Cyclic Fatigue of Dental NiTi Instruments after Plasma Nitriding

Abstract

:1. Introduction

2. Materials and Methods

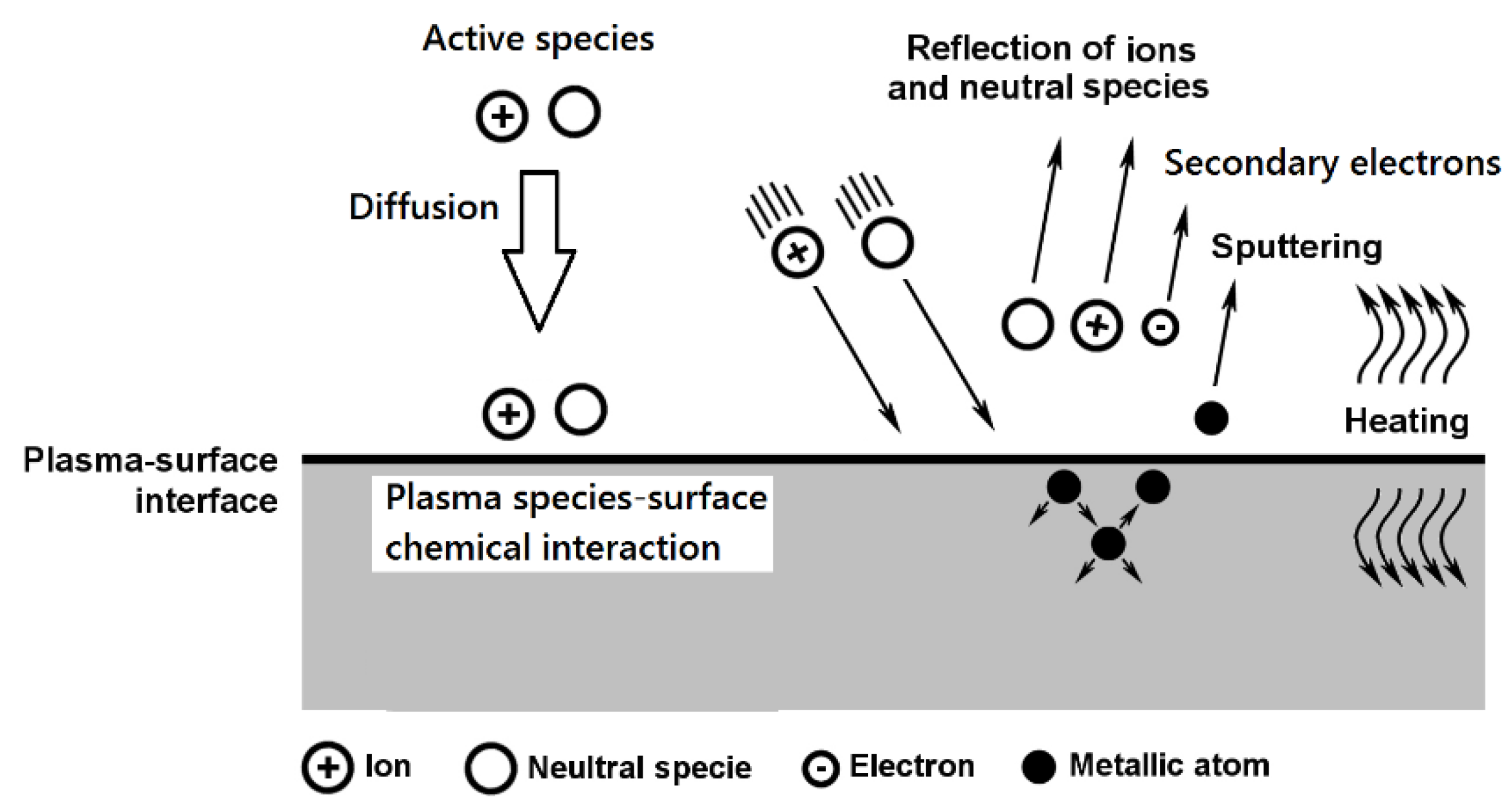

2.1. Surface Treatment

2.2. Chemical Composition

2.3. Sample Preparation for Evaluation of Nitrided Layer

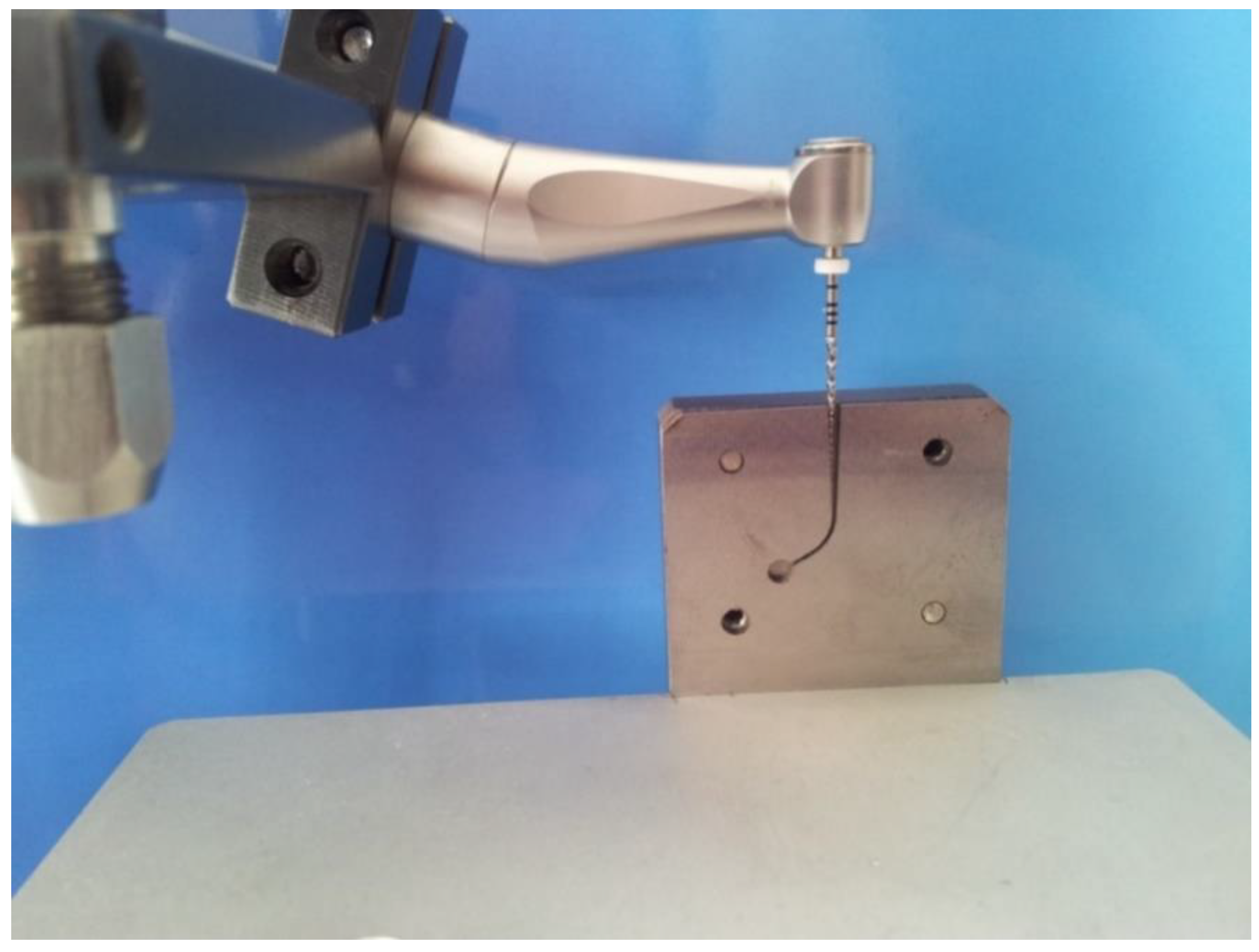

2.4. Cyclic Fatigue Test

3. Results and Discussion

3.1. Chemical Composition

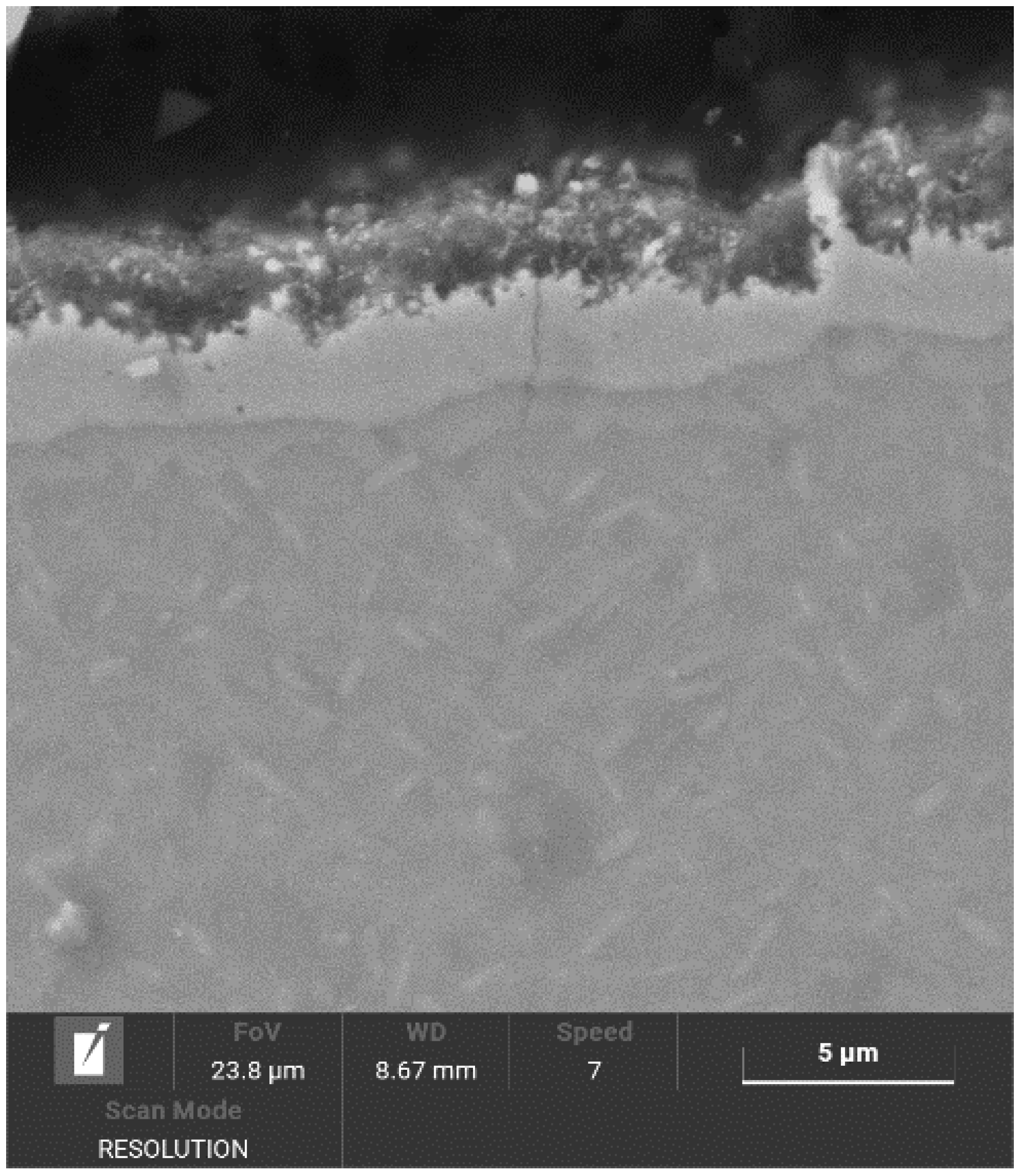

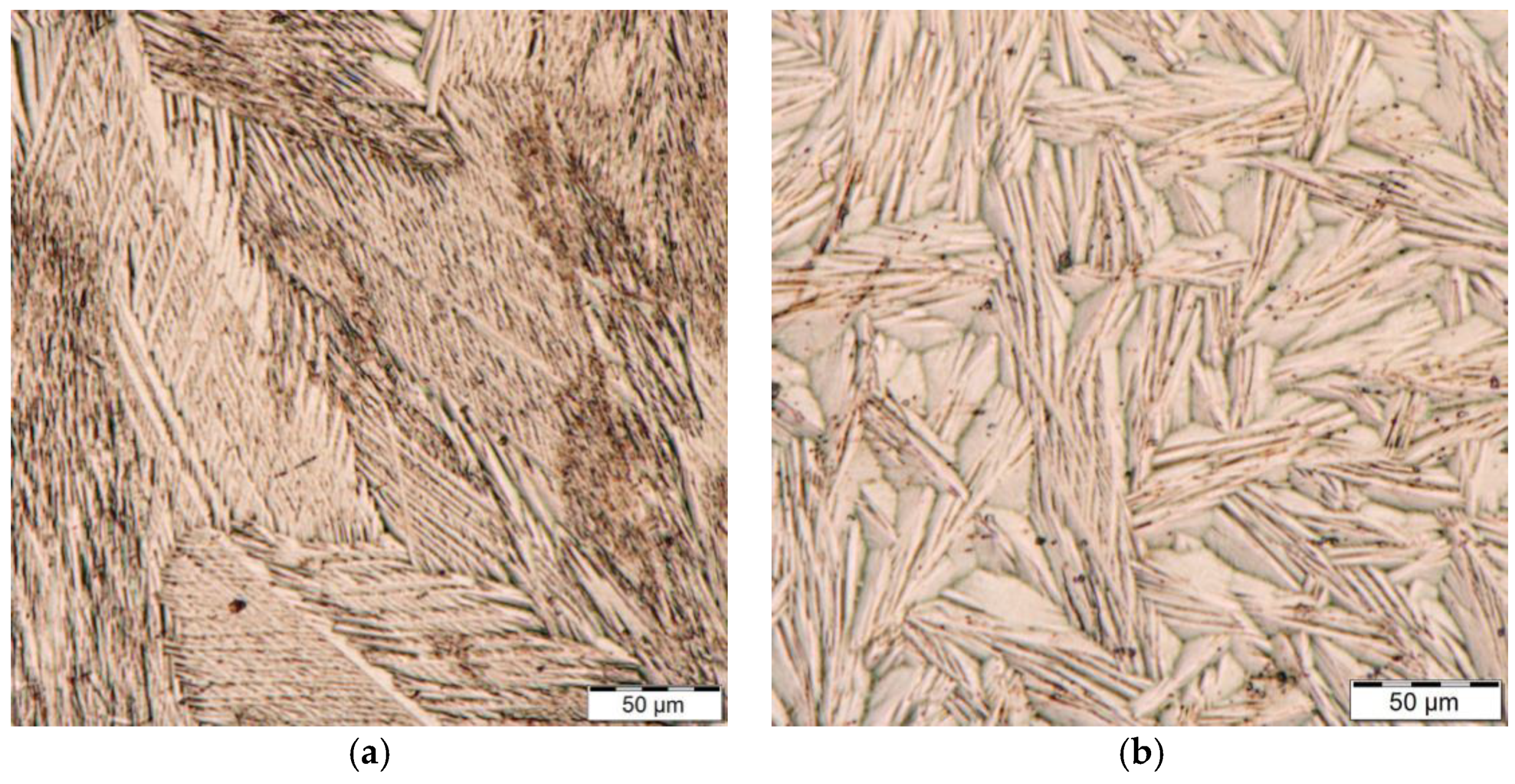

3.2. Assessment of Nitrided Layer

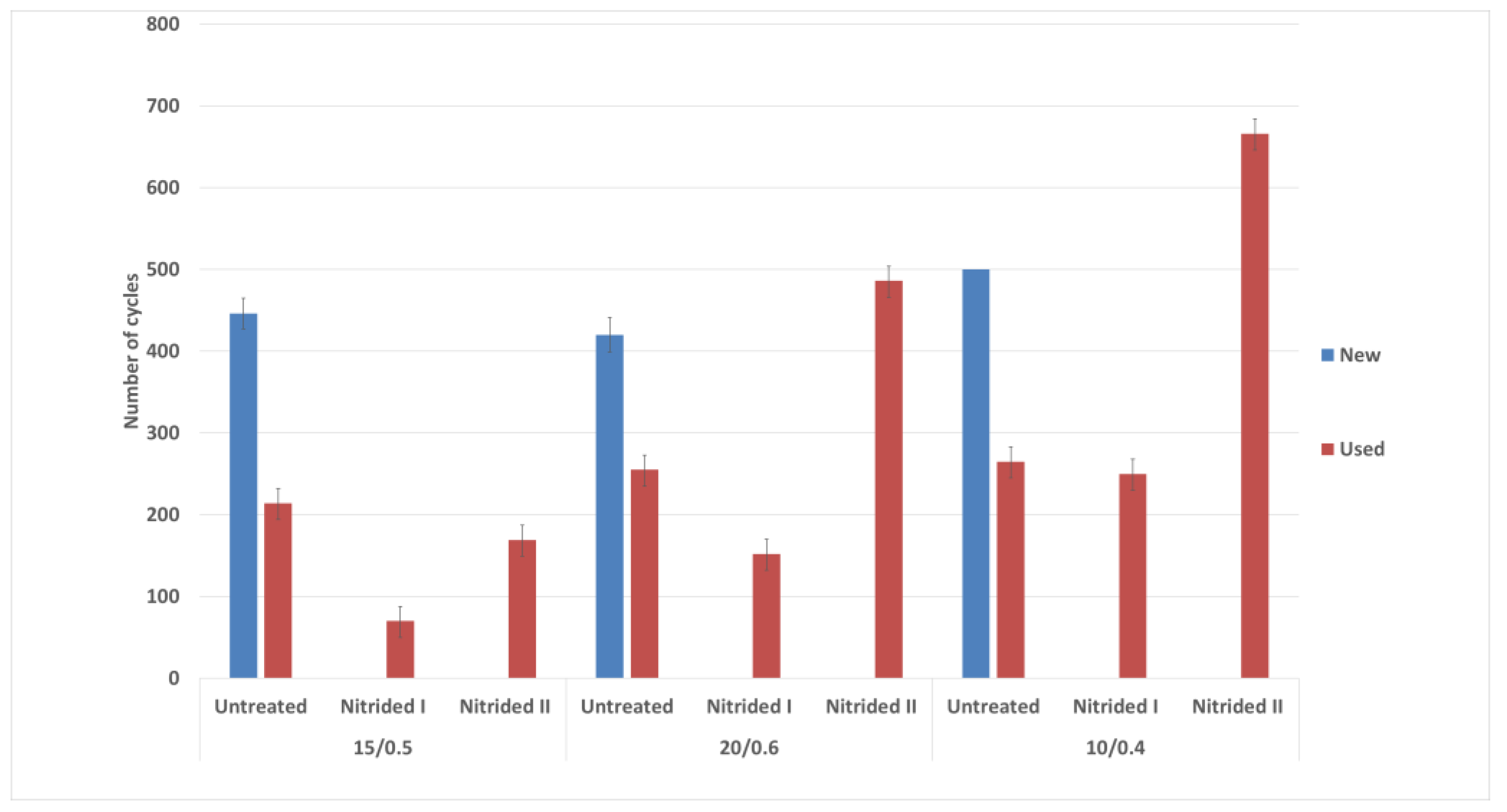

3.3. Cyclic Fatigue Test

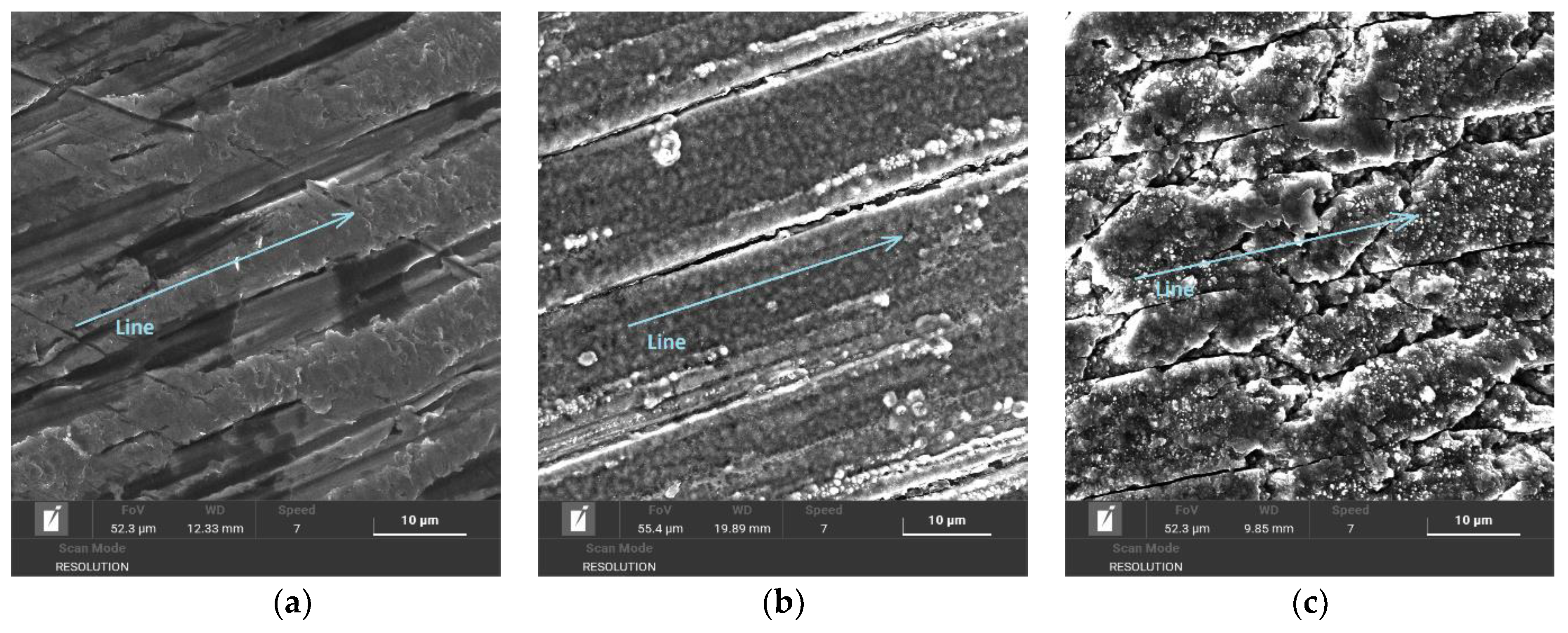

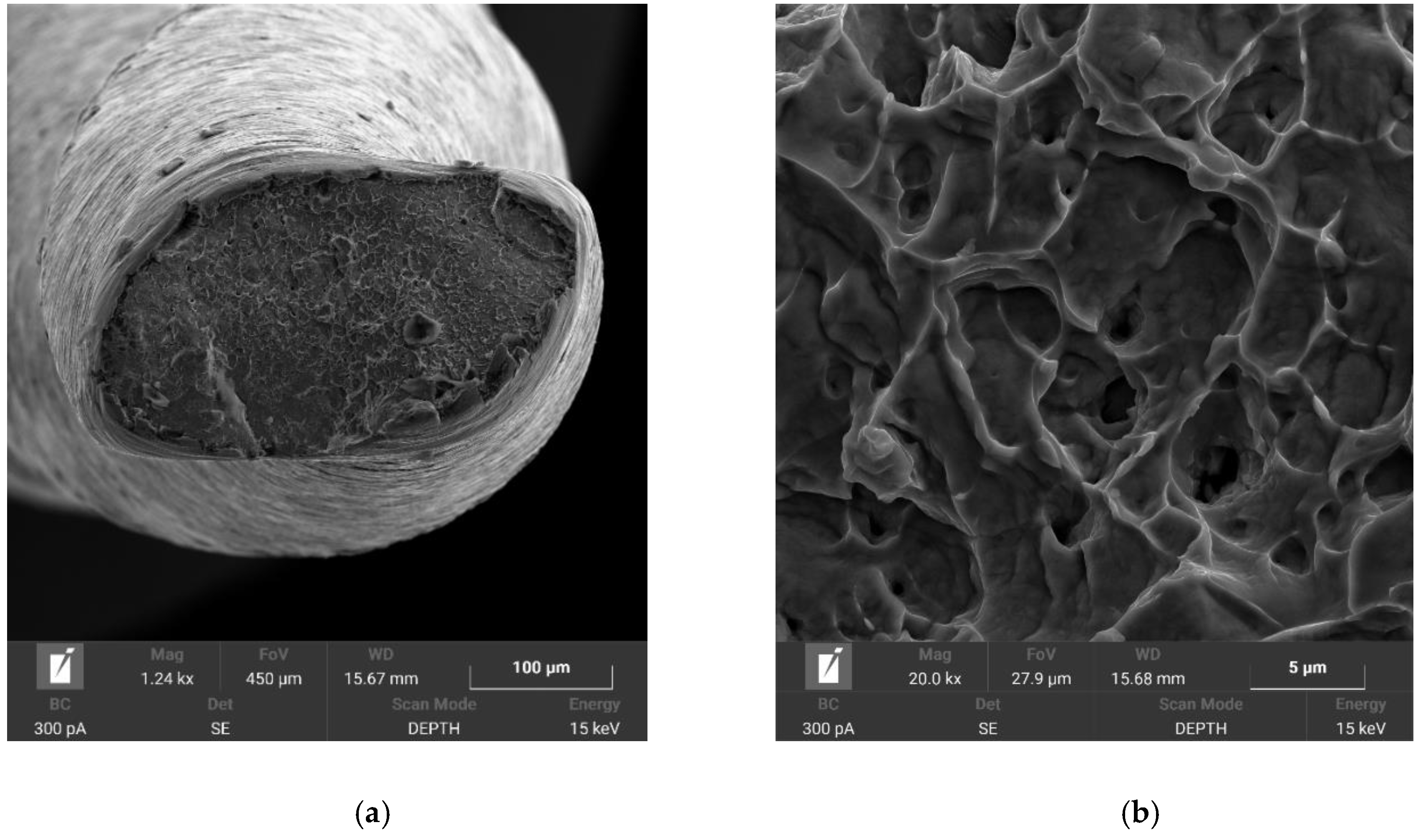

3.4. Fractographic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Torrisi, L. The NiTi superelastic alloy application to the dentistry field. BioMed. Mater. Eng. 1999, 9, 39–47. [Google Scholar] [PubMed]

- Thompson, S.A. An overview of nickel-titanium alloys used in dentistry. Int. Endod. J. 2000, 33, 297–310. [Google Scholar] [CrossRef] [Green Version]

- Cheung, G.S.P.; Zhang, E.W.; Zheng, Y.F. A numerical method for predicting the bending fatigue life of NiTi and stain-less steel root canal instruments. Int. Endod. J. 2011, 44, 357–361. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Grande, N.M.; Cordaro, M.; Testarelli, L.; Gambarini, G. A Review of Cyclic Fatigue Testing of Nickel-Titanium Rotary Instruments. J. Endod. 2009, 35, 1469–1476. [Google Scholar] [CrossRef] [PubMed]

- Alrahabi, M. Comparative study of root-canal shaping with stainless steel and rotary NiTi files performed by preclinical dental students. Technol. Health Care 2015, 23, 257–265. [Google Scholar] [CrossRef]

- Parashos, P.; Gordon, I.; Messer, H.H. Factors Influencing Defects of Rotary Nickel-Titanium Endodontic Instruments after Clinical Use. J. Endod. 2004, 30, 722–725. [Google Scholar] [CrossRef]

- Schirrmeister, J.F.; Strohl, C.; Altenburger, M.J.; Wrbas, K.T.; Hellwig, E. Shaping ability and safety of five different rotary nick-el-titanium instruments compared with stainless steel hand instrumentation in simulated curved root canals. Oral Surg. Oral Med. Oral Pathol. Oral Radio Endod. 2006, 101, 807–813. [Google Scholar] [CrossRef] [PubMed]

- Spili, P.; Parashos, P.; Messer, H.H. The Impact of Instrument Fracture on Outcome of Endodontic Treatment. J. Endod. 2005, 31, 845–850. [Google Scholar] [CrossRef]

- Li, U.M.; Lee, B.S.; Shih, C.T.; Lan, W.H.; Lin, C.P. Cyclic fatigue of endodontic nickel titanium rotary instruments: Static and dy-namic tests. J. Endod. 2002, 28, 448–451. [Google Scholar] [CrossRef]

- Tripi, T.R.; Bonaccorso, A.; Condorelli, G.G. Cyclic fatigue of different nickel-titanium endodontic rotary instruments. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2006, 102, e106–e114. [Google Scholar] [CrossRef]

- Berutti, E.; Chiandussi, G.; Gaviglio, I.; Ibba, A. Comparative Analysis of Torsional and Bending Stresses in Two Mathematical Models of Nickel-Titanium Rotary Instruments: ProTaper versus ProFile. J. Endod. 2003, 29, 15–19. [Google Scholar] [CrossRef] [PubMed]

- Turpin, Y.L.; Chagneau, F.; Vulcain, J.M. Impact of two theoretical cross-sections on torsional and bending stresses of nickelti-tanium root canal instrument models. J. Endod. 2000, 26, 414–417. [Google Scholar] [CrossRef] [PubMed]

- Hornbogen, E. Some effects of martensitic transformation on fatigue resistance. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 785–790. [Google Scholar] [CrossRef]

- Gavini, G.; Dos Santos, M.; Caldeira, C.L.; Machado, M.E.D.L.; Freire, L.G.; Iglecias, E.F.; Peters, O.A.; Candeiro, G.T.D.M. Nickel–titanium instruments in endodontics: A concise review of the state of the art. Braz. Oral Res. 2018, 32, 67. [Google Scholar] [CrossRef] [PubMed]

- Loska, S.; Basiaga, M.; Pochrząst, M.; Łukomska-Szymańska, M.; Walke, W.; Tyrlik-Held, J. Comparative characteristics of endodon-tic drills. Acta Bioeng. Biomech. 2015, 17, 75–83. [Google Scholar]

- Hamdy, T.M.; Galal, M.; Ismail, A.G.; Abdelraouf, R.M. Evaluation of Flexibility, Microstructure and Elemental Analysis of Some Contemporary Nickel-Titanium Rotary Instruments. Open Access Maced. J. Med. Sci. 2019, 7, 3647–3654. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bastos, M.M.B.; Hanan, A.R.A.; Marques, A.A.F.; Garcia, L.D.F.R.; Júnior, E.C.S. Topographic and Chemical Analysis of Reciprocating and Rotary Instruments Surface after Continuous Use. Braz. Dent. J. 2017, 28, 461–466. [Google Scholar] [CrossRef] [Green Version]

- Anderson, M.E.; Price, J.W.; Parashos, P. Fracture Resistance of Electropolished Rotary Nickel–Titanium Endodontic Instruments. J. Endod. 2007, 33, 1212–1216. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Kumar Tewari, R.; Kharade, P.; Kharade, P. Comparative Evaluation of the Effect of Manufacturing Process on Dis-tortion of Rotary ProFile and Twisted File: An in Vitro SEM Study. J. Dent. Res. Dent. Clin. Dent. Prospect. 2015, 9, 216–220. [Google Scholar] [CrossRef]

- Gavini, G.; Pessoa, O.F.; Barletta, F.B.; Vasconcellos, M.A.; Caldeira, C.L. Cyclic fatigue resistance of rotary nickel titanium instru-ments submitted to nitrogen ion implantation. J. Endod. 2010, 36, 1183–1186. [Google Scholar] [CrossRef] [PubMed]

- Zhao, N.; Man, H.; Cui, Z.; Yang, X. Structure and wear properties of laser gas nitrided NiTi surface. Surf. Coat. Technol. 2006, 200, 4879–4884. [Google Scholar] [CrossRef]

- Dos Santos, M.; Gavini, G.; Siqueira, E.L.; Da Costa, C. Effect of Nitrogen Ion Implantation on the Flexibility of Rotary Nickel-Titanium Instruments. J. Endod. 2012, 38, 673–675. [Google Scholar] [CrossRef]

- Shevchenko, N.; Pham, M.-T.; Maitz, M. Studies of surface modified NiTi alloy. Appl. Surf. Sci. 2004, 235, 126–131. [Google Scholar] [CrossRef]

- Wolle, C.F.; Vasconcellos, M.A.; Hinrichs, R.; Becker, A.N.; Barletta, F.B. The effect of argon and nitrogen ion implantation on nickeletitanium rotary instruments. J. Endod. 2009, 35, 1558–1562. [Google Scholar] [CrossRef]

- Al Jabbari, Y.S.; Fehrman, J.; Barnes, A.; Zapf, A.; Zinelis, S.; Berzins, D. Titanium nitride and nitrogen ion implanted coated dental materials. Coatings 2012, 2, 160–178. [Google Scholar] [CrossRef]

- Firstov, G.; Vitchev, R.; Kumar, H.; Blanpain, B.; Van Humbeeck, J. Surface oxidation of NiTi shape memory alloy. Biomaterials 2002, 23, 4863–4871. [Google Scholar] [CrossRef]

- Aun, D.P.; Peixoto, I.F.D.C.; Houmard, M.; Buono, V.T.L. Enhancement of NiTi superelastic endodontic instruments by TiO2 coat-ing. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 68, 675–680. [Google Scholar] [CrossRef] [PubMed]

- Gil, F.J.; Solano, E.; Campos, A.; Boccio, F.; Sáez, I.; Alfonso, M.V.; Planell, J.A. Improvement of the friction behaviour of NiTi ortho-dontic archwires by nitrogen diffusion. Biomed. Mater Eng. 1998, 8, 335–342. [Google Scholar] [PubMed]

- Vojtech, D.; Fojt, J.; Joska, L.; Novak, P. Surface treatment of NiTi shape memory alloy and its influence on corrosion behavior. Surf. Coat. Technol. 2010, 204, 3895–3901. [Google Scholar] [CrossRef]

- Lutz, J.; Lindner, J.; Mändl, S. Marker experiments to determine diffusing species and diffusion path in medical Nitinol alloys. Appl. Surf. Sci. 2008, 255, 1107–1109. [Google Scholar] [CrossRef]

- Rodrigo, P.C.; Marcio, M.; Silvio, F.B. Low-Temperature Thermochemical Treatments of Stainless Steels—An Introduction. In Plasma Science and Technology—Progress in Physical States and Chemical Reactions; Mieno, T., Ed.; IntechOpen: London, UK, 20 April 2016. [Google Scholar] [CrossRef] [Green Version]

- Lelątko, J.; Goryczka, T.; Wierzchoń, T.; Ossowski, M.; Łosiewicz, B.; Rówiński, E.; Morawiec, H. Structure of Low Temperature Nitrided/Oxidized Layer Formed on NiTi Shape Memory Alloy. Solid State Phenom. 2010, 163, 127–130. [Google Scholar] [CrossRef]

- Prochazka, J.; Pokorny, Z.; Dobrocky, D. Service Behavior of Nitride Layers of Steels for Military Applications. Coatings 2020, 10, 975. [Google Scholar] [CrossRef]

- Fišerová, E.; Chvosteková, M.; Bělašková, S.; Bumbálek, M.; Joska, Z. Survival Analysis of Factors Influencing Cyclic Fatigue of Nickel-Titanium Endodontic Instruments. Adv. Mater. Sci. Eng. 2015, 2015, 189703. [Google Scholar] [CrossRef] [Green Version]

| Plasma Sputtering | |||||

|---|---|---|---|---|---|

| Temperature (°C) | Time (h) | Gas Flow H2 (l·min−1) | Bias (V) | Pressure (Pa) | Pulse Length (µs) |

| 450 | 0.5 | 8 | 800 | 80 | 100 |

| Plasma Nitriding | ||||||

|---|---|---|---|---|---|---|

| Temperature (°C) | Time (h) | Gas Flow N2 (l·min−1) | Bias (V) | Pressure (Pa) | Pulse Length (µs) | |

| Process No. 1 | 470 | 4 | 8 | 800 | 80 | 100 |

| Process No. 2 | 550 | 20 | 8 | 800 | 80 | 100 |

| Ni | Ti | N | ||

|---|---|---|---|---|

| EDS | ||||

| Untreated surface | 46 | 53 | 0 | |

| Surface after Process No. 1 | 42 | 49 | 9 | |

| Surface after Process No. 2 | 32 | 54 | 14 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bumbalek, M.; Joska, Z.; Pokorny, Z.; Sedlak, J.; Majerik, J.; Neumann, V.; Klima, K. Cyclic Fatigue of Dental NiTi Instruments after Plasma Nitriding. Materials 2021, 14, 2155. https://doi.org/10.3390/ma14092155

Bumbalek M, Joska Z, Pokorny Z, Sedlak J, Majerik J, Neumann V, Klima K. Cyclic Fatigue of Dental NiTi Instruments after Plasma Nitriding. Materials. 2021; 14(9):2155. https://doi.org/10.3390/ma14092155

Chicago/Turabian StyleBumbalek, Michal, Zdenek Joska, Zdenek Pokorny, Josef Sedlak, Jozef Majerik, Vlastimil Neumann, and Karel Klima. 2021. "Cyclic Fatigue of Dental NiTi Instruments after Plasma Nitriding" Materials 14, no. 9: 2155. https://doi.org/10.3390/ma14092155