Comparison of Testing Designs for Flexural Strength of 3Y-TZP and 5Y-PSZ Considering Different Surface Treatment

Abstract

:1. Introduction

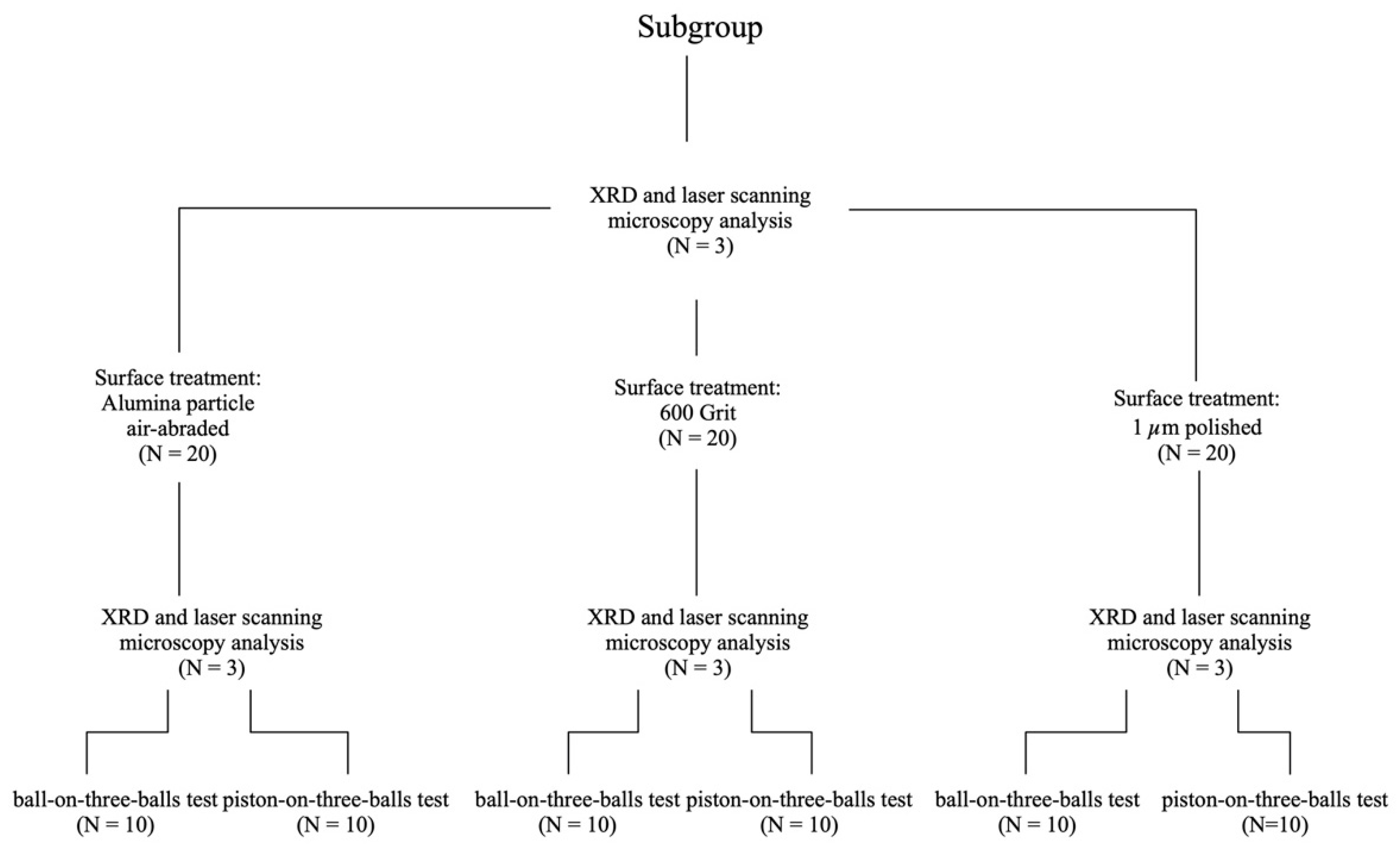

2. Materials and Methods

2.1. Specimen Fabrication

2.2. Surface Analysis

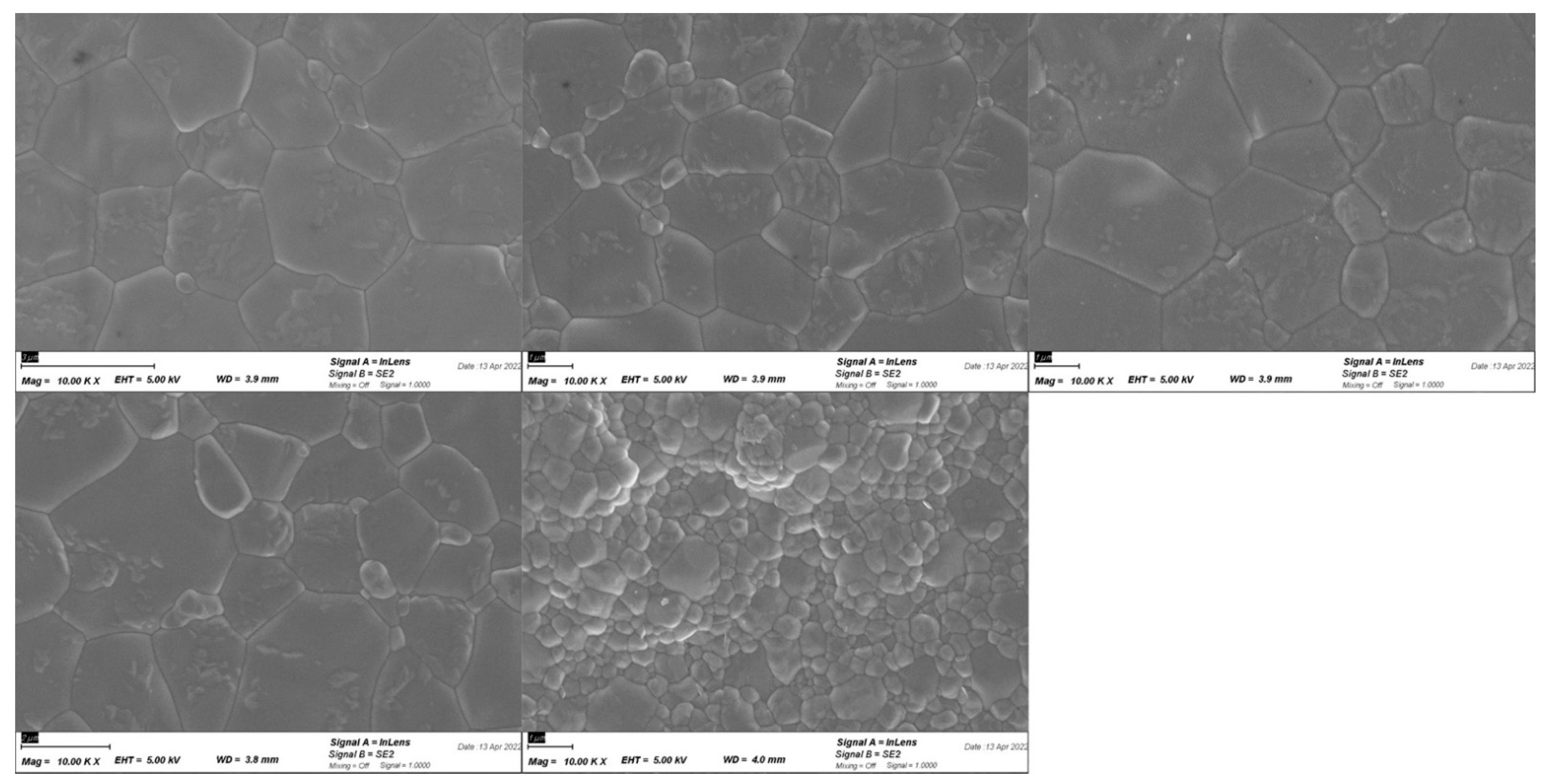

2.3. Analysis of Grain Size

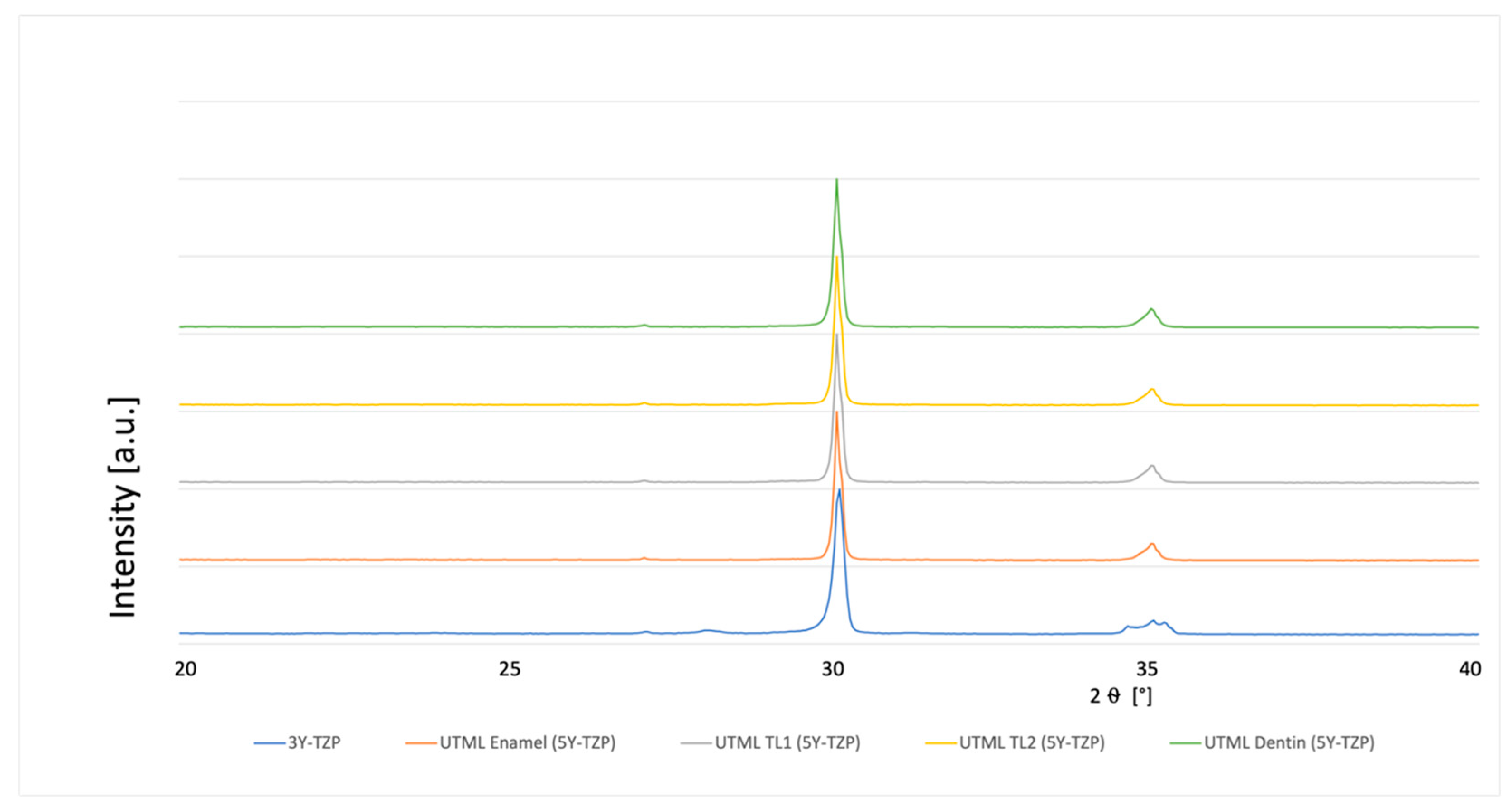

2.4. Structural Analysis

2.5. Flexural Strength Testing

2.6. Piston-on-Three-Balls Test

2.7. Ball-on-Three-Balls Test

2.8. Statistical Analysis

3. Results

3.1. Sintering State during Cutting Process

3.2. Surface Roughness Evaluation

3.3. Analysis of Grain Size

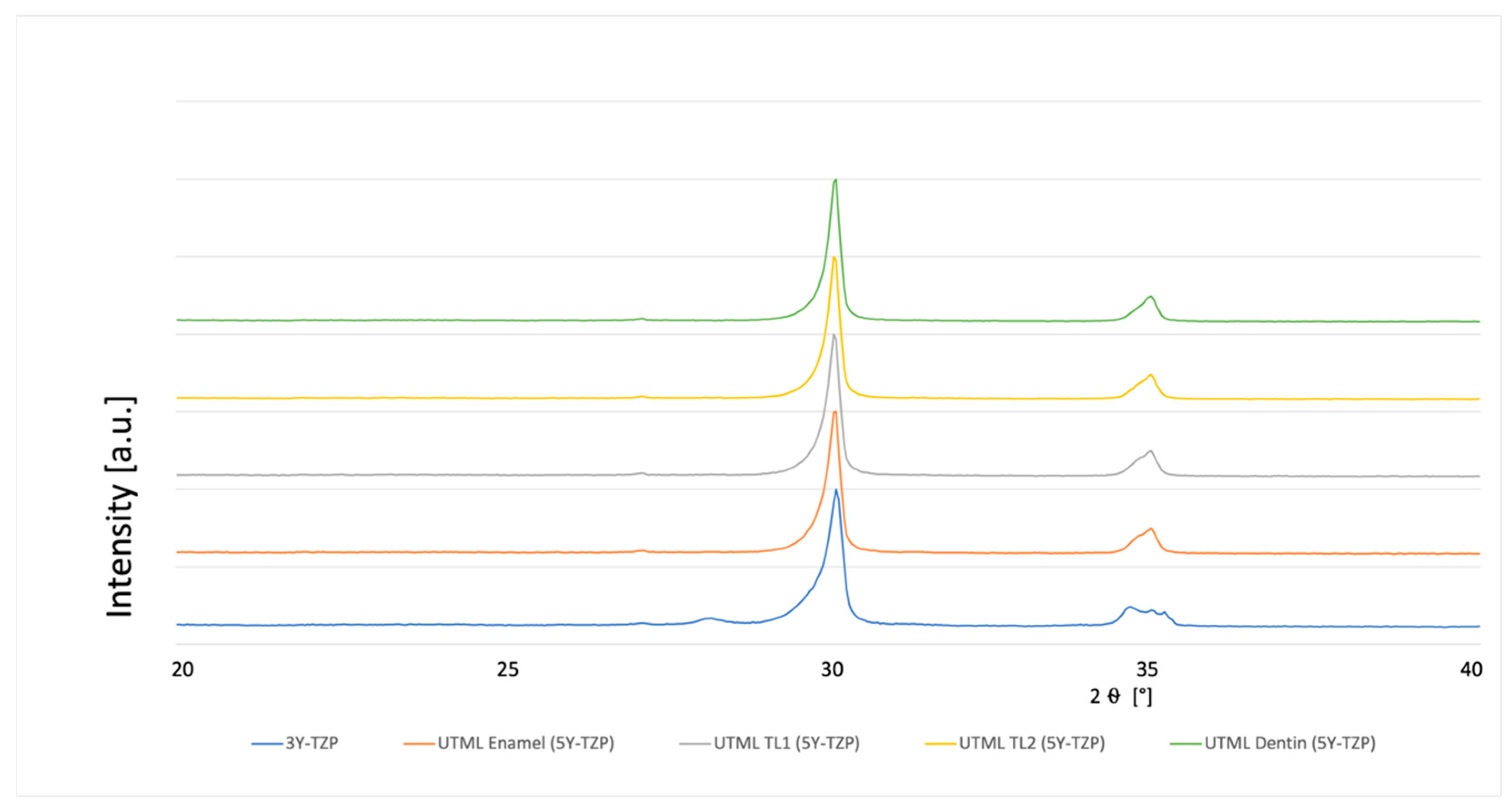

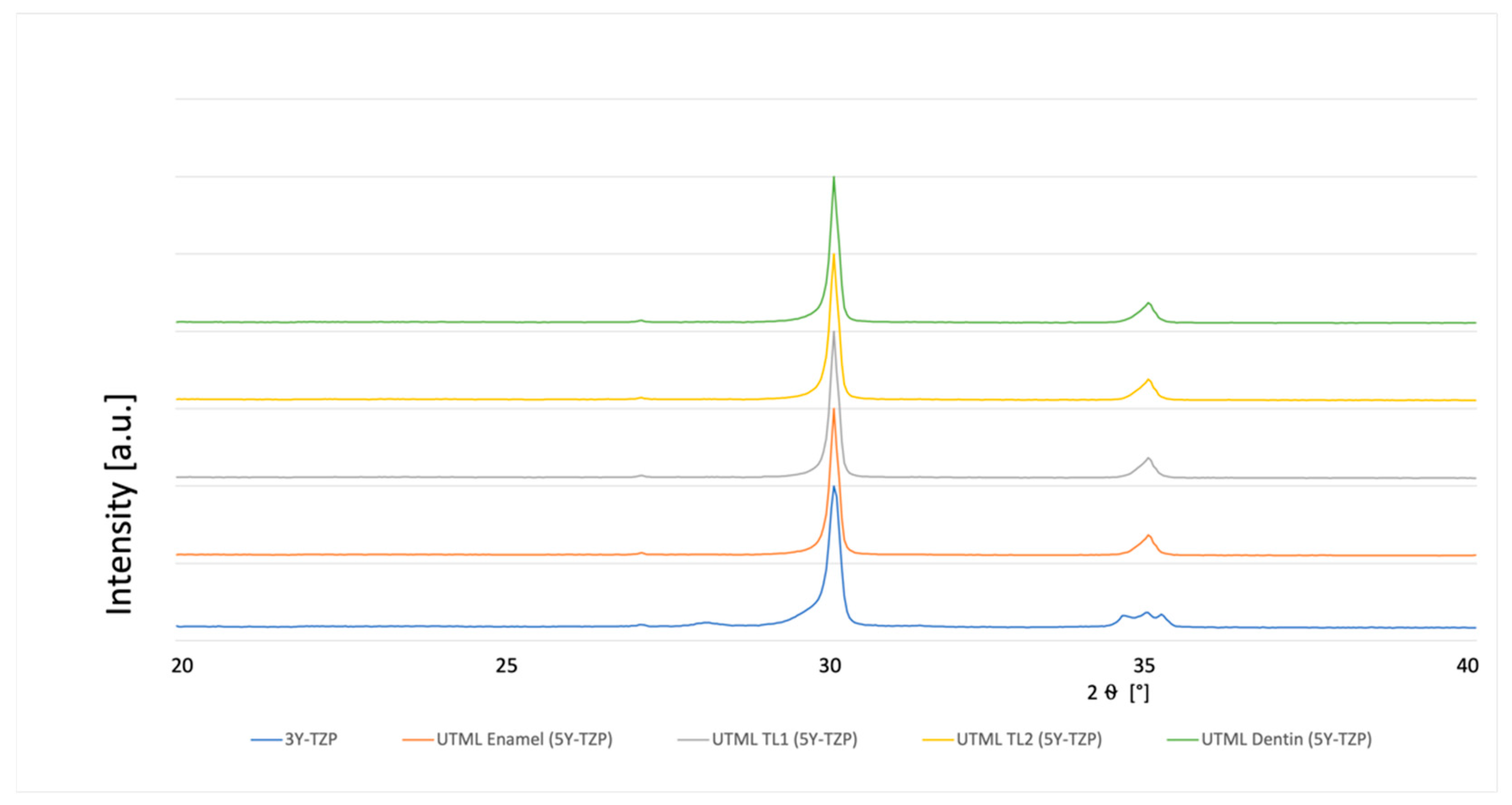

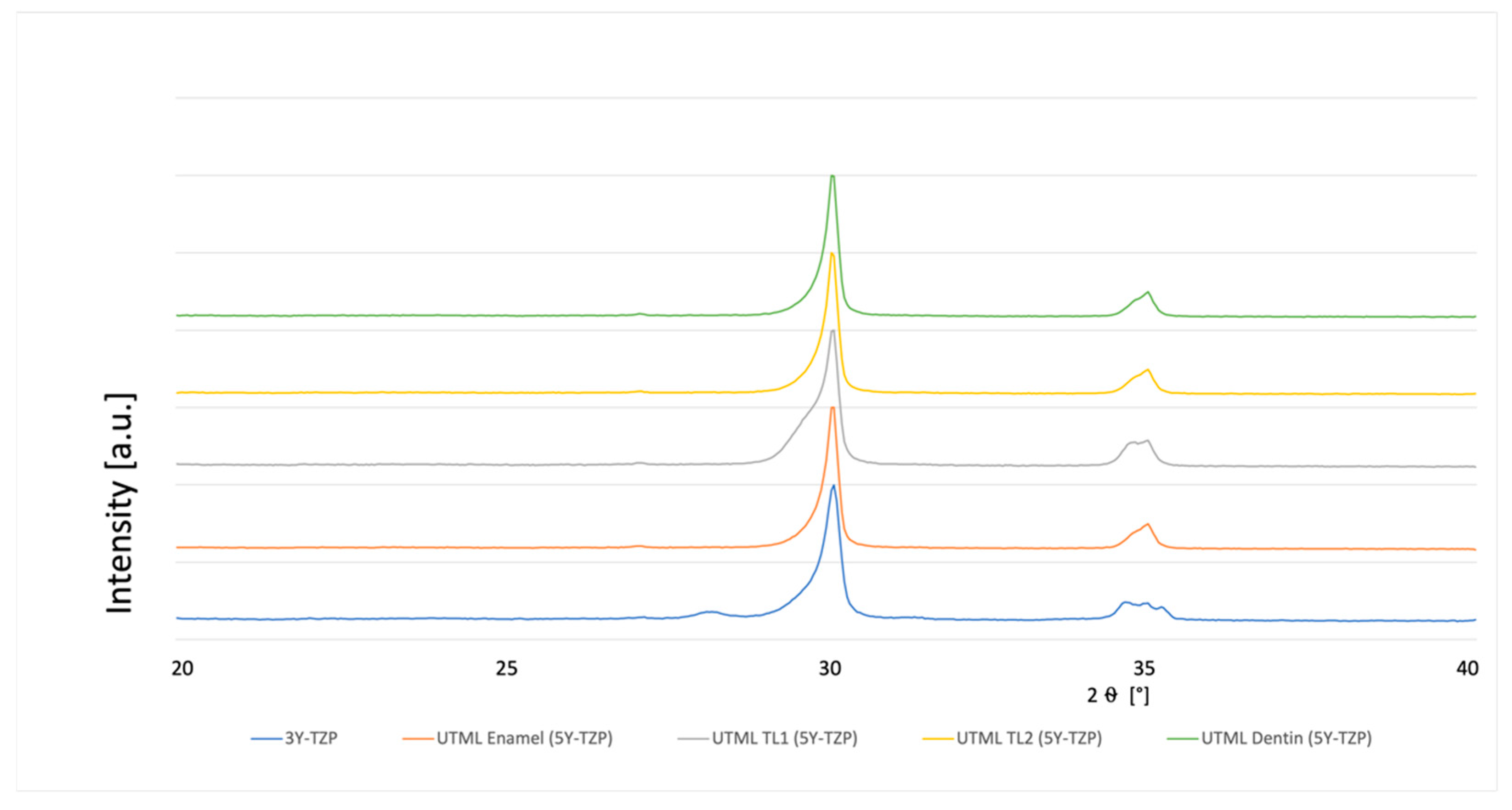

3.4. Phase Analysis

3.5. Biaxial Flexural Strength Testing

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manicone, P.F.; Rossi Iommetti, P.; Raffaelli, L. An overview of zirconia ceramics: Basic properties and clinical applications. J. Dent. 2007, 35, 819–826. [Google Scholar] [CrossRef] [PubMed]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef]

- Pecho, O.E.; Ghinea, R.; Ionescu, A.M.; Cardona, J.D.L.C.; Paravina, R.D.; Pérez, M.D.M. Color and translucency of zirconia ceramics, human dentine and bovine dentine. J. Dent. 2012, 40, e34–e40. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.J.; Lawson, N.C.; McLaren, E.E.; Nejat, A.H.; Burgess, J.O. Comparison of the mechanical properties of translucent zirconia and lithium disilicate. J. Prosthet. Dent. 2018, 120, 132–137. [Google Scholar] [CrossRef] [PubMed]

- Kosmač, T.; Oblak, C.; Jevnikar, P.; Funduk, N.; Marion, L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent. Mater. 1999, 15, 426–433. [Google Scholar] [CrossRef]

- Monaco, C.; Tucci, A.; Esposito, L.; Scotti, R. Microstructural changes produced by abrading Y-TZP in presintered and sintered conditions. J. Dent. 2013, 41, 121–126. [Google Scholar] [CrossRef]

- Passos, S.P.; Linke, B.; Major, P.W.; Nychka, J.A. The effect of air-abrasion and heat treatment on the fracture behavior of Y-TZP. Dent. Mater. 2015, 31, 1011–1021. [Google Scholar] [CrossRef]

- Carrabba, M.; Keeling, A.J.; Aziz, A.; Vichi, A.; Fabian Fonzar, R.; Wood, D.; Ferrari, M. Translucent zirconia in the ceramic scenario for monolithic restorations: A flexural strength and translucency comparison test. J. Dent. 2017, 60, 70–76. [Google Scholar] [CrossRef] [Green Version]

- Aboushelib, M.N.; Wang, H. Effect of surface treatment on flexural strength of zirconia bars. J. Prosthet. Dent. 2010, 104, 98–104. [Google Scholar] [CrossRef]

- Michida, S.M.D.A.; Kimpara, E.T.; dos Santos, C.; Souza, R.O.A.; Bottino, M.A.; Özcan, M. Effect of air-abrasion regimens and fine diamond bur grinding on flexural strength, weibull modulus and phase transformation of zirconium dioxide. J. Appl. Biomater. Func. 2015, 13, 266–273. [Google Scholar] [CrossRef] [Green Version]

- Cheng, M.; Chen, W.; Sridhar, K.R. Biaxial flexural strength distribution of thin ceramic substrates with surface defects. Int. J. Solids Struct. 2003, 40, 2249–2266. [Google Scholar] [CrossRef]

- Ebeid, K.; Wille, S.; Hamdy, A.; Salah, T.; El-Etreby, A.; Kern, M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent. Mater. 2014, 30, e419–e424. [Google Scholar] [CrossRef] [PubMed]

- Karakoca, S.; Yılmaz, H. Influence of surface treatments on surface roughness, phase transformation, and biaxial flexural strength of Y-TZP ceramics. J. Biomed. Mater. Res. B 2009, 91B, 930–937. [Google Scholar] [CrossRef] [PubMed]

- Börger, A.; Supancic, P.; Danzer, R. The ball on three balls test for strength testing of brittle discs: Stress distribution in the disc. J. Europ. Ceram. Soc. 2002, 22, 1425–1436. [Google Scholar] [CrossRef]

- Dewith, G.; Wagemans, H.H.M. Ball-on-ring test revisited. J. Am. Ceram. Soc. 1989, 72, 1538–1541. [Google Scholar]

- Luthardt, R.G.; Holzhüter, M.; Sandkuhl, O.; Herold, V.; Schnapp, J.D.; Kuhlisch, E.; Walter, M. Reliability and properties of ground Y-TZP-zirconia ceramics. J. Dent. Res. 2002, 81, 487–491. [Google Scholar] [CrossRef]

- Wang, H.; Aboushelib, M.N.; Feilzer, A.J. Strength influencing variables on CAD/CAM zirconia frameworks. Dent. Mater. 2008, 24, 633–638. [Google Scholar] [CrossRef]

- Wille, S.; Zumstrull, P.; Kaidas, V.; Jessen, L.K.; Kern, M. Low temperature degradation of single layers of multilayered zirconia in comparison to conventional unshaded zirconia: Phase transformation and flexural strength. J. Mech. Behav. Biomed. 2018, 77, 171–175. [Google Scholar] [CrossRef]

- Grambow, J.; Wille, S.; Kern, M. Impact of changes in sintering temperatures on characteristics of 4YSZ and 5YSZ. J. Mech. Behav. Biomed. Mater. 2021, 120, 104586. [Google Scholar] [CrossRef]

- Lumkemann, N.; Stawarczyk, B. Impact of hydrothermal aging on the light transmittance and flexural strength of colored yttria-stabilized zirconia materials of different formulations. J. Prosthet. Dent. 2021, 125, 518–526. [Google Scholar] [CrossRef]

- Chen, B.; Yan, Y.; Xie, H.; Meng, H.; Zhang, H.; Chen, C. Effects of Tribochemical Silica Coating and Alumina-Particle Air Abrasion on 3Y-TZP and 5Y-TZP: Evaluation of Surface Hardness, Roughness, Bonding, and Phase Transformation. J. Adhes. Dent. 2020, 22, 373–382. [Google Scholar] [CrossRef] [PubMed]

- Jerman, E.; Lumkemann, N.; Eichberger, M.; Zoller, C.; Nothelfer, S.; Kienle, A.; Stawarczyk, B. Evaluation of translucency, Marten’s hardness, biaxial flexural strength and fracture toughness of 3Y-TZP, 4Y-TZP and 5Y-TZP materials. Dent. Mater. 2021, 37, 212–222. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.W.; Hsueh, C.H. Piston-on-three-ball versus piston-on-ring in evaluating the biaxial strength of dental ceramics. Dent. Mater. 2011, 27, e117–e123. [Google Scholar] [CrossRef] [PubMed]

- Shin, H.S.; Lee, J.S. Comparison of surface topography and roughness in different yttrium oxide compositions of dental zirconia after grinding and polishing. J. Adv. Prosthodont. 2021, 13, 258–267. [Google Scholar] [CrossRef] [PubMed]

- Danzer, R. On the relationship between ceramic strength and the requirements for mechanical design. J. Europ. Ceram. Soc. 2014, 34, 3435–3460. [Google Scholar] [CrossRef]

- Amarante, J.E.V.; Pereira, M.V.S.; de Souza, G.M.; Pais Alves, M.F.R.; Simba, B.G.; dos Santos, C. Roughness and its effects on flexural strength of dental yttria-stabilized zirconia ceramics. Mater. Sci. Eng. A 2019, 739, 149–157. [Google Scholar] [CrossRef]

- de Araújo-Júnior, E.N.S.; Bergamo, E.T.P.; Bastos, T.M.C.; Benalcázar Jalkh, E.B.; Lopes, A.C.O.; Monteiro, K.N.; Cesar, P.F.; Tognolo, F.C.; Migliati, R.; Tanaka, R.; et al. Ultra-translucent zirconia processing and aging effect on microstructural, optical, and mechanical properties. Dent. Mater. 2022, 38, 587–600. [Google Scholar] [CrossRef]

- Mao, L.; Kaizer, M.R.; Zhao, M.; Guo, B.; Song, Y.F.; Zhang, Y. Graded Ultra-Translucent Zirconia (5Y-PSZ) for Strength and Functionalities. J. Dent. Res. 2018, 97, 1222–1228. [Google Scholar] [CrossRef]

- Kolakarnprasert, N.; Kaizer, M.R.; Kim, D.K.; Zhang, Y. New multi-layered zirconias: Composition, microstructure and translucency. Dent. Mater. 2019, 35, 797–806. [Google Scholar] [CrossRef]

- Kontonasaki, E.; Giasimakopoulos, P.; Rigos, A.E. Strength and aging resistance of monolithic zirconia: An update to current knowledge. Jpn. Dent. Sci. Rev. 2020, 56, 1–23. [Google Scholar] [CrossRef]

- Inokoshi, M.; Vanmeensel, K.; Zhang, F.; De Munck, J.; Eliades, G.; Minakuchi, S.; Naert, I.; Van Meerbeek, B.; Vleugels, J. Aging resistance of surface-treated dental zirconia. Dent. Mater. 2015, 31, 182–194. [Google Scholar] [CrossRef] [PubMed]

- Börger, A.; Supancic, P.; Danzer, R. The ball on three balls test for strength testing of brittle discs: Part II: Analysis of possible errors in the strength determination. J. Europ. Ceram. Soc. 2004, 24, 2917–2928. [Google Scholar] [CrossRef]

- Schatz, C.; Strickstrock, M.; Roos, M.; Edelhoff, D.; Eichberger, M.; Zylla, I.-M.; Stawarczyk, B. Influence of specimen preparation and test methods on the flexural strength results of monolithic zirconia materials. Materials 2016, 9, 180. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Material | Type | LOT Number | ZrO2 (Wt%) | Y2O3 (wt%) |

|---|---|---|---|---|

| KATANA UTML fully-sintered | 5Y-PSZ | DRJXC | 87–92 | 8–11 |

| KATANA HT fully-sintered | 3Y-PSZ | DESUEX | 90–95 | 5–8 |

| KATANA UTML presintered | 5Y-PSZ | DSUEX | 87–92 | 8–11 |

| KATANA HT presintered | 3Y-TZP | DTGUO | 90–95 | 5–8 |

| Treatment | Sintering Stage at Treatment | 3Y-TZP | 5Y-PSZ Enamel | 5Y-PSZ TL1 | 5Y-PSZ TL2 | 5Y-PSZ Dentin |

|---|---|---|---|---|---|---|

| 1 µm polished | Fully sintered | 0.025 | 0.025 | 0.018 | 0.024 | 0.025 |

| (0.012) | (0.006) | (0.000) | (0.004) | (0.003) | ||

| Pre-sintered | 0.023 | 0.014 | 0.013 | 0.020 | 0.028 | |

| (0.007) | (0.001) | (0.005) | (0.003) | (0.011) | ||

| 600 Grit SiC Paper grinded | Fully sintered | 0.076 | 0.150 | 0.136 | 0.151 | 0.160 |

| (0.015) | (0.013) | (0.008) | (0.005) | (0.005) | ||

| Pre-sintered | 0.075 | 0.147 | 0.114 | 0.115 | 0.110 | |

| (0.005) | (0.103) | (0.026) | (0.002) | (0.016) | ||

| Alumina particle air-abraded | Fully sintered | 0.300 | 0.386 | 0.395 | 0.366 | 0.373 |

| (0.059) | (0.028) | (0.052) | (0.023) | (0.031) | ||

| Pre-sintered | 0.291 | 0.311 | 0.341 | 0.291 | 0.348 | |

| (0.027) | (0.008) | (0.024) | (0.054) | (0.029) |

| Material | Enamel Layer (5Y-PSZ) | Transition Layer 1 (5Y-PSZ) | Transition Layer 2 (5Y-PSZ) | Dentin Layer (5Y-PSZ) | 3Y-TZP |

|---|---|---|---|---|---|

| Mean (SD) | 3.82 | 3.47 | 3.66 | 3.40 | 0.18 |

| (0.65) | (0.25) | (0.44) | (0.30) | (0.011) |

| Treatment | Sintering Stage at Treatment | 3Y-TZP | 5Y-PSZ Enamel | 5Y-PSZ TL1 | 5Y-PSZ TL2 | 5Y-PSZ Dentin | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Median | Mean (SD) | Median | Mean (SD) | Median | Mean (SD) | Median | Mean (SD) | Median | Mean (SD) | ||

| 1 µm polished | Fully sintered | 719 | 718 | 470 | 474 | 514 | 494 | 500 | 486 | 494 | 481 |

| A, a, β | (40) | B, a, α | (39) | B, a, α | (46) | B, a, α | (70) | B, a, α | (43) | ||

| Pre-sintered | 1056 | 1049 | 528 | 504 | 550 | 548 | 527 | 520 | 547 | 529 | |

| A, a, α | (53) | B, a, α | (83) | B, a, α | (50) | B, a, α | (51) | B, a, α | (75) | ||

| 600 Grit SiC Paper grinded | Fully sintered | 761 | 774 | 458 | 471 | 490 | 492 | 479 | 468 | 489 | 486 |

| A, a, β | (100) | B, a, β | (64) | B, a, α | (55) | B, a, α | (39) | B, a, α | (50) | ||

| Pre-sintered | 1050 | 1030 | 650 | 629 | 583 | 568 | 581 | 574 | 568 | 562 | |

| A, a, α | (133) | B, a, α | (69) | B, a, α | (79) | B, a, α | (64) | B, a, α | (68) | ||

| Alumina particle air-abraded | Fully sintered | 760 | 741 | 324 | 330 | 362 | 368 | 342 | 339 | 359 | 347 |

| A, a, β | (81) | B, b, α | (38) | B, b, α | (28) | B, b, α | (16) | B, b, α | (34) | ||

| Pre-sintered | 1128 | 1133 | 337 | 341 | 330 | 336 | 331 | 350 | 334 | 358 | |

| A, a, α | (109) | B, b, α | (49) | B, b, α | (49) | B, b, α | (51) | B, b, α | (58) | ||

| Treatment | Sintering Stage at Treatment | 3Y-TZP | 5Y-PSZ Enamel | 5Y-PSZ TL1 | 5Y-PSZ TL2 | 5Y-PSZ Dentin | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Median | Mean (SD) | Median | Mean (SD) | Median | Mean (SD) | Median | Mean (SD) | Median | Mean (SD) | ||

| 1 µm polished | Fully sintered | 841 | 860 | 574 | 570 | 546 | 550 | 578 | 564 | 537 | 514 |

| A, a, β | (131) | B, a, α | (43) | B, a, α | (49) | B, a, α | (43) | B, a, α | (99) | ||

| presintered | 1240 | 1226 | 662 | 607 | 595 | 584 | 618 | 616 | 662 | 654 | |

| A, a, α | (78) | B, a, α | (83) | B, a, α | (60) | B, a, α | (50) | B, a, α | (53) | ||

| 600 Grit SiC Paper grinded | Fully sintered | 880 | 907 | 570 | 561 | 587 | 575 | 605 | 590 | 577 | 587 |

| A, a, β | (89) | B, a, α | (61) | B, a, α | (43) | B, a, α | (54) | B, a, β | (44) | ||

| presintered | 1362 | 1302 | 636 | 649 | 594 | 601 | 683 | 681 | 683 | 696 | |

| A, a, α | (224) | B, a, α | (96) | B, a, α | (92) | B, a, α | (52) | B, a, α | (44) | ||

| Alumina particle air-abraded | Fully sintered | 821 | 851 | 379 | 380 | 366 | 362 | 370 | 377 | 357 | 358 |

| A, a, β | (96) | B, b, α | (33) | B, b, α | (30) | B, b, α | (49) | B, a, β | (21) | ||

| presintered | 1350 | 1302 | 380 | 394 | 388 | 390 | 447 | 440 | 432 | 433 | |

| A, a, α | (146) | B, b, α | (41) | B, b, α | (25) | B, b, α | (44) | B, b, α | (38) | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hergeröder, C.; Wille, S.; Kern, M. Comparison of Testing Designs for Flexural Strength of 3Y-TZP and 5Y-PSZ Considering Different Surface Treatment. Materials 2022, 15, 3915. https://doi.org/10.3390/ma15113915

Hergeröder C, Wille S, Kern M. Comparison of Testing Designs for Flexural Strength of 3Y-TZP and 5Y-PSZ Considering Different Surface Treatment. Materials. 2022; 15(11):3915. https://doi.org/10.3390/ma15113915

Chicago/Turabian StyleHergeröder, Carsten, Sebastian Wille, and Matthias Kern. 2022. "Comparison of Testing Designs for Flexural Strength of 3Y-TZP and 5Y-PSZ Considering Different Surface Treatment" Materials 15, no. 11: 3915. https://doi.org/10.3390/ma15113915