Potential of Rapid Tooling in Rapid Heat Cycle Molding: A Review

Abstract

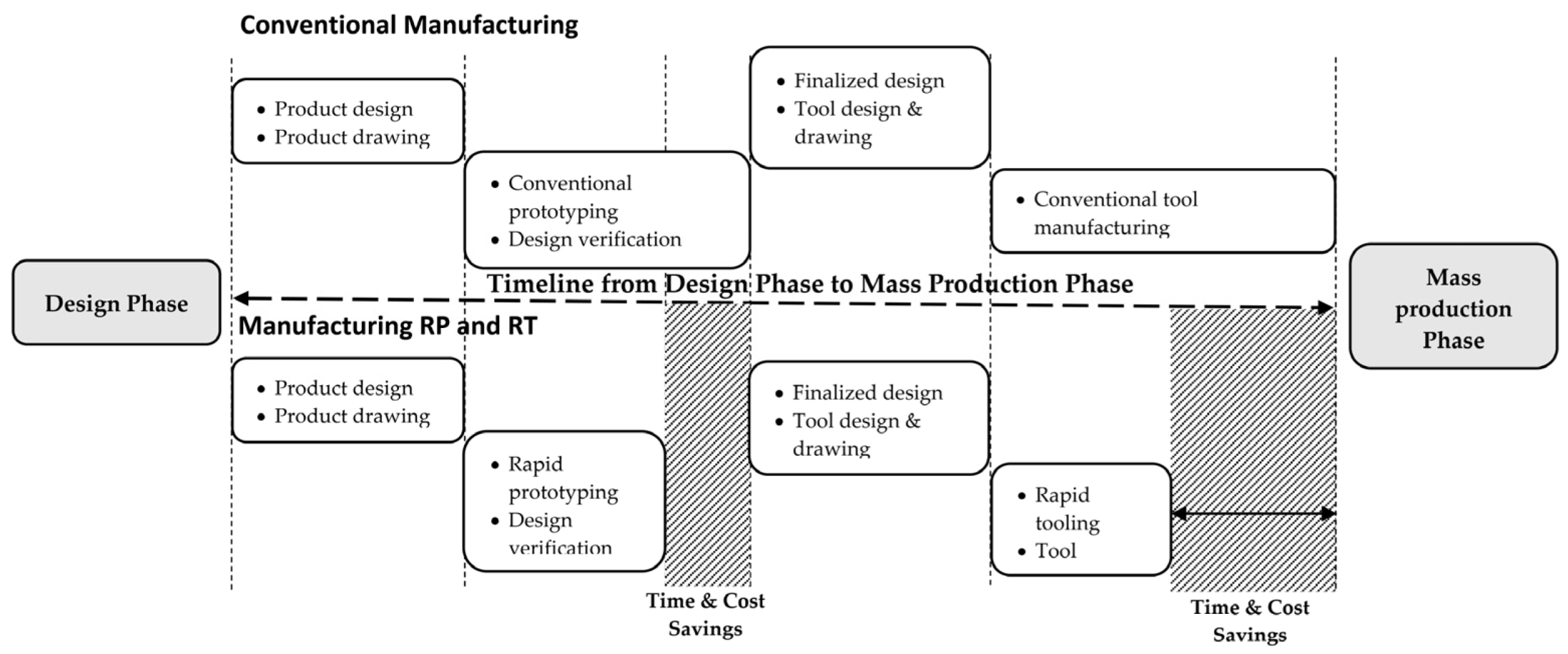

:1. Introduction

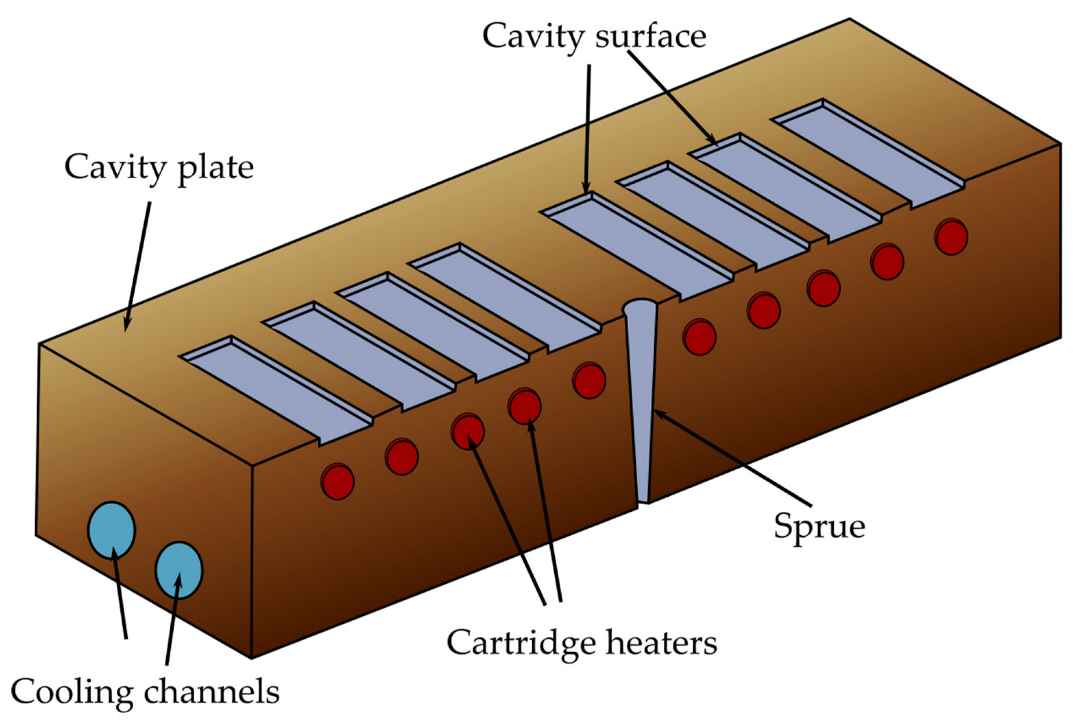

2. Injection Molding Process

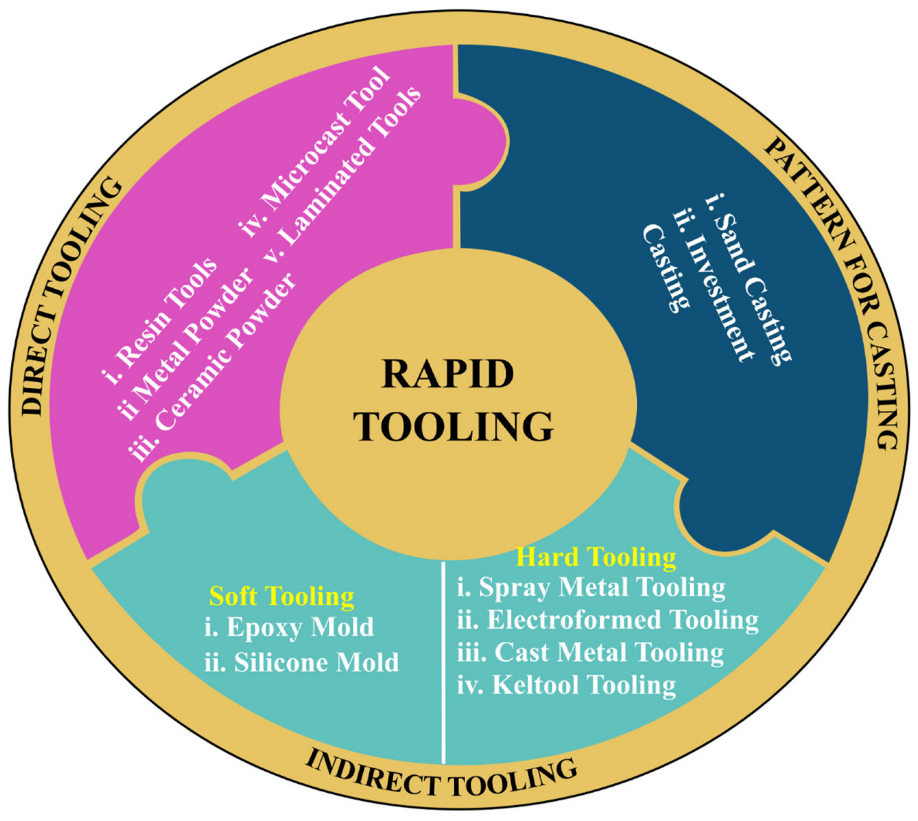

3. Rapid Tooling

4. Materials for Injection Mold

4.1. Mold Base Material

4.2. Mold Insert Material

4.2.1. Mold Inserts for Conventional Injection Molding

4.2.2. Mold Inserts for Rapid Heat Cycle Molding

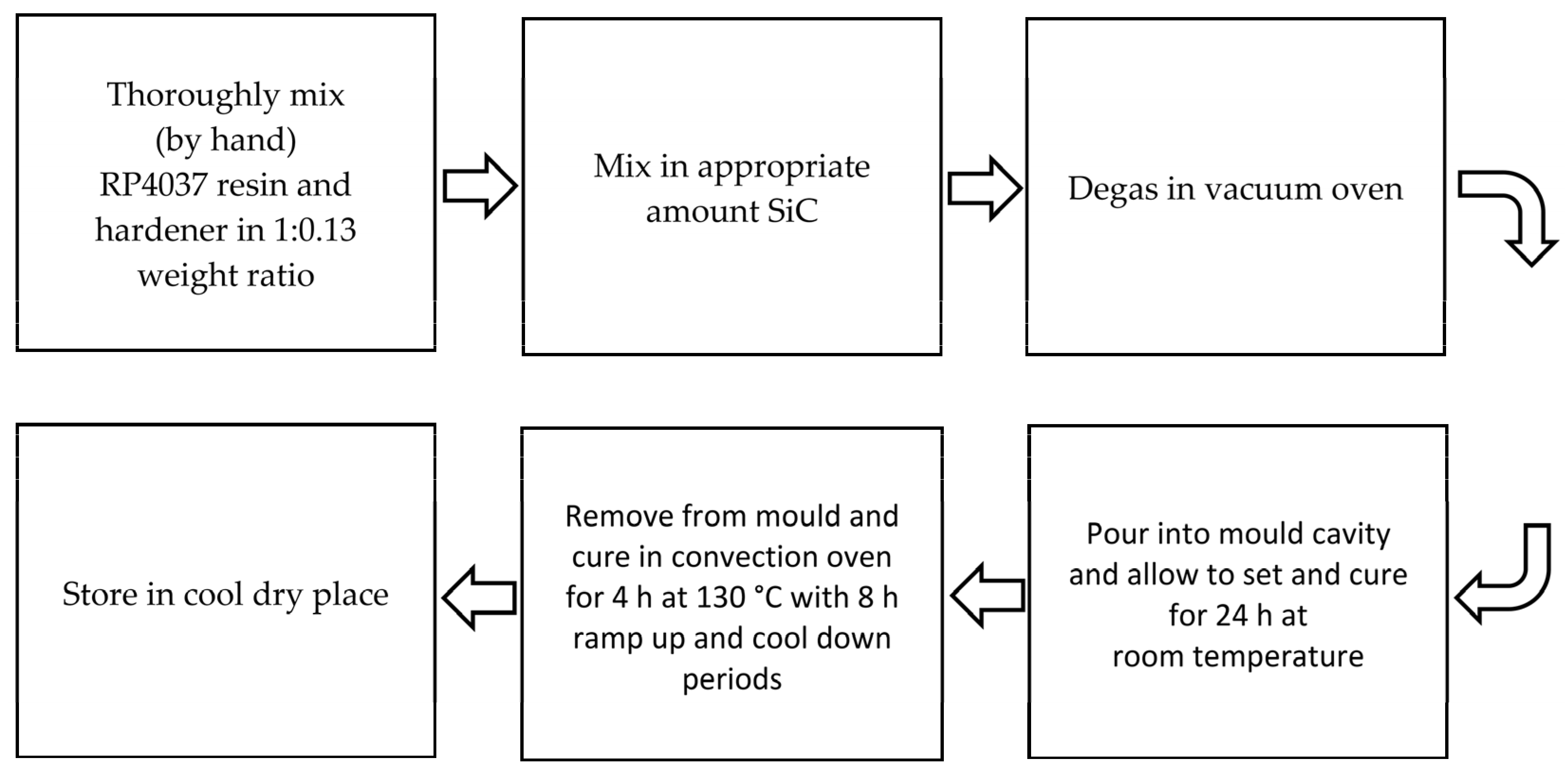

4.2.3. Mold Inserts for Rapid Tooling

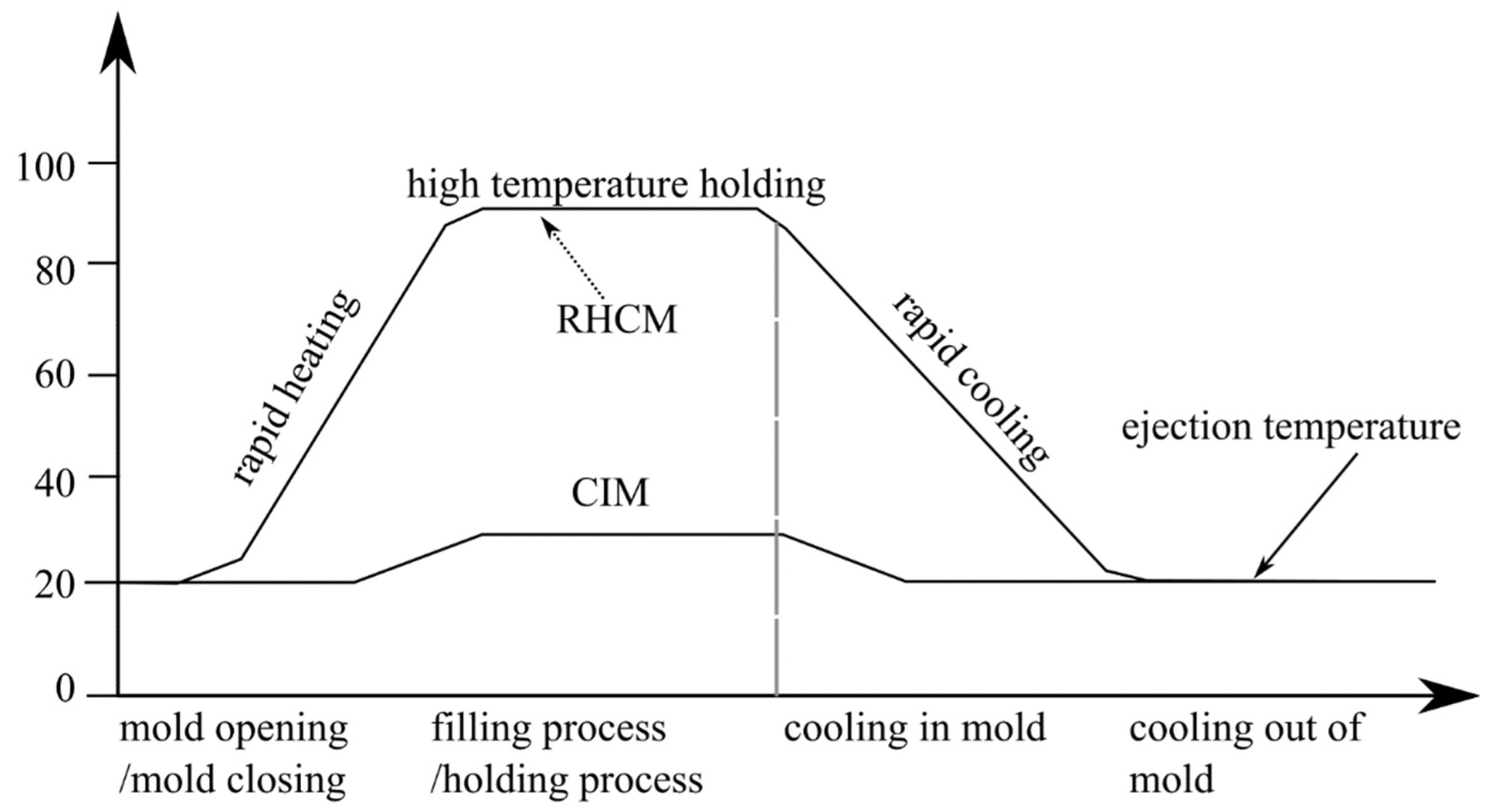

5. Rapid Heat Cycle Molding

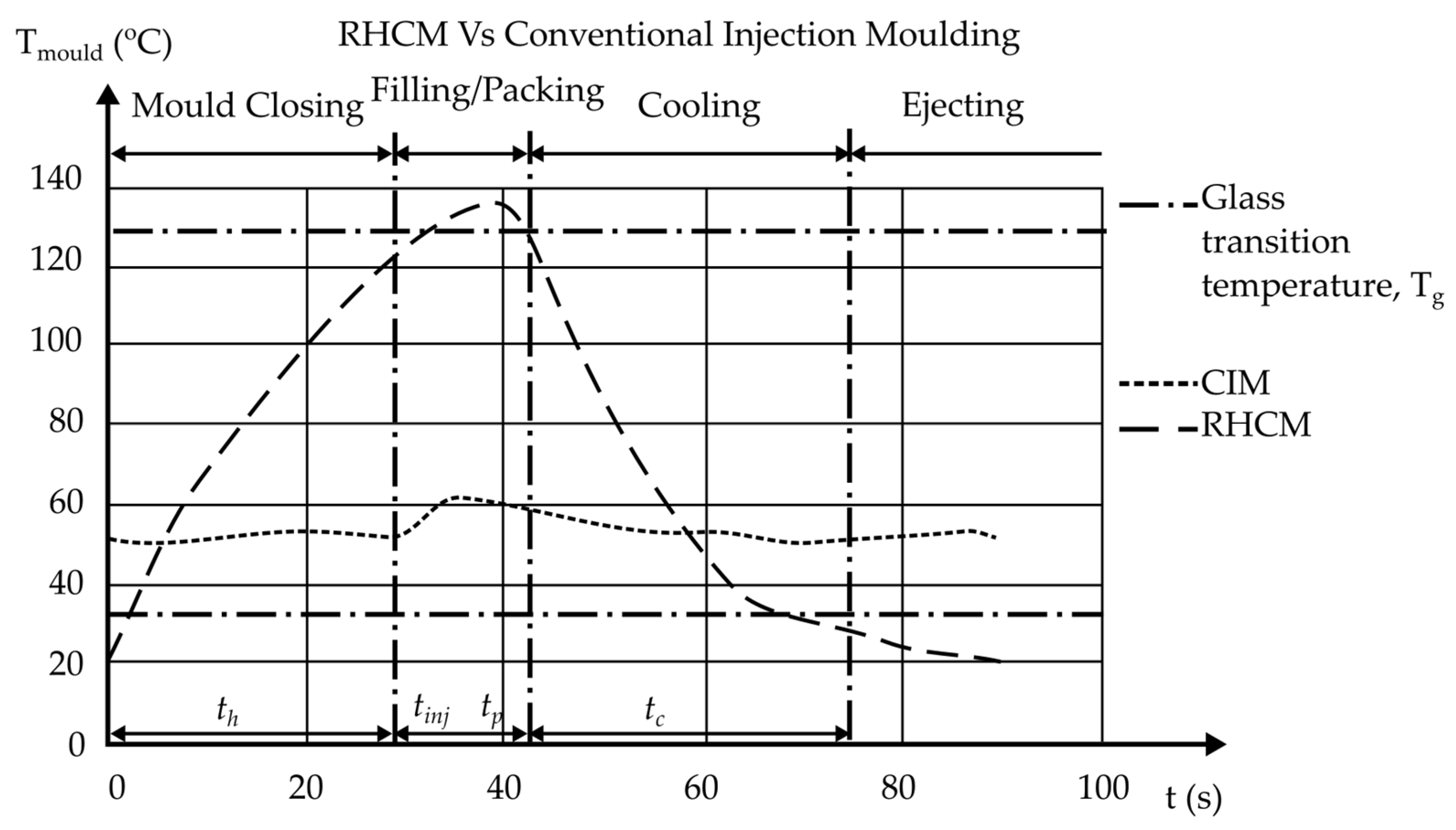

6. RHCM versus Conventional Injection Molding

6.1. Application of RHCM in CIM

6.2. RHCM Technologies

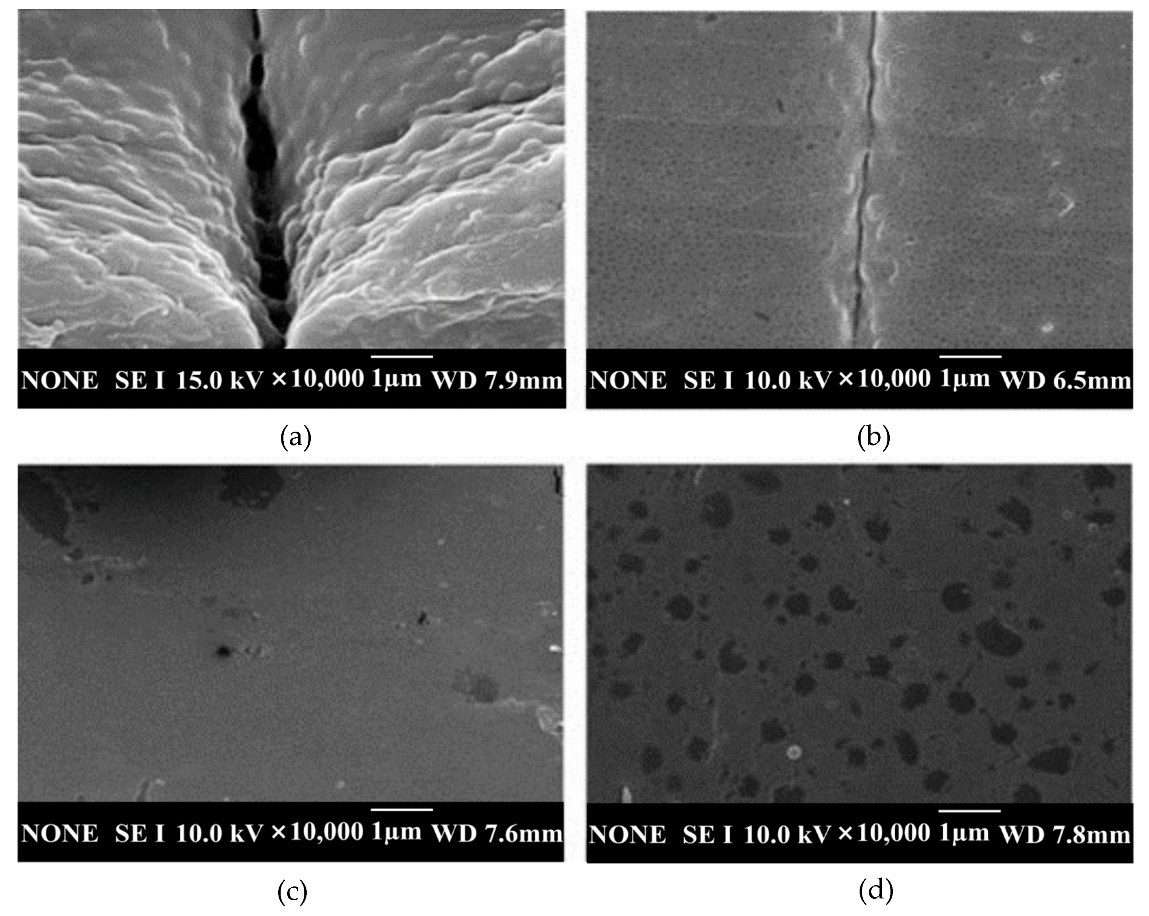

7. Effect of RHCM on the Molded Parts

8. Summary and Future Works

- Previous researchers attempted to integrate new compositions of mold insert materials such as epoxy resin composites containing aluminum (Al) particles as filler to improve the mechanical properties of the injected parts. Thus, various types of metal fillers that can be used as fillers in epoxy resin composites should be studied. Studies should be aimed at looking for a new metal epoxy composites as the mold insert materials in RT with the best compositions of epoxy resin ratio and metal filler ratio.

- The performance of new metal epoxy composite designs in terms of flexural strength, hardness, thermal conductivity, tensile strength, compressive strength, density, thermal diffusivity, and surface roughness must be studied before they can be used as mold inserts in the injection molding process.

- Previous research on RHCM parts produced with conventional mold inserts discovered that the weld line was reduced while the strength was increased. Thus, there is a lot of potential in researching the use of mold inserts made by RT in RHCM technology to yield molded parts with good surface appearance and properties.

- Previous research did not yield a positive correlation between the heating time by induction heating and temperature distribution pattern on mold plates produced by the RT technique. Therefore, further investigation is required.

- Lastly, investigating the temperature distribution on the surface of the mold insert is critical in determining the effect of heating on the molded parts. Thus, further studies into the temperature distribution on the mold insert surface of different materials of mold inserts in RHCM should be conducted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MacDonald, E.; Salas, R.; Espalin, D.; Perez, M.; Aguilera, E.; Muse, D.; Wicker, R.B. 3D Printing for the Rapid Prototyping of Structural Electronics. IEEE Access 2014, 2, 234–242. [Google Scholar] [CrossRef]

- Matzler, K.; Hinterhuber, H.H. How to make product development projects more successful by integrating Kano’s model of customer satisfaction into quality function deployment. Technovation 1998, 18, 25–38. [Google Scholar] [CrossRef]

- Rahmati, S.; Dickens, P. Rapid tooling analysis of Stereolithography injection mould tooling. Int. J. Mach. Tools Manuf. 2007, 47, 740–747. [Google Scholar] [CrossRef]

- Rodríguez-Pinto, J.; Carbonell, P.; Rodríguez-Escudero, A.I. Speed or quality? How the order of market entry influences the relationship between market orientation and new product performance. Int. J. Res. Mark. 2011, 28, 145–154. [Google Scholar] [CrossRef]

- Rajapathirana, R.P.J.; Hui, Y. Relationship between innovation capability, innovation type, and firm performance. J. Innov. Knowl. 2018, 3, 44–55. [Google Scholar] [CrossRef]

- Mendible, G.A.; Rulander, J.A.; Johnston, S.P. Comparative study of rapid and conventional tooling for plastics injection molding. Rapid Prototyp. J. 2017, 23, 344–352. [Google Scholar] [CrossRef]

- Costabile, G.; Fera, M.; Fruggiero, F.; Lambiase, A.; Pham, D. Cost models of additive manufacturing: A literature review. Int. J. Ind. Eng. Comput. 2016, 8, 263–283. [Google Scholar] [CrossRef]

- Equbal, A.; Sood, A.K.; Shamim, M. Rapid tooling: A major shift in tooling practice. Manuf. Ind. Eng. 2015, 14, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Rajaguru, J.C.; Duke, M.B.; Au, C. Development of rapid tooling by rapid prototyping technology and electroless nickel plating for low-volume production of plastic parts. Int. J. Adv. Manuf. Technol. 2015, 78, 31–40. [Google Scholar] [CrossRef]

- Andrew, Y.C.; Nee, A. Handbook of Manufacturing Engineering and Technology; Springer: London, UK, 2015. [Google Scholar]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Rayna, T.; Striukova, L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technol. Forecast. Soc. Chang. 2016, 102, 214–224. [Google Scholar] [CrossRef] [Green Version]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Volpato, N.; Solis, D.M.; Costa, C.A. An analysis of Digital ABS as a rapid tooling material for polymer injection moulding. Int. J. Mater. Prod. Technol. 2016, 52, 3–16. [Google Scholar] [CrossRef]

- Harris, R.A.; Newlyn, H.; Dickens, P.M. Selection of mould design variables in direct stereolithography injection mould tooling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2005, 216, 499–505. [Google Scholar] [CrossRef] [Green Version]

- Altaf, K.; Qayyum, J.A.; Rani, A.M.A.; Ahmad, F.; Megat-Yusoff, P.S.M.; Baharom, M.; Aziz, A.R.A.; Jahanzaib, M.; German, R.M. Performance Analysis of Enhanced 3D Printed Polymer Molds for Metal Injection Molding Process. Metals 2018, 8, 433. [Google Scholar] [CrossRef] [Green Version]

- Altaf, K.; Rani, A.M.A.; Ahmad, F.; Baharom, M.; Raghavan, V.R. Determining the effects of thermal conductivity on epoxy molds using profiled cooling channels with metal inserts. J. Mech. Sci. Technol. 2016, 30, 4901–4907. [Google Scholar] [CrossRef]

- Thomas, P.A.; Aahlada, P.K.; Kiran, N.S.; Ivvala, J. A Review on Transition in the Manufacturing of Mechanical Components from Conventional Techniques to Rapid Casting Using Rapid Prototyping. Mater. Today Proc. 2018, 5, 11990–12002. [Google Scholar] [CrossRef]

- Tuteski, O.; Kočov, A. Mold Design and Production by Using Additive Manufacturing (AM)–Present Status and Future Perspectives. Industry 2018, 3, 82–85. Available online: https://www.eos.info (accessed on 7 December 2021).

- Bagalkot, A.; Pons, D.; Clucas, D.; Symons, D. A methodology for setting the injection moulding process parameters for polymer rapid tooling inserts. Rapid Prototyp. J. 2019, 25, 1493–1505. [Google Scholar] [CrossRef]

- Legesse, F.; Kapil, S.; Vithasth, H.; Karunakaran, K. Additive manufacturing of H13 tooling element with conformal cooling channel using MIG cladding. Int. J. Rapid Manuf. 2018, 7, 1. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Li, M.-R. Development of sheet metal forming dies with excellent mechanical properties using additive manufacturing and rapid tooling technologies. Int. J. Adv. Manuf. Technol. 2017, 90, 21–25. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef] [Green Version]

- Kampker, A.; Ayvaz, P.; Lukas, G. Direct Polymer Additive Tooling-Economic Analysis of Additive Manufacturing Technologies for Fabrication of Polymer Tools for Injection Molding. Key Eng. Mater. 2020, 843, 9–18. [Google Scholar] [CrossRef]

- Udroiu, R.; Braga, I.C. Polyjet technology applications for rapid tooling. MATEC Web Conf. 2017, 112, 03011. [Google Scholar] [CrossRef] [Green Version]

- Kuo, C.-C.; Qiu, S.-X.; Lee, G.-Y.; Zhou, J.; He, H.-Q. Characterizations of polymer injection molding tools with conformal cooling channels fabricated by direct and indirect rapid tooling technologies. Int. J. Adv. Manuf. Technol. 2021, 117, 343–360. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R. Development of Rapid Tooling Using Fused Deposition Modeling. Addit. Manuf. Emerg. Mater. 2018, 1, 251–277. [Google Scholar] [CrossRef]

- Sathies, T.; Senthil, P.; Anoop, M.S. A review on advancements in applications of fused deposition modelling process. Rapid Prototyp. J. 2020, 26, 669–687. [Google Scholar] [CrossRef]

- Afonso, D.; de Sousa, R.A.; Torcato, R.; Pires, L. Fundamentals of Rapid Tooling. In Incremental Forming as a Rapid Tooling Process; Springer Nature: Cham, Switzerland, 2019; pp. 1–22. [Google Scholar] [CrossRef]

- Bagalkot, A.; Pons, D.; Symons, D.; Clucas, D. Analysis of Raised Feature Failures on 3D Printed Injection Moulds. Polymers 2021, 13, 1541. [Google Scholar] [CrossRef]

- Krizsma, S.; Kovács, N.; Kovács, J.; Suplicz, A. In-situ monitoring of deformation in rapid prototyped injection molds. Addit. Manuf. 2021, 42, 102001. [Google Scholar] [CrossRef]

- Zink, B.; Kovács, N.K.; Kovács, J.G. Thermal analysis based method development for novel rapid tooling applications. Int. Commun. Heat Mass Transf. 2019, 108, 104297. [Google Scholar] [CrossRef]

- Sarkar, P.; Modak, N.; Sahoo, P. Mechanical and Tribological Characteristics of Aluminium Powder filled Glass Epoxy Composites. Mater. Today Proc. 2018, 5, 5496–5505. [Google Scholar] [CrossRef]

- Srivastava, V.K.; Verma, A. Mechanical Behaviour of Copper and Aluminium Particles Reinforced Epoxy Resin Composites. Am. J. Mater. Sci. 2015, 5, 84–89. [Google Scholar] [CrossRef]

- Fernandes, A.D.C.; Souza, A.F.D.; Howarth, J.L.L. Mechanical and dimensional characterisation of polypropylene injection moulded parts in epoxy resin / aluminium inserts for rapid tooling. Int. J. Mater. Prod. Technol. 2016, 52, 37–52. [Google Scholar] [CrossRef]

- Park, K.; Sohn, D.-H.; Cho, K.-H. Eliminating weldlines of an injection-molded part with the aid of high-frequency induction heating. J. Mech. Sci. Technol. 2010, 24, 149–152. [Google Scholar] [CrossRef]

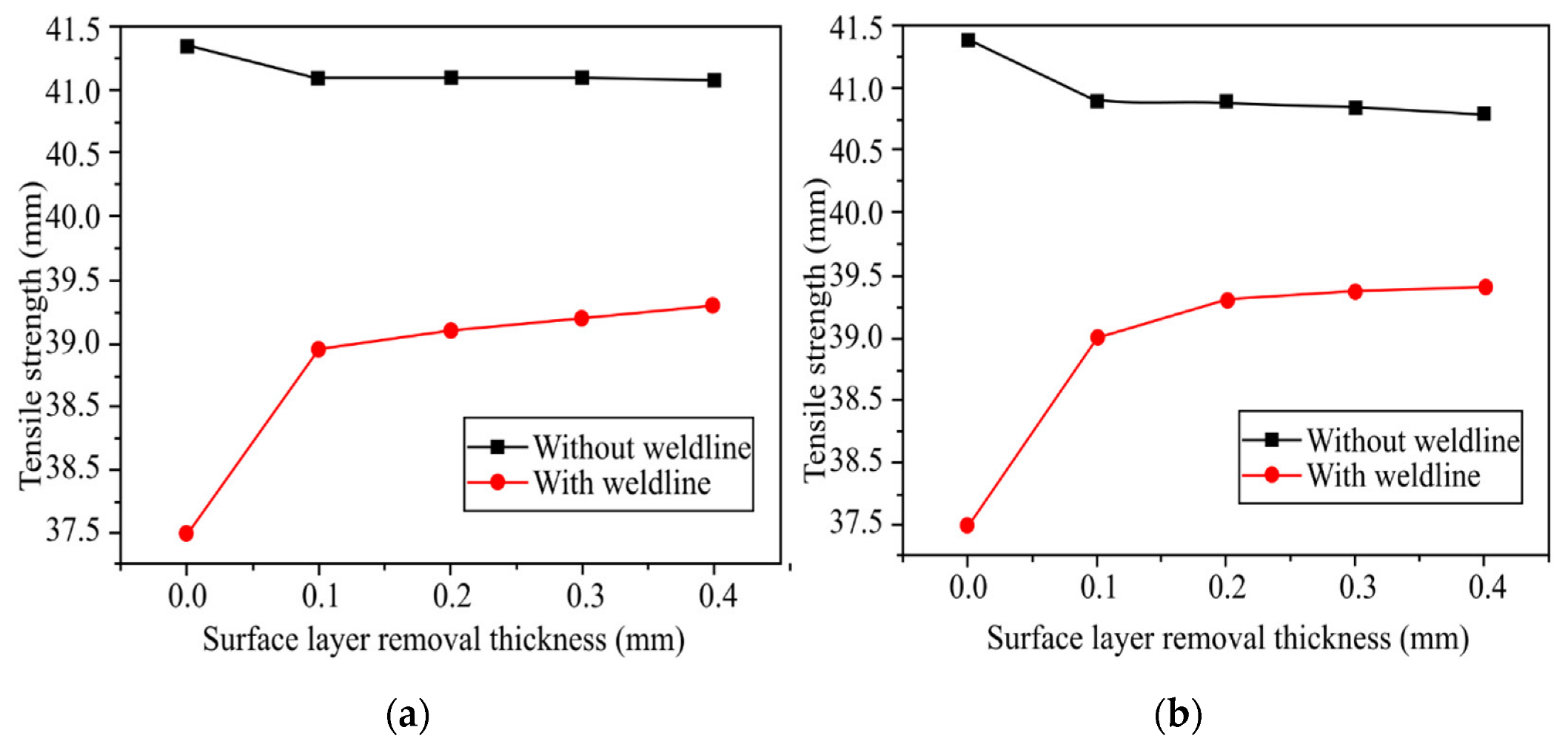

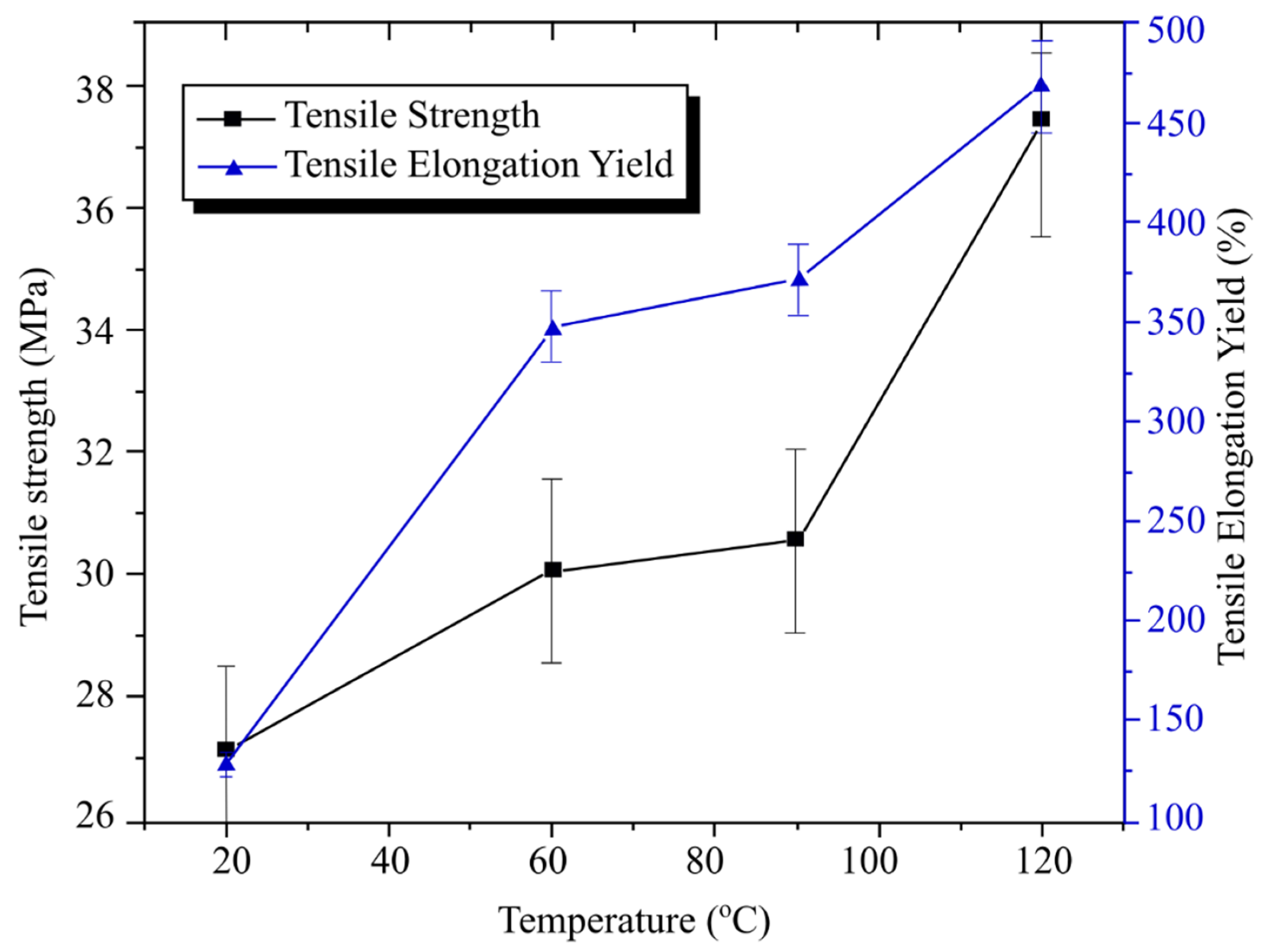

- Wang, G.; Zhao, G.; Wang, X. Effects of cavity surface temperature on mechanical properties of specimens with and without a weld line in rapid heat cycle molding. Mater. Des. 2013, 46, 457–472. [Google Scholar] [CrossRef]

- Shayfull, Z.; Sharif, S.; Zain, A.M.; Ghazali, M.F.; Saad, R.M. Potential of Conformal Cooling Channels in Rapid Heat Cycle Molding: A Review. Adv. Polym. Technol. 2014, 33, 1–24. [Google Scholar] [CrossRef]

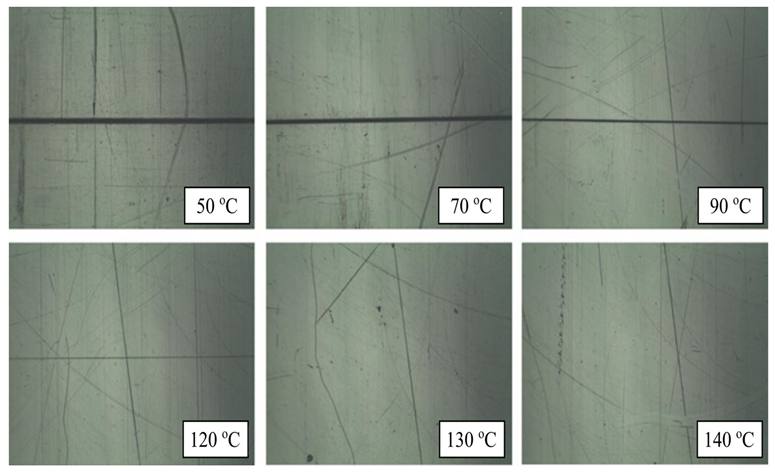

- Chen, S.-C.; Jong, W.-R.; Chang, J.-A. Dynamic mold surface temperature control using induction heating and its effects on the surface appearance of weld line. J. Appl. Polym. Sci. 2006, 101, 1174–1180. [Google Scholar] [CrossRef]

- Zhang, A.; Zhao, G.; Guan, Y. Effects of mold cavity temperature on surface quality and mechanical properties of nanoparticle-filled polymer in rapid heat cycle molding. J. Appl. Polym. Sci. 2015, 132, 1–9. [Google Scholar] [CrossRef]

- Yang, H.; Yilmaz, G.; Han, G.; Eriten, M.; Zhang, Z.; Yu, S.; Shi, M.; Yan, H.; Yang, W.; Xie, P.; et al. A quick response and tribologically durable graphene heater for rapid heat cycle molding and its applications in injection molding. Appl. Therm. Eng. 2020, 167, 114791. [Google Scholar] [CrossRef]

- Su, Q.; Zhang, N.; Gilchrist, M.D. The use of variotherm systems for microinjection molding. J. Appl. Polym. Sci. 2016, 133, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.-S.; Tai, N.-S. Experimental Rapid Surface Heating by Induction for Micro-Injection Molding of Light-Guided Plates Ming-Shyan. J. Appl. Polym. Sci. 2009, 113, 1345–1354. [Google Scholar] [CrossRef]

- Huang, M.-S.; Yu, J.-C.; Lin, Y.-Z. Effect of rapid mold surface inducting heating on the replication ability of microinjection molding light-guided plates with V-grooved microfeatures. J. Appl. Polym. Sci. 2010, 118, 3058–3065. [Google Scholar] [CrossRef]

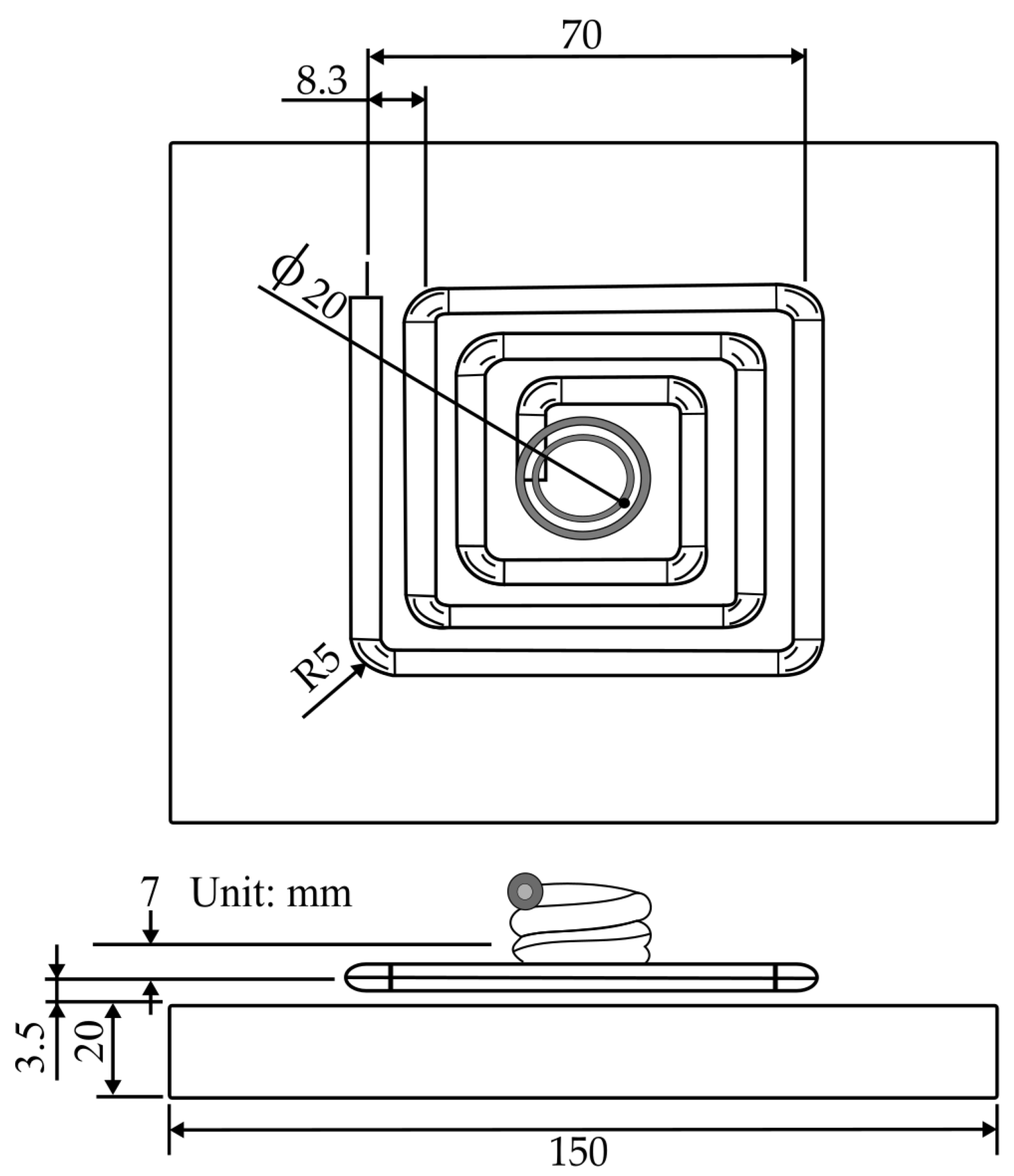

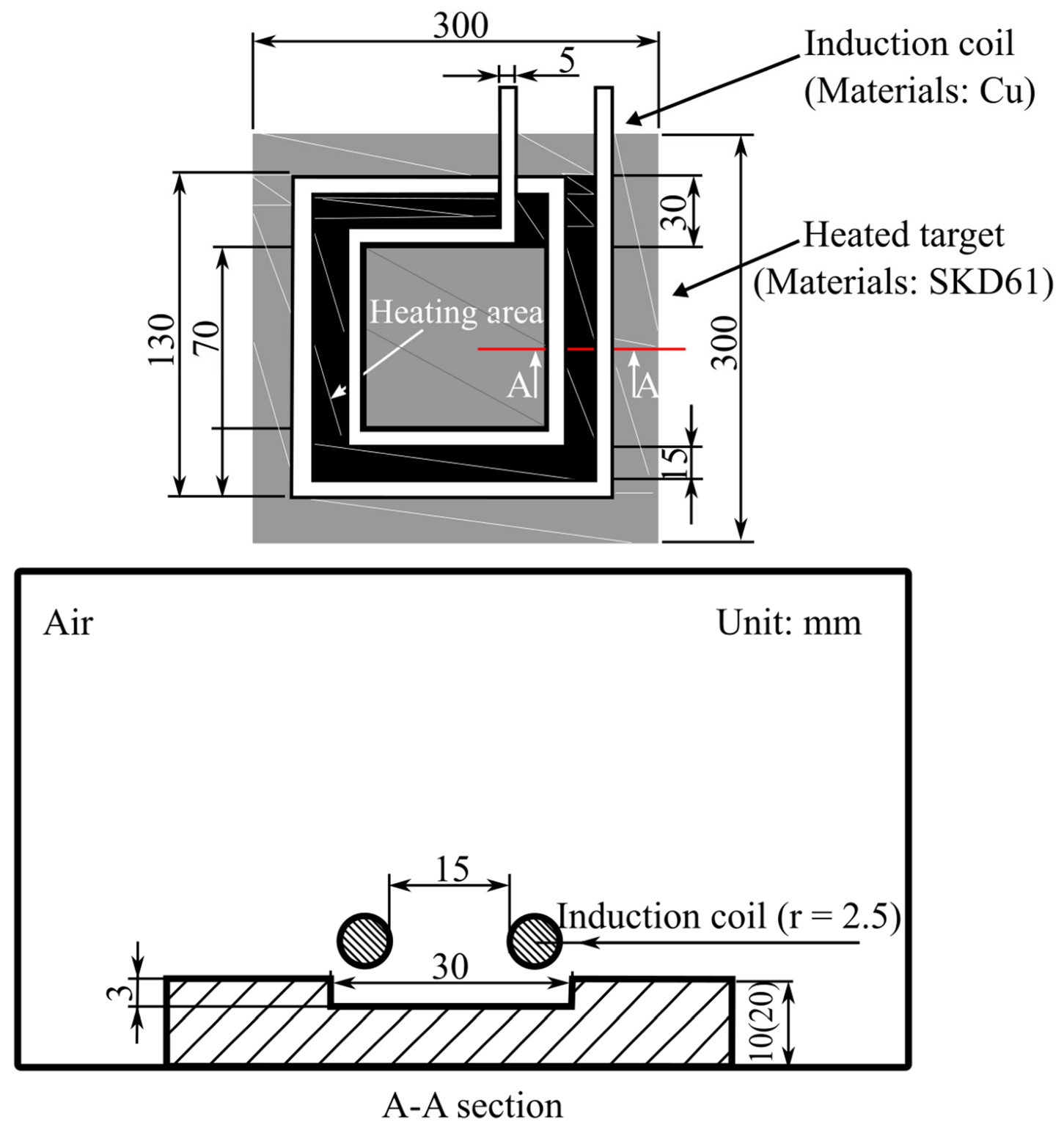

- Nian, S.-C.; Tsai, S.-W.; Huang, M.-S.; Huang, R.-C.; Chen, C.-H. Key parameters and optimal design of a single-layered induction coil for external rapid mold surface heating. Int. Commun. Heat Mass Transf. 2014, 57, 109–117. [Google Scholar] [CrossRef]

- Tsai, Y.-P.; Wang, J.-C.; Hsu, R.-Q. The effect of vapor chamber in an injection molding process on part tensile strength. Exp. Tech. 2011, 35, 60–64. [Google Scholar] [CrossRef]

- Wang, G.-L.; Zhao, G.-Q.; Wang, X.-X. Heating/cooling channels design for an automotive interior part and its evaluation in rapid heat cycle molding. Mater. Des. 2014, 59, 310–322. [Google Scholar] [CrossRef]

- Li, J.; Yang, S.; Turng, L.S.; Xie, Z.; Jiang, S. Comparative study of weldline strength in conventional injection molding and rapid heat cycle molding. Mater. Plast. 2016, 53, 448–453. [Google Scholar]

- Xie, P.; Yang, H.; Zhao, Y.; Yu, W.; Cheng, L.; Yang, W.; Yan, H.; Tan, J. Carbide-bonded graphene coating of mold insert for rapid thermal cycling in injection molding. Appl. Therm. Eng. 2017, 122, 19–26. [Google Scholar] [CrossRef]

- Liu, F.; Li, T.; Xu, F.; Li, J.; Jiang, S. Microstructure, Tensile Property, and Surface Quality of Glass Fiber-Reinforced Polypropylene Parts Molded by Rapid Heat Cycle Molding. Adv. Polym. Technol. 2020, 2020, 3161068. [Google Scholar] [CrossRef]

- Tosello, G.; Gava, A.; Hansen, H.N.; Lucchetta, G.; Marinello, F. Characterization and analysis of weld lines on micro-injection moulded parts using atomic force microscopy (AFM). Wear 2009, 266, 534–538. [Google Scholar] [CrossRef]

- Guilong, W.; Guoqun, Z.; Huiping, L.; Yanjin, G. Analysis of thermal cycling efficiency and optimal design of heating/cooling systems for rapid heat cycle injection molding process. Mater. Des. 2010, 31, 3426–3441. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Wang, X. Effects of cavity surface temperature on reinforced plastic part surface appearance in rapid heat cycle moulding. Mater. Des. 2013, 44, 509–520. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Guan, Y. Thermal response of an electric heating rapid heat cycle molding mold and its effect on surface appearance and tensile strength of the molded part. J. Appl. Polym. Sci. 2012, 128, 1339–1352. [Google Scholar] [CrossRef]

- Li, X.-P.; Zhao, G.-Q.; Guan, Y.-J.; Ma, M.-X. Optimal design of heating channels for rapid heating cycle injection mold based on response surface and genetic algorithm. Mater. Des. 2009, 30, 4317–4323. [Google Scholar] [CrossRef]

- Li, X.-P.; Zhao, G.-Q.; Guan, Y.-J. Characteristic of rapid heating cycle moulding and warpage analysis of products. Plast. Rubber Compos. 2011, 40, 425–432. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, G.; Wu, X.; Li, X.; Wang, C. Investigation on phosphorus halogen-free flame-retardancy systems in short glass fiber-reinforced PC/ABS composites under rapid thermal cycle molding process condition. Polym. Compos. 2015, 36, 1653–1663. [Google Scholar] [CrossRef]

- Zhang, A.; Hui, Y.; Hou, J. Effect of Resin Viscosity and Lubricants on Surface and Mechanical Properties of Glass Fiber Reinforced Polymer in Rapid Heat Cycle Molding. Polym. Korea 2018, 42, 974–981. [Google Scholar] [CrossRef]

- Seaman, C.; Desrochers, A.; List, G. Multiobjective optimization of a plastic injection molding process. IEEE Trans. Control. Syst. Technol. 1994, 2, 157–168. [Google Scholar] [CrossRef]

- Chen, W.; Wang, M.; Fu, G.; Chen, C. Optimization of plastic injection molding process via Taguchis parameter design method, BPNN, and DFP. In Proceedings of the 2008 International Conference on Machine Learning and Cybernetics, Kunming, China, 15 July 2008; Volume 6, pp. 3315–3321. [Google Scholar] [CrossRef]

- Xu, G.; Yang, Z.-T.; Long, G.-D. Multi-objective optimization of MIMO plastic injection molding process conditions based on particle swarm optimization. Int. J. Adv. Manuf. Technol. 2012, 58, 521–531. [Google Scholar] [CrossRef]

- Yang, J.K.; Xu, Y.J. Warpage Analysis of Injection Molding Based on Mold Flow. Adv. Mater. Res. 2012, 538–541, 1192–1196. [Google Scholar] [CrossRef]

- Park, H.S.; Dang, X.P. Technology for Improving Productivity and Quality of Injection Molding. In DAAAM International Scientific Book; EBSCO Publishing, Inc.: Ipswich, MA, USA, 2018. [Google Scholar]

- Sachs, E.; Wylonis, E.; Allen, S.; Cima, M.; Guo, H. Production of injection molding tooling with conformal cooling channels using the three dimensional printing process. Polym. Eng. Sci. 2000, 40, 1232–1247. [Google Scholar] [CrossRef] [Green Version]

- Ciofu, C.; Mindru, D.T. Injection and micro injection of polymeric plastics materials: A review. Int. J. Mod. Manufact. Technol. 2013, 1, 49–68. [Google Scholar]

- Agrawal, A.R.; Pandelidis, I.O.; Pecht, M. Injection-molding process control? A review. Polym. Eng. Sci. 1987, 27, 1345–1357. [Google Scholar] [CrossRef]

- Jansen, K.M.B.; van Dijk, D.J.; Husselman, M.H. Effect of processing conditions on shrinkage in injection molding. Polym. Eng. Sci. 1998, 38, 838–846. [Google Scholar] [CrossRef] [Green Version]

- Jansen, K.M.B.; Titomanlio, G. Effect of pressure history on shrinkage and residual stresses? Injection molding with constrained shrinkage. Polym. Eng. Sci. 1996, 36, 2029–2040. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Valino, A.D.; Souza, L.R.; Espera, A.; Chen, Q.; Advincula, R.C. Three-dimensional-printed molds and materials for injection molding and rapid tooling applications. MRS Commun. 2019, 9, 1267–1283. [Google Scholar] [CrossRef]

- Zhou, H.; Li, D. Numerical Simulation and Experimental Study of Warpage of Injection-Molded Parts. Polym. Technol. Eng. 2005, 44, 603–617. [Google Scholar] [CrossRef]

- Sánchez, R.; Aisa, J.; Martinez, A.; Mercado, D. On the relationship between cooling setup and warpage in injection molding. Measurement 2012, 45, 1051–1056. [Google Scholar] [CrossRef]

- Rahimi, M.; Esfahanian, M.; Moradi, M. Effect of reprocessing on shrinkage and mechanical properties of ABS and investigating the proper blend of virgin and recycled ABS in injection molding. J. Mater. Process. Technol. 2014, 214, 2359–2365. [Google Scholar] [CrossRef]

- Park, K. A Study on Flow Simulation and Deformation Analysis for Injection-Molded Plastic Parts Using Three-Dimensional Solid Elements. Polym. Technol. Eng. 2005, 43, 1569–1585. [Google Scholar] [CrossRef]

- Kurt, M.; Kaynak, Y.; Kamber, O.S.; Mutlu, B.; Bakir, B.; Koklu, U. Influence of molding conditions on the shrinkage and roundness of injection molded parts. Int. J. Adv. Manuf. Technol. 2010, 46, 571–578. [Google Scholar] [CrossRef]

- Khan, R.M.; Acharya, G. Plastic Injection Molding Process and Its Aspects for Quality: A Review. Eur. J. Adv. Eng. Technol. 2016, 3, 66–70. Available online: www.ejaet.com (accessed on 30 October 2020).

- Kitayama, S.; Ishizuki, R.; Takano, M.; Kubo, Y.; Aiba, S. Optimization of mold temperature profile and process parameters for weld line reduction and short cycle time in rapid heat cycle molding. Int. J. Adv. Manuf. Technol. 2019, 103, 1735–1744. [Google Scholar] [CrossRef]

- Kagitci, Y.C.; Tarakcioglu, N. The effect of weld line on tensile strength in a polymer composite part. Int. J. Adv. Manuf. Technol. 2016, 85, 1125–1135. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Li, D.-Y.; Lin, Z.-C.; Kang, Z.-F. Characterizations of Polymer Gears Fabricated by Differential Pressure Vacuum Casting and Fused Deposition Modeling. Polymers 2021, 13, 4126. [Google Scholar] [CrossRef]

- Dobránsky, J.; Bĕhálek, L.; Baron, P. Gate Location and its Impact to Flowing Characteristics of Plastic Moldings. Key Eng. Mater. 2016, 669, 36–43. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Research on optimization design of the heating/cooling channels for rapid heat cycle molding based on response surface methodology and constrained particle swarm optimization. Expert Syst. Appl. 2011, 38, 6705–6719. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, Y.; Wen, J.; Cui, S. Mould cooling simulation for injection moulding using a fast boundary element method approach. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 224, 653–662. [Google Scholar] [CrossRef]

- Calaon, M.; Baruffi, F.; Fantoni, G.; Cirri, I.; Santochi, M.; Hansen, H.N.; Tosello, G. Functional Analysis Validation of Micro and Conventional Injection Molding Machines Performances Based on Process Precision and Accuracy for Micro Manufacturing. Micromachines 2020, 11, 1115. [Google Scholar] [CrossRef]

- Correia, L.; Brito, A.M.; Faria, L.; Félix, M.J.; Santos, G.; Laranjeira, J.; Simoes, R. Dynamic temperature control influence on pressure during injection molding of plastic parts to improve part quality. Int. J. Qual. Res. 2020, 14, 635–646. [Google Scholar] [CrossRef]

- Zhou, J.A. Design of Injection Mold for a Large LCD TV Panel. Appl. Mech. Mater. 2013, 423–426, 1982–1989. [Google Scholar] [CrossRef]

- Hussain, A.R.J.; Alahyari, A.A.; Eastman, S.A.; Thibaud-Erkey, C.; Johnston, S.; Sobkowicz, M. Review of polymers for heat exchanger applications: Factors concerning thermal conductivity. Appl. Therm. Eng. 2017, 113, 1118–1127. [Google Scholar] [CrossRef] [Green Version]

- Ogorodnyk, O.; Martinsen, K.; Ogorodnyk, O.; Martinsen, K. Monitoring and Control for Thermoplastics Injection Molding a Review. Procedia CIRP 2018, 67, 380–385. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Research of thermal response simulation and mold structure optimization for rapid heat cycle molding processes, respectively, with steam heating and electric heating. Mater. Des. 2010, 31, 382–395. [Google Scholar] [CrossRef]

- Li, J.; Bei, J.; Liu, W.; Xia, X.; Zhou, B.; Peng, X.; Jiang, S. Warpage Prediction of RHCM Crystalline Parts Based on Multi-Layers. Polymers 2021, 13, 1814. [Google Scholar] [CrossRef]

- De Santis, F.; Pantani, R. Development of a rapid surface temperature variation system and application to micro-injection molding. J. Mater. Process. Technol. 2016, 237, 1–11. [Google Scholar] [CrossRef]

- Wang, G.; Hui, Y.; Zhang, L.; Zhao, G. Research on temperature and pressure responses in the rapid mold heating and cooling method based on annular cooling channels and electric heating. Int. J. Heat Mass Transf. 2018, 116, 1192–1203. [Google Scholar] [CrossRef]

- Mrozek, K.; Muszyński, P.; Poszwa, P. Application of Magnetic Concentrator for Improvement in Rapid Temperature Cycling Technology. Polymers 2020, 13, 91. [Google Scholar] [CrossRef]

- Barahate, M.R.; Shete, M.T. Modeling and Simulation of Rapid Heating and Cooling of Injection Mold by FEM-A Review. Int. Res. J. Eng. Technol. 2017, 2718–2723. [Google Scholar]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Ma, S.; Gibson, I.; Balaji, G.; Hu, Q. Development of epoxy matrix composites for rapid tooling applications. J. Mater. Process. Technol. 2007, 192, 75–82. [Google Scholar] [CrossRef]

- Atzeni, E.; Iuliano, L.; Minetola, P.; Salmi, A. Redesign and cost estimation of rapid manufactured plastic parts. Rapid Prototyp. J. 2010, 16, 308–317. [Google Scholar] [CrossRef]

- Rosochowski, A.; Matuszak, A. Rapid tooling: The state of the art. J. Mater. Process. Technol. 2000, 106, 191–198. [Google Scholar] [CrossRef]

- Ingole, D.S.; Kuthe, A.M.; Thakare, S.B.; Talankar, A.S. Rapid prototyping–a technology transfer approach for development of rapid tooling. Rapid Prototyp. J. 2009, 15, 280–290. [Google Scholar] [CrossRef]

- Chua, C.K.; Hong, K.H.; Ho, S.L. Rapid tooling technology. Part 1. A comparative study. Int. J. Adv. Manuf. Technol. 1999, 15, 604–608. [Google Scholar] [CrossRef]

- Karapatis, N.P.; van Griethuysen, J.-P.S.; Glardon, R. Direct Rapid Tooling. Rapid Prototyp. J. 1998, 4, 77–89. [Google Scholar] [CrossRef]

- Khushairi, M.T.M.; Sharif, S.; Ani, J.S.M. Evaluation of Mechanical Properties of Filled Epoxy Composite for Improving Mould Performance—A Review. Appl. Mech. Mater. 2015, 735, 13–18. [Google Scholar] [CrossRef]

- Pouzada, A.S. Hybrid moulds: A case of integration of alternative materials and rapid prototyping for tooling. Virtual Phys. Prototyp. 2009, 4, 195–202. [Google Scholar] [CrossRef]

- Jain, P.; Kuthe, A. Feasibility Study of Manufacturing Using Rapid Prototyping: FDM Approach. Procedia Eng. 2013, 63, 4–11. [Google Scholar] [CrossRef] [Green Version]

- Pontes, A.J.; Queirós, M.P.; Martinho, P.G.; Bártolo, P.J.; Pouzada, A.S. Experimental assessment of hybrid mould performance. Int. J. Adv. Manuf. Technol. 2010, 50, 441–448. [Google Scholar] [CrossRef]

- Jurković, M.; Mahmić, M.; Jurković, Z. Evolution and Application of Rapid Prototyping Technologies. J. Technol. Plast. 2005, 30, 1–2. [Google Scholar]

- Kerkstra, R. “TOOLING: How to Select the Right Tool Steel for Mold Cavities”, Plastic Technology. 2016. Available online: https://www.ptonline.com/articles/tooling-how-to-select-the-right-tool-steel-for-mold-cavities (accessed on 30 October 2020).

- Atesmesh, “Mold Design and Tooling for Injection Molding”, Design World. 2013. Available online: https://www.designworldonline.com/mold-design-tooling-for-injection-molding (accessed on 30 October 2020).

- Jaycon Systems. “Injection Mold Tooling Materials: Aluminum vs. Steel|by Jaycon Systems|Jaycon Systems|Medium”, Jaycon Systems. 2017. Available online: https://medium.com/jaycon-systems/injection-mold-tooling-materials-aluminum-vs-steel-7b5f64ee1112 (accessed on 30 October 2020).

- Ozcelik, B.; Ozbay, A.; Demirbas, E. Influence of injection parameters and mold materials on mechanical properties of ABS in plastic injection molding. Int. Commun. Heat Mass Transf. 2010, 37, 1359–1365. [Google Scholar] [CrossRef]

- Lau, J. The Types of Mold Base for Plastic Injection Mold. Available online: https://www.injectionmould.org/2019/03/23/the-types-of-mold-base/ (accessed on 1 May 2022).

- Asnafi, N. Application of Laser-Based Powder Bed Fusion for Direct Metal Tooling. Metals 2021, 11, 458. [Google Scholar] [CrossRef]

- ASSAB, ASSAB Tool Steel for Plastic Moulding. 2019. Available online: https://www.assab.com/app/uploads/sites/133/2019/05/ASSAB_Plastic-Mould_EN.pdf (accessed on 28 October 2021).

- Britton, P.W. Considerations for Mold Base Material Selection; International Mold Steel, Inc.: Hebron, KY, USA, 2013; Available online: https://www.moldmakingtechnology.com/articles/considerations-for-mold-base-material-selection (accessed on 28 October 2021).

- Raus, A.A.; Wahab, M.S.; Ibrahim, M.; Kamarudin, K.; Ahmed, A.; Sáude, N. A Comparative Study of Mould Base Tool Materials in Plastic Injection Moulding to Improve Cycle Time and Warpage Using Statistical Method. J. Mech. Eng. 2017, 4, 1–17. [Google Scholar]

- Tang, S.; Tan, Y.; Sapuan, M.S.; Sulaiman, S.; Ismail, N.; Samin, R. The use of Taguchi method in the design of plastic injection mould for reducing warpage. J. Mater. Process. Technol. 2007, 182, 418–426. [Google Scholar] [CrossRef]

- Menges, G.; Michaeli, W.; Mohren, P.; Menges, G.; Michaeli, W.; Mohren, P. How to Make Injection Molds, 3rd ed.; Hanser Gardner Publications, Inc.: Cincinnati, OH, USA, 2001. [Google Scholar]

- Zhong, Z.; Khoo, L.; Han, S. Prediction of surface roughness of turned surfaces using neural networks. Int. J. Adv. Manuf. Technol. 2006, 28, 688–693. [Google Scholar] [CrossRef]

- Zhong, Z.W. Recent Advances in Polishing of Advanced Materials. Mater. Manuf. Process. 2008, 23, 449–456. [Google Scholar] [CrossRef]

- Wan, Y.H.; Wang, G. Polishing Robot: Status and Outlook. Adv. Mater. Res. 2009, 69–70, 311–315. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, S.-I.; Lee, K.-I.; Lee, D.-H.; Bang, Y.-B.; Lee, K.-I. Development of a programmable vibration cutting tool for diamond turning of hardened mold steels. Int. J. Adv. Manuf. Technol. 2009, 40, 26–40. [Google Scholar] [CrossRef]

- Stavax, U. Stavax Esr. Alloy Dig. 1989, 38. [Google Scholar] [CrossRef]

- Chiang, K.-T.; Chang, F.-P. Analysis of shrinkage and warpage in an injection-molded part with a thin shell feature using the response surface methodology. Int. J. Adv. Manuf. Technol. 2007, 35, 468–479. [Google Scholar] [CrossRef]

- Nasir, S.; Ismail, K.; Shayfull, Z. Application of RSM to Optimize Moulding Conditions for Minimizing Shrinkage in Thermoplastic Processing. Key Eng. Mater. 2016, 700, 12–21. [Google Scholar] [CrossRef]

- Xiao, C.-L.; Huang, H.-X. Development of a rapid thermal cycling molding with electric heating and water impingement cooling for injection molding applications. Appl. Therm. Eng. 2014, 73, 712–722. [Google Scholar] [CrossRef]

- Sateesh, N.; Reddy, S.D.; Kumar, G.P.; Subbiah, R. Optimization of Injection Moulding Process in Manufacturing the Top Cap of Water Meter. Mater. Today Proc. 2019, 18, 4556–4565. [Google Scholar] [CrossRef]

- Chung, C.-Y. Integrated Optimum Layout of Conformal Cooling Channels and Optimal Injection Molding Process Parameters for Optical Lenses. Appl. Sci. 2019, 9, 4341. [Google Scholar] [CrossRef] [Green Version]

- Okubo, K.; Tanaka, S.; Ito, H. The effects of metal particle size and distributions on dimensional accuracy for micro parts in micro metal injection molding. Microsyst. Technol. 2010, 16, 2037–2041. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, G.; Guan, Y.; Li, H. Research and application of a new rapid heat cycle molding with electric heating and coolant cooling to improve the surface quality of large LCD TV panels. Polym. Adv. Technol. 2011, 22, 476–487. [Google Scholar] [CrossRef]

- Sánchez, R.; Martinez, A.; Mercado, D.; Carbonel, A.; Aisa, J. Rapid heating injection moulding: An experimental surface temperature study. Polym. Test. 2021, 93, 106928. [Google Scholar] [CrossRef]

- Hopkinson, N.; Dickens, P. A comparison between stereolithography and aluminium injection moulding tooling. Rapid Prototyp. J. 2000, 6, 253–258. [Google Scholar] [CrossRef] [Green Version]

- Harris, R.; Newlyn, H.; Hague, R.; Dickens, P. Part shrinkage anomilies from stereolithography injection mould tooling. Int. J. Mach. Tools Manuf. 2003, 43, 879–887. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, J. Manufacturing core-boxes for foundry with rapid tooling technology. J. Mater. Process. Technol. 2004, 155–156, 1118–1123. [Google Scholar] [CrossRef]

- Gibbons, G.J.; Hansell, R.G. Direct tool steel injection mould inserts through the Arcam EBM free-form fabrication process. Assem. Autom. 2005, 25, 300–305. [Google Scholar] [CrossRef]

- Ong, H.; Chua, C.; Cheah, C. Rapid Moulding Using Epoxy Tooling Resin. Int. J. Adv. Manuf. Technol. 2002, 20, 368–374. [Google Scholar] [CrossRef]

- Kovács, J.G.; Bercsey, T. Influence of Mold Properties on the Quality of Injection Molded Parts. Period. Polytech. Mech. Eng. 2005, 49, 115–122. Available online: https://pp.bme.hu/me/article/view/1346/750 (accessed on 30 October 2020).

- Rossi, S.; Deflorian, F.; Venturini, F. Improvement of surface finishing and corrosion resistance of prototypes produced by direct metal laser sintering. J. Mater. Process. Technol. 2004, 148, 301–309. [Google Scholar] [CrossRef]

- Tomori, T.; Melkote, S.; Kotnis, M. Injection mold performance of machined ceramic filled epoxy tooling boards. J. Mater. Process. Technol. 2004, 145, 126–133. [Google Scholar] [CrossRef]

- Senthilkumar, N.; Kalaichelvan, K.; Elangovan, K. Mechanical behaviour of aluminum particulate epoxy composite-experimental study and numerical simulation. Int. J. Mech. Mater. Eng. 2012, 7, 214–221. [Google Scholar]

- Khushairi, M.T.M.; Sharif, S.; Jamaludin, K.R.; Mohruni, A.S. Effects of Metal Fillers on Properties of Epoxy for Rapid Tooling Inserts. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 1155. [Google Scholar] [CrossRef] [Green Version]

- Kuo, C.-C.; Lin, J.-X. Fabrication of the Fresnel lens with liquid silicone rubber using rapid injection mold. Int. J. Adv. Manuf. Technol. 2019, 101, 615–625. [Google Scholar] [CrossRef]

- Chen, S.-C.; Lin, Y.-W.; Chien, R.-D.; Li, H.-M. Variable mold temperature to improve surface quality of microcellular injection molded parts using induction heating technology. Adv. Polym. Technol. 2008, 27, 224–232. [Google Scholar] [CrossRef]

- Wadhwa, R.R.; Kim, B.H. Experimental Results of Low Thermal Inertia Molding. I. Length of Filling. Polym. Technol. Eng. 1988, 27, 509–518. [Google Scholar] [CrossRef]

- Yao, D.; Kim, B. Development of rapid heating and cooling systems for injection molding applications. Polym. Eng. Sci. 2002, 42, 2471–2481. [Google Scholar] [CrossRef]

- Saito, T.; Satoh, I.; Kurosaki, Y. A new concept of active temperature control for an injection molding process using infrared radiation heating. Polym. Eng. Sci. 2002, 42, 2418–2429. [Google Scholar] [CrossRef]

- Yao, D.; Chen, S.-C.; Kim, B.H. Rapid thermal cycling of injection molds: An overview on technical approaches and applications. Adv. Polym. Technol. 2008, 27, 233–255. [Google Scholar] [CrossRef]

- FORESHOT, “RHCM|Plastic Injection Molding Manufacturer”. Available online: https://www.foreshot.com.tw/en/product/rhcm_rapid-heat-cycle-molding.html (accessed on 29 April 2022).

- Letoplast, “Injection Moulding”. Available online: https://www.letoplast.cz/en/technologies/injection-moulding/ (accessed on 29 April 2022).

- Chang, P.-C.; Hwang, S.-J. Simulation of infrared rapid surface heating for injection molding. Int. J. Heat Mass Transf. 2006, 49, 3846–3854. [Google Scholar] [CrossRef]

- Fischer, C.; Jungmeier, A.; Peters, G.; Drummer, D. Influence of a locally variable mold temperature on injection molded thin-wall components. J. Polym. Eng. 2018, 38, 475–481. [Google Scholar] [CrossRef]

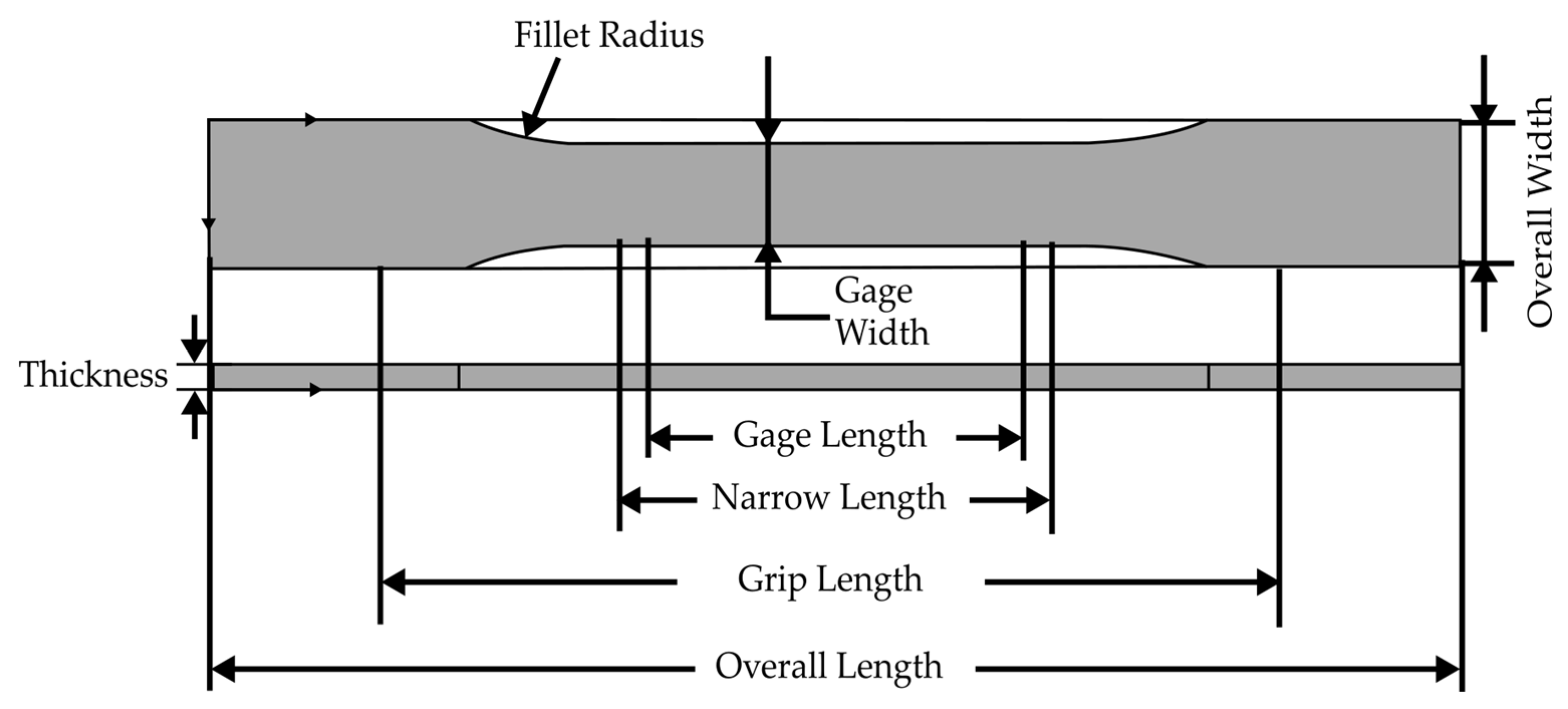

- Miller, A.; Brown, C.; Warner, G. Guidance on the Use of Existing ASTM Polymer Testing Standards for ABS Parts Fabricated Using FFF. Smart Sustain. Manuf. Syst. 2019, 3, 122–138. [Google Scholar] [CrossRef]

- Selden, R. Effect of processing on weld line strength in five thermoplastics. Polym. Eng. Sci. 1997, 37, 205–218. [Google Scholar] [CrossRef]

- Oh, G.-H.; Jeong, J.-H.; Park, S.-H.; Kim, H.-S. Terahertz time-domain spectroscopy of weld line defects formed during an injection moulding process. Compos. Sci. Technol. 2018, 157, 67–77. [Google Scholar] [CrossRef]

| No. | RHCM Technology | Researchers |

|---|---|---|

| 1 | Electromagnetic induction heating | Chen et al., 2006 [39] |

| 2 | Induction heating | Huang and Tai, 2009 [43]; Huang et al., 2010 [44]; Nian et al., 2014 [45] |

| 3 | Hot oil | Huang and Tai, 2009 [43] |

| 4 | Combination of hot oil and induction heating | Huang and Tai, 2009 [43] |

| 5 | Steam heating (vapor chamber) | Tsai, 2011 [46]; Wang, 2014 [47] |

| 6 | Electric heating | Li, 2016 [48]; Xie, 2017 [49]; Liu, 2020 [50] |

| Type of Material | Density (g/cm3) | Specific Heat (J/g·°C) | Thermal Conductivity (W/m·K) | Hardness (HB) | Authors |

|---|---|---|---|---|---|

| Aluminum (2000) series | 2.78 | 0.869 | 139 | 135 | Ozcelik et al. [108] |

| AISI (1020) steel | 7.87 | 0.486 | 51.9 | 170 | Ozcelik et al. [108] |

| Aluminum (QC-10) | 2.85 | N/A | 159.12 | 150–170 | Raus et al. [113] |

| Copper Alloy (C18000) | 8.81 | N/A | 225 | 94 | Raus et al. [113] |

| Steel (PC-20) | 7.87 | N/A | 34.59 | 264–331 | Raus et al. [113] |

| Carbon steel AISI 1050 | 7.85 | 0.486 | 49.8 | 196 | Tang et al. [114] |

| Type of Material | Density (g/cm3) | Specific Heat (J/g·°C) | Thermal Conductivity (W/m·K) | Authors |

|---|---|---|---|---|

| P20 mold steel | 7.8 | 460 | 29 | Nasir et al. [122] |

| AISI P20 | 7.85 | 460 | 34 | Xiao and Huang [123] |

| P20 tool steel | 7.86 | N/A | 41.5 | Sateesh [124] |

| Tool steel SKD-61 | 7.76 | 460 | 25 | Chiang and Chang [121] |

| NAK80 (pre-hardened steel) | 7.72 | N/A | 41.3 | Chung [125] |

| (45–55 HRC, STAVAX) (pre-hardened steel) | 7.8 | 460 | 16 | Okubo et al. [126] |

| Type of Material | Density (g/cm3) | Specific Heat (J/g·°C) | Thermal Conductivity (W/m·K) | Authors |

|---|---|---|---|---|

| Hot work tool steel (Vidar Superior) | 7.78 | 460 | 30 | Li et al. [55] |

| AISI P20 | 7.85 | 460 | 34 | Wang et al. [87] |

| AMPCO 940 | 8.71 | 380 | 208 | Wang at al. [87] |

| CENA 1 | 7.78 | 495 | 22.9 | Wang et al. [47] |

| Researcher | Epoxy Resin/Hardener | Particles/Fillers Used | Weight Percentage of Filler (wt.%) | Particle Size | Mechanical Test | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Arithmetic Mean Roughness (Ra) (µm) | Flexural Strength (MPa) | Hardness Test (RH) | Thermal Conductivity (W/m·K) | Fatigue Test | Tensile Strength (MPa) | Compressive Strength (MPa) | Vickers Hardness, (kgF/mm2) | Shore D Hardness Test | Density (g/cm3) | Thermal Diffusivity (mm2/s) | Surface Roughness | ||||||

| 1. | Tomori et al. (2004) [136] |

|

|

| N/A | 1.03 to 1.35 | 58.75 to 66.49 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

| 2. | Senthilkumar et al. (2012) [137] |

|

|

| 45– 150 µm | N/A | N/A | 69 to 89 | 3.97 to 5.39 | 15,786 to 734 | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

| 3. | Srivastava and Verma (2015) [34] |

|

|

| N/A | N/A | N/A | N/A | N/A | N/A | <85 (pure epoxy) | Cu = 65 at 10 wt.% | Cu = 22.4 at 8 wt.%. | N/A | N/A | N/A | N/A |

| 4. | Fernandes et al. (2016) [35] |

|

|

| N/A | N/A | N/A | N/A | N/A | N/A |

| N/A | N/A |

| N/A | N/A | N/A |

| 5 | Khushairi et al. (2017) [138] |

|

|

| N/A | N/A | N/A | N/A |

| N/A | N/A |

| N/A | N/A |

|

| N/A |

| 6 | Kuo and Lin (2019) [139] |

| N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

|

| No. | Researcher | Plastic Material Used | Parameter Settings | Output Response | Technology Used | Material for Mold Inserts | Type of Analysis | Result | |

|---|---|---|---|---|---|---|---|---|---|

| Simulation | Experiment | ||||||||

| 1 | Chen et al., 2006 [39] | ABS |

|

| Electromagnetic induction heating | AISI 4130 steel | ANSYS | Yes |

|

| 2 | Huang and Tai, 2009 [43] | PMMA |

|

| N/A | Not specified | No | Yes |

|

| Hot oil | No | Yes | ||||||

| Combination of hot oil and induction heating | No | Yes | ||||||

| Induction heating | No | Yes | ||||||

| 3 | Huang et al., 2010 [44] | PMMA |

|

| Induction heating | Ni | No | Yes |

|

| 4 | Tsai, 2011 [46] | ABS |

|

| Steam heating (vapor chamber) | P20 mould steel | No | Yes |

|

| 5 | Wang, 2013 [54] |

|

|

| Electric heating (cartridge heater) | AISI H13 | ANSYS | Yes |

|

| 6 | Wang, 2014 [47] | PC |

|

| Steam heating | CENA1 |

| Yes |

|

| 7 | Nian et al., 2014 [45] | Not specified |

|

| Induction heating | SKD61 | COMSOL Multiphysics | Yes |

|

| 8 | Li, 2016 [48] | iPP |

|

| Electric heating (electrical heating rods) | Not specified | N/A | Yes |

|

| 9 | Xie, 2017 [49] | PP |

|

| Electric heating (thin-film resistance heater, graphene coating) | Silicon insert (coated with carbide-bonded graphene) | N/A | Yes |

|

| PS |

|

| Yes |

| |||||

| 10 | Liu, 2020 [50] | PP with 30% short glass fiber |

|

| Electric heating (electrical heating rods) | Not specified | Autodesk Moldflow | Yes |

|

| No. | Authors | Plastic Material | Heating Technology | Parameters | Response | Results |

|---|---|---|---|---|---|---|

| 1 | Wang et al. [37] |

|

| Cavity surface temperature, Tcs | Tensile strength |

|

| 2 | Zhao et al. [127] |

|

| Designed of RHCM mold structures | Weld marks |

|

| 3 | Wang et al. [54] |

|

| Thermal responses |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huzaim, N.H.M.; Rahim, S.Z.A.; Musa, L.; Abdellah, A.E.-h.; Abdullah, M.M.A.B.; Rennie, A.; Rahman, R.; Garus, S.; Błoch, K.; Sandu, A.V.; et al. Potential of Rapid Tooling in Rapid Heat Cycle Molding: A Review. Materials 2022, 15, 3725. https://doi.org/10.3390/ma15103725

Huzaim NHM, Rahim SZA, Musa L, Abdellah AE-h, Abdullah MMAB, Rennie A, Rahman R, Garus S, Błoch K, Sandu AV, et al. Potential of Rapid Tooling in Rapid Heat Cycle Molding: A Review. Materials. 2022; 15(10):3725. https://doi.org/10.3390/ma15103725

Chicago/Turabian StyleHuzaim, Nurul Hidayah Mohamad, Shayfull Zamree Abd Rahim, Luqman Musa, Abdellah El-hadj Abdellah, Mohd Mustafa Al Bakri Abdullah, Allan Rennie, Rozyanti Rahman, Sebastian Garus, Katarzyna Błoch, Andrei Victor Sandu, and et al. 2022. "Potential of Rapid Tooling in Rapid Heat Cycle Molding: A Review" Materials 15, no. 10: 3725. https://doi.org/10.3390/ma15103725

APA StyleHuzaim, N. H. M., Rahim, S. Z. A., Musa, L., Abdellah, A. E.-h., Abdullah, M. M. A. B., Rennie, A., Rahman, R., Garus, S., Błoch, K., Sandu, A. V., Vizureanu, P., & Nabiałek, M. (2022). Potential of Rapid Tooling in Rapid Heat Cycle Molding: A Review. Materials, 15(10), 3725. https://doi.org/10.3390/ma15103725