Synthesis, Spectroscopic, Thermal, and Catalytic Properties of Eight New Complexes of Metal(II) Formates or Propionates with Imidazole; Relationship between the Carbon Chain Length and Catalytic Activity

Abstract

:1. Introduction

2. Materials and Methods

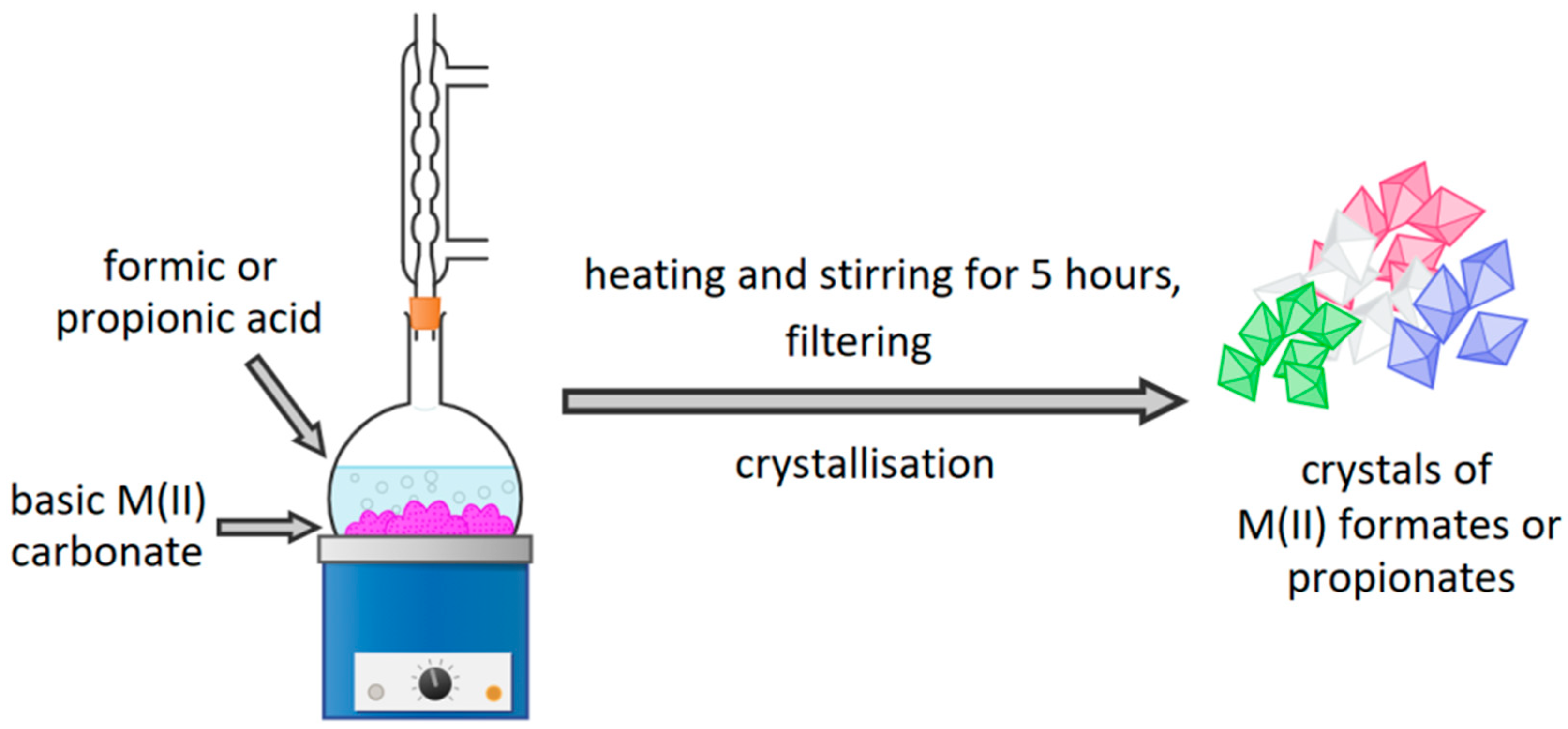

2.1. Synthesis of M(II) Formates and Propionates

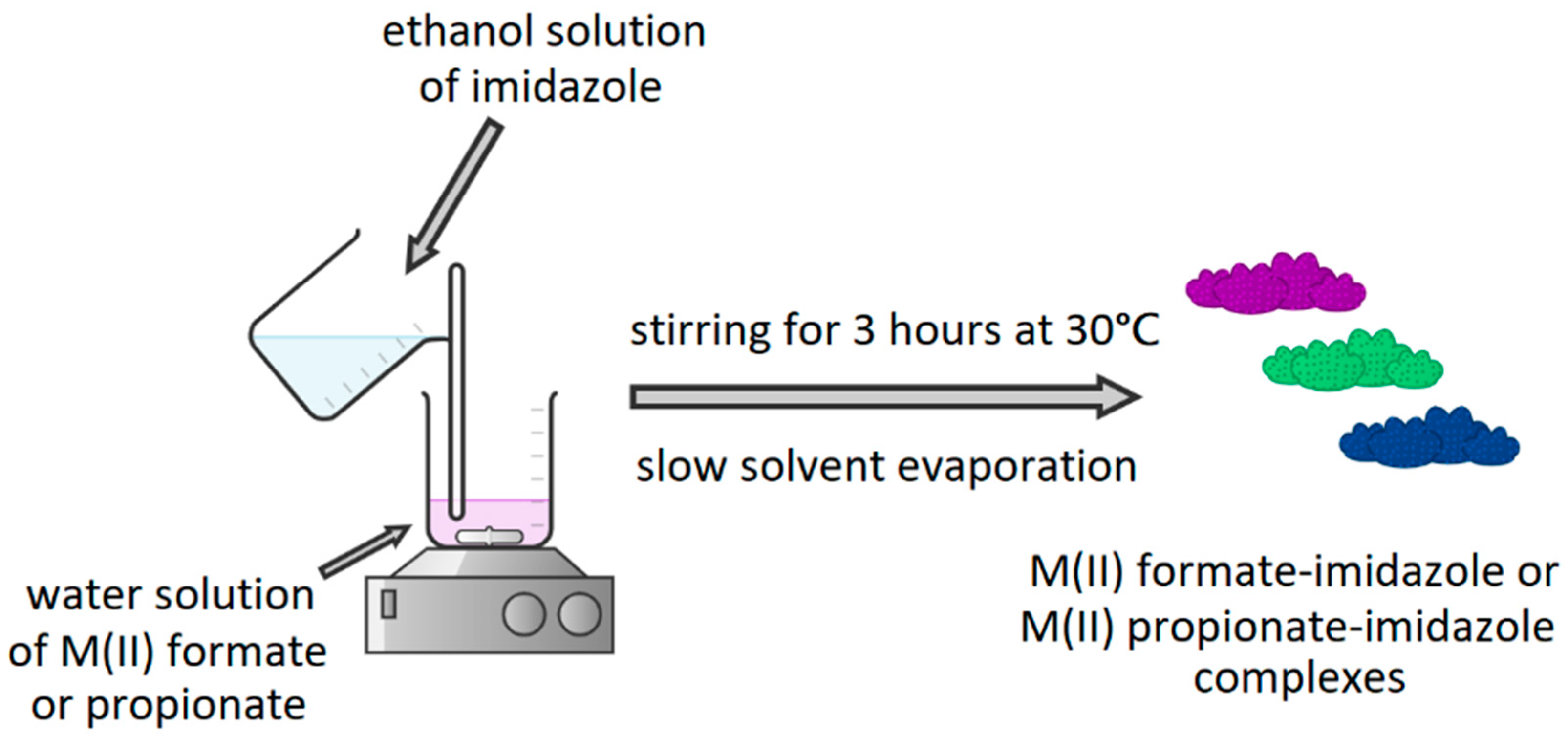

2.2. Synthesis of M(II) Formate and Propionate Complexes with Imidazole

3. Results and Discussion

3.1. Atomic Absorption Spectrometry

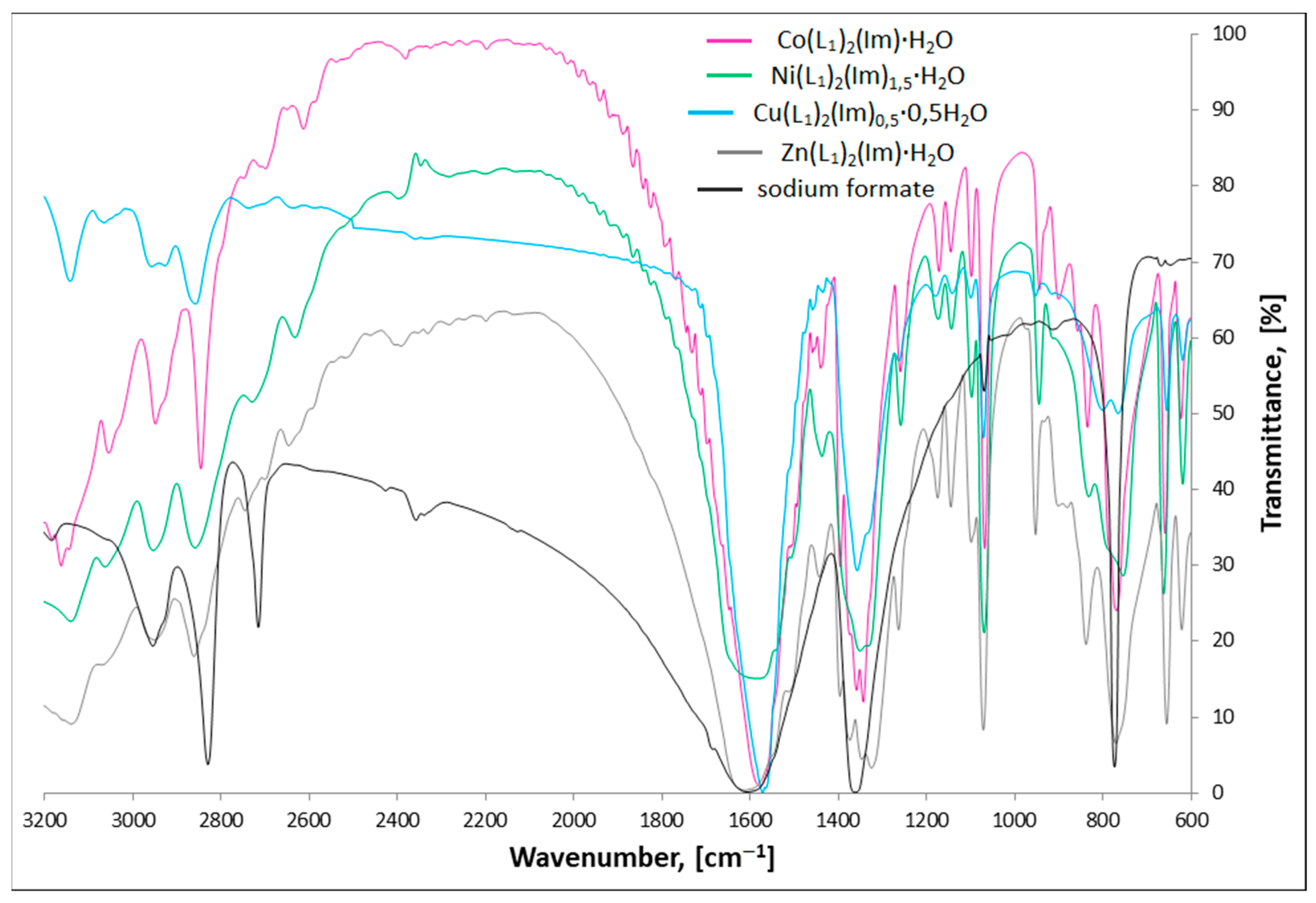

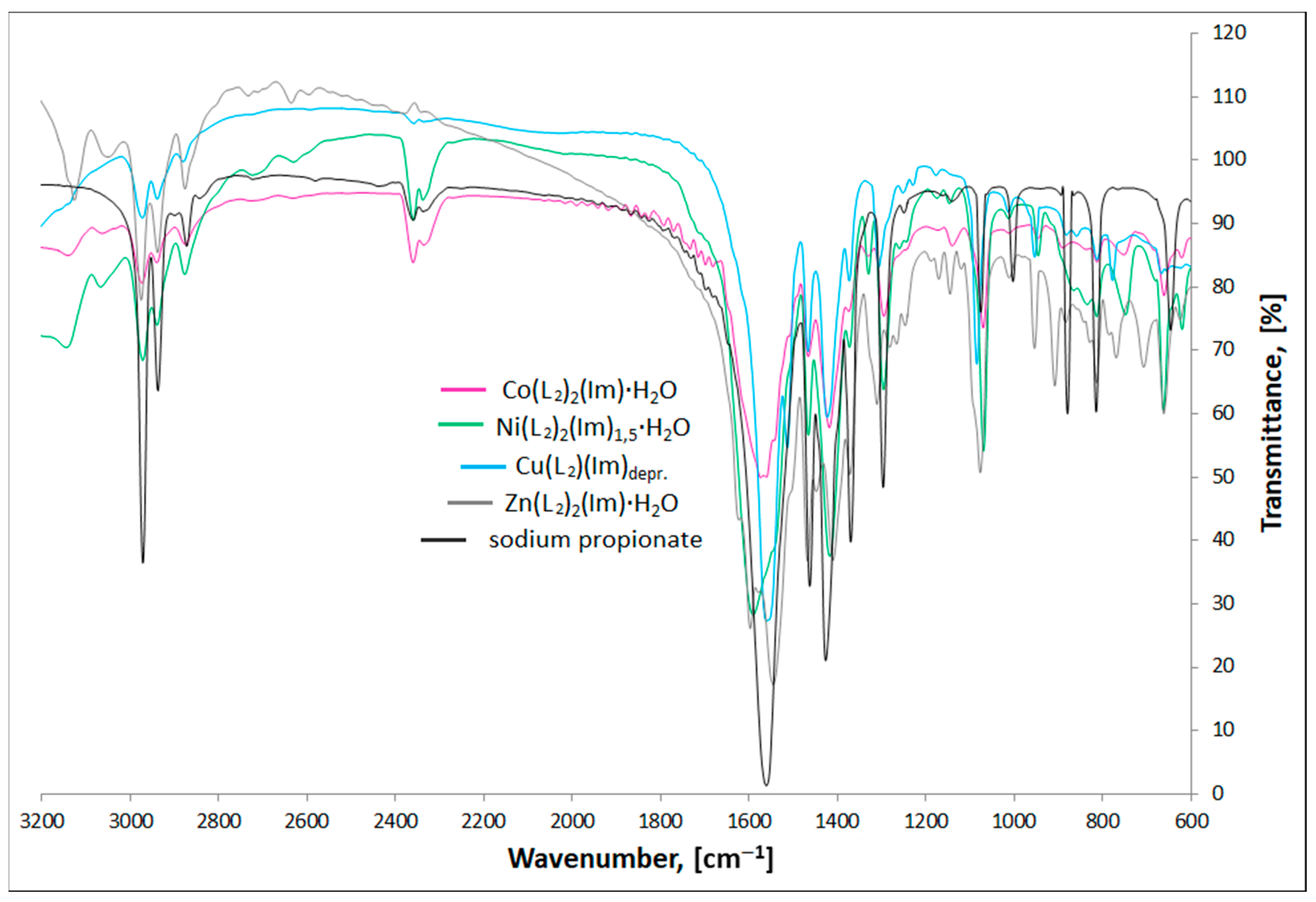

3.2. FTIR Spectra

3.3. Thermogravimetric Studies in Air

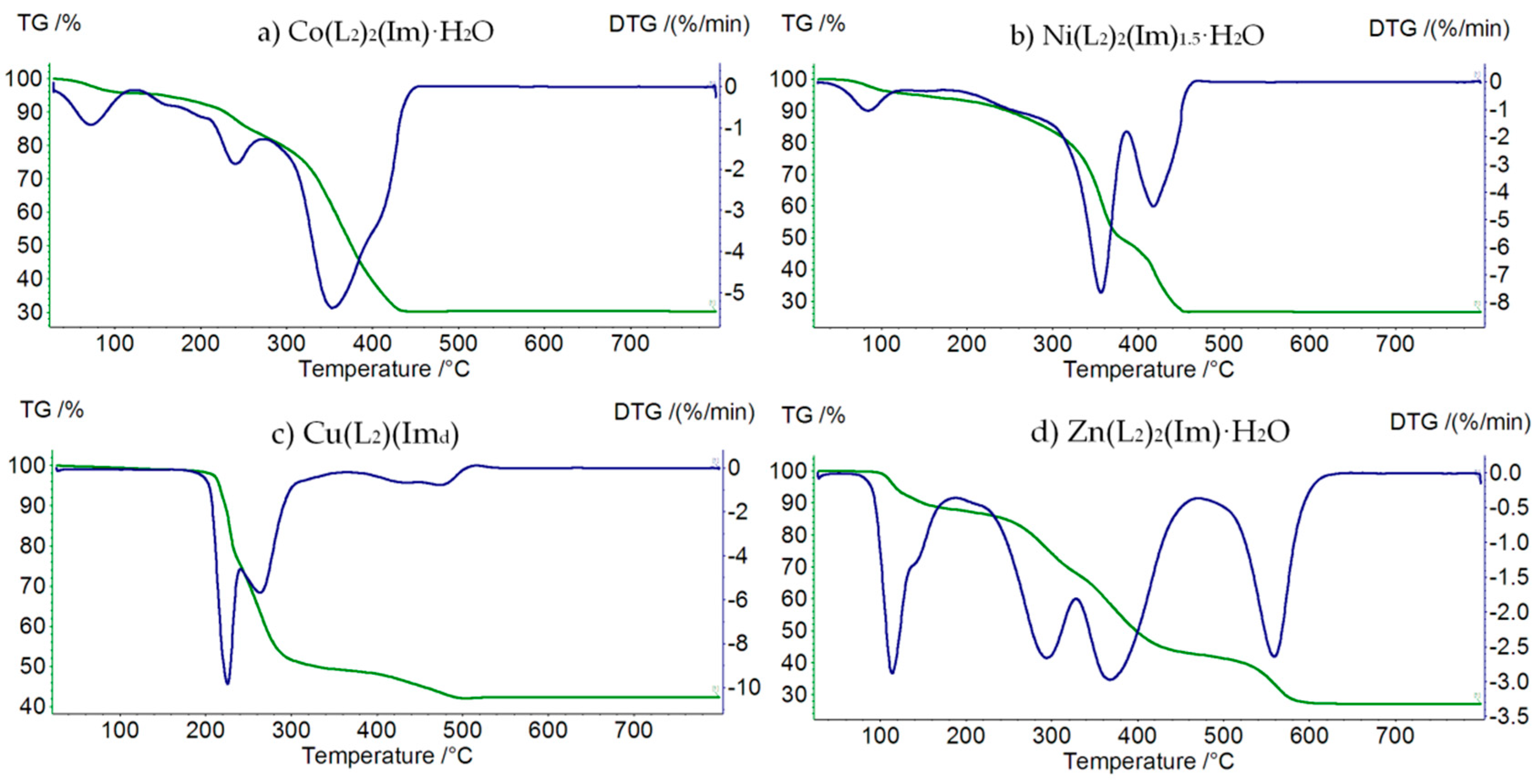

3.3.1. Thermolysis of M(II) Formate Complexes with Imidazole

3.3.2. Thermolysis of M(II) Propionate Complexes with Imidazole

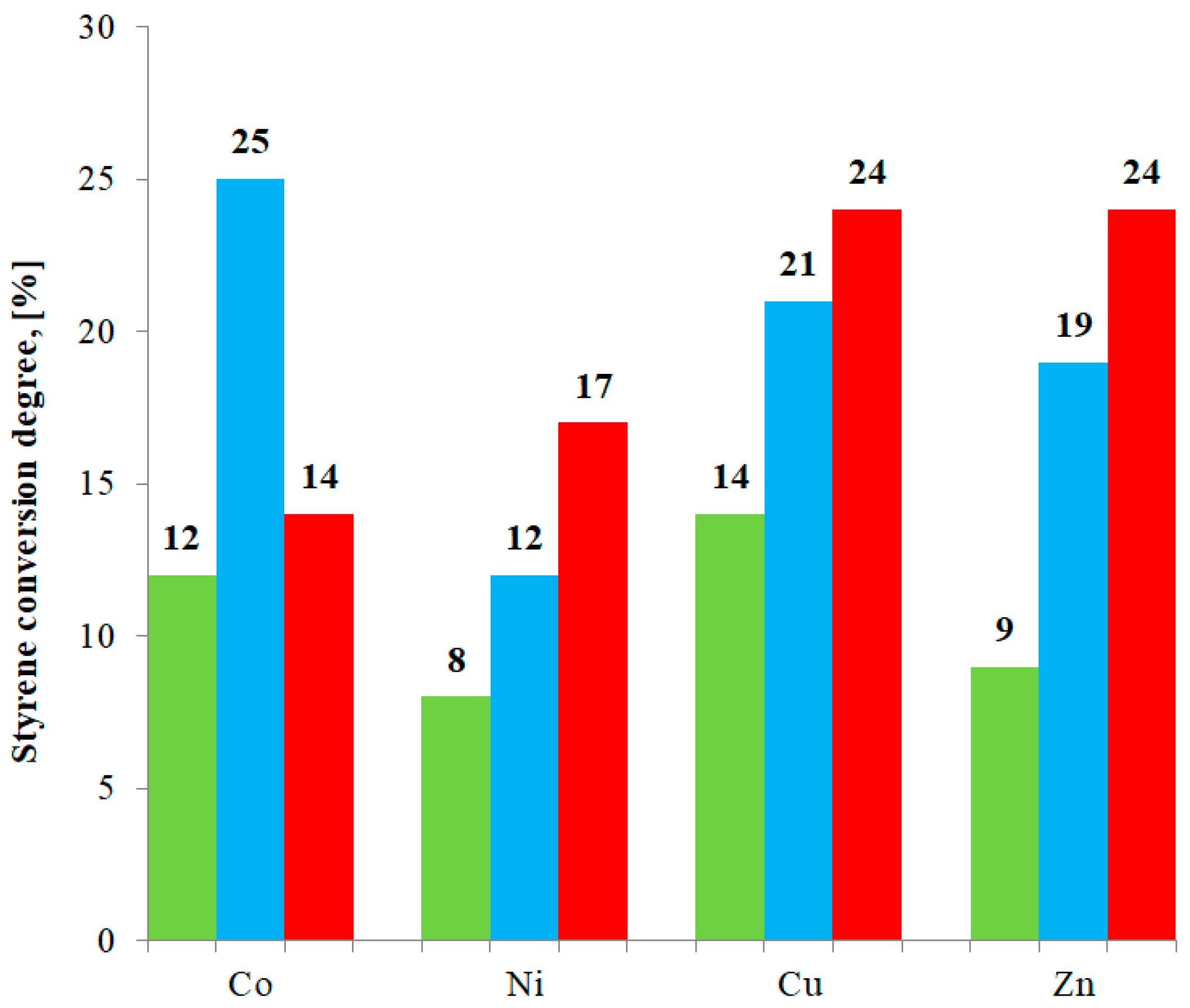

3.4. Catalytic Activity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shalini, K.; Sharma, P.K.; Kumar, N. Imidazole and its biological activities: A review. Der. Chem. Sin. 2010, 1, 36–47. [Google Scholar]

- Siwach, A.; Verma, P.K. Synthesis and therapeutic potential of imidazole containing compounds. BMC Chem. 2021, 15, 69. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.; Kant, V. A Review on Biological Activity of Imidazole and Thiazole Moieties and their Derivatives. Sci. Int. 2013, 1, 253–260. [Google Scholar] [CrossRef] [Green Version]

- De Luca, L. Naturally occurring and synthetic imidazoles: Their chemistry and their biological activities. Curr. Med. Chem. 2006, 13, 1–23. [Google Scholar]

- Sharma, D.; Narasimhan, B.; Kumar, P.; Judge, V.; Narang, R.; De Clercq, E.; Balzarini, J. Synthesis, antimicrobial and antiviral evaluation of substituted imidazole derivatives. Eur. J. Med. Chem. 2009, 44, 2347–2353. [Google Scholar] [CrossRef]

- Sharma, P.; LaRosa, C.; Antwi, J.; Govindarajan, R.; Werbovetz, K.A. Imidazoles as Potential Anticancer Agents: An Update on Recent Studies. Molecules. 2021, 26, 4213. [Google Scholar] [CrossRef]

- Mlostoń, G.; Celeda, M.; Poper, W.; Kowalczyk, M.; Gach-Janczak, K.; Janecka, A.; Jasiński, M. Synthesis, Selected Transformations, and Biological Activity of Alkoxy Analogues of Lepidilines A and C. Materials 2020, 13, 4190. [Google Scholar] [CrossRef]

- Gholami, Z.; Tišler, Z.; Rubáš, V. Recent advances in Fischer-Tropsch synthesis using cobalt-based catalysts: A review on supports, promoters, and reactors. Catal. Rev. 2021, 63, 512–595. [Google Scholar] [CrossRef]

- Mirzaei, A.A.; Arsalanfar, M.; Bozorgzadeh, H.R.; Samimi, A. A review of Fischer-Tropsch synthesis on the cobalt based catalysts. Phys. Chem. Res. 2014, 2, 179–201. [Google Scholar] [CrossRef]

- Zhou, H.; Song, J.; Fan, H.; Zhang, B.; Yang, Y.; Hu, J.; Zhu, Q.; Han, B. Cobalt catalysts: Very efficient for hydrogenation of biomass-derived ethyl levulinate to gammavalerolactone under mild conditions. Green Chem. 2014, 16, 3870. [Google Scholar] [CrossRef]

- Zybert, M.; Tarka, A.; Mierzwa, B.; Raróg-Pilecka, W. Cobalt-lanthanum catalyst precursors for ammonia synthesis: Determination of calcination temperature and storage conditions. Pol. J. Chem. Tech. 2017, 19, 61–66. [Google Scholar] [CrossRef] [Green Version]

- Izumi, Y.; Imaida, M.; Fukawa, H.; Akabori, S. Asymmetric Hydrogenation with Modified Raney Nickel. Studies on Modified Hydrogenation Catalyst. Bull. Chem. Soc. Jpn. 1963, 36, 155–160. [Google Scholar] [CrossRef]

- Harada, T.; Izumi, Y. Improved modified Raney Nickel catalyst for enantioface-differentiating (asymmetric) hydrogenation of methyl acetoacetate. Chem. Lett. 1978, 7, 1195–1196. [Google Scholar] [CrossRef]

- Studentschnig, A.F.H.; Schober, S.; Mittelbach, M. Conversion of Crude Palm Oil into Hydrocarbons over Commercial Raney Nickel. Energy Fuels 2013, 27, 7480–7484. [Google Scholar] [CrossRef]

- Abudayyeh, A.M.; Schott, O.; Feltham, H.L.C.; Hanan, G.S.; Brooker, S. Copper catalysts for photo- and electro-catalytic hydrogen production. Inorg. Chem. Front. 2021, 8, 1015–1029. [Google Scholar] [CrossRef]

- Bluhm, H.; Hävecker, M.; Knop-Gericke, A.; Kleimenov, E.; Schlogl, R. Methanol Oxidation on a Copper Catalyst Investigated Using in Situ X-ray Photoelectron Spectroscopy. J. Phys. Chem. B 2004, 108, 14340–14347. [Google Scholar] [CrossRef]

- Górecka, S.; Pacultová, K.; Fridrichová, D.; Górecki, K.; Bílková, T.; Žebrák, R.; Obalová, L. Catalytic Oxidation of Ammonia over Cerium-Modified Copper Aluminium Zinc Mixed Oxides. Materials 2021, 14, 6581. [Google Scholar] [CrossRef] [PubMed]

- Nisa, R.U.; Mahmood, T.; Ludwig, R.; Ayub, K. Theoretical mechanistic investigation of zinc(II) catalyzed oxidation of alcohols to aldehydes and esters. RSC Adv. 2016, 6, 31876–31883. [Google Scholar] [CrossRef] [Green Version]

- Cheung, E.; Alberti, C.; Enthaler, S. Chemical Recycling of End-of-Life Poly(lactide) via Zinc-Catalyzed Depolymerization and Polymerization. ChemistryOpen 2020, 9, 1224–1228. [Google Scholar] [CrossRef] [PubMed]

- Adam, F.; Iqbal, A. The oxidation of styrene by chromium–silica heterogeneous catalyst prepared from rice husk. Chem. Eng. J. 2010, 160, 742–750. [Google Scholar] [CrossRef]

- Kumar, S.B.; Mirajkar, S.P.; Pais, G.C.G.; Kumar, P.; Kumar, R. Epoxidation of Styrene over a Titanium Silicate Molecular Sieve TS1 Using Dilute H2O2 as Oxidizing Agent. J. Catal. 1995, 156, 163–166. [Google Scholar] [CrossRef]

- Gao, D.; Gao, Q. Selective oxidation of styrene to benzaldehyde over VSB-5 and isomorphously substituted cobalt VSB-5. Catal. Commun. 2007, 8, 681–685. [Google Scholar] [CrossRef]

- Aberkouks, A.; Mekkaoui, A.A.; Boualy, B.; El Houssame, S.; Ali, M.A.; El Firdoussi, L. Selective oxidation of styrene to benzaldehyde by Co-Ag codoped ZnO catalyst and H2O2 as oxidant. Adv. Mater. Sci. Eng. 2018, 2018, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Titinchi, S.J.; VonWillingh, G.; Abbo, H.S.; Prasad, R. Tri- and tetradentate copper complexes: A comparative study on homogeneous and heterogeneous catalysis over oxidation reactions. Catal. Sci. Technol. 2015, 5, 325–338. [Google Scholar] [CrossRef]

- Czylkowska, A.; Rogalewicz, B.; Raducka, A.; Błaszczyk, N.; Maniecki, T.; Wieczorek, K.; Mierczyński, P. Synthesis, Spectroscopic, Thermal and Catalytic Properties of Four New Metal (II) Complexes with Selected N- and O-Donor Ligands. Materials 2020, 13, 3217. [Google Scholar] [CrossRef]

- Gueorguiev, G.K.; Pacheco, J.M. Shapes of cagelike metal carbide clusters: First-principles calculations. Phys. Rev. B 2003, 68, 241401(R). [Google Scholar] [CrossRef]

- Dos Santos, R.B.; Rivelino, R.; de Brito Mota, F.; Gueorguiev, G.K.; Kakanakova-Georgieva, A. Dopant species with Al–Si and N–Si bonding in the MOCVD of AlN implementing trimethylaluminum, ammonia and silane. J. Phys. D Appl. Phys. 2015, 48, 295104. [Google Scholar] [CrossRef]

- Tavares, S.R.; Vaiss, V.S.; Novais Antunes, F.P.; Fonseca, C.G.; Nangoi, I.M.; Moraes, P.I.R.; Soares, C.V.; Haddad, J.F.S.; Lima, L.L.; Silva, B.N.N.; et al. DFT calculations for structural prediction and applications of intercalated lamellar compounds. Dalton Trans. 2018, 47, 2852–2866. [Google Scholar] [CrossRef] [PubMed]

- Nakamoto, K. Infrared and Raman Spectra of Inorganic and Coordination Compounds; John and Wiley and Sons: New York, NY, USA, 2009. [Google Scholar]

- Alcock, N.W.; Tracy, V.M.; Waddington, T.C. Acetates and acetato-complexes. Part 2. Spectroscopic studies. J. Chem. Soc. Dalton Trans. 1976, 21, 2243–2246. [Google Scholar] [CrossRef]

| Co(L1)2(Im)⸱H2O | Co(Ac)2(Im)⸱H2O | Co(L2)2(Im)⸱H2O |

| Ni(L1)2(Im)1.5⸱H2O | Ni(Ac)2(Im)1,5⸱2H2O | Ni(L2)2(Im)1,5⸱H2O |

| Cu(L1)2(Im)0.5⸱0.5H2O | Cu2(Ac)4(Im) | Cu(L2)(Imd) |

| Zn(L1)2(Im)⸱H2O | Zn(Ac)2(Im)⸱H2O | Zn(L2)2(Im)⸱H2O |

| Compound | M(II) Content [%] | |

|---|---|---|

| Measured | Theoretical | |

| Co(L1)2(Im)⸱H2O | 25.26 | 25.07 |

| Ni(L1)2(Im)1.5⸱H2O | 21.66 | 21.83 |

| Cu(L1)2(Im)0.5⸱0.5H2O | 32.60 | 32.32 |

| Zn(L1)2(Im)⸱H2O | 27.19 | 27.07 |

| Co(L2)2(Im)⸱H2O | 20.09 | 20.24 |

| Ni(L2)2(Im)1.5⸱H2O | 19.01 | 18.06 |

| Cu(L2)(Im)d | 32.14 | 31.05 |

| Zn(L2)2(Im)⸱H2O | 22.07 | 21.97 |

| ν(NH) | ν(CH)aliphat. | π(CH), δ(Imidazole Ring) | ν(COO)as. | ν(COO)sym. | Δν(COO) | |

|---|---|---|---|---|---|---|

| Sodium formate | - | 2946, 2826 | - | 1585 | 1350 | 235 |

| Co(L1)2(Im)⸱H2O | 3158, 3139 | 2942, 2843 | 943, 884, 834, 767 | 1570 | 1339, 1324 | 231, 246 |

| Ni(L1)2(Im)1.5⸱H2O | 3129 | 2939, 2845 | 943, 825, 765 | 1571 | 1331 | 240 |

| Cu(L1)2(Im)0.5⸱0.5H2O | 3135 | 2939, 2917, 2849 | 951, 794, 759 | 1572 | 1351 | 221 |

| Zn(L1)2(Im)⸱H2O | 3126 | 2941, 2854 | 955, 887, 935, 768 | 1605 | 1386, 1355, 1328, 1317 | 219, 250, 277, 288 |

| Sodium propoionate | - | 2973, 2939, 2869 | - | 1565 | 1461, 1424 | 89, 141 |

| Co(L2)2(Im)⸱H2O | 3127 | 2970, 2934, 2868 | 943, 899, 822, 811, 746 | 1566 | 1476, 1415 | 90, 151 |

| Ni(L2)2(Im)1.5⸱H2O | 3136, 3055 | 2969, 2936, 2871 | 944, 852, 819, 812, 746 | 1584 | 1464, 1414 | 120, 170 |

| Cu(L2)(Im)d | - | 2969, 2934, 2874 | 953, 879, 855, 811, 777 | 1550 | 1476, 1418 | 74, 132 |

| Zn(L2)2(Im)⸱H2O | 3122, 3037 | 2973, 2941, 2873 | 953, 906, 880, 823, 812, 777, 767 | 1542 | 1467, 1408 | 75, 134 |

| Compound/Solid Intermediate | Temperature Range, [°C] | Mass Loss, [%] | Solid Intermediate/Final Residue | |

|---|---|---|---|---|

| Found | Calculated | |||

| Co(L1)2(Im)⸱H2O | 50–170 | 8.0 | 7.67 | Co(L1)2(Im) |

| Co(L1)2(Im) | 170–280 | 21.5 | 21.72 | Co(L1)2(Im)0.25 |

| Co(L1)2(Im)0.25 | 280–700 | 38.0 | 38.74 | CoO |

| Compound/Solid Intermediate | Temperature Range, [°C] | Mass Loss, [%] | Solid Intermediate/Final Residue | |

|---|---|---|---|---|

| Found | Calculated | |||

| Ni(L1)2(Im)1.5⸱H2O | 50–170 | 6.0 | 6.70 | Ni(L1)2(Im)1.5 |

| Ni(L1)2(Im)1.5 | 170–310 | 38.0 | 37.99 | Ni(L1)2 |

| Ni(L1)2 | 310–600 | 27.0 | 27.54 | NiO |

| Compound/Solid Intermediate | Temperature Range, [°C] | Mass Loss. [%] | Solid Intermediate/Final Residue | |

|---|---|---|---|---|

| Found | Calculated | |||

| Cu(L1)2(Im)0.5⸱0.5H2O | 40–140 | 5.0 | 4.58 | Cu(L1)2(Im)0.5 |

| Cu(L1)2(Im)0.5 | 140–280 | 46.0 | 45.93 | Cu(L1)0.75 |

| Cu(L1)0.75 | 280–560 | 9.5 | 9.03 | CuO |

| Compound/Solid Intermediate | Temperature Range, [°C] | Mass Loss. [%] | Solid Intermediate/Final Residue | |

|---|---|---|---|---|

| Found | Calculated | |||

| Zn(L1)2(Im)⸱H2O | 50–270 | 6.0 | 6.70 | Zn(L1)2 |

| Zn(L1)2 | 270–620 | 30.0 | 30.65 | ZnO |

| Compound/Solid Intermediate | Temperature Range, [°C] | Mass Loss. [%] | Solid Intermediate/Final Residue | |

|---|---|---|---|---|

| Found | Calculated | |||

| Co(L2)2(Im)⸱H2O | 40–120 | 5.0 | 6.19 | Co(L2)2(Im) |

| Co(L2)2(Im) | 140–330 | 23.0 | 23.38 | Co(L2)2 |

| Co(L2)2 | 330–440 | 42.0 | 41.95 | Co2O3 |

| Compound/Solid Intermediate | Temperature Range, [°C] | Mass Loss. [%] | Solid Intermediate/Final Residue | |

|---|---|---|---|---|

| Found | Calculated | |||

| Ni(L2)2(Im)1.5⸱H2O | 60–140 | 5.0 | 5.54 | Ni(L2)2(Im)1.5 |

| Ni(L2)2(Im)1.5 | 140–370 | 42.5 | 42.67 | Ni(L2)1.5 |

| Ni(L2)1.5 | 370–560 | 26.5 | 26.34 | Ni2O3 |

| Compound/Solid Intermediate | Temperature Range, [°C] | Mass Loss. [%] | Solid Intermediate/Final Residue | |

|---|---|---|---|---|

| Found | Calculated | |||

| Cu(L2)(Imd) | 160–340 | 49.5 | 50.86 | Cu(L2)0.5 |

| Cu(L2)0.5 | 340–540 | 9.0 | 10.27 | CuO |

| Compound/Solid Intermediate | Temperature Range, [°C] | Mass Loss. [%] | Solid Intermediate/Final Residue | |

|---|---|---|---|---|

| Found | Calculated | |||

| Zn(L2)2(Im)⸱H2O | 80–130 | 7.0 | 6.05 | Zn(L2)2(Im) |

| Zn(L2)2(Im) | 130–320 | 23.0 | 22.88 | Zn(L2)2 |

| Zn(L2)2 | 320–610 | 43.5 | 43.73 | ZnO |

| Compound | Styrene Conversion Degree [%] |

|---|---|

| Co(L1)2(Im)⸱H2O | 12 |

| Ni(L1)2(Im)1.5⸱H2O | 8 |

| Cu(L1)2(Im)0.5⸱0.5H2O | 14 |

| Zn(L1)2(Im)⸱H2O | 9 |

| Co(Ac)2(Im)⸱H2O | 25 |

| Ni(Ac)2(Im)1.5⸱2H2O | 12 |

| Cu2(Ac)4(Im) | 21 |

| Zn(Ac)2(Im)⸱H2O | 19 |

| Co(L2)2(Im)⸱H2O | 14 |

| Ni(L2)2(Im)1.5⸱H2O | 17 |

| Cu(L2)(Imd) | 24 |

| Zn(L2)2(Im)⸱H2O | 24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogalewicz, B.; Maniecki, T.; Ciesielski, R.; Czylkowska, A. Synthesis, Spectroscopic, Thermal, and Catalytic Properties of Eight New Complexes of Metal(II) Formates or Propionates with Imidazole; Relationship between the Carbon Chain Length and Catalytic Activity. Materials 2022, 15, 142. https://doi.org/10.3390/ma15010142

Rogalewicz B, Maniecki T, Ciesielski R, Czylkowska A. Synthesis, Spectroscopic, Thermal, and Catalytic Properties of Eight New Complexes of Metal(II) Formates or Propionates with Imidazole; Relationship between the Carbon Chain Length and Catalytic Activity. Materials. 2022; 15(1):142. https://doi.org/10.3390/ma15010142

Chicago/Turabian StyleRogalewicz, Bartłomiej, Tomasz Maniecki, Radosław Ciesielski, and Agnieszka Czylkowska. 2022. "Synthesis, Spectroscopic, Thermal, and Catalytic Properties of Eight New Complexes of Metal(II) Formates or Propionates with Imidazole; Relationship between the Carbon Chain Length and Catalytic Activity" Materials 15, no. 1: 142. https://doi.org/10.3390/ma15010142