Shoulder Damage Model and Its Application for Single Point Diamond Machining of ZnSe Crystal

Abstract

:1. Introduction

2. Shoulder Damage Model

- (i)

- The tool wear effect is ignored, and its vibration amplitude is stable at all speeds;

- (ii)

- The movement error of the workpiece spindle is ignored;

- (iii)

- The deformations of the tool and the workpiece are not considered.

3. Experimental Details

4. Results and Discussions

4.1. Material Properties of ZnSe

4.2. Critical UCT of ZnSe

4.3. Shoulder Damage of ZnSe

4.4. Verification of Shoulder Damage Model

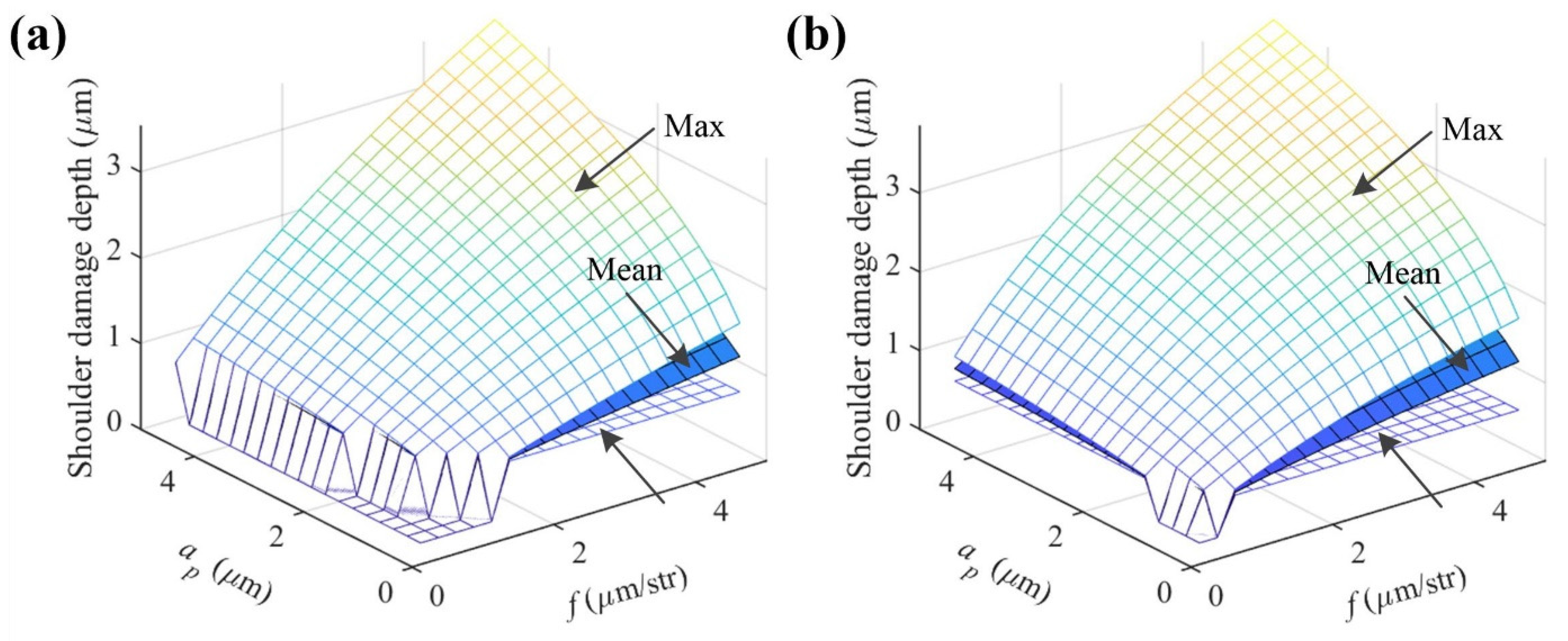

4.5. Application of Shoulder Damage Model

5. Conclusions

- (1)

- The shoulder damage depth has a positive correlation with the instantaneous undeformed chip thickness, which increases with the feed or cutting depth. The effect of the feed on the shoulder damage depth at a high cutting depth is larger than that at a low one. Moreover, the interaction effect is especially obvious when the feed is small.

- (2)

- The shoulder damage depth and the SSD depth bound of a cutting surface can be evaluated effectively. The shoulder damage model has an average relative error of less than 7%. The upper bound of the SSD depth generally increases with the feed or cutting depth.

- (3)

- A smooth ZnSe surface with roughness Sa = 1.0 nm is machined by SPDT.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, Z.Q.; Wang, S.J.; Chen, X.D.; To, S.; Yin, Z.Q.; Liu, J.H. Modeling and prediction of surface topography with three tool-work vibration components in single-point diamond turning. Int. J. Adv. Des. Manuf. Technol. 2018, 98, 1627–1639. [Google Scholar]

- Abdulkadir, L.N.; Abou-El-Hossein, K.; Jumare, A.I.; Odedeyi, P.B.; Liman, M.M.; Olaniyan, T.A. Ultra-precision diamond turning of optical silicon-a review. Int. J. Adv. Des. Manuf. Technol. 2018, 96, 173–208. [Google Scholar] [CrossRef]

- Jumare, A.I.; Abou-El-Hossein, K.; Abdulkadir, L. Review of ultra-high precision diamond turning of silicon for infrared optics. PONTE Int. Sci. Res. J. 2017, 73, 58–123. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Arif, M.; Liu, K.; Kumar, A.S.; Rahman, M. A model to predict the critical undeformed chip thickness in vibration-assisted machining of brittle materials. Int. J. Mach. Tool Manufact. 2013, 69, 57–66. [Google Scholar] [CrossRef]

- Zong, W.J.; Cao, Z.M.; He, C.L.; Xue, C.X. Theoretical modelling and FE simulation on the oblique diamond turning of ZnS crystal. Int. J. Mach. Tool Manufact. 2016, 100, 55–71. [Google Scholar] [CrossRef]

- Wang, S.F.; An, C.H.; Zhang, F.H.; Wang, J.; Lei, X.Y.; Zhang, J.F. An experimental and theoretical investigation on the brittle ductile transition and cutting force anisotropy in cutting KDP crystal. Int. J. Mach. Tool Manufact. 2016, 106, 98–108. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, H.J.; Zong, W.J. Modeling and simulation on the effect of tool rake angle in diamond turning of KDP crystal. J. Mater. Process Technol. 2019, 273, 116259. [Google Scholar] [CrossRef]

- Nakamura, M.; Sumomogi, T.; Endo, T. Evaluation of surface and subsurface cracks on nano-scale machined brittle materials by scanning force microscope and scanning laser microscope. Surf. Coat. Tech. 2003, 169–170, 743–747. [Google Scholar] [CrossRef]

- Yan, J.W.; Asami, T.; Harada, H.; Kuriyagawa, T. Fundamental investigation of subsurface damage in single crystalline silicon caused by diamond machining. Precis. Eng. 2009, 33, 378–386. [Google Scholar] [CrossRef]

- Kakinuma, Y.; Azami, S.; Tanabe, T. Evaluation of subsurface damage caused by ultra-precision turning in fabrication of CaF2 optical micro resonator. CIRP Ann. Manuf. Technol. 2015, 64, 117–120. [Google Scholar] [CrossRef]

- Tie, G.P.; Dai, Y.F.; Guan, C.L.; Chen, S.S.; Song, B. Research on subsurface defects of potassium dihydrogen phosphate crystals fabricated by single point diamond turning technique. Opt. Eng. 2013, 52, 033401. [Google Scholar] [CrossRef]

- Yan, J.W.; Asami, T.; Kuriyagawa, T. Nondestructive measurement of machining-induced amorphous layers in single-crystal silicon by laser micro-Raman spectroscopy. Precis. Eng. 2008, 32, 186–195. [Google Scholar] [CrossRef]

- Yan, J.W.; Asami, T.; Harada, H.; Kuriyagawa, T. Crystallographic effect on subsurface damage formation in silicon microcutting. CIRP Ann. Manuf. Technol. 2012, 61, 131–134. [Google Scholar] [CrossRef]

- Lai, M.; Zhang, X.D.; Fang, F.Z.; Bi, M.H. Effects of crystallographic orientation and negative rake angle on the brittle-ductile transition and subsurface deformation in machining of monocrystalline germanium. Precis. Eng. 2019, 56, 164–171. [Google Scholar] [CrossRef]

- Blackley, W.S.; Scattergood, R.O. Ductile-regime machining model for diamond turning of brittle materials. Precis. Eng. 1991, 13, 95–103. [Google Scholar] [CrossRef]

- Zong, W.J.; Cao, Z.M.; He, C.L.; Sun, T. Critical undeformed chip thickness of brittle materials in single point diamond turning. Int. J. Adv. Des. Manuf. Technol. 2015, 81, 975–984. [Google Scholar] [CrossRef]

- Yu, D.P.; Wong, Y.S.; Hong, G.S. A novel method for determination of the subsurface damage depth in diamond turning of brittle materials. Int. J. Mach. Tool Manufact. 2011, 51, 918–927. [Google Scholar] [CrossRef]

- Xiao, H.P.; Liang, R.G.; Spires, O.; Wang, H.R.; Wu, H.; Zhang, Y.Y. Evaluation of surface and subsurface damages for diamond turning of ZnSe crystal. Opt. Express 2019, 27, 28364–28382. [Google Scholar] [CrossRef] [Green Version]

- Venkatachalam, S.; Li, X.P.; Liang, S.Y. Predictive modeling of transition undeformed chip thickness in ductile-regime micro-machining of single crystal brittle materials. J. Mater. Process Technol. 2009, 209, 3306–3319. [Google Scholar] [CrossRef]

- Merchant, M.E. Mechanics of the metal cutting process. II. Plasticity conditions in orthogonal cutting. J. Appl. Phys. 1945, 16, 318–324. [Google Scholar] [CrossRef]

- Arif, M.; Zhang, X.Q.; Rahman, M.; Kumar, S. A predictive model of the critical undeformed chip thickness for ductile-brittle transition in nano-machining of brittle materials. Int. J. Mach. Tool Manufact. 2013, 64, 114–122. [Google Scholar] [CrossRef]

- Arcona, C.; Dow, T.A. An empirical tool force model for precision machining. ASME J. Manuf. Sci. Eng. 1998, 120, 700–707. [Google Scholar] [CrossRef]

- Gu, W.; Yao, Z.; Li, K. Evaluation of subsurface crack depth during scratch test for optical glass BK7. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2011, 225, 2767–2774. [Google Scholar] [CrossRef]

- Bifano, T.G.; Fawcett, S.C. Specific grinding energy as an in-process control variable for ductile-regime grinding. Precis. Eng. 1991, 13, 256–262. [Google Scholar] [CrossRef]

- Scheel, H.J.; Capper, P. Crystal Growth Technology: From Fundamentals and Simulation to Large-Scale Production; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2008; p. 67. [Google Scholar]

- Arif, M.; Rahman, M.; San, W.Y. Analytical model to determine the critical feed per edge for ductile-brittle transition in milling process of brittle materials. Int. J. Mach. Tool Manufact. 2011, 51, 170–181. [Google Scholar] [CrossRef]

- Xiao, H.P.; Chen, Z.; Wang, H.R.; Wang, J.H.; Zhu, N. Effect of grinding parameters on surface roughness and subsurface damage and their evaluation in fused silica. Opt. Express 2018, 26, 4638–4655. [Google Scholar] [CrossRef]

- Xiao, H.P.; Yin, S.X.; Wang, H.R.; Liu, Y.H.; Wu, H.; Liang, R.G.; Cao, H.J. Models of grinding-induced surface and subsurface damages in fused silica considering strain rate and micro shape/geometry of abrasive. Ceram. Int. 2021, 47, 24924–24941. [Google Scholar] [CrossRef]

- Chen, H.F.; Wang, J.M.; Dai, Y.F.; Zheng, Z.W. Research on critical chip thickness of KDP crystals by spirally grooving. J. Synth. Cryst. 2010, 40, 22–26. [Google Scholar]

- Li, L.; Cui, H.W.; Lian, Z.S.; Wang, Q.L. Modeling and optimization of soft start-up for hydroviscous drive applied to scraper conveyor. Math. Probl. Eng. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Huang, W.H.; Yan, J.W. Surface formation mechanism in ultraprecision diamond turning of coarse-grained polycrystalline ZnSe. Int. J. Mach. Tool Manufact. 2020, 153, 103554. [Google Scholar] [CrossRef]

| Tool No. | Nose Radius R (mm) | Nominal Rake Angle α (°) | Clearance Angle θf (°) | Cutting Edge Radius r (nm) |

|---|---|---|---|---|

| 1 | 1.004 | 0 | 12 | ≈25 |

| 2 | 0.201 | −25 | 12 | ≈20 |

| 3 | 0.098 | 0 | 15 | ≈20 |

| 4 | 0.052 | −25 | 12 | ≈15 |

| No. of Cutting Surface or Shoulder Region | Group A | Group B | ||

|---|---|---|---|---|

| f (μm/str) | ap (μm) | f (μm/str) | ap (μm) | |

| 1 | 1.1 | 0.5 | 3.1 | 2.4 |

| 2 | 2.4 | 1.1 | 1.1 | 1.8 |

| 3 | 5.0 | 1.8 | 2.4 | 0.5 |

| 4 | 1.8 | 2.4 | 0.5 | 3.7 |

| 5 | 0.5 | 3.1 | 4.4 | 1.1 |

| 6 | 4.4 | 3.7 | 1.8 | 5.0 |

| 7 | 3.7 | 4.4 | 3.7 | 4.4 |

| 8 | 3.1 | 5.0 | 5.0 | 3.1 |

| No. of Shoulder | Damage Depth under Group A (μm) | Damage Depth under Group B (μm) | ||||||

|---|---|---|---|---|---|---|---|---|

| Tool 1 | Tool 2 | Tool 3 | Tool 4 | Tool 1 | Tool 2 | Tool 3 | Tool 4 | |

| 1 | ≈0.00 | 0.47 | 0.49 | 0.57 | 1.41 | 1.34 | 1.66 | 1.46 |

| 2 | 0.96 | 0.88 | 0.93 | 0.94 | 0.63 | 0.80 | 0.68 | 0.86 |

| 3 | 1.47 | 1.52 | 1.92 | 2.03 | 0.83 | 0.82 | 0.87 | 0.84 |

| 4 | 1.04 | 1.16 | 0.96 | 1.07 | 0.52 | 0.64 | 0.54 | 0.66 |

| 5 | ≈0.00 | 0.61 | 0.54 | 0.54 | 1.30 | 1.50 | 1.47 | 1.58 |

| 6 | 2.01 | 1.86 | 2.34 | 2.36 | 1.07 | 1.16 | 1.27 | 1.29 |

| 7 | 1.99 | 2.14 | 2.25 | 2.00 | 1.63 | 1.83 | 1.97 | 1.97 |

| 8 | 1.51 | 2.01 | 2.11 | 2.22 | 2.06 | 2.00 | 2.45 | 2.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Xiao, H.; Kang, W.; Wu, H.; Liang, R. Shoulder Damage Model and Its Application for Single Point Diamond Machining of ZnSe Crystal. Materials 2022, 15, 233. https://doi.org/10.3390/ma15010233

Yin S, Xiao H, Kang W, Wu H, Liang R. Shoulder Damage Model and Its Application for Single Point Diamond Machining of ZnSe Crystal. Materials. 2022; 15(1):233. https://doi.org/10.3390/ma15010233

Chicago/Turabian StyleYin, Shenxin, Huapan Xiao, Wenjun Kang, Heng Wu, and Rongguang Liang. 2022. "Shoulder Damage Model and Its Application for Single Point Diamond Machining of ZnSe Crystal" Materials 15, no. 1: 233. https://doi.org/10.3390/ma15010233