Fresh and Rheological Performances of Air-Entrained 3D Printable Mortars

Abstract

:1. Introduction

2. Experimental Methodology

2.1. Materials

2.2. Proportions of Mortar Components, Mix Design, and Coding

2.3. Test Procedures

2.3.1. Experimental Procedure of Preparation of the Samples

2.3.2. Consistency, Unit Weight, and Air Content of Fresh Mortar

2.3.3. Extrudability

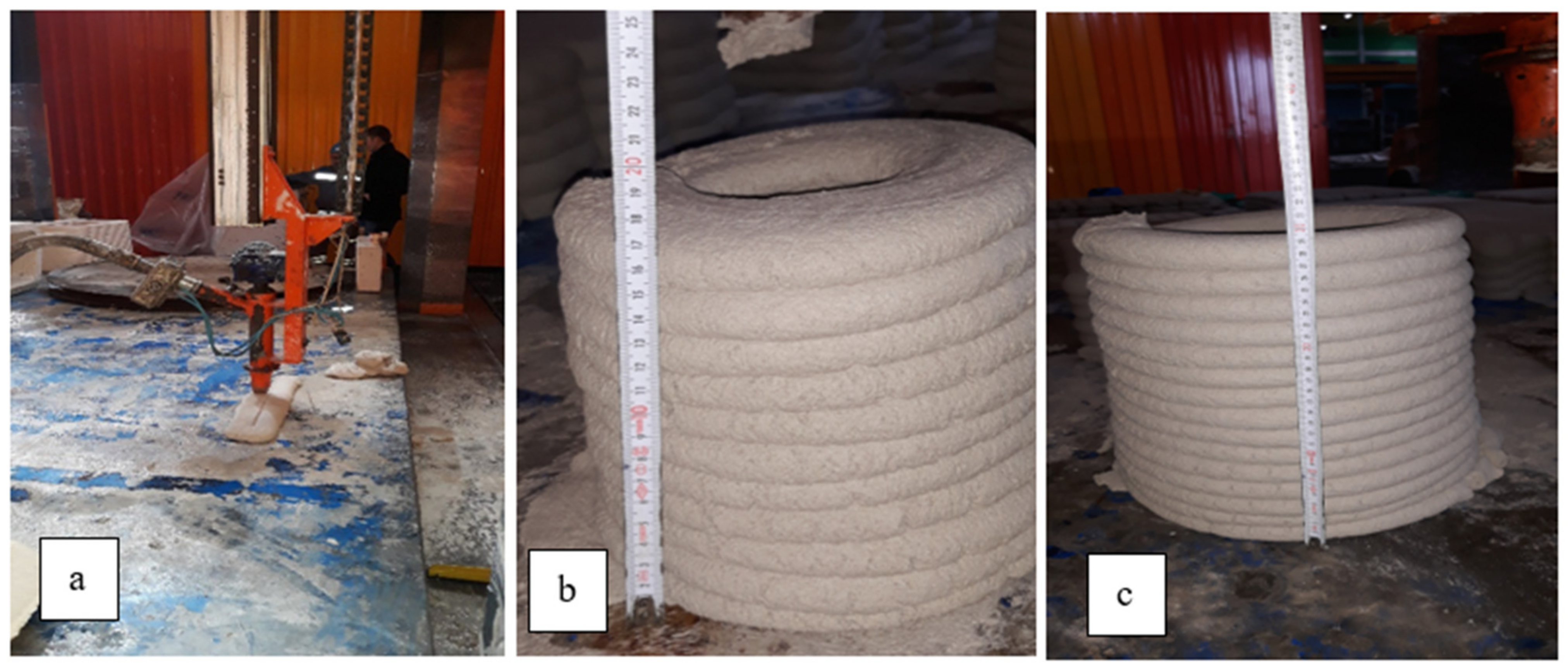

2.3.4. Buildability

2.3.5. Open Time

2.3.6. Rheological Properties

3. Results and Discussion

3.1. Evaluation of Unit Weight Tests Results

3.2. Evaluation of Air Content Test Results

3.3. Evaluation of Flow Table Test Results

3.4. Evaluation of Initial Setting Time Results

3.5. Evaluation of Compression Strength Test Results

3.6. Evaluation of Rheological Properties of 3D Printable Mortar Mixtures

4. Conclusions

- It is recommended to develop a unique chemical admixture for 3D printable mortars, considering the active ingredients of the chemical additives that affect the behavior of fresh mortar such as superplasticizer, viscosity modifying and cement hydration control.

- Increasing the amount of entrained air in fresh 3D printable mortar mixture by adding AEA increased the air content, but decreased the unit weights of the mixtures, as in conventional mortar or concrete. However, although the amount of air content of the mixes increased, the spread diameters of the mortars did not change significantly.

- Although the initial setting time of the group without AEA (A0) was very short (35 min), the initial setting times of 3D printable mortars increased with the addition of AEA and the group with the highest dosage of AEA (A2) started to set after 90 min. However, even 90 min is lower than the initial setting times of Super White Cement (CEM I 52.5R) and GGBFS selected for the mixtures. As a result of the combined effect of many chemical additives that were chosen consciously in order to acquire the most appropriate mix design for the interrelated characteristics (extrudability, constructability, and open time) determined for 3D printable mortar in the literature, the initial setting times of the mixtures decreased.

- Increasing the dosage of AEA dramatically reduced the 28-day compressive strength of 3D printable mortars. The reductions in compressive strength were, respectively, 47.5, 65, and 78% for the A1, A1.5, and A2 groups compared to that of A0 group. Therefore, it is recommended to pay attention to the use of air-entraining additives in 3D mortar or concrete applications where compressive strength is an important priority.

- The addition of AEA to 3D printable mortars reduced the viscosity and shear stress of the mixtures, and the A1.5 group had the lowest values. Yield stress varying between 50 and 262 Pa was obtained in the study and these values were found to be sufficient for the printability of 3D printable mortar mixes. The thixotropy values of the samples without AEA (A0) and containing AEA at low dosage (A1 and A1.5) were very close to each other, but mixtures containing the highest dosage of AEA (A2) had higher thixotropy values than the other groups.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nadarajah, N. Development of Concrete 3D Printing. Master Thesis, University School of Engineering, Building Technology, Aalto, Finland, 2018. [Google Scholar]

- ASTM F 2792-12a. Committee F42 on Additive Manufacturing Technologies, and ASTM Committee F42 on Additive Manufacturing Technologies. Subcommittee F42. 91 on Terminology; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Mohammed, B.S. Industry revolution IR 4.0: Future opportunities and challenges in construction industry. MATEC Web Conf. 2018, 203, 02010. [Google Scholar] [CrossRef] [Green Version]

- Khoshnevis, B. Automated construction by contour crafting—related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef] [Green Version]

- Wolfs, R. 3D Printing of Concrete Structures. Master Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2015. [Google Scholar]

- Feng, P.; Meng, X.; Chen, J.F.; Ye, L. Mechanical properties of structures 3D printable with cementitious powders. Constr. Build. Mater. 2015, 93, 486–497. [Google Scholar] [CrossRef] [Green Version]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D printing of buildings and building components as the future of sustainable construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef] [Green Version]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Craveiro, F.; Bartolo, H.M.; Gale, A.; Duarte, J.P.; Bartolo, P.J. A design tool for resource-efficient fabrication of 3d-graded structural building components using additive manufacturing. Autom. Constr. 2017, 82, 75–83. [Google Scholar] [CrossRef] [Green Version]

- Camacho, D.D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of additive manufacturing in the construction industry–A forward-looking review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Chen, Q.; de Soto, B.G.; Adey, B.T. Construction automation: Research areas, industry concerns and suggestions for advancement. Autom. Constr. 2018, 94, 22–38. [Google Scholar] [CrossRef]

- Davtalab, O.; Kazemian, A.; Khoshnevis, B. Perspectives on a BIM-integrated software platform for robotic construction through Contour Crafting. Autom. Constr. 2018, 89, 13–23. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Corker, J.; Fan, M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom. Constr. 2018, 93, 1–11. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.; Tan, M.J.; Gibson, I. A review of 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Li, M.; Lim, J.H.; Weng, Y.; Tay, Y.W.D.; Pham, H.; Pham, Q.C. Large-scale 3D printing by a team of mobile robots. Autom. Constr. 2018, 95, 98–106. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Maresova, P.; Krejcar, O.; David, O.O. Industry 4.0 for the construction industry: Review of management perspective. Economies 2019, 7, 68. [Google Scholar] [CrossRef] [Green Version]

- Bridges, S.M.; Keiser, K.; Sissom, N.; Graves, S.J. Cyber Security for Additive Manufacturing. In Proceedings of the 10th Annual Cyber and Information Security Research Conference, Oak Ridge, TN, USA, 6–8 April 2015; pp. 1–3. [Google Scholar]

- Kreiger, M.A.; MacAllister, B.A.; Wilhoit, J.M.; Case, M.P. The Current State of 3D Printing for Use in Construction. In Proceedings of the 2015 Conference on Autonomous and Robotic Construction of Infrastructure, Ames, IA, USA, 2–3 June 2015; pp. 149–158. [Google Scholar]

- Perkins, I.; Skitmore, M. Three-dimensional printing in the construction industry: A review. Int. J. Constr. Manag. 2015, 15, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef] [Green Version]

- Uppala, S.S.; Tadikamalla, M.R. A review on 3D printing of concrete-the future of sustainable construction. I-Manag. J. Civ. Eng. 2017, 7, 49. [Google Scholar]

- Panda, B.; Tay, Y.W.D.; Paul, S.C.; Tan, M.J. Current challenges and future potential of 3D concrete printing: Aktuelle Herausforderungen und Zukunftspotenziale des 3D-Druckens bei Beton. Mater. Werkst. 2018, 49, 666–673. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Ingaglio, J.; Fox, J.; Naito, C.J.; Bocchini, P. Material characteristics of binder jet 3D printed hydrated CSA cement with the addition of fine aggregates. Constr. Build. Mater. 2019, 206, 494–503. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995; Volume 4. [Google Scholar]

- Şahin, R. Optimization of Frost Resistance of Normal Portland Cement Mortars by Taguchi Method and Damage Analysis. Ph.D. Thesis, Atatürk University, Erzurum, Turkey, 2003. (Turkish with English abstract). [Google Scholar]

- Sun, J.; Huang, Y.; Aslani, F.; Ma, G. Properties of a double-layer EMW-absorbing structure containing a graded nano-sized absorbent combing extruded and sprayed 3D printing. Constr. Build. Mater. 2020, 261, 120031. [Google Scholar] [CrossRef]

- Banfill, P.F.G. Rheological methods for assessing the flow properties of mortar and related materials. Constr. Build. Mater. 1994, 8, 43–50. [Google Scholar] [CrossRef]

- 3D Print Canal House. Available online: http://3dprintcanalhouse.com/construction-technique (accessed on 10 June 2020).

- Lu, B.; Qian, Y.; Li, M.; Weng, Y.; Leong, K.F.; Tan, M.J.; Qian, S. Designing spray-based 3D printable cementitious materials with fly ash cenosphere and air entraining agent. Constr. Build. Mater. 2019, 211, 1073–1084. [Google Scholar] [CrossRef]

- Assaad, J.J.; Hamzeh, F.; Hamad, B. Qualitative assessment of interfacial bonding in 3D printing concrete exposed to frost attack. Case Stud. Constr. Mater. 2020, 13, e00357. [Google Scholar] [CrossRef]

- Das, A.; Song, Y.; Mantellato, S.; Wangler, T.; Flatt, R.J.; Lange, D.A. Influence of Pumping/Extrusion on the Air-Void System of 3D Printed Concrete. In Second RILEM International Conference on Concrete and Digital Fabrication; Bos, F., Lucas, S., Wolfs, R., Salet, T., Eds.; Springer: Eindhoven, The Netherlands, 2020; Volume 28. [Google Scholar]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete -technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. 3D printable concrete: Mixture design and test methods. Cem. Concr. Compos. 2019, 97, 13–23. [Google Scholar] [CrossRef]

- Buswell, R.A.; De Silva, W.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.; Flatt, R.J. Digital concrete: A review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110. [Google Scholar] [CrossRef]

- Nerella, V.N.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos. 2019, 95, 260–270. [Google Scholar] [CrossRef]

- Bos, F.P.; Kruger, P.J.; Lucas, S.S.; van Zijl, G.P.A.G. Juxtaposing fresh material characterisation methods for buildability assessment of 3D printable cementitious mortars. Cem. Concr. Compos. 2021, 120, 104024. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef] [Green Version]

- Jeon, K.H.; Park, M.B.; Kang, M.K.; Kim, J.H. Development of an automated freeform construction system and its construction materials. In Proceedings of the 30th ISARC International Symposium on Automation and Robotics in Construction, Montreal, Canada, 11–15 August 2013. [Google Scholar]

- Hambach, M.; Rutzen, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. In 3D Concrete Printing Technology; Sanjayan, J., Naazri, A., Nematollahi, B., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 73–113. [Google Scholar]

- Kazemian, A.; Yuan, X.; Meier, R.; Khoshnevis, B. Performance-based testing of Portland cement concrete for construction-scale 3D printing. In 3D Concrete Printing Technology; Sanjayan, J., Naazri, A., Nematollahi, B., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 13–35. [Google Scholar]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Panda, B.; Ruan, S.; Unluer, C.; Tan, M.J. Investigation of the properties of alkali-activated slag mixes involving the use of nanoclay and nucleation seeds for 3D printing. Compos. Part B Eng. 2020, 186, 107826. [Google Scholar] [CrossRef]

- Srinivasan, R.; DeFord, D.; Shah, S.P. The use of extrusion rheometry in the development of extruded fiber-reinforced cement composites. Concr. Sci. Eng. 1999, 1, 26–36. [Google Scholar]

- Kuder, K.G.; Shah, S.P. Rheology of extruded cement-based materials. ACI Mater. J. 2007, 104, 283. [Google Scholar]

- Tregger, N.A.; Pakula, M.E.; Shah, S.P. Influence of clays on the rheology of cement pastes. Cem. Concr. Res. 2010, 40, 384–391. [Google Scholar] [CrossRef]

- Voigt, T.; Mbele, J.J.; Wang, K.; Shah, S.P. Using fly ash, clay, and fibers for simultaneous improvement of concrete green strength and consolidatability for slip-form pavement. J. Mater. Civ. Eng. 2010, 22, 196–206. [Google Scholar] [CrossRef]

- Panda, B.; Ruan, S.; Unluer, C.; Tan, M.J. Improving the 3D printability of high volume fly ash mixtures via the use of nano attapulgite clay. Compos. Part B Eng. 2019, 165, 75–83. [Google Scholar] [CrossRef]

- Kondepudi, K.; Subramaniam, K.V. Formulation of alkali-activated fly ash-slag binders for 3D concrete printing. Cem. Concr. Compos. 2021, 119, 103983. [Google Scholar] [CrossRef]

- Quanji, Z.; Lomboy, G.R.; Wang, K. Influence of nano-sized highly purified magnesium alumino silicate clay on thixotropic behavior of fresh cement pastes. Constr. Build. Mater. 2014, 69, 295–300. [Google Scholar] [CrossRef]

- Conte, T.; Chaouche, M. Rheological behavior of cement pastes under large amplitude oscillatory shear. Cem. Concr. Res. 2016, 89, 332–344. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Tarhan, Y. Investigation of Freeze-Thaw Resistance and Pore Structure of Digitally Fabricated Cement-Based Composites. Ph.D. Thesis, Atatürk University, Erzurum, Turkey, 2020. (Turkish with English abstract). [Google Scholar]

- CIMSA Cement Factories. Available online: https://www.cimsa.com.tr/en/products-services/cement/white-cement/cimsa-super-white-cem-i-52-5-r-white-portland-cement/i-278 (accessed on 22 March 2021).

- Figueiredo, S.C.; Rodríguez, C.R.; Ahmed, Z.Y.; Bos, D.H.; Xu, Y.; Salet, T.M.; Çopuroğlu, O.; Schlangen, E.; Bos, F.P. An approach to develop printable strain hardening cementitious composites. Mater. Des. 2019, 169, 107651. [Google Scholar] [CrossRef]

- Rahul, A.V.; Sharma, A.; Santhanam, M. A desorptivity-based approach for the assessment of phase separation during extrusion of cementitious materials. Cem. Concr. Compos. 2020, 108, 103546. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Chen, Y.; Figueiredo, S.C.; Li, Z.; Chang, Z.; Jansen, K.; Çopuroğlu, O.; Schlangen, E. Improving printability of limestone-calcined clay-based cementitious materials by using viscosity-modifying admixture. Cem. Concr. Res. 2020, 132, 106040. [Google Scholar] [CrossRef]

- NANOKIM Chemistry Company. Available online: https://www.nanokim.com.tr/en/dolgular/ (accessed on 22 March 2021).

- Kaszyńska, M.; Hoffmann, M.; Skibicki, S.; Zieliński, A.; Techman, M.; Olczyk, N.; Wróblewski, T. Evaluation of suitability for 3D printing of high performance concretes. MATEC Web Conf. 2018, 163, 01002. [Google Scholar] [CrossRef]

- TS EN 12350-5. Testing Fresh Concrete—Part 5: Flow Table Test; Turkish Standards Institute: Ankara, Turkey, 2019.

- ASTM C230/C230. M-14 Standard Specification for Flow Table for Use in Tests of Hydraulic Cement; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar]

- ASTM, C1437. Standard Test Method for Flow of Hydraulic Cement Mortar; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- TS EN 12350-6. Concrete—Fresh Concrete Tests—Part 6: Density; Turkish Standards Institute: Ankara, Turkey, 2019.

- TS EN 12350-7. Testing Fresh Concrete—Part 7: Air Content—Pressure Methods; Turkish Standards Institute: Ankara, Turkey, 2019.

- Lachemi, M.; Hossain, K.M.A.; Lambros, V.; Nkinamubanzi, P.C.; Bouzoubaa, N. Performance of new viscosity modifying admixtures in enhancing the rheological properties of cement paste. Cem. Concr. Res. 2004, 34, 185–193. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Şahin, R.; Polat, R.; İçelli, O.; Çelik, C. Determination of transmission factors of concretes with different water/cement ratio, curing condition, and dosage of cement and air entraining agent. Ann. Nucl. Energy 2011, 38, 1505–1511. [Google Scholar] [CrossRef]

- Bao, Y.; Xu, M.; Soltan, D.; Xia, T.; Shih, A.; Clack, H.L.; Li, V.C. Three-dimensional printing multifunctional engineered cementitious composites (ECC) for structural elements. In First RILEM International Conference on Concrete and Digital Fabrication; Wangler, T., Flatt, R., Eds.; Springer: Eindhoven, The Netherlands, 2018; Volume 19. [Google Scholar]

- Özalp, F.; Yilmaz, H.D. Fresh and Hardened Properties of 3D High-Strength Printing Concrete and Its Recent Applications. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 44, 319–330. [Google Scholar] [CrossRef]

- TS EN 196-3. Cement Test Methods—Part 3: Setting Times and Expansion Determination; Turkish Standards Institute: Ankara, Turkey, 2017.

- Banfill, P.F.G. Rheology of Fresh Cement and Concrete: Proceedings of an International Conference; CRC Press: Liverpool, UK, 2019. [Google Scholar]

- Banfill, P.F.G. The rheology of fresh cement and concrete-a review. In Proceedings of the 11th International Cement Chemistry Congress, Durban, South Africa, 11–16 May 2003. [Google Scholar]

- Çelebi, N. Modern Pharmaceutical Technology. In Rheology (In Turkish); Turkish Pharmacists Association Pharmacy Academy Publication: Ankara, Turkey, 2009; pp. 263–265. [Google Scholar]

- Çankayalı, A.; Gökçe, M.; Levent, K.Y. Investigation of Rheological Properties of Fine Material Paste in Fresh Concrete (In Turkish). In Proceedings of the 3rd Symposium on Chemical Additives in Buildings, Ankara, Turkey, 2–3 April 2009; pp. 25–42. [Google Scholar]

- TS EN 206: 2013 + A1. Concrete—Feature, Performance, Manufacturing and Conformity; Turkish Standards Institute: Ankara, Turkey, 2017.

- Şahin, R.; Taşdemir, M.A.; Rüstem, G.; Çelik, C. Optimization study and damage evaluation in concrete mixtures exposed to slow freeze-thaw cycles. J. Mater. Civ. Eng. 2007, 19, 609–615. [Google Scholar] [CrossRef]

- Şahin, Y. Characterization of Air-entraining Admixtures and Effects of Test Conditions on Freezing-Thawing Damage of Concrete. Ph.D. Thesis, Istanbul Technical University, İstanbul, Turkey, 2013. (Turkish with English abstract). [Google Scholar]

- Zhang, Z.; Ansari, F. Fracture mechanics of air-entrained concrete subjected to compression. Eng. Fract. Mech. 2006, 73, 1913–1924. [Google Scholar] [CrossRef]

- Bizinotto, M.B.; Faleschini, F.; Fernández, C.G.J.; Hernández, D.F.A. Effects of chemical admixtures on the rheology of fresh recycled aggregate concretes. Constr. Build. Mater. 2017, 151, 353–362. [Google Scholar] [CrossRef]

- Chatterji, S. Freezing of air-entrained cement-based materials and specific actions of air-entraining agents. Cem. Mortar Compos. 2003, 25, 759–765. [Google Scholar] [CrossRef]

- Du, L.; Folliard, K.J. Mechanisms of air entrainment in concrete. Cem. Concr. Res. 2005, 35, 1463–1471. [Google Scholar] [CrossRef]

- Szwabowski, J.; Łaźniewska-Piekarczyk, B. The increase of air content in SCC mixes under the influence of carboxylate superplasticizer. Cem. Wapno Beton 2008, 13, 205–215. [Google Scholar]

- Barfield, M.; Ghafoori, N. Air-entrained self-consolidating concrete: A study of admixture sources. Constr. Build. Mater. 2012, 26, 490–496. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M. Evaluating the printability of mortars containing lightweight coarse aggregates. Cem. Mortar Compos. 2020, 109, 103570. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability region for 3D concrete printing using slump and slump flow test. Compos. Part B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Rubio, M.; Sonebi, M.; Amziane, S. 3D printing of fiber cement-based materials: Fresh and rheological performances. In Proceedings of the Second International Conference on Bio-based Building Materials, Clermont-Ferrand, France, 21–23 June 2017. [Google Scholar]

- ACI PRC-363-10. Report on High-Strength Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2010. [Google Scholar]

- Qunaji, Z. Thixotropic Behavior of Cement-Based Materials: Effect of Clay and Cement Types. Master Thesis, Iowa State University, Ames, IA, USA, 2010. [Google Scholar]

- Zhang, Y.; Zhang, Y.; She, W.; Yang, L.; Liu, G.; Yang, Y. Rheological and harden properties of the high-thixotropy 3D printing concrete. Constr. Build. Mater. 2019, 201, 278–285. [Google Scholar] [CrossRef]

- Roussel, N. A thixotropy model for fresh fluid concretes: Theory, validation and applications. Cem. Concr. Res. 2006, 36, 1797–1806. [Google Scholar] [CrossRef]

- Banfill, P.F.G. Rheology of fresh cement and concrete. In Rheology Reviews 2006; The British Society of Rheology: Aberystwyth, UK, 2006; pp. 61–130. [Google Scholar]

- Secrieru, E.; Cotardo, D.; Mechtcherine, V.; Lohaus, L.; Schröfl, C.; Begemann, C. Changes in concrete properties during pumping and formation of lubricating material under pressure. Cem. Concr. Res. 2018, 108, 129–139. [Google Scholar] [CrossRef]

- Nair, S.A.; Panda, S.; Santhanam, M.; Sant, G.; Neithalath, N. A critical examination of the influence of material characteristics and extruder geometry on 3D printing of cementitious binders. Cem. Concr. Compos. 2020, 112, 103671. [Google Scholar] [CrossRef]

| CEM I 52.5 R | GGBFS | Kaolin Clay | |

|---|---|---|---|

| Chemical Compositions (%) | |||

| SiO2 | 21.21 | 37.40 | 49–55 |

| Al2O3 | 3.86 | 10.38 | 42–46 |

| Fe2O3 | 0.32 | 1.30 | 0.7 max |

| CaO | 65.85 | 30.93 | 0.5 max |

| MgO | 1.05 | 7.21 | 0.3 max |

| SO3 | 3.51 | 0.77 | - |

| Na2O | 0.20 | 0.39 | 0.2 max |

| K2O | 0.49 | 0.67 | 0.1 max |

| TiO2 | - | 0.85 | 0.8 max |

| Loss of ignition | 3.30 | - | 0.5 max |

| Klor (Cl−) | 0.01 | 0.0160 | - |

| Physical Characteristics | |||

| Initial setting time (min) | 110 | 170 | - |

| Final setting time (min) | 130 | 230 | - |

| Volume expansion (mm) | 1 | 0 | - |

| Specific Gravity (g/cm3) | 3.04 | 2.88 | 2.65–2.75 |

| Bulk density (kg/L) | - | - | 0.3–0.5 |

| Spec. Surf. Area (cm2/g) | 4650 | 4183 | - |

| Fineness 45 µm (%) | 1 | 1.3 | - |

| Particle size (<2 µm, %) | - | - | 83–86 |

| Screen res. (325 mesh, %) | - | - | 0.005 max |

| Whiteness | 85.5 | - | 93.5–94 |

| Comp. Str., 2 days (MPa) | 37 | - | - |

| Comp. Str., 3 days (MPa) | 43 | - | - |

| Comp. Str., 7 days (MPa) | 50 | 55.3 | - |

| Comp. Str., 28 days (MPa) | 60 | 74.2 | - |

| Oil Absorption (g/100 g) | - | - | 50–60 |

| Moisture (105 °C, %) | - | - | 0.5 max |

| NO | Effect | Spec. W. (kg/L) | pH | Color | Cl Ion. (W., %) | Service Tem (°C) | Dosage (%) |

|---|---|---|---|---|---|---|---|

| I | Viscosity modifying (VMA 1) | 1.01 ± 0.01 | 7.5 ± 1.5 | Brown liquid | <0.10 | - | %0.1–1 |

| II | Superplasticizer | 1.084 ± 0.02 | 4–5 | Dark brown | <0.10 | - | 0.8–1.5 |

| III | Cement hydration control | 1.10 ± 0.02 | <2 | Red | <0.10 | - | 0.2–1 |

| IV | Viscosity modifying and strength enhancer (VMA 2) | 1.13 | 9.4 | Changeable | - | - | 0.325–2.6 |

| V | Setting accelerator | 1.50 ± 0.03 | 2.75 ± 0.75 | Beige | - | - | 3–10 |

| VI | Plasticizer/set retarding | 1.14–1.2 | 7–9 | Pink | <0.10 | (−20)~(+80) | 0.25–2 |

| VII | Air-entraining | 1.00–1.10 | 5–6 | Brown liquid | <0.10 | (−20)~(+80) | 0.1–0.6 |

| CODE | Cem. | GGBFS | Water | Microfiber | Clay | Type of Chemical Admixture * | Aggregate | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | II | III | IV | V | VI | VII | 0–0.5 | 0–1 | ||||||

| A0 | 680 | 136 | 285.6 | 1.82 | 2.45 | 0.88 | 8.16 | 4.08 | 4.08 | 8.16 | 4.08 | 0 | 333 | 675 |

| A1 | 680 | 136 | 285.6 | 1.82 | 2.45 | 0.88 | 8.16 | 4.08 | 4.08 | 8.16 | 4.08 | 0.82 | 332 | 674 |

| A1.5 | 680 | 136 | 285.6 | 1.82 | 2.45 | 0.88 | 8.16 | 4.08 | 4.08 | 8.16 | 4.08 | 1.22 | 332 | 673 |

| A2 | 680 | 136 | 285.6 | 1.82 | 2.45 | 0.88 | 8.16 | 4.08 | 4.08 | 8.16 | 4.08 | 1.63 | 332 | 673 |

| CODE | Unit Weight (kg/m3) | Air Content (%) | Flow Diam. (cm) | Initial Setting Time (min) | Comp. Strength (MPa) |

|---|---|---|---|---|---|

| A0 | 2130 | 2.5 | 14.5 | 35 | 54.5 |

| A1 | 1820 | 6.5 | 16.3 | 60 | 28.6 |

| A1.5 | 1780 | 7.5 | 16.5 | 75 | 18.9 |

| A2 | 1670 | 8.5 | 16.7 | 90 | 11.8 |

| Code | Yield Stress (Pa) | Bingham Viscosity (mPa.s) | Thixotropy (Athix) | Thixotropy | ||

|---|---|---|---|---|---|---|

| Up | Down | Up | Down | Hysteresis Area (Pa/s) | Hysteresis Area (Pa/(s·cm3)) | |

| A0 | 262.2 | 131.8 | 37,232 | 47,697 | A = 18,792 | A_rel = 536.92 |

| A1 | 155.4 | 68.3 | 26,457 | 26,959 | A = 18,288 | A_rel = 522.52 |

| A1.5 | 99.0 | 50.9 | 26,343 | 24,606 | A = 19,372 | A_rel = 553.49 |

| A2 | 116.0 | 59.4 | 31,110 | 26,523 | A = 25,877 | A_rel = 739.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarhan, Y.; Şahin, R. Fresh and Rheological Performances of Air-Entrained 3D Printable Mortars. Materials 2021, 14, 2409. https://doi.org/10.3390/ma14092409

Tarhan Y, Şahin R. Fresh and Rheological Performances of Air-Entrained 3D Printable Mortars. Materials. 2021; 14(9):2409. https://doi.org/10.3390/ma14092409

Chicago/Turabian StyleTarhan, Yeşim, and Remzi Şahin. 2021. "Fresh and Rheological Performances of Air-Entrained 3D Printable Mortars" Materials 14, no. 9: 2409. https://doi.org/10.3390/ma14092409