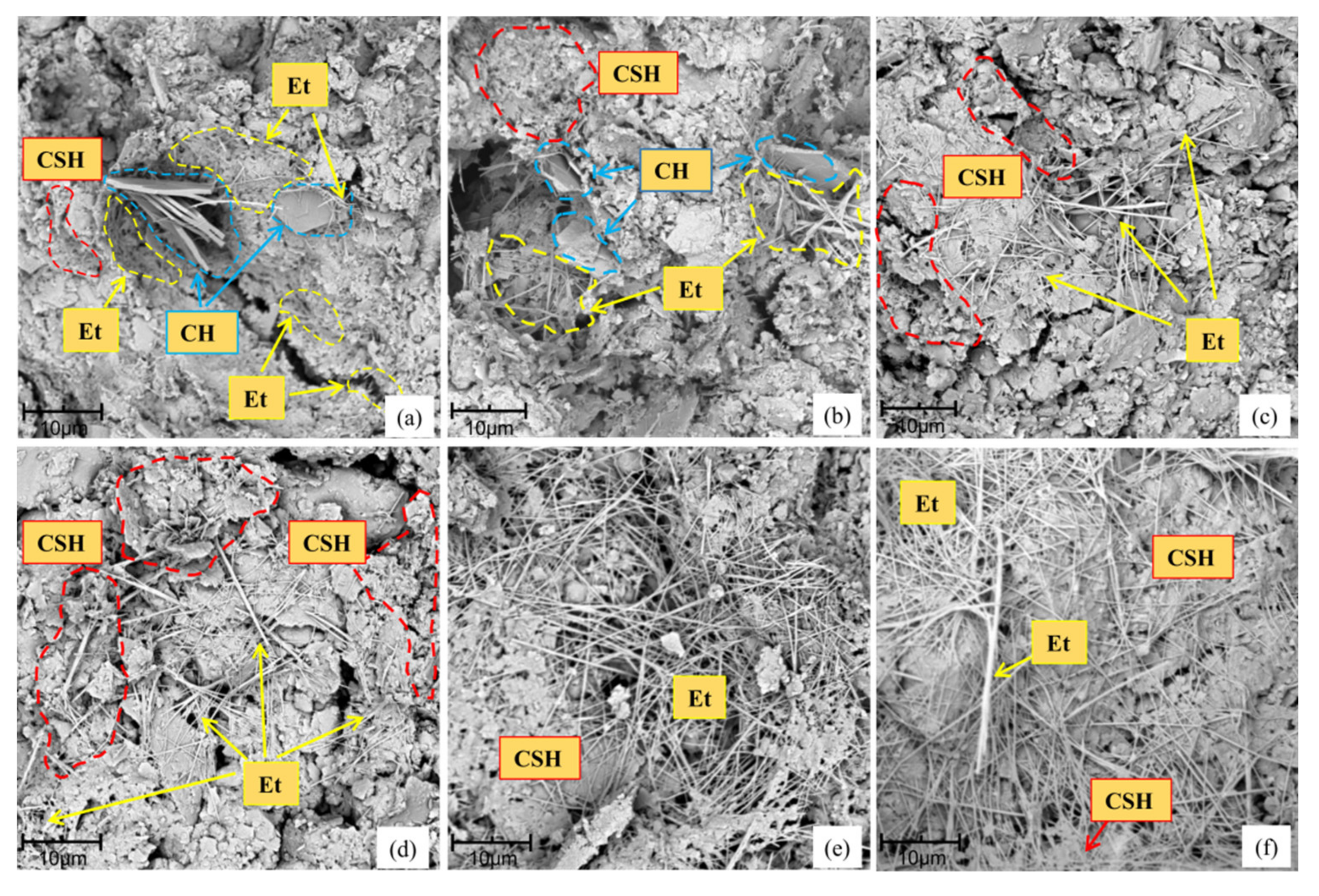

3.2. Microscopic Characteristics of Cement Stabilized Soil Admixed with Silica Fume Versus Curing Time

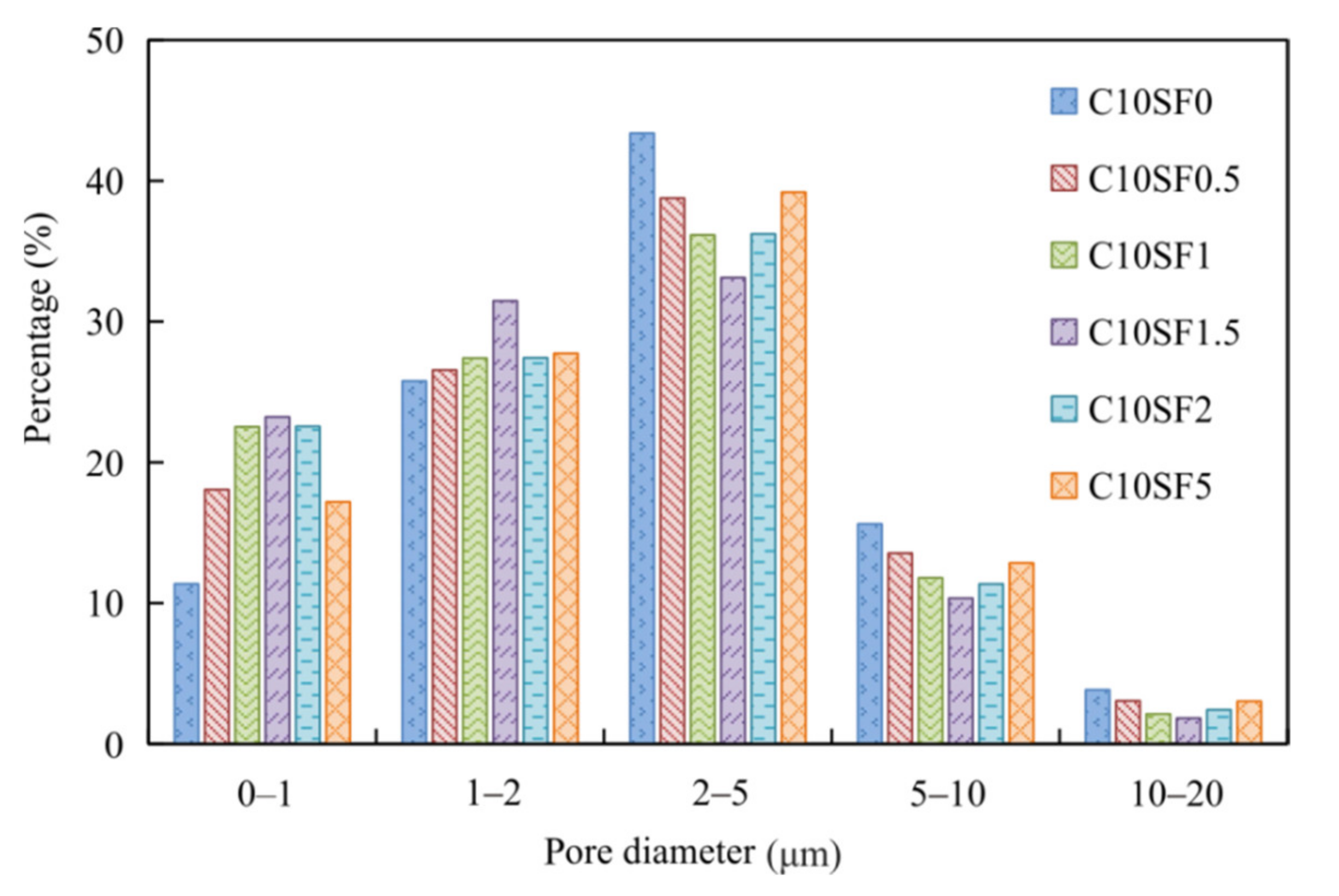

3.3. Pore Distribution Characteristics of Cement Stabilized Soil with Different Silica Fume Contents

4. Discussion

5. Conclusions

- According to the results of UCT, UCS increases almost linearly within cement content from 4% to 10%, while the growth rate slows down from cement content of 10% to 13%; the SF content has an important influence on the strength characteristics of cement stabilized soil. The UCS of C10SF1.5 at 28 days is 1.22 times that of C10SF0, and is also higher than the UCS of SF1C13, indicating that the addition of SF can reduce the cement content used and increase the compressive strength. The 1.5% SF of the cement content is considered optimum, excessive SF will not further increase the strength. SF played a role in the early stage, the UCS growth rate of 3 days exceeded 33%, it helped to accelerate the cement hydration reaction and significantly improve the early-age strength of stabilized soil, which can improve construction efficiency in engineering.

- SEM analysis shows that SF started to react with calcium hydroxide (CH) at 3 days, which prevents CH from forming weak zones in the pores and promotes cement hydration to form calcium silicate hydrate gel (CSH), the formed CSH bonds the soil particles together gradually, this binding produces a stronger soil matrix with the increase of curing time, resulting in an increase in compressive strength.

- According to the pores size analysis of cement stabilized soil with different SF content in the standard age of 28 days, when the SF content is lower than the optimum, the small pores of the cement stabilized soil increase due to the generation of CSH, and the optimum SF content helps the cement stabilized soil to be more uniform. The increase in water demand with excessive SF will increase the self-shrinkage of cement stabilized soil and produce micro cracks, which are manifested by the increase of large pores and the decrease of compressive strength of cement stabilized soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Committee, A. Silica Fume in Concrete. Concrete 1987, 44, 1–12. [Google Scholar]

- Xue, Z.; Tang, X.; Yang, Q.; Tian, Z.; Zhang, Y. Influence of salt content on clay electro-dewatering with copper and stainless steel anodes. Dry. Technol. 2019, 37, 2005–2019. [Google Scholar] [CrossRef]

- Xue, Z.; Tang, X.; Yang, Q.; Tian, Z.; Zhang, Y.; Xu, W. Mechanism of electro-osmotic chemical for clay improvement: Process analysis and clay property evolution. Appl. Clay Sci. 2018, 166, 18–26. [Google Scholar] [CrossRef]

- Dingwen, Z.; Libin, F.; Songyu, L.; Yongfeng, D. Experimental Investigation of Unconfined Compression Strength and Stiffness of Cement Treated Salt-Rich Clay. Mar. Georesour. Geotechnol. 2013, 31, 360–374. [Google Scholar] [CrossRef]

- Liu, S.; Hryciw, R.D. Evaluation and Quality Control of Dry-Jet-Mixed Clay Soil-Cement Columns by Standard Penetration Test. Transp. Res. Rec. J. Transp. Res. Board 2003, 1849, 47–52. [Google Scholar] [CrossRef]

- Kang, G.-O.; Tsuchida, T.; Kim, Y.-S. Strength and stiffness of cement-treated marine dredged clay at various curing stages. Constr. Build. Mater. 2017, 132, 71–84. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, J.; Li, Y.-P.; Li, L.-H. Statistical evaluation of the overall strength of a soil-cement column under axial compression. Constr. Build. Mater. 2017, 132, 51–60. [Google Scholar] [CrossRef]

- Yao, K.; Chen, Q.; Ho, J.; Xiao, H.; Lee, F.H. Strain-dependent shear stiffness of cement-treated marine Clay. J. Mater. Civ. Eng. 2018, 30, 04018255. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2013, 47, 1055–1065. [Google Scholar] [CrossRef]

- Davis, S.J.; Lewis, N.S.; Matthew, S.; Sonia, A.; Doug, A.; Azevedo, I.L.; Benson, S.M.; Thomas, B.; Jack, B.; Yet-Ming, C. Net-zero emissions energy systems. Science 2018, 360, eaas9793. [Google Scholar] [CrossRef]

- Garcia, M.D.L.; Sousa-Coutinho, J. Strength and durability of cement with forest waste bottom ash. Constr. Build. Mater. 2013, 41, 897–910. [Google Scholar] [CrossRef]

- Puppala, A.J.; Hoyos, L.R.; Potturi, A.K. Resilient Moduli Response of Moderately Cement-Treated Reclaimed Asphalt Pavement Aggregates. J. Mater. Civ. Eng. 2011, 23, 990–998. [Google Scholar] [CrossRef]

- Yazc, H. The effect of silica fume and high-volume Class C fly ash on mechanical properties, chloride penetration and freeze–thaw resistance of self-compacting concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar]

- Guellue, H.; Girisken, S. Performance of fine-grained soil treated with industrial wastewater sludge. Environ. Earth. Sci. 2013, 70, 777–788. [Google Scholar] [CrossRef]

- Güllü, H. Factorial experimental approach for effective dosage rate of stabilizer: Application for fine-grained soil treated with bottom ash. Soils Found. 2014, 54, 462–477. [Google Scholar] [CrossRef]

- Bayasi, Z.; Zhou, J. Properties of Silica Fume Concrete and Mortar. ACI Mater. J. 1993, 90, 349–356. [Google Scholar]

- Collins, F.; Sanjayan, J. Effects of ultra-fine materials on workability and strength of concrete containing alkali-activated slag as the binder. Cem. Concr. Res. 1999, 29, 459–462. [Google Scholar] [CrossRef]

- Chung, Y. Improving the workability and strength of silica fume concrete by using silane-treated silica fume. Cem. Concr. Res. 1999, 29, 451–453. [Google Scholar]

- Mazloom, M.; Ramezanianpour, A.; Brooks, J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Chaipanich, A.; Rianyoi, R.; Nochaiya, T. The effect of carbon nanotubes and silica fume on compressive strength and flexural strength of cement mortars. Mater. Today Proc. 2017, 4, 6065–6071. [Google Scholar] [CrossRef]

- Lange-Kornbak, D.; Karihaloo, B. Design of Fiber-Reinforced DSP Mixes for Minimum Brittleness. Adv. Cem. Based Mater. 1998, 7, 89–101. [Google Scholar] [CrossRef]

- Poon, C.; Kou, S.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Frías-Rojas, M.; Sánchez-De-Rojas-Gómez, M.I.; Medina-Martínez, C.; Villar-Cociña, E. New trends for nonconventional cement-based materials. Sustain. Nonconv. Constr. Mater. Using Inorg. Bond. Fiber Compos. 2017, 165–183. [Google Scholar] [CrossRef]

- Temiz, H.; Karakeçi, A. An investigation on microstructure of cement paste containing fly ash and silica fume. Cem. Concr. Res. 2002, 32, 1131–1132. [Google Scholar] [CrossRef]

- Marmol, G.; Savastano, H., Jr. Study of the degradation of non-conventional MgO-SiO2 cement reinforced with lignocellulosic fibers. Cement Concrete Comp. 2017, 80, 258–267. [Google Scholar] [CrossRef]

- Koksal, F.; Sahin, Y.; Gencel, O. Influence of expanded vermiculite powder and silica fume on properties of foam concretes. Constr. Build. Mater. 2020, 257, 119547. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, Z.; Niu, Y.; Li, J.; Zhang, Y. Study on the preparation and properties of high-porosity foamed concretes based on ordinary Portland cement. Mater. Des. 2016, 92, 949–959. [Google Scholar] [CrossRef]

- Pjcm, A.; Radrf, A.; Ladcm, A.; Dp, B. Characterization and properties of cementitious composites with cellulose fiber, silica fume and latex. Constr. Build. Mater. 2020, 257, 119602. [Google Scholar]

- Bajja, Z.; Dridi, W.; Darquennes, A.; Bennacer, R.; Le Bescop, P.; Rahim, M. Influence of slurried silica fume on microstructure and tritiated water diffusivity of cement pastes. Constr. Build. Mater. 2017, 132, 85–93. [Google Scholar] [CrossRef]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; MohdSalleh, M.A. Experimental investigation of the size effects of SiO2 nano-particles on the mechanical properties of binary blended concrete. Compos. Part B Eng. 2010, 41, 673–677. [Google Scholar] [CrossRef]

- ASTM C150—Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C618—Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral. Admixture in Concrete; ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM D2166-06—Standard Test. Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA, 2006.

- Wong, H.; Razak, H.A. Efficiency of calcined kaolin and silica fume as cement replacement material for strength performance. Cem. Concr. Res. 2005, 35, 696–702. [Google Scholar] [CrossRef]

- Malhotra, V.M. Role of Silica Fume in Concrete: A Review. Adv. Concr. Technol. 1992, 1, 925–991. [Google Scholar]

- Gupta, S.; Kua, H.W. Combination of Biochar and Silica Fume as Partial Cement Replacement in Mortar: Performance Evaluation Under Normal and Elevated Temperature. Waste Biomass Valorization 2019, 11, 2807–2824. [Google Scholar] [CrossRef]

- Shi, X.L. The study on mix proportion design method of high performance porous cement concrete for tunnels’ pavement. Master’s Thesis, Hefei University of Technology, Hefei, China, 2012. [Google Scholar]

- Punkki, J.; Golaszewski, J.; Gjørv, O.E. Workability Loss of High-Strength Concrete. Aci Mater. J. 1996, 93, 427–431. [Google Scholar]

- Krstulović, J. The role of silica fume in the kinetics and mechanisms during the early stage of cement hydration. Cement Concrete Res. 2000, 30, 1655–1662. [Google Scholar]

- Yang, Q.; Du, C.; Zhang, J.; Yang, G. Influence of Silica Fume and Additives on Unconfined Compressive Strength of Cement-Stabilized Marine Soft Clay. J. Mater. Civ. Eng. 2020, 32, 04019346. [Google Scholar] [CrossRef]

- Jamsawang, P.; Poorahong, H.; Yoobanpot, N.; Songpiriyakij, S.; Jongpradist, P. Improvement of soft clay with cement and bagasse ash waste. Constr. Build. Mater. 2017, 154, 61–71. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Raksachon, Y. Role of Fly Ash on Strength and Microstructure Development in Blended Cement Stabilized Silty Clay. Soils Found. 2009, 49, 85–98. [Google Scholar] [CrossRef]

- Wang, D.; Abriak, N.E.; Zentar, R. Strength and deformation properties of Dunkirk marine sediments solidified with cement, lime and fly ash. Eng. Geol. 2013, 166, 90–99. [Google Scholar] [CrossRef]

- Negi, C.; Yadav, R.K.; Singhai, A.K. Effect of Silica Fume on Engineering Properties of Black Cotton Soil. Int. J. Comput. Eng. Res. 2013, 3, 1–10. [Google Scholar]

| Specific Gravity | Natural Moisture Content (%) | Wet Density (g/cm3) | Initial Void Ratio | Liquid Limit (%) | Plasticity Index (%) | Sand (%) | Silt (%) | Clay (%) |

|---|---|---|---|---|---|---|---|---|

| 2.68 | 45.0 | 1.75 | 1.21 | 41.8 | 20.3 | 1.8 | 68.1 | 30.1 |

| Components | SiO2 | Al2O3 | Fe2O3 | MgO | CaO | Na2O | K2O | Other |

|---|---|---|---|---|---|---|---|---|

| SF (%) | 95.02 | 0.43 | 0.08 | 0.64 | 0.45 | 0.34 | 1.12 | 1.89 |

| Soft soil (%) | 60.56 | 18.24 | 8.09 | 2.86 | 1.95 | 1.47 | 3.48 | 3.32 |

| OPC (%) | 21.75 | 5.66 | 4.63 | 1.69 | 64.29 | 0.41 | 0.76 | 0.81 |

| Number | Mix Ratio (s:c:w) | SF Content (%) | Cement Content (%) | Symbol | Curing Time (Day) |

|---|---|---|---|---|---|

| UCT-1 | 100:5.8:47.93 | 1 | 4 | SF1C4 | 28 |

| 100:10.2:50.13 | 7 | SF1C7 | |||

| 100:14.5:52.32 | 10 | SF1C10 | |||

| 100:18.9:54.52 | 13 | SF1C13 | |||

| UCT-2 | 100:14.5:52.25 | 0 | 10 | C10SF0 | 3,7,14,28,90 |

| 100:14.5:52.29 | 0.5 | C10SF0.5 | |||

| 100:14.5:52.32 | 1 | C10SF1 | |||

| 100:14.5:52.36 | 1.5 | C10SF1.5 | |||

| 100:14.5:52.40 | 2 | C10SF2 | |||

| 100:14.5:52.61 | 5 | C10SF5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, N.; Wang, C.; Wang, Z.; Li, B.; Liu, Y.-a. Strength Characteristics and Microstructure of Cement Stabilized Soft Soil Admixed with Silica Fume. Materials 2021, 14, 1929. https://doi.org/10.3390/ma14081929

Jiang N, Wang C, Wang Z, Li B, Liu Y-a. Strength Characteristics and Microstructure of Cement Stabilized Soft Soil Admixed with Silica Fume. Materials. 2021; 14(8):1929. https://doi.org/10.3390/ma14081929

Chicago/Turabian StyleJiang, Nan, Changming Wang, Zeping Wang, Bailong Li, and Yi-ao Liu. 2021. "Strength Characteristics and Microstructure of Cement Stabilized Soft Soil Admixed with Silica Fume" Materials 14, no. 8: 1929. https://doi.org/10.3390/ma14081929

APA StyleJiang, N., Wang, C., Wang, Z., Li, B., & Liu, Y.-a. (2021). Strength Characteristics and Microstructure of Cement Stabilized Soft Soil Admixed with Silica Fume. Materials, 14(8), 1929. https://doi.org/10.3390/ma14081929