Production of Electrolytic Composite Powder by Nickel Plating of Shredded Polyurethane Foam

Abstract

1. Introduction

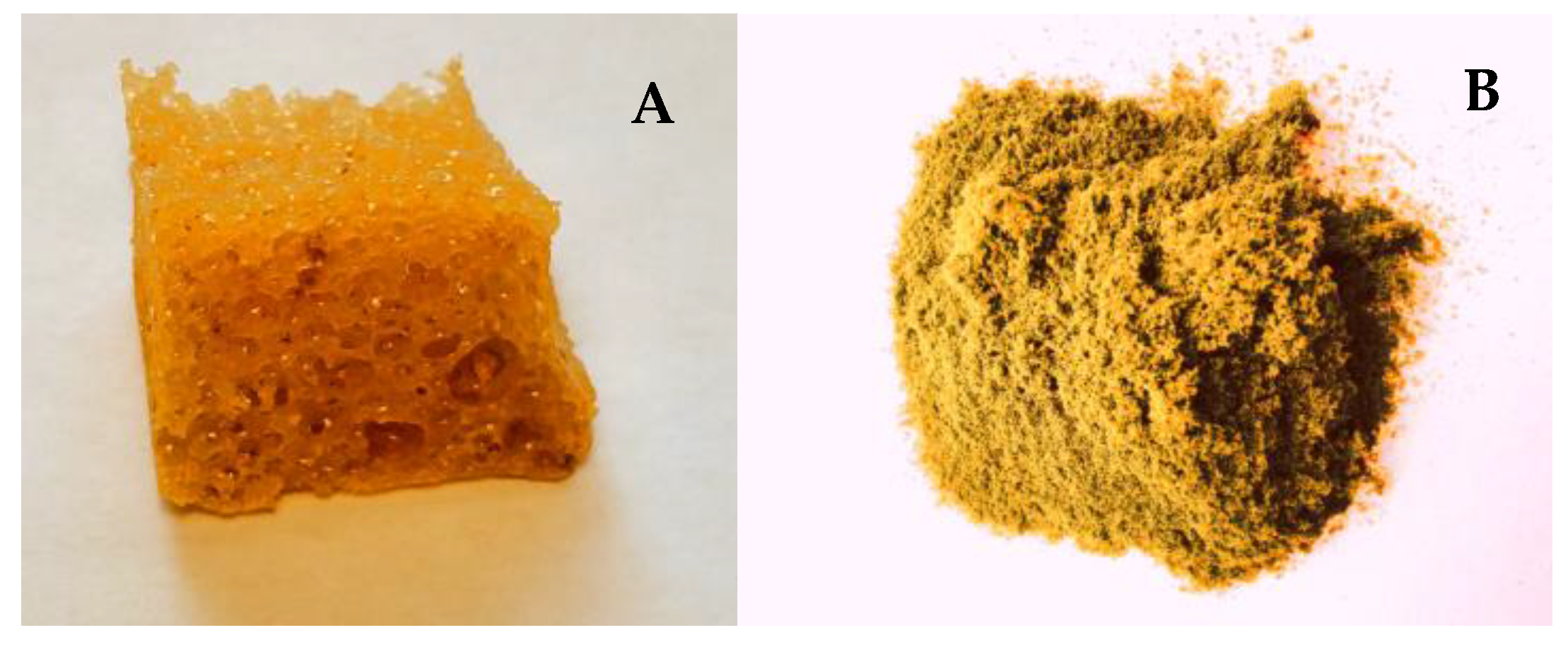

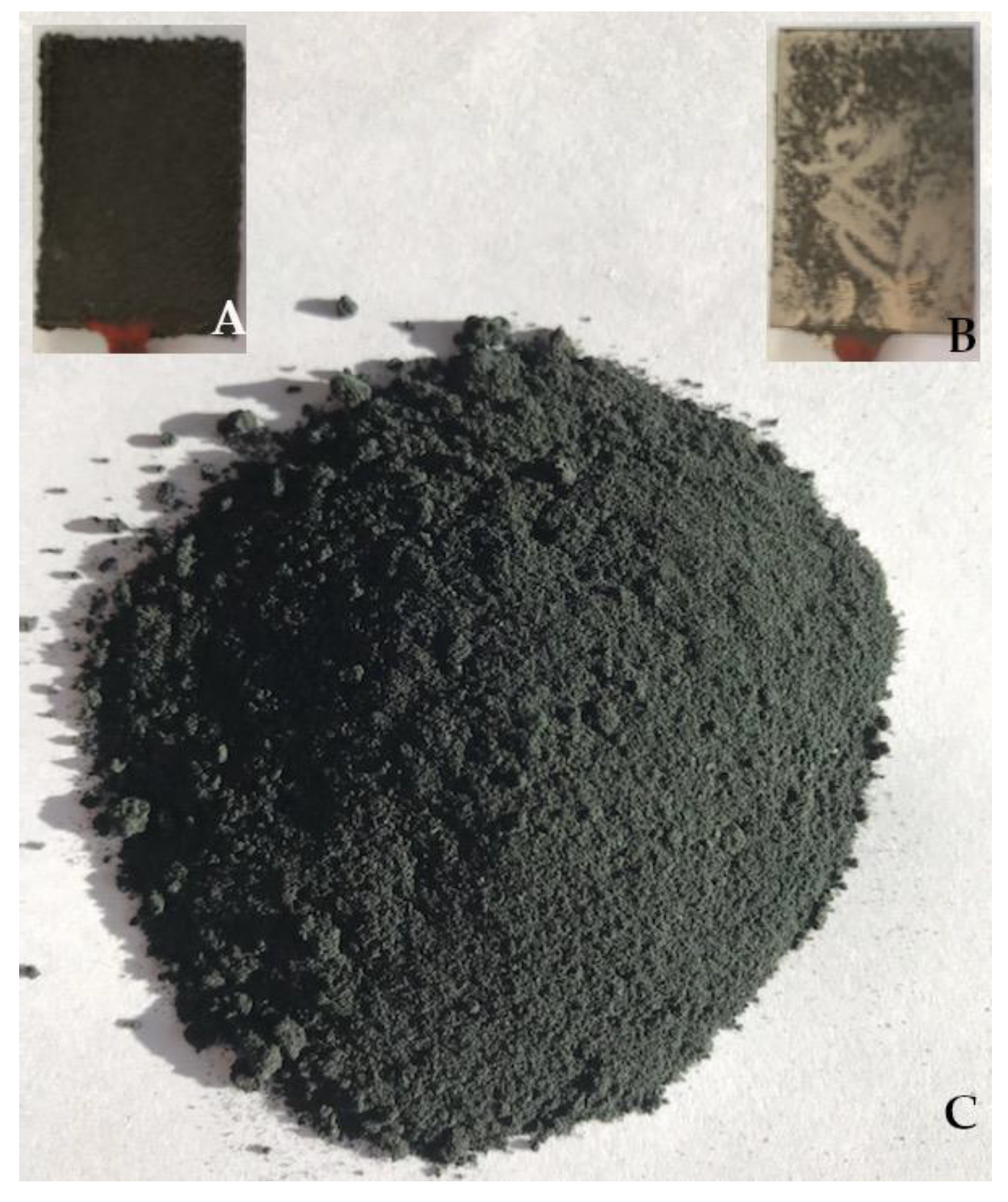

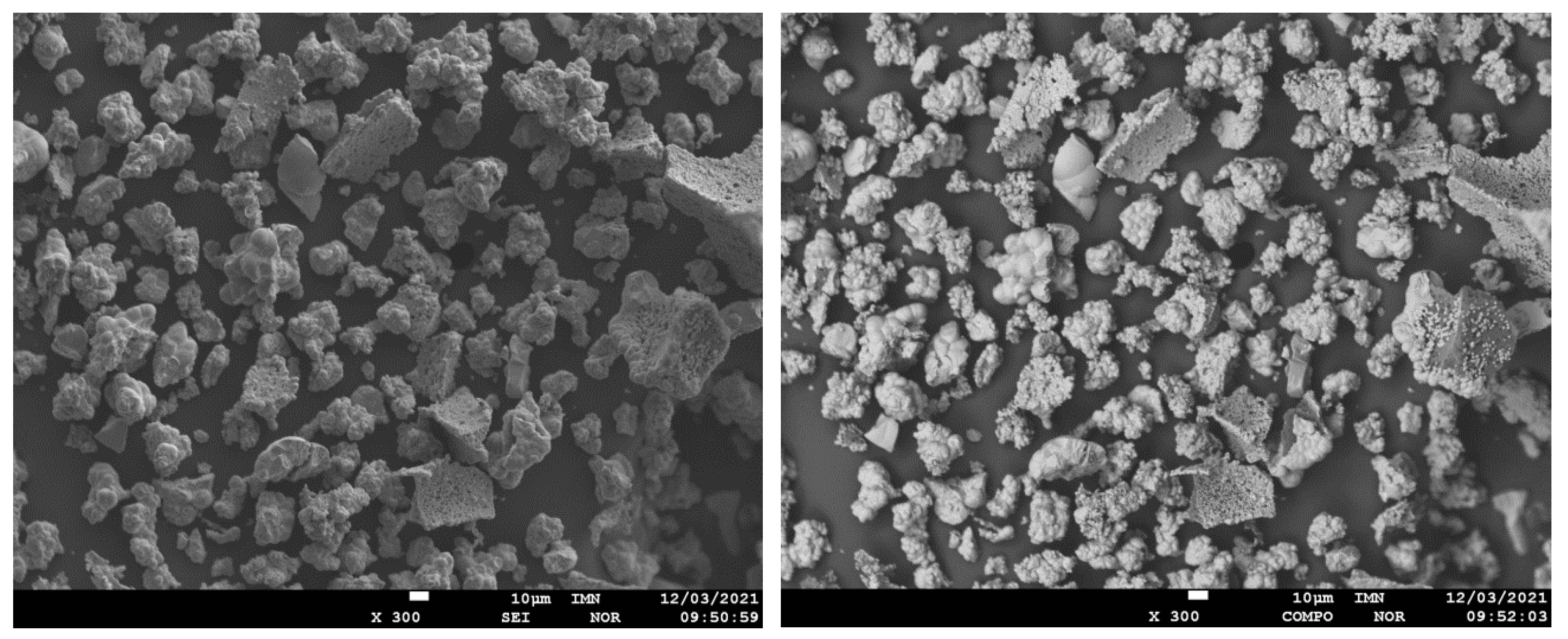

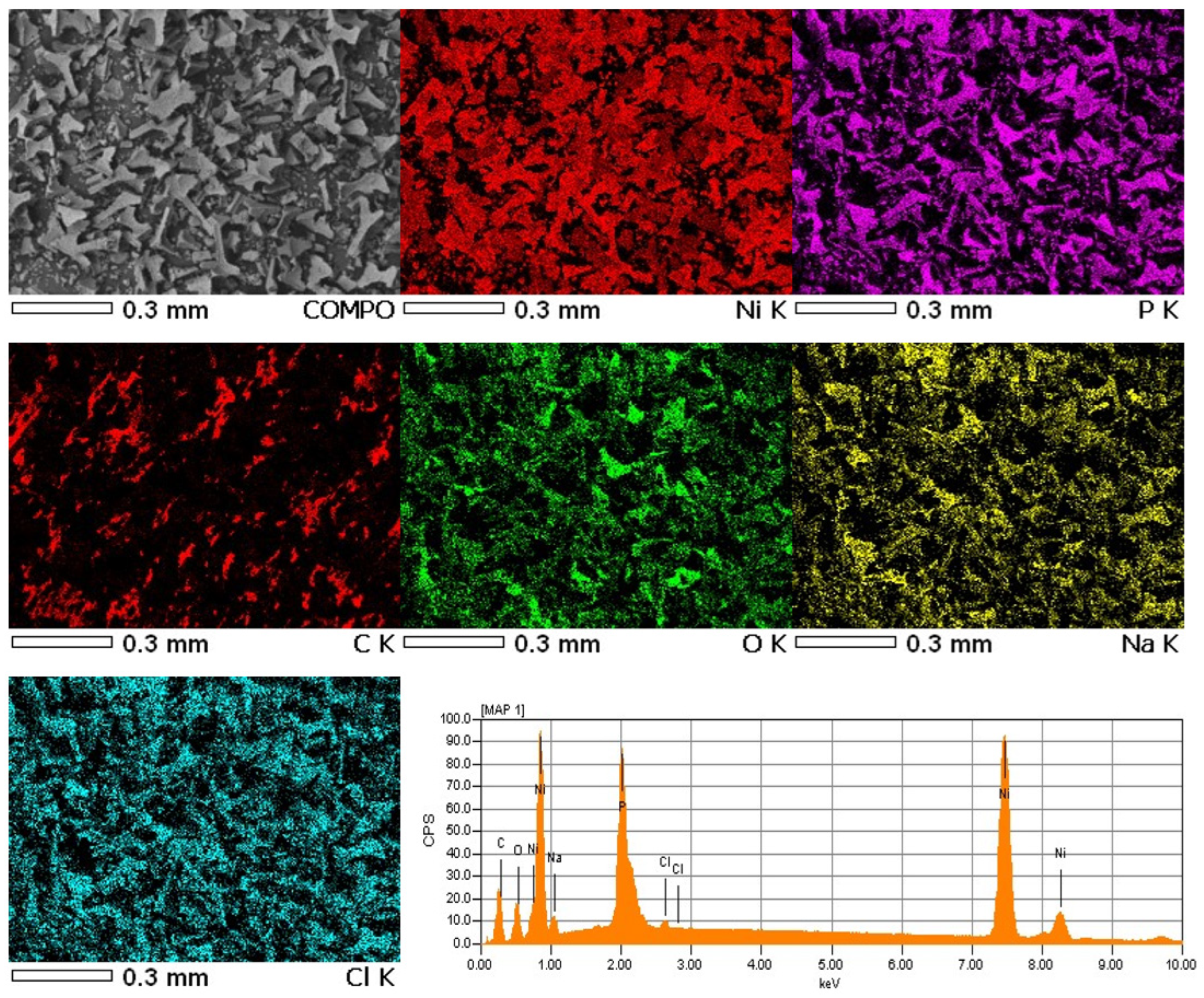

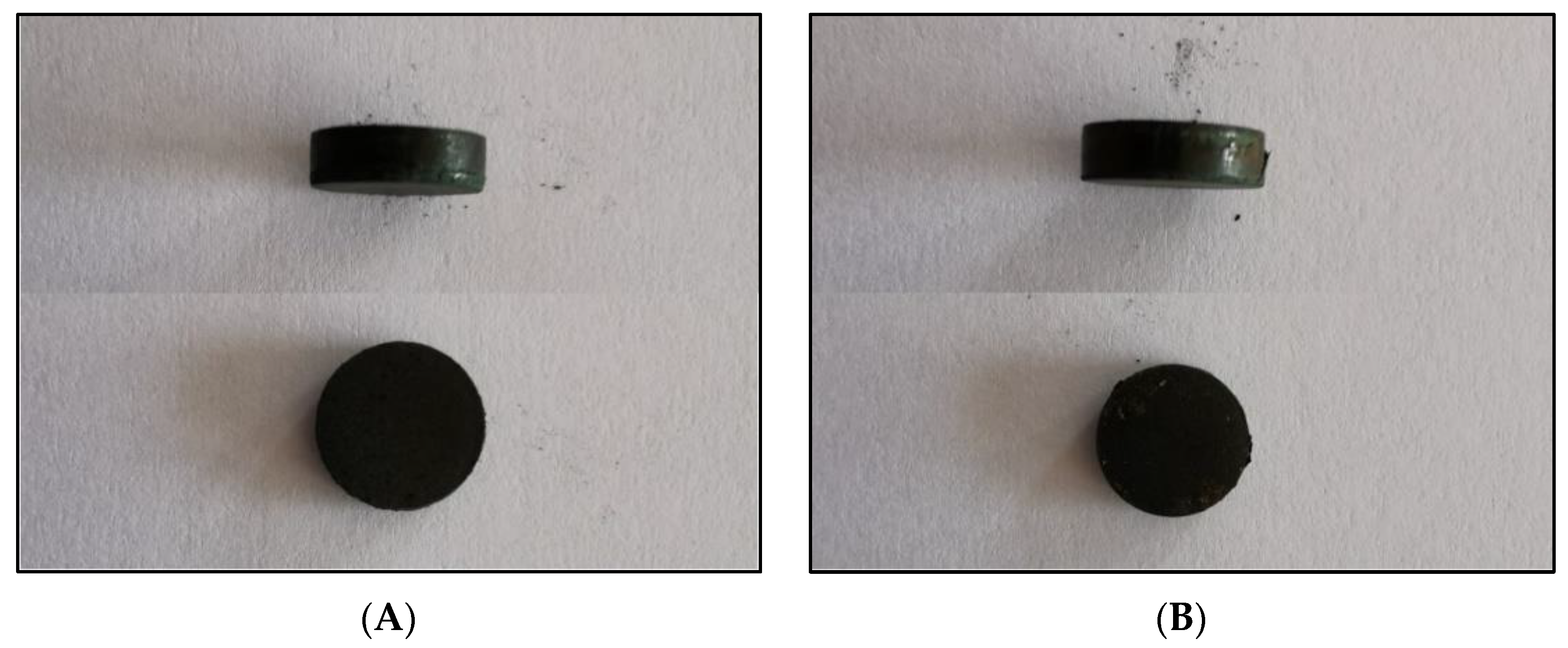

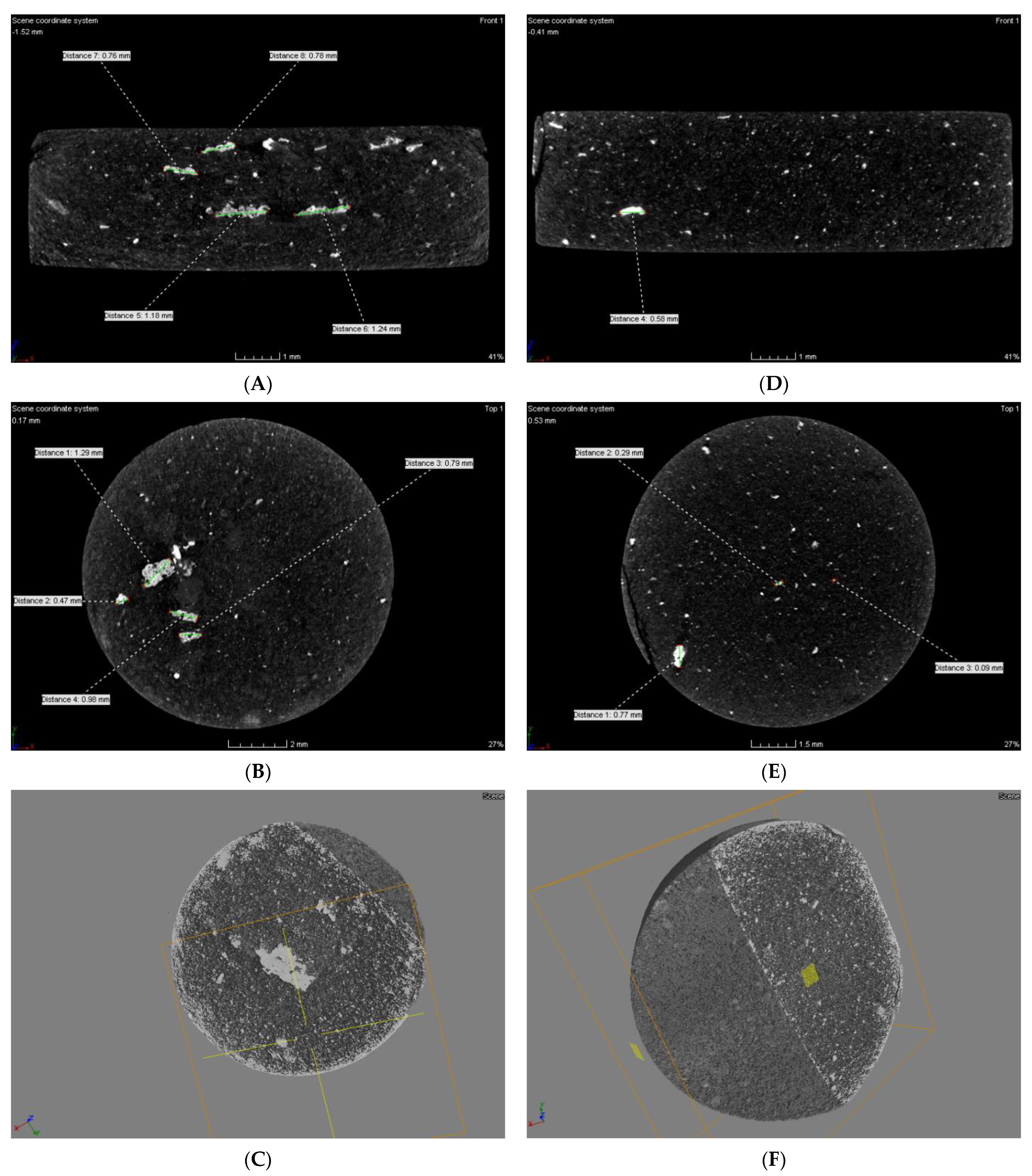

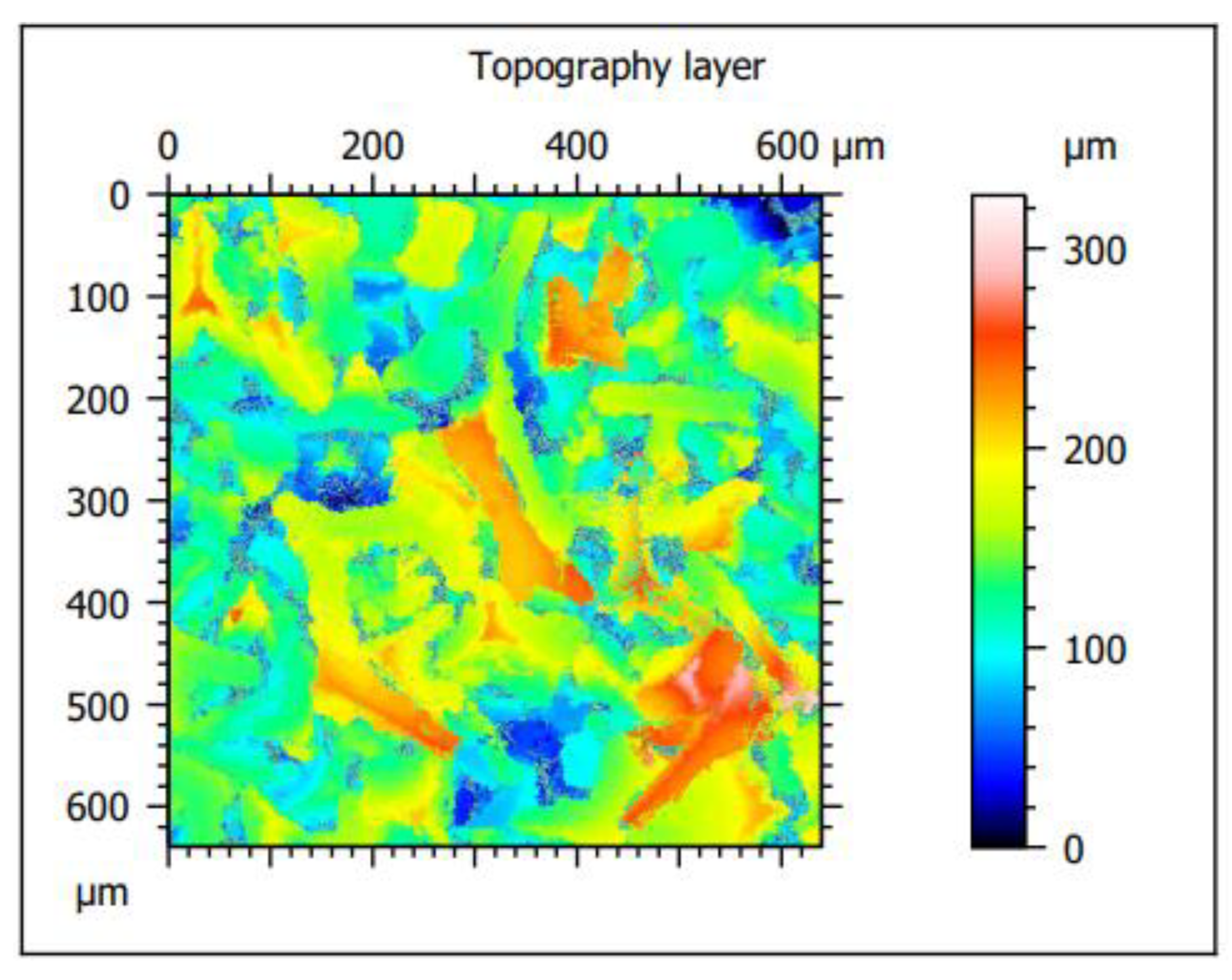

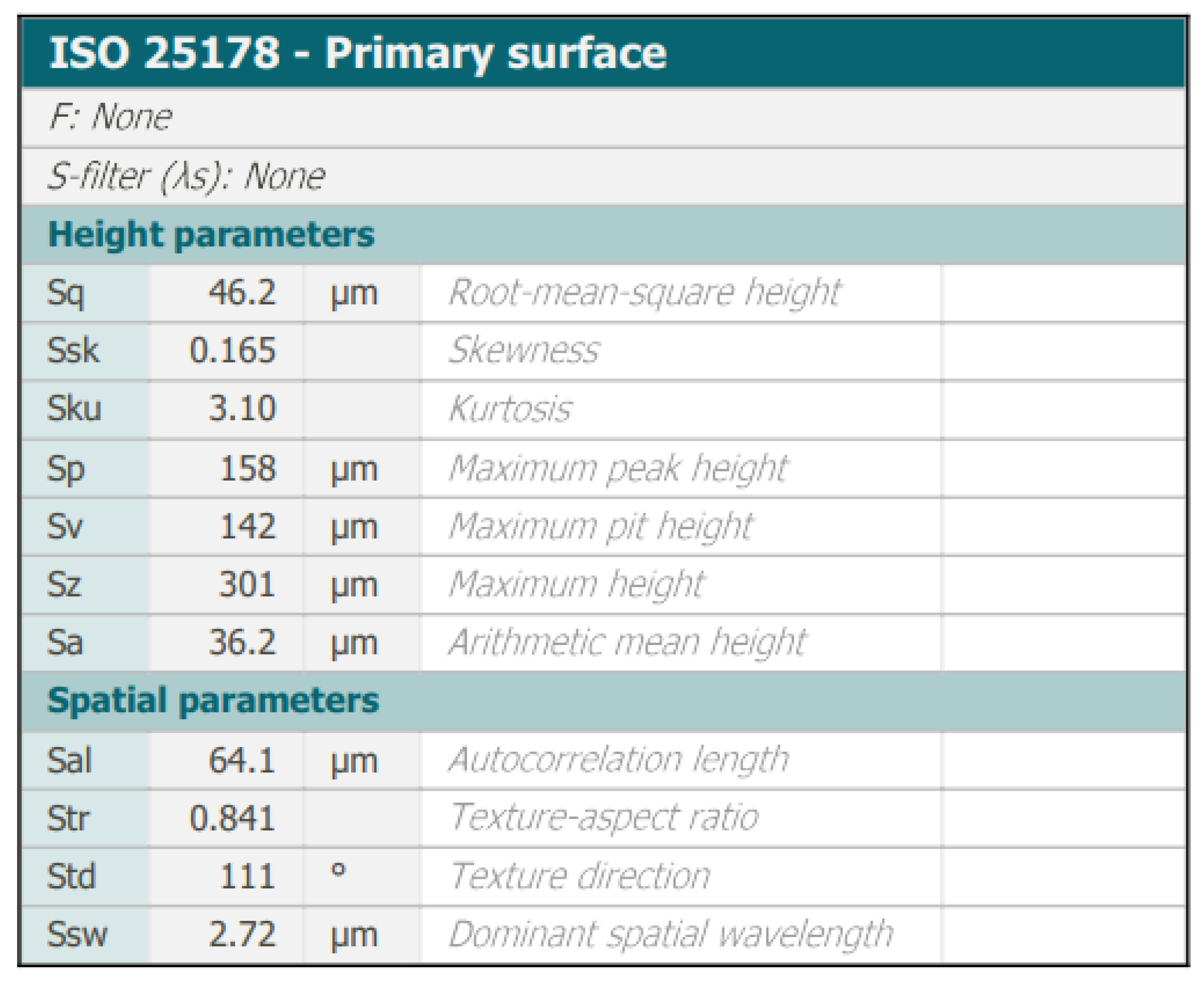

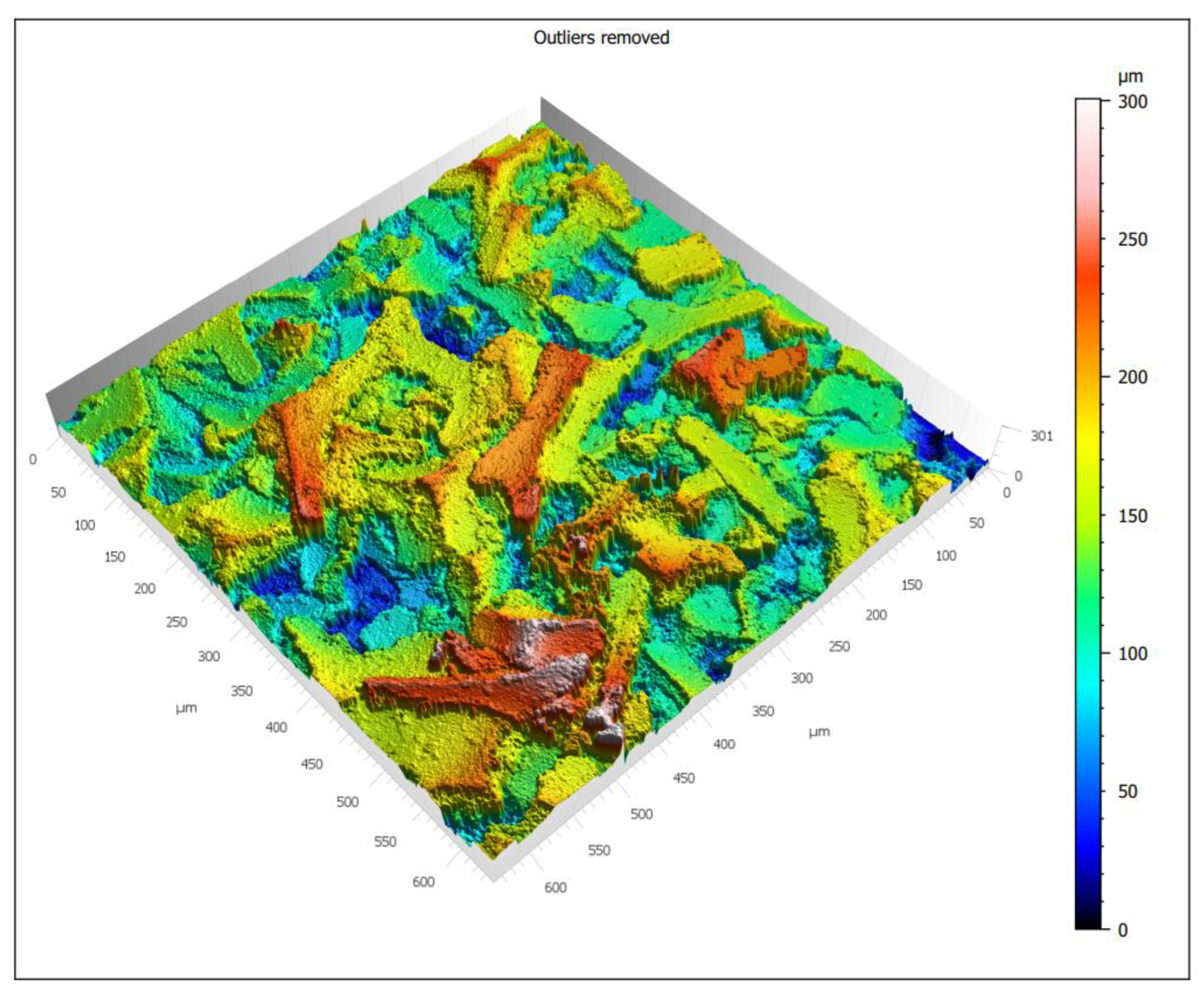

2. Materials and Methods

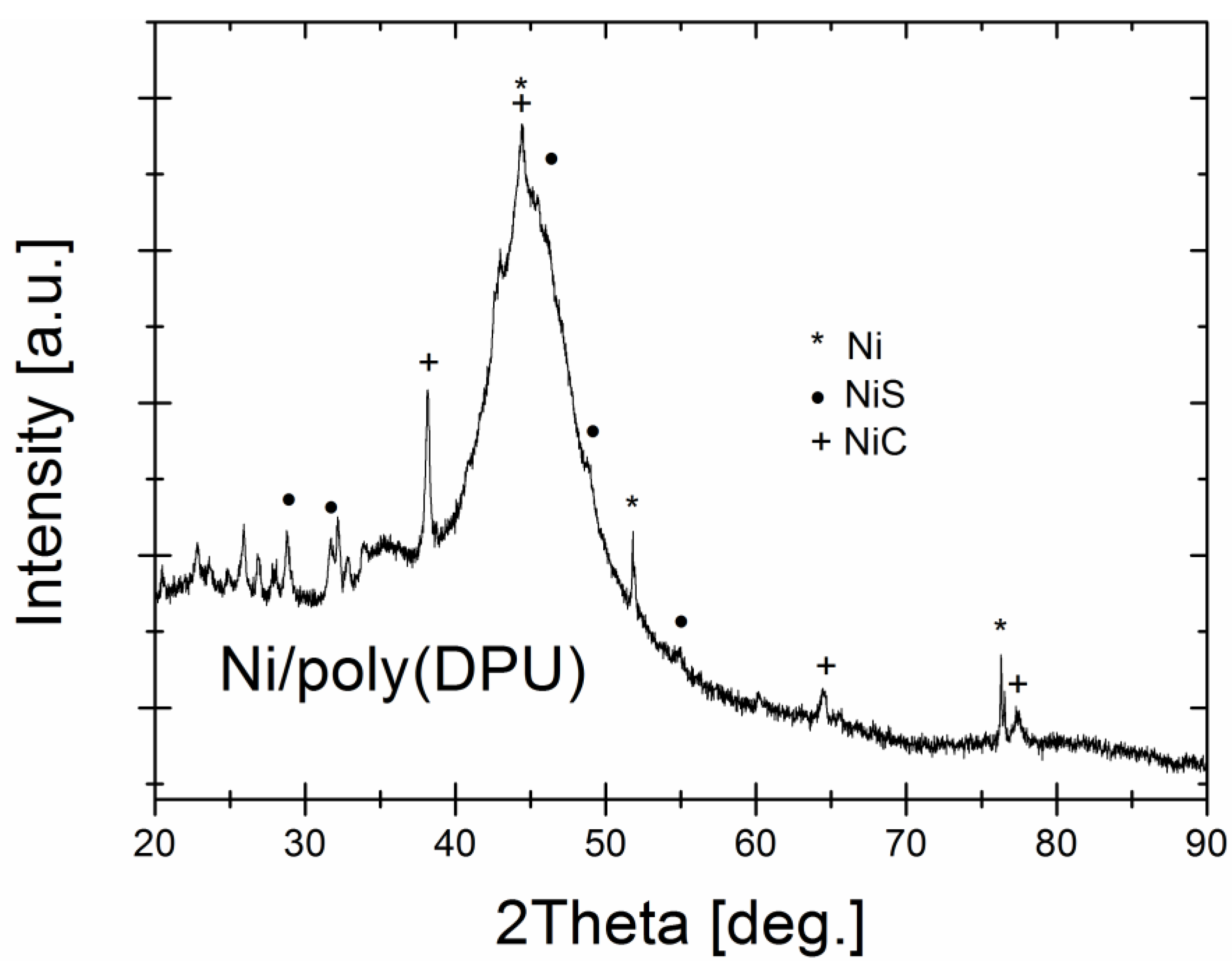

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wykpis, K.; Popczyk, M.; Niedbała, J.; Bierska-Piech, B.; Budniok, A.; Łągiewka, E. Influence of thermal treatment on the corrosion resistance of electrolytic Zn-Ni+Ni composite coatings. Adv. Compos. Mater. 2015, 24, 431–438. [Google Scholar] [CrossRef]

- Popczyk, M.; Kubisztal, J.; Swinarew, A.S.; Waśkiewicz, Z.; Stanula, A.; Knechtle, B. Corrosion resistance of heat-treated Ni-W alloy coatings. Materials 2020, 13, 1172. [Google Scholar] [CrossRef] [PubMed]

- Popczyk, M. The influence of molybdenum and silicon on activity of Ni+W composite coatings in the hydrogen evolution reaction. Surf. Interface Anal. 2008, 40, 246–249. [Google Scholar] [CrossRef]

- Wykpis, K.; Niedbała, J.; Popczyk, M.; Budniok, A.; Łągiewka, E. The electrodeposition and properties of Zn-Ni + Ni composite coatings. Russ. J. Electrochem. 2012, 48, 1123–1129. [Google Scholar] [CrossRef]

- Popczyk, M. The hydrogen evolution reaction on electrolytic nickel—Based coatings containing metallic molybdenum. Mater. Sci. Forum 2010, 636–637, 1036–1041. [Google Scholar] [CrossRef]

- Nambiar, S.; Yeow, J.T.W. Polymer-Composite Materials for Radiation Protection. ACS Appl. Mater. Interfaces 2012, 4, 5717–5726. [Google Scholar] [CrossRef]

- Seo, S.; Alvarez Perez, G.; Tewari, K.; Comas, X.; Kim, M. Catalytic activity of nickel nanoparticles stabilized by adsorbing polymers for enhanced carbon sequestration. Sci. Rep. 2018, 8, 11786. [Google Scholar] [CrossRef]

- Yu, Y.; Luan, D.; Bi, C.; Yu, M.; Chen, Y.; Zhao, D. Synthesis of Polystyrene Microsphere-Supported Ag-Ni-Alloyed Catalysts with Core-Shell Structures for Electrocatalytic Performance. Polym. Plast. Technol. Eng. 2018, 57, 875–883. [Google Scholar] [CrossRef]

- Niedbała, J. Surface morphology and corrosion resistance of electrodeposited composite coatings containing polyethylene or polythiophene in Ni-Mo base. Bull. Mat. Sci. 2011, 34, 993–996. [Google Scholar] [CrossRef]

- Niedbała, J.; Budniok, A.; Łągiewka, E. Hydrogen evolution on the polyethylene-modified Ni-Mo composite layers. Thin Solid Films 2008, 516, 6191–6196. [Google Scholar] [CrossRef]

- Niedbała, J. Wpływ Obecności Aktywatorów Polimerowych w Powłokach Ni-Mo na Proces Wydzielania Wodoru (Influence of the Presence of Polymer Activators in Ni-Mo Coatings on the Process of Hydrogen Evolution); Wydawnictwo Uniwersytetu Śląskiego: Katowice, Poland, 2014; ISBN 978-83-8012-227-7. [Google Scholar]

- Zhou, Z.; Kong, D.; Zhu, H.; Wang, N.; Wang, Z.; Wang, Q.; Liu, W.; Li, Q.; Zhang, W.; Ren, Z. Preparation and adsorption characteristics of an ion-imprinted polymer for fast removal of Ni(II) ions from aqueous solution. J. Hazard. Mater. 2018, 341, 355–364. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jian, J.; Yuan, Z.; Zeng, J.; Zhang, L.; Wang, T.; Zhou, H. In situ loading of polyurethane/negative ion powder composite film with visible-light-responsive Ag3PO4@AgBr particles for photocatalytic and antibacterial applications. Eur. Polym. J. 2020, 125, 109515. [Google Scholar] [CrossRef]

- Tor-Świątek, A. Innovative hybrid polymer composites cellular polymer-metal powder obtained in extrusion process. Acta Innov. 2015, 17, 12–21. [Google Scholar]

- Hanemann, T.; Szabó, D.V. Polymer-Nanoparticle Composites: From Synthesis to Modern Applications. Materials 2010, 3, 3468–3517. [Google Scholar] [CrossRef]

- Lin, K.-J.; Wu, H.-M.; Yu, Y.-H.; Ho, C.-Y.; Wei, M.-H.; Lu, F.-H.; Tseng, W.J. Preparation of PMMA-Ni core-shell composite particles by electroless plating on polyelectrolyte-modified PMMA beads. Appl. Surf. Sci. 2013, 282, 741–745. [Google Scholar] [CrossRef]

- Lotfy, A.; Mohamed, E.; Handam, A.K.; Barkov, R.Y. Investigation of Polymer-70% Aluminum Powder Composite. Int. J. Metal. Met. Phys. 2020, 5, 51. [Google Scholar]

- Jin, Z.; Liang, F.; Lu, W.; Dai, J.; Meng, S.; Lin, Z. Effect of Particle Sizes of Nickel Powder on Thermal Conductivity of Epoxy Resin-Based Composites under Magnetic Alignment. Polymers 2019, 11, 1990. [Google Scholar] [CrossRef]

- Adamenko, N.A.; Kazurov, A.V.; Agafonova, G.V.; Savin, D.V. Structure Formation in Nickel-Polytetrafluorethylene Composite Materials upon Explosive Pressing of Powders. Inorg. Mater. Appl. Res. 2020, 11, 982–990. [Google Scholar] [CrossRef]

- Gui, C.; Yao, C.; Huang, J.; Chen, Z.; Yang, G. Preparation of polymer brush/Ni particle and its application in electroless copper plating on PA12 powder. Appl. Surf. Sci. 2020, 506, 144935. [Google Scholar] [CrossRef]

- Griffiths, E.; Wilmers, J.; Bargmann, S.; Reddy, B.D. Nanoporous metal based composites: Giving polymers strength and making metals move. J. Mech. Phys. Solid 2020, 137, 103848. [Google Scholar] [CrossRef]

- Los, P.; Lukomska, A.; Jeziorska, R. Metal-polymer composites for electromagnetic interference shielding applications. Polimery 2016, 61, 663–669. [Google Scholar] [CrossRef]

- Adamenko, N.A.; Kazurov, A.V.; Savin, D.V.; Agafonova, G.V. Structure and thermophysical properties of polytetrafluoroethylene-aluminum composite materials produced by explosive pressing. MIST Aerosp. 2018 IOP Conf. Ser. Mater. Sci. Eng. 2018, 450, 032044. [Google Scholar] [CrossRef]

- Augustyn, P.; Rytlewski, P.; Moraczewski, K.; Mazurkiewicz, A. A review on the direct electroplating of polymeric materials. J. Mater. Sci. 2021, 56, 14881–14899. [Google Scholar] [CrossRef]

- Li, J.; Zhou, G.; Jin, X.; Hong, Y.; He, W.; Wang, S.; Chen, Y.; Yang, W.; Su, X. Direct activation of copper electroplating on conductive composite of polythiophene surface-coated with nickel nanoparticles. Compos. Part B Eng. 2018, 154, 257–262. [Google Scholar] [CrossRef]

- Mao, Y.; Xu, H.P.; Zhao, H.; Yuan, W.Z.; Qin, A.; Yu, Y.; Faisal, M.; Xiao, A.Z.; Sun, J.Z.; Tang, B.Z. Composites of quaternized poly(pyridylacetylene) and silver nanoparticles: Nanocomposite preparation, conductivity, and photoinduced patterning. J. Mater. Chem. 2011, 21, 13627–13633. [Google Scholar] [CrossRef][Green Version]

- Mehdizadeh, M.; Khorasanian, M.; Baghal, S.M.L. Direct electroplating of nickel on ABS plastic using polyaniline silver surface composite synthesized using different acids. J. Coat. Technol. Res. 2018, 15, 1433–1442. [Google Scholar] [CrossRef]

- Kusunose, T.; Yagi, T.; Firoz, S.H.; Sekino, T. Fabrication of epoxy/silicon nitride nanowire composites and evaluation of their thermal conductivity. J. Mater. Chem. A 2013, 1, 3440–3445. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, J.T.; Yao, Y.M.; Zeng, X.L.; Sun, J.J.; Pan, G.R.; Sun, R.; Xu, J.B.; Wong, C.P. Manipulating Orientation of Silicon Carbide Nanowire in Polymer Composites to Achieve High Thermal Conductivity. Adv. Mater. Interfaces 2017, 4, 1700446. [Google Scholar] [CrossRef]

- Huang, X.Y.; Zhi, C.Y.; Jiang, P.K.; Golberg, D.; Bando, Y.; Tanaka, T. Polyhedral Oligosilsesquioxane—Modified Boron Nitride Nanotube Based Epoxy Nanocomposites: An Ideal Dielectric Material with High Thermal Conductivity. Adv. Funct. Mater. 2013, 23, 1824–1831. [Google Scholar] [CrossRef]

- Bian, W.C.; Yao, T.; Chen, M.; Zhang, C.; Shao, T.; Yang, Y. The synergistic effects of the micro-BN and nano-Al2O3 in micro-nano composites on enhancing the thermal conductivity for insulating epoxy resin. Compos. Sci. Technol. 2018, 168, 420–428. [Google Scholar] [CrossRef]

- Li, B.; Dong, S.; Wu, X.; Wang, C.P.; Wang, X.J.; Fang, J. Anisotropic thermal property of magnetically oriented carbon nanotube/graphene polymer composites. Compos. Sci. Technol. 2017, 147, 52–61. [Google Scholar] [CrossRef]

- Song, S.H.; Park, K.H.; Kim, B.H.; Choi, Y.W.; Jun, G.H.; Lee, D.J.; Kong, B.S.; Paik, K.W.; Jeon, S. Enhanced thermal conductivity of epoxy-graphene composites by using non-oxidized graphene flakes with non-covalent functionalization. Adv. Mater. 2013, 25, 732–737. [Google Scholar] [CrossRef] [PubMed]

- Cui, W.; Du, F.P.; Zhao, J.C.; Zhang, W.; Yang, Y.K.; Xie, X.L.; Mai, Y.W. Improving thermal conductivity while retaining high electrical resistivity of epoxy composites by incorporating silica-coated multi-walled carbon nanotubes. Carbon 2011, 49, 495–500. [Google Scholar] [CrossRef]

- Liu, S.; Zhao, B.; Jiang, L.; Zhu, Y.-W.; Fu, X.-Z.; Sun, R.; Xu, J.-B.; Wong, C.-P. Core–shell Cu@rGO hybrids filled in epoxy composites with high thermal conduction. J. Mater. Chem. C 2018, 6, 257–265. [Google Scholar] [CrossRef]

- Ren, L.L.; Li, Q.; Lu, J.B.; Zeng, X.L.; Sun, R.; Wu, J.B.; Xu, J.B.; Wong, C.P. Enhanced thermal conductivity for Ag-deposited alumina sphere/epoxy resin composites through manipulating interfacial thermal resistance. Compos. Part A 2018, 107, 561–569. [Google Scholar] [CrossRef]

- Choi, J.R.; Rhee, K.Y.; Park, S.J. Influence of electrolessly silver-plated multi-walled carbon nanotubes on thermal conductivity of epoxy matrix nanocomposites. Compos. Part B 2015, 80, 379–384. [Google Scholar] [CrossRef]

- Dang, T.M.L.; Kim, C.Y.; Zhang, Y.M.; Yang, J.F.; Masaki, T.; Yoon, D.H. Enhanced thermal conductivity of polymer composites via hybrid fillers of anisotropic aluminum nitride whiskers and isotropic spheres. Compos. Part B 2017, 114, 237–246. [Google Scholar] [CrossRef]

- Hu, J.T.; Huang, Y.; Zeng, X.L.; Li, Q.; Ren, L.L.; Sun, R.; Xu, J.B.; Wong, C.P. Polymer composite with enhanced thermal conductivity and mechanical strength through orientation manipulating of BN. Compos. Sci. Technol. 2018, 160, 127–137. [Google Scholar] [CrossRef]

- Chen, C.H.; Jian, J.Y.; Yen, F.S. Preparation and characterization of epoxy/gamma-aluminum oxide nanocomposites. Compos. Part A 2009, 40, 463–468. [Google Scholar] [CrossRef]

- Felten, M.; Fries, M.; Fíla, T.; Zlámal, P.; Falta, J.; Jiroušek, O.; Jung, A. High Strain-Rate Compression Experiments on Ni/ Polyurethane Hybrid Metal Foams Using the Split—Hopkinson Pressure Bar Technique. Adv. Eng. Mater. 2022, 24, 2100872. [Google Scholar] [CrossRef]

- Swinarew, A.S.; Grobelny, Z.; Jasik, K.; Rozwadowska, B.; Nowicki, G.; Flak, T.; Gabor, J.; Łężniak, M.; Okła, H. Sposób Wytwarzania Poliuretanu Modyfikowanego Nanokrzemionką (PL Patent No. 228980); The Patent Office of the Republic of Poland: Katowice, Poland, 2018. [Google Scholar]

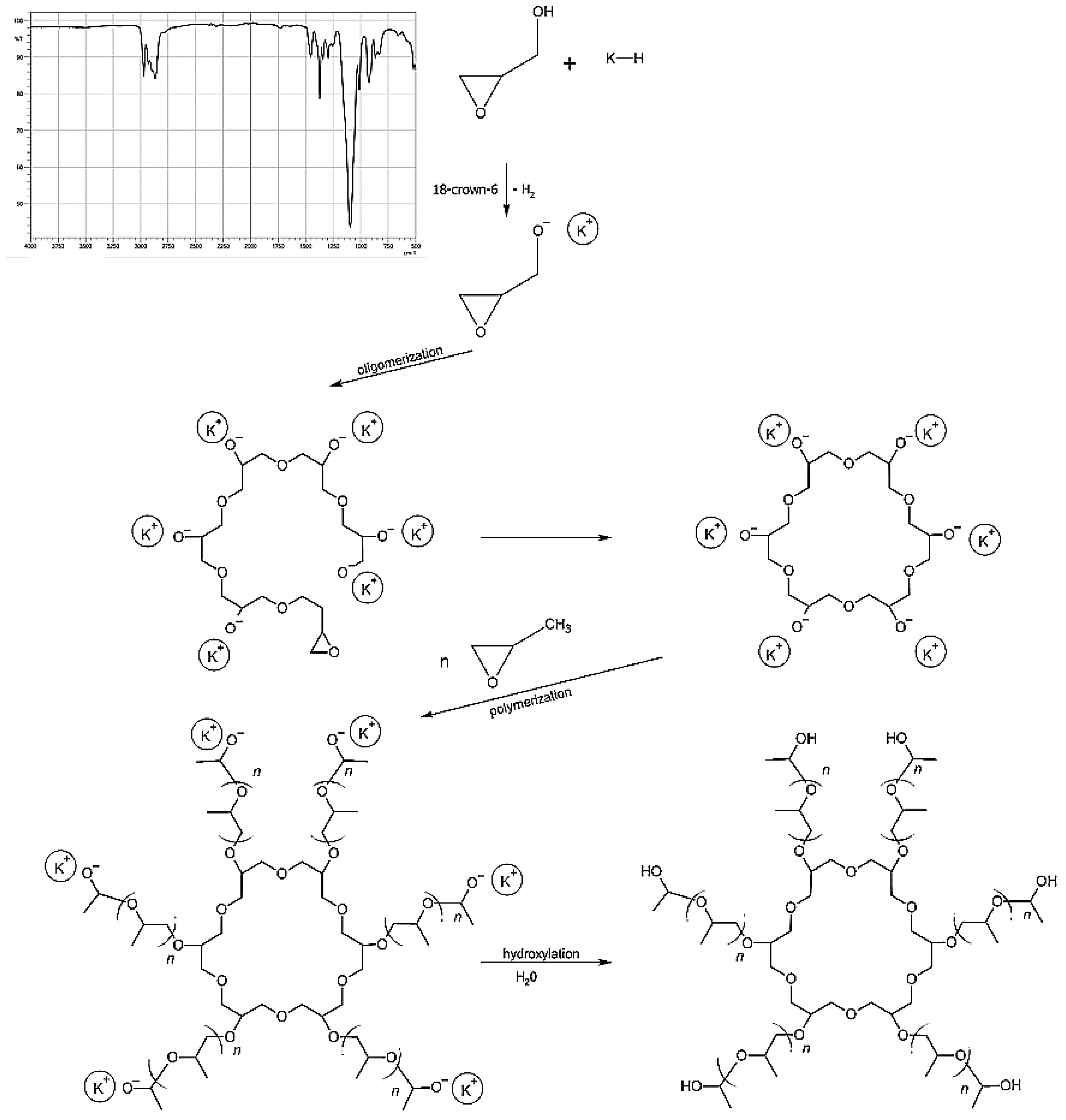

- Swinarew, A.S.; Swinarew, B.; Gabor, J.; Popczyk, M.; Kubik, K.; Stanula, A.; Waśkiewicz, Z.; Rosemann, T.; Knechtle, B. New kind of polymer materials based on selected complexing star-shaped polyethers. Polymers 2019, 11, 1554. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.; Sun, D.; Yu, H.; Meng, H.; Fan, Z.; Wang, X. Preparation of amorphous-nanocrystalline composite structured Ni-P electrodeposits. Surf. Coat. Technol. 2007, 202, 294–300. [Google Scholar] [CrossRef]

- Niedbała, J.; Popczyk, M.; Benke, G.; Okła, H.; Gabor, J.; Wrzalik, R.; Stanula, A.; Swinarew, A.S. The use of ZrO2 waste for the electrolytic production of composite Ni-P-ZrO2 powder. Materials 2021, 14, 6597. [Google Scholar] [CrossRef] [PubMed]

- Kubisztal, J.; Kubisztal, M.; Haneczok, G. Quantitative characterization of material surface—Application to Ni + Mo electrolytic composite coatings. Mater. Charact. 2016, 12, 45–53. [Google Scholar] [CrossRef]

- Hosseini, M.; Teymorinia, H.; Farzaneh, A.; Khameneh-asl, S. Evaluation of corrosion, mechanical and structural properties of new Ni-W-PCTFE nanocomposite coating. Surf. Coat. Technol. 2016, 298, 114–120. [Google Scholar] [CrossRef]

- Kosmela, P.; Suchorzewski, J.; Formela, K.; Kazimierski, P.; Haponiuk, J.T.; Piszczyk, Ł. Microstructure—Property relationship of polyurethane foams modified with Baltic Sea biomass: Microcomputed tomography vs. scanning electron microscopy. Materials 2020, 13, 5734. [Google Scholar] [CrossRef]

| Element | % Ni | % C | % O | % P | % S |

|---|---|---|---|---|---|

| Content (weight %) | 41.7 | 16.4 | 15.7 | 8.2 | 0.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niedbała, J.; Popczyk, M.; Hawełek, Ł.; Orda, S.; Okła, H.; Gabor, J.; Stach, S.; Swinarew, A.S. Production of Electrolytic Composite Powder by Nickel Plating of Shredded Polyurethane Foam. Materials 2022, 15, 3895. https://doi.org/10.3390/ma15113895

Niedbała J, Popczyk M, Hawełek Ł, Orda S, Okła H, Gabor J, Stach S, Swinarew AS. Production of Electrolytic Composite Powder by Nickel Plating of Shredded Polyurethane Foam. Materials. 2022; 15(11):3895. https://doi.org/10.3390/ma15113895

Chicago/Turabian StyleNiedbała, Jolanta, Magdalena Popczyk, Łukasz Hawełek, Szymon Orda, Hubert Okła, Jadwiga Gabor, Sebastian Stach, and Andrzej S. Swinarew. 2022. "Production of Electrolytic Composite Powder by Nickel Plating of Shredded Polyurethane Foam" Materials 15, no. 11: 3895. https://doi.org/10.3390/ma15113895

APA StyleNiedbała, J., Popczyk, M., Hawełek, Ł., Orda, S., Okła, H., Gabor, J., Stach, S., & Swinarew, A. S. (2022). Production of Electrolytic Composite Powder by Nickel Plating of Shredded Polyurethane Foam. Materials, 15(11), 3895. https://doi.org/10.3390/ma15113895