Influence of Age and Harvesting Season on The Tensile Strength of Bamboo-Fibre-Reinforced Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Studies Area Description

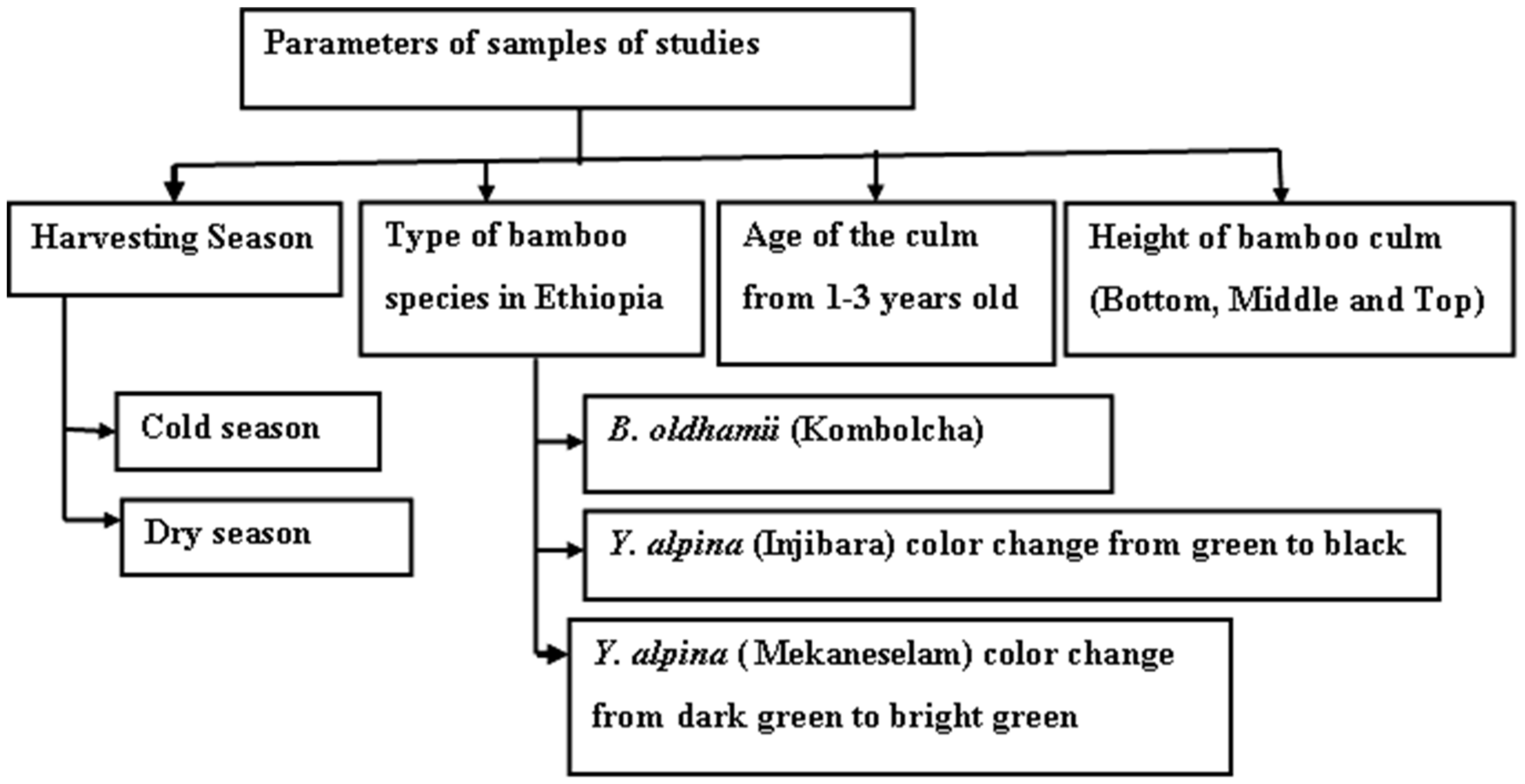

2.2. Sampling Technique

2.3. Microscopic Observations

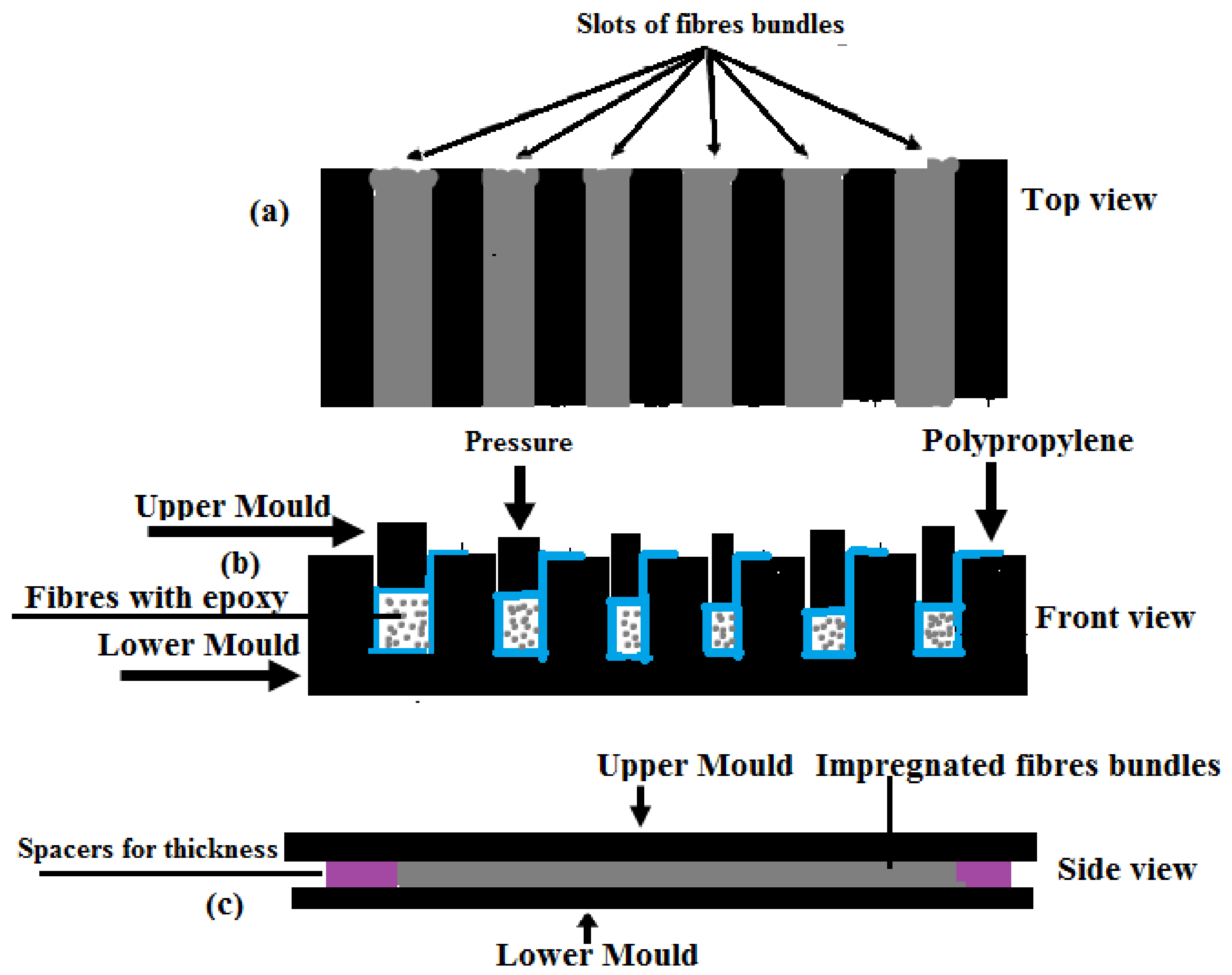

2.4. Composite Production

2.5. Determination of Fibre Volume Fraction

2.6. Back-Calculation of The Fibre Properties

2.7. Preparation of Resin

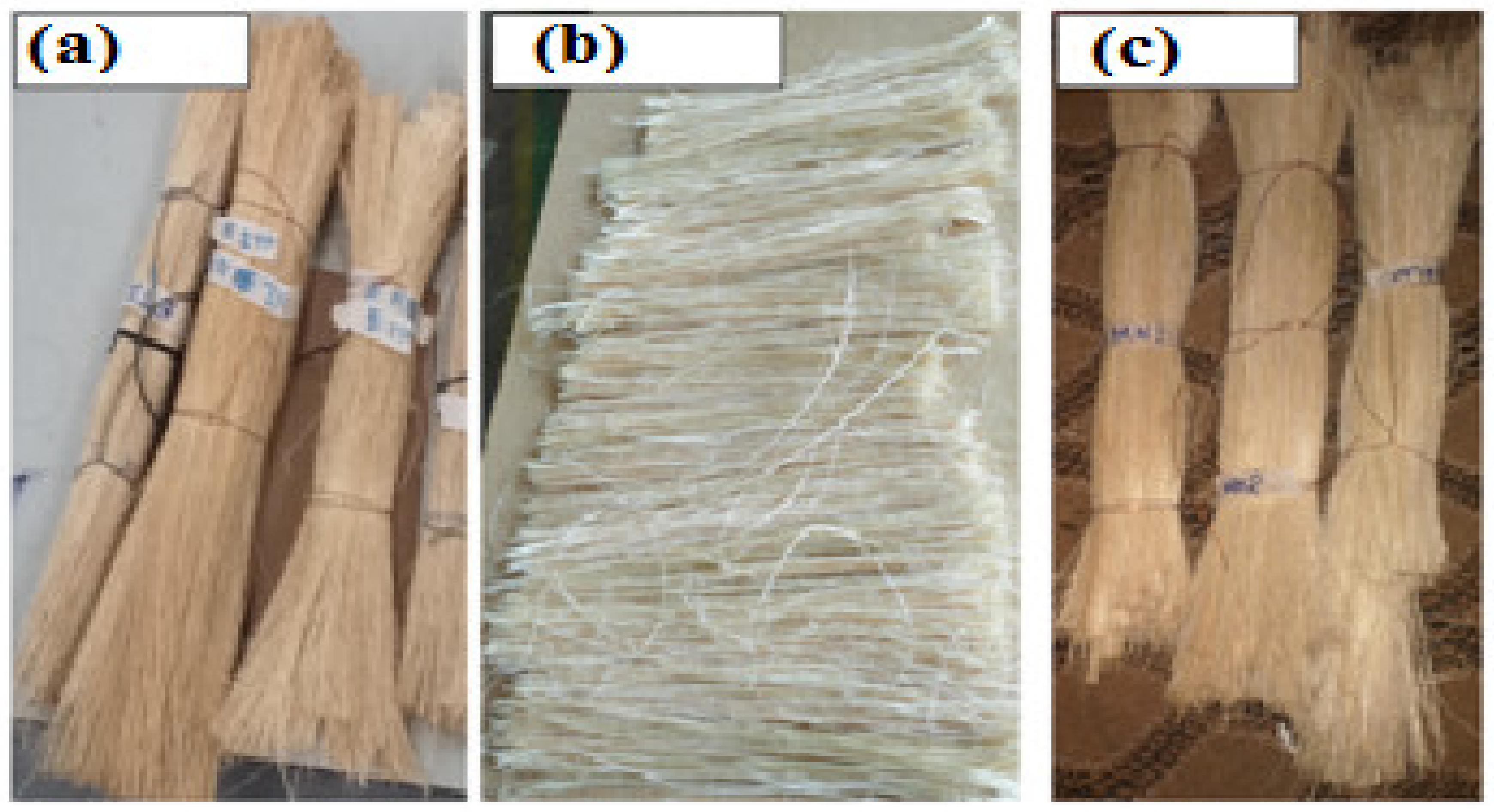

2.8. Extraction of Bamboo Fibres Using A Rolling Machine

2.9. Bundle Test of Impregnated Fibre

2.10. Tensile Test

2.11. Statistical Analysis

3. Results and Discussions

3.1. Tensile Strength Measurement

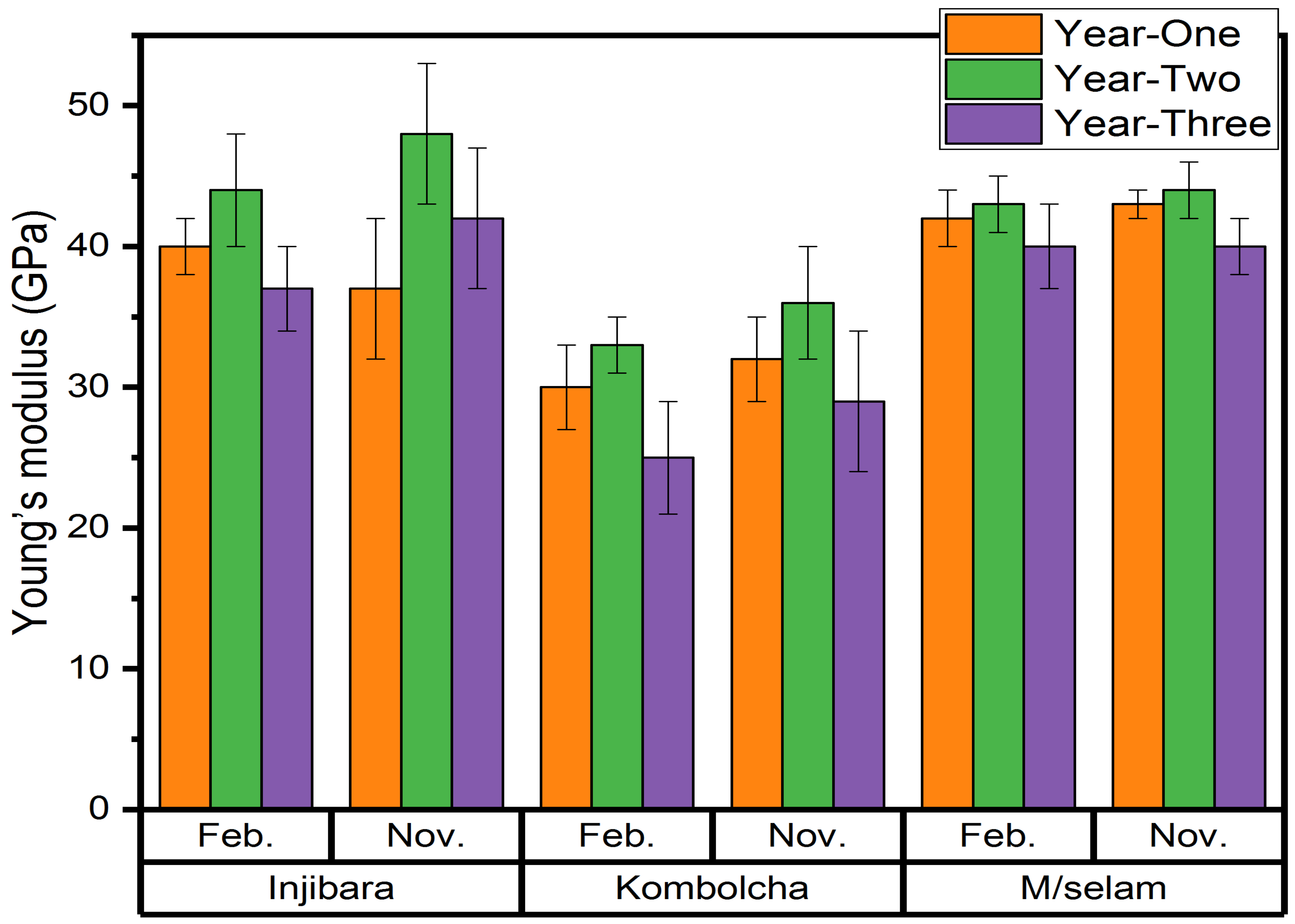

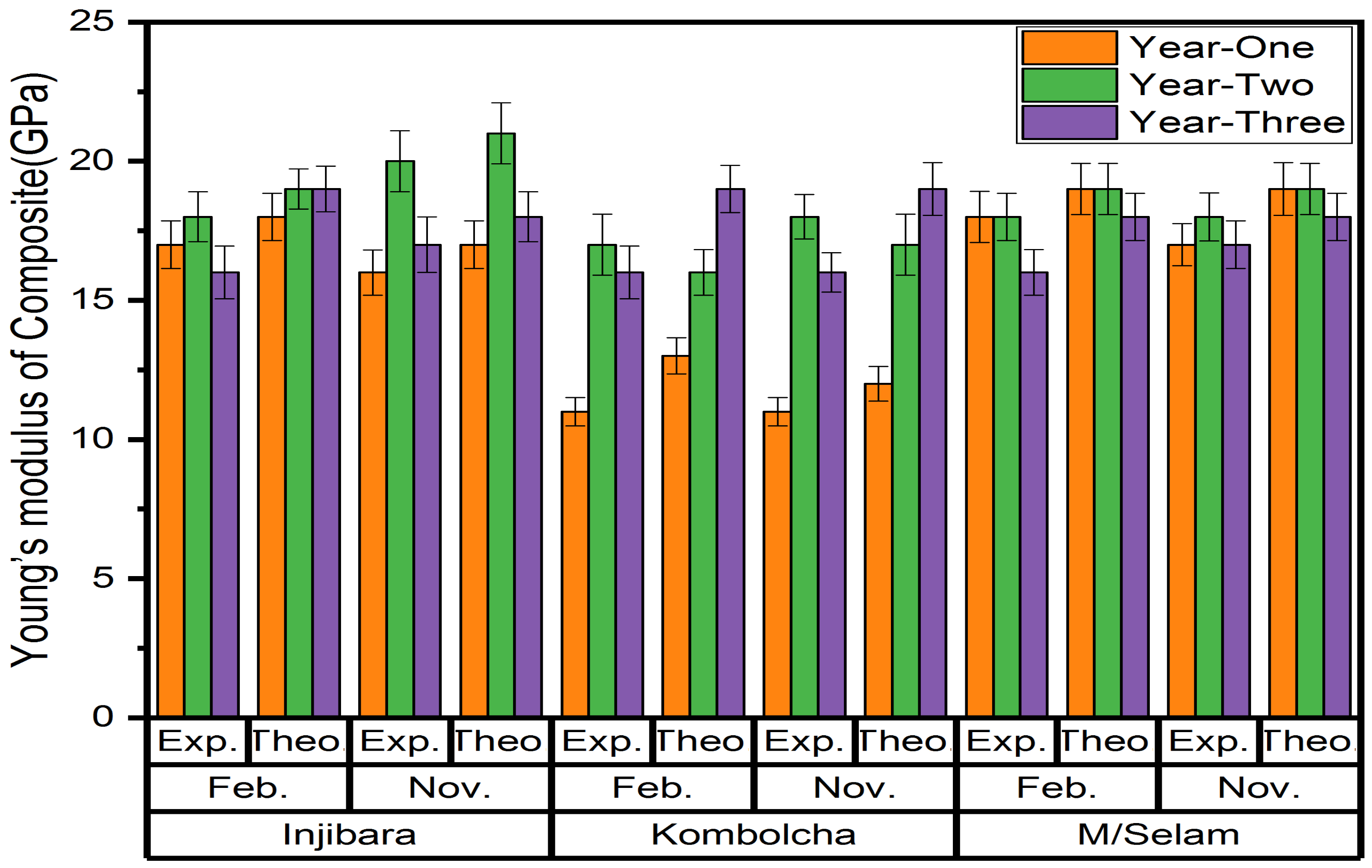

3.2. Young’s Modulus Measurement

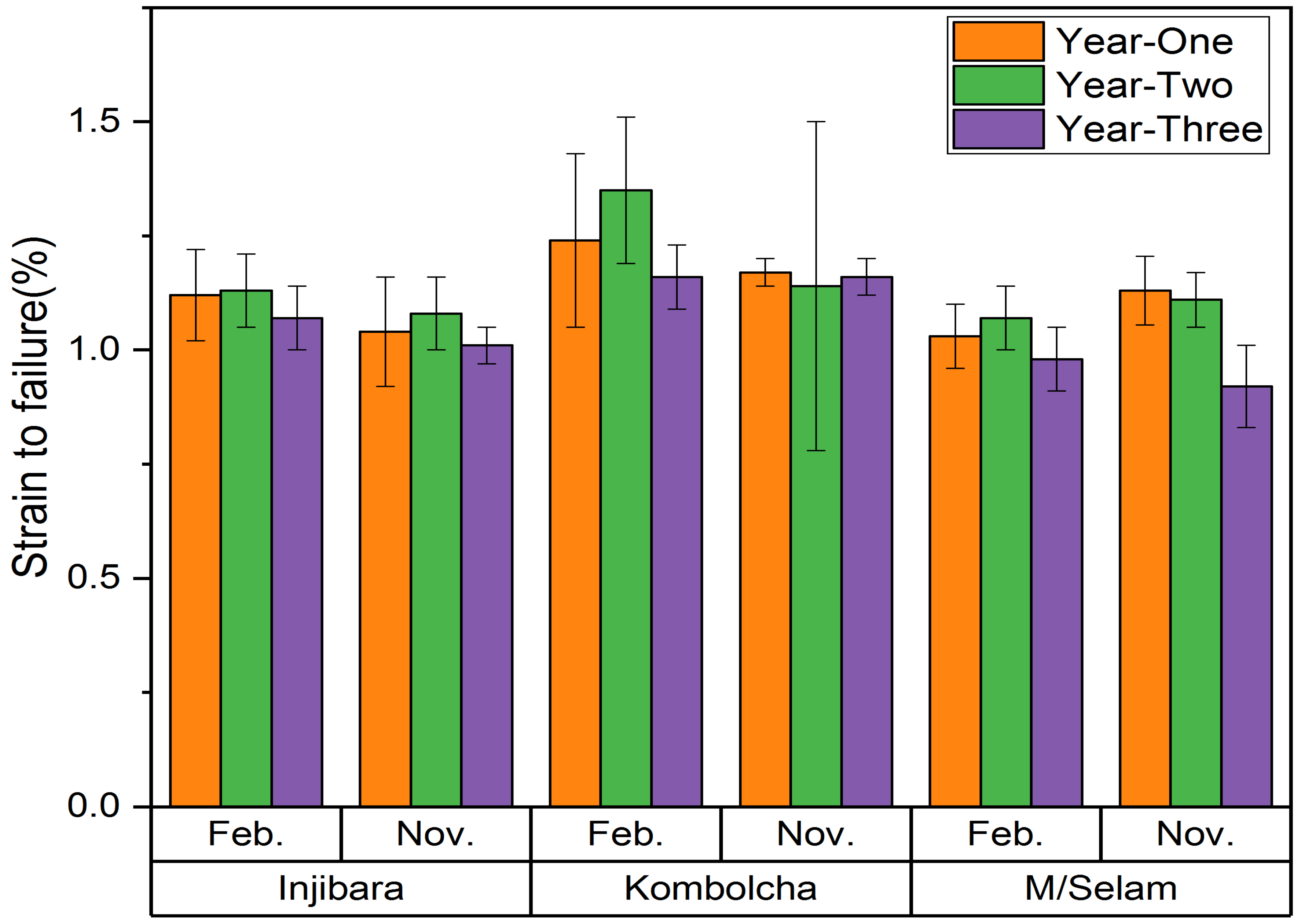

3.3. Strain to Failure Measurement

3.4. Young’s Moduli of Composites Using IFBTs

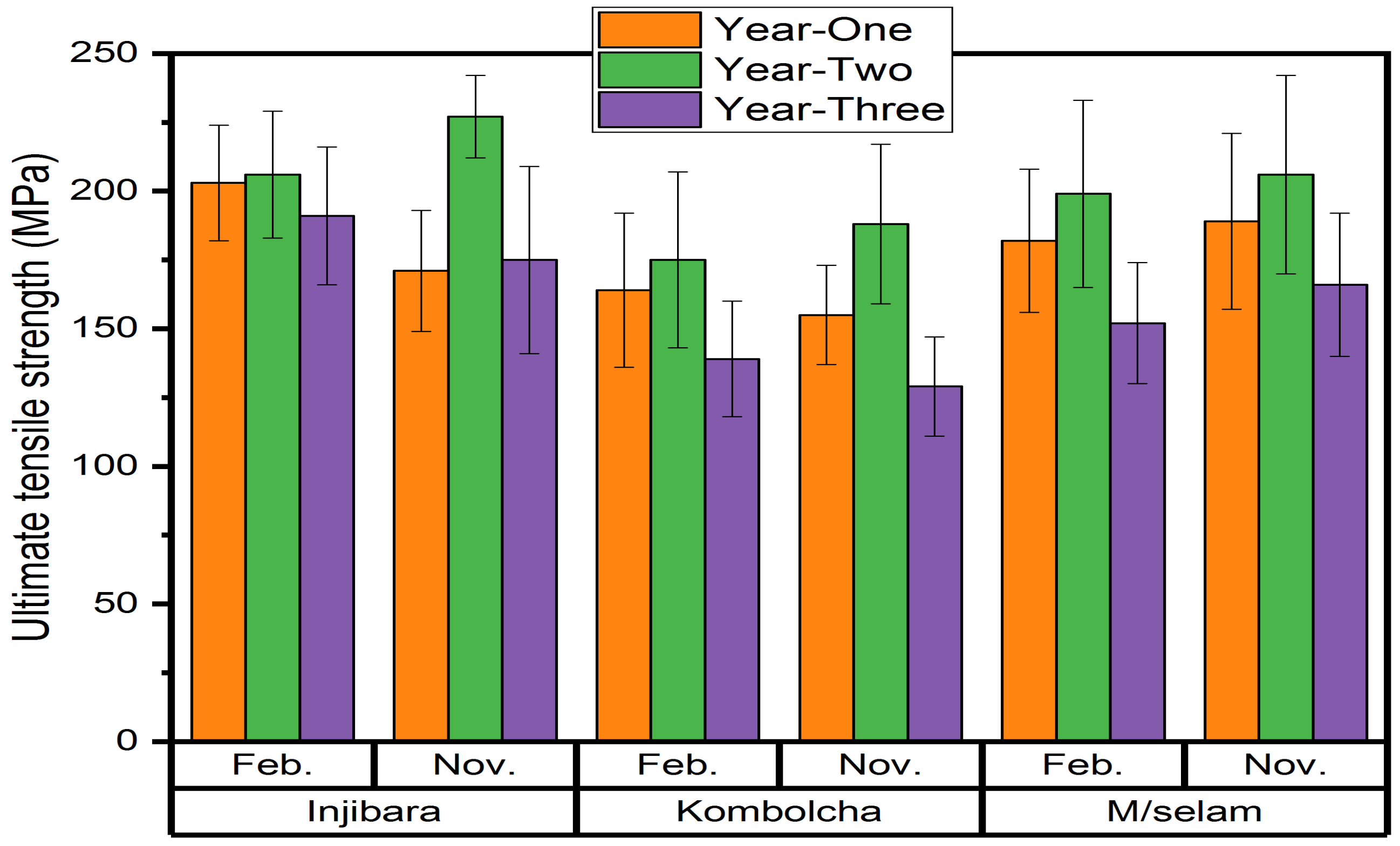

3.5. Ultimate Tensile Strength of Bamboo Fibre Composites

3.6. Statistical Experimental Results of Tensile Strength

| Tukey’s Method | |||||||

|---|---|---|---|---|---|---|---|

| Factors | UTS | Coeffi. | Std. Error | t | α>/t/ | 95% Confid. Interval | |

| Year | 2 and 1 | 79.6 | 29.3649 | 2.71 | 0.03 | 6.79216 | 152.408 |

| 3 and 1 | −19.1 | 29.3649 | −0.65 | 0.794 | −91.908 | 53.7078 | |

| 3 and 2 | −98.7 | 29.3649 | −3.36 | 0.006 | −171.51 | −25.892 | |

| Month | 2 and 11 | −3.4 | 28.5467 | −0.12 | 0.906 | −61.875 | 55.0753 |

3.7. Young’s Modulus of Kombolcha Bamboo Using ANOVA

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Okubo, K.; Fujii, T. Eco-composites using natural fibers and their mechanical properties. High Perform. Struct. Mater. 2002, 4, 77–85. [Google Scholar]

- Ticoalu, A.; Aravinthan, T.; Cardona, F. A Review of Current Development in Natural Fiber Composites for Structural and Infrastructure Applications. In Proceedings of the Southern Region Engineering Conference (SREC2010), Toowoomba, Australia, 11–12 November 2010. [Google Scholar]

- Mohmod, A.L. Effects of Age and Height of Three Bamboo Species on Their Machining. J. Trop. For. Sci. 1993, 5, 528–535. [Google Scholar]

- Osorio, L.; Trujillo, E.; Van Vuure, A.W.; Verpoest, I. Morphological aspects and mechanical properties of single bamboo fibers and flexural characterization of bamboo/epoxy composites. J. Reinf. Plast. Compos. 2011, 30, 396–408. [Google Scholar] [CrossRef]

- Mohan, S.K.; Ganesan, A.T.; Ramarao, M.; Mangrulkar, A.L.; Rajesh, S.; al Obaid, S.; Alfarraj, S.; Sivakumar, S.; Ganesan, M. Evaluation of Mechanical Properties of Sisal and Bamboo Fibres Reinforced with Polymer Matrix Composites Prepared by Compression Moulding Process. Adv. Mater. Sci. Eng. 2021, 2021, 2832149. [Google Scholar] [CrossRef]

- Banga, H.; Singh, V.K.; Choudhary, S.K. Fabrication and Study of Mechanical Properties of Bamboo Fibre Reinforced Bio-Composites. Innov. Syst. Des. Eng. 2015, 6, 84–99. [Google Scholar]

- Azwa, Z.; Yousif, B.; Manalo, A.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Zakikhani, P.; Zahari, R.; Sultan MT, H.; Majid, D.L. Bamboo Fibre Extraction and Its Reinforced Polymer Composite material. Int. J. Chem. Biomol. Metall. Mater. Sci. Eng. 2014, 8, 271–274. [Google Scholar]

- Yang, X.; Shang, L.; Liu, X.; Yang, S.; Tian, G. Changes in bamboo fiber subjected to different chemical treatments and freeze-drying as measured by nanoindentation. J. Wood Sci. 2017, 63, 24–30. [Google Scholar] [CrossRef]

- Huang, Y.H.; Fei, B.H.; Yu, Y.; Zhao, R.J. Plant age effect on mechanical properties of moso bamboo (Phyllostachys heterocycla var. pubescens). Wood Fiber Sci. 2012, 44, 196–201. [Google Scholar]

- Ramesh, M.; Deepa, C.; Ravanan, A. Bamboo Fiber Composites; Springer: Singapore, 2021. [Google Scholar]

- Killmann, W.; Lim, S.C. Anatomy and Properties of Oil Palm Stem; Bamboo Work: Frome, UK, 1985; pp. 18–42. [Google Scholar]

- Ely, F.; Araque, O.; Jaimez, R. Growth and ecophysiological response in juvenile clones of Guadua (Guaduinae: Bambusoideae) cultivated in an altered lowland tropical region. Photosynthetica 2017, 55, 264–275. [Google Scholar] [CrossRef]

- Depuydt, D.E.; Billington, L.; Fuentes, C.; Sweygers, N.; Dupont, C.; Appels, L.; Ivens, J.; Van Vuure, A.W. European bamboo fibres for composites applications, study on the seasonal influence. Ind. Crop. Prod. 2019, 133, 304–316. [Google Scholar] [CrossRef]

- Hamdan, H.U.M.K.; Anwar, U.M.K.; Zaidon, A.; Tamizi, M.M. Mechanical properties and failure behaviour of gigantochloa scortechinii. J. Trop. For. Sci. 2009, 21, 336–344. [Google Scholar]

- Jimenez, J.P.; Macalinao, M.G.M.; Sapin, G.N. Physico-mechanical properties of two Philippine bamboos thermally modified in a steam environment. Philipp. J. Sci. 2021, 150, 171–182. [Google Scholar]

- Mohmod, A.L.; Ariffin WT, W.; Ahmad, F. Anatomical features and mechanical properties of three Malaysian bamboos. J. Trop. For. Sci. 1990, 2, 227–234. [Google Scholar]

- Jyoti, N.A.; Lal, R.; Das, A.K. Ethnopedology and soil quality of bamboo (Bambusa sp.) based agroforestry system. Sci. Total Environ. 2015, 521–522, 372–379. [Google Scholar] [CrossRef] [PubMed]

- Correal, D.J.F.; Arbeláez, C.J. Influence of age and height position on colombian Guadua angustifolia bambo mechanical properties. Maderas. Cienc. Y Tecnol. 2010, 12, 105–113. [Google Scholar] [CrossRef]

- Singnar, P.; Nath, A.J.; Das, A.K. Culm characteristics and volume-weight relationship of a forest bamboo (Melocanna baccifera (Roxb.) Kurz) from northeast India. J. For. Res. 2015, 26, 841–849. [Google Scholar] [CrossRef]

- Safri, S.N.; Sultan, M.T.; Saba, N.; Jawaid, M. Effect of benzoyl treatment on flexural and compressive properties of sugar palm/glass fibres/epoxy hybrid composites. Polym. Test. 2018, 71, 362–369. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, H.; Lu, F.; Tian, G.; Lin, J. Bamboo fibers for composite applications: A mechanical and morphological nvestigation. J. Mater. Sci. 2014, 49, 2559–2566. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Bourmaud, A.; Morvan, C.; Baley, C. Elementary flax fibre tensile properties: Correlation between stress-strain behaviour and fibre composition. Ind. Crop. Prod. 2014, 52, 762–769. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Baillie, C.A.; Zafeiropoulos, N.; Mwaikambo, L.Y.; Ansell, M.P.; Dufresne, A.; Entwistle, K.M.; Herrera-Franco, P.; Escamilla, G.C.; Groom, L.; et al. Current international research into cellulosic fibres and composites. J. Mater. Sci. 2001, 36, 2107–2131. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.; Yahaya, R.; Majid, M.S.A. Thermal degradation and viscoelastic properties of Kevlar/Cocos nucifera sheath reinforced epoxy hybrid composites. Compos. Struct. 2019, 219, 194–202. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.R.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Tex. 2020. [Google Scholar] [CrossRef]

- Ismail, M.F.; Sultan, M.T.; Hamdan, A.; Shah, A.U.; Jawaid, M. Low velocity impact behaviour and post-impact characteristics of kenaf/glass hybrid composites with various weight ratios. J. Mater. Res. Technol. 2019, 8, 2662–2673. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Sultan, M.T.H.; Shenoy, S.B.; Kini, C.R.; Samant, R.; Shah, A.U.M.; Amuthakkannan, P. Potential of Natural Fibers in Composites for Ballistic Applications—A Review. J. Nat. Fibers 2022, 19, 1648–1658. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant fibre based bio-composites: Sustainable and renewable green materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Wang, H.; An, X.; Li, W.; Wang, H.; Yu, Y. Variation of mechanical properties of single bamboo fibers (Dendrocalamus latiflorus Munro) with respect to age and location in culms. Holzforschung 2014, 68, 291–297. [Google Scholar] [CrossRef]

- Shao, Z.P.; Fang, C.H.; Huang, S.X.; Tian, G.L. Tensile properties of Moso bamboo (Phyllostachys pubescens) and its components with respect to its fiber-reinforced composite structure. Wood Sci. Technol. 2010, 44, 655–666. [Google Scholar] [CrossRef]

- Biswas, S.; Satapathy, A.; Patnaik, A. Effect of ceramic fillers on mechanical properties of bamboo fiber reinforced epoxy composites: A comparative Study. Adv. Mater. Res. 2010, 123–125, 1031–1034. [Google Scholar] [CrossRef]

- Birara, H.; Pandey, R.P.; Mishra, S.K. Trend and variability analysis of rainfall and temperature in the tana basin region, Ethiopia. J. Water Clim. Change 2018, 9, 555–569. [Google Scholar] [CrossRef]

- Rosell, S.; Holmer, B. Rainfall change and its implications for Belg harvest in South Wollo, Ethiopia. Geogr. Ann. Ser. A Phys. Geogr. 2007, 89, 287–299. [Google Scholar] [CrossRef]

- Yesuph, A.Y.; Dagnew, A.B. Soil erosion mapping and severity analysis based on RUSLE model and local perception in the Beshillo Catchment of the Blue Nile Basin, Ethiopia. Environ. Syst. Res. 2019, 8, 17. [Google Scholar] [CrossRef]

- Coroller, G.; Lefeuvre, A.; Le Duigou, A.; Bourmaud, A.; Ausias, G.; Gaudry, T.; Baley, C. Effect of flax fibres individualisation on tensile failure of flax/epoxy unidirectional composite. Compos. Part A Appl. Sci. Manuf. 2013, 51, 62–70. [Google Scholar] [CrossRef]

- Trujillo, E.; Moesen, M.; Osorio, L.; Van Vuure, A.; Ivens, J.; Verpoest, I. Bamboo fibres for reinforcement in composite materials: Strength Weibull analysis. Compos. Part A Appl. Sci. Manuf. 2014, 61, 115–125. [Google Scholar] [CrossRef]

- Bensadoun, F.; Verpoest, I.; Baets, J.; Müssig, J.; Graupner, N.; Davies, P.; Gomina, M.; Kervoelen, A.; Baley, C. Impregnated fibre bundle test for natural fibres used in composites. J. Reinf. Plast. Compos. 2017, 36, 942–957. [Google Scholar] [CrossRef]

- Prapavesis, A.; Tojaga, V.; Östlund, S.; Van Vuure, A.W. Back calculated compressive properties of flax fibers utilizing the Impregnated Fiber Bundle Test (IFBT). Compos. Part A Appl. Sci. Manuf. 2020, 135, 105930. [Google Scholar] [CrossRef]

- Perremans, D.; Trujillo, E.; Ivens, J.; Van Vuure, A. Effect of discontinuities in bamboo fibre reinforced epoxy composites. Compos. Sci. Technol. 2018, 155, 50–57. [Google Scholar] [CrossRef]

- Deshpande, A.; Rao, M.B.; Rao, C.L. Extraction of bamboo fibers and their use as reinforcement in polymeric composites. J. Appl. Polym. Sci. 2000, 76, 83–92. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2014.

- Thomas, T.C.; Aswini Kumar, K.; Mohamed, S.; Krishnan, V.; Mathew, A.; Manju, V. The effect on the flexural strength, flexural modulus and compressive strength of fibre reinforced acrylic with that of plain unfilled acrylic resin—An in vitro study. J. Clin. Diagn. Res. 2015, 9, ZC12–ZC14. [Google Scholar] [CrossRef]

- Depuydt, D.E.; Sweygers, N.; Appels, L.; Ivens, J.; Van Vuure, A.W. Bamboo fibres sourced from three global locations: A microstructural, mechanical and chemical composition study. J. Reinf. Plast. Compos. 2019, 38, 397–412. [Google Scholar] [CrossRef]

- Guo, R.; Xian, G.; Li, C.; Huang, X.; Xin, M. Effect of fiber hybridization types on the mechanical properties of carbon/glass fiber reinforced polymer composite rod. Mech. Adv. Mater. Struct. 2021, 1, 1974620. [Google Scholar] [CrossRef]

| Factors | E | Tukey’s Method | |||||

|---|---|---|---|---|---|---|---|

| Coeffi. | Std. Error | t | α>/t/ | 95% Confid. Interval | |||

| Years | 2 and 1 | 7.1 | 2.19106 | 3.24 | 0.009 | 1.66745 | 12.5326 |

| 3 and 1 | 0.6 | 2.191059 | 0.27 | 0.96 | −4.83255 | 6.032551 | |

| 3 and 2 | −6.5 | 2.191059 | −2.97 | 0.017 | −11.9326 | −1.06745 | |

| Months | 2 and 11 | 2.06667 | 2.10004 | 0.98 | 0.333 | −2.2351 | 6.3684 |

| Factors | UTS | Tukey’s Method | |||||

|---|---|---|---|---|---|---|---|

| Coeffi. | Std. Error | t | α>/t/ | 95% Confid. Interval | |||

| Ages (Yrs) | 2 and 1 | 144 | 30.46 | 4.73 | 0.000 | 68.45 | 219.55 |

| 3 and 1 | 129 | 30.46 | 4.23 | 0.001 | 53.45 | 204.55 | |

| 3 and 2 | −15 | 30.46 | −0.49 | 0.876 | −90.55 | 60.55 | |

| Months | 2 and 11 | 23.13 | 34.27 | 0.67 | 0.505 | −47.069 | 93.34 |

| Factors | Compar. | Tukey’s Method | |||||

|---|---|---|---|---|---|---|---|

| Coeffi. | Std. Error | t | >/t/ | 95% Confid. Interval | |||

| Ages (Yrs) | 2 and 1 | 11.3 | 2.93 | 3.86 | 0.002 | 4.033 | 18.57 |

| 3 and 1 | 12.6 | 2.93 | 4.3 | 0.001 | 5.33 | 19.87 | |

| 3 and 2 | 1.3 | 2.93 | 0.44 | 0.898 | -5.97 | 8.57 | |

| Months | 2 and 11 | 6.47 | 2.93 | 2.2 | 0.036 | 0.459 | 12.475 |

| Factors | Comparison | Tukey’s Method | |||||

|---|---|---|---|---|---|---|---|

| Coeffi. | Std. Error | t | α>/t/ | 95% Confid. Interval | |||

| Ages (Yrs) | 2 and 1 | 16.4 | 19.37 | 0.85 | 0.678 | −31.63 | 64.43 |

| 3 and 1 | −97.7 | 19.37 | −5.04 | 0.000 | −145.73 | −49.67 | |

| 3 and 2 | −114.1 | 19.37 | −5.89 | 0.000 | −162.13 | −66.07 | |

| Months | 2 and 11 | 23.2 | 24.17 | 0.96 | 0.345 | −26.32 | 72.72 |

| Factors | Comparison | Tukey’s Method | |||||

|---|---|---|---|---|---|---|---|

| Coeffi. | Std. Error | t | α>/t/ | 95% Confid. Interval | |||

| Ages (Yrs) | 2 and 1 | 1.1 | 0.918 | 1.2 | 0.464 | −1.18 | 3.38 |

| 3 and 1 | −3 | 0.918 | −3.27 | 0.008 | −5.28 | −0.72 | |

| 3 and 2 | −4.1 | 0.918 | −4.47 | 0.000 | −6.38 | −1.82 | |

| Months | 2 and 11 | 0.667 | 0.977 | 0.68 | 0.501 | −1.335 | 2.668 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dessalegn, Y.; Singh, B.; van Vuure, A.W.; Rajhi, A.A.; Ahmed, G.M.S.; Hossain, N. Influence of Age and Harvesting Season on The Tensile Strength of Bamboo-Fibre-Reinforced Epoxy Composites. Materials 2022, 15, 4144. https://doi.org/10.3390/ma15124144

Dessalegn Y, Singh B, van Vuure AW, Rajhi AA, Ahmed GMS, Hossain N. Influence of Age and Harvesting Season on The Tensile Strength of Bamboo-Fibre-Reinforced Epoxy Composites. Materials. 2022; 15(12):4144. https://doi.org/10.3390/ma15124144

Chicago/Turabian StyleDessalegn, Yalew, Balkeshwar Singh, Aart W. van Vuure, Ali A. Rajhi, Gulam Mohammed Sayeed Ahmed, and Nazia Hossain. 2022. "Influence of Age and Harvesting Season on The Tensile Strength of Bamboo-Fibre-Reinforced Epoxy Composites" Materials 15, no. 12: 4144. https://doi.org/10.3390/ma15124144

APA StyleDessalegn, Y., Singh, B., van Vuure, A. W., Rajhi, A. A., Ahmed, G. M. S., & Hossain, N. (2022). Influence of Age and Harvesting Season on The Tensile Strength of Bamboo-Fibre-Reinforced Epoxy Composites. Materials, 15(12), 4144. https://doi.org/10.3390/ma15124144