Microstructure and Mechanical Properties of Novel Lightweight TaNbVTi-Based Refractory High Entropy Alloys

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

4. Conclusions

- (1)

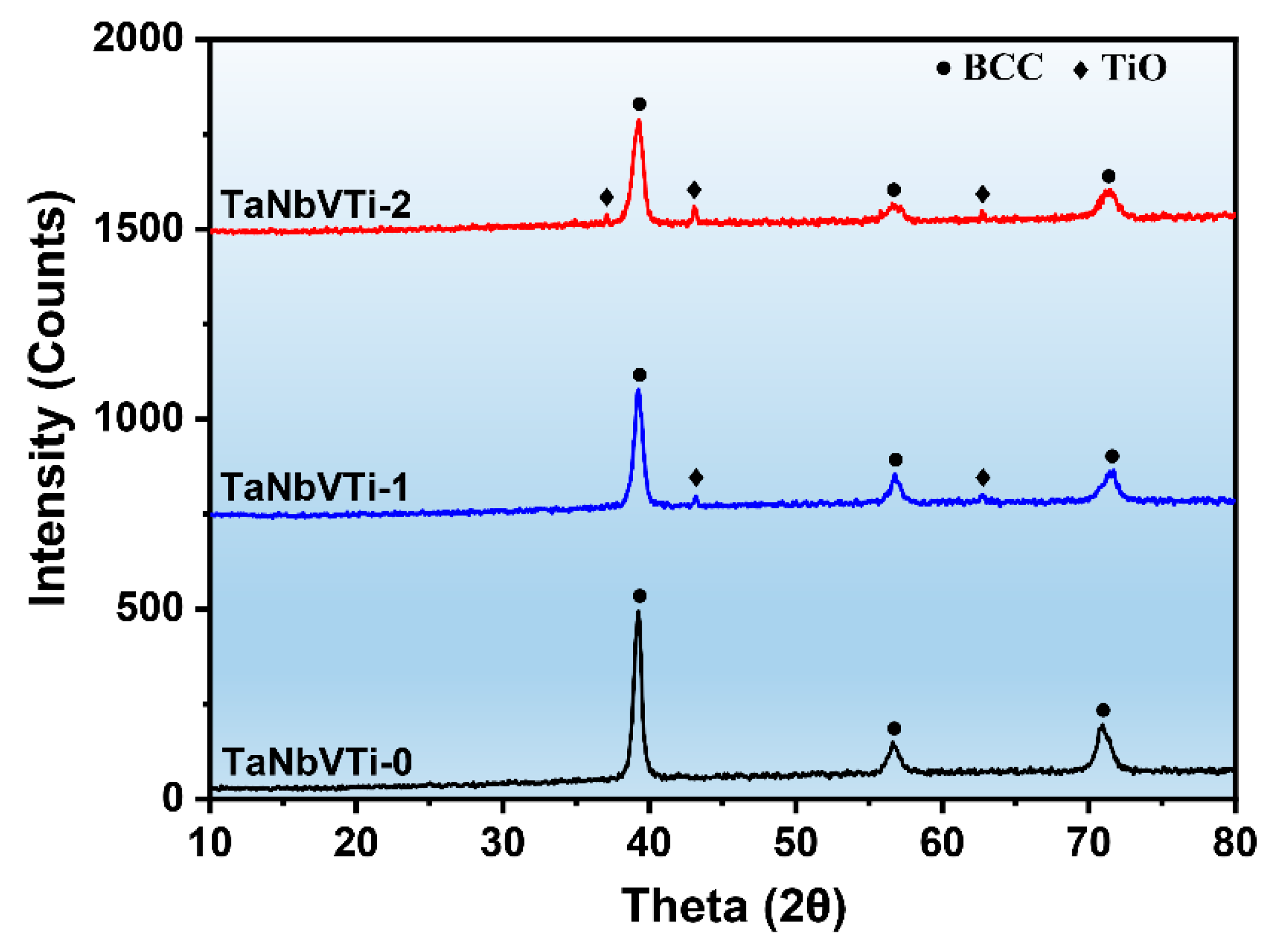

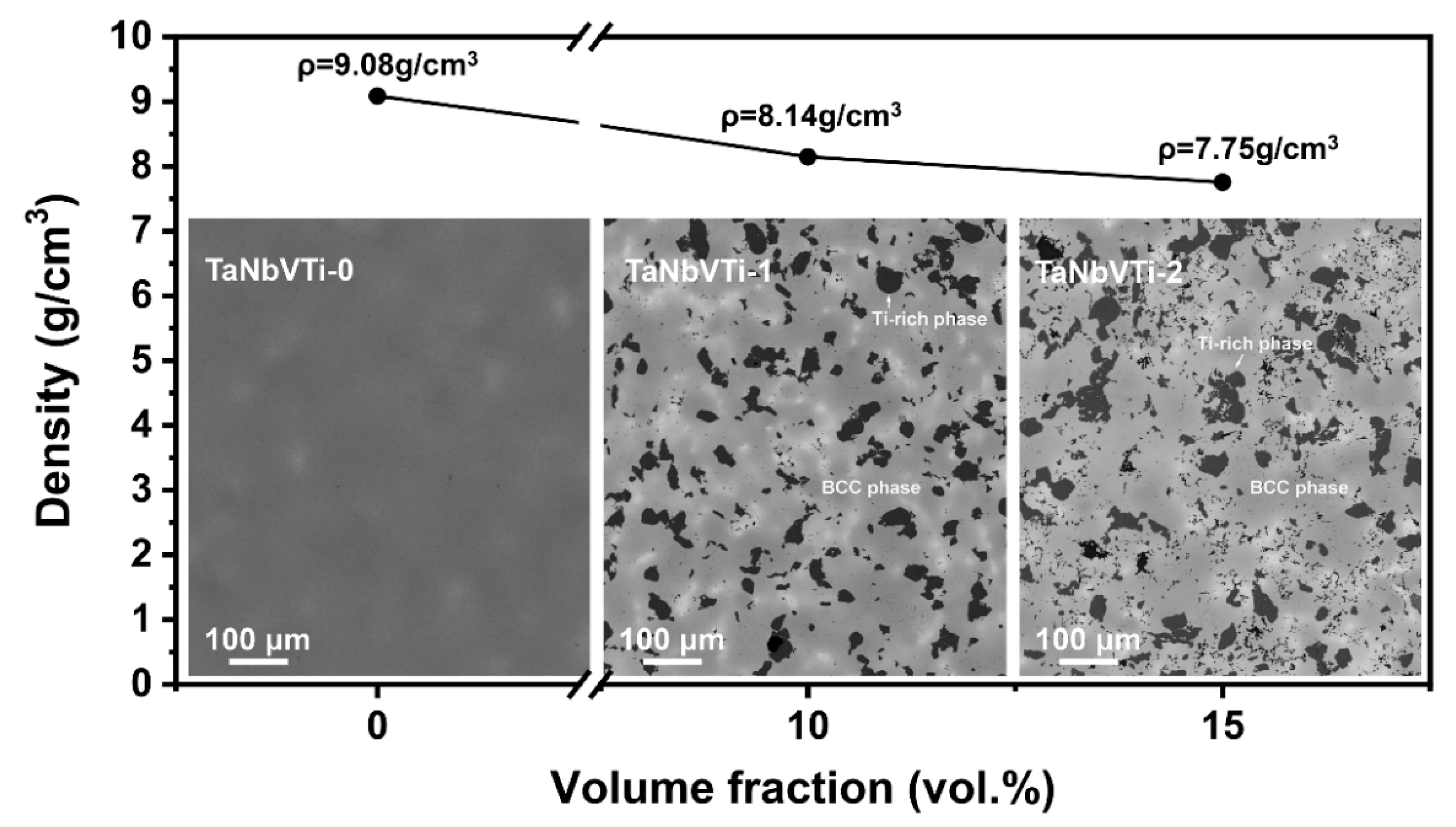

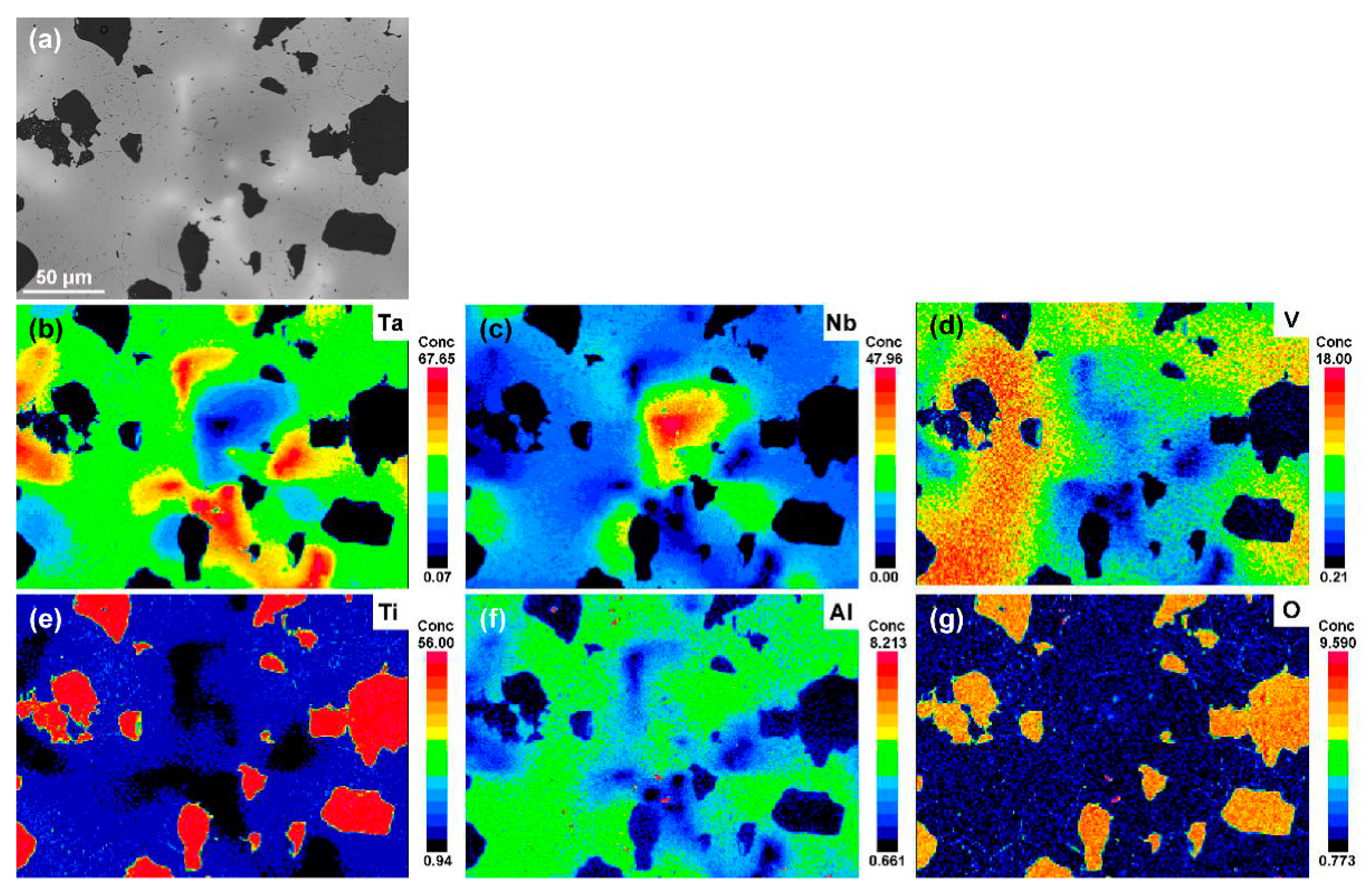

- Novel lightweight TaNbVTi-based RHEAs has been successfully developed through the addition of Al2O3 ceramic particles. The introduction of Al2O3 can promotes the formation of TiO precipitates in the BCC matrix. Meanwhile, Al atoms decomposed from Al2O3 could diffuse and dissolve into the matrix.

- (2)

- The TaNbVTi-2 RHEA has a relative low density of 7.75 g/cm3 with a high compressive yield strength of 1837 MPa, which are 32% higher and 15% lower, respectively, compared to the RHEA without Al2O3 addition. The specific yield strength of TaNbVTi-2 RHEA is better than most reported RHEAs. The newly developed RHEAs are promising for applying in aerospace field (such as aero-engine, nozzle, etc.) due to the high specific strength.

- (3)

- The improved strength is mainly ascribed to the introduction high volume fraction of Al2O3 additives, resulting in solid solution strengthening and precipitation strengthening. Moreover, the ductile matrix is responsible for the good compressive plasticity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Lei, Z.; Liu, X.; Wu, Y.; Wang, H.; Jiang, S.; Wang, S.; Hui, X.; Wu, Y.; Gault, B.; Kontis, P.; et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 2018, 563, 546–550. [Google Scholar] [CrossRef]

- Zou, Y.; Maiti, S.; Steurer, W.; Spolenak, R. Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Mater. 2014, 65, 85–97. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Lu, W.; Liu, B.; Li, J.; Fang, Q.; Li, Z.; Liu, Y. A novel supersaturated medium entropy alloy with superior tensile properties and corrosion resistance. Scr. Mater. 2020, 186, 381–386. [Google Scholar] [CrossRef]

- Klimova, M.; Stepanov, N.; Shaysultanov, D.; Chernichenko, R.; Yurchenko, N.; Sanin, V.; Zherebtsov, S. Microstructure and mechanical properties evolution of the Al, C-containing CoCrFeNiMn-type high-entropy alloy during cold rolling. Materials 2018, 11, 53. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Zhao, Y.; Huang, S.; Zhu, S.; Wang, F.; Li, D. Manufacturing and analysis of high-performance refractory high-entropy alloy via selective laser melting (SLM). Materials 2019, 12, 720. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Senkov, O.N.; Senkova, S.V.; Woodward, C.; Miracle, D.B. Low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system: Microstructure and phase analysis. Acta Mater. 2013, 61, 1545–1557. [Google Scholar] [CrossRef]

- Guo, W.; Liu, B.; Liu, Y.; Li, T.; Fu, A.; Fang, Q.; Nie, Y. Microstructures and mechanical properties of ductile NbTaTiV refractory high entropy alloy prepared by powder metallurgy. J. Alloys Compd. 2019, 776, 428–436. [Google Scholar] [CrossRef]

- Juan, C.C.; Tsai, M.H.; Tsai, C.W.; Lin, C.M.; Wang, W.R.; Yang, C.C.; Chen, S.K.; Lin, S.J.; Yeh, J.W. Enhanced mechanical properties of HfMoTaTiZr and HfMoNbTaTiZr refractory high-entropy alloys. Intermetallics 2015, 62, 76–83. [Google Scholar] [CrossRef]

- Roh, A.; Kim, D.; Nam, S.; Kim, D.I.; Kim, H.Y.; Lee, K.A.; Choi, H.; Kim, J.H. NbMoTaW refractory high entropy alloy composites strengthened by in-situ metal-non-metal compounds. J. Alloys Compd. 2020, 822, 153423. [Google Scholar] [CrossRef]

- Kvashnin, A.G.; Tantardini, C.; Zakaryan, H.A.; Kvashnina, Y.A.; Oganov, A.R. Computational Search for New W−Mo−B Compounds. Chem. Mater. 2020, 32, 7028–7035. [Google Scholar] [CrossRef]

- Wang, Q.; Han, J.; Liu, Y.; Zhang, Z.; Dong, C.; Liaw, P.K. Coherent precipitation and stability of cuboidal nanoparticles in body-centered-cubic Al0.4Nb0.5Ta0.5TiZr0.8 refractory high entropy alloy. Scr. Mater. 2021, 190, 40–45. [Google Scholar] [CrossRef]

- Bai, Z.C.; Ding, X.F.; Hu, Q.; Yang, M.; Fan, Z.T.; Liu, X.W. Unique deformation behavior and microstructure evolution in high-temperature processing of a low-density TiAlVNb2 refractory high-entropy alloy. J. Alloys Compd. 2021, 885, 160962. [Google Scholar] [CrossRef]

- Liu, X.W.; Bai, Z.C.; Ding, X.F.; Yao, J.Q.; Wang, L.; Su, Y.Q.; Fan, Z.T.; Guo, J.J. A novel light-weight refractory high-entropy alloy with high specific strength and intrinsic deformability. Mater. Lett. 2021, 287, 129255. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Z.; Wang, M.; Li, Y.; Wu, C.; Yang, Y. A single-phase V0.5Nb0.5ZrTi refractory high-entropy alloy with outstanding tensile properties. Mater. Sci. Eng. A 2020, 792, 139774. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C. Effect of aluminum on the microstructure and properties of two refractory high-entropy alloys. Acta Mater. 2014, 68, 214–228. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Liaw, P.K. Microstructure and compressive properties of NbTiVTaAlx high entropy alloys. Procedia Eng. 2012, 36, 292–298. [Google Scholar] [CrossRef] [Green Version]

- Xin, C.; Liu, W.; Li, N.; Yan, J.; Shi, S. Metallization of Al2O3 ceramic by magnetron sputtering Ti/Mo bilayer thin films for robust brazing to Kovar alloy. Ceram. Int. 2016, 42, 9599–9604. [Google Scholar] [CrossRef]

- Guo, Y.; Li, M.; Li, P.; Chen, C.; Zhan, Q.; Chang, Y.; Zhang, Y. Microstructure and mechanical properties of oxide dispersion strengthened FeCoNi concentrated solid solution alloys. J. Alloys Compd. 2020, 820, 153104. [Google Scholar] [CrossRef]

- Yamashita, S.; Ohtsuka, S.; Akasaka, N.; Ukai, S.; Ohnuki, S. Formation of nanoscale complex oxide particles in mechanically alloyed ferritic steel. Philos. Mag. Lett. 2004, 84, 525–529. [Google Scholar] [CrossRef]

- He, P.; Gao, P.; Tian, Q.; Lv, J.; Yao, W. An in situ SANS study of nanoparticles formation in 9Cr ODS steel powders. Mater. Lett. 2017, 209, 535–538. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, W.; Liu, B.; Liu, Y.; Du, M.; Fu, A. Phase decomposition behavior and its effects on mechanical properties of TiNbTa0.5ZrAl0.5 refractory high entropy alloy. J. Mater. Sci. Technol. 2021, 66, 10–20. [Google Scholar] [CrossRef]

- Fan, Q.C.; Li, B.S.; Zhang, Y. The microstructure and properties of (FeCrNiCo)AlxCuy high-entropy alloys and their TiC-reinforced composites. Mater. Sci. Eng. A 2014, 598, 244–250. [Google Scholar] [CrossRef]

- Agustianingrum, M.P.; Yoshida, S.; Tsuji, N.; Park, N. Effect of aluminum addition on solid solution strengthening in CoCrNi medium-entropy alloy. J. Alloys Compd. 2019, 781, 866–872. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Couzinié, J.P.; Senkov, O.N.; Miracle, D.B.; Dirras, G. Comprehensive data compilation on the mechanical properties of refractory high-entropy alloys. Data Brief 2018, 21, 1622–1641. [Google Scholar] [CrossRef]

| Raw Powders | Average Particle Size (μm) | C (wt.%) | O (wt.%) | H (wt.%) | N (wt.%) |

|---|---|---|---|---|---|

| Ta | 24.5 | 0.020 | 0.130 | 0.0008 | 0.0064 |

| Nb | 26.1 | 0.011 | 0.340 | 0.0015 | 0.0220 |

| V | 22.6 | 0.028 | 0.290 | 0.0014 | 0.0096 |

| Ti | 29.1 | 0.018 | 0.280 | 0.0147 | 0.0150 |

| Al2O3 | 0.3 | 0.013 | 16.56 | 0.0653 | 0.0070 |

| As-Milled Powders | Average Particle Size (μm) | Nb (at.%) | Ta (at.%) | Ti (at.%) | V (at.%) | Al (at.%) | O (at.%) |

|---|---|---|---|---|---|---|---|

| TaNbVTi-0 | 21.5 | 22.66 | 27.61 | 24.25 | 23.17 | 0 | 2.31 |

| TaNbVTi-1 | 23.2 | 19.27 | 23.39 | 20.33 | 19.58 | 6.73 | 10.70 |

| TaNbVTi-2 | 24.3 | 17.47 | 22.21 | 18.57 | 17.67 | 9.72 | 14.37 |

| Alloys | Testing Method | Yield Strength (MPa) | Fracture Strength (MPa) | Fracture Strain/Elongation (%) |

|---|---|---|---|---|

| TaNbVTi-0 | Compression | 1391 | 1932 | 16..7 |

| TaNbVTi-1 | 1776 | 2004 | 12.0 | |

| TaNbVTi-2 | 1837 | 2030 | 11.2 | |

| TaNbVTi-0 | Tensile | 1345 | 1724 | 7.2 |

| TaNbVTi-1 | 1694 | 1908 | 2.3 | |

| TaNbVTi-2 | 1762 | 1927 | 2.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, A.; Cao, Y.; Liu, Y.; Xu, S. Microstructure and Mechanical Properties of Novel Lightweight TaNbVTi-Based Refractory High Entropy Alloys. Materials 2022, 15, 355. https://doi.org/10.3390/ma15010355

Fu A, Cao Y, Liu Y, Xu S. Microstructure and Mechanical Properties of Novel Lightweight TaNbVTi-Based Refractory High Entropy Alloys. Materials. 2022; 15(1):355. https://doi.org/10.3390/ma15010355

Chicago/Turabian StyleFu, Ao, Yuankui Cao, Yuxi Liu, and Shenghang Xu. 2022. "Microstructure and Mechanical Properties of Novel Lightweight TaNbVTi-Based Refractory High Entropy Alloys" Materials 15, no. 1: 355. https://doi.org/10.3390/ma15010355

APA StyleFu, A., Cao, Y., Liu, Y., & Xu, S. (2022). Microstructure and Mechanical Properties of Novel Lightweight TaNbVTi-Based Refractory High Entropy Alloys. Materials, 15(1), 355. https://doi.org/10.3390/ma15010355