Investigation of Photonic-Crystal-Structured p-GaN Nanorods Fabricated by Polystyrene Nanosphere Lithography Method to Improve the Light Extraction Efficiency of InGaN/GaN Green Light-Emitting Diodes

Abstract

:1. Introduction

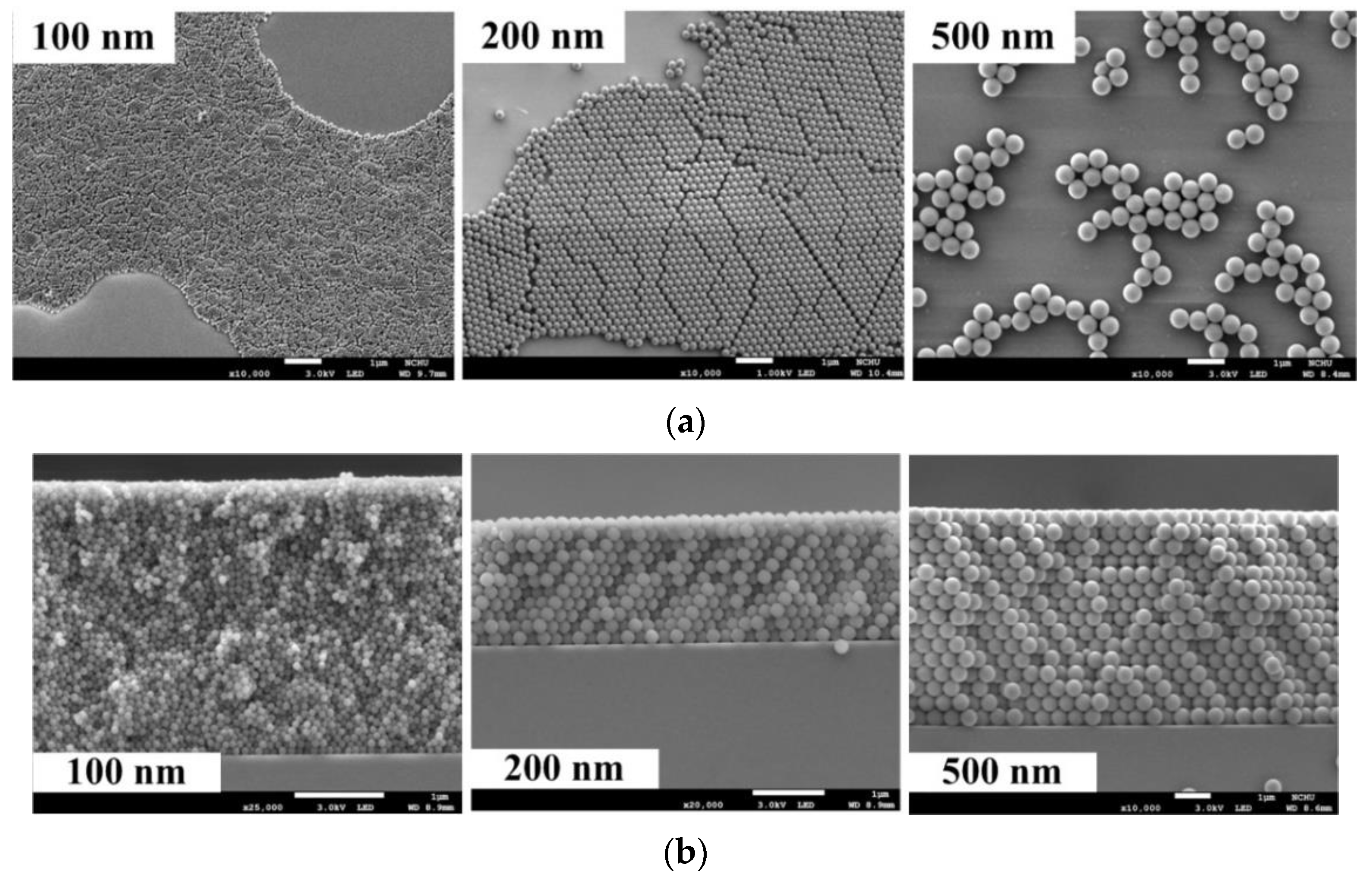

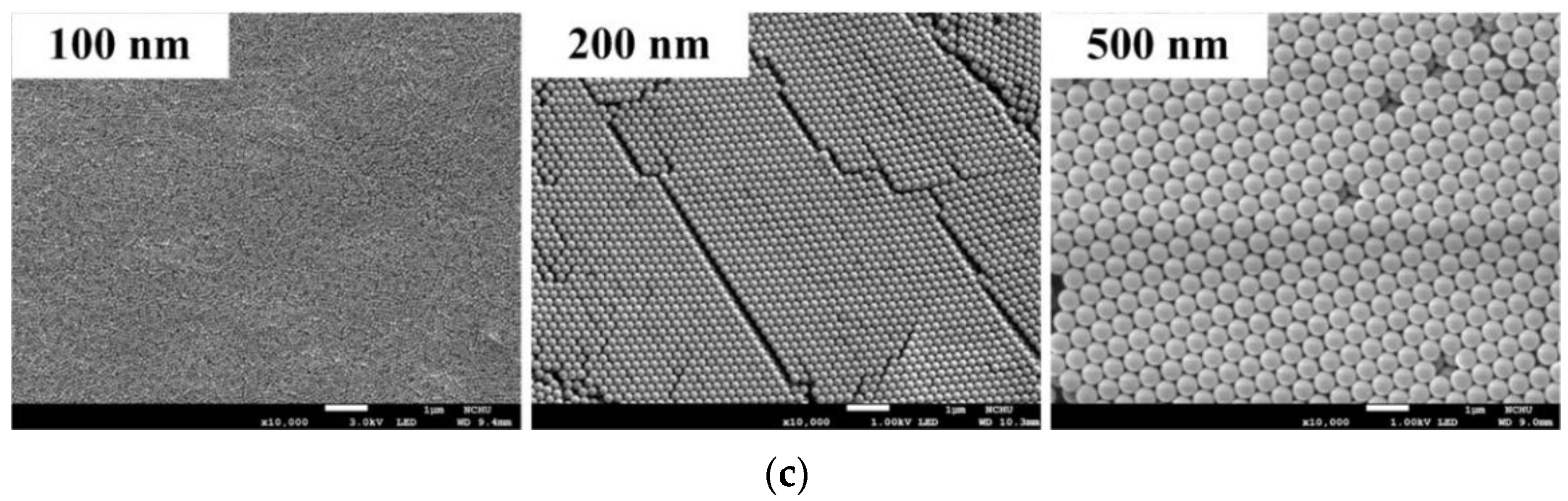

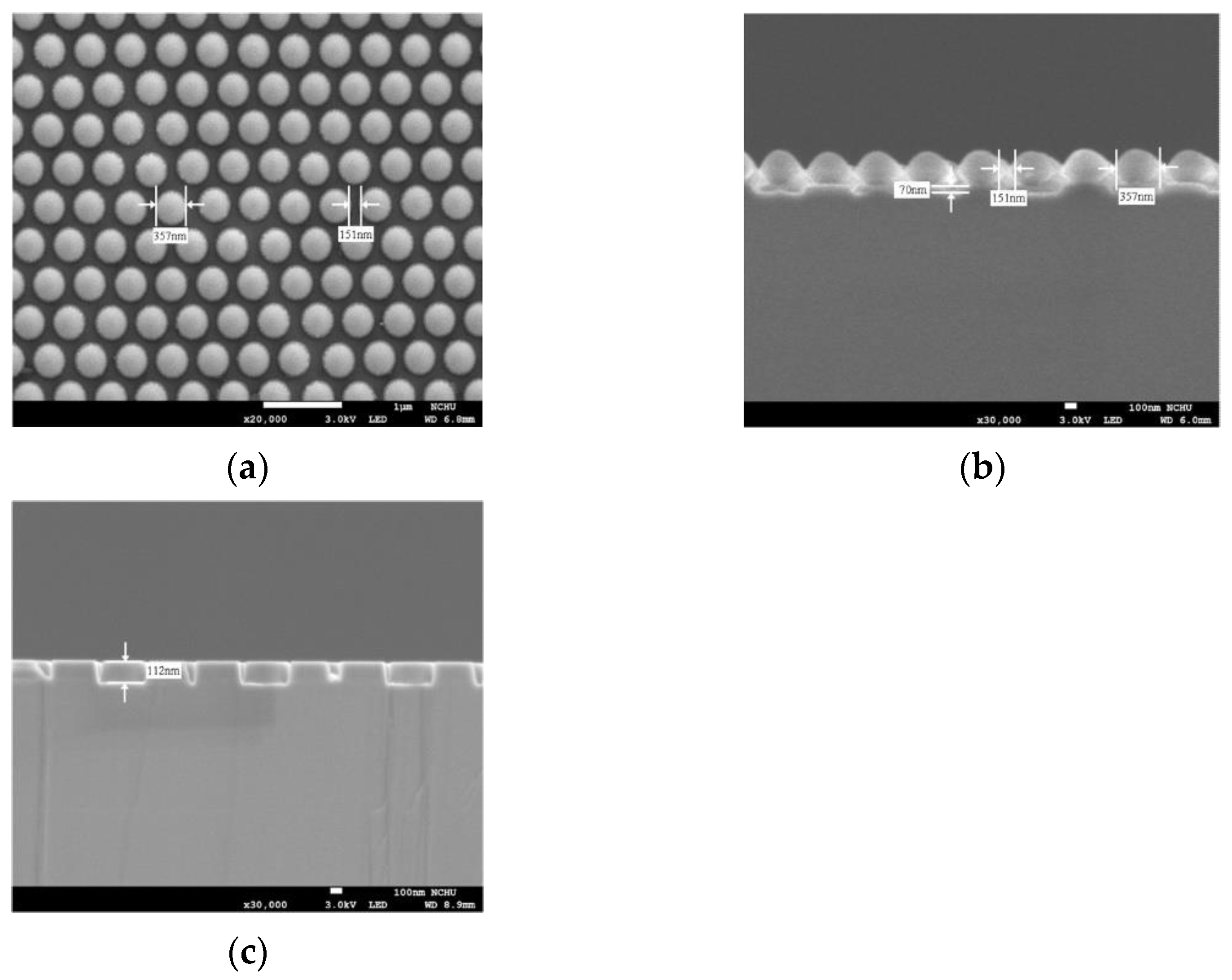

2. Materials and Methods

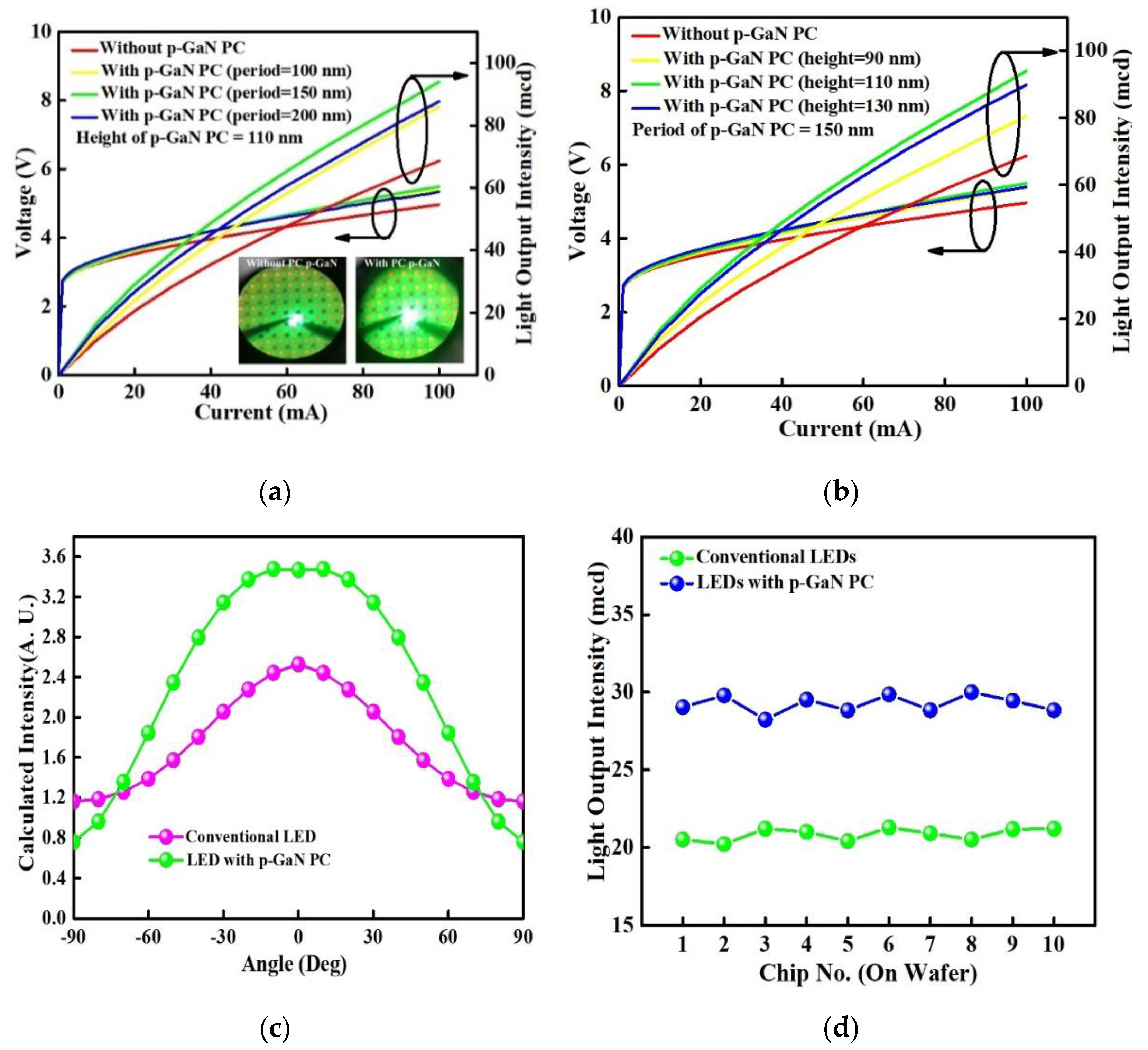

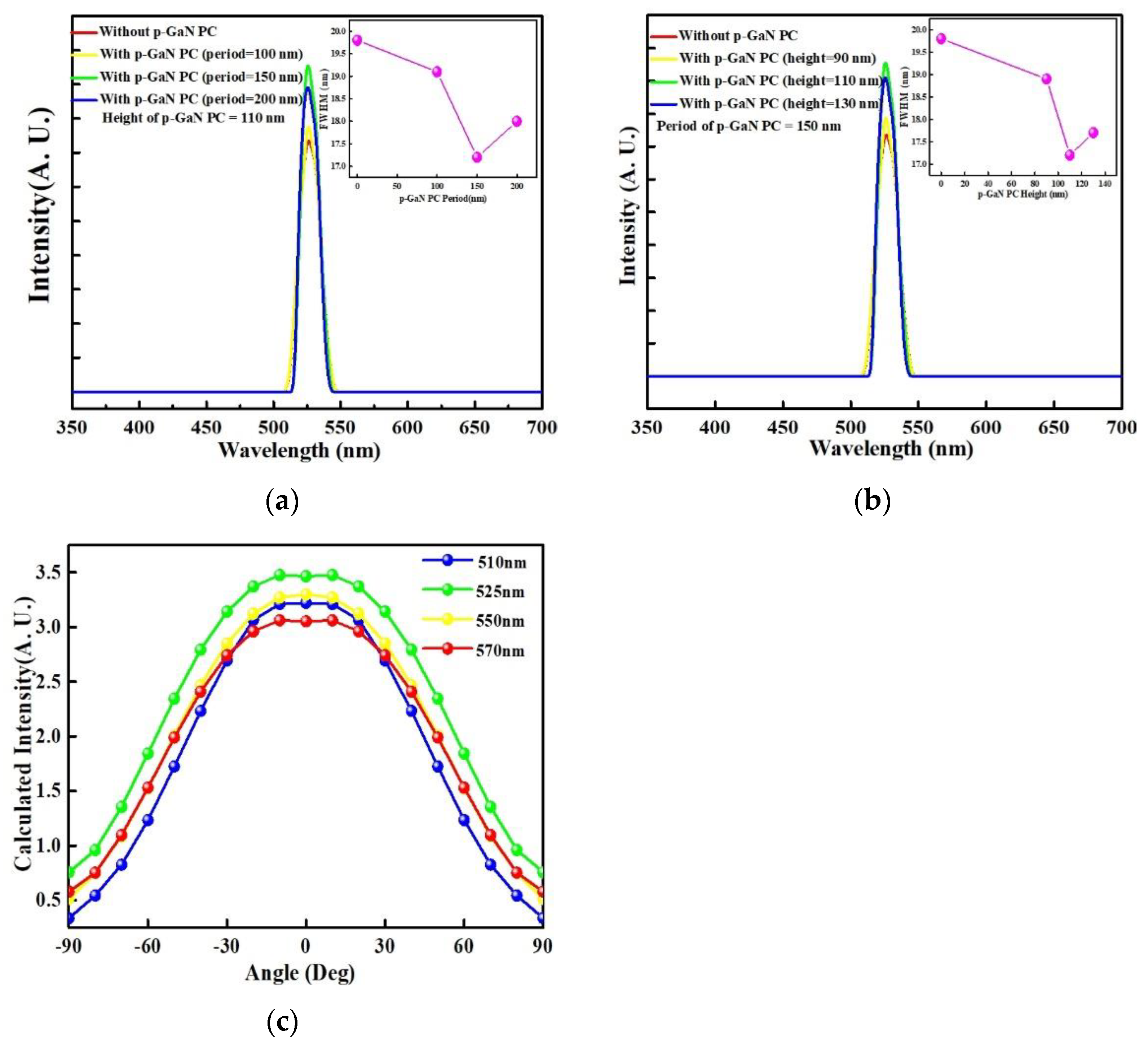

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, X.G.; Zheng, C.D.; Mo, C.L.; Wang, X.L.; Zhang, J.L.; Quan, Z.J.; Liu, J.L.; Jiang, F.Y. Study on the performance of InGaN-based green LED by designing different preparing layers. Opt. Mater. 2019, 89, 505–511. [Google Scholar] [CrossRef]

- Lin, T.C.; Chen, Y.T.; Yin, Y.F.; You, Z.X.; Kao, H.Y.; Huang, C.Y.; Lin, Y.H.; Tsai, C.T.; Lin, G.R.; Huang, J.J. Large-signal modulation performance of light-emitting diodes with photonic crystals for visible light communication. IEEE Trans. Electron. Dev. 2018, 85, 4375–4380. [Google Scholar] [CrossRef]

- Tsai, C.L.; Lu, Y.C.; Chang, S.H. InGaN LEDs fabricated with parallel-connected multi-pixel geometry for underwater optical communications. Opt. Laser Technol. 2019, 118, 69–74. [Google Scholar] [CrossRef]

- Ananda, S.; Mahalad, P.; Singhe, S.; Pal, S. Reduction of efficiency droop in GaN/InGaN based multiple quantum well light emitting diode by varying Si-doping and thickness in barrier layers. Optik 2019, 178, 645–649. [Google Scholar] [CrossRef]

- Siekacz, M.; Wolny, P.; Ernst, T.; Grzanka, E.; Staszczak, G.; Suski, T.; Zmuda, A.F.; Sawicka, M.; Moneta, J.; Anikeeva, M.; et al. Impact of the substrate lattice constant on the emission properties of InGaN/GaN short-period superlattices grown by plasma assisted MBE. Superlattices Microstruct. 2019, 133, 106209. [Google Scholar] [CrossRef]

- Wang, N.Y.; Yin, Y.A.; Zhao, B.J.; Mei, T. Performance analysis of GaN-based light-emitting diodes with lattice-matched InGaN/AlInN/InGaN quantum-well barriers. J. Disp. Technol. 2015, 11, 1056–1060. [Google Scholar] [CrossRef]

- Zhang, Z.D.; Sun, H.Q.; Li, X.; Sun, H.; Zhang, C.; Fan, X.C.; Guo, Z.Y. Performance enhancement of blue light-emitting diodes with an undoped AlGaN electron-blocking layer in the active region. J. Disp. Technol. 2016, 12, 573–576. [Google Scholar] [CrossRef]

- Park, J.S.; Han, J.C.; Seong, T.Y. Improving the output power of GaN-based light-emitting diode using Ag particles embedded within a SiO2 current blocking layer. Superlattices Microstruct. 2015, 83, 361–366. [Google Scholar] [CrossRef]

- Tsai, S.C.; Li, M.J.; Fang, H.C.; Tu, C.H.; Liu, C.P. Efficiency enhancement of blue light emitting diodes by eliminating V-defects from InGaN/GaN multiple quantum well structures through GaN capping layer control. Appl. Surf. Sci. 2018, 439, 1127–1132. [Google Scholar] [CrossRef]

- Cao, D.H.; Zhao, C.C.; Yang, X.K.; Xiao, H.D. Fabrication and improved properties of InGaN-based LED with multilayer GaN/nanocavity structure. J. Alloys Compd. 2019, 806, 487–491. [Google Scholar] [CrossRef]

- Hu, X.L.; Xiao, F.A.; Zhou, Q.B.; Zheng, Y.D.; Liu, W.J. High-luminous efficacy green light-emitting diodes with InGaN/GaN quasi-superlattice interlayer and Al-doped indium tin oxide film. J. Alloys Compd. 2019, 794, 137–143. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, X.J.; Li, D.W.; Yu, L.; Li, K.; Zhang, Y.W.; Diao, J.S.; Wang, X.F.; Li, S.T. Effect of Mg doping in GaN interlayer on the performance of green light-emitting diodes. IEEE Photon. Technol. Lett. 2015, 27, 117–120. [Google Scholar] [CrossRef]

- Lee, K.J.; Lee, C.R.; Chung, T.H.; Park, J.Y.; Leem, J.Y.; Jeong, K.U.; Kim, J.S. Influences of graded superlattice on the electrostatic discharge characteristics of green InGaN/GaN light-emitting diodes. J. Cryst. Growth 2017, 464, 138–142. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, D.G.; Jiang, D.S.; Chen, P.; Zhu, J.J.; Liu, Z.S.; Le, L.C.; He, X.G.; Li, X.J.; Liu, J.P.; et al. Investigation on the performance and efficiency droop behaviors of InGaN/GaN multiple quantum well green LEDs with various GaN cap layer thicknesses. Vacuum 2016, 129, 99–104. [Google Scholar] [CrossRef]

- Usman, M.; Mushtaq, U.; Saba, K.; Han, D.P.; Muhammad, N.; Imtiaz, W.A.; Jahangir, A. Improved optoelectronic performance of green light-emitting diodes by employing GaAlInN quantum wells without electron blocking layer. Phys. E Low Dimens. Syst. Nanostruct. 2019, 106, 68–72. [Google Scholar] [CrossRef]

- Yang, G.F.; Chang, J.J.; Zhao, J.L.; Tong, Y.Y.; Xie, F.; Wang, J.; Zhang, Q.; Huang, H.J.; Yan, D.W. Investigation of light output performance for gallium nitride-based light-emitting diodes grown on different shapes of patterned sapphire substrate. Mater. Sci. Semicond. Proc. 2015, 33, 149–153. [Google Scholar] [CrossRef]

- Sung, Y.H.; Park, J.M.; Choi, E.S.; Chung, T.H.; Lee, T.W.; Kim, H.J.; Baik, J.M.; Lee, H. InGaN/GaN light emitting diodes grown on nanoimprint-based hollow patterned sapphire substrates. Microelectron. Eng. 2019, 216, 111082. [Google Scholar] [CrossRef]

- Lin, Z.T.; Yang, H.; Zhou, S.Z.; Wang, H.Y.; Hong, X.S.; Li, G.Q. Pattern design of and epitaxial growth on patterned sapphire substrates for highly efficient GaN-based LEDs. Cryst. Growth Des. 2012, 12, 2836–2841. [Google Scholar] [CrossRef]

- Lin, T.H.; Wang, S.J.; Tu, Y.C.; Hung, C.H.; Yu, H.T. Improving the performance of power GaN-based thin-film flip-chip LEDs through a twofold roughened surface. Mater. Sci. Semicond. Proc. 2016, 45, 69–75. [Google Scholar] [CrossRef]

- Lee, Y.W.; Reddy, M.S.P.; Kim, B.M.; Park, C.H. Surface morphological, structural, electrical and optical properties of GaN-based light-emitting diodes using submicron-scaled Ag islands and ITO thin films. Opt. Mater. 2018, 81, 109–114. [Google Scholar] [CrossRef]

- Get, R.; Singh, S.; Goyala, A.K.; Kumar, S.; Lunia, A.K.; Pal, S.; Dhanavantri, C. Enhancement of light extraction efficiency in InGaN/GaN vertical bluelight emitting diodes by surface patterning: Design and simulation. Optik 2015, 126, 3004–3306. [Google Scholar] [CrossRef]

- Feng, J.Y.; Xia, H.D.; You, F.F.; Mao, H.B.; Ma, X.; Tao, H.Z.; Zhao, X.J.; Wang, M.C. Alignment of Ag nanowires on glass sheet by dip-coating technique. J. Alloys Compd. 2018, 735, 607–612. [Google Scholar] [CrossRef]

- Chung, Y.W.; Leu, I.C.; Lee, J.H.; Hon, M.H. Fabrication and characterization of core-shell photonic crystals via a dipping process. Collids Surf. A Phys. Eng. Asp. 2006, 290, 256–262. [Google Scholar] [CrossRef]

- Sandu, I.; Dumitru, M.; Fleaca, C.T.; Dumitrache, F. Hanging colloidal drop: A new photonic crystal synthesis routeIon. Photon. Nanostruct. 2018, 29, 42–48. [Google Scholar] [CrossRef]

- Xu, K.; Xu, J.H.; Lu, Y.C.; Luo, G.S. Extraction-derived self-organization of colloidal photonic crystal particles within confining aqueous droplets. Cryst. Growth Des. 2013, 13, 926–935. [Google Scholar] [CrossRef]

- He, Y.; Zhu, B.; Zeng, X.C.; Yang, R.Y.; Lv, X.L.; Yuan, W.Z. Fabrication of large-area, close-packed, monolayer colloidal crystals via a hybrid method of spin coating and peeling- draining. Thin Solid Folms 2017, 639, 98–106. [Google Scholar] [CrossRef]

- Zhu, Z.C.; Wu, S.; Xue, C.F.; Zhao, J.; Wang, L.S.; Wu, Y.Q.; Liu, B.; Cheng, C.W.; Gu, M.; Chen, H.; et al. Enhanced light extraction of scintillator using large-area photonic crystal structures fabricated by soft-X-ray interference lithography. Appl. Phys. Lett. 2015, 106, 241901. [Google Scholar] [CrossRef]

- Dalmisa, R.; Birlik, I.; Azem, N.F.A.; Çelik, E. Modification of the sedimentation method for PMMA photonic crystal coatings. Collids Surf. A 2019, 577, 194–201. [Google Scholar] [CrossRef]

- Liau, L.C.K.; Huang, Y.K. Effects of influential factors on sedimentation self-assembly processing of photonic band gap crystals by relative humidity-controlled environments. Chem. Eng. Proc. 2008, 47, 1578–1584. [Google Scholar] [CrossRef]

- Hu, C.; Chen, Y. Uniformization of silica particles by theory directed rate-zonal centrifugation to build high quality photonic crystals. Chem. Eng. J. 2015, 271, 128–134. [Google Scholar] [CrossRef]

- Hung, P.S.; Liao, C.H.; Chou, Y.S.; Wang, G.R.; Wang, C.J.; Chung, W.A.; Wu, P.W. High throughput fabrication of large-area colloidal crystals via a two stage electrophoretic deposition method. Electrochim. Acta 2019, 317, 52–60. [Google Scholar] [CrossRef]

- Rogach, A.L.; Kotov, N.A.; Koktysh, D.S.; Ostrander, J.W.; Ragoisha, G.A. Electrophoretic deposition of latex-based 3D colloidal photonic crystals: A technique for rapid production of high-quality opals. Chem. Mater. 2000, 12, 2721–2726. [Google Scholar] [CrossRef]

- Amos, R.M.; Rarity, J.G.; Tapster, P.R.; Shepherd, T.J.; Kitson, S.C. Fabrication of large-area face-centered-cubic hard-sphere colloidal crystals by shear alignment. Phys. Rev. E 2000, 61, 2929–2935. [Google Scholar] [CrossRef]

- Parchine, M.; McGrath, J.; Bardosova, M.; Pemble, M.E. Large area 2D and 3D colloidal photonic crystals fabricated by a roll-to-roll Langmuir-Blodgett method. Langmuir 2016, 32, 5862–5869. [Google Scholar] [CrossRef]

- Retsch, M.; Zhou, Z.; Rivera, S.; Kappl, M.; Zhao, X.S.; Jonas, U. Fabrication of large area, transferable colloidal monolayers utilizing self-assembly at the air/water interface. Macromol. Chem. Phys. 2009, 210, 230–241. [Google Scholar] [CrossRef]

- Xu, X.; Majetich, S.A.; Asher, A.S. Mesoscopic monodisperse ferromagnetic colloids enable magnetically controlled photonic crystals. J. Am. Chem. Soc. 2002, 124, 13864–13868. [Google Scholar] [CrossRef]

- Fu, P.H.; Lin, G.H.; Wang, H.P.; Lai, K.Y.; He, J.H. Enhanced light extraction of light-emitting diodes via nano-honeycomb photonic crystals. Nano Energy 2014, 8, 78–83. [Google Scholar] [CrossRef]

- Suslik, L.; Pudis, D.; Goraus, M.; Nolte, R.; Kovac, J.; Durisova, J.; Gaso, P.; Hronec, P.; Schaaf, P. Photonic crystal and photonic quasicrystal patterned in PDMS surface and their effect on LED radiation properties. Appl. Surf. Sci. 2017, 395, 220–225. [Google Scholar] [CrossRef]

- Hu, X.L.; Wen, R.L.; Qi, Z.Y.; Wang, H. III-nitride ultraviolet, blue and green LEDs with SiO2 photonic crystals fabricated by UV-nanoimprint lithography. Mater. Sci. Semicond. Process. 2018, 79, 61–65. [Google Scholar] [CrossRef]

- Yin, Y.F.; Lan, W.Y.; Lin, T.C.; Wang, C.; Feng, M.; Huang, J.J. High-speed visible light communication using GaN-based light-emitting diodes with photonic crystals. IEEE Lightwave Technol. 2017, 35, 258–264. [Google Scholar] [CrossRef]

- Feng, L.S.; Zhang, N.; Wang, J.X.; Li, J.M. Effect of photonic crystals on the light extraction of GaN-based LED for different polarization modes of spontaneous radiation. Res. Phys. 2019, 15, 102632. [Google Scholar] [CrossRef]

- Choi, J.Y.; Alford, T.L.; Honsberg, C.B. Solvent-Controlled Spin-Coating Method for Large-Scale Area Deposition of Two-Dimensional Silica Nanosphere Assembled Layers. Langmuir 2014, 30, 5732–5739. [Google Scholar] [CrossRef]

- Colson, P.; Cloots, R.; Henrist, C. Experimental Design Applied to Spin Coating of 2D Colloidal Crystal Masks: A Relevant Method? Langmuir 2011, 27, 12800–12806. [Google Scholar] [CrossRef]

- Zhao, Y.; Marshall, J.S. Spin coating of a colloidal suspension. Phys. Fluid 2008, 20, 043302. [Google Scholar] [CrossRef]

- Fudouzi, H. Fabricating high-quality opal films with uniform structure over a large area. J. Colloid Interface Sci. 2004, 257, 277–283. [Google Scholar] [CrossRef]

- Schubert, E.F. Light-Emitting Diodes, 2nd ed.; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Adawi, A.M.; Kullock, R.; Turner, J.L.; Vasilev, C.; Lidzey, D.G.; Tahraoui, A.; Fry, P.W.; Gibson, D.; Smith, E.; Foden, C.; et al. Improving the light extraction efficiency of polymeric light emitting diodes using two-dimensional photonic crystals. Org. Electron. 2006, 7, 222–228. [Google Scholar] [CrossRef]

- Geng, C.; Wei, T.B.; Wang, X.Q.; Shen, D.Z.; Hao, Z.B.; Yan, Q.F. Enhancement of Light Output Power from LEDs Based on Monolayer Colloidal Crystal. Small 2014, 10, 1668–1686. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kwon, M.K.; Lee, K.S.; Park, S.J.; Kim, S.H.; Lee, K.D. Enhanced light extraction from GaN-based green light-emitting diode with photonic crystal. Appl. Phys. Lett. 2007, 91, 181109. [Google Scholar] [CrossRef]

- Du, P.W.; Cheng, Z.Y. Enhancing light extraction efficiency of vertical emission of AlGaN nanowire light emitting diodes with photonic crystal. IEEE Photon. J. 2019, 11, 1600109. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Wei, T.B.; Wang, J.X.; Fan, C.; Chen, Y.; Hu, Q.; Li, J.M. Efficiency improvement of InGaN light emitting diodes with embedded self-assembled SiO2 nanosphere arrays. J. Cryst. Growth 2014, 394, 7–10. [Google Scholar] [CrossRef]

| PS NS Diameter (nm) | First-Time Spin-Coating (Spin Speed/Spin Time) | Second-Time Spin-Coating (Spin Speed/Spin Time) |

|---|---|---|

| 100 | 300 rpm/10 s → 2700 rpm/30 s | 300 rpm/10 s → 2000 rpm/30 s |

| 200 | 300 rpm/10 s → 2000 rpm/30 s | 300 rpm/10 s → 1300 rpm/30 s |

| 500 | 500 rpm/30 s | 300 rpm/30 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, P.-H.; Yang, P.-C.; Huang, P.-C. Investigation of Photonic-Crystal-Structured p-GaN Nanorods Fabricated by Polystyrene Nanosphere Lithography Method to Improve the Light Extraction Efficiency of InGaN/GaN Green Light-Emitting Diodes. Materials 2021, 14, 2200. https://doi.org/10.3390/ma14092200

Lei P-H, Yang P-C, Huang P-C. Investigation of Photonic-Crystal-Structured p-GaN Nanorods Fabricated by Polystyrene Nanosphere Lithography Method to Improve the Light Extraction Efficiency of InGaN/GaN Green Light-Emitting Diodes. Materials. 2021; 14(9):2200. https://doi.org/10.3390/ma14092200

Chicago/Turabian StyleLei, Po-Hsun, Po-Chun Yang, and Po-Chun Huang. 2021. "Investigation of Photonic-Crystal-Structured p-GaN Nanorods Fabricated by Polystyrene Nanosphere Lithography Method to Improve the Light Extraction Efficiency of InGaN/GaN Green Light-Emitting Diodes" Materials 14, no. 9: 2200. https://doi.org/10.3390/ma14092200

APA StyleLei, P.-H., Yang, P.-C., & Huang, P.-C. (2021). Investigation of Photonic-Crystal-Structured p-GaN Nanorods Fabricated by Polystyrene Nanosphere Lithography Method to Improve the Light Extraction Efficiency of InGaN/GaN Green Light-Emitting Diodes. Materials, 14(9), 2200. https://doi.org/10.3390/ma14092200