Corrosion Resistance of L120G13 Steel Castings Zone-Reinforced with Al2O3

Abstract

:1. Introduction

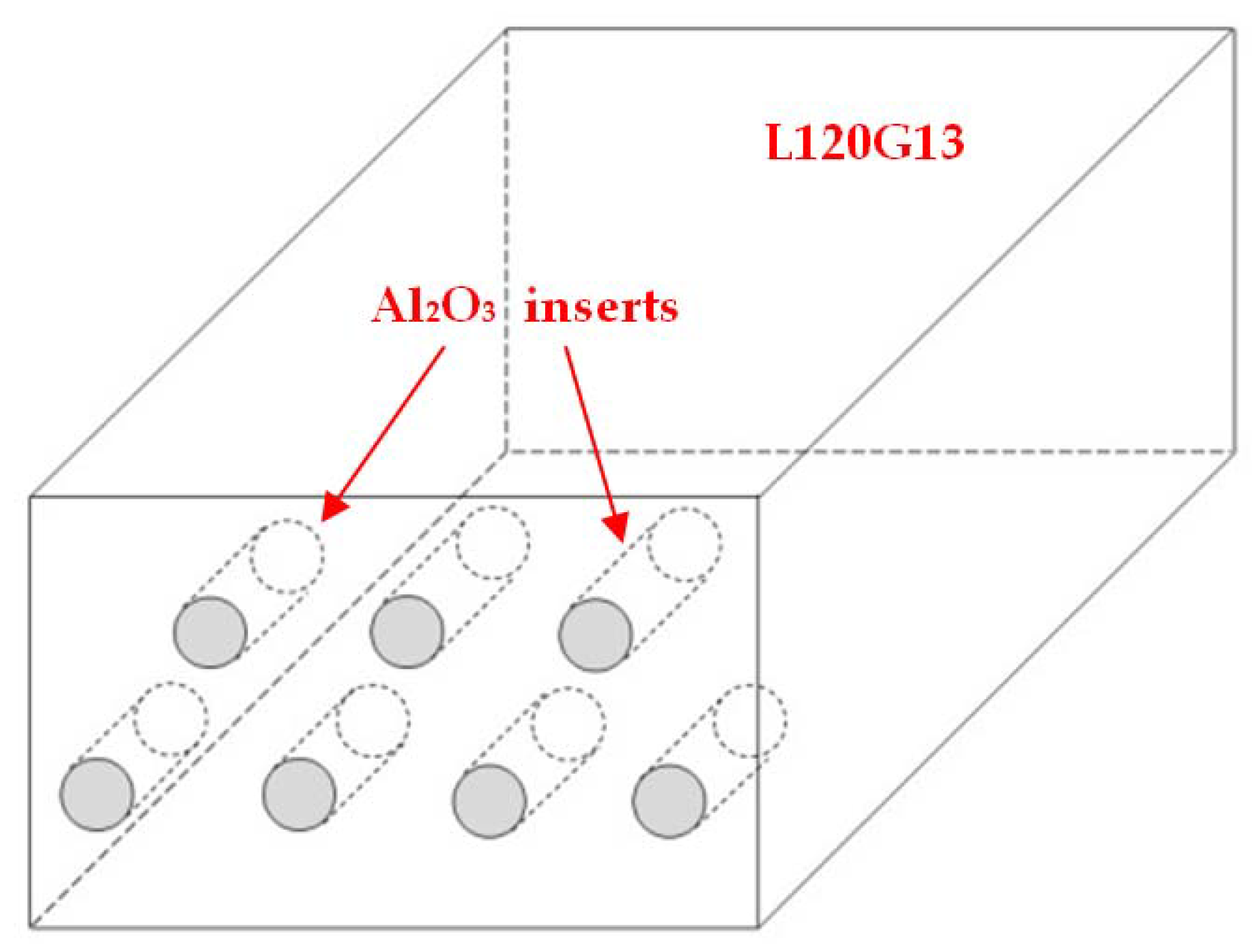

2. Materials and Methods

3. Results and Discussions

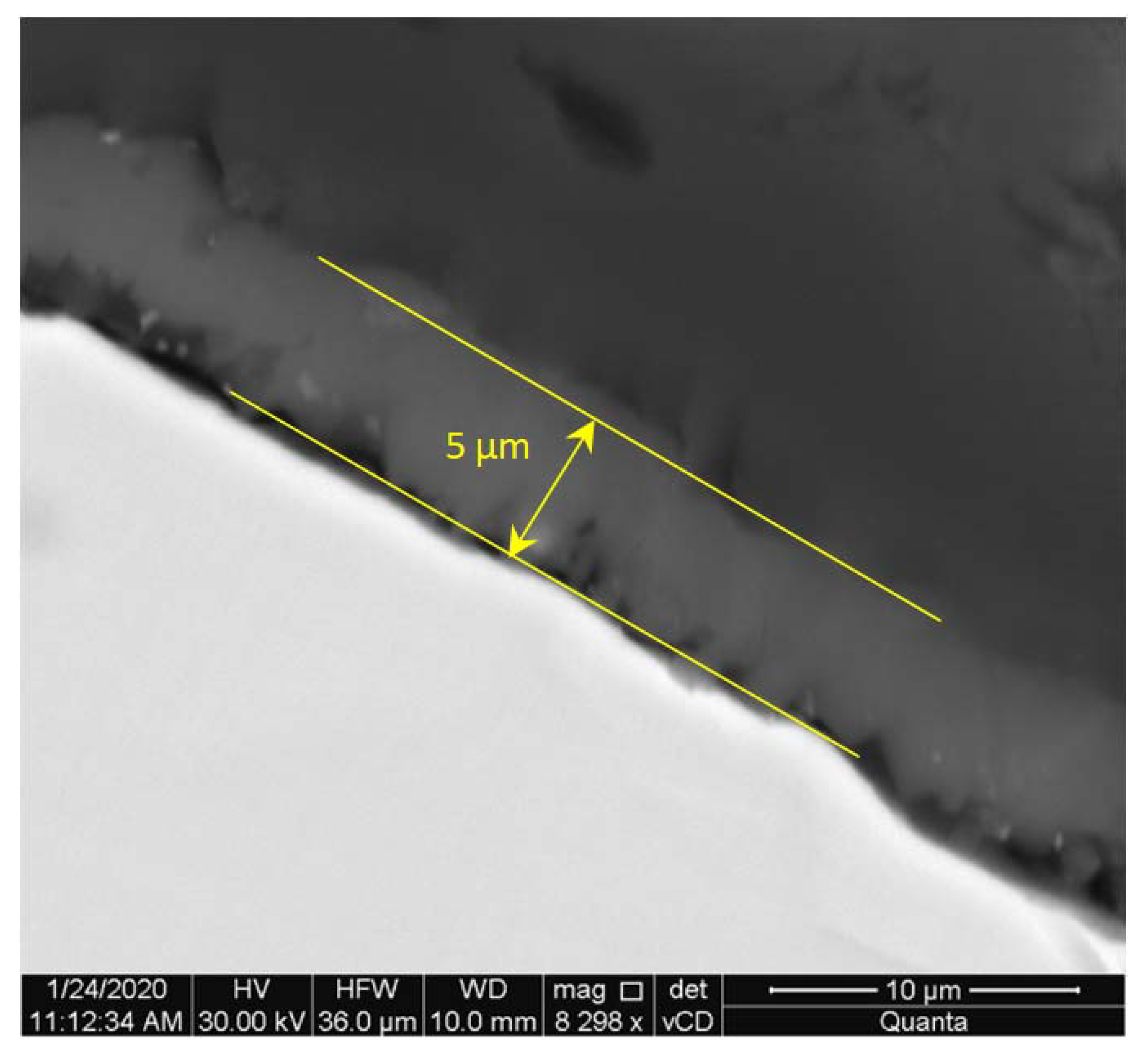

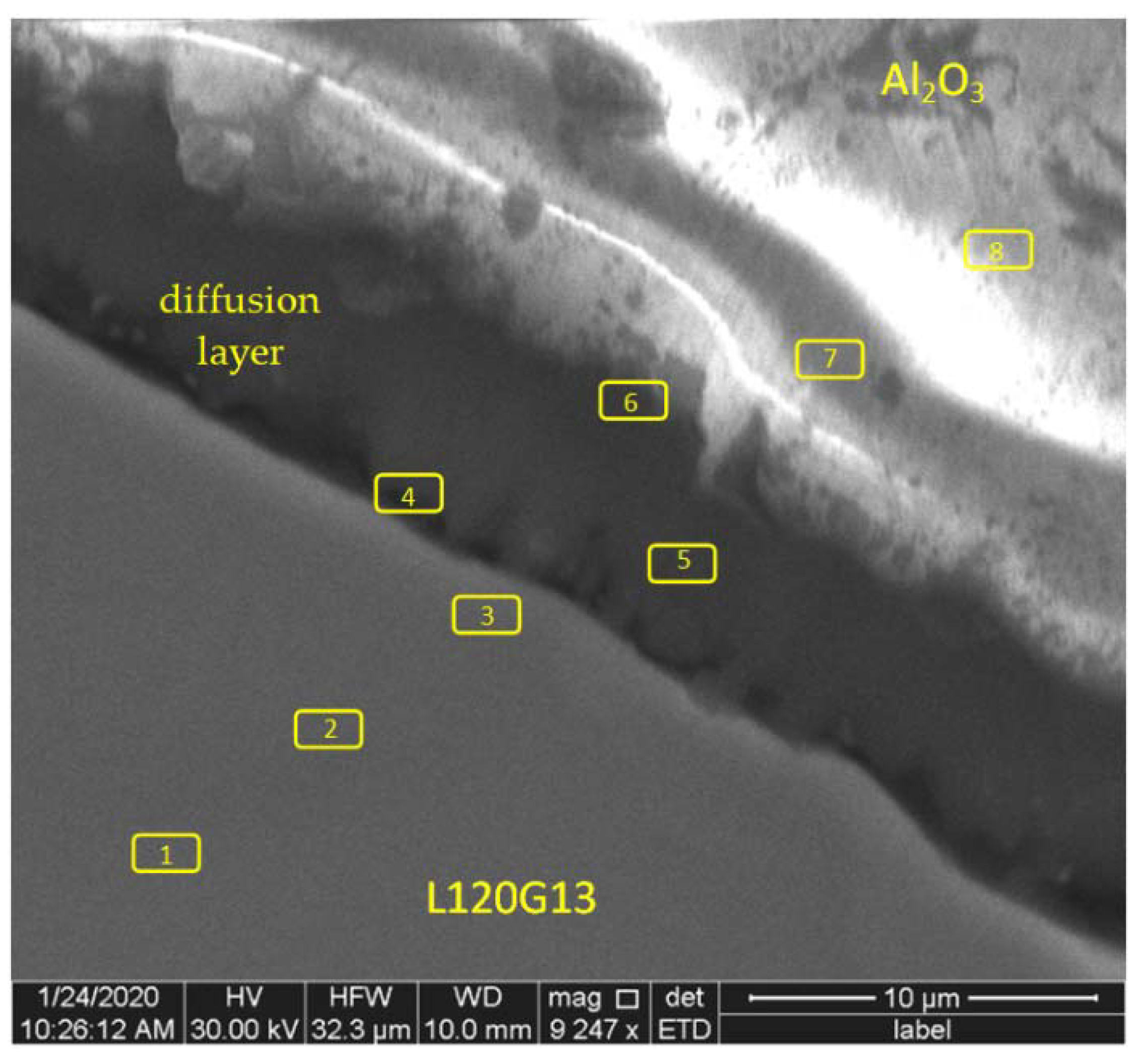

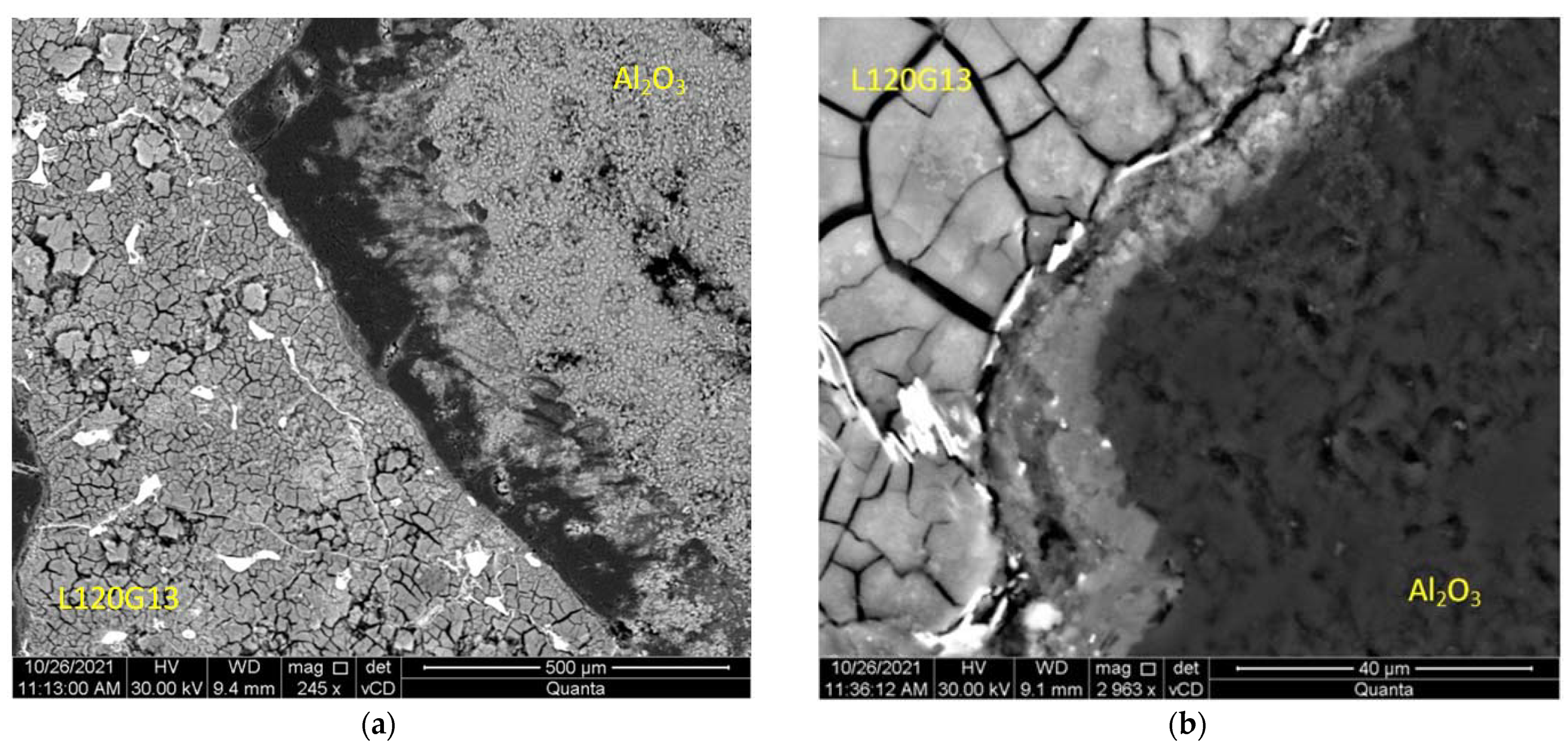

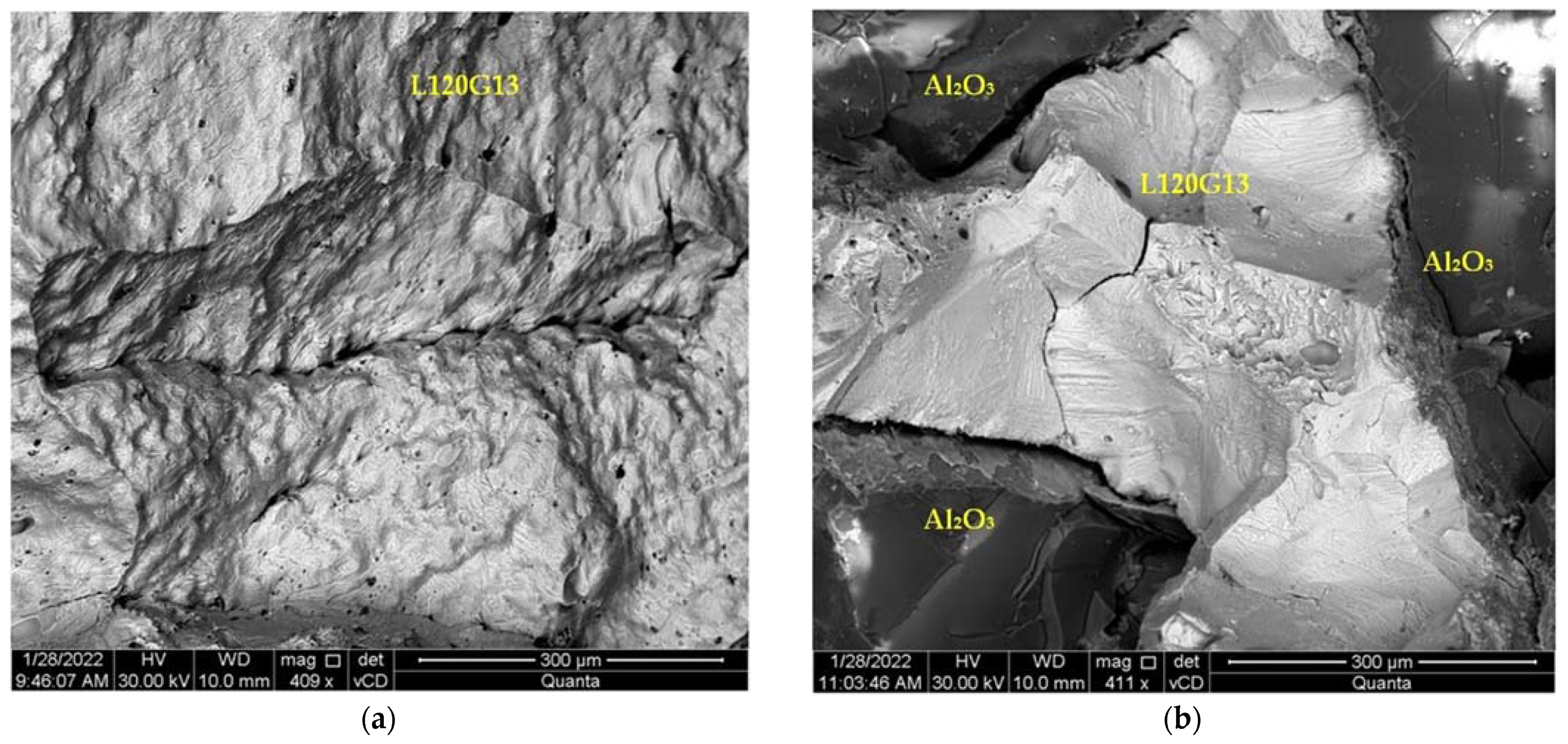

3.1. Microscopic Observations of Samples from Raw Castings

3.2. Corrosion Tests

3.2.1. Gravimetric Measurements

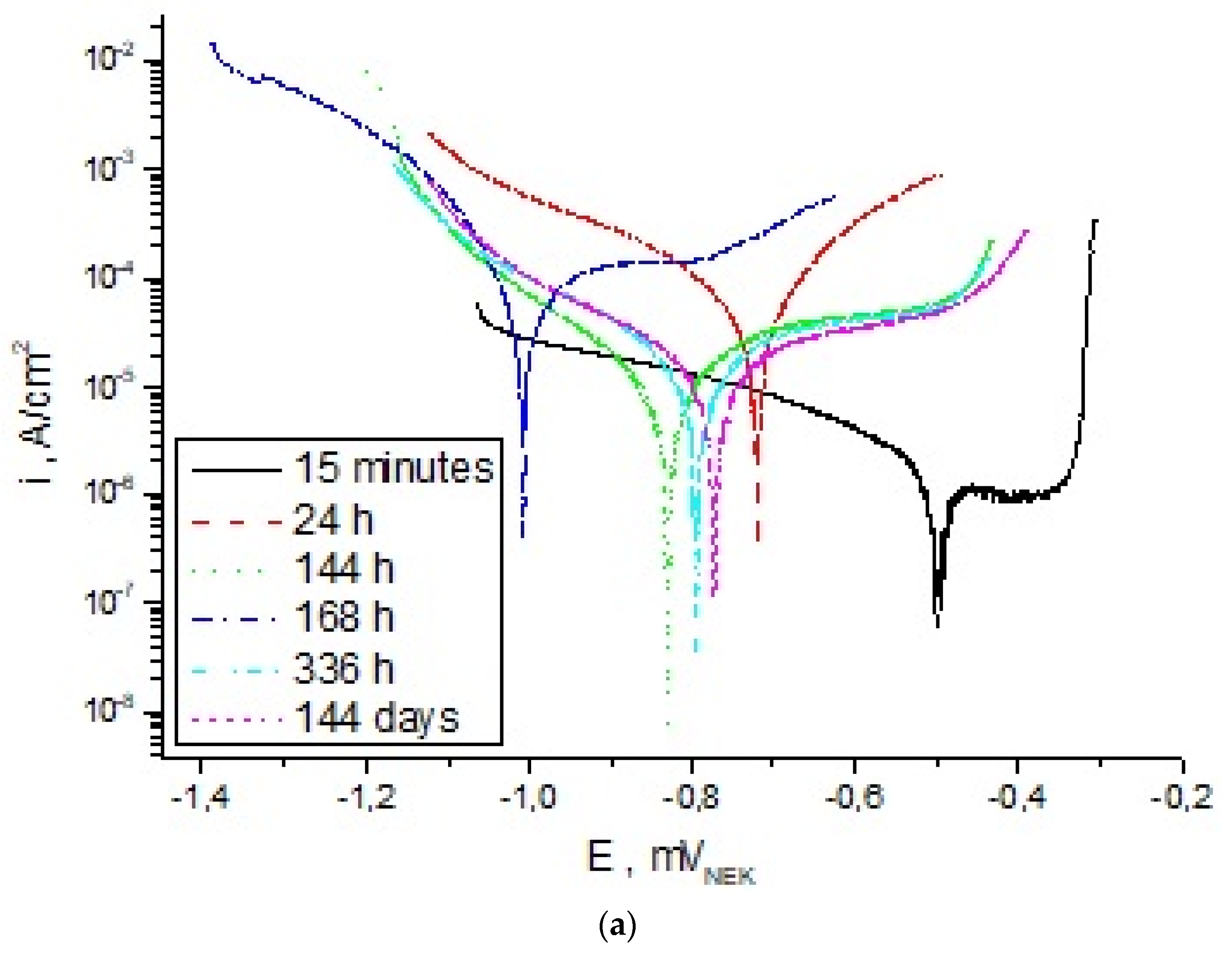

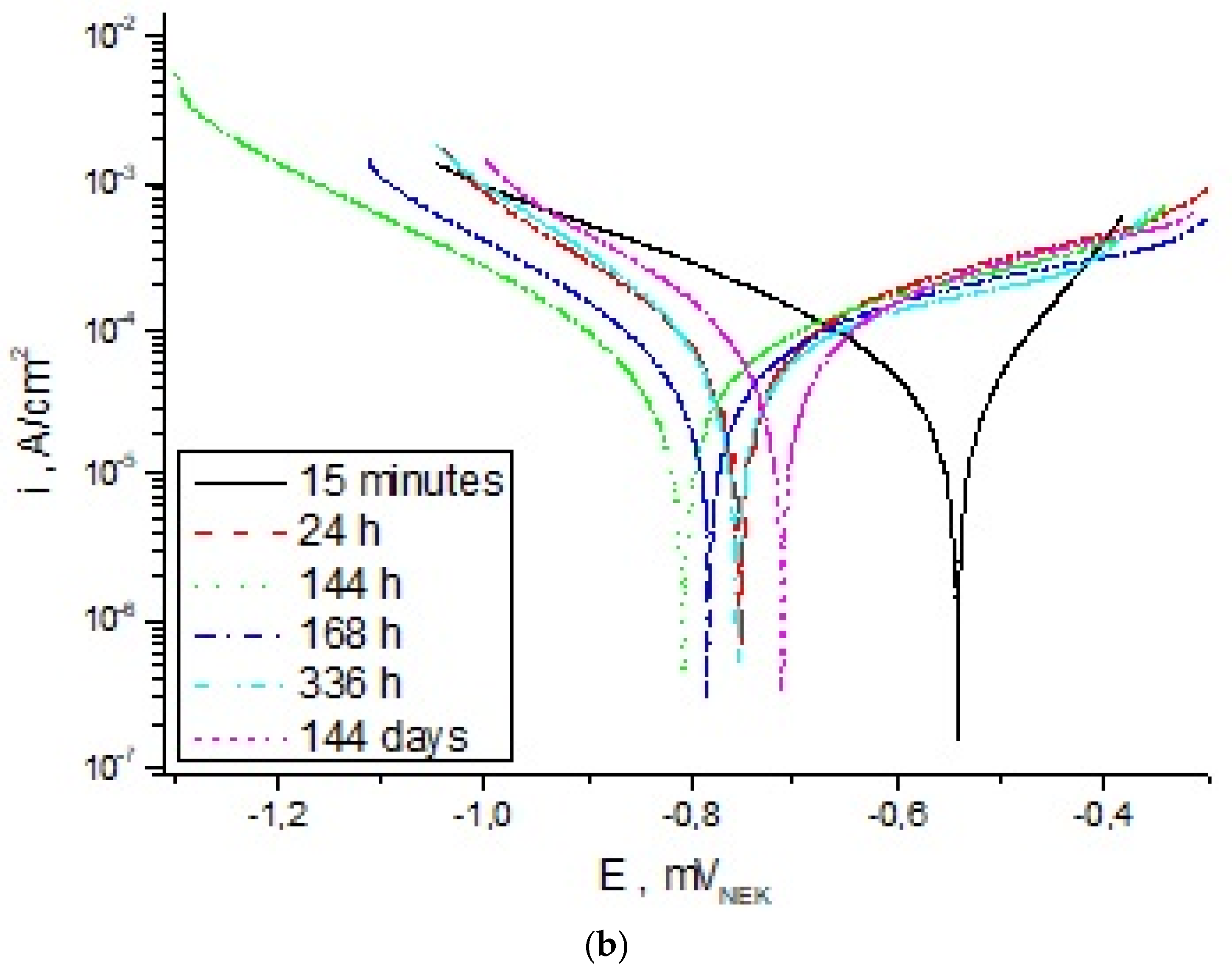

3.2.2. Potentiodynamic Measurements

3.3. Microscopic Observations of Samples after Corrosion Tests

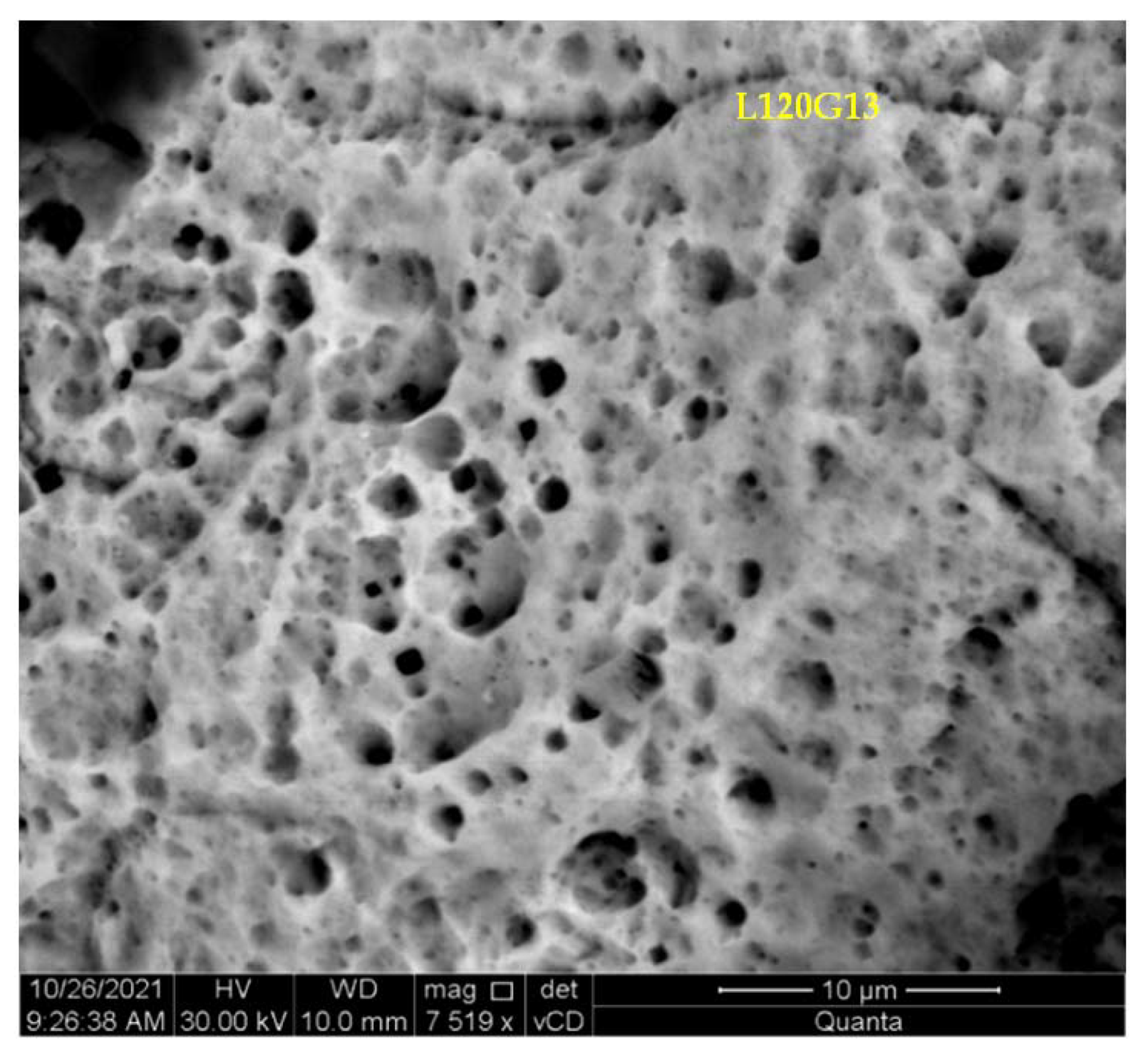

3.3.1. Observations of the Surface of Samples

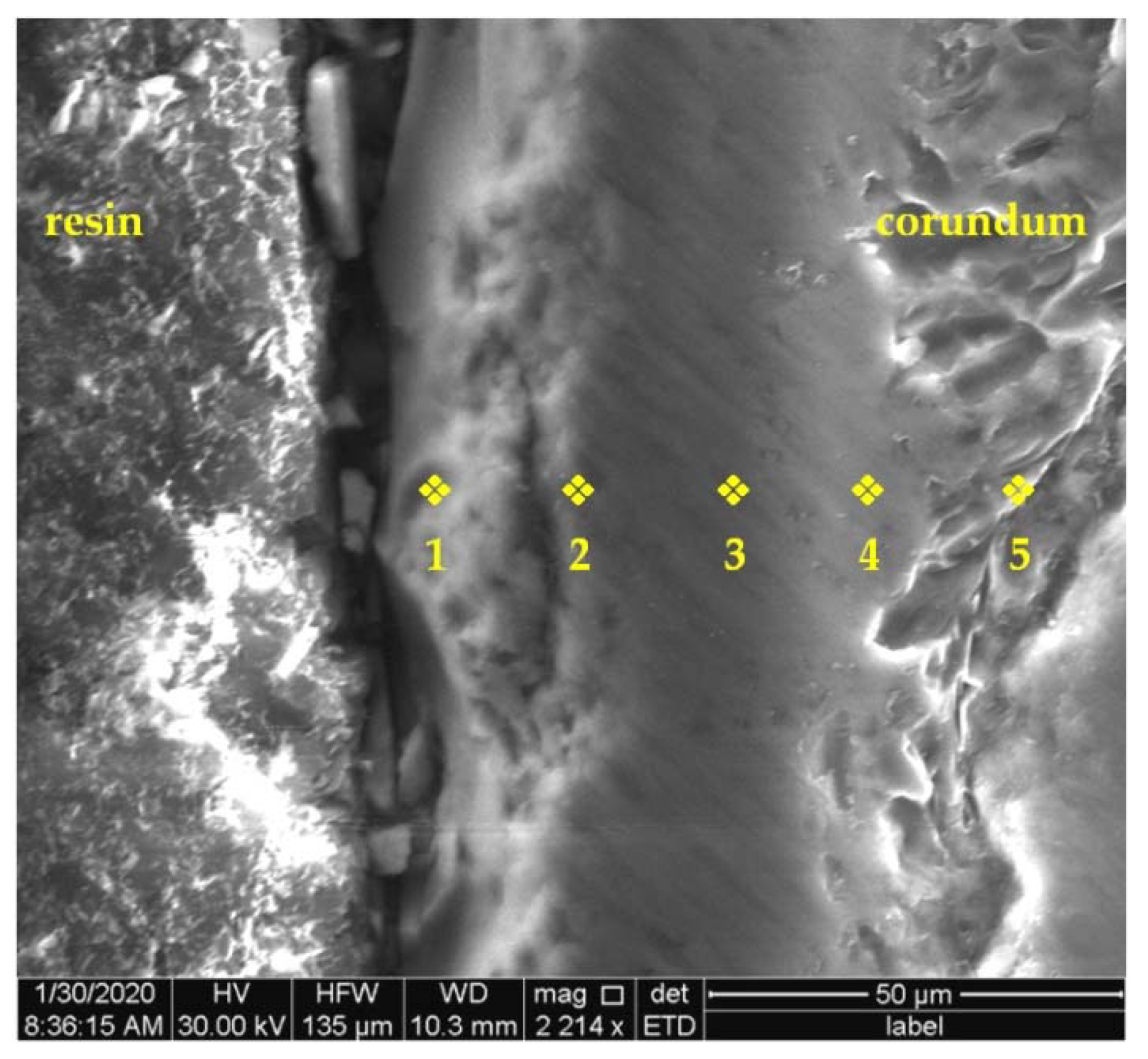

3.3.2. Observations of Breakthroughs Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Matthews, F.L.; Rawlings, R.D. Composite Materials: Engineering and Science; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Kaw Autar, K. Mechanics of Composite Materials; Taylor & Francis: Oxfordshire, UK, 2016. [Google Scholar]

- Parveen, G.; Proyanshu, M. Effect of Composite Material Electrode on Common Die Steel in EDM: Investigating the Effect of Composite Material Electrode on Common Die Steel Material in EDM; Lap Lambert Academic Publishing: Chisinau, Moldova, 2019. [Google Scholar]

- Sahoo, S. Recent Advances in Layered Materials and Structures, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Sukumar, S.; Mahendran, S.; Kannan, T.T.M. Experimental Investigation of Aluminium Based Composite. Composite Materials; Scholars’ Press: Chisinau, Moldova, 2021. [Google Scholar]

- Clyne, T.W.; Withers, P.J. An Introduction to Metal Matrix Composites; Cambridge University Press: New York, NY, USA, 1993. [Google Scholar]

- Tjong, S.; Ma, Z. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Král, P.; Strunz, P. Characterization of innovative rotary swaged Cu-Al clad composite wire conductors. Mater. Des. 2018, 160, 828–835. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Dvořák, K.; Macháčková, A. Rotary swaged laminated Cu-Al composites: Effect of structure on residua stress and mechanical and electric properties. Mater. Sci. Eng. A 2019, 742, 743–750. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. Deformation behaviour of Cu-Al cladcomposites produced by rotary swaging. IOP Conf. Ser. Mater. Sci. Eng. 2018, 369, 012029. [Google Scholar] [CrossRef]

- Górny, Z.; Sobczak, J. Modern Casting Materials Based on Non-Ferrous Metals; ZA-PIS: Krakow, Poland, 2005. (In Polish) [Google Scholar]

- Sobczak, J.; Sobczak, N. Pressure infiltration of porous fibrous structures with aluminum and magnesium alloys. Composites 2001, 1, 155–158. (In Polish) [Google Scholar]

- Kaczmar, J.; Janus, A.; Samsonowicz, Z. Influence of Technological Parameters on the Production of Selected Machine Parts Reinforced with Ceramic Fibers; Reports of Institute of Machine Technology and Automation of Wrocław University of Science and Technology SPR No. 5; Wrocław University of Science and Technology: Wroclaw, Poland, 1997. (In Polish) [Google Scholar]

- Kaczmar, J.; Janus, A.; Kurzawa, A. Development of the Basics of Technology for the Production of Machine Parts and Devices from Aluminum Composites Reinforced with Zones of Ceramic Particles; Reports of Institute of Machine Technology and Automation of Wrocław University of Science and Technology SPR No. 11; Wrocław University of Science and Technology: Wroclaw, Poland, 2002. (In Polish) [Google Scholar]

- Dmitruk, A.G.; Naplocha, K.; Żak, A.M.; Strojny-Nędza, A.; Dieringa, H.; Kainer, K. Development of pore-free Ti-Si-C MAX/Al-Si composite materials manufactured by squeeze casting infiltration. J. Mater. Eng. Perform. 2019, 28, 6248–6257. [Google Scholar] [CrossRef] [Green Version]

- Szajnar, J.; Wróbel, P.; Dulska, A. Manufacturing Methods of Alloy Layers on Casting Surfaces. J. Cast. Mater. Eng. 2017, 1, 2. [Google Scholar] [CrossRef] [Green Version]

- Marcinkowska, J. Wear-resistant casting coatings on cast steel. Solidif. Met. Alloys 1986, 6, 37–42. (In Polish) [Google Scholar]

- Baron, C.; Gawroński, J. Abrasive wear resistance of sandwich composites based on iron alloys. Composites. 2006, 6, 45–49. (In Polish) [Google Scholar]

- Gawroński, J.; Cholewa, M.; Szajnar, J.; Wróbel, P. Composite Alloy Layers on the Steel Cast; Engineering and Functional Materials EFM’97: Lviv, Ukraine, 1997. [Google Scholar]

- Medyński, D.; Janus, A. Microsegregation of Elements in Steel Composite Reinforced with Ceramic. Arch. Foundry Eng. 2021, 21, 63–66. [Google Scholar]

- Dziubek, M.; Rutkowska, G.; Dudziński, W.; Grygier, D. Investigation into Changes of Microstructure and Abrasive Wear Resistance Occurring in High Manganese Steel X120Mn12 during Isothermal Annealing and Re-Austenitisation Process. Materials 2022, 15, 2622. [Google Scholar] [CrossRef] [PubMed]

- Davis, G.D.; Groff, G.B.; Zatorski, R.A. Plasma Spray Coatings as Treatments for Aluminum, Titanium and Steel Adherends. Surf. Interface Anal. 1998, 25, 366–373. [Google Scholar] [CrossRef]

- Sobolev, A.; Peretz, T.; Borodianskiy, K. Synthesis and growth mechanism of ceramic coatings on an Al-Cu alloy using plasma electrolytic oxidation in molten salt. J. Alloys Compd. 2021, 869, 159309. [Google Scholar] [CrossRef]

- Mehdizade, M.; Eivani, A.R.; Soltanieh, M. Characterization of the anodic oxide layer deposited on severely deformed and aged AA6063 aluminum Allom. J. Mater. Res. Technol. 2021, 15, 68–85. [Google Scholar] [CrossRef]

- Medyński, D.; Janus, A. Effect of Chemical composition on structure and corrosion resistance of Ni-Mn-Cu cast iron. Arch. Foundry Eng. 2016, 16, 59–62. [Google Scholar] [CrossRef] [Green Version]

- Medyński, D.; Janus, A. Effect of austenite transformation on abrasive wear and corrosion resistance of spheroidal Ni-Mn-Cu cast iron. Arch. Foundry Eng. 2016, 16, 63–66. [Google Scholar] [CrossRef] [Green Version]

- Medyński, D.; Samociuk, B.; Janus, A.; Chęcmanowski, J. Effect of Cr, Mo and Al on Microstructure, Abrasive Wear and Corrosion Resistance of Ni-Mn-Cu Cast Iron. Materials 2019, 12, 3500. [Google Scholar] [CrossRef] [Green Version]

- Cheng-Hsun, H.; Ming-Li, C. Corrosion behavior of nickel alloyed and austempered ductile iron in 3% sodium chloricum. Corros. Sci. 2010, 52, 2945–2949. [Google Scholar]

- Medyński, D.; Janus, A.; Chęcmanowski, J. Effect of annealing on nature of corrosion damages of medium-nickel austenitic cast iron. Arch. Foundry Eng. 2017, 17, 85–90. [Google Scholar] [CrossRef] [Green Version]

- Hryniewicz, T. Electrochemistry for Surface Engineering; Publishing House of the Koszalin University of Technology: Koszalin, Poland, 2005. (In Polish) [Google Scholar]

| Measurement No. | Chemical Composition (%mas) | Ratio Al/O | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L120G13 | Al2O3 | ||||||||||||||

| Fe | C | Si | Mn | Cr | Ni | P | S | Al | O | Ti | Si | Mg | Ca | - | |

| 1 | 81.72 | 1.35 | 0.77 | 13.95 | 1.24 | 0.85 | 0.04 | 0.08 | - | - | - | - | - | - | - |

| 2 | 83.38 | 1.45 | 0.67 | 12.54 | 1.03 | 0.81 | 0.05 | 0.07 | - | - | - | - | - | - | - |

| 3 | 86.77 | 1.18 | 0.73 | 9.03 | 1.15 | 1.01 | 0.04 | 0.09 | - | - | - | - | - | - | - |

| 4 | 12.58 | - | - | 10.04 | 0.96 | - | - | - | 37.96 | 37.99 | - | 0.24 | 0.16 | 0.07 | 0.99 |

| 5 | 3.45 | - | - | 12.07 | 0.69 | - | - | - | 43.32 | 39.71 | 0.73 | - | - | 0.03 | 1.09 |

| 6 | 0.55 | - | - | 15.01 | 0.24 | - | - | - | 43.38 | 40.69 | 0.07 | - | 0.06 | - | 1.06 |

| 7 | - | - | - | 3.05 | - | - | - | - | 51.03 | 45.77 | - | 0.08 | - | 0.07 | 1.11 |

| 8 | - | - | - | - | - | - | - | - | 53.08 | 46.55 | 0.24 | 0.13 | - | - | 1.14 |

| Measurement No. | Chemical Composition (%mas) | Ratio Al/O | |||||

|---|---|---|---|---|---|---|---|

| Al | O | Ti | Si | Mg | Ca | ||

| 1 | 53.86 | 45.23 | 0.72 | - | 0.12 | 0.07 | 1.19 |

| 2 | 52.96 | 47.00 | 0.31 | 0.15 | - | - | 1.13 |

| 3 | 51.81 | 46.03 | 0.92 | - | 0.09 | - | 1.13 |

| 4 | 54.21 | 45.31 | - | 0.23 | 0.14 | 0.11 | 1.19 |

| 5 | 53.45 | 45.72 | 0.71 | - | - | 0.12 | 1.17 |

| Cast | VP (mm/Year) after Exposure for Specified Time (Days) | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 5 | 8 | 13 | 18 | 25 | |

| L120G13 | 0.56 | 0.59 | 0.55 | 0.52 | 0.45 | 0.44 | 0.38 |

| L120G13 + Al2O3 | 0.59 | 0.60 | 0.54 | 0.50 | 0.48 | 0.40 | 0.36 |

| Cast | Time of Exposure to 3% NaCl | EOC (mV) | EK-A (mV) | icorr (μA/cm2) | Rp (kΩ × cm2) |

|---|---|---|---|---|---|

| L120G13 | 15 min | −566.4 | −496.0 | 1.39 ×10−6 | 1878.1 |

| 1 day | −667.0 | −793.0 | 9.57 ×10−6 | 2724.0 | |

| 6 days | −668.0 | −832.0 | 7.64 × 10−6 | 3411.0 | |

| 7 days | −641.0 | −861.0 | 6.31 × 10−6 | 413.6 | |

| 14 days | −675.0 | −770.0 | 5.96 × 10−6 | 2669.0 | |

| 144 days | −676.0 | −719.0 | 4.07 × 10−6 | 641.2 | |

| L120G13 + Al2O3 | 15 min | −546.0 | −542.0 | 2.41 × 10−5 | 1083.0 |

| 1 day | −545.0 | −753.0 | 3.44 × 10−5 | 756.0 | |

| 6 day | −552.0 | −808.0 | 2.43 × 10−5 | 1069.0 | |

| 7 days | −564.0 | −781.0 | 2.64 × 10−5 | 987.0 | |

| 14 days | −551.0 | −710.0 | 4.01 × 10−5 | 651.9 | |

| 144 days | −588.0 | −751.0 | 3.63 × 10−5 | 717.5 |

| Measurement No. | Chemical Composition (%mas) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L120G13 + Al2O3 | ||||||||||||||

| Fe | C | Si | Mn | Cr | Ni | P | S | Al | O | Ti | Si | Mg | Ca | |

| 1 | 45.97 | 1.33 | - | 3.14 | 6.50 | 1.23 | 0.08 | - | - | 40.78 | 0.07 | 0.80 | - | 0.10 |

| 2 | 46.41 | 1.48 | 0.63 | 2.98 | 5.45 | 1.15 | 0.05 | - | - | 41.05 | 0.08 | 0.63 | - | 0.09 |

| 3 | 30.88 | 1.41 | 0.99 | 3.55 | 2.16 | 0.22 | 0.07 | - | 6.84 | 52.47 | 0.86 | 0.56 | - | 1.25 |

| 4 | 1.22 | - | - | 1.59 | - | - | - | - | 51.23 | 45.96 | 0.97 | - | - | 0.07 |

| 5 | 1.40 | - | - | - | - | - | - | - | 52.81 | 44.84 | 0.87 | 0.02 | 0.01 | 0.06 |

| Cast | Casting Surface Topography Indicator (μm) | ||

|---|---|---|---|

| RpAVR | RvAVR | RzAVR | |

| L120G13 | 4.15 | 6.82 | 10.97 |

| L120G13 + AlzO3 | 5.13 | 6.50 | 11.63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medyński, D.; Chęcmanowski, J. Corrosion Resistance of L120G13 Steel Castings Zone-Reinforced with Al2O3. Materials 2022, 15, 4090. https://doi.org/10.3390/ma15124090

Medyński D, Chęcmanowski J. Corrosion Resistance of L120G13 Steel Castings Zone-Reinforced with Al2O3. Materials. 2022; 15(12):4090. https://doi.org/10.3390/ma15124090

Chicago/Turabian StyleMedyński, Daniel, and Jacek Chęcmanowski. 2022. "Corrosion Resistance of L120G13 Steel Castings Zone-Reinforced with Al2O3" Materials 15, no. 12: 4090. https://doi.org/10.3390/ma15124090

APA StyleMedyński, D., & Chęcmanowski, J. (2022). Corrosion Resistance of L120G13 Steel Castings Zone-Reinforced with Al2O3. Materials, 15(12), 4090. https://doi.org/10.3390/ma15124090