Characteristics of Particles Emitted from Waste Fires—A Construction Materials Case Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. General Description

2.2. Experimental Setup of the Impactor

2.3. Material Fire Experiments

2.4. Size Distribution of Particulates Emitted from Fires

2.4.1. Volume Size Distribution

2.4.2. Mass Size Distribution and Density

2.4.3. Goodness of Fit and Uncertainties

3. Results and Discussion

3.1. Raw ELPI Result

3.2. Parametrization of the Particulates from Fire Experiments

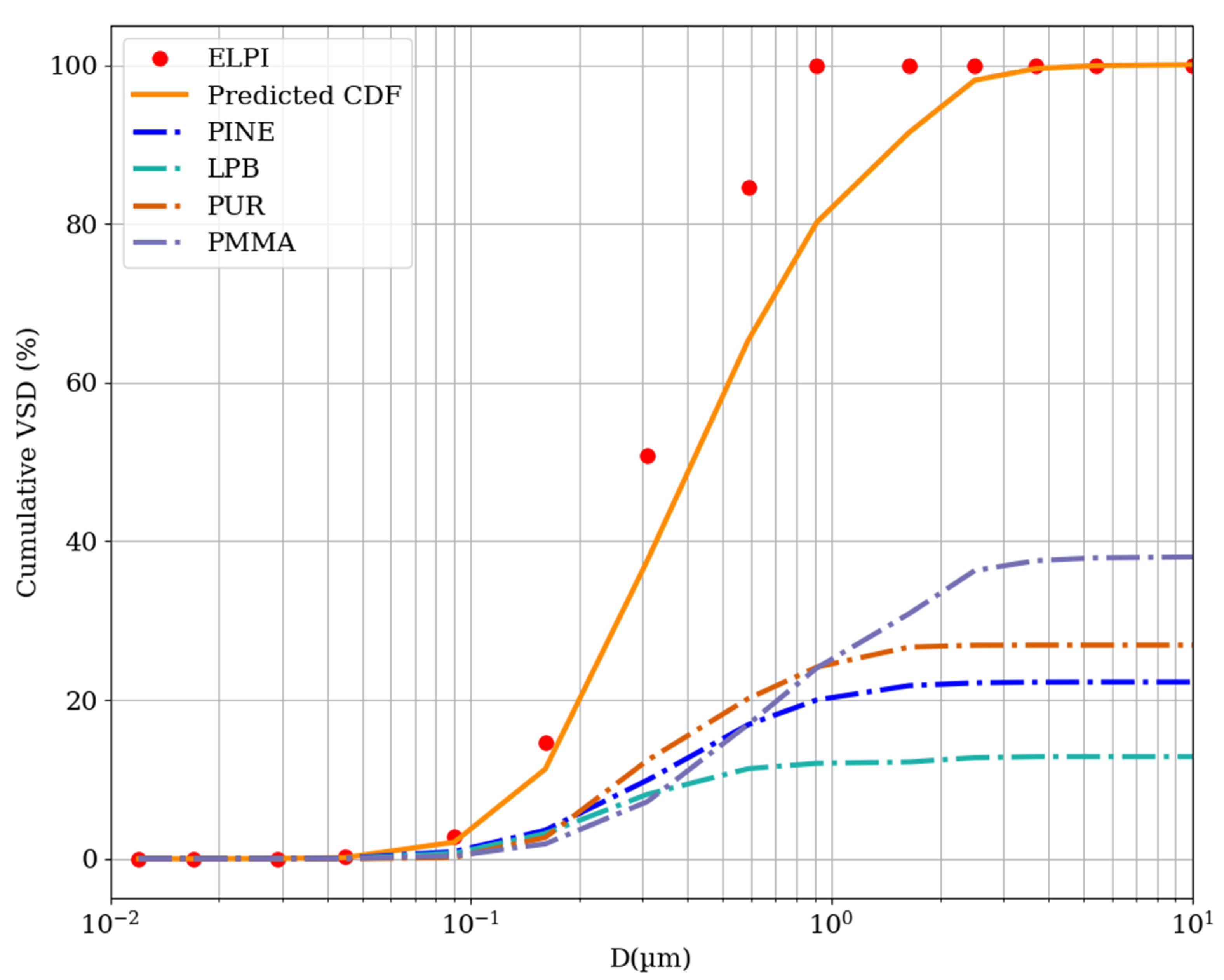

Predicting VSD of Particles

4. Conclusions

- The mathematical limitations do not allow for the determination of the absolute density of particles based on comparing VSD and MSD. However, it has been proven that the densities of the particles can be expressed as a function of the density of the first type of particles if at least two types of particles can be distinguished (i.e., the fit contains at least two summands). The use of VSD and MSD in this work shows that it is possible to provide more precise results by violating the approach in which a constant density is assumed for all particulates.

- The relative density obtained for one population of particles, from the fire of LPB, is questionable, which is mainly due to the resolving power of the distribution measured by the impactor.

- The results show that the use of the cascade impactor with only 15 stages is adequate, even for the determination of six parameter distributions; however, it should be treated as the edge of applicability if more than 90% of the volume of particles is in the range of 100 nm to 1 µm.

- The prediction of the VSD from the burning of the mixture of materials based on the VSD of the raw material led to a distribution shift toward larger Stokes diameters than that measured with the impactor, which indicates a more complete thermal decomposition during the MIX fire because LPB decomposes at higher temperatures than raw wood. Another possible cause is the interference between the decomposition products of different materials.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaligot, R.; Chenal, J. Decoupling municipal solid waste generation and economic growth in the canton of Vaud, Switzerland. Resour. Conserv. Recycl. 2018, 130, 260–266. [Google Scholar] [CrossRef]

- Jambeck, J.; Hardesty, B.D.; Brooks, A.L.; Friend, T.; Teleki, K.; Fabres, J.; Beaudoin, Y.; Bamba, A.; Francis, J.; Ribbink, A.J.; et al. Challenges and emerging solutions to the land-based plastic waste issue in Africa. Mar. Policy 2018, 96, 256–263. [Google Scholar] [CrossRef]

- Borrelle, S.B.; Ringma, J.; Law, K.L.; Monnahan, C.C.; Lebreton, L.; McGivern, A.; Murphy, E.; Jambeck, J.; Leonard, G.H.; Hilleary, M.A.; et al. Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science 2020, 369, 1515–1518. [Google Scholar] [CrossRef]

- Powęzka, A.; Szulej, J.; Ogrodnik, P. Reuse of Heat Resistant Glass Cullet in Cement Composites Subjected to Thermal Load. Materials 2020, 13, 4434. [Google Scholar] [CrossRef] [PubMed]

- Lee, J. Recycled plastic is now more expensive than PET. That’s not just an economic problem. The Print, 7 October 2019; 5. [Google Scholar]

- Ambrose, J. War on plastic waste faces setback as cost of recycled material soars. Guardian, 13 October 2019; 2. [Google Scholar]

- EUROSTAT. Municipal Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics#Municipal_waste_treatment (accessed on 21 August 2021).

- Agbeshie, A.A.; Adjei, R.; Anokye, J.; Banunle, A. Municipal waste dumpsite: Impact on soil properties and heavy metal concentrations, Sunyani, Ghana. Sci. Afr. 2020, 8, e00390. [Google Scholar] [CrossRef]

- Das, B.; Bhave, P.V.; Sapkota, A.; Byanju, R.M. Estimating emissions from open burning of municipal solid waste in municipalities of Nepal. Waste Manag. 2018, 79, 481–490. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, K.; Wu, W.; Tian, H.; Yi, P.; Zhi, G.; Fan, J.; Liu, S. Atmospheric emissions of typical toxic heavy metals from open burning of municipal solid waste in China. Atmos. Environ. 2017, 152, 6–15. [Google Scholar] [CrossRef]

- Cheng, K.; Hao, W.; Wang, Y.; Yi, P.; Zhang, J.; Ji, W. Understanding the emission pattern and source contribution of hazardous air pollutants from open burning of municipal solid waste in China. Environ. Pollut. 2020, 263, 114417. [Google Scholar] [CrossRef]

- Chaudhary, P.; Garg, S.; George, T.; Shabin, M.; Saha, S.; Subodh, S.; Sinha, B. Underreporting and open burning—The two largest challenges for sustainable waste management in India. Resour. Conserv. Recycl. 2021, 175, 105865. [Google Scholar] [CrossRef]

- Blakeman, J.S. A Retrospective Analysis of Open Burning Activity in Kentucky. Master’s Thesis, University of Kentucky, Lexington, KY, USA, 2017. [Google Scholar]

- Badyda, A.; Krawczyk, P.; Bihałowicz, J.S.; Bralewska, K.; Rogula-Kozłowska, W.; Majewski, G.; Oberbek, P.; Marciniak, A.; Rogulski, M. Are BBQs Significantly Polluting Air in Poland? A Simple Comparison of Barbecues vs. Domestic Stoves and Boilers Emissions. Energies 2020, 13, 6245. [Google Scholar] [CrossRef]

- Zhang, M.; Buekens, A.; Li, X. Open burning as a source of dioxins. Crit. Rev. Environ. Sci. Technol. 2017, 47, 543–620. [Google Scholar] [CrossRef]

- Chen, C.-M. The emission inventory of PCDD/PCDF in Taiwan. Chemosphere 2004, 54, 1413–1420. [Google Scholar] [CrossRef]

- Zhang, G.; Huang, X.; Liao, W.; Kang, S.; Ren, M.; Hai, J. Measurement of Dioxin Emissions from a Small-Scale Waste Incinerator in the Absence of Air Pollution Controls. Int. J. Environ. Res. Public Health 2019, 16, 1267. [Google Scholar] [CrossRef] [Green Version]

- Balthi, M.R. Evaluation of greenhouse gas emissions from solid waste management practices in state capitals of North Eastern Nigeria. J. Eng. Stud. Res. 2021, 26, 40–46. [Google Scholar] [CrossRef]

- Balcom, P.; Cabrera, J.M.; Carey, V.P. Extended exergy sustainability analysis comparing environmental impacts of disposal methods for waste plastic roof tiles in Uganda. Dev. Eng. 2021, 6, 100068. [Google Scholar] [CrossRef]

- Pansuk, J.; Junpen, A.; Garivait, S. Assessment of Air Pollution from Household Solid Waste Open Burning in Thailand. Sustainability 2018, 10, 2553. [Google Scholar] [CrossRef] [Green Version]

- US EPA. AP-42: Compilation of Air Pollutant Emission Factors; United States Enviromental Protection Agency: Washington, DC, USA, 1995.

- EEA. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2016; European Environment Agency: Copenhagen, Denmark, 2016.

- Akagi, S.K.; Yokelson, R.J.; Wiedinmyer, C.; Alvarado, M.J.; Reid, J.S.; Karl, T.; Crounse, J.D.; Wennberg, P.O. Emission factors for open and domestic biomass burning for use in atmospheric models. Atmos. Chem. Phys. 2011, 11, 4039–4072. [Google Scholar] [CrossRef] [Green Version]

- Lemieux, P.M.; Lutes, C.C.; Santoianni, D.A. Emissions of organic air toxics from open burning: A comprehensive review. Prog. Energy Combust. Sci. 2004, 30, 1–32. [Google Scholar] [CrossRef]

- Wu, D.; Li, Q.; Shang, X.; Liang, Y.; Ding, X.; Sun, H.; Li, S.; Wang, S.; Chen, Y.; Chen, J. Commodity plastic burning as a source of inhaled toxic aerosols. J. Hazard. Mater. 2021, 416, 125820. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Jo, S.; Woo, J.; Jeon, E.-C. Studies on characteristics of fine particulate matter emissions from agricultural residue combustion. Energy Environ. 2021, 32, 1361–1377. [Google Scholar] [CrossRef]

- Kim Oanh, N.T.; Ly, B.T.; Tipayarom, D.; Manandhar, B.R.; Prapat, P.; Simpson, C.D.; Sally Liu, L.-J. Characterization of particulate matter emission from open burning of rice straw. Atmos. Environ. 2011, 45, 493–502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, T.; Dai, Q.; Bi, X.; Wu, J.; Zhang, Y.; Feng, Y. Size distribution and chemical characteristics of particles from crop residue open burning in North China. J. Environ. Sci. 2021, 109, 66–76. [Google Scholar] [CrossRef] [PubMed]

- Oleniacz, R. Świadomość społeczna z zakresu niekontrolowanego spalania odpadów i problemu dioksyn. In Dioksyny w Przemyśle i Środowisku, Proceedings of the X Konferencja Naukowa, Kraków, Poland, 12–13 June 2008; Politechnika Krakowska, Laboratorium Analiz Śladowych/EmiPro/Hamilton Poland Ltd.: Kraków, Poland, 2008. [Google Scholar]

- Urząd Gminy w Choceniu Urząd Gminy w Choceniu Problem Spalania Śmieci w Paleniskach Domowych. Available online: https://chocen.pl/8-aktualnosci/4601-problem-spalania-smieci-w-paleniskach-domowych.html (accessed on 22 August 2021).

- Toborek, P. W Polsce odpady dzielą się na palne i niepalne. Gospodarka o obiegu zamkniętym? Nie za naszego życia. Portal Samorządowy, 22 May 2017; 2. [Google Scholar]

- Local Administrative Units (LAU)—NUTS—Nomenclature of Territorial Units for Statistics—Eurostat. Available online: https://ec.europa.eu/eurostat/web/nuts/local-administrative-units (accessed on 24 May 2021).

- Eriksson, L.; Gustavsson, L.; Hänninen, R.; Kallio, A.; Hurttala, H.; Pingoud, K.; Pohjola, J.; Sathre, R.; Svanaes, J.; Valsta, L. Climate Implications of Increased Wood Use in the Construction Sector—Towards an Integrated Modeling Framework. Eur. J. For. Res. 2009, 131, 131–144. [Google Scholar] [CrossRef]

- Brus, D.J.; Hengeveld, G.M.; Walvoort, D.J.J.; Goedhart, P.W.; Heidema, A.H.; Nabuurs, G.J.; Gunia, K. Statistical mapping of tree species over Europe. Eur. J. For. Res. 2012, 131, 145–157. [Google Scholar] [CrossRef]

- Dudek, T. Influence of selected features of forests on forest landscape aesthetic value—Example of se Poland. J. Environ. Eng. Landsc. Manag. 2018, 26, 275–284. [Google Scholar] [CrossRef] [Green Version]

- Krzosek, S.; Burawska-Kupniewska, I.; Mańkowski, P. The Influence of Scots Pine Log Type (Pinus sylvestris L.) on the Mechanical Properties of Lumber. Forests 2020, 11, 1257. [Google Scholar] [CrossRef]

- Fernandes, C.; Gaspar, M.J.; Pires, J.; Alves, A.; Simões, R.; Rodrigues, J.C.; Silva, M.E.; Carvalho, A.; Brito, J.E.; Lousada, J.L. Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal. IForest 2017, 10, 669–679. [Google Scholar] [CrossRef] [Green Version]

- Kodur, V.K.R.; Harmathy, T.Z. Properties of Building Materials. In SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 277–324. [Google Scholar]

- Alapieti, T.; Castagnoli, E.; Salo, L.; Mikkola, R.; Pasanen, P.; Salonen, H. The effects of paints and moisture content on the indoor air emissions from pinewood (Pinus sylvestris) boards. Indoor Air 2021, 31, 1563–1576. [Google Scholar] [CrossRef] [PubMed]

- Gottuk, D.T.; Lattimer, B.Y. Effect of Combustion Conditions on Species Production. In SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 486–528. [Google Scholar]

- Deng, C.; Liaw, S.B.; Wu, H. Characterization of Size-Segregated Soot from Pine Wood Pyrolysis in a Drop Tube Furnace at 1300 °C. Energy Fuels 2019, 33, 2293–2300. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Forest Products Annual Market Review 2019–2020; Food and Agriculture Organization: Rome, Italy, 2020. [Google Scholar]

- Moreno, A.I.; Font, R.; Conesa, J.A. Combustion of furniture wood waste and solid wood: Kinetic study and evolution of pollutants. Fuel 2017, 192, 169–177. [Google Scholar] [CrossRef] [Green Version]

- Babrauskas, V. Heat Release Rates. In SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 799–904. [Google Scholar]

- Hurley, M.J.; Gottuk, D.; Hall, J.R.; Harada, K.; Kuligowski, E.; Puchovsky, M.; Torero, J.; Watts, J.M.; Wieczorek, C. (Eds.) SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; ISBN 978-1-4939-2564-3. [Google Scholar]

- McKenna, S.T.; Hull, T.R. The fire toxicity of polyurethane foams. Fire Sci. Rev. 2016, 5, 3. [Google Scholar] [CrossRef] [Green Version]

- Dahlin, J.; Spanne, M.; Dalene, M.; Karlsson, D.; Skarping, G. Size-separated sampling and analysis of isocyanates in workplace aerosols—Part II: Aging of aerosols from thermal degradation of polyurethane. Ann. Occup. Hyg. 2008, 52, 375–383. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, R.; Zeng, F.; Chen, Z.; Wang, J.-S.; Huang, C.-M.; Wu, Z. The Comparison of Predicting Storm-Time Ionospheric TEC by Three Methods: ARIMA, LSTM, and Seq2Seq. Atmosphere 2020, 11, 316. [Google Scholar] [CrossRef] [Green Version]

- Zeng, W.R.; Li, S.F.; Chow, W.K. Preliminary Studies on Burning Behavior of Polymethylmethacrylate (PMMA). J. Fire Sci. 2002, 20, 297–317. [Google Scholar] [CrossRef]

- Zeng, W.R.; Li, S.F.; Chow, W.K. Review on Chemical Reactions of Burning Poly (methyl methacrylate) PMMA. J. Fire Sci. 2002, 20, 401–433. [Google Scholar] [CrossRef]

- An, W.; Hu, K.; Wang, T.; Peng, L.; Li, S.; Hu, X. Effects of Overlap Length on Flammability and Fire Hazard of Vertical Polymethyl Methacrylate (PMMA) Plate Array. Polymers 2020, 12, 2826. [Google Scholar] [CrossRef]

- Khoo, B.; Skitt, J. The 1973 Summerland disaster-lessons to the building industry from the process industry. Loss Prev. Bull. 2019, 269, 3. [Google Scholar]

- Rogula-Kozłowska, W.; Majewski, G.; Czechowski, P.O. The size distribution and origin of elements bound to ambient particles: A case study of a Polish urban area. Environ. Monit. Assess. 2015, 187, 240. [Google Scholar] [CrossRef] [Green Version]

- Rivas, I.; Beddows, D.C.S.; Amato, F.; Green, D.C.; Järvi, L.; Hueglin, C.; Reche, C.; Timonen, H.; Fuller, G.W.; Niemi, J.V.; et al. Source apportionment of particle number size distribution in urban background and traffic stations in four European cities. Environ. Int. 2020, 135, 105345. [Google Scholar] [CrossRef]

- Ramachandran, G.; Werner, M.A.; Vincent, J.H. Assessment of particle size distributions in workers’ aerosol exposures. Analyst 1996, 121, 1225. [Google Scholar] [CrossRef]

- Bralewska, K.; Rogula-Kozłowska, W.; Bralewski, A. Size-Segregated Particulate Matter in a Selected Sports Facility in Poland. Sustainability 2019, 11, 6911. [Google Scholar] [CrossRef] [Green Version]

- Nielsen, E.; Dybdahl, M.; Larsen, P.B. Health effects assessment of exposure to particles from wood smoke. Toxicol. Lett. 2007, 172, S120. [Google Scholar] [CrossRef] [Green Version]

- Dekati Ltd. Dekati ELPI+ User Manual Ver. 1.55; Dekati Ltd.: Kangasala, Finland, 2018. [Google Scholar]

- Kuskowska, K.; Rogula-Kozłowska, W.; Widziewicz, K. A preliminary study of the concentrations and mass size distributions of particulate matter in indoor sports facilities before and during athlete training. Environ. Prot. Eng. 2019, 45, 103–112. [Google Scholar] [CrossRef]

- van Rossum, G.; Drake, F.L. Python 3 Reference Manual; CreateSpace: Scotts Valley, CA, USA, 2009; ISBN 1441412697. [Google Scholar]

- Kolmogorov, A.N. Uber das logarithmisch normale Verteilungsgesetz der Teilchen bei Zerstuckelung. Dokl. Akad. Nauk SSSR-C. R. Acad. Sci. URSS Seriya A 1941, 31, 99–101. [Google Scholar]

- Hinds, W.C. Aerosol Technology: Properties, Behaviour, and Measurement of Airborne Particles; John Wiley & Sons: Hoboken, NJ, USA, 1982. [Google Scholar]

- Björck, Å. Least squares methods. In Handbook of Numerical Analysis; North-Holland Publishing Company: Amsterdam, The Netherlands, 1990; pp. 465–652. [Google Scholar]

- Newville, M.; Otten, R.; Nelson, A.; Ingargiola, A.; Stensitzki, T.; Allan, D.; Fox, A.; Carter, F.; Michał; Pustakhod, D.; et al. Lmfit/lmfit-py, version 1.0.2; CERN: Geneva, Switzerland, 2021. [Google Scholar]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental algorithms for scientific computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef] [Green Version]

- Hase, T.; Hughes, I. Measurements and Their Uncertainties; Oxford University Press: Oxford, UK, 2010. [Google Scholar]

- Whitby, K.T. The Physical Characteristics of Sulfur Aerosols. In Sulfur in the Atmosphere; Elsevier: Amsterdam, The Netherlands, 1978; pp. 135–159. [Google Scholar]

- Cleary, T. Particle Size Distributions from Smokes and Cooking Aerosols Sampled from Room Fire Experiments. In Proceedings of the Suppression, Detection, and Signaling Research and Aplication Conference (SUPDET 2017)/16th International Conference on Fire Detection (AUBE 2017), College Park, MD, USA, 12–14 September 2017; National Fire Protection Association: Quincy, MA, USA, 2017. [Google Scholar]

- Motzkus, C.; Chivas-Joly, C.; Guillaume, E.; Ducourtieux, S.; Saragoza, L.; Lesenechal, D.; Macé, T.; Lopez-Cuesta, J.-M.; Longuet, C. Aerosols emitted by the combustion of polymers containing nanoparticles. J. Nanoparticle Res. 2012, 14, 687. [Google Scholar] [CrossRef]

- Kumar, M.; Chung, J.S.; Hur, S.H. Controlled atom transfer radical polymerization of MMA onto the surface of high-density functionalized graphene oxide. Nanoscale Res. Lett. 2014, 9, 345. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, X.; Tan, S.; Zhang, X.; Huang, Z.; Jiang, D. Low-temperature sintering of SiC reticulated porous ceramics with MgO–Al2O3–SiO2 additives as sintering aids. J. Mater. Sci. 2007, 42, 4960–4966. [Google Scholar] [CrossRef]

| Parameter | Pinewood | LPB | PUR | PMMA | MIX |

|---|---|---|---|---|---|

| C (cm−3) | 3.53 × 106 | 2.03 × 106 | 4.25 × 106 | 5.97 × 106 | 6.54 × 106 |

| NMD (µm) | 0.058 | 0.045 | 0.077 | 0.109 | 0.115 |

| VMD (µm) | 0.359 | 0.277 | 0.365 | 0.666 | 0.426 |

| Material | Parameter | Fit 1 | Fit 2 |

|---|---|---|---|

| PINE | a (%) | 99.6 ± 0.7 | |

| Dm (µm) | 0.344 ± 0.008 | ||

| GSD | 2.15 ± 0.06 | ||

| LPB | a (%) | 94.8 ± 0.6 | 5.2 ± 0.8 |

| Dm (µm) | 0.238 ± 0.003 | 2.38 1 | |

| GSD | 1.81 ± 0.03 | 1.05 1 | |

| b (%) | 73.6 ± 3.4 | 27.0 ± 4.0 | |

| PUR | a (%) | 68 ± 13 | 32 ± 13 |

| Dm (µm) | 0.26 ± 0.03 | 0.75 ± 0.15 | |

| GSD | 1.55 ± 0.08 | 1.5 ± 0.2 | |

| b (%) | 68.9 ± 9.5 | 30 ± 10 | |

| PMMA | a (%) | 91.8 ± 2.6 | 8.6 ± 2.5 |

| Dm (µm) | 0.60 ± 0.03 | 2.45 1 | |

| GSD | 2.27 ± 0.09 | 1.05 1 | |

| b (%) | 88.8 ± 1.6 | 9.5 ± 2.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bihałowicz, J.S.; Rogula-Kozłowska, W.; Krasuski, A.; Majder-Łopatka, M.; Walczak, A.; Fliszkiewicz, M.; Rogula-Kopiec, P.; Mach, T. Characteristics of Particles Emitted from Waste Fires—A Construction Materials Case Study. Materials 2022, 15, 152. https://doi.org/10.3390/ma15010152

Bihałowicz JS, Rogula-Kozłowska W, Krasuski A, Majder-Łopatka M, Walczak A, Fliszkiewicz M, Rogula-Kopiec P, Mach T. Characteristics of Particles Emitted from Waste Fires—A Construction Materials Case Study. Materials. 2022; 15(1):152. https://doi.org/10.3390/ma15010152

Chicago/Turabian StyleBihałowicz, Jan Stefan, Wioletta Rogula-Kozłowska, Adam Krasuski, Małgorzata Majder-Łopatka, Agata Walczak, Mateusz Fliszkiewicz, Patrycja Rogula-Kopiec, and Tomasz Mach. 2022. "Characteristics of Particles Emitted from Waste Fires—A Construction Materials Case Study" Materials 15, no. 1: 152. https://doi.org/10.3390/ma15010152