Ultra-Violet Protection and Anti-Static Characteristics with Heat Release/Shielding of Al2O3/ATO/TiO2-Imbedded Multi-Functional Fabrics

Abstract

:1. Introduction

2. Materials and Methods

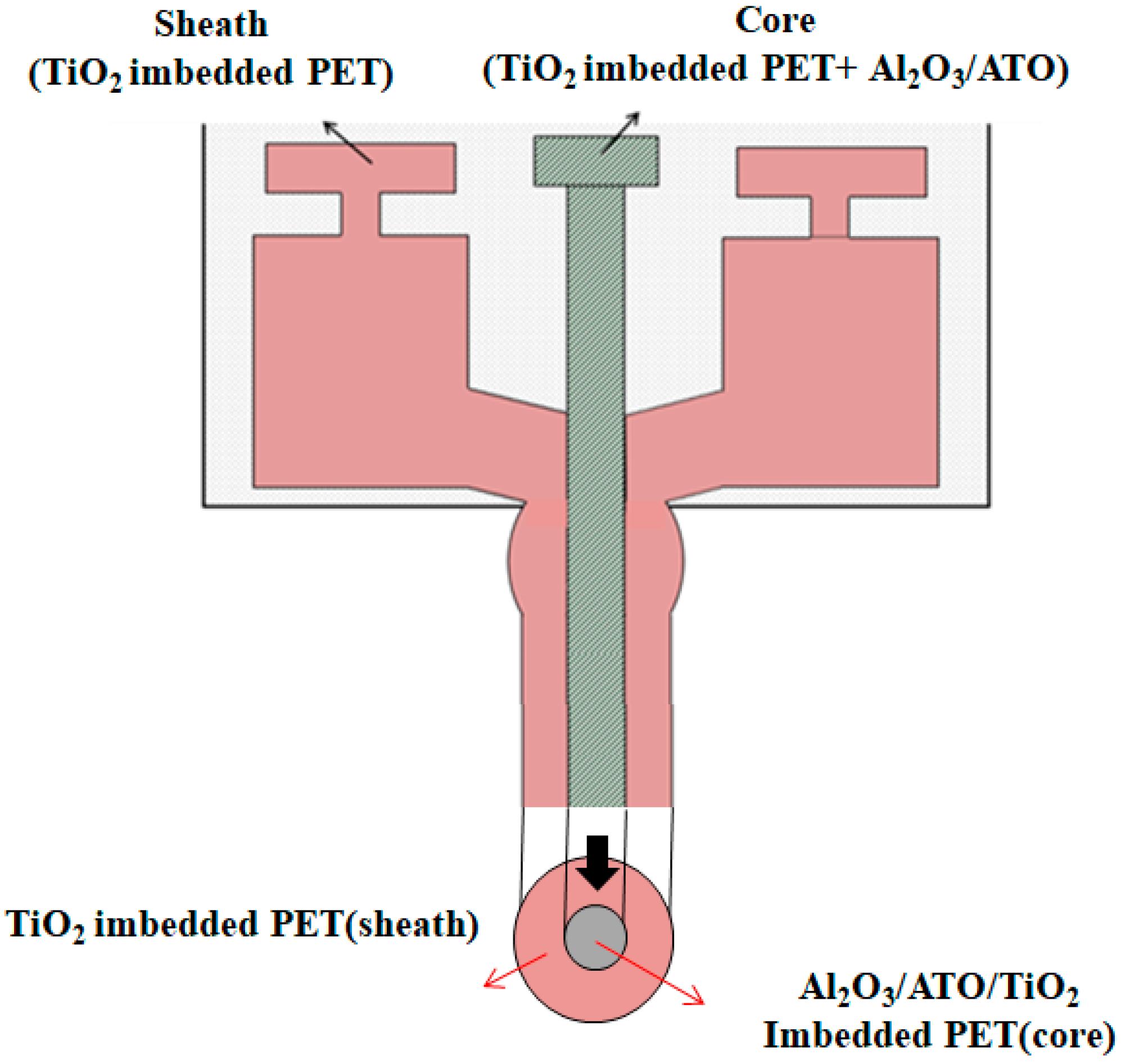

2.1. Spinning of Yarn Specimens

2.2. Preparation of Fabric Specimens

2.3. Elemental Analysis and FIR Measurement of the Yarn Specimens

2.4. Light Heat Emission Measurement

2.5. Measurement of UV Protection

2.6. Anti-Static and Electric Resistance Measurement

2.7. Measurement of Fabric Mechanical Property

3. Results and Discussion

3.1. Elemental Analysis and Heat Release Characteristics of the Al2O3/ATO/TiO2-Imbedded Fabrics

3.2. UPF of the Al2O3/ATO/TiO2-Imbedded Fabrics

3.3. Anti-Static Property of the Al2O3/ATO-Imbedded Fabrics

3.4. Tactile Hand Feel of Al2O3/ATO/TiO2-Imbedded Fabric Specimens

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Negishi, N.; Kikuchi, M. Infrared ray effects in biological systems. Ceram. Jpn. 1988, 23, 335–339. [Google Scholar]

- Furuta, T.; Shimizu, Y.; Kondo, Y. Evaluating the temperature and humidity characteristics of solar energy absorbing and retaining fabric. Text. Res. J. 1996, 66, 123–130. [Google Scholar] [CrossRef]

- Bahng, G.W.; Lee, J.D. Development of heat-generating polyester fiber harnessing catalytic ceramic powder combined with heat-generating super microorganisms. Text. Res. J. 2014, 84, 1220–1230. [Google Scholar] [CrossRef]

- Kim, H.A.; Kim, S.J. Far-infrared emission characteristics and wear comfort property of ZrC-imbedded heat storage knitted fabrics for emotional garments. Autex Res. J. 2017, 17, 142–151. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.A.; Kim, S.J. Heat storage and release characteristics of ceramic-imbedded woven fabric for emotional clothing. Autex Res. J. 2019, 19, 165–172. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.A.; Kim, S.J. Wear comfort properties of ZrC/Al2O3/graphite embedded heat storage woven fabrics for garments. Text. Res. J. 2019, 89, 1394–1407. [Google Scholar] [CrossRef]

- Unitika. Unitika’s Activity Fields: Connected Through Technologies and Principles. Available online: https://www.unitika.co.jp/e/company/img-pdf/download/p03-04.pdf (accessed on 10 June 2017).

- Kurray. Fabric, Manmade Leather, Nonwoven Fabric, Hook and Loop Fasteners. Available online: https://www.kuraray.com/products/fiber (accessed on 13 June 2017).

- Mitsubishi Chemical Holdings Group. Fibers & Textiles | Products | Mitsubishi Chemical Corporation. Available online: www.m-chemical.co.jp (accessed on 16 May 2022).

- KB Seiren. FLETHERMO. Available online: https://www.kbseiren.com/english/pro-flethermo.html (accessed on 22 July 2017).

- Fan, J.; Hunter, L. Engineering Apparel Fabrics and Garments; The Textile Institute: Cambridge, UK; Woodhead Publishing Limited: Cambridge, UK; CRC Press: Boca Raton, FL, USA, 2009; pp. 309–338. [Google Scholar]

- Wong, Y.W.H.; Yuen, C.W.M.; Leung, M.Y.S.; Ku, S.K.A.; Lam, H.L.I. Selected Applications of Nanotechnology in Textile. Autex Res. J. 2006, 6, 1. [Google Scholar]

- Xin, J.J.; Daoud, W.A.; Kong, Y.Y. A New Approach to UV-Blocking Treatment for Cotton Fabrics. Text. Res. J. 2004, 74, 97–100. [Google Scholar] [CrossRef]

- Bumiston, N.; Bygott, C.; Stratton, J. Nano Technology Meets Titanium Dioxide. Surf. Coat. Int. Part A 2004, 87, 179–184. [Google Scholar]

- Sherman, J. Nanoparticle Titanium Dioxide Coating and Processes for the Production and Use Thereof. U.S. Patent 6653356B2, 25 November 2003. [Google Scholar]

- Yang, H.Y.; Zhu, S.K.; Pan, N. Studying the Mechanisms of Titanium Dioxide as Ultraviolet-Blocking Additive for Films and Fabrics by and Improved Scheme. J. Appl. Polym. Sci. 2003, 92, 3201–3210. [Google Scholar] [CrossRef]

- Saito, M. Antibacterial, Deodorizing, and UV Absorbing Materials Obtained with Zinc Oxide (ZnO) Coated Fabrics. J. Coat. Fabr. 1993, 23, 150–164. [Google Scholar] [CrossRef]

- Xiong, M.N.; Gu, G.X.; You, B.; Wu, L.M. Preparation and Characterization of Poly (styrenebutylacrylate) Latex/Nano-ZnO Nanocomposites. J. Appl. Polym. Sci. 2003, 90, 1923–1931. [Google Scholar] [CrossRef]

- Wang, R.H.; Xin, J.J.; Tao, X.M.; Daoud, W.A. ZnO nanorods grown on cotton fabrics at low temperature. Chem. Phys. Lett. 2004, 398, 250–255. [Google Scholar] [CrossRef]

- Deopura, B.L.; Alagirusamy, R.; Joshi, M.; Gupta, B. Polyesters and Polyamides, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 2008; pp. 171–199. [Google Scholar]

- Dong, W.G.; Huang, G. Research on properties of nano polypropylene/TiO2 composite fiber. Text. Res. J. 2002, 23, 22–23. [Google Scholar]

- Wu, Y.; Chi, Y.B.; Nie, J.X.; Yu, A.P.; Chen, X.H.; Gu, H.C. Preparation and application of novel fabric finishing agent containing nano ATO. J. Funct. Polym. 2002, 15, 43–47. [Google Scholar]

- Ahn, T.X.; Tung, D.T.; Nhan, D.Q.; Hoang, T.V.; Trung, D.Q.; Thu, L.D.; Hoang, P.H.; Cuong, N.D. Study of ATO nanoparticles by the solvothermal method for thermal insulated coated glass: A green energy application. Green Process. Synth. 2016, 5, 529–535. [Google Scholar] [CrossRef]

- Sun, H.; Liu, X.; Liu, B.; Yin, Z. Preparation and properties of antimony doped tin oxide nanopowders and their conductivity. Mater. Res. Bull. 2016, 83, 354–359. [Google Scholar] [CrossRef]

- Muller, V.; Rathousky, J.; Rasp, M.; Stefanic, G.; Gunter, S.; Niederberger, M.; Fattakhova-Rohlfing, D. Highly conducting nanosized monodispersed antimony-doped tin oxide particles synthesized via nonaqueous sol-gel procedure. Chem. Mater. 2009, 21, 5229–5236. [Google Scholar] [CrossRef]

- JIS L 1094; Testing Methods for Electrostatic Propensity of Woven and Knitted Fabrics. Japanese Standards Association: Tokyo, Japan, 1999.

- KS K 0170; Test Methods for Surface Electrical Resistivity of Fabrics. Korea Ind. Stand. Commission: Seoul, Korea, 2019.

- CSIRO Division of Wool Technology. The FAST System for the Objective Measurement of Fabric Properties Operation, Interpretation and Application; CDW Technology: Geelong, Australia, 1989. [Google Scholar]

- Reinert, Y.; Fuso, F.; Hilfiker, R.; Schmidt, E. UV-protecting properties of textile fabrics and their improvement. Text. Chem. Col. 1997, 29, 36–43. [Google Scholar]

- Schuierer, M. Practical experience with solartex products in finishing of sun protection fabrics. Mell. Int. 1997, 3, 168–169. [Google Scholar]

- Hunter, L. Ultraviolet Protection of Fabrics and Garments, p309 in Engineering Apparel Fabrics and Garments; Woodhead Publishing Limited: Cambridge, UK; The Textile Institute: Cambridge, UK, 2009. [Google Scholar]

- Muller, V.; Rathousky, J.; Rasp, M.; Stafanic, G.; Gunther, S.; Niederberger, M.; Fattakhova-Rohlfing, D. Highly conducting nanosized monodispersed antimony-doped tin oxide particles synthesized via nonaqueous Sol-Gel method. NSTI-Nanotech 2010, 1, 340–343. [Google Scholar]

- Kim, H.A. Tactile hand and wear comfort of flame-retardant rayon/anti-static PET imbedded woven fabrics. Text. Res. J. 2019, 89, 4658–4669. [Google Scholar] [CrossRef]

- Tadesse, M.G.; Nagy, L.; Nierstrasz, V.; Loghin, C.; Chen, Y.; Wang, L. Low-stress mechanical property study of various functional fabrics for tactile property evaluation. Materials 2018, 11, 2466. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| PET Chip (kg) | M/B Chip Weight (kg) | Mixed Polymer (kg) | Mixing Ratio wt.% of M/B | ||||

|---|---|---|---|---|---|---|---|

| Al2O3 | ATO | Al2O3 | ATO | Total (wt.%) | |||

| Concentration of M/B chip (wt.%) | - | 20 (wt.%) | 20 (wt.%) | ||||

| Al2O3/ATO PET | 47.25 | 2 | 0.75 | 50 | 0.8 | 0.3 | 1.1 |

| Characteristics | Spinning Conditions | |||

|---|---|---|---|---|

| Spinning temp. | Spinbeam temp. (°C) | 287 | ||

| Mainfold temp. (°C) | 290/290 | |||

| Extruder heating temp. (°C) (S/C) | 300–305/301–304 | |||

| Roller speed and temp. | First GR speed (m/min) | 1446 | ||

| Second GR speed (m/min) | 3910 | |||

| First GR temp. (°C) | 85 | |||

| Second GR temp. (°C) | 105 | |||

| F/R speed (m/min) | 4000 | |||

| Yarn specification | Yarn linear density (d/f) | SDY 50d/24f | ||

| Sheath/core weight ratio (%) | 50:50 | 40:60 | 30:70 | |

| Specimen No. | Yarn Count (d/f) | Sheath: Core (S/C) Ratio | Fabric Density (Picks, Ends/In) | Thickness | Weight | ||

|---|---|---|---|---|---|---|---|

| Wp | Wf | Wp | Wf | (mm) | (g/m2) | ||

| 1 | PET 50/72 | Al2O3/ATO | 5:5 | 154 | 100 | 0.13 | 85.4 |

| 2 | PET 50/72 | S/C PET | 4:6 | 154 | 100 | 0.12 | 84.8 |

| 3 | PET 50/72 | 50/24 | 3:7 | 154 | 100 | 0.13 | 85.6 |

| 4 | PET 50/72 | Reg PET 50/72 | - | 154 | 100 | 0.12 | 84.2 |

| Specimens | Specimen 1 | Specimen 2 | Specimen 3 | Specimen 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Mean | Dev. | Mean | Dev. | Mean | Dev. | Mean | Dev. | |

| Emissivity | 0.885 | 0.1 × 10−3 | 0.884 | 0.2 × 10−3 | 0.882 | 0.1 × 10−3 | 0.866 | 0.2 × 10−3 |

| Emissive power (W/m2·µm) | 3.44 × 102 | 0.001 × 102 | 3.43 × 102 | 0.002 × 102 | 3.42 × 102 | 0.001 × 102 | 3.40 × 102 | 0.001 × 103 |

| Specimens | UPF | Rub-Voltage (V) | Surface Electrical Resistivity (Ω/sq) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | Dev. | Cotton | Wool | ||||||

| Mean | Dev. | Mean | Dev. | Mean | Dev. | ||||

| 1 | Al2O3/ATO 50% PET | 252.5 | 11.0 | 6250 | 99 | 5850 | 93 | 7.70 × 1010 | 0.4 × 1010 |

| 2 | Al2O3/ATO 60% PET | 214.2 | 10.0 | 5860 | 77 | 4980 | 74 | 7.30 × 1010 | 0.3 × 1010 |

| 3 | Al2O3/ATO 70% PET | 182.5 | 15.5 | 4210 | 44 | 3820 | 51 | 5.44 × 1010 | 0.4 × 1010 |

| 4 | TiO2-imbedded regular PET | 382.3 | 19.3 | 6980 | 111 | 6750 | 68 | 14.30 × 1010 | 0.6 × 1010 |

| Physical Properties | F-Value (F0) | F (3, 16, 0.95) | p-Value | |

|---|---|---|---|---|

| UPF | 1801.5 | 3.24 | 1.92 × 10–20 | |

| Rub-voltage | Cotton | 6042.3 | 3.24 | 1.22 × 10–24 |

| Wool | 9768.9 | 3.24 | 2.62 × 10–26 | |

| SER | 2836.0 | 3.24 | 5.14 × 10–22 | |

| Specimens | E 100 (%) | G (N/m) | B (µN·m) | ST (mm) | |||

|---|---|---|---|---|---|---|---|

| Wp | Wf | Wp | Wf | ||||

| 1 | Al2O3/ATO 50% PET | 0.87 | 0.45 | 52.0 | 31.3 | 34.5 | 0.017 |

| 2 | Al2O3/ATO 60% PET | 0.80 | 0.42 | 55.1 | 32.5 | 39.5 | 0.016 |

| 3 | Al2O3/ATO 70% PET | 0.73 | 0.40 | 57.4 | 33.0 | 40.2 | 0.015 |

| 4 | TiO2-imbedded regular PET | 0.97 | 0.47 | 43.8 | 30.3 | 33.2 | 0.019 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-A. Ultra-Violet Protection and Anti-Static Characteristics with Heat Release/Shielding of Al2O3/ATO/TiO2-Imbedded Multi-Functional Fabrics. Materials 2022, 15, 3652. https://doi.org/10.3390/ma15103652

Kim H-A. Ultra-Violet Protection and Anti-Static Characteristics with Heat Release/Shielding of Al2O3/ATO/TiO2-Imbedded Multi-Functional Fabrics. Materials. 2022; 15(10):3652. https://doi.org/10.3390/ma15103652

Chicago/Turabian StyleKim, Hyun-Ah. 2022. "Ultra-Violet Protection and Anti-Static Characteristics with Heat Release/Shielding of Al2O3/ATO/TiO2-Imbedded Multi-Functional Fabrics" Materials 15, no. 10: 3652. https://doi.org/10.3390/ma15103652

APA StyleKim, H.-A. (2022). Ultra-Violet Protection and Anti-Static Characteristics with Heat Release/Shielding of Al2O3/ATO/TiO2-Imbedded Multi-Functional Fabrics. Materials, 15(10), 3652. https://doi.org/10.3390/ma15103652