Study for Performance Increase of a Extractor Device by Steel Replacement of AISI 304 Steel for AISI 420 Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

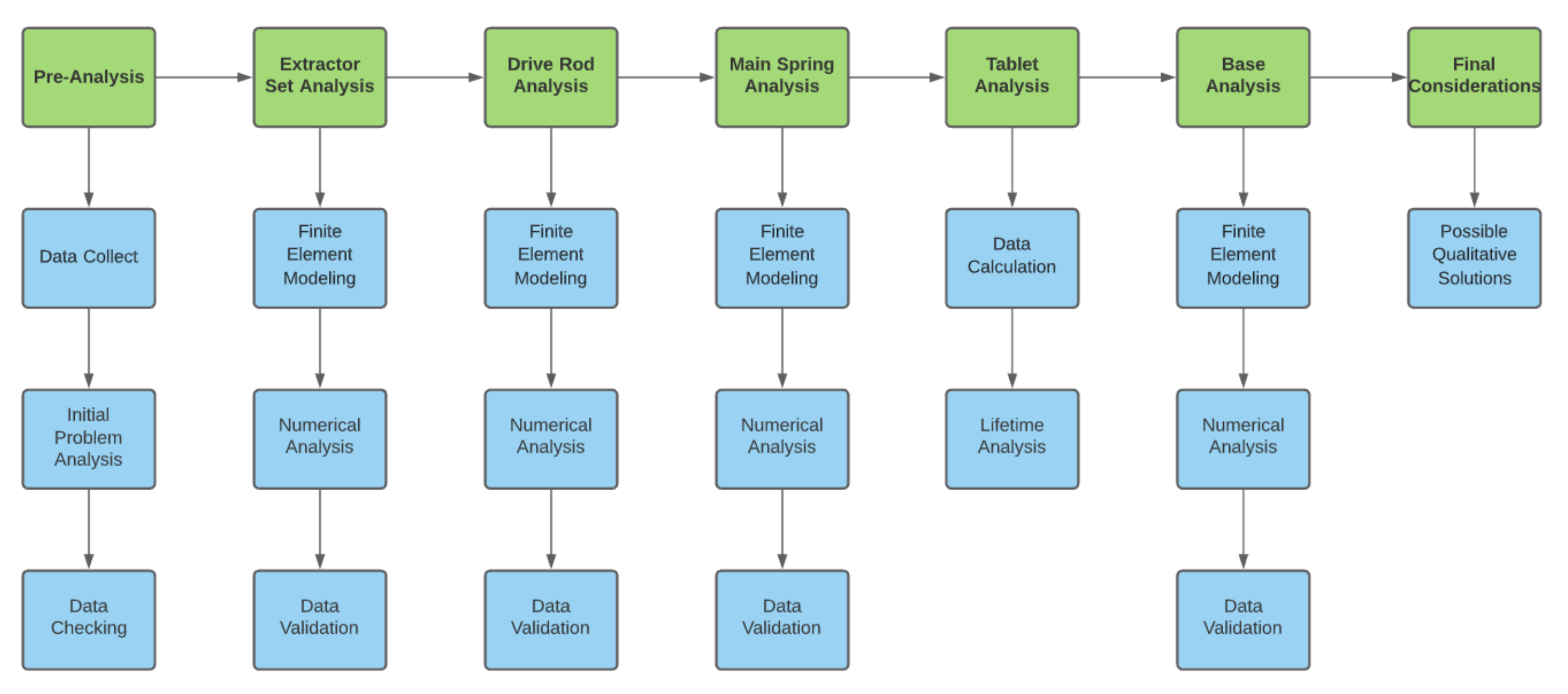

2.2. Methods

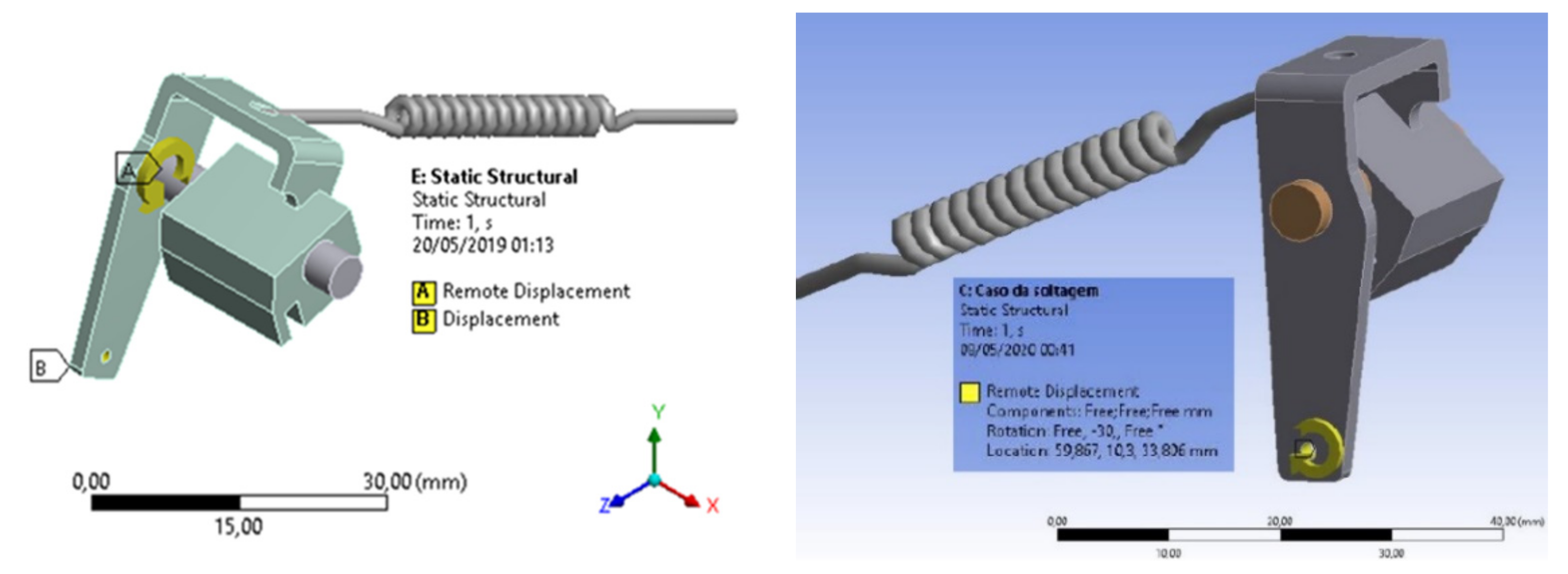

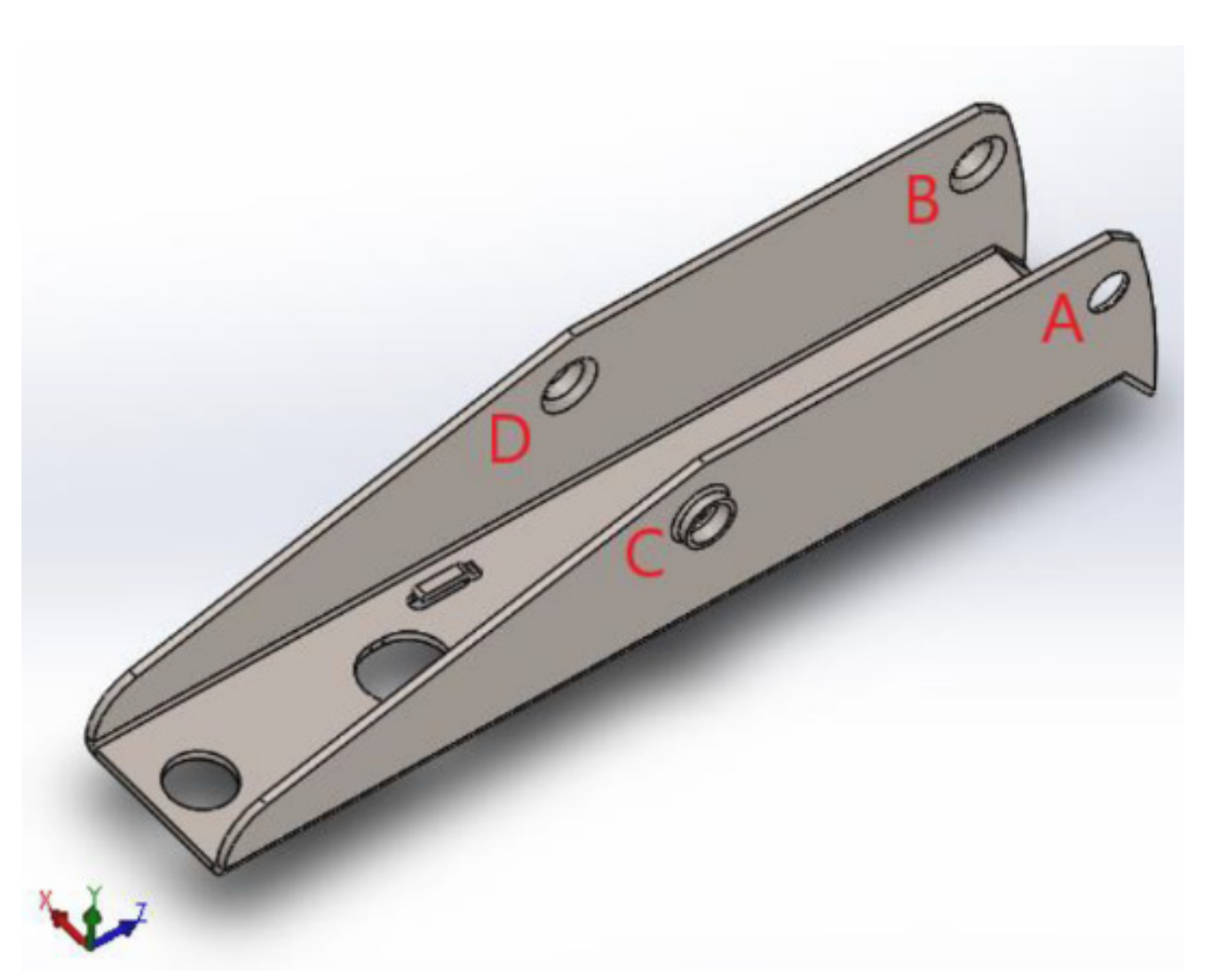

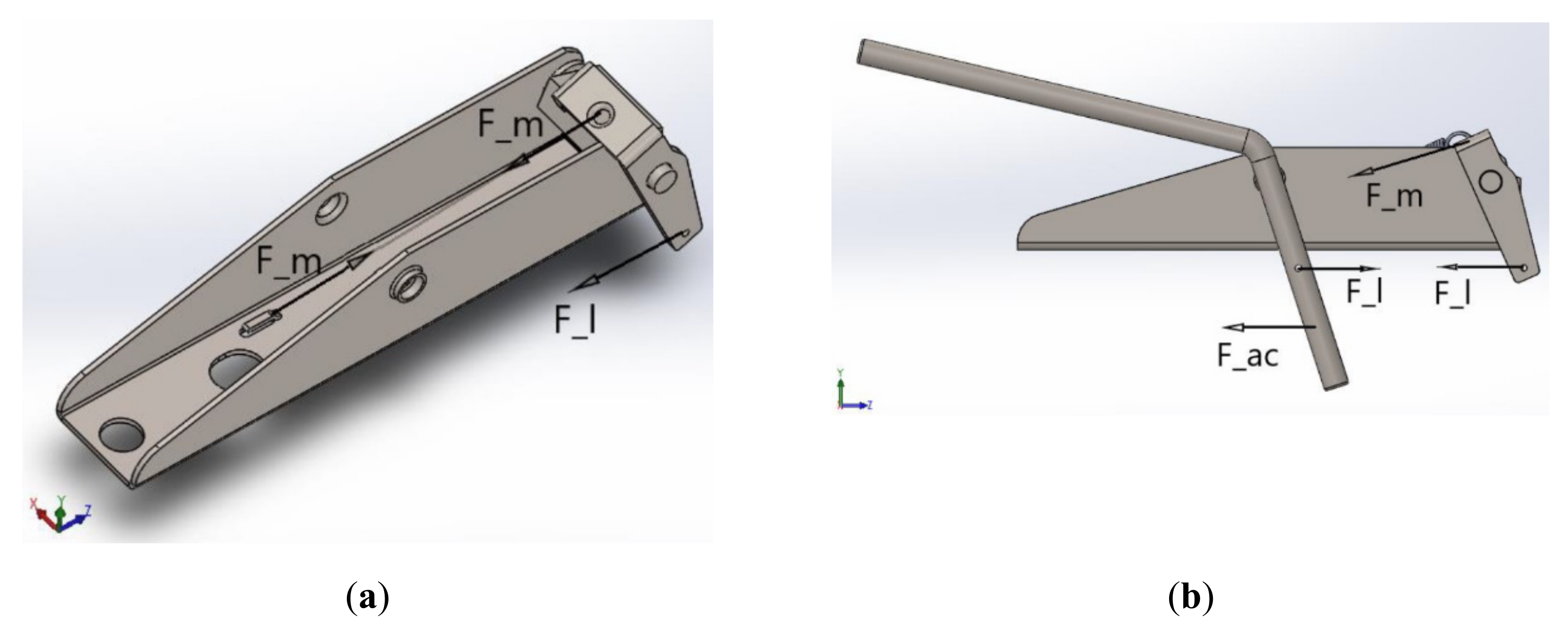

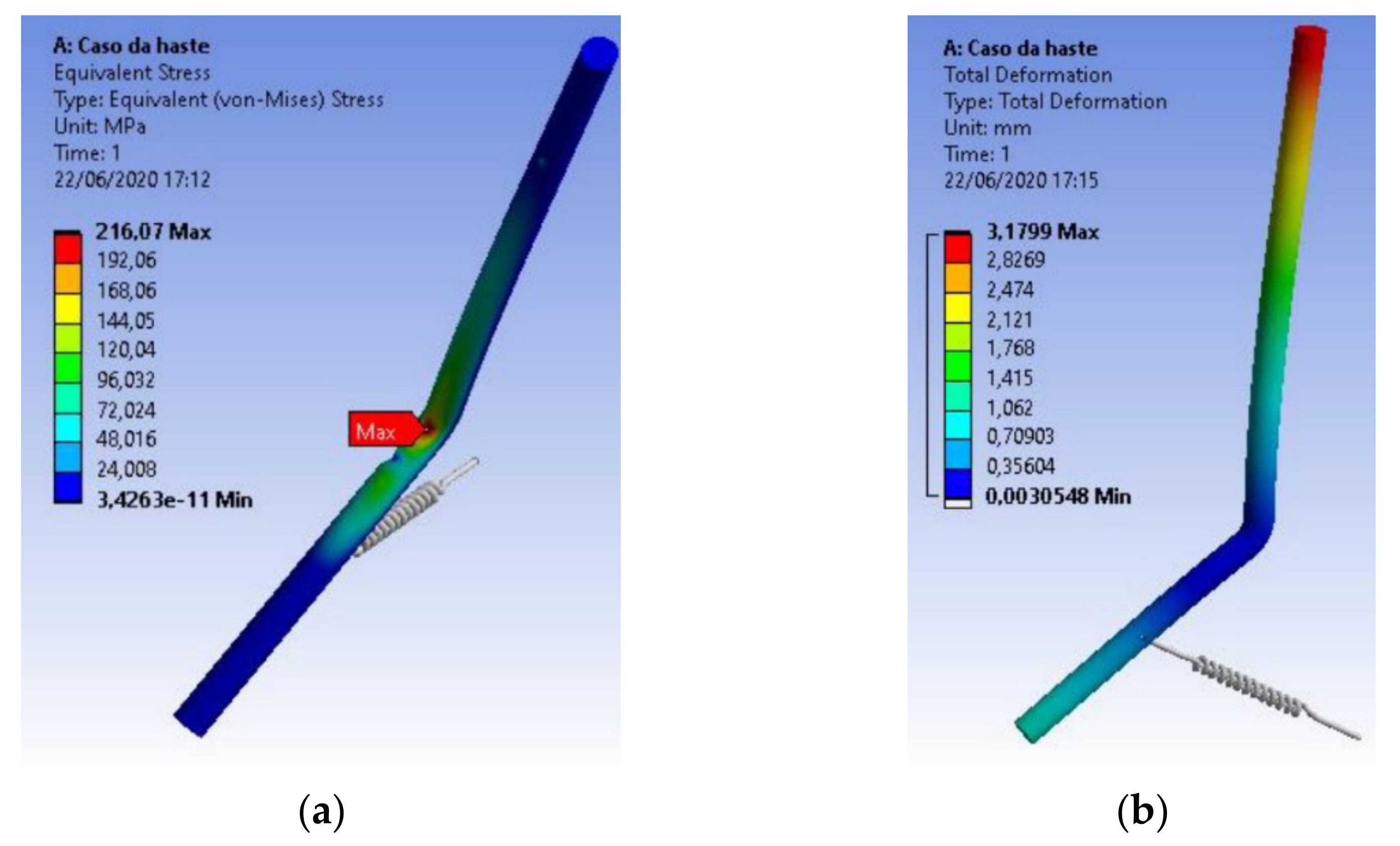

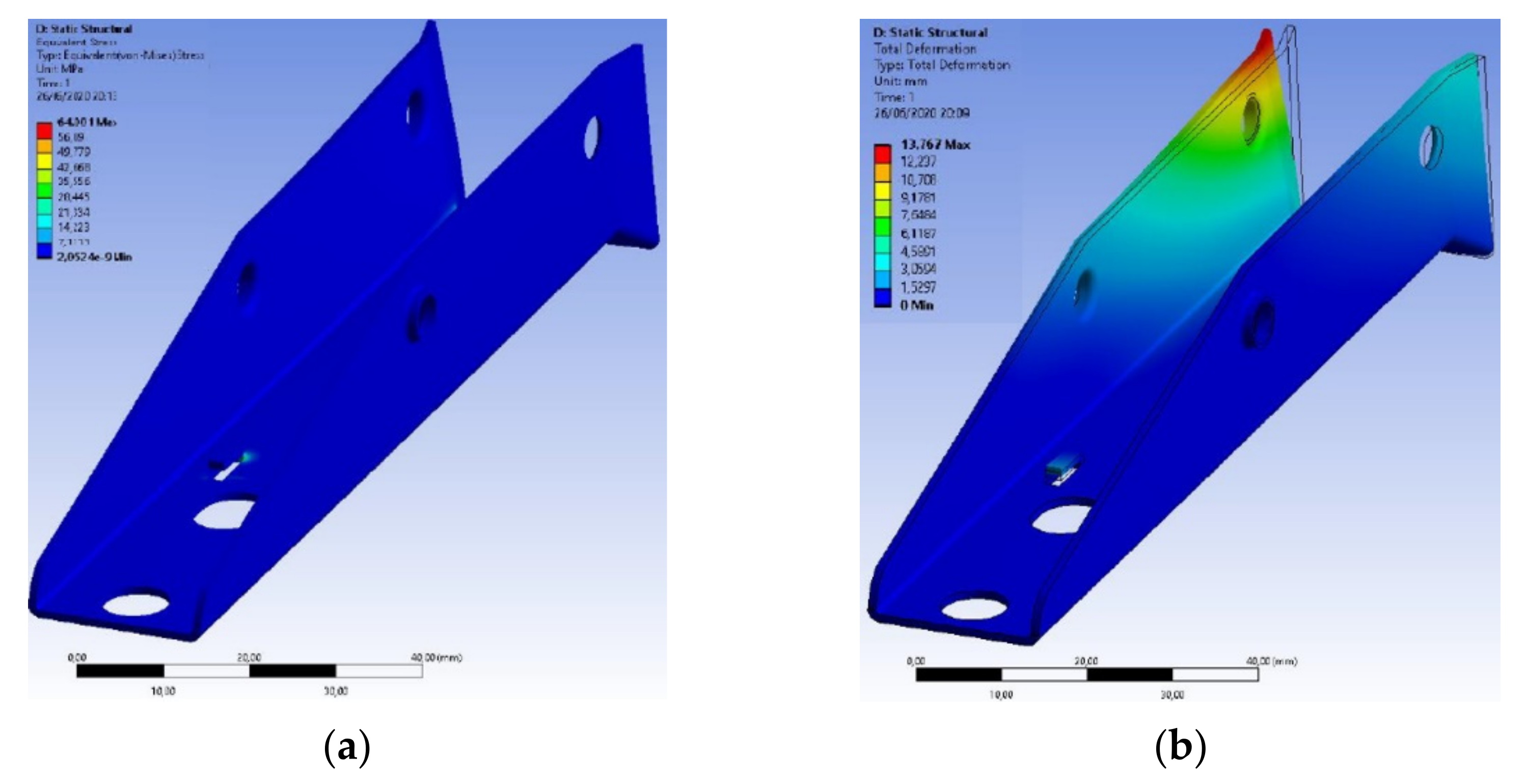

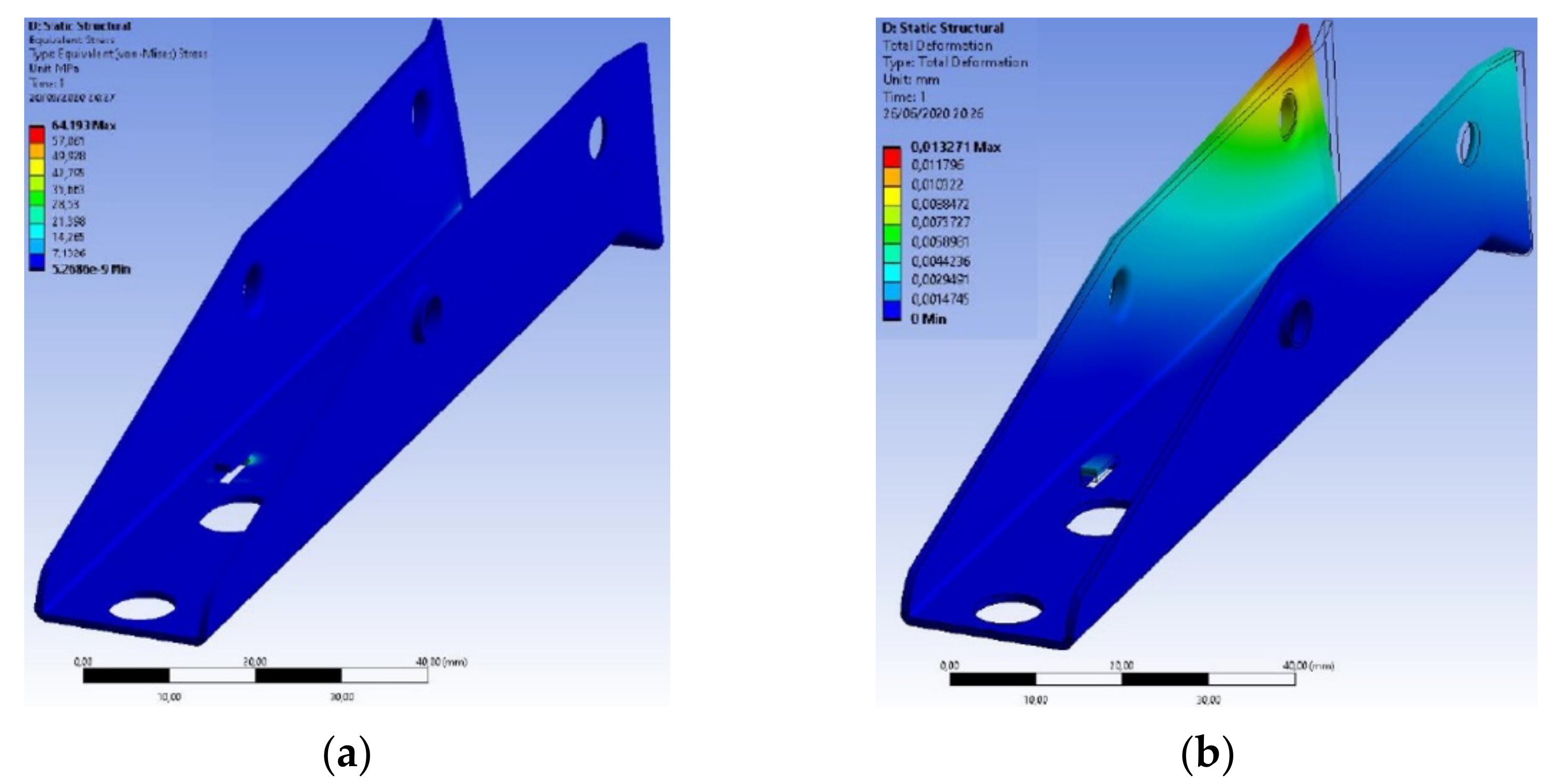

2.2.1. Structural Analysis of Components

- Part I: Forces acting on the extractor set and their influence on supports A and B;

- Part II: Forces acting on the drive rod and their influence on supports C and D.

2.2.2. Tensile Test

2.2.3. Hardness Analysis

Vickers Hardness Analysis

Hockwell Hardness Analysis

3. Results

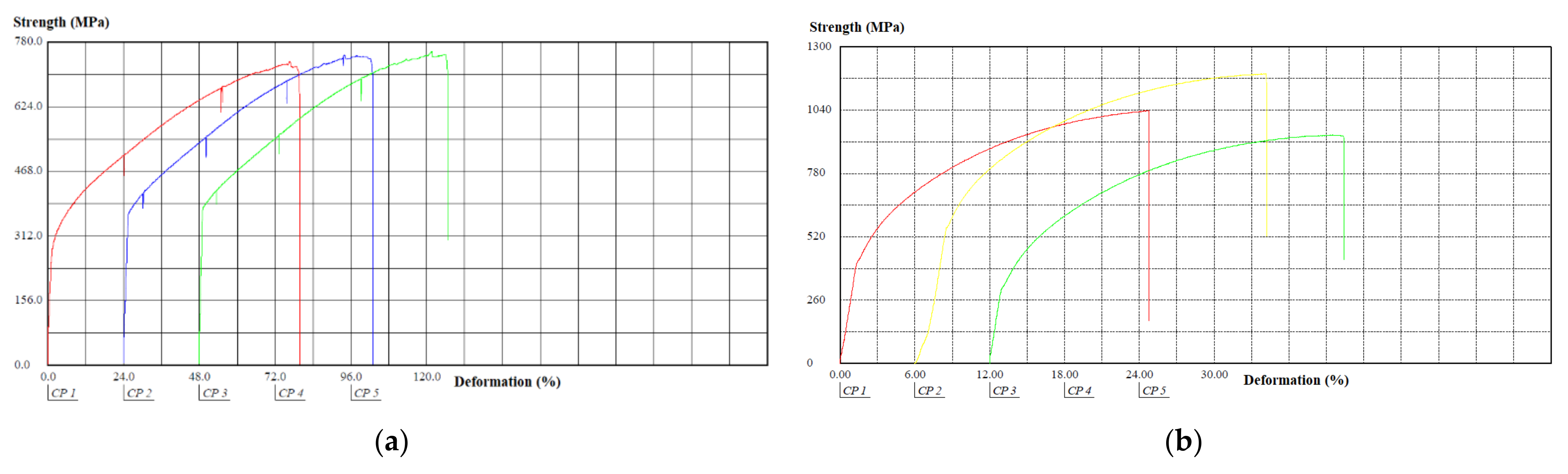

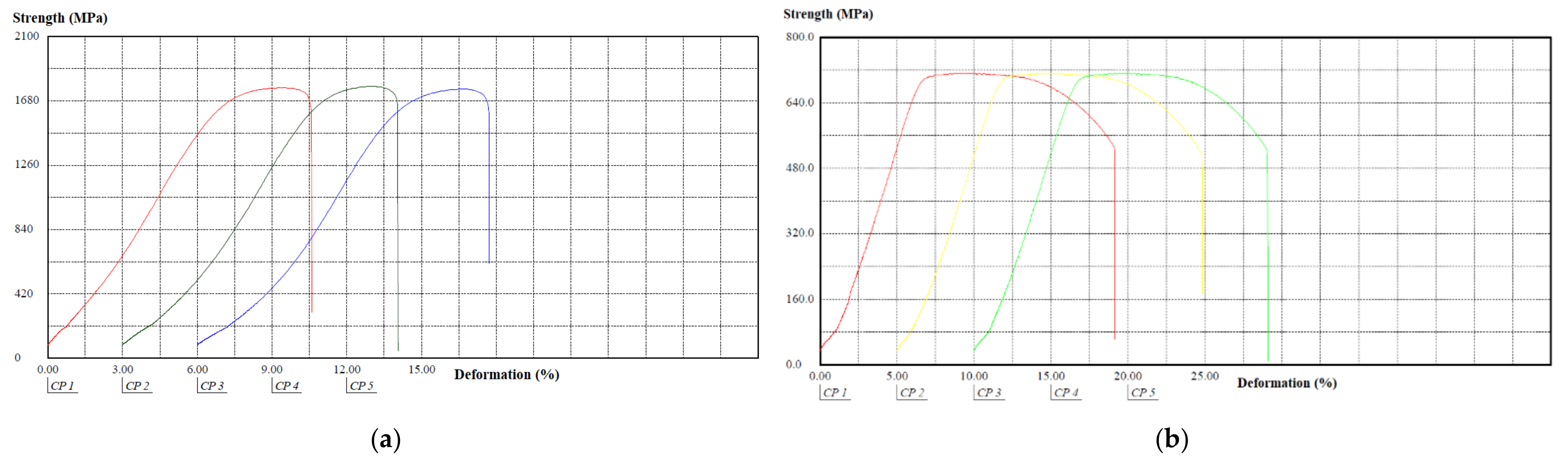

3.1. Component Tensile Tests

3.2. Component Hardness Analysis

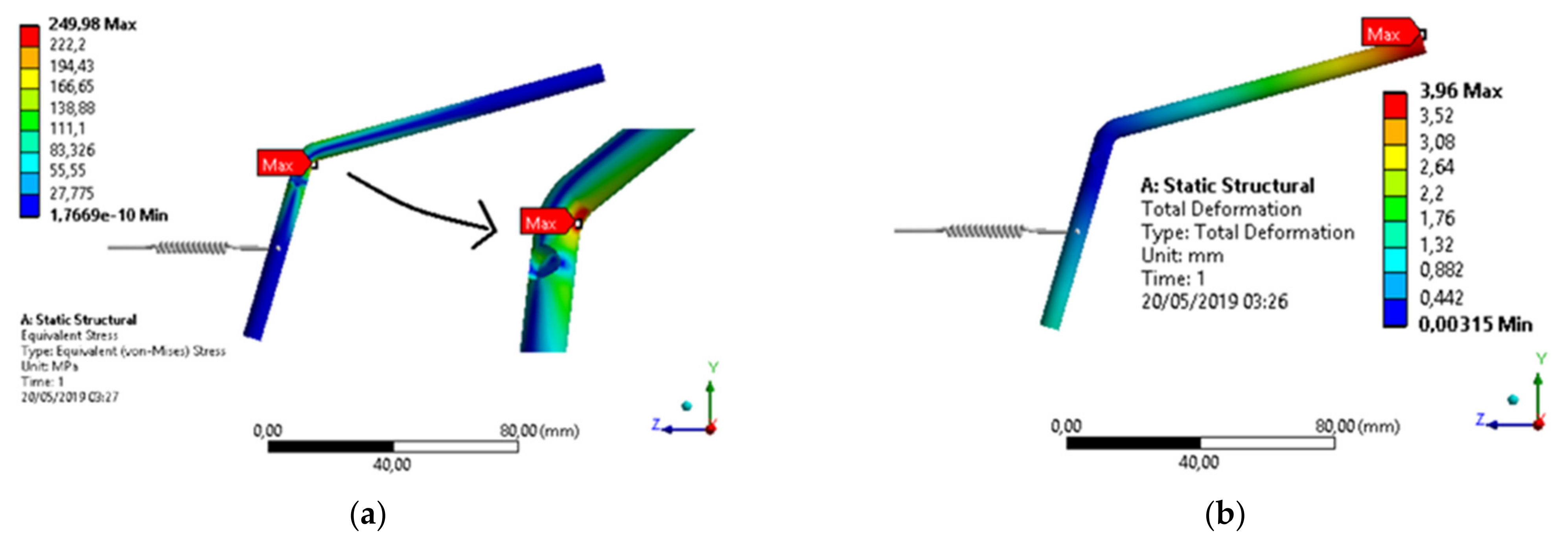

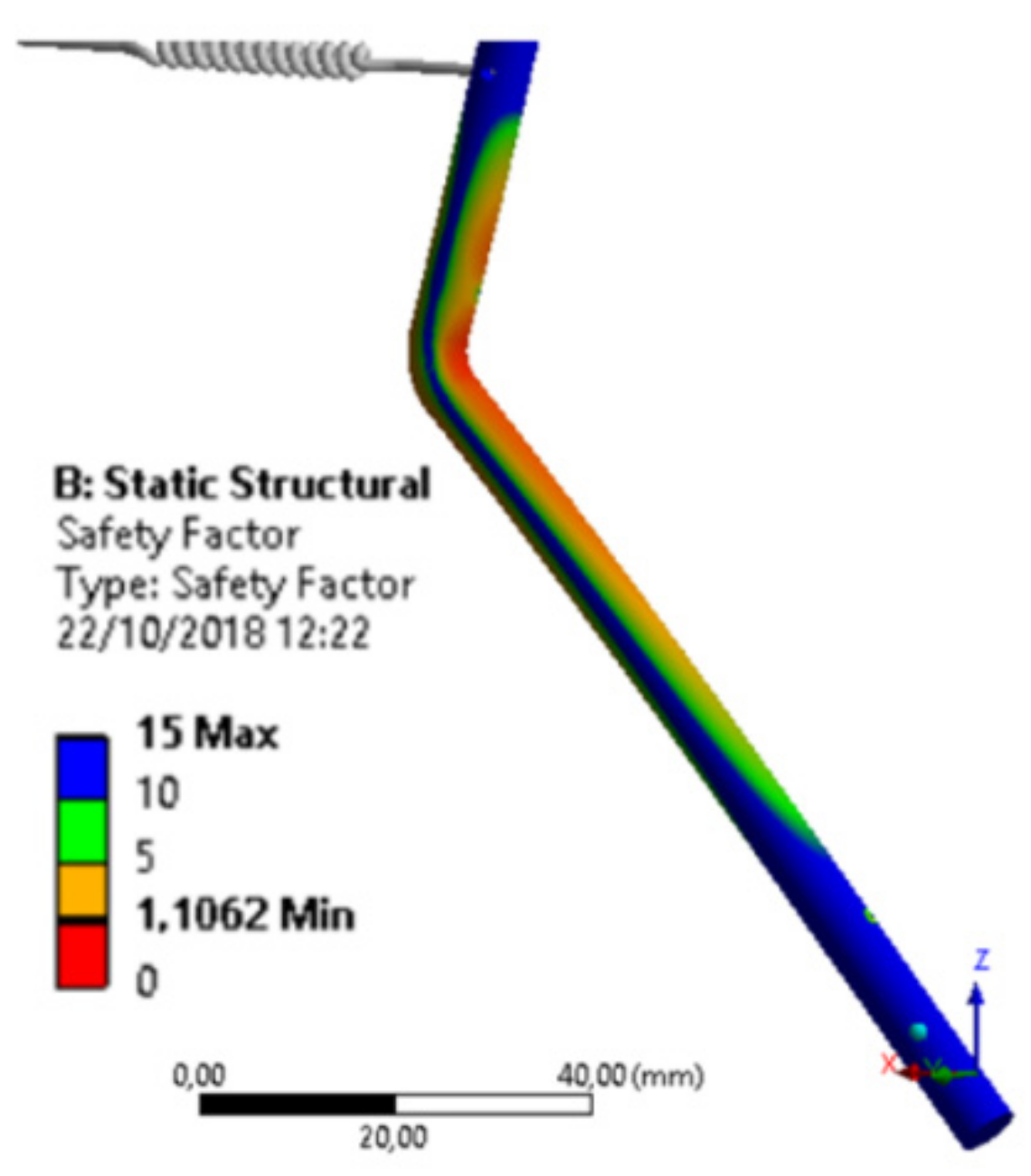

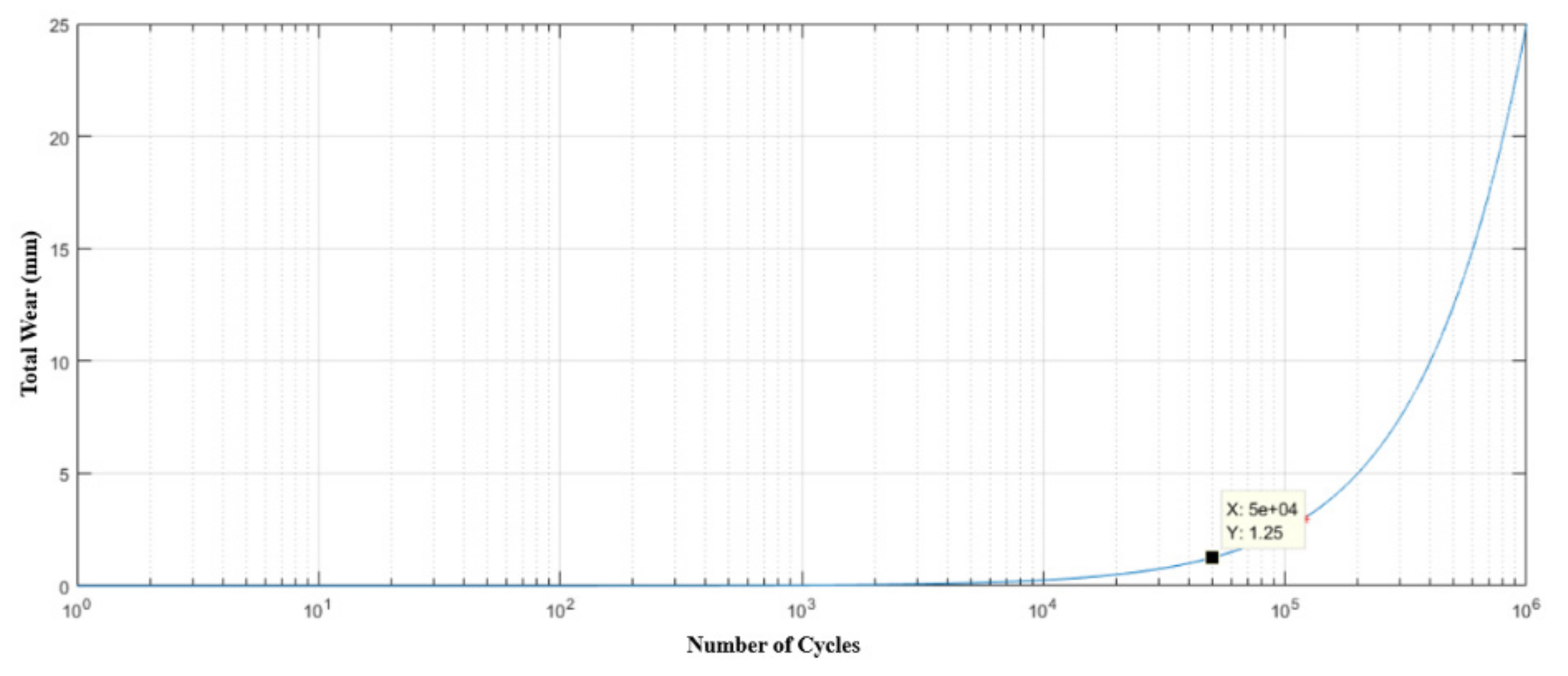

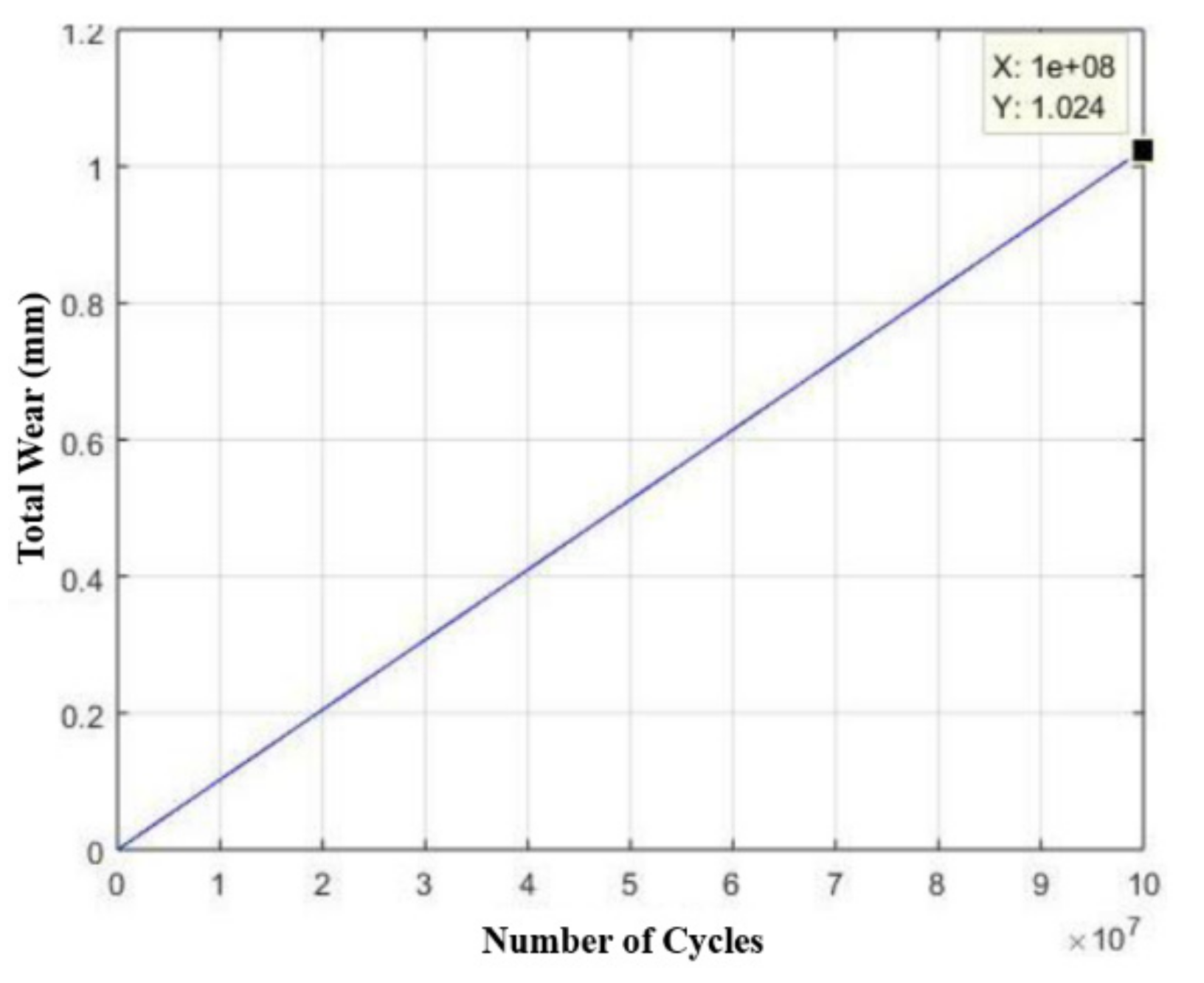

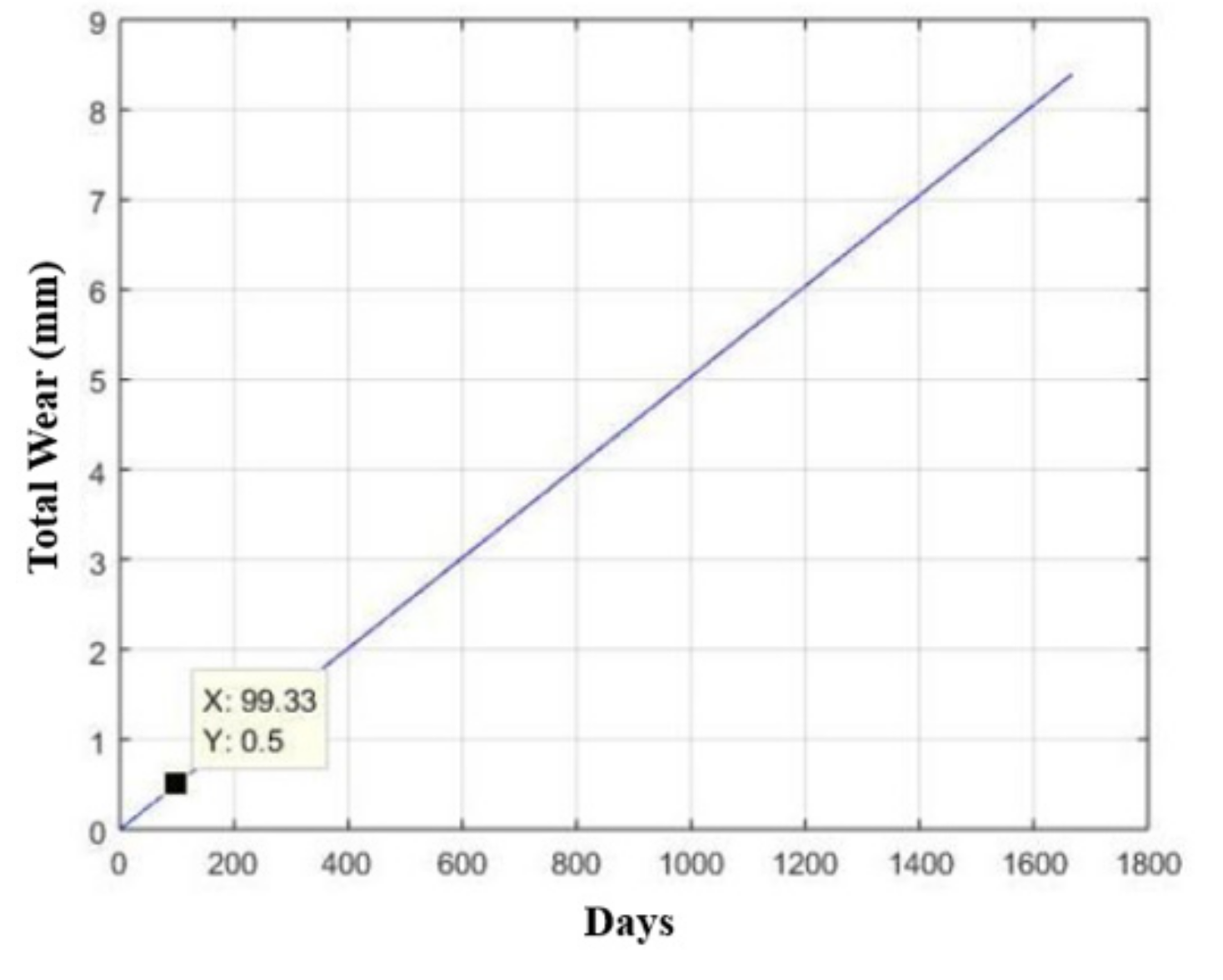

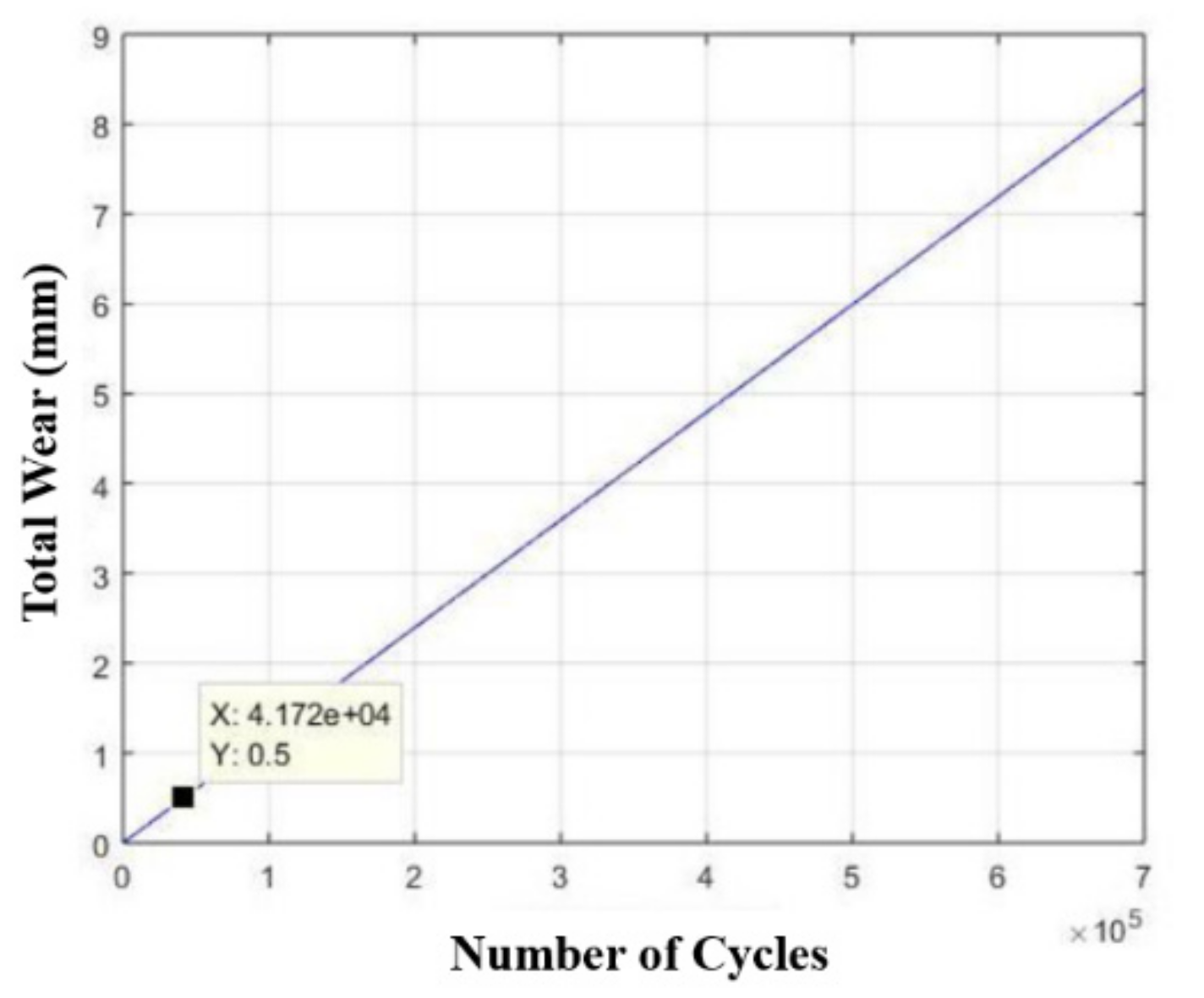

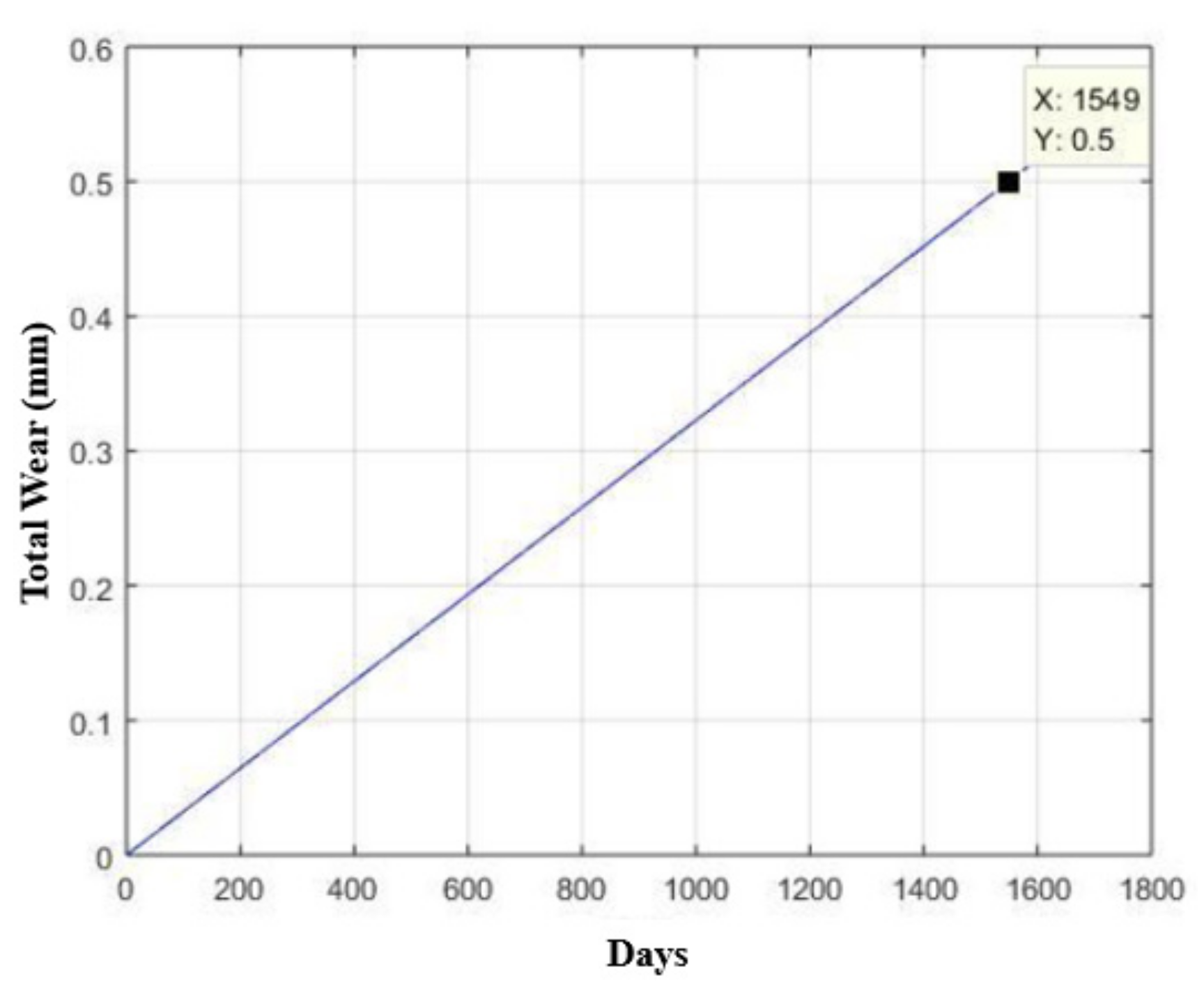

3.3. Structural Analysis of Components

4. Conclusions

- The use of AISI 420 stainless steel in the device components provided significant increases in their mechanical strength, ranging from 67% to 85%.

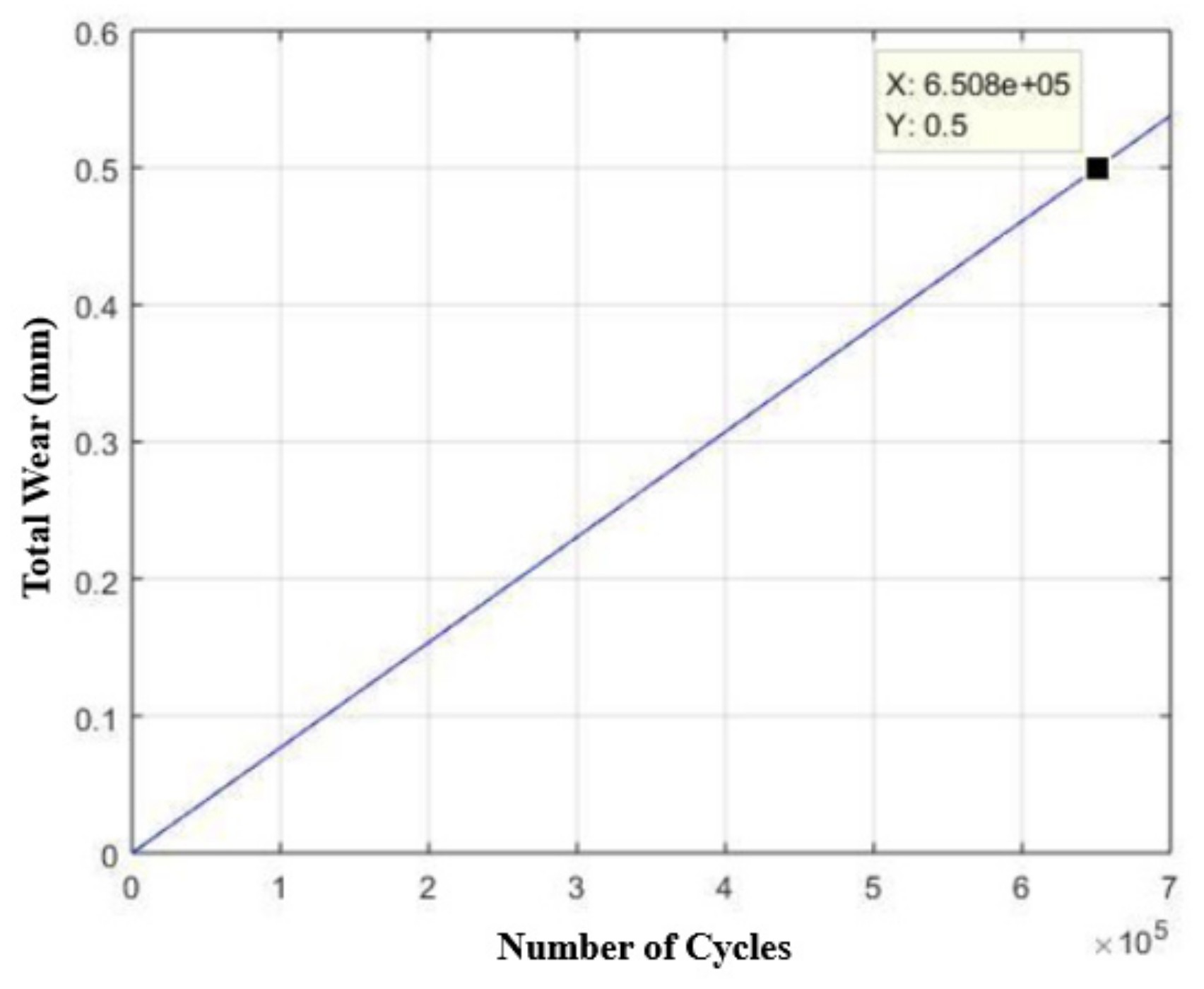

- There were considerable increases in the values of the respective safety factors associated with the use of AISI 420 stainless steel, ranging from 83% to 164%, and consequent increases in the useful life of the components, which ranged from 30% to 650%, when compared to the same performance parameters of the components where AISI 304 stainless steel was used.

- The improvement in these parameters guarantees, thus far, a replacement time (systematic time for preventive maintenance) of devices using AISI 420 stainless steel twice as long as the replacement time of extraction devices using stainless steel AISI 304, directly impacting the associated cost [33].

- The total cost of manufacturing the extraction device using AISI 420 stainless steel was around one third of the cost of the extraction device using AISI 304 stainless steel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Antunes, J. Sistemas de Produção: Conceitos e Práticas para Projeto e Gestão da Produção Enxuta, 1st ed.; Editora Bookman: Porto Alegre, Brazil, 2008. [Google Scholar]

- Yamashina, H.; Kubo, T. Manufacturing Cost Deployment. Int. J. Prod. Res. 2002, 40, 4077–4091. [Google Scholar] [CrossRef]

- Askeland, D.R.; Phulé, P.P. Ciência e Engenharia de Materiais; Cengage Learning: São Paulo, Brazil, 2011. [Google Scholar]

- Telles, P.C.D. Materiais Para Equipamentos de Processo, 6th ed.; Editora Interciência: Rio de Janeiro, Brazil, 2003. [Google Scholar]

- Faria, A.C. Redução de Custos sob a ótica da Manufatura Enxuta em Empresa. Rev. Gestão Ind. 2012, 8, 186–208. [Google Scholar] [CrossRef]

- Charyya, A.B.; Ham, I. Design of Cutting Principles; Society of Manufacturing Engineers: Southfield, MI, USA, 2013. [Google Scholar]

- Norton, R.L. Projeto de Máquinas: Uma Abordagem Integrada, 4th ed.; Editora Bookman: Porto Alegre, Brazil, 2013. [Google Scholar]

- Harmsworth, C.L. Fatigue, Tensile and Creep Properties of 17-7 ph TH 1050 AM 350 SCT Sheet; Techincal Report AFML-TR-69-331; USAF: Washington, DC, USA, 1970. [Google Scholar]

- Roberts, A.D.; Lapidge, S.C. Manufacturing Processes; McGraw-Hill, Co.: New York, NY, USA, 1977. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design; Butterworth-Heinemann Led: Oxford, UK, 1995. [Google Scholar]

- Askeland, D.R.; Fulay, P.P. Essentials of Materials Science and Engineering, 2nd ed.; Cengage Learning: Toronto, ON, Canada, 2009. [Google Scholar]

- Ashby, M.F.; Jones, D.R.H. Engenharia de Materiais, 2nd ed.; Elsevier Editora LTDA: Rio de Janeiro, Brazil, 2007. [Google Scholar]

- Shigley, J.E.; Mischke, C.R. Mechanical Engineering Design, 15th ed.; McGraw-Hill, Inc.: New York, NY, USA, 1989. [Google Scholar]

- Moaveni, S. Finite Element Analysis. Theory and Aplications with ANSYS; Editora Prentice-Hall: Única, São Paulo, Brazil, 1999. [Google Scholar]

- Herlach, D. Metalurgia Mecânica; Dois, G., Ed.; LIMUSA: Johannesburg, South Africa, 1976. [Google Scholar]

- Lee, H.-H. Finite Element Simulations with ANSYS Workbench, 14th ed.; SDC Publications: Mission, KS, USA, 2014. [Google Scholar]

- Kiminami, E.S.; Castro, W.B.; Oliveira, M.F. Introdução aos Processos de Fabricação de Produtos Metálicos; Editora Blucher: São Paulo, Brazil, 2015. [Google Scholar]

- Mohammad, B.B.S. Institute of Advanced Technology; Atlas Specialty Metals®: Seri Kembangan, Malaysia, 2014. [Google Scholar]

- Shackelford, J.F. Ciência dos Materiais, 6th ed.; Editora Pearson Prentice Hall: São Paulo, Brazil, 2008. [Google Scholar]

- Callister, W.D. Ciência e Engenharia dos Materiais: Uma introdução, 8th ed.; Editora LTC: Rio de Janeiro, Brazil, 2012. [Google Scholar]

- Van Vlack, L.H. Elements of Materials Science; Addison-Wesley Publishing, Co.: Boston, MA, USA,, 1964. [Google Scholar]

- Doyle, L.E.; Morris, J.L.; Leach, J.L.; Scharader, G.F. Manufacturing Process and Materials for Engineers; Prentice-Hall Inc.: Hoboken, NJ, USA, 1964. [Google Scholar]

- Chiaverini, V. Aços e Ferros Fundidos: Características Gerais, Tratamentos Térmicos, Principais Tipos, 7th ed.; ABM: São Paulo, Brazil, 2008. [Google Scholar]

- FARIAS, Maria Cristina Moré, Universidade de Caxias do Sul (UCS). Available online: https://www.ucs.br/site/midia/arquivos/18_04_Palestras_Tribologia_Profa_MCristinaMFarias.pdf (accessed on 20 December 2020).

- Chiaverini, V. Processos de Fabricação e Tratamento—Volume II, 2nd ed.; Editora McGraw Hill: São Paulo, Brazil, 1986. [Google Scholar]

- Cozaciuc, I. Ensaios de Materiais, 1st ed.; Fundação Roberto Marinho: Rio de Janeiro, Brazil, 2009. [Google Scholar]

- ISO. ISO 6892-1:2016 (Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature); ISO: Geneva, Switzerland, 2016. [Google Scholar]

- ISO. ISO 6507-1:2018 (Metallic Materials—Vickers Hardness Test—Part 1: Test Method); ISO: Geneva, Switzerland, 2018. [Google Scholar]

- ISO. ISO 6508-1:2015 (Metallic Materials—Rockwell Hardness Test—Part 1: Test Method); ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Ferreira, R.A.S. Conformação Plástica—Fundamentos Metalúrgicos e Mecânicos, 2nd ed.; Editora Universitária UFPE: Recife, Brazil, 2010. [Google Scholar]

- ASTM Stainless Steel—Grade Datasheets, Atlas Steels. Available online: http://www.worldstainless.org/Files/issf/non-image-files/PDF/Atlas_Grade_datasheet_-_all_datasheets_rev_Aug_2013.pdf (accessed on 17 November 2019).

- North American Stainless (NAS). Long Products Stainless Steel Grade Sheet; North American Stainless (NAS): East Ghent, KY, USA, 2013. [Google Scholar]

- Gajdzik, B. World Class Manufacturing in metallurgical enterprise. Metalurgija 2013, 52, 131–134. [Google Scholar]

| Specification of Materials Prototype | Specification of Materials Final Version of the Developed Device |

|---|---|

| ASTM A240 2B AISI 304L Steel Sheet 1.00 × 1300 × 2000 mm | AISI 420 Steel Sheet 1.00 × 300 × 1000 mm |

| ASTM A240 2B AISI 304L Steel Sheet 2.00 × 1300 × 2000 mm | AISI 420 Cylindrical Steel Bar Diameter 5 mm |

| AISI 304L Steel Bar Cylindrical Diameter 5 mm | AISI 420 Cylindrical Steel Bar Diameter 6 mm |

| AISI 304L Steel Bar Cylindrical Diameter 6 mm | AISI 420 Cylindrical Steel Bar Diameter 6.35 mm |

| AISI 304L Steel Bar Cylindrical Diameter 6.35 mm | AISI 420 Cylindrical Steel Bar Diameter 9.53 mm |

| AISI 304L Steel Bar Cylindrical Diameter 9.53 mm | AISI 420 Cylindrical Steel Bar Diameter 11.11 mm |

| AISI 304L Steel Bar Cylindrical Diameter 11.11 mm | AISI 420 Cylindrical Steel Bar Diameter 12.70 mm |

| AISI 304L Steel Bar Cylindrical Diameter 12.70 mm | AISI 420 Cylindrical Steel Bar Diameter 22.22 mm |

| AISI 304L Steel Bar Cylindrical Diameter 22.22 mm | AISI 420 Square Steel Bar Thickness 15.87 mm |

| AISI 304 Steel Bar Square Thickness 15.87 mm |

| Sample Format | Assessed Magnitude | |

|---|---|---|

| Tensile Strength Limit (MPa) | Rupture Strain (MPa) | |

| Plate 1 | 732.38 | 633.86 |

| Plate 2 | 748.84 | 650.08 |

| Plate 3 | 757.71 | 661.53 |

| Cylinder 1 | 1038.34 | 1038.34 |

| Cylinder 2 | 1189.78 | 1038.34 |

| Cylinder 3 | 938.11 | 936.34 |

| Sample Format | Assessed Magnitude | |

|---|---|---|

| Tensile Strength Limit (MPa) | Breaking Stress (MPa) | |

| Plate 1 | 1768.12 | 1598.62 |

| Plate 2 | 1777.49 | 1668.64 |

| Plate 3 | 1759.67 | 1604.46 |

| Cylinder 1 | 712.75 | 531.86 |

| Cylinder 2 | 712.83 | 517.79 |

| Cylinder 3 | 712.92 | 525.06 |

| Analysis Type | Sheet Shape | Cylindrical Shape | ||

|---|---|---|---|---|

| Average Hardness | Standard Deviation | Average Hardness | Standard Deviation | |

| Vickers Hardness | 198.66 HV | 4.46 | 238.20 HV | 5.34 |

| Hardness Hockwell | 11.00 HR | 4.46 | 20.00 HR | 5.34 |

| Analysis Type | Sheet Shape | Cylindrical Shape | ||

|---|---|---|---|---|

| Average Hardness | Standard Deviation | Average Hardness | Standard Deviation | |

| Vickers Hardness | 227.80 HV | 5.83 | 271.00 HV | 6.93 |

| Hardness Hockwell | 17.00 HR | 5.83 | 26.00 HR | 6.93 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Júnior, F.A.d.L.; Ferreira, R.A.S.; Lima, R.R.d.A. Study for Performance Increase of a Extractor Device by Steel Replacement of AISI 304 Steel for AISI 420 Steel. Materials 2022, 15, 280. https://doi.org/10.3390/ma15010280

Júnior FAdL, Ferreira RAS, Lima RRdA. Study for Performance Increase of a Extractor Device by Steel Replacement of AISI 304 Steel for AISI 420 Steel. Materials. 2022; 15(1):280. https://doi.org/10.3390/ma15010280

Chicago/Turabian StyleJúnior, Francisco Alves de Lima, Ricardo Artur Sanguinetti Ferreira, and Rômulo Rocha de Araújo Lima. 2022. "Study for Performance Increase of a Extractor Device by Steel Replacement of AISI 304 Steel for AISI 420 Steel" Materials 15, no. 1: 280. https://doi.org/10.3390/ma15010280

APA StyleJúnior, F. A. d. L., Ferreira, R. A. S., & Lima, R. R. d. A. (2022). Study for Performance Increase of a Extractor Device by Steel Replacement of AISI 304 Steel for AISI 420 Steel. Materials, 15(1), 280. https://doi.org/10.3390/ma15010280