Biobased Composites by Photoinduced Polymerization of Cardanol Methacrylate with Microfibrillated Cellulose

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Photocurable Resin and Composites

2.3. Photoinduced Polymerization of the Resin and Composites

2.4. Characterization Methods

3. Results

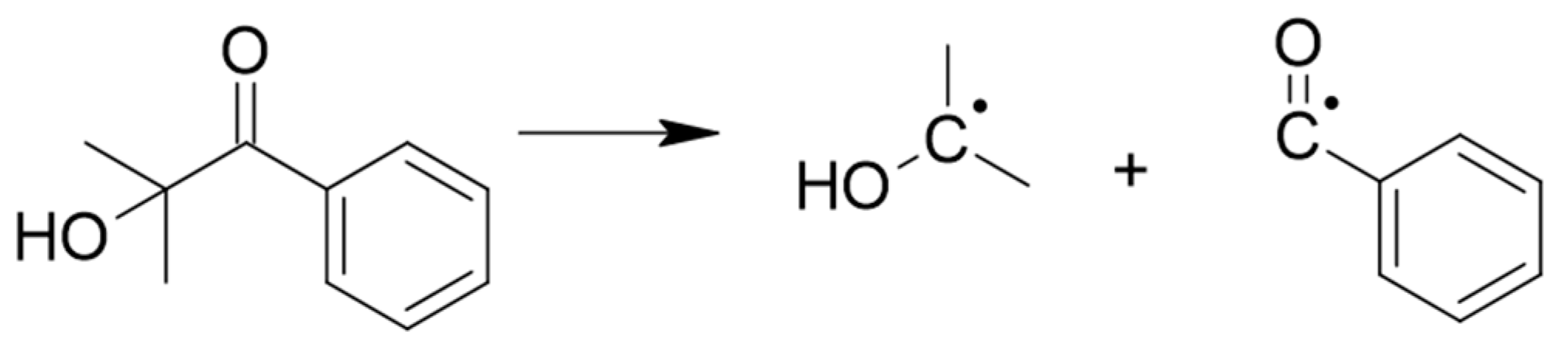

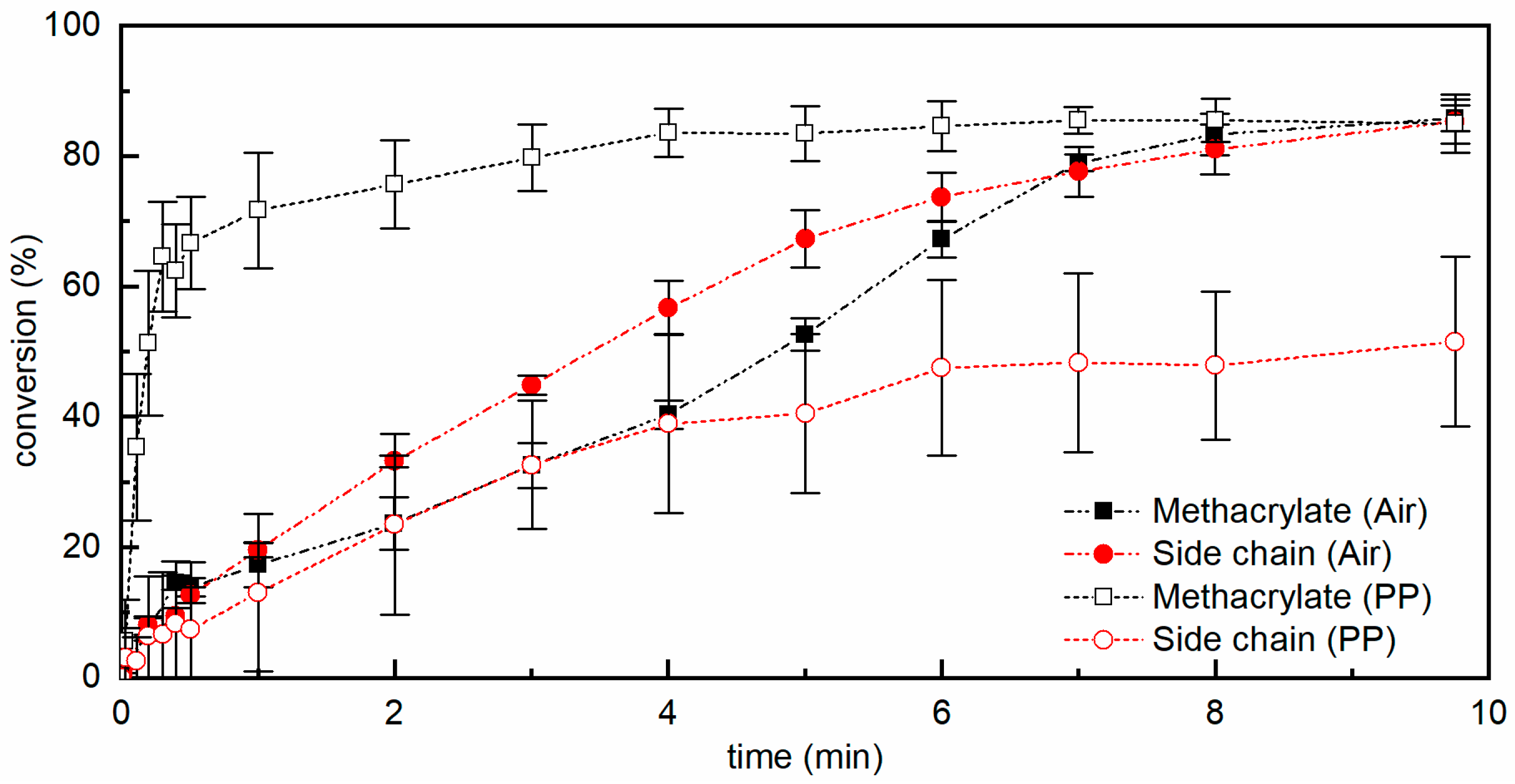

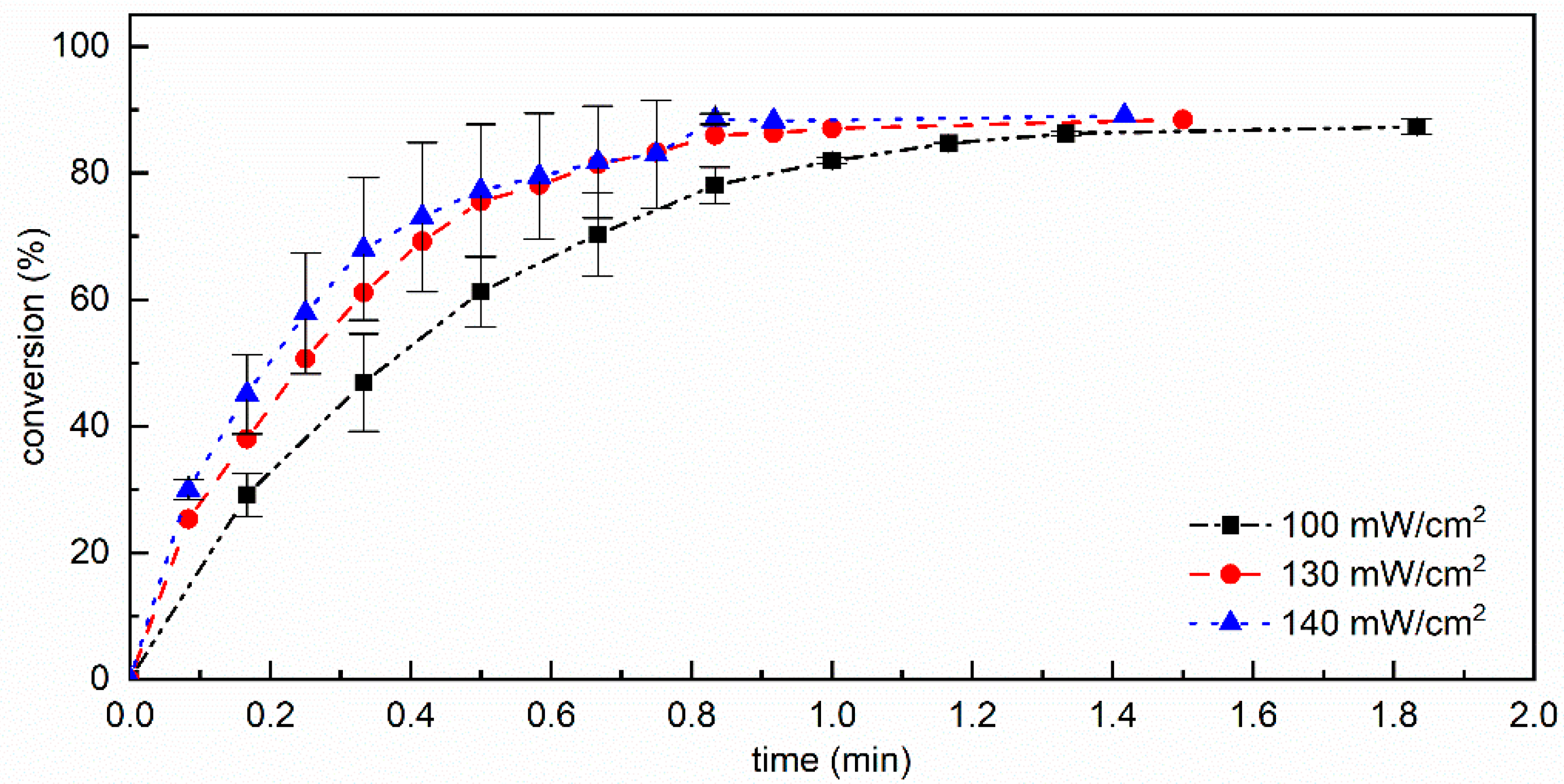

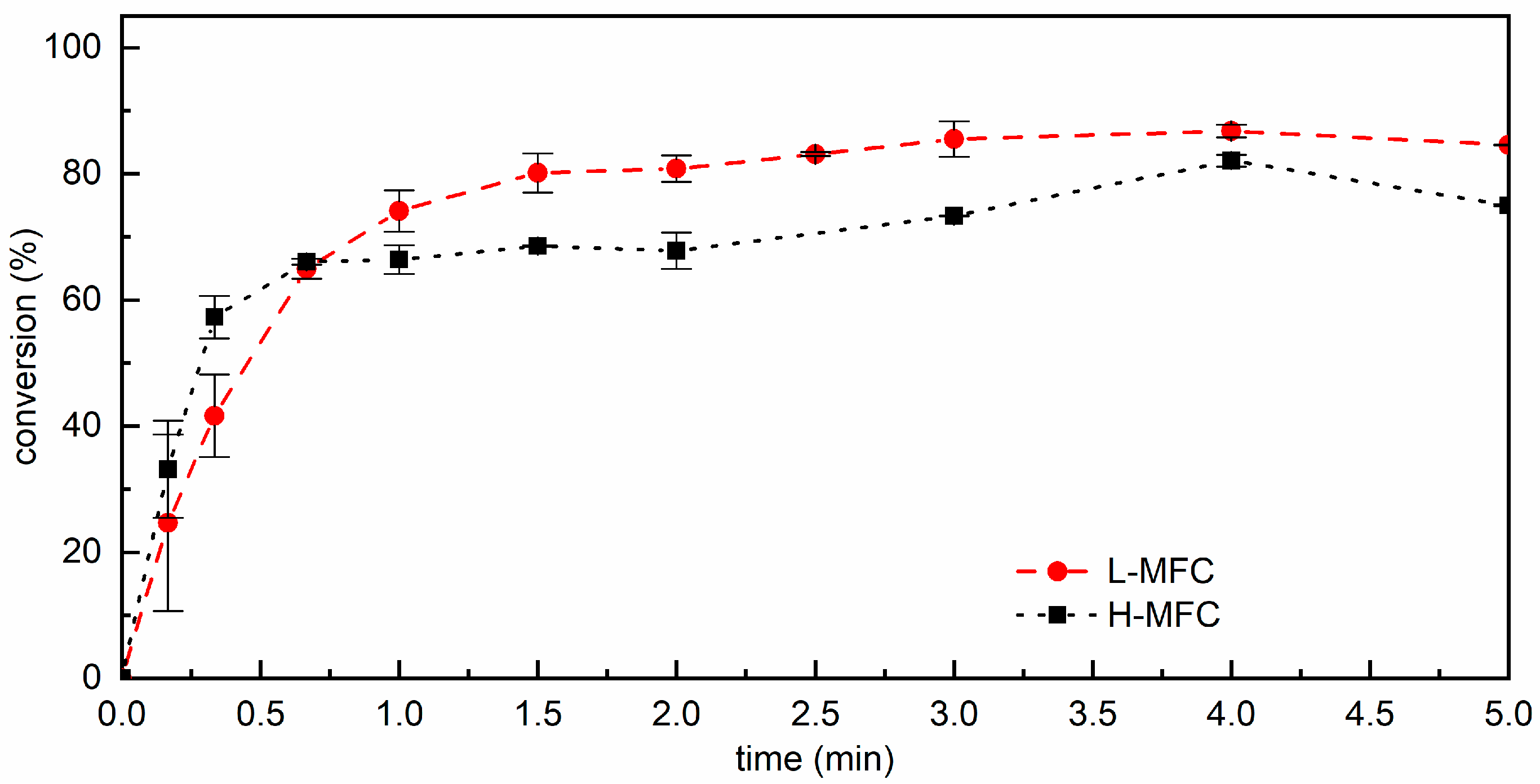

3.1. Photoinduced Polymerization of Cardanol Methacrylate and Its Composites with MFC

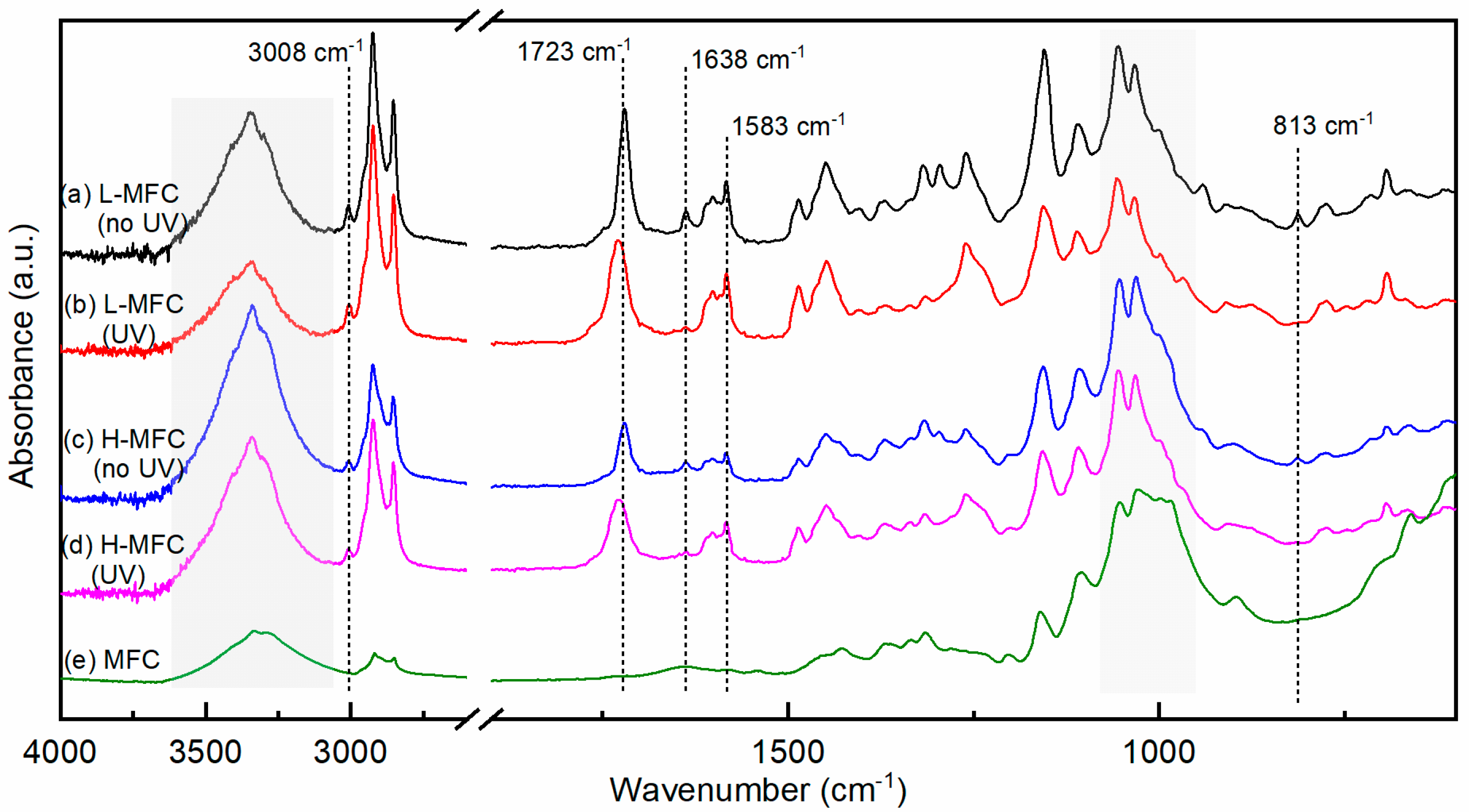

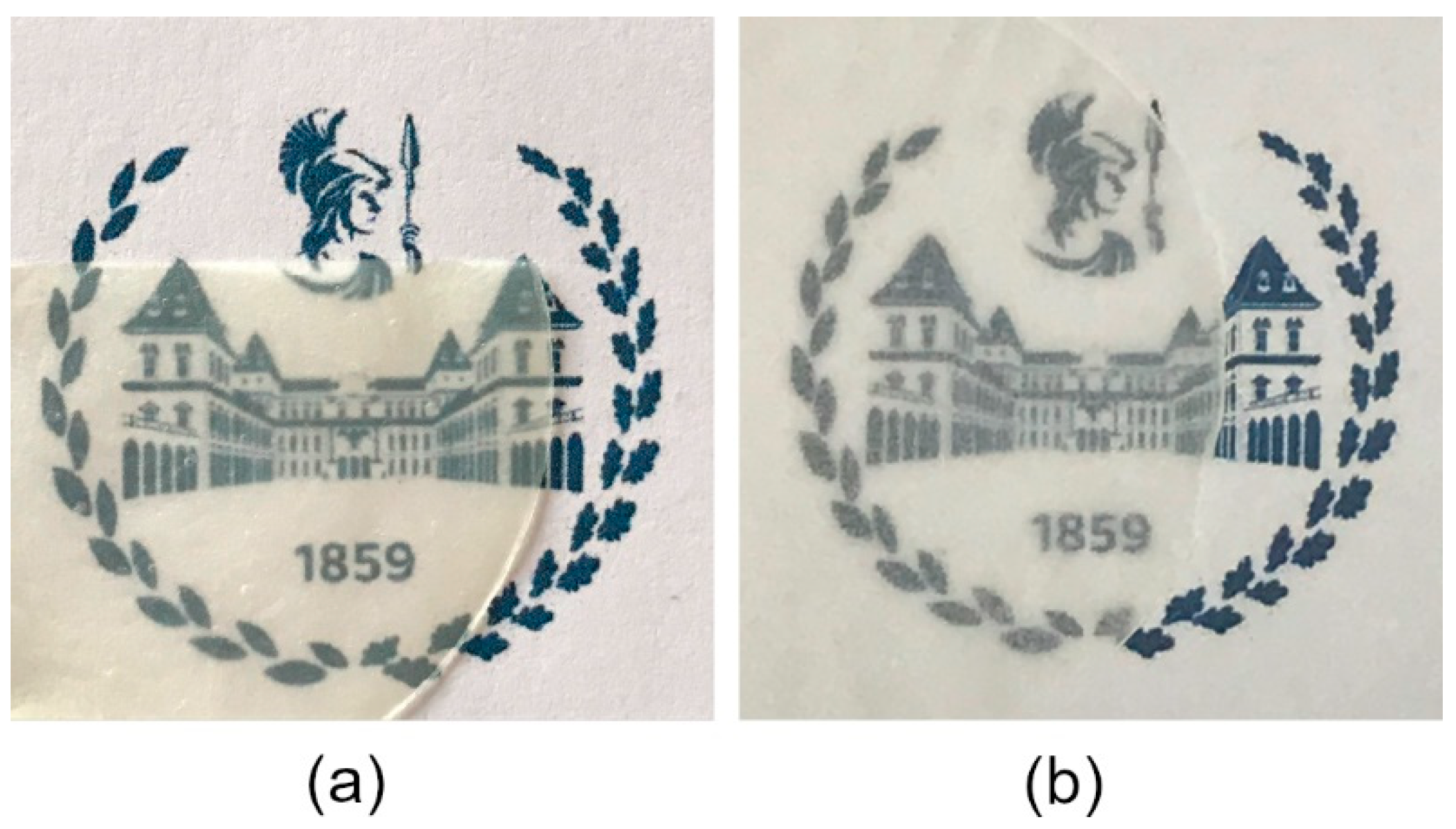

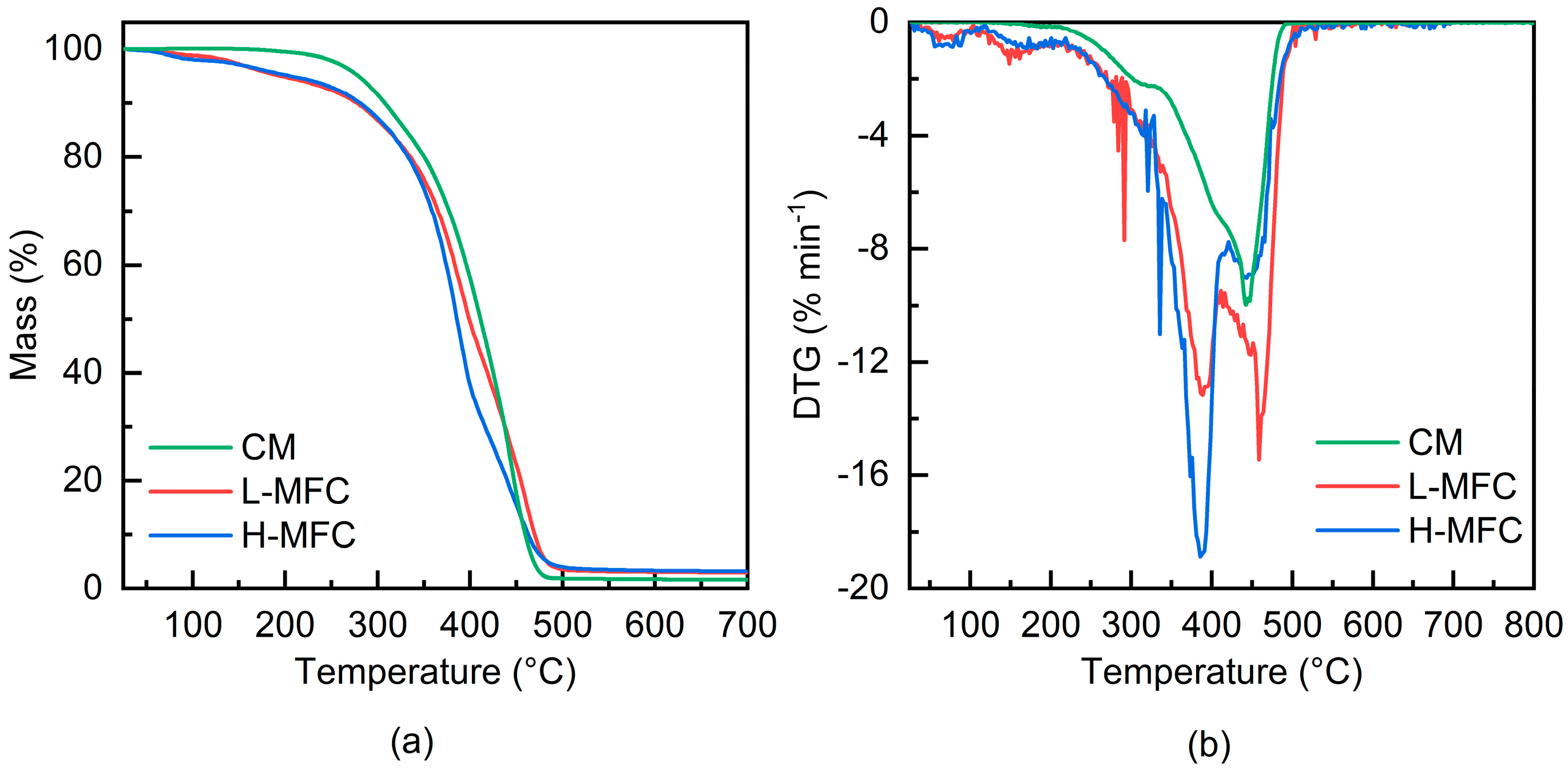

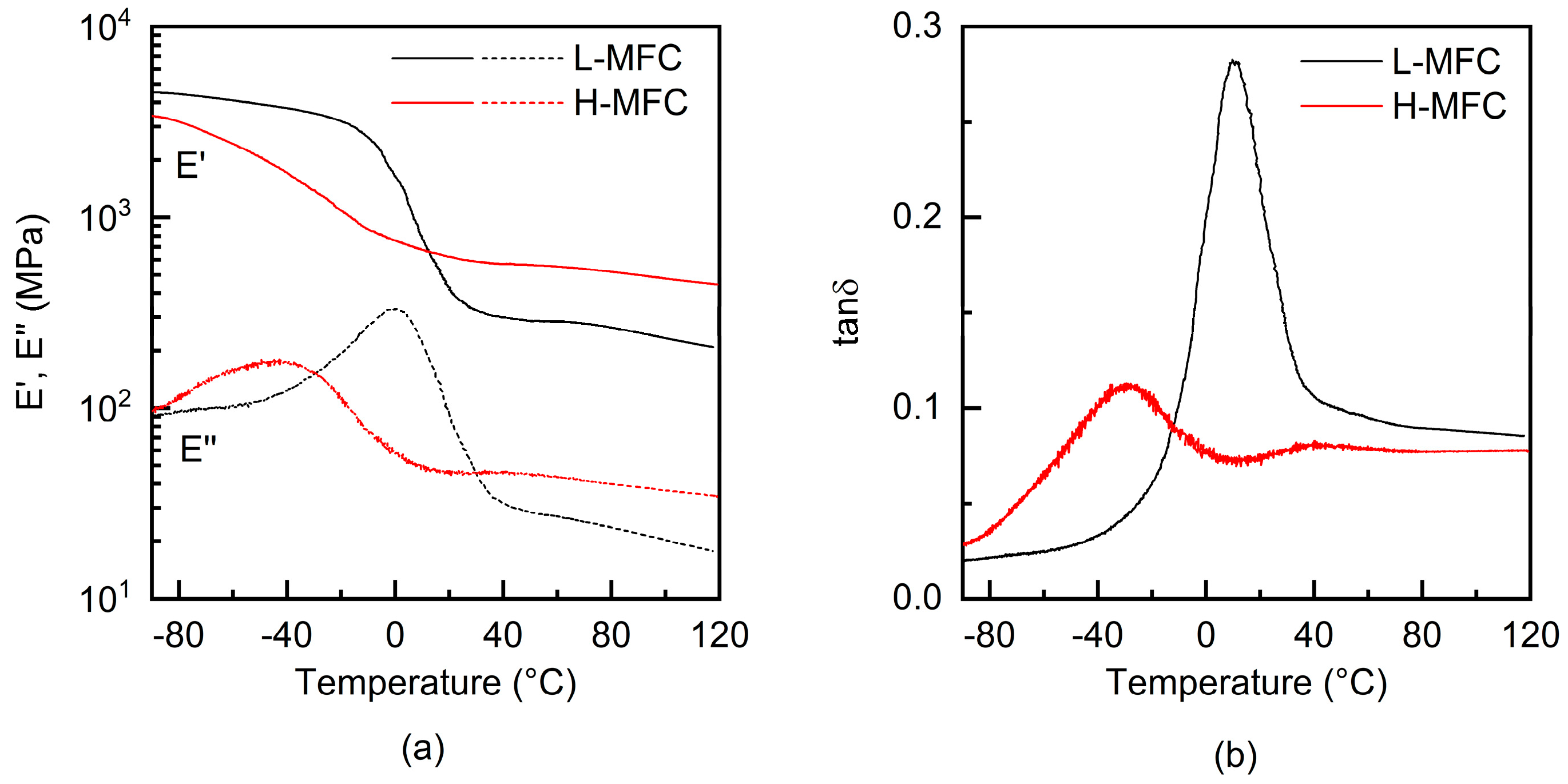

3.2. Properties of the Photocured Resin and Its Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Noè, C.; Malburet, S.; Bouvet-Marchand, A.; Graillot, A.; Loubat, C.; Sangermano, M. Cationic Photopolymerization of Bio-Renewable Epoxidized Monomers. Prog. Org. Coat. 2019, 133, 131–138. [Google Scholar] [CrossRef]

- Tehfe, M.-A.; Lalevée, J.; Gigmes, D.; Fouassier, J.P. Green Chemistry: Sunlight-Induced Cationic Polymerization of Renewable Epoxy Monomers Under Air. Macromolecules 2010, 43, 1364–1370. [Google Scholar] [CrossRef]

- Wang, S.; Wu, Y.; Dai, J.; Teng, N.; Peng, Y.; Cao, L.; Liu, X. Making Organic Coatings Greener: Renewable Resource, Solvent-Free Synthesis, UV Curing and Repairability. Eur. Polym. J. 2020, 123, 109439. [Google Scholar] [CrossRef]

- Tehfe, M.; Louradour, F.; Lalevée, J.; Fouassier, J.-P. Photopolymerization Reactions: On the Way to a Green and Sustainable Chemistry. Appl. Sci. 2013, 3, 490–514. [Google Scholar] [CrossRef]

- Bongiovanni, R.; Vacche, S.D.; Vitale, A. Photoinduced Processes as a Way to Sustainable Polymers and Innovation in Polymeric Materials. Polymers 2021, 13, 2293. [Google Scholar] [CrossRef] [PubMed]

- Noè, C.; Hakkarainen, M.; Sangermano, M. Cationic UV-Curing of Epoxidized Biobased Resins. Polymers 2021, 13, 89. [Google Scholar] [CrossRef]

- Voet, V.S.D.; Guit, J.; Loos, K. Sustainable Photopolymers in 3D Printing: A Review on Biobased, Biodegradable, and Recyclable Alternatives. Macromol. Rapid Commun. 2021, 42, 2000475. [Google Scholar] [CrossRef]

- Felipe-Mendes, C.; Ruiz-Rubio, L.; Vilas-Vilela, J.L. Biomaterials Obtained by Photopolymerization: From UV to Two Photon. Emergent Mater. 2020, 3, 453–468. [Google Scholar] [CrossRef]

- Li, W.S.J.; Negrell, C.; Ladmiral, V.; Lai-Kee-Him, J.; Bron, P.; Lacroix-Desmazes, P.; Joly-Duhamel, C.; Caillol, S. Cardanol-Based Polymer Latex by Radical Aqueous Miniemulsion Polymerization. Polym. Chem. 2018, 9, 2468–2477. [Google Scholar] [CrossRef]

- Voirin, C.; Caillol, S.; Sadavarte, N.V.; Tawade, B.V.; Boutevin, B.; Wadgaonkar, P.P. Functionalization of Cardanol: Towards Biobased Polymers and Additives. Polym. Chem. 2014, 5, 3142–3162. [Google Scholar] [CrossRef]

- Noè, C.; Malburet, S.; Milani, E.; Bouvet-Marchand, A.; Graillot, A.; Sangermano, M. Cationic UV-Curing of Epoxidized Cardanol Derivatives. Polym. Int. 2020, 69, 668–674. [Google Scholar] [CrossRef]

- Dalle Vacche, S.; Vitale, A.; Bongiovanni, R. Photocuring of Epoxidized Cardanol for Biobased Composites with Microfibrillated Cellulose. Molecules 2019, 24, 3858. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dalle Vacche, S.; Karunakaran, V.; Ronchetti, S.M.; Vitale, A.; Bongiovanni, R. Nanocellulose from Unbleached Hemp Fibers as a Filler for Biobased Photocured Composites with Epoxidized Cardanol. J. Compos. Sci. 2021, 5, 11. [Google Scholar] [CrossRef]

- Cai, Y.; Jessop, J.L.P. Photopolymerization, Free Radical. In Encyclopedia of Polymer Science and Technology; Wiley: Hoboken, NJ, USA, 2002; ISBN 978-0-471-44026-0. [Google Scholar]

- John, G.; Pillai, C.K.S. Synthesis and Characterization of a Self-Crosslinkable Polymer from Cardanol: Autooxidation of Poly(Cardanyl Acrylate) to Crosslinked Film. J. Polym. Sci. Part A Polym. Chem. 1993, 31, 1069–1073. [Google Scholar] [CrossRef]

- Nguyen, T.K.L.; Livi, S.; Soares, B.G.; Barra, G.M.O.; Gérard, J.-F.; Duchet-Rumeau, J. Development of Sustainable Thermosets from Cardanol-Based Epoxy Prepolymer and Ionic Liquids. ACS Sustain. Chem. Eng. 2017, 5, 8429–8438. [Google Scholar] [CrossRef]

- John, G.; Thomas, S.K.; Pillai, C.K.S. Cardanyl Acrylate/Methacrylate Based Cross-Linked Copolymers as Novel Supports: Synthesis and Characterization. J. Appl. Polym. Sci. 1994, 53, 1415–1423. [Google Scholar] [CrossRef]

- Suresh, K.I.; Jaikrishna, M. Synthesis of Novel Crosslinkable Polymers by Atom Transfer Radical Polymerization of Cardanyl Acrylate. J. Polym. Sci. Part A Polym. Chem. 2005, 43, 5953–5961. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, S.; Zhou, X.; Yang, Z.; Yuan, T. A Novel Multi-Functional Bio-Based Reactive Diluent Derived from Cardanol for High Bio-Content UV-Curable Coatings Application. Prog. Org. Coat. 2020, 148, 105880. [Google Scholar] [CrossRef]

- Hu, Y.; Shang, Q.; Wang, C.; Feng, G.; Liu, C.; Xu, F.; Zhou, Y. Renewable Epoxidized Cardanol-Based Acrylate as a Reactive Diluent for UV-Curable Resins. Polym. Adv. Technol. 2018, 29, 1852–1860. [Google Scholar] [CrossRef]

- Hu, Y.; Shang, Q.; Tang, J.; Wang, C.; Zhang, F.; Jia, P.; Feng, G.; Wu, Q.; Liu, C.; Hu, L.; et al. Use of Cardanol-Based Acrylate as Reactive Diluent in UV-Curable Castor Oil-Based Polyurethane Acrylate Resins. Ind. Crops Prod. 2018, 117, 295–302. [Google Scholar] [CrossRef]

- Li, W.S.J.; Cuminet, F.; Ladmiral, V.; Lacroix-Desmazes, P.; Caillol, S.; Negrell, C. Phosphonated and Methacrylated Biobased Cardanol Monomer: Synthesis, Characterization and Application. Prog. Org. Coat. 2021, 153, 106093. [Google Scholar] [CrossRef]

- Phalak, G.; Patil, D.; Patil, A.; Mhaske, S. Synthesis of Acrylated Cardanol Diphenyl Phosphate for UV Curable Flame-Retardant Coating Application. Eur. Polym. J. 2019, 121, 109320. [Google Scholar] [CrossRef]

- Hu, Y.; Feng, G.; Shang, Q.; Bo, C.; Jia, P.; Liu, C.; Xu, F.; Zhou, Y. Bio-Based Reactive Diluent Derived from Cardanol and Its Application in Polyurethane Acrylate (PUA) Coatings with High Performance. J. Coat. Technol Res. 2019, 16, 499–509. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, X.; Zhu, J.; Liu, X.; Wang, Z.; Yan, J. UV-Curable Coatings from Multiarmed Cardanol-Based Acrylate Oligomers. ACS Sustain. Chem. Eng. 2015, 3, 1313–1320. [Google Scholar] [CrossRef]

- Liu, J.; Liu, R.; Zhang, X.; Li, Z.; Tang, H.; Liu, X. Preparation and Properties of UV-Curable Multi-Arms Cardanol-Based Acrylates. Prog. Org. Coat. 2016, 90, 126–131. [Google Scholar] [CrossRef]

- Li, J.-J.; Sun, J.; Xie, Y.-X.; Zhao, C.; Ma, H.-X.; Liu, C.-M. A Novel Star-Shaped, Cardanol-Based Bio-Prepolymer: Synthesis, UV Curing Characteristics and Properties of Cured Films. Polym. Degrad. Stab. 2018, 158, 124–135. [Google Scholar] [CrossRef]

- Yuan, Y.; Chen, M.; Zhou, Q.; Liu, R. Synthesis and Properties of UV-Curable Cardanol-Based Acrylate Oligomers with Cyclotriphosphazene Core. J. Coat. Technol. Res. 2019, 16, 179–188. [Google Scholar] [CrossRef]

- Liu, J.; Su, X.; Nan, Y.; Wu, Z.; Liu, R. Synthesis of Three Kinds of Multi-Armed Cardanol-Based Acrylic Resins Based on Different Routes for UV/EB-Cured Coatings. Prog. Org. Coat. 2021, 151, 106035. [Google Scholar] [CrossRef]

- Molina-Gutiérrez, S.; Dalle Vacche, S.; Vitale, A.; Ladmiral, V.; Caillol, S.; Bongiovanni, R.; Lacroix-Desmazes, P. Photoinduced Polymerization of Eugenol-Derived Methacrylates. Molecules 2020, 25, 3444. [Google Scholar] [CrossRef]

- Guillén, M.D.; Cabo, N. Relationships between the Composition of Edible Oils and Lard and the Ratio of the Absorbance of Specific Bands of Their Fourier Transform Infrared Spectra. Role of Some Bands of the Fingerprint Region. J. Agric. Food Chem. 1998, 46, 1788–1793. [Google Scholar] [CrossRef]

- Lerma-García, M.J.; Ramis-Ramos, G.; Herrero-Martínez, J.M.; Simó-Alfonso, E.F. Authentication of Extra Virgin Olive Oils by Fourier-Transform Infrared Spectroscopy. Food Chem. 2010, 118, 78–83. [Google Scholar] [CrossRef]

- Natarajan, M.; Murugavel, S.C. Thermal Stability and Thermal Degradation Kinetics of Bio-Based Epoxy Resins Derived from Cardanol by Thermogravimetric Analysis. Polym. Bull. 2017, 74, 3319–3340. [Google Scholar] [CrossRef]

- Rohman, A.; Man, Y.B.C. Fourier Transform Infrared (FTIR) Spectroscopy for Analysis of Extra Virgin Olive Oil Adulterated with Palm Oil. Food Res. Int. 2010, 43, 886–892. [Google Scholar] [CrossRef]

- Cheon, J.; Cho, D.; Song, B.K.; Park, J.; Kim, B.; Lee, B.C. Thermogravimetric and Fourier-Transform Infrared Analyses on the Cure Behavior of Polycardanol Containing Epoxy Groups Cured by Electron Beam. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Chen, J.; Nie, X.; Liu, Z.; Mi, Z.; Zhou, Y. Synthesis and Application of Polyepoxide Cardanol Glycidyl Ether as Biobased Polyepoxide Reactive Diluent for Epoxy Resin. ACS Sustain. Chem. Eng. 2015, 3, 1164–1171. [Google Scholar] [CrossRef]

- Belaidi, O.; Bouchaour, T.; Maschke, U. Structural Preferences and Vibrational Analysis of 2-Hydroxy-2-Methyl-1-Phenylpropan-1-One: A Computational and Infrared Spectroscopic Research. Available online: https://www.hindawi.com/journals/jstruc/2013/942302/ (accessed on 18 March 2019).

- Pynaert, R.; Buguet, J.; Croutxé-Barghorn, C.; Moireau, P.; Allonas, X. Effect of Reactive Oxygen Species on the Kinetics of Free Radical Photopolymerization. Polym. Chem. 2013, 4, 2475–2479. [Google Scholar] [CrossRef]

- Decker, C.; Jenkins, A.D. Kinetic Approach of Oxygen Inhibition in Ultraviolet- and Laser-Induced Polymerizations. Macromolecules 1985, 18, 1241–1244. [Google Scholar] [CrossRef]

- Wight, F.R. Oxygen Inhibition of Acrylic Photopolymerization. J. Polym. Sci. Polym. Lett. Ed. 1978, 16, 121–127. [Google Scholar] [CrossRef]

- Lee, T.Y.; Guymon, C.A.; Jönsson, E.S.; Hoyle, C.E. The Effect of Monomer Structure on Oxygen Inhibition of (Meth)Acrylates Photopolymerization. Polymer 2004, 45, 6155–6162. [Google Scholar] [CrossRef]

- Lazzari, M.; Chiantore, O. Drying and Oxidative Degradation of Linseed Oil. Polym. Degrad. Stab. 1999, 65, 303–313. [Google Scholar] [CrossRef]

- Cintrón, M.S.; Hinchliffe, D.J. FT-IR Examination of the Development of Secondary Cell Wall in Cotton Fibers. Fibers 2015, 3, 30–40. [Google Scholar] [CrossRef] [Green Version]

- Mondragon, G.; Fernandes, S.; Retegi, A.; Peña, C.; Algar, I.; Eceiza, A.; Arbelaiz, A. A Common Strategy to Extracting Cellulose Nanoentities from Different Plants. Ind. Crops Prod. 2014, 55, 140–148. [Google Scholar] [CrossRef]

- Rosa, M.F.; Medeiros, E.S.; Malmonge, J.A.; Gregorski, K.S.; Wood, D.F.; Mattoso, L.H.C.; Glenn, G.; Orts, W.J.; Imam, S.H. Cellulose Nanowhiskers from Coconut Husk Fibers: Effect of Preparation Conditions on Their Thermal and Morphological Behavior. Carbohydr. Polym. 2010, 81, 83–92. [Google Scholar] [CrossRef]

- Lawther, J.M.; Sun, R. The Fractional Characterisation of Polysaccharides and Lignin Components in Alkaline Treated and Atmospheric Refined Wheat Straw. Ind. Crops Prod. 1996, 5, 87–95. [Google Scholar] [CrossRef]

- Abraham, R.; Wong, C.; Puri, M. Enrichment of Cellulosic Waste Hemp (Cannabis Sativa) Hurd into Non-Toxic Microfibres. Materials 2016, 9, 562. [Google Scholar] [CrossRef] [Green Version]

- Alemdar, A.; Sain, M. Biocomposites from Wheat Straw Nanofibers: Morphology, Thermal and Mechanical Properties. Compos. Sci. Technol. 2008, 68, 557–565. [Google Scholar] [CrossRef]

- Li, R.; Fei, J.; Cai, Y.; Li, Y.; Feng, J.; Yao, J. Cellulose Whiskers Extracted from Mulberry: A Novel Biomass Production. Carbohydr. Polym. 2009, 76, 94–99. [Google Scholar] [CrossRef]

- Kangas, H.; Lahtinen, P.; Sneck, A.; Saariaho, A.-M.; Laitinen, O.; Hellén, E. Characterization of Fibrillated Celluloses. A Short Review and Evaluation of Characteristics with a Combination of Methods. Nord. Pulp Pap. Res. J. 2014, 29, 129–143. [Google Scholar] [CrossRef]

- Larsson, P.A.; Riazanova, A.V.; Cinar Ciftci, G.; Rojas, R.; Øvrebø, H.H.; Wågberg, L.; Berglund, L.A. Towards Optimised Size Distribution in Commercial Microfibrillated Cellulose: A Fractionation Approach. Cellulose 2019, 26, 1565–1575. [Google Scholar] [CrossRef] [Green Version]

- Cinar Ciftci, G.; Larsson, P.A.; Riazanova, A.V.; Øvrebø, H.H.; Wågberg, L.; Berglund, L.A. Tailoring of Rheological Properties and Structural Polydispersity Effects in Microfibrillated Cellulose Suspensions. Cellulose 2020, 27, 9227–9241. [Google Scholar] [CrossRef]

- Bongiovanni, R.; Zeno, E.; Pollicino, A.; Serafini, P.M.; Tonelli, C. UV Light-Induced Grafting of Fluorinated Monomer onto Cellulose Sheets. Cellulose 2011, 18, 117–126. [Google Scholar] [CrossRef]

- Princi, E.; Vicini, S.; Pedemonte, E.; Mulas, A.; Franceschi, E.; Luciano, G.; Trefiletti, V. Thermal Analysis and Characterisation of Cellulose Grafted with Acrylic Monomers. Thermochim. Acta 2005, 425, 173–179. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vitale, A.; Molina-Gutiérrez, S.; Li, W.S.J.; Caillol, S.; Ladmiral, V.; Lacroix-Desmazes, P.; Dalle Vacche, S. Biobased Composites by Photoinduced Polymerization of Cardanol Methacrylate with Microfibrillated Cellulose. Materials 2022, 15, 339. https://doi.org/10.3390/ma15010339

Vitale A, Molina-Gutiérrez S, Li WSJ, Caillol S, Ladmiral V, Lacroix-Desmazes P, Dalle Vacche S. Biobased Composites by Photoinduced Polymerization of Cardanol Methacrylate with Microfibrillated Cellulose. Materials. 2022; 15(1):339. https://doi.org/10.3390/ma15010339

Chicago/Turabian StyleVitale, Alessandra, Samantha Molina-Gutiérrez, W. S. Jennifer Li, Sylvain Caillol, Vincent Ladmiral, Patrick Lacroix-Desmazes, and Sara Dalle Vacche. 2022. "Biobased Composites by Photoinduced Polymerization of Cardanol Methacrylate with Microfibrillated Cellulose" Materials 15, no. 1: 339. https://doi.org/10.3390/ma15010339

APA StyleVitale, A., Molina-Gutiérrez, S., Li, W. S. J., Caillol, S., Ladmiral, V., Lacroix-Desmazes, P., & Dalle Vacche, S. (2022). Biobased Composites by Photoinduced Polymerization of Cardanol Methacrylate with Microfibrillated Cellulose. Materials, 15(1), 339. https://doi.org/10.3390/ma15010339